Use of Mining Waste to Produce Ultra-High-Performance Fibre-Reinforced Concrete

Abstract

1. Introduction

2. Experimental Study

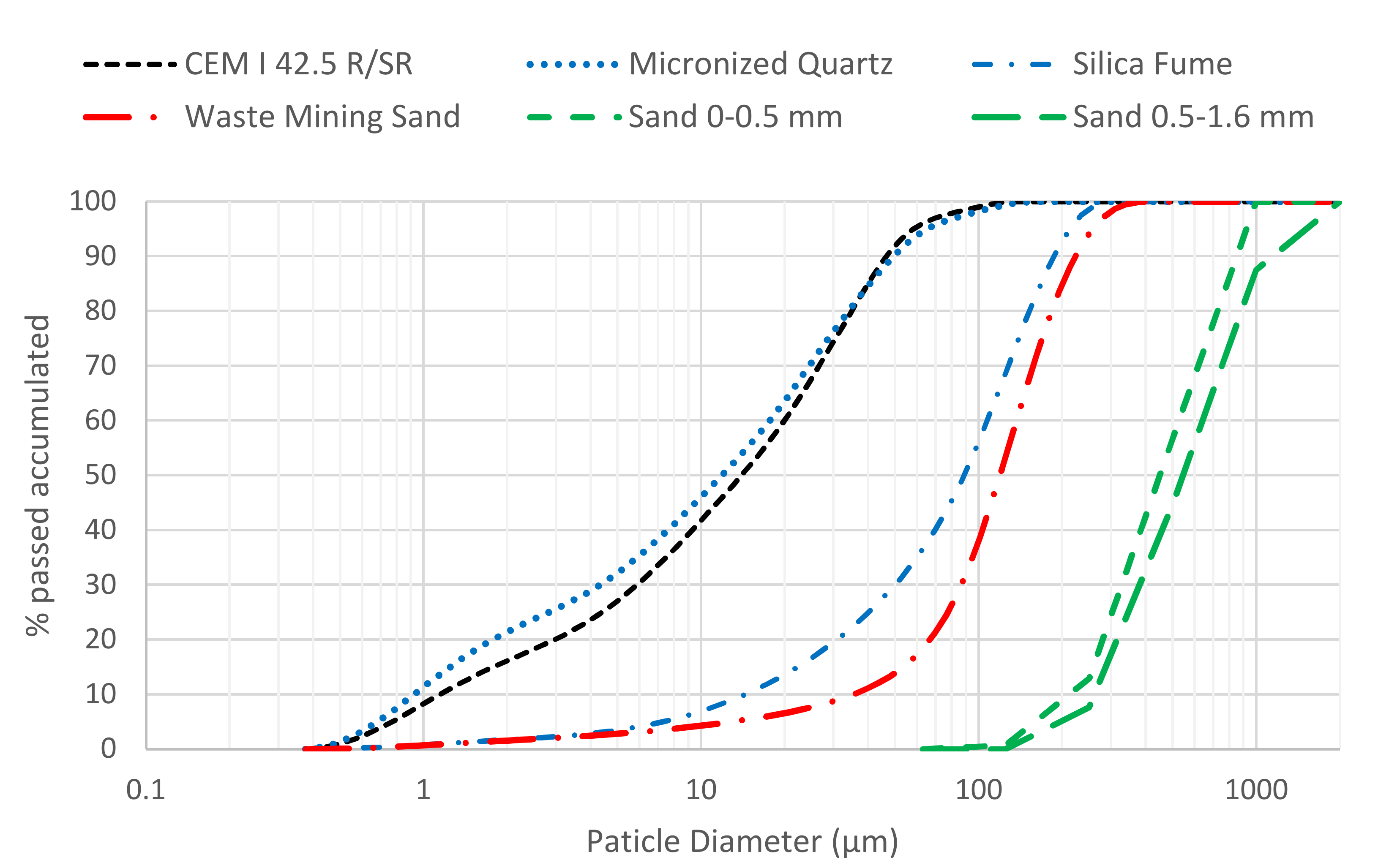

2.1. Description of the Materials Used

2.2. Mix Design

2.3. Development of the Experimental Program

3. Analysis of Results

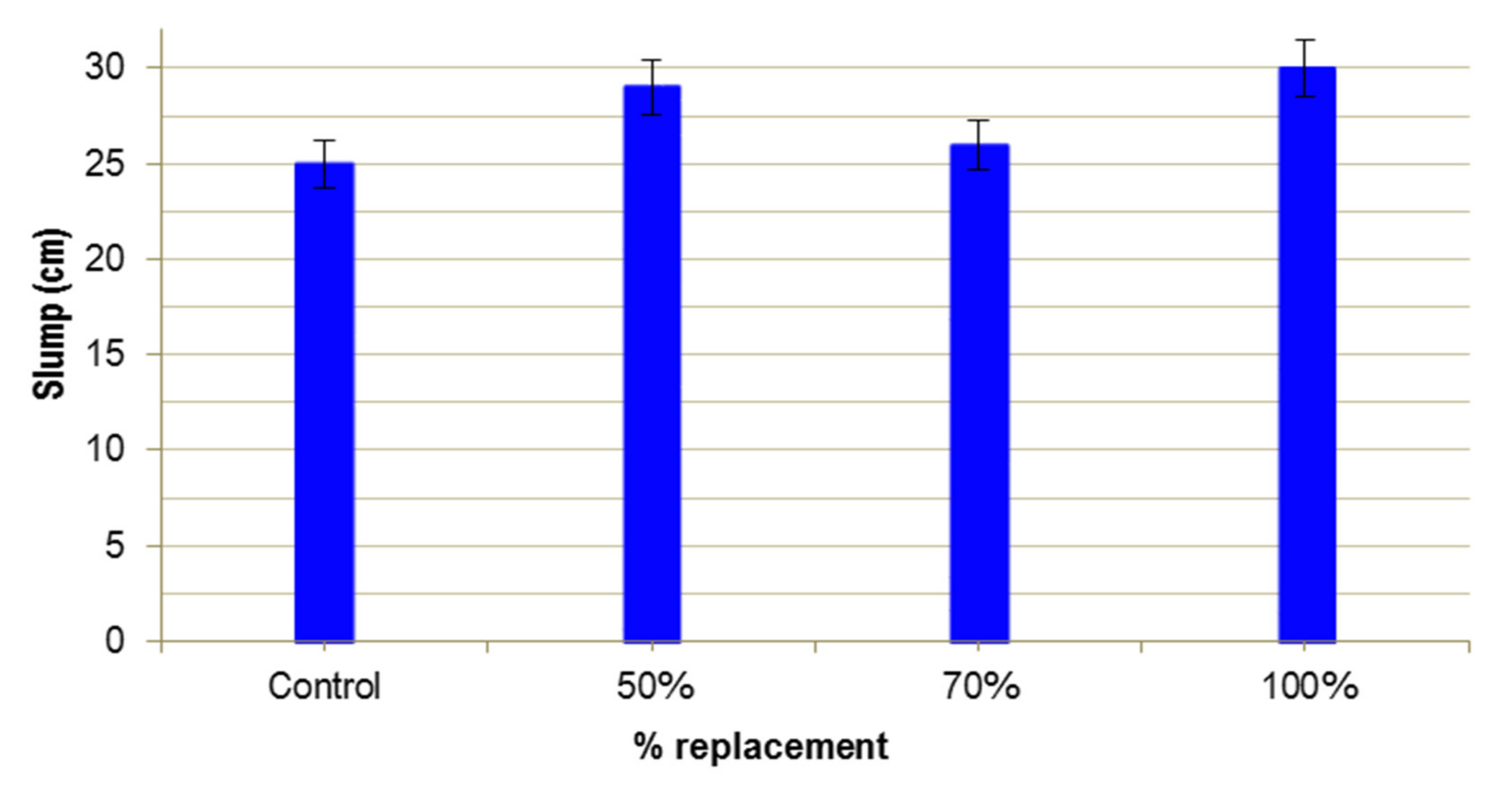

3.1. Consistency of Fresh UHPFRC

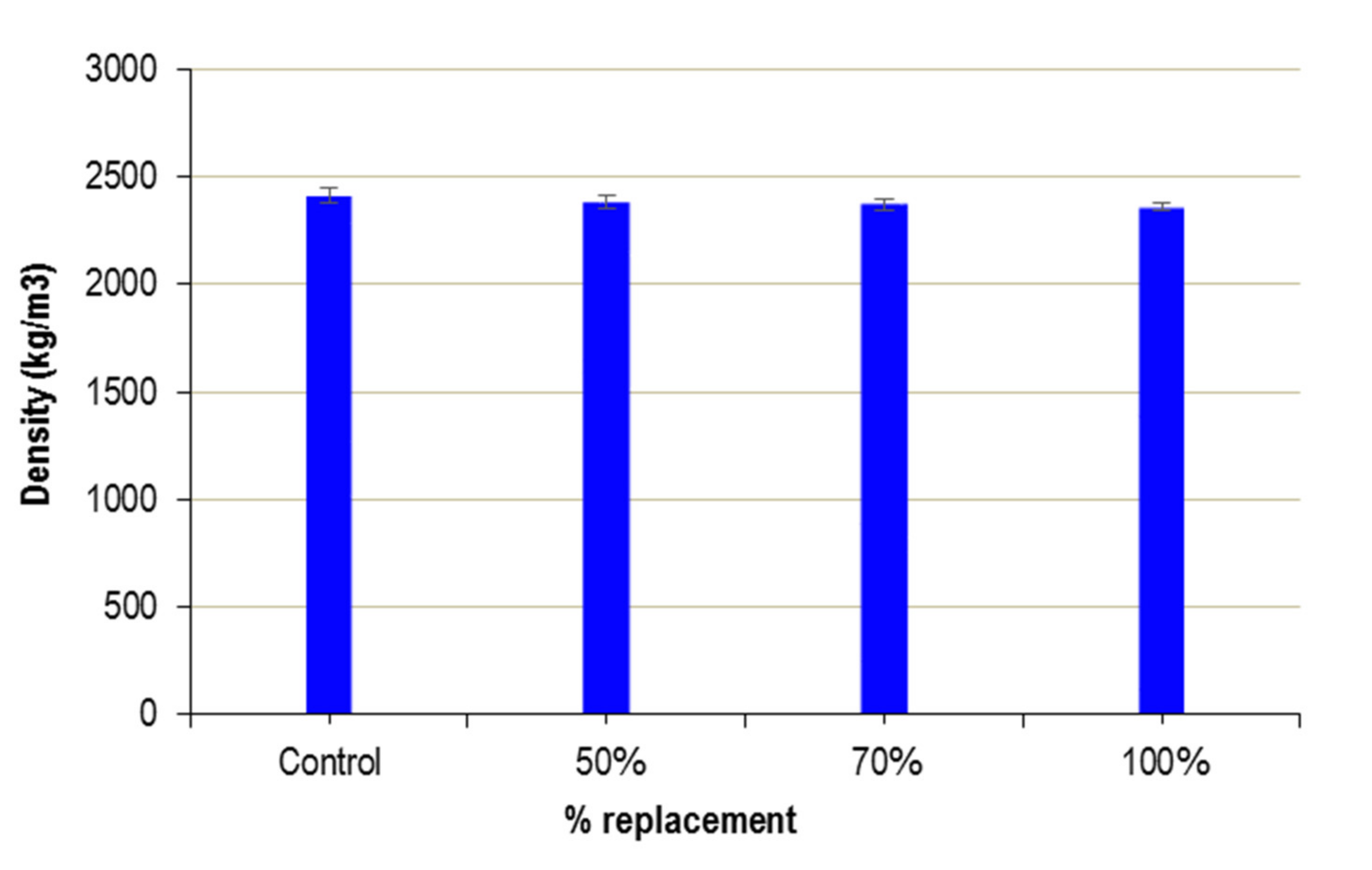

3.2. Density of the Hardened UHPFRC

3.3. Compressive Strength

4. Elasticity Modulus

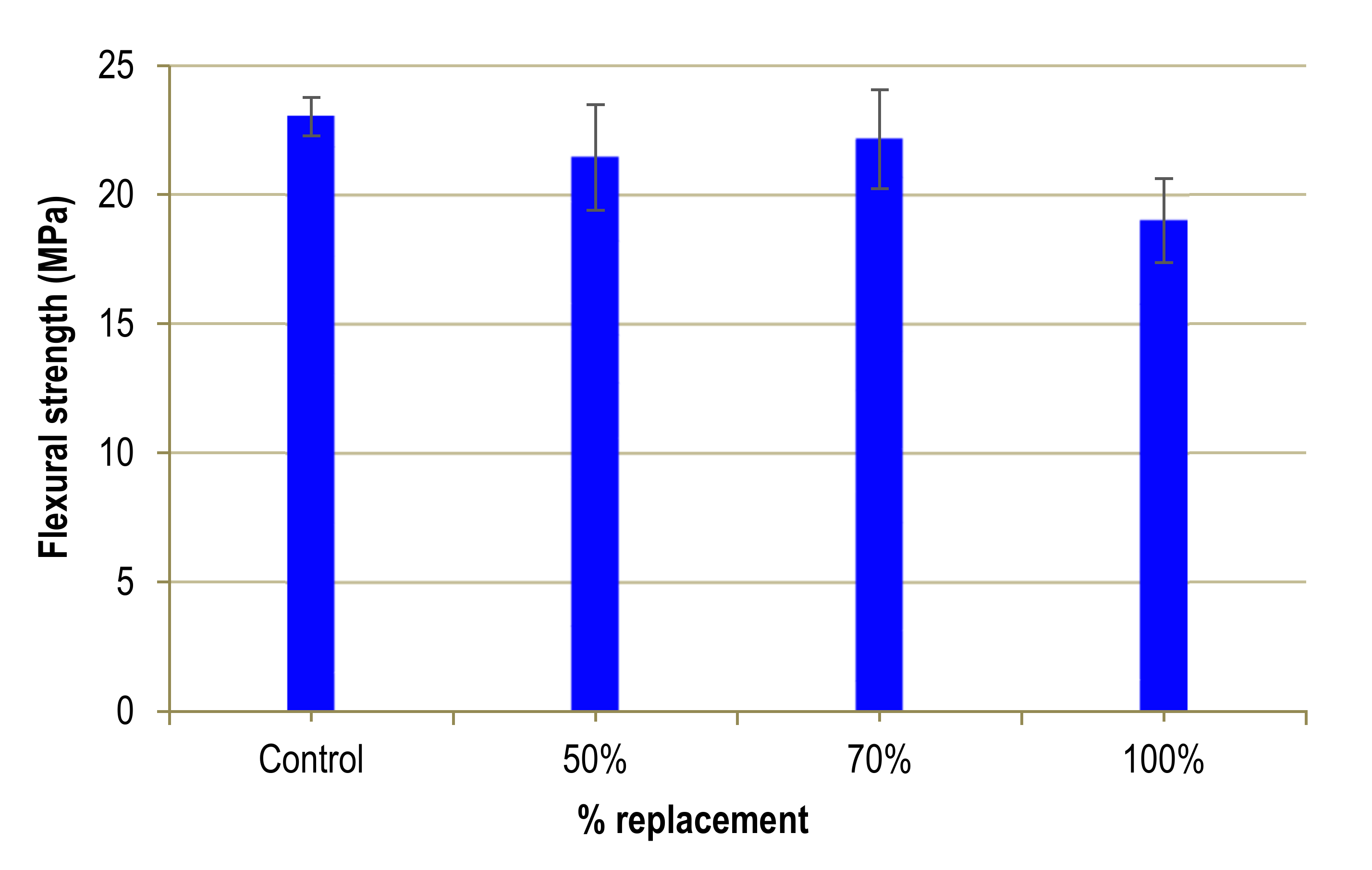

4.1. Flexural Strength

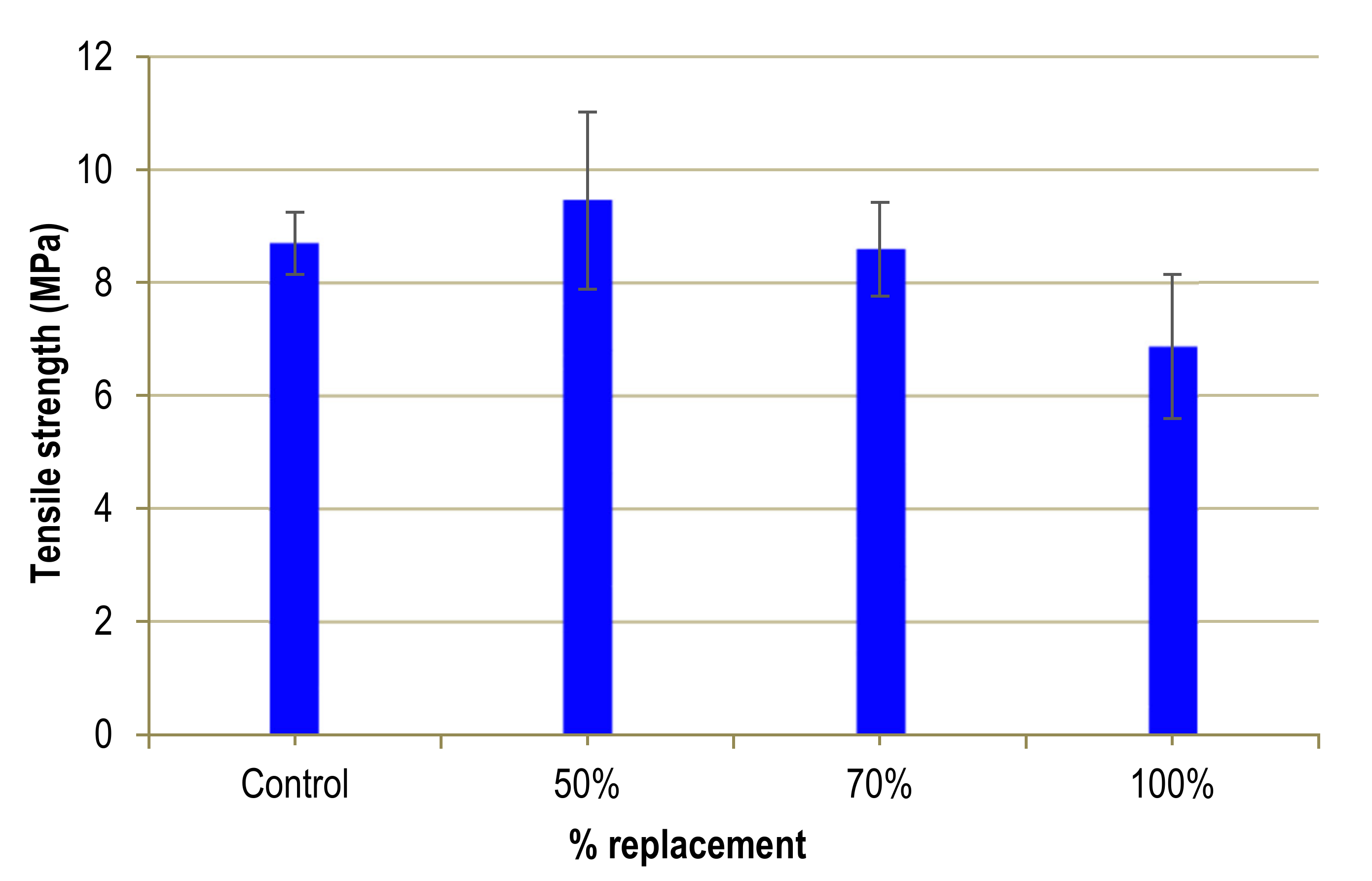

4.2. Tensile Strength

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Richard, P.; Cheyrezy, M. Composition of reactive powder concretes. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- Bétons Fibrés à Ultra-Hautes Performances, Recommandations Provisoires, Ultra High Performance Fibre-Reinforced Concretes, Interim Recommendations, SETRA-AFGC, Groupe de travail BFUP: Paris, France, January 2002. (in French and English). Available online: http://dtrf.setra.fr/pdf/pj/Dtrf/0002/Dtrf-0002989/DT2989.pdf?openerPage=resultats&qid=sdx_q0 (accessed on 27 May 2020).

- Schmidt, C.; Glotzbach, S.; Fröhlich, S.; Piotrowski, S. Sustainable building with UHPC—Coordinated research program in Germany. In Proceedings of the Hipermat 2012 3rd International Symposium on UHPC and Nanotechnology for High Performance Construction Materials, Kassel, Germany, 7–9 March 2012. [Google Scholar]

- Abbas, S.; Soliman, A.M.; Nehdi, M.L. Exploring mechanical and durability properties of ultra-high performance concrete incorporating various steel fiber lengths and dosages. Constr. Build. Mater. 2015, 75, 429–441. [Google Scholar] [CrossRef]

- Fernandez Cánovas, M. Hormigón; Colegio de Ingenieros de Caminos, Canales y Puertos: Madrid, Spain, 2013. [Google Scholar]

- Ambily, P.; Umarani, C.; Ravisankar, K.; Prem, P.R.; Bharatkumar, B.; Iyer, N.R. Studies on ultra high performance concrete incorporating copper slag as fine aggregate. Constr. Build. Mater. 2015, 77, 233–240. [Google Scholar] [CrossRef]

- Zhu, Z.; Li, B.; Zhou, M. The Influences of Iron Ore Tailings as Fine Aggregate on the Strength of Ultra-High Performance Concrete. Adv. Mater. Sci. Eng. 2015, 2015, 412878. [Google Scholar] [CrossRef]

- Zhao, S.; Fan, J.; Sun, W. Utilization of iron ore tailings as fine aggregate in ultra-high performance concrete. Constr. Build. Mater. 2014, 50, 540–548. [Google Scholar] [CrossRef]

- Yang, S.; Millard, S.; Soutsos, M.; Barnett, S.; Le, T. Influence of aggregate and curing regime on the mechanical properties of ultra-high performance fibre reinforced concrete (UHPFRC). Constr. Build. Mater. 2009, 23, 2291–2298. [Google Scholar] [CrossRef]

- Soliman, N.; Tagnit-Hamou, A. Using glass sand as an alternative for quartz sand in UHPC. Constr. Build. Mater. 2017, 145, 243–252. [Google Scholar] [CrossRef]

- Zegardlo, B.; Szeląg, M.; Ogrodnik, P. Ultra-high strength concrete made with recycled aggregate from sanitary ceramic wastes—The method of production and the interfacial transition zone. Constr. Build. Mater. 2016, 122, 736–742. [Google Scholar] [CrossRef]

- Singh, S.; Nagar, R.; Agrawal, V.; Rana, A.; Tiwari, A. Sustainable utilization of granite cutting waste in high strength concrete. J. Clean. Prod. 2016, 116, 223–235. [Google Scholar] [CrossRef]

- Boadella, I.L.; Gayarre, F.L.; González, J.M.S.; Gómez-Soberón, J.M.; Pérez, C.L.-C.; Serrano-Lopez, M.A.; De Brito, J. The Influence of Granite Cutting Waste on The Properties of Ultra-High Performance Concrete. Materials 2019, 12, 634. [Google Scholar] [CrossRef] [PubMed]

- Kala, D. Effect of granite Powder on Strength Properties of Concret. Int. J. Eng. Sci. 2013, 2, 36–50. [Google Scholar]

- Estadísticas Sobre Residuos—Statistics Explained. 2018. Available online: http://ec.europa.eu/eurostat/statistics-explained/index.php?title=Waste_statistics/es (accessed on 27 May 2020).

- Estadísticas Sobre la Recogida y Tratamiento de Residuos. Encuesta Sobre Generación de Residuos en la Industria. 2014. Available online: http://www.ine.es/prensa/np1004.pdf (accessed on 27 May 2020).

- Yu, R.; Spiesz, P.; Brouwers, H. Mix design and properties assessment of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC). Cem. Concr. Res. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- EN 12390-1. Testing Hardened Concrete, Part 1: Shape, Dimensions and other Requirements for Specimens and Moulds; AENOR: Madrid, Spain, 2013. Available online: https://www.une.org/ (accessed on 27 May 2020).

- UNE-EN 12390-2. Testing Hardened Concrete, Part 2: Making and Curing Specimens for Strength Test; AENOR: Madrid, Spain, 2009. Available online: https://www.une.org/ (accessed on 27 May 2020).

- NF P 18-470. Bétons—Bétons Fibrés à Ultra Hautes Performances—Spécification, Performance, Production et Conformité, AFNOR: France. 2016. Available online: https://m.boutique.afnor.org/ (accessed on 27 May 2020).

- EN 12390-7. Testing Hardened Concrete, Part 7: Density of Hardened Concrete; AENOR: Madrid, Spain, 2009; Available online: https://www.une.org/ (accessed on 27 May 2020).

- EN 12390-13. Testing Hardened Concrete, Part 13: Determination of Secant Modulus of Elasticity in Compression; AENOR: Madrid, Spain, 2014; Available online: https://www.une.org/ (accessed on 27 May 2020).

- EN 12390-3. Testing Hardened Concrete, Part 3: Compressive Strength of Test Specimens; AENOR: Madrid, Spain, 2009; Available online: https://www.une.org/ (accessed on 27 May 2020).

- Vogt, C. Ultrafine Particles in Concrete: Influence of Ultrafine Particles on Concrete Properties and Application to Concrete Mix Design. Ph.D. Thesis, School of Architecture and the Built Environment Division of Concrete Structures, Stockholm, Sweden, 2010. [Google Scholar]

- Pyo, S.; Tafesse, M.; Kim, B.-J.; Kim, H.-K. Effects of quartz-based mine tailings on characteristics and leaching behavior of ultra-high performance concrete. Constr. Build. Mater. 2018, 166, 110–117. [Google Scholar] [CrossRef]

- Kou, S.-C.; Xing, F. The Effect of Recycled Glass Powder and Reject Fly Ash on the Mechanical Properties of Fibre-Reinforced Ultrahigh Performance Concrete. Adv. Mater. Sci. Eng. 2012, 2012, 263243. [Google Scholar] [CrossRef]

- Albarwary, I.H.M.; AlDoski, Z.N.S.; Askar, L.K. Effect of Aggregate Maximum Size upon Compressive Strength of Concrete. J. Univ. Duhok 2017, 20, 790–797. [Google Scholar] [CrossRef]

- Raheem, A.H.A.; Mahdy, M.; Mashaly, A.A. Mechanical and fracture mechanics properties of ultra-high-performance concrete. Constr. Build. Mater. 2019, 213, 561–566. [Google Scholar] [CrossRef]

- Ibrahim, M.A.; Farhat, M.; Issa, M.A.; Hasse, J.A. Effect of Material Constituents on Mechanical and Fracture Mechanics Properties of Ultra-High-Performance Concrete. ACI Mater. J. 2017, 114, 453–465. [Google Scholar] [CrossRef]

- Alsalman, A.; Dang, C.; Prinz, G.S.; Hale, W.M. Evaluation of modulus of elasticity of ultra-high performance concrete. Constr. Build. Mater. 2017, 153, 918–928. [Google Scholar] [CrossRef]

- Gonzalez-Corominas, A.; Etxeberria, M. Properties of high performance concrete made with recycled fine ceramic and coarse mixed aggregates. Constr. Build. Mater. 2014, 68, 618–626. [Google Scholar] [CrossRef]

- Taha, B.; Nounu, G. Properties of concrete contains mixed colour waste recycled glass as sand and cement replacement. Constr. Build. Mater. 2008, 22, 713–720. [Google Scholar] [CrossRef]

- Martínez, J.A.L. Characterisation of the Tensile Behaviour of Uhpfrc by Means of Four-Point Bending Tests. Ph.D. Thesis, Universitat Politecnica de Valencia, Valencia, Spain, 2017. [Google Scholar]

| Properties | Aggregate 0–0.5 mm | Aggregate 0.5–1.6 mm | Micronized Quartz | Silica Fume | Waste Mining Sand |

|---|---|---|---|---|---|

| Bulk density (kg/m3) | 2616 | 2616 | 2609 | 2300 | 2717 |

| Sand equivalent | 97 | 97 | - | - | 28 |

| Absorption 24 h | 0.28% | 0.53% | - | - | - |

| Humidity (%) | 0% | 0% | < 0.2% | < 3.00% | 0% |

| Material | SiO2 | CaO | Fe2O3 | Al2O3 | MgO | K2O | Na2O | TiO2 | P2O5 | MnO | L.O.I |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Waste mining sand | 71.65 | 10.8 | 1.66 | 1.5 | 1.21 | 0.57 | 0.13 | 0.11 | 0.03 | 0.01 | 8.82 |

| Aggregate 0–0.5 mm | 99.34 | < 0.1 | < 0.13 | 0.30 | < 0.1 | < 0.1 | < 0.03 | < 0.1 | < 0.1 | - | 0.23 |

| Material | Control | 50% WMS | 70% WMS | 100% WMS |

|---|---|---|---|---|

| Cement | 800 | 800 | 800 | 800 |

| Sand 0–0.5 mm | 302 | 151 | 91 | - |

| Waste mining sand | - | 161 | 225 | 321 |

| Sand 0.5–1.6 mm | 565 | 565 | 565 | 565 |

| Micronized quartz | 225 | 225 | 225 | 225 |

| Silica fume | 175 | 175 | 175 | 175 |

| Water | 175 | 175 | 175 | 175 |

| Superplasticizer | 10 | 10 | 10 | 10 |

| Steel fibres | 160 | 160 | 160 | 160 |

| Properties | Control | Difference (%) | ||

|---|---|---|---|---|

| 50% WMS | 70% WMS | 100% WMS | ||

| Slump (cm) | 25.0 | 16.0% | 4.0% | 20.0% |

| Density (kg/m3) | 2410.0 | −1.2% | −1.7% | −2.1% |

| Compressive strength (MPa) | 117.2 | 9.9% | 11.8% | 11.2% |

| Modulus of elasticity (GPa) | 45.2 | −3.5% | −5.8% | −6.4% |

| Flexural strength (MPa) | 23.0 | −7.0% | −3.5% | −17.4% |

| Tensile strength (MPa) | 8.7 | 9.2% | −1.1% | −20.7% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suárez González, J.; Lopez Boadella, I.; López Gayarre, F.; López-Colina Pérez, C.; Serrano López, M.; Stochino, F. Use of Mining Waste to Produce Ultra-High-Performance Fibre-Reinforced Concrete. Materials 2020, 13, 2457. https://doi.org/10.3390/ma13112457

Suárez González J, Lopez Boadella I, López Gayarre F, López-Colina Pérez C, Serrano López M, Stochino F. Use of Mining Waste to Produce Ultra-High-Performance Fibre-Reinforced Concrete. Materials. 2020; 13(11):2457. https://doi.org/10.3390/ma13112457

Chicago/Turabian StyleSuárez González, Jesús, Iñigo Lopez Boadella, Fernando López Gayarre, Carlos López-Colina Pérez, Miguel Serrano López, and Flavio Stochino. 2020. "Use of Mining Waste to Produce Ultra-High-Performance Fibre-Reinforced Concrete" Materials 13, no. 11: 2457. https://doi.org/10.3390/ma13112457

APA StyleSuárez González, J., Lopez Boadella, I., López Gayarre, F., López-Colina Pérez, C., Serrano López, M., & Stochino, F. (2020). Use of Mining Waste to Produce Ultra-High-Performance Fibre-Reinforced Concrete. Materials, 13(11), 2457. https://doi.org/10.3390/ma13112457