Characterization of GMAW (Gas Metal Arc Welding) Penetration Using Ultrasonics

Abstract

:1. Introduction

2. Methods and Measurement Systems

2.1. Methods

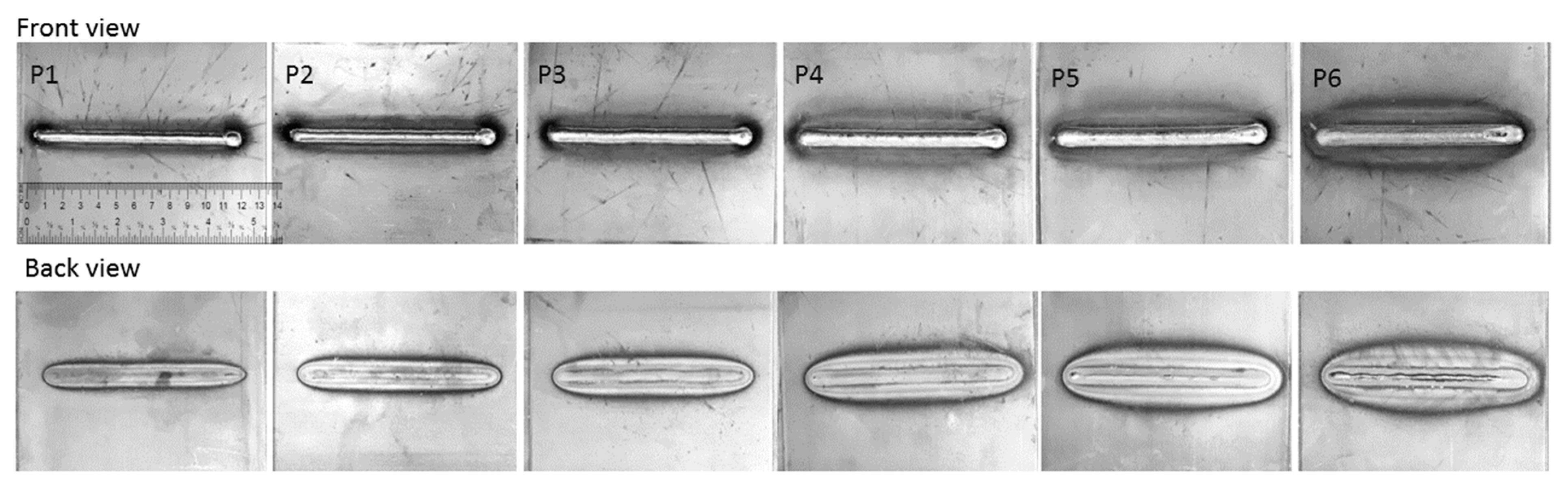

2.2. Materials Preparation

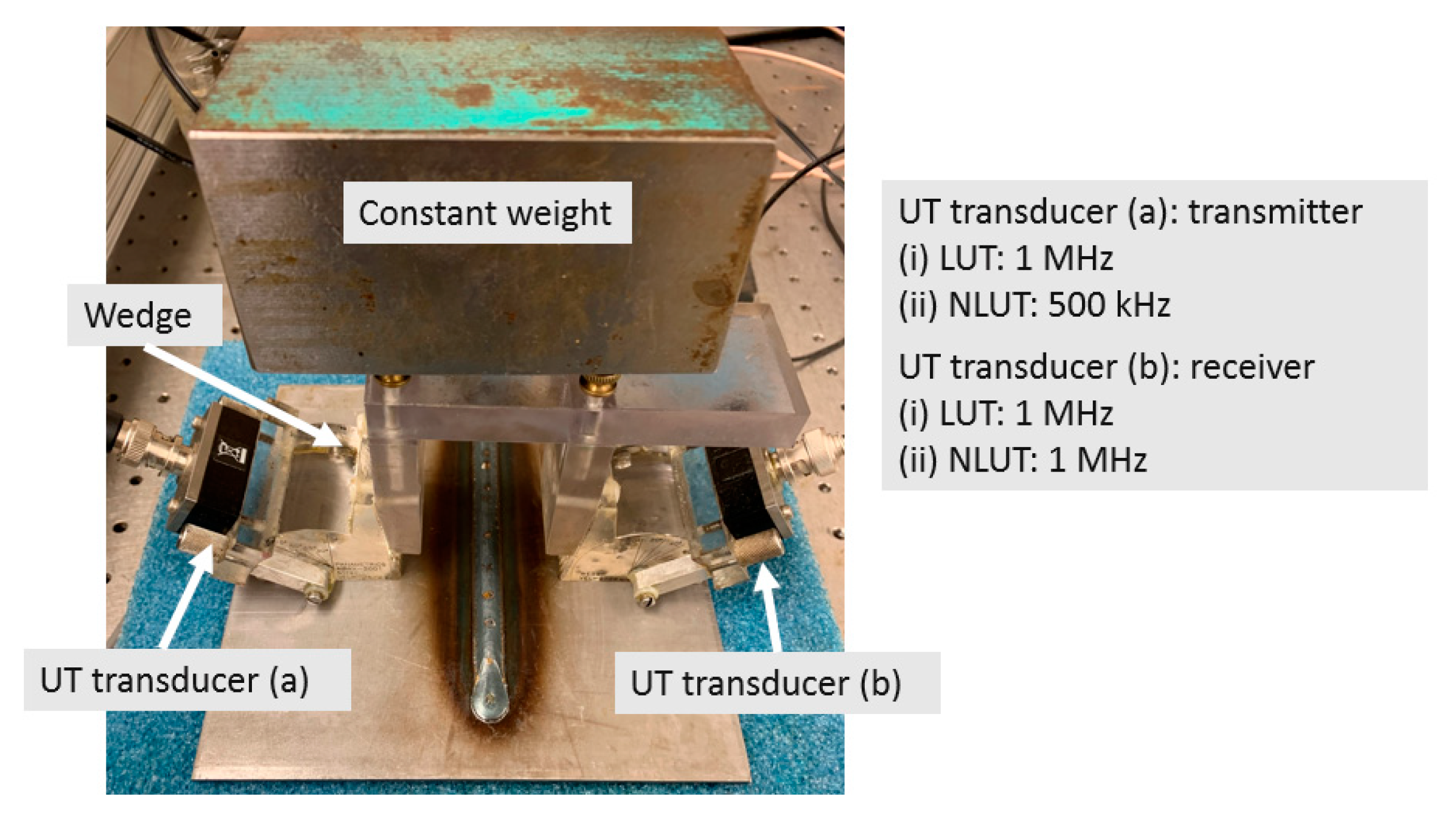

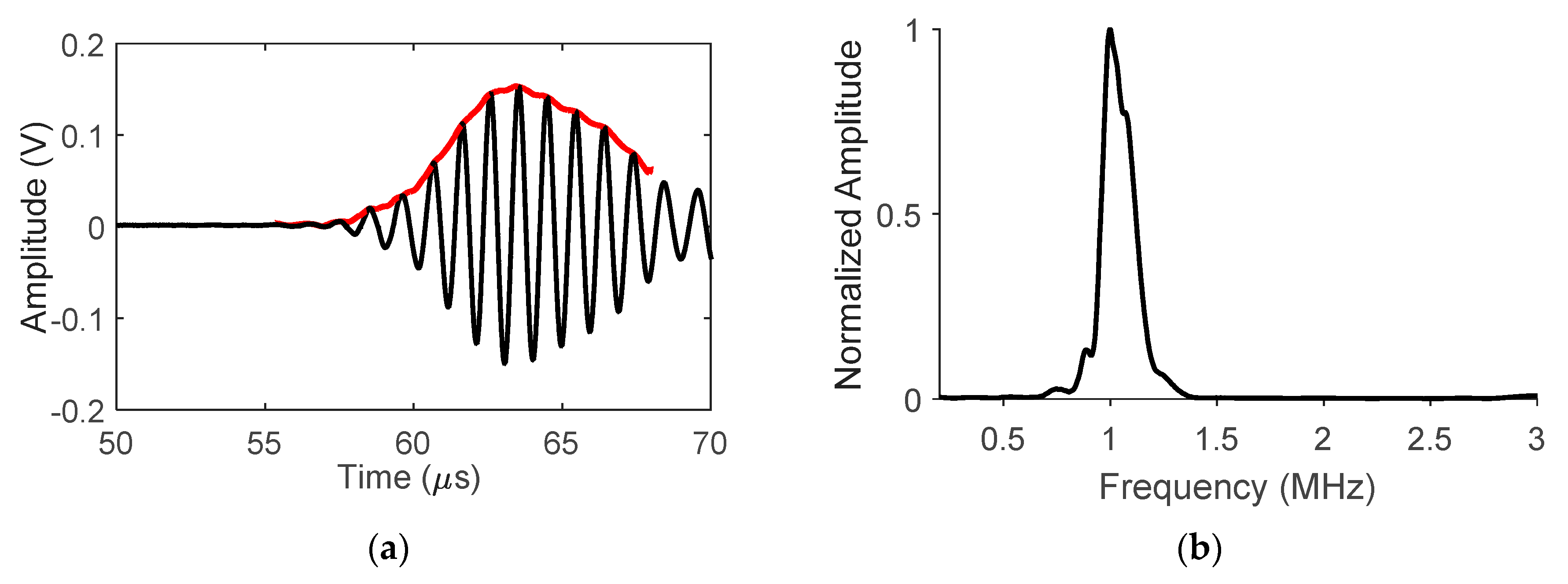

2.3. Ultrasonic Measurement

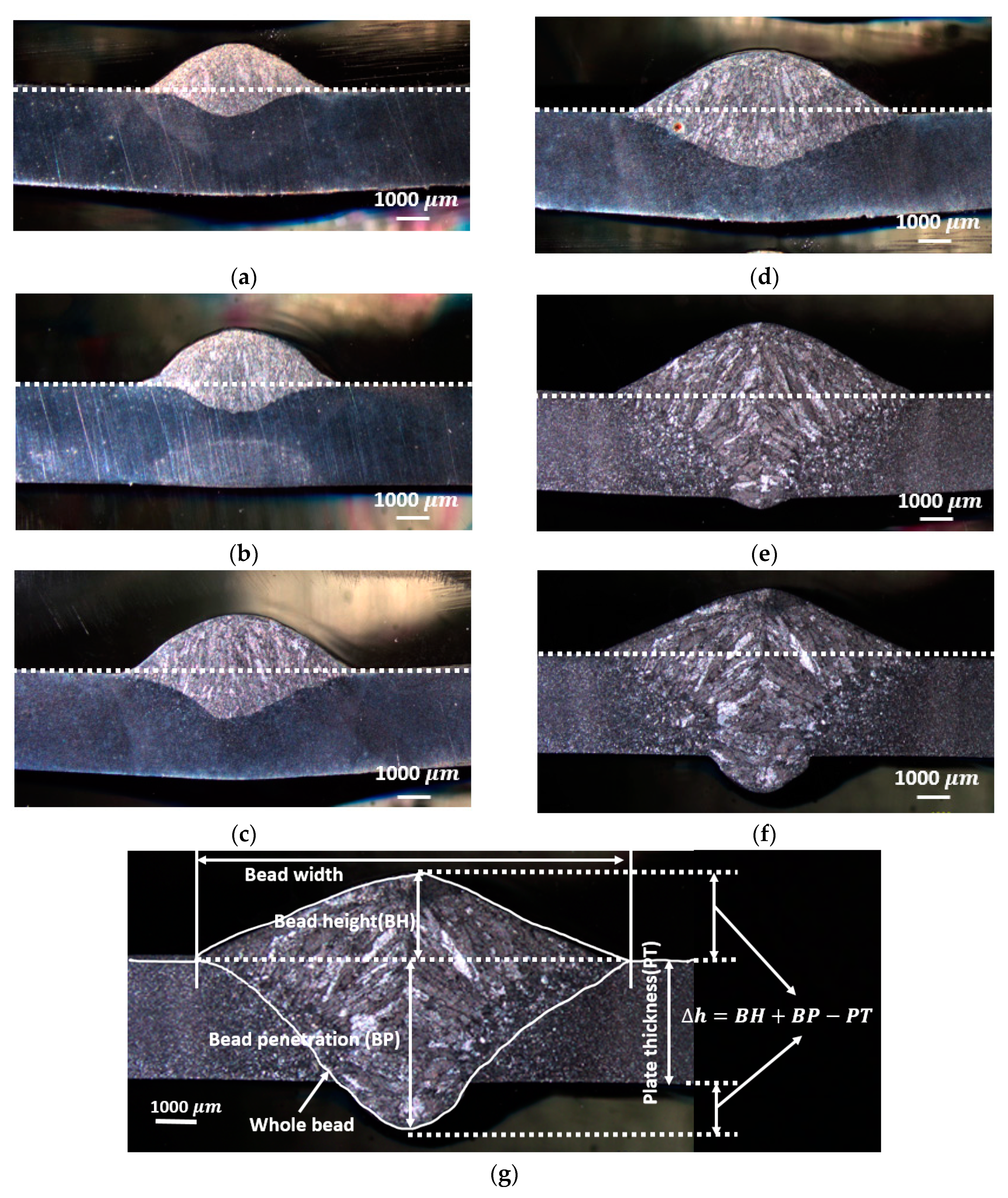

2.4. Metallographic Assessment

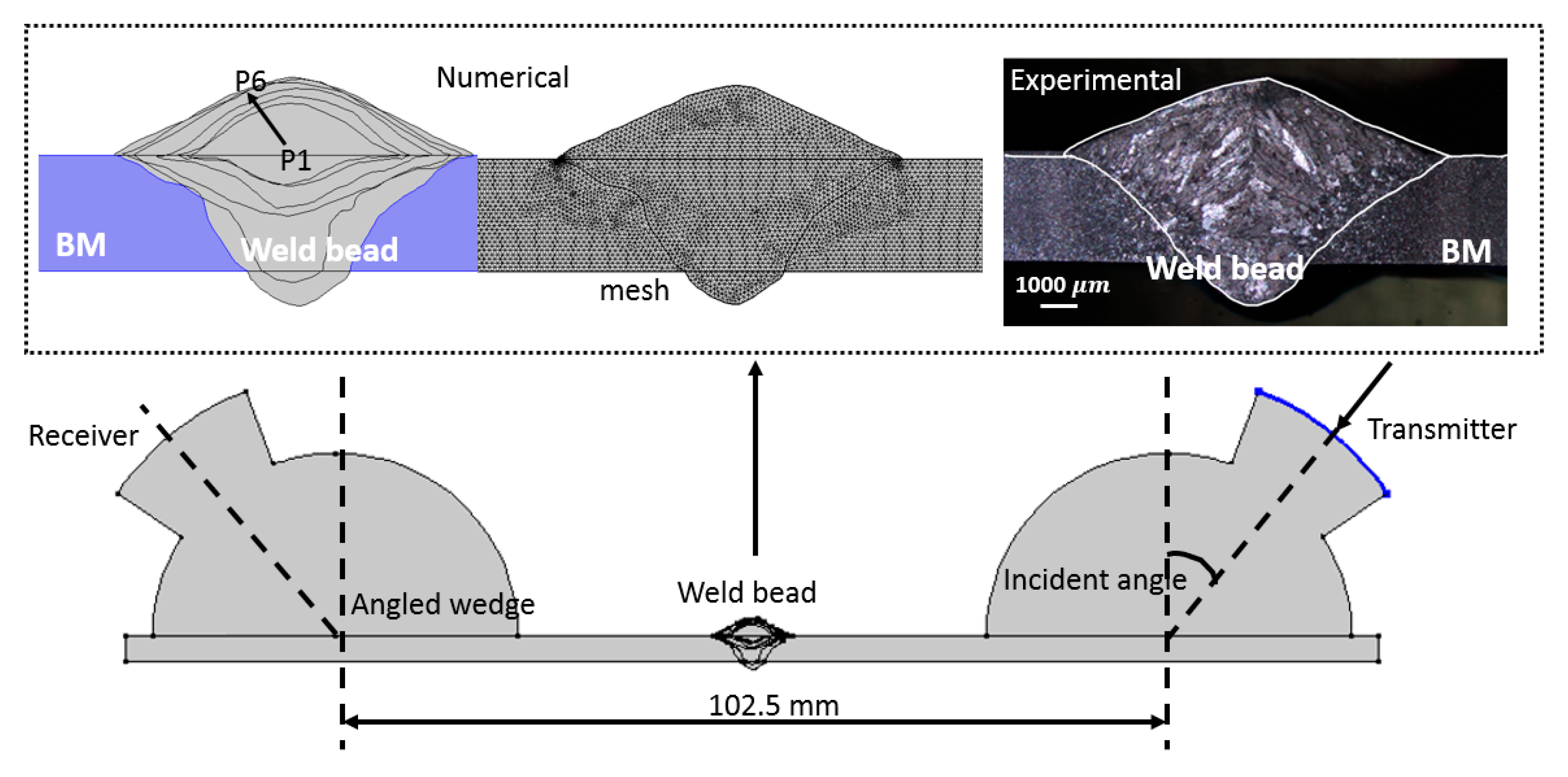

2.5. Numerical Models

3. Results

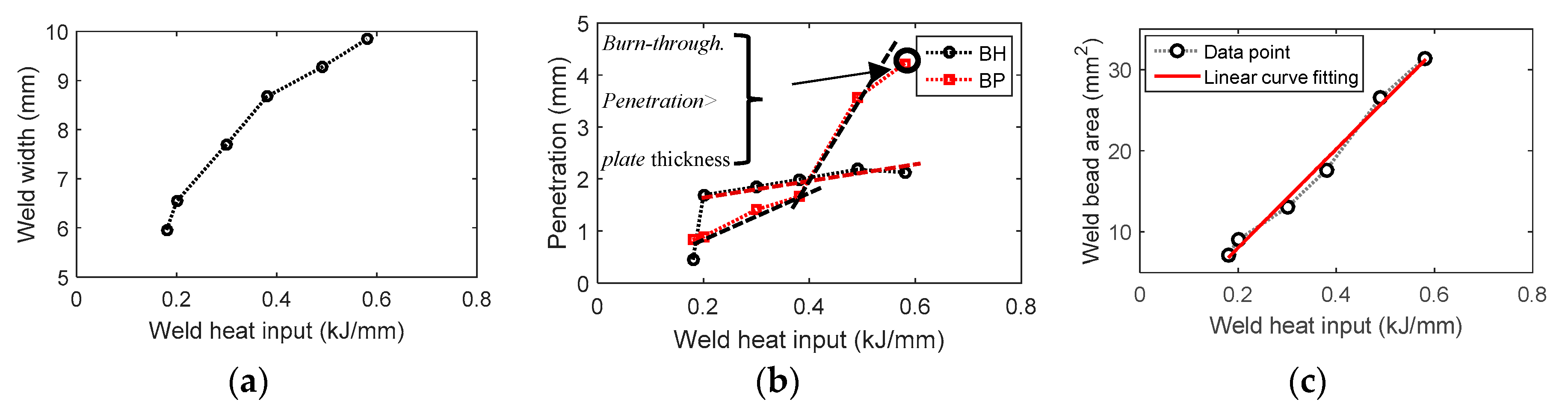

3.1. The Correlation of Heat Input and Weld Morphology

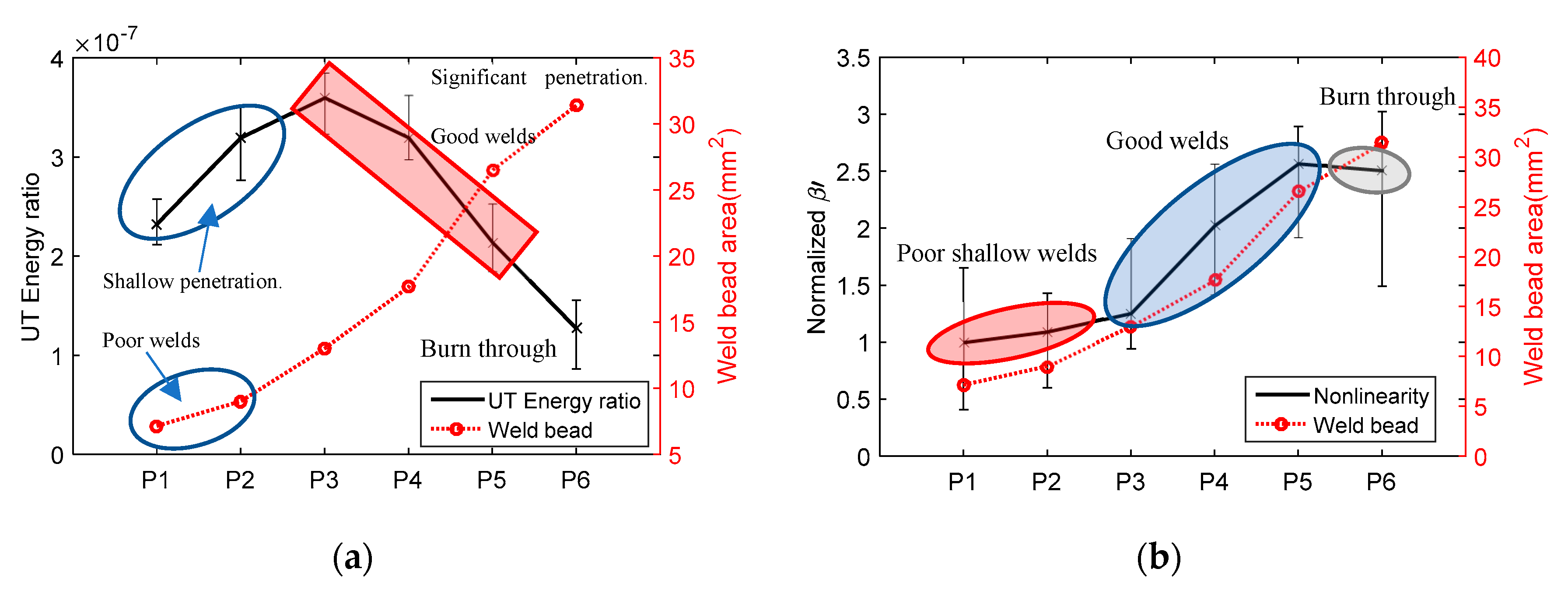

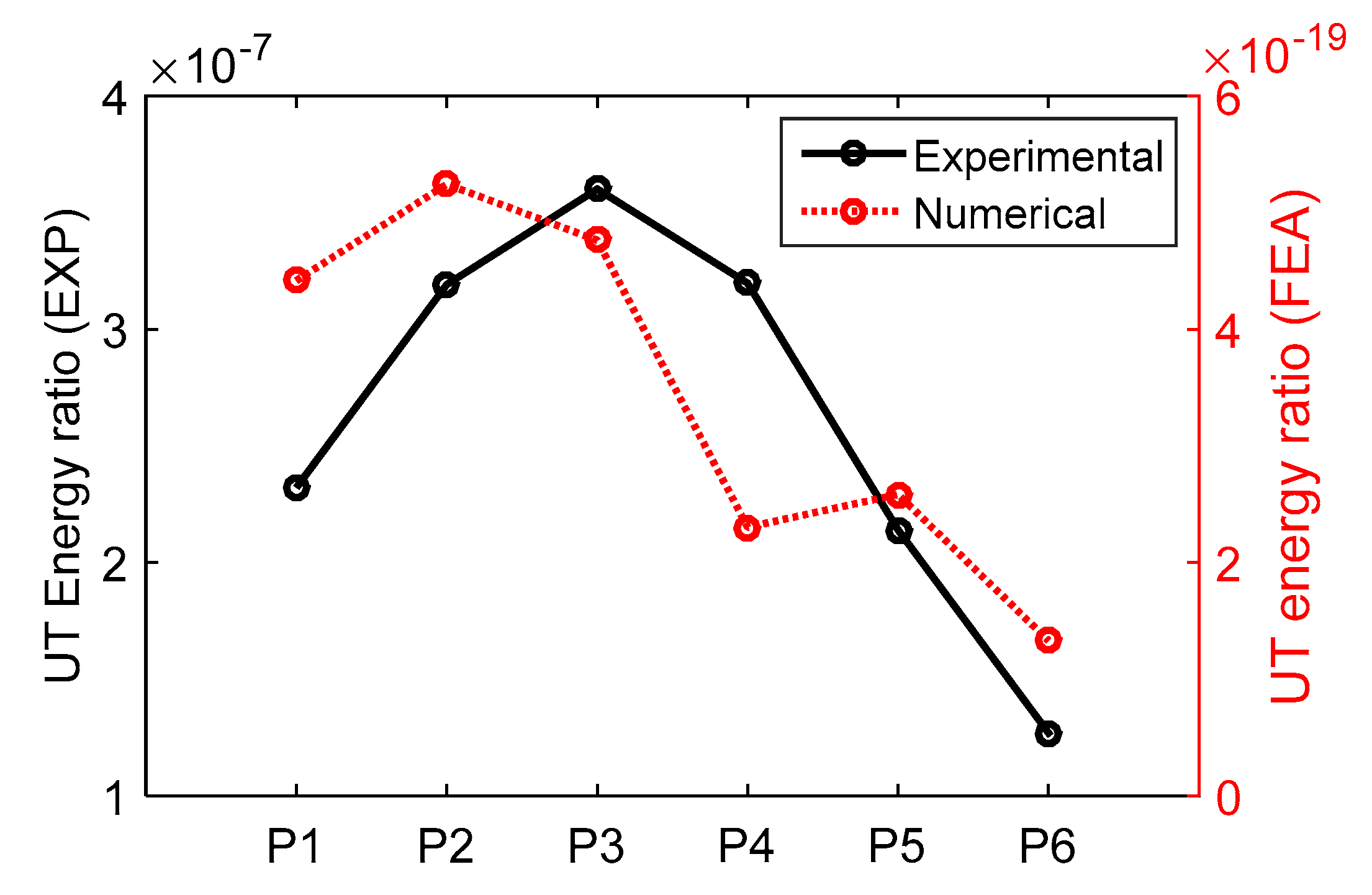

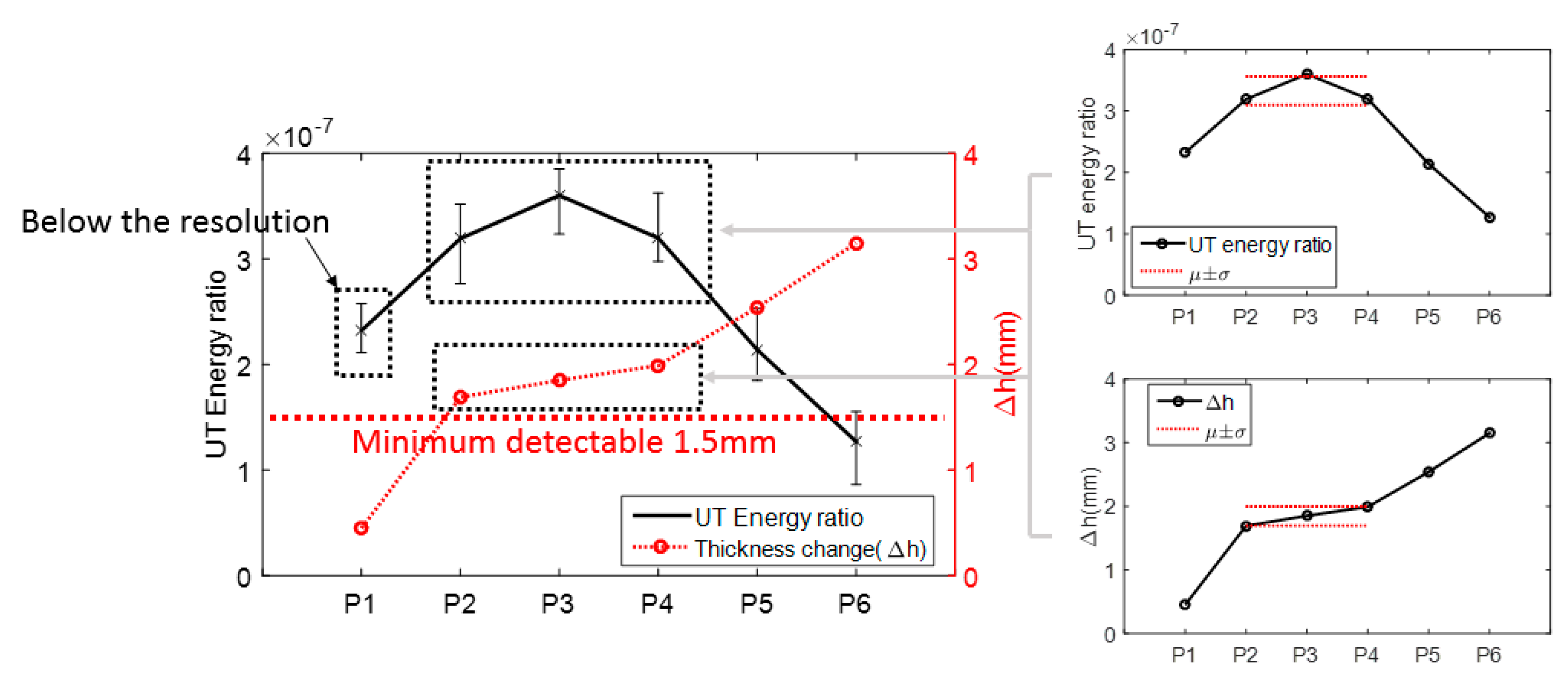

3.2. The Correlation between UT and Weld Morphology

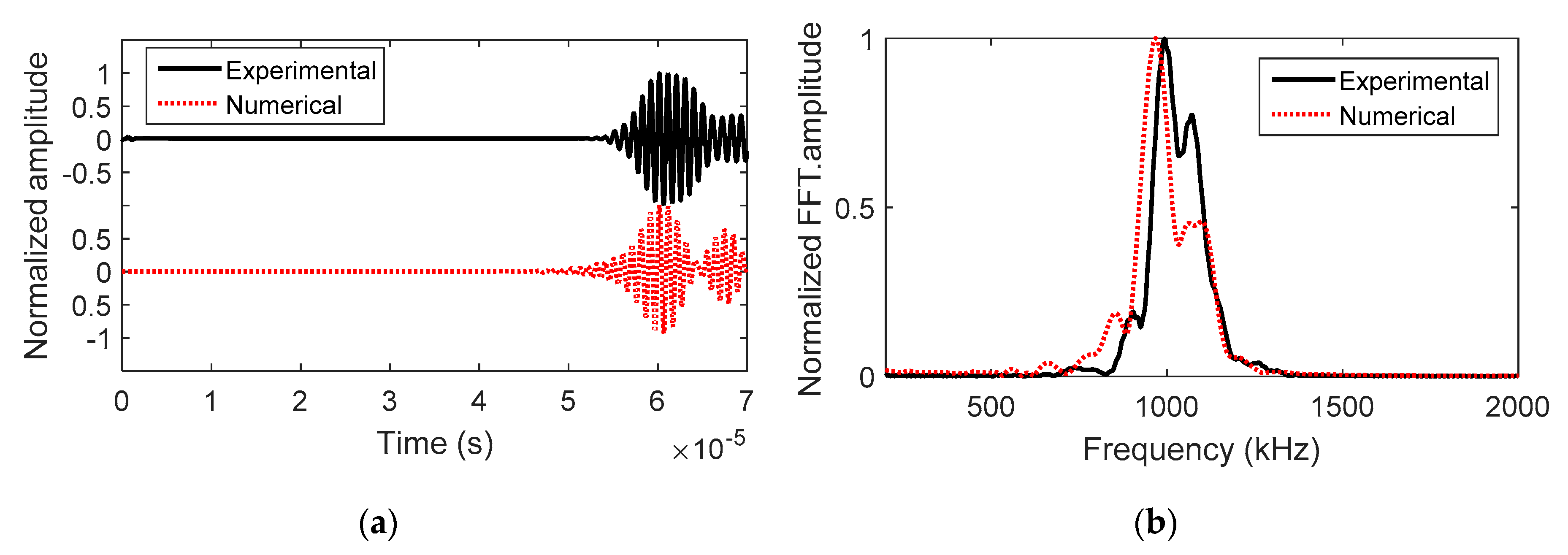

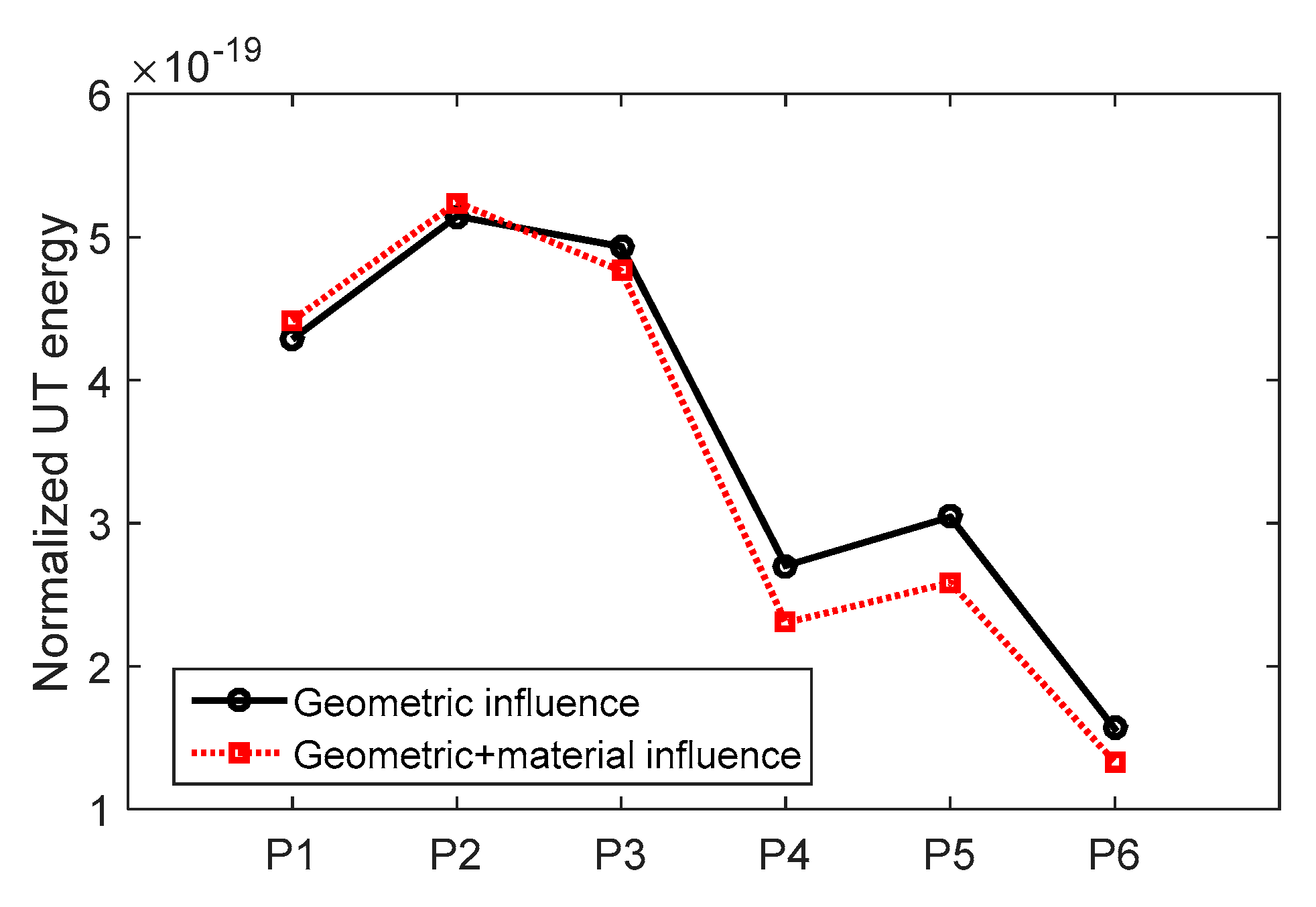

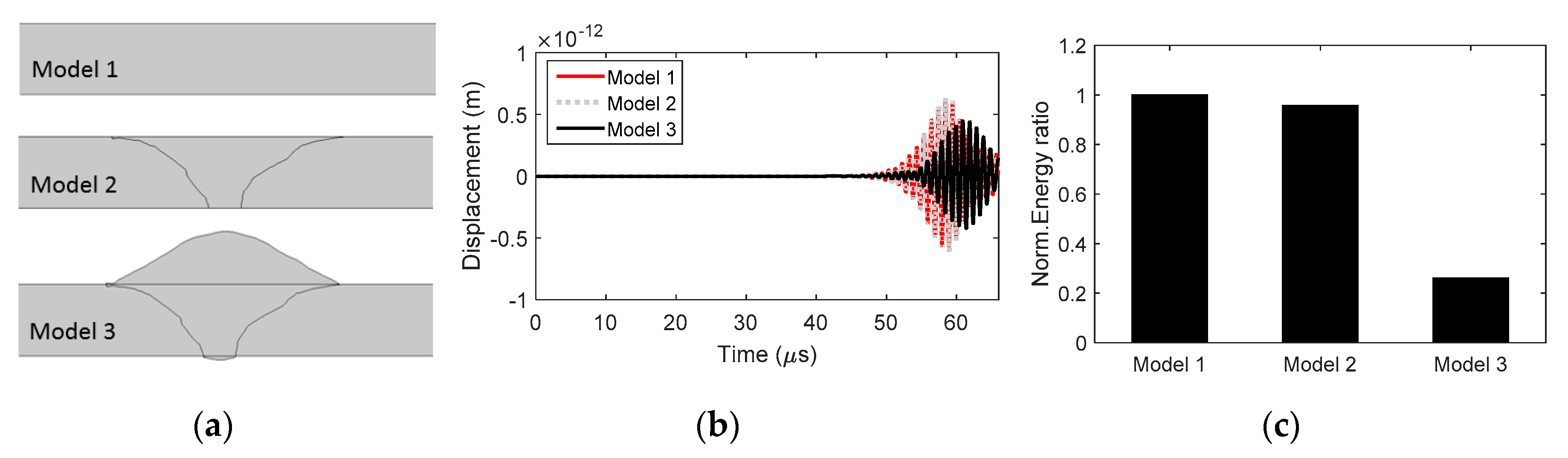

3.3. Numerical Results to Support LUT Data

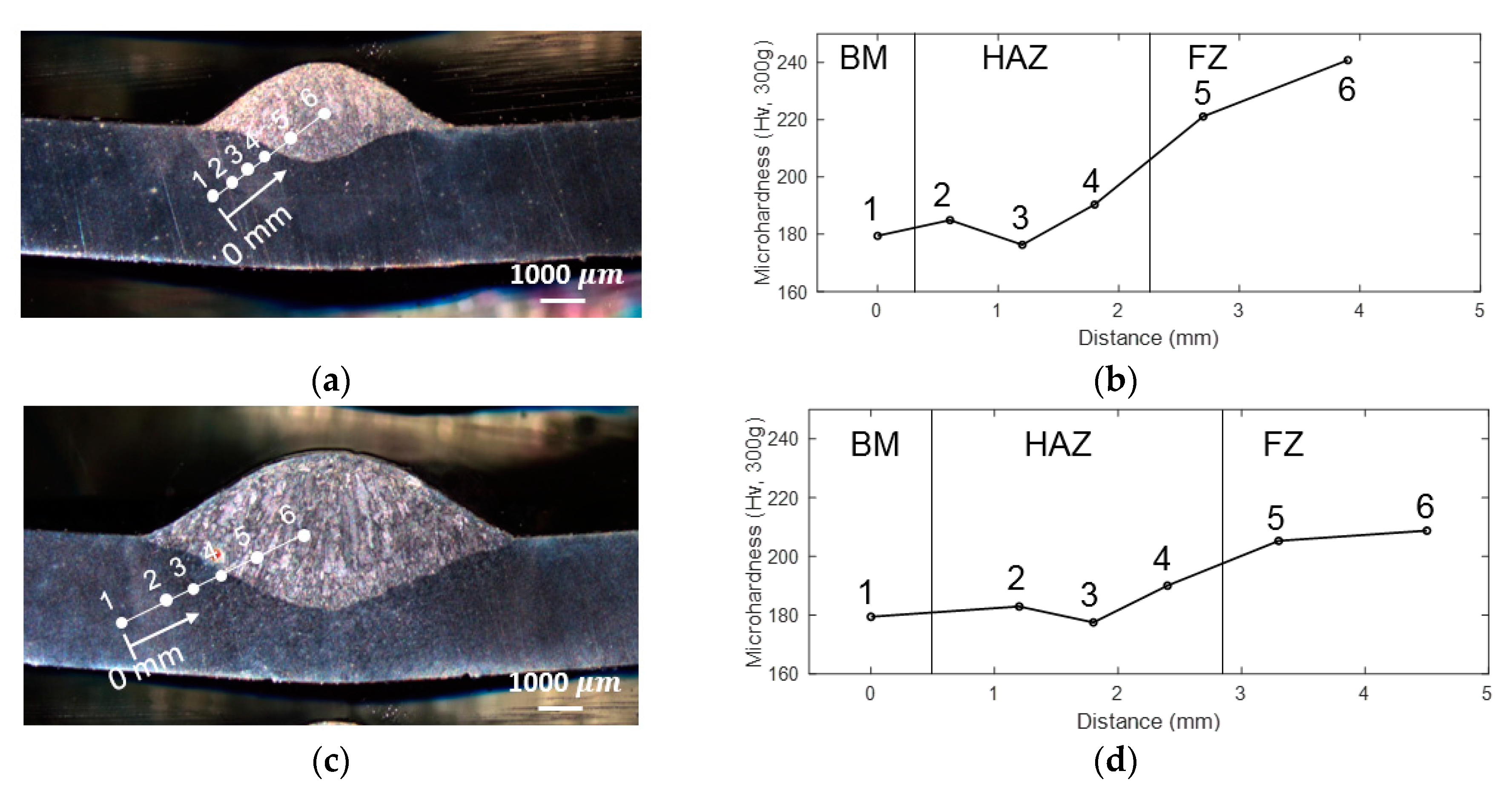

4. Microhardness Results

5. Conclusions

- (1)

- The numerical models connected with macrographs through digitized images provide an accurate representation of weld morphology. The numerical results show that LUT is influenced by the presence of weld exceeding the base plate thickness, other than the materials’ properties of weld, as compared to base metal.

- (2)

- The experimental and numerical results show that excessive weld penetration causes a decrease in the ultrasonic energy. Heat input increases with weld penetration. However, unless a visual inspection is conducted, or it is known that heat input is excessive, the excessive weld penetration cannot be predicted by only heat input. UT provides a quantitative and automated assessment of weld quality.

- (3)

- While LUT is influenced only by geometric variability of weld morphology, NLUT shows the dependence on both geometry and heterogeneity. The two methods can be used concurrently for more accurate assessment of weld quality.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nadzam, J.; Armao, F.; Byall, L.; Kotecki, D.; Miller, D. Gas metal arc welding product and procedure selection; Lincoln global Inc.: Santa Fe Springs, CA, USA, 2014. [Google Scholar]

- Zergoug, M.; Lebaili, S.; Boudjellal, H.; Benchaala, A. Relation between mechanical microhardness and impedance variations in eddy current testing. NDT E Int. 2004, 37, 65–72. [Google Scholar] [CrossRef]

- Komura, I.; Hirasawa, T.; Nagai, S.; Takabayashi, J.I.; Naruse, K. Crack detection and sizing technique by ultrasonic and electromagnetic methods. Nucl. Eng. Des. 2001, 206, 351–362. [Google Scholar] [CrossRef]

- Da Silva, R.R.; Calôba, L.P.; Siqueira, M.H.S.; Rebello, J.M.A. Pattern recognition of weld defects detected by radiographic test. NDT E Int. 2004, 37, 461–470. [Google Scholar] [CrossRef]

- Augustyniak, M.; Usarek, Z. Finite Element Method Applied in Electromagnetic NDTE: A Review. J. Nondestruct. Eval. 2016, 35, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Atabaki, M.M.; Ma, J.; Liu, W.; Kovacevic, R. Pore formation and its mitigation during hybrid laser/arc welding of advanced high strength steel. Mater. Des. 2015, 67, 509–521. [Google Scholar] [CrossRef]

- Zhang, L.; Mostavi, A.; Basantes-Defaz, A.-D.-C.; Ozevin, D.; Indacochea, J.E. The Measurement of Weld Morphology and Inclusions using Ultrasonics. Measurement 2019, 144, 33–43. [Google Scholar] [CrossRef]

- Ogilvy, J.A. Computerized ultrasonic ray tracing in austenitic steel. NDT Int. 1985, 18, 67–77. [Google Scholar] [CrossRef]

- Ogilvy, J.A. Ultrasonic beam profiles and beam propagation in an austenitic weld using a theoretical ray tracing model. Ultrasonics 1986, 24, 337–347. [Google Scholar] [CrossRef]

- Fu, Y.; Wu, J.; Liu, Z.; Wang, R.; Jiang, B.; Wen, W. Phased array ultrasonic test of vertical defect on butt-joint weld of CFETR vacuum vessel port stub. Fusion Eng. Des. 2019, 141, 1–8. [Google Scholar] [CrossRef]

- Alleyne, D.N.; Cawley, P. Optimization of lamb wave inspection techniques. NDT E Int. 1992, 25, 11–22. [Google Scholar] [CrossRef]

- Ruiz, A.; Fuentes-Corona, K.J.; López, V.H.; León, C.A. Microstructural and ultrasonic characterization of 2101 lean duplex stainless steel welded joint. Appl. Acoust. 2017, 117, 12–19. [Google Scholar] [CrossRef]

- Kumar, S.; Ghosh, A.; Sagar, S.P.; Singh, P.K.; Sahu, M.; Ghosh, M. Assessment of Mechanical Properties for Dissimilar Metal Welds: A Nondestructive Approach. J. Mater. Eng. Perform. 2019, 28, 900–907. [Google Scholar] [CrossRef]

- Marinho, L.B.; Filho, P.P.R.; de Albuquerque, V.H.C. Ultrasonic sensor signals and self organized mapping with nearest neighbors for the microstructural characterization of thermally-aged Inconel 625 alloy. Comput. Ind. 2019, 107, 1–10. [Google Scholar] [CrossRef]

- Hua, L.; Wang, B.; Wang, X.; He, X.; Guan, S. In-situ ultrasonic detection of resistance spot welding quality using embedded probe. J. Mater. Process. Technol. 2019, 267, 205–214. [Google Scholar] [CrossRef]

- Lee, J.; Park, J.; Cho, Y. A novel ultrasonic NDE for shrink fit welded structures using interface waves. Ultrasonics 2016, 68, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Delrue, S.; Tabatabaeipour, M.; Hettler, J.; Van Den Abeele, K. Applying a nonlinear, pitch-catch, ultrasonic technique for the detection of kissing bonds in friction stir welds. Ultrasonics 2016, 68, 71–79. [Google Scholar] [CrossRef] [PubMed]

- Doerr, C.; Lakocy, A.; Kim, J.Y.; Singh, P.M.; Wall, J.J.; Qu, J.; Jacobs, L.J. Evaluation of the heat-affected zone (HAZ) of a weld joint using nonlinear Rayleigh waves. Mater. Lett. 2017, 190, 221–224. [Google Scholar] [CrossRef]

- Burkov, M.V.; Eremin, A.V.; Lyubutin, P.S.; Byakov, A.V.; Panin, S.V. Applying an Ultrasonic Lamb Wave Based Rechnique to Testing the Condition of V96ts3T12 Aluminum Alloy. Russ. J. Nondestruct. Test. 2017, 53, 817–829. [Google Scholar] [CrossRef]

- Voort, G.F.V. Metallography and Microstructures; ASM International: Materials Park, OH, USA, 2004; Volume 9. [Google Scholar]

- Specification for Low-Alloy, High-Strength Low-Alloy with Improved Formability, Solution Hardened, and Bake Hardenable; ASTM International: Materials Park, OH, USA, 2018; ASTM A1008/A1008M-18.

- Abbasi, Z.; Yuhas, D.; Zhang, L.; Basantes, A.D.C.; Tehrani, N.N.; Ozevin, D.; Indacochea, E. The detection of burn-through weld defects using noncontact ultrasonics. Materials 2018, 11, 128. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, L.; Abbasi, Z.; Yuhas, D.; Ozevin, D.; Indacochea, E. Real-time nondestructive monitoring of the gas tungsten arc welding (GTAW) process by combined airborne acoustic emission and non-contact ultrasonics. In Nondestructive Characterization and Monitoring of Advanced Materials, Aerospace, Civil Infrastructure, and Transportation XII; SPIE Press: Bellingham, DC, USA, 2018; Volume 10599, p. 105991V. [Google Scholar]

| Application | Experimental Configuration | Material | Weld | Reference |

|---|---|---|---|---|

| Evaluate and visualize V-butt joint weld | Ultrasonic-based tomography | Austenitic material | V-butt joint | [8,9] |

| Detect the internal defects hidden inside butt-joint weld | Linear phase array ultrasonic technique | Chromium-zirconium copper | Butt-joint weld | [10] |

| Identify the simulated weld defects by Lamb wave | Linear ultrasonic transducer with variable angle probes (through-transmission) | Steel | Simulated weld (no actual weld) | [11] |

| Assess the microstructure change | Immersion UT | Duplex stainless steel | GMAW (Gas metal arc welding) | [12] |

| Correlate UT measurement to the mechanical properties within the weld bead | Immersion UT | Stainless steel 304L | V-butt joint | [13] |

| Evaluate microstructural deterioration due to thermal aging treatment | Pulse-echo UT measurement | 625 nickel-based alloy | Butt weld | [14] |

| Evaluate the weld quality in-situ | Embedded the ultrasonic probe into the electrode in pulse-echo mode | Dual-phase steel DP590 | Resistance spot weld | [15] |

| Identify the shrink-cased defect in the weld bead | Multi-transducer guided wave in pulse-echo mode | Stainless steel 316 | Weld joint | [16] |

| Identify the kissing bond flaws in welded butt joint | Nonlinear ultrasonic method in through-transmission mode | Aluminum alloy | Butt-joint weld (friction stir welding) | [17] |

| Identify the range of HAZ (Heat affected zone) | Nonlinear ultrasonic method in through-transmission mode | Stainless steel 304 | V-butt joint | [18] |

| Test the mechanical performance of weld joint | Linear ultrasonic by Lamb wave | Aluminum alloy | Weld joint | [19] |

| Sample | Wire Speed (mm/s) | Gas Flow Rate (Liter/min) | Travel Speed (mm/s) | Heat Input (kJ/mm) |

|---|---|---|---|---|

| P1 | 42.3 | 18.83 | 11 | 0.18 |

| P2 | 50.8 | 18.83 | 11 | 0.20 |

| P3 | 67.7 | 18.83 | 11 | 0.30 |

| P4 | 84.7 | 18.83 | 11 | 0.38 |

| P5 | 101.6 | 18.83 | 11 | 0.49 |

| P6 | 118.5 | 18.83 | 11 | 0.58 |

| Property | Base Metal | Angled Wedge (Acrylic Plastic) | Weld Metal |

|---|---|---|---|

| Young’s Modulus (GPa) | 190 | 50.8 | 205 |

| Poisson’s ratio | 0.28 | 0.34 | 0.295 |

| Density (kg/m3) | 7800 | 1160 | 7850 |

| Sample | Width (mm) | Bead Height (BH) (mm) | Bead Penetration (BP) (mm) | Area of Weld Bead (mm2) | Weld Heat Input (kJ/mm) |

|---|---|---|---|---|---|

| P1 | 5.96 | 0.45 | 0.83 | 7.14 | 0.18 |

| P2 | 6.54 | 1.69 | 0.89 | 9.01 | 0.20 |

| P3 | 7.70 | 1.85 | 1.41 | 13.01 | 0.30 |

| P4 | 8.67 | 1.99 | 1.66 | 17.65 | 0.38 |

| P5 | 9.27 | 2.18 | 3.56 * | 26.54 | 0.49 |

| P6 | 9.84 | 2.13 | 4.22 * | 31.38 | 0.58 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Okudan, G.; Basantes-Defaz, A.-D.-C.; Gneiting, R.M.; Subramaniam, S.; Ozevin, D.; Indacochea, E. Characterization of GMAW (Gas Metal Arc Welding) Penetration Using Ultrasonics. Materials 2020, 13, 2307. https://doi.org/10.3390/ma13102307

Zhang L, Okudan G, Basantes-Defaz A-D-C, Gneiting RM, Subramaniam S, Ozevin D, Indacochea E. Characterization of GMAW (Gas Metal Arc Welding) Penetration Using Ultrasonics. Materials. 2020; 13(10):2307. https://doi.org/10.3390/ma13102307

Chicago/Turabian StyleZhang, Lu, Gorkem Okudan, Alexandra-Del-Carmen Basantes-Defaz, Ryan M. Gneiting, Sankaran Subramaniam, Didem Ozevin, and Ernesto Indacochea. 2020. "Characterization of GMAW (Gas Metal Arc Welding) Penetration Using Ultrasonics" Materials 13, no. 10: 2307. https://doi.org/10.3390/ma13102307