Flexural Damage of Honeycomb Paperboard—A Numerical and Experimental Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Research

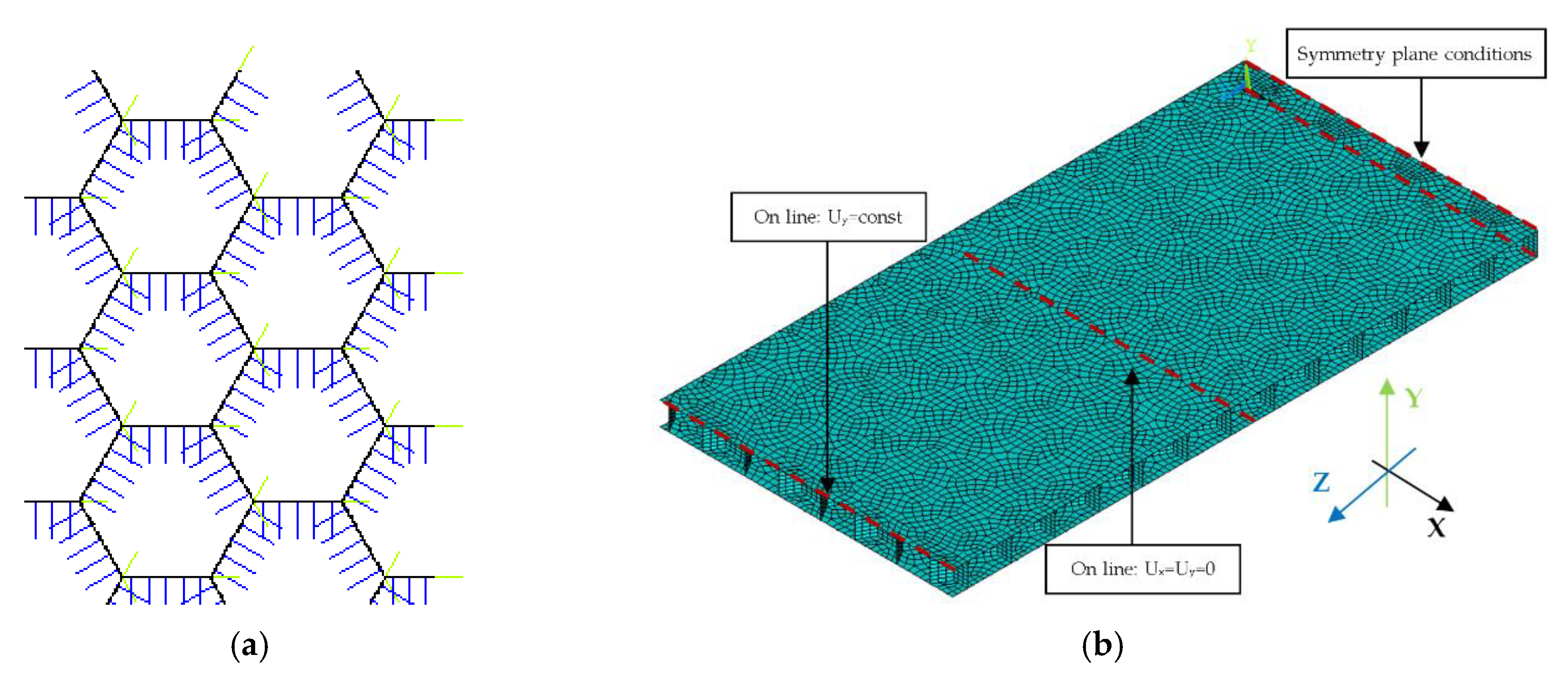

2.2. FE Model

3. Results and Discussion

4. Conclusions and Final Remarks

- Models with reduced paper mechanical properties provided curves close to the experimental curves.

- By comparing the maximum loads, the numerical prediction of failure loads gave lower results but it should be underlined that the failure criteria used only indicate (determine) the initiation of the damage in selected points based on an actual stress state (where the strength condition is fulfilled) but the failure criteria do not change in these locations the material properties. In experiments, local damage in panel might be possible what could lead to the load-carrying capacity of the bent panel being reached. Hence, discrepancies in failure loads based on both methods can amount to a few dozen percent, at most. It seems that these results can be acceptable.

- In general, among all considered failure criteria, the Tsai-Wu criterion indicated the failure propagation at slightly lower load.

- As far as the influence of the honeycomb cell on the results is concerned, models with the ideal cell shape were closer to the experimental study results for the MD.

- In all analysed cases the failure occurred on the face subjected to compression. Referring to both the experimental and numerical results, a pretty good agreement was attained. Moreover, the failure locations in the numerical model were observed in similar places to those where the failure of real specimens occurred.

- Model 2 reflects well the initial, straight line segment of the relationship between the deflection of the bending sample and the force causing the bending, which allows one to determine the bending stiffness of cardboard.

- Based on the experiments, an increase of the paperboard thickness causes an almost proportional increase of the maximum loads and a quadratic increase of stiffness (see Table 4).

- Validated models can be used for the creation of models with complex geometry.

Author Contributions

Funding

Conflicts of Interest

References

- Barboutis, I.; Vassiliou, V. Strength Properties of Lightweight Paper Honeycomb Panels for the Furniture; Faculty of Forestry and Natural Environment, Aristotle University of Thessaloniki: Thessaloniki, Greece, 2005; pp. 1–6. [Google Scholar]

- Sam-Brew, S.; Semple, K.; Smith, G.D. Preliminary Experiments on the Manufacture of Hollow Core Composite Panels. For. Prod. J. 2011, 61, 381–389. [Google Scholar] [CrossRef]

- Kmita-Fudalej, G.; Szewczyk, W. Board products with the honeycomb structure Part1. Application and manufacture. Przegląd Papierniczy 2015, 71, 443–449. [Google Scholar]

- Bitzer, T.N. Honeycomb Technology: Materials, Design, Manufacturing, Aplications and Testing; Springer: Dordrecht, The Netherlands, 1997; ISBN 978-94-011-5856-5. [Google Scholar] [CrossRef]

- Davies, J.M. Lightweight Sandwich Construction; Published on Behalf of CIB Working Commission; W056 Sandwich Panels (Joint CIB-ECCS Commission), Blackwell Science: Hoboken, NJ, USA, 2001; p. 370. [Google Scholar]

- Fell, D. Trend Spotting: Doors. Woodworking 2008, 22. Available online: www.woodworkingcanada.com (accessed on 4 August 2015).

- Wernuld, G. Wood Goes “High Tech” Finally: Honeycomb Panels Offer Performance, Design Flexibility and, Most Importantly, Much Lighter Weight. Wood & Wood Products; Vance Publishing Corporation: Lincolnshire, IL, USA, 2004. [Google Scholar]

- Paul, R.; Klusmeier, W. Structhan®—A Composite with a Future; Status Report; Bayer AG: Leverkusen, Germany, 1997. [Google Scholar]

- Fadiji, T.; Coetzeea, C.J.; Berry, T.M.; Opara, U.L. Investigating the role of geometrical configurations of ventilated fresh produce packaging to improve the mechanical strength—Experimental and numerical approaches. Food Packag. Shelf Life 2019, 20, 100312. [Google Scholar] [CrossRef]

- Fadiji, T.; Ambaw, A.; Coetzee, C.J.; Berry, T.M.; Opara, U.L. Application of finite element analysis to predict the mechanical strength of ventilated corrugated paperboard packaging for handling fresh produce. Biosyst. Eng. 2018, 174, 260–281. [Google Scholar] [CrossRef]

- Fadiji, T.; Coetzee, C.J.; Oparab, U.L. Analysis of the creep behaviour of ventilated corrugated paperboard packaging for handling fresh produce—An experimental study. Food Bioprod. Process. 2019, 117, 126–137. [Google Scholar] [CrossRef]

- Fadiji, T.; Coetzee, C.; Opara, U.L. Compression strength of ventilated corrugated paperboard packages: Numerical modelling, experimental validation and effects of vent geometric design. Biosyst. Eng. 2016, 151, 231–247. [Google Scholar] [CrossRef]

- Zaheer, M.; Awais, M.; Rautkari, L.; Sorvari, J. Finite element analysis of paperboard package under compressional load. Procedia Manuf. 2018, 17, 1162–1170. [Google Scholar] [CrossRef]

- Patel, P.; Nordstrand, T.; Carlsson, L.A. Local buckling and collapse of corrugated board under biaxial stress. Compos. Struct. 1997, 39, 93–110. [Google Scholar] [CrossRef]

- Allansson, A.; Svard, B. Stability and Collapce of Corrugated Board; Division of Structural Mechanics, LTH, Lund University: Lund, Sweden, 2001; ISSN 0281-6679. [Google Scholar]

- Bai, J.; Wang, J.; Pan, L.; Lu, L.; Lu, G. Quasi-static axial crushing of single wall corrugated paperboard. Compos. Struct. 2019, 226. [Google Scholar] [CrossRef]

- Wang, N. Impact behavior and energy absorption of paper honeycomb sandwich panels. Int. J. Impact Eng. 2009, 36, 110–114. [Google Scholar] [CrossRef]

- Chen, Z.; Yan, N. Investigation of elastic moduli of Kraft paper honeycomb core sandwich panels. Compos. Part B: Eng. 2012, 43, 2107–2114. [Google Scholar] [CrossRef]

- Gu, X.; Wang, J.; Lu, G.; Pan, L.; Lu, L. Modelling for the in-plane plateau stress of honeycomb paperboard based on the induce effect of face paper with honeycomb core. Int. J. Mech. Sci. 2020, 168, 105289. [Google Scholar] [CrossRef]

- Wang, N.; Liang, N.; Guo, Y. Finite element analysis on the out-of-plane compression for paper honeycomb. J. Strain Anal. Eng. Des. 2018, 54, 36–43. [Google Scholar] [CrossRef]

- Utassy, V.; Denes, L. Modeling the elastic properties of paper honeycomb panels using the finite element method. In Proceedings of the XXVIth International Conference Research for Furniture Industry, Poznan, Poland, 23–28 September 2013. [Google Scholar]

- Czechowski, L.; Bieńkowska, M.; Szewczyk, W. Paperboard tubes failure due to lateral compression-experimental and numerical study. Compos. Struct. 2018, 203, 132–141. [Google Scholar] [CrossRef]

- Kołakowski, Z.; Szewczyk, W.; Bieńkowska, M.; Czechowski, L. New Method for Evaluation of Radial Crush Strength of Paper Cores. Mechanika 2018, 24, 169–173. [Google Scholar] [CrossRef]

- Spottiswoode, A.J.; Bank, L.C.; Shapira, A. Investigation of paperboard tubes as formwork for concrete bridge decks. Constr. Build. Mater. 2012, 30, 767–775. [Google Scholar] [CrossRef]

- Muc, A.; Barski, M. Design of Particulate-Reinforced Composite Materials. Materials 2018, 11, 234. [Google Scholar] [CrossRef] [Green Version]

- Zaczynska, M.; Kołakowski, Z. The Influence of the Internal Forces of the Buckling Modes on the Load-Carrying Capacity of Composite Medium-Length Beams under Bending. Materials 2020, 13, 455. [Google Scholar] [CrossRef] [Green Version]

- Kołakowski, Z.; Mania, R. Semi-analytical method versus the FEM for analysis of the local post-buckling of thin-walled composite structures. Compos. Struct. 2013, 97, 99–106. [Google Scholar] [CrossRef]

- Tornabene, F.; Fantuzzi, N.; Bacciocchi, M. Linear Static Behavior of Damaged Laminated Composite Plates and Shells. Materials 2017, 10, 811. [Google Scholar] [CrossRef] [Green Version]

- Kopecki, T.; Mazurek, P.; Lis, T. Experimental and Numerical Analysis of a Composite Thin-Walled Cylindrical Structures with Different Variants of Stiffeners, Subjected to Torsion. Materials 2019, 12, 3230. [Google Scholar] [CrossRef] [Green Version]

- Zhu, X.; Xiong, C.; Yin, J.; Yin, D.; Deng, H. Bending Experiment and Mechanical Properties Analysis of Composite Sandwich Laminated Box Beams. Materials 2019, 12, 2959. [Google Scholar] [CrossRef] [Green Version]

- Debski, H.; Jonak, J. Failure analysis of thin-walled composite channel section columns. Compos. Struct. 2015, 132, 567–574. [Google Scholar] [CrossRef]

- Urbaniak, M.; Teter, A.; Kubiak, T. Influence of boundary conditions on the critical and failure load in the GFPR channel cross-section columns subjected to compression. Compos. Struct. 2015, 134, 199–208. [Google Scholar] [CrossRef]

- Zhang, G.; Mao, C.; Wang, J.; Fan, N.; Guo, T. Numerical Analysis and Experimental Studies on the Residual Stress of W/2024Al Composites. Materials 2019, 12, 2746. [Google Scholar] [CrossRef] [Green Version]

- Kubiak, T.; Borkowski, Ł.; Wiącek, N. Experimental Investigations of Impact Damage Influence on Behavior of Thin-Walled Composite Beam Subjected to Pure Bending. Materials 2019, 12, 1127. [Google Scholar] [CrossRef] [Green Version]

- Kubiak, T.; Kołakowski, Z.; Swiniarski, J.; Urbaniak, M.; Gliszczyński, A. Local buckling and post-buckling of composite channel-section beams—Numerical and experimental investigations. Compos. Part B: Eng. 2016, 91, 176–188. [Google Scholar] [CrossRef]

- Nunes, F.; Correia, M.; Correia, J.R.; Silvestre, N.; Moreira, A. Experimental and numerical study on the structural behaviour of eccentrically loaded GFRP columns. Thin-Walled Struct. 2013, 72, 175–187. [Google Scholar] [CrossRef]

- Chen, J.; Morozov, E.; Shankar, K. A combined elastoplastic damage model for progressive failure analysis of composite materials and structures. Compos. Struct. 2012, 94, 3478–3489. [Google Scholar] [CrossRef]

- Gliszczyński, A.; Kubiak, T. Progressive failure analysis of thin-walled composite columns subjected to uniaxial compression. Compos. Struct. 2017, 169, 52–61. [Google Scholar] [CrossRef]

- Bolzon, G.; Talassi, M. A combined experimental and numerical study of the behaviour of paperboard composites up to failure. Compos. Part B Eng. 2014, 66, 358–367. [Google Scholar] [CrossRef]

- Mentrasti, L.; Cannella, F.; Pupilli, M.; Dai, J.S. Large bending behavior of creases paperboard. I. Experimental investigations. Int. J. Solid Struct. 2013, 50, 3089–3096. [Google Scholar] [CrossRef] [Green Version]

- Mentrasti, L.; Cannella, F.; Pupilli, M.; Dai, J.S. Large bending behavior of creases paperboard. II. Experimental investigations. Int. J. Solid Struct. 2013, 50, 3097–3105. [Google Scholar] [CrossRef] [Green Version]

- Borgqvist, E.; Wallin, M.; Ristinmaa, M.; Tryding, J. An anistropic in-plane and out-of-plane elsto-Plastic continuum model for paper board. Compos. Struct. 2015, 126, 184–195. [Google Scholar] [CrossRef]

- Hua, G.J.; Shen, Y.; Zhao, D.; Xie, Y. Experimental and Numerical Analysis of the Edge Effect for Corrugated and Honeycomb Fiberboard. Strength Mater. 2017, 49, 188–197. [Google Scholar] [CrossRef]

- Wang, Z. Experimental Investigation and Finite Element Analysis for Impact Compression of Honeycomb Paperboards. Chin. J. Mech. Eng. 2012, 48, 49. [Google Scholar] [CrossRef]

- Mou, X.-N.; Lu, L.; Zhang, W.; Yang, H. Characterization of in-plane load bearing of a honeycomb paperboard. Packag. Technol. Sci. 2018, 32, 23–37. [Google Scholar] [CrossRef] [Green Version]

- Hua, G.J.; Xie, Y. Finite element analysis of honeycomb and corrugated fiberboard side compression strength. Packag. Eng. 2009, 30, 1–2. [Google Scholar]

- Gao, S.; Wang, B.Z. Finite element analysis of double deck honeycomb board based on ANSYS. Mech. Eng. Autom. 2012, 14, 69–71. [Google Scholar]

- User’s Guide; ANSYS® 19.2. Ansys, Inc.: Canonsburg, PA, USA. Available online: http://www.pmt.usp.br/academic/martoran/notasmodelosgrad/ANSYS%20Fluent%20Users%20Guide.pdf (accessed on 16 November 2019).

- PN-EN 20187:2000. Paper, Board and Pulps—Standard Atmosphere for Conditioning and Testing and Procedure for Monitoring the Atmosphere and Conditioning of Samples; Polish Committee for Standardization: Warsaw, Poland, 2000. [Google Scholar]

- Niskansen, K. Mechanics of Paper Products; De Gruyter: Berlin, Germany; Boston, MA, USA, 2012; ISBN 978-3-11-025463-1. [Google Scholar]

- Tsai, S.W.; Wu, E.M. A General Theory of Strength for Anisotropic Materials. J. Compos. Mater. 1971, 5, 58–80. [Google Scholar] [CrossRef]

| Wall Length of a Single Ideal Cell | Wall Length of the Double Ideal Cell | Wall Length of a Single Real Cell | Wall Length of the Double Real Cell | Single Thickness Wall | Double Thickness Well | Real Cell Height | Real Cell Width |

|---|---|---|---|---|---|---|---|

| a (mm) | b (mm) | ar (mm) | br (mm) | g1 (mm) | g2 (mm) | h (mm) | c (mm) |

| 8.66 | 8.66 | 12.4 | 3.84 | 0.204 | 0.408 | 16.66 | 22.2 |

| Variation |

Young’s Modules in Cross Direction (GPa) |

Young’s Modules in Machine Direction (GPa) |

Shear Modulus (GPa) |

Poisson’s Ratio, (-) |

Poisson’s Ratio (-) |

|---|---|---|---|---|---|

| 1 | 1.846 | 5.323 | 0.934 | 0.315 | 0.109 |

| 2 | 1.476 | 4.258 | 0.747 | 0.315 | 0.109 |

| 3 | 2.215 | 6.387 | 1.120 | 0.315 | 0.109 |

| Strength Parameters | MPa |

|---|---|

| T1—tensile strength in direction MD | 43 |

| T2—tensile strength in direction CD | 13 |

| C1—Compressive strength in direction MD | 16 |

| C2—Compressive strength in direction CD | 8 |

| S12—Shear Strength | 11 |

| Denotation of the Sample | Maximum Load Fmax (N) | BS (Nm) | ΔF/Δd (N/mm) |

|---|---|---|---|

| Experiment 1.1 MD | 20.1 | 15.3 | 6.1 |

| Experiment 1.2 MD | 19.7 | 15.6 | 6.2 |

| Experiment 1.1 CD | 20.2 | 9.6 | 3.8 |

| Experiment 1.2 CD | 19.1 | 9.2 | 3.7 |

| Experiment 2.1 MD | 48.5 | 87.4 | 35.0 |

| Experiment 2.2 MD | 50.2 | 89.5 | 35.8 |

| Experiment 2.1 CD | 38.9 | 50.2 | 20.1 |

| Experiment 2.2 CD | 38.0 | 52.6 | 21.0 |

| Experiment 4.1 MD | 71.2 | 179.4 | 71.8 |

| Experiment 4.1 CD | 65.3 | 118.4 | 47.4 |

| Model | Cell Type | Tsai-Wu | Max-Stress | Max-Strain | |||

|---|---|---|---|---|---|---|---|

| Failure Load [N] | Failure Location | Failure Load [N] | Failure Location | Failure Load [N] | Failure Location | ||

| Model 1.2 | MD | 19 | Near support | 19 | Near support | 20 | In the middle |

| MD R | 15 | In the middle | 15 | In the middle | 15 | In the middle | |

| Model 2.2 | MD | 44 | Near support | 44 | Near support | 44 | Near support |

| MD R | 35 | In the middle | 35 | In the middle | 35 | In the middle | |

| Model 3.2 | MD | 54 | Near support | 55 | In the middle | 55 | In the middle |

| MD R | 41 | In the middle | 41 | In the middle | 41 | In the middle | |

| Model 4.2 | MD | 72 | In the middle | 72 | In the middle | 72 | In the middle |

| MD R | 51 | In the middle | 51 | In the middle | 51 | In the middle | |

| Model 5.2 | MD | 84 | In the middle | 84 | In the middle | 84 | In the middle |

| MD R | 62 | In the middle | 62 | In the middle | 62 | In the middle | |

| Model | Cell Type | Tsai-Wu | Max-Stress | Max-Strain | |||

|---|---|---|---|---|---|---|---|

| Failure Load | Failure Location | Failure Load | Failure Location | FAILURE Load | Failure Location | ||

| Model 1.2 | CD | 12 | Near support | 12 | Near support | 12 | Near support |

| CD R | 13 | In the middle | 13 | In the middle | 14 | In the middle | |

| Model 2.2 | CD | 26 | Near support | 26 | Near support | 28 | Near support |

| CD R | 33 | In the middle | 33 | In the middle | 33 | In the middle | |

| Model 3.2 | CD | 32 | Near support | 34 | Near support | 34 | Near support |

| CD R | 40 | In the middle | 40 | In the middle | 42 | In the middle | |

| Model 4.2 | CD | 48 | In the middle | 48 | In the middle | 48 | In the middle |

| CD R | 59 | Near support | 64 | Near support | 64 | Near support | |

| Model 5.2 | CD | 49 | Near support | 49 | Near support | 49 | Near support |

| CD R | 67 | In the middle | 67 | In the middle | 69 | In the middle | |

| F = 5 N | F = 10 N | F = 15 N | F = 20 N | F = 25 N | F = 30 N | |

|---|---|---|---|---|---|---|

| Tsai-Wu |  |  |  |  |  |  |

| Max-Stress |  |  |  |  |  |  |

| Max-Strain |  |  |  |  |  |  |

| ||||||

| F = 5 N | F = 10 N | F = 15 N | F = 20 N | F = 25 N | |

|---|---|---|---|---|---|

| Tsai-Wu |  |  |  |  |  |

| Max-Stress |  |  |  |  |  |

| Max-Strain |  |  |  |  |  |

| |||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Czechowski, L.; Śmiechowicz, W.; Kmita-Fudalej, G.; Szewczyk, W. Flexural Damage of Honeycomb Paperboard—A Numerical and Experimental Study. Materials 2020, 13, 2601. https://doi.org/10.3390/ma13112601

Czechowski L, Śmiechowicz W, Kmita-Fudalej G, Szewczyk W. Flexural Damage of Honeycomb Paperboard—A Numerical and Experimental Study. Materials. 2020; 13(11):2601. https://doi.org/10.3390/ma13112601

Chicago/Turabian StyleCzechowski, Leszek, Wojciech Śmiechowicz, Gabriela Kmita-Fudalej, and Włodzimierz Szewczyk. 2020. "Flexural Damage of Honeycomb Paperboard—A Numerical and Experimental Study" Materials 13, no. 11: 2601. https://doi.org/10.3390/ma13112601