Gas Barrier, Rheological and Mechanical Properties of Immiscible Natural Rubber/Acrylonitrile Butadiene Rubber/Organoclay (NR/NBR/Organoclay) Blend Nanocomposites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of the Blend Nanocomposite

2.3. Characterisation

2.3.1. Gas Permeability

2.3.2. Rheological Analysis

2.3.3. Mechanical Analysis

2.3.4. Scanning Electron Microscopy

2.3.5. Transmission Electron Microscopy

3. Results and Discussion

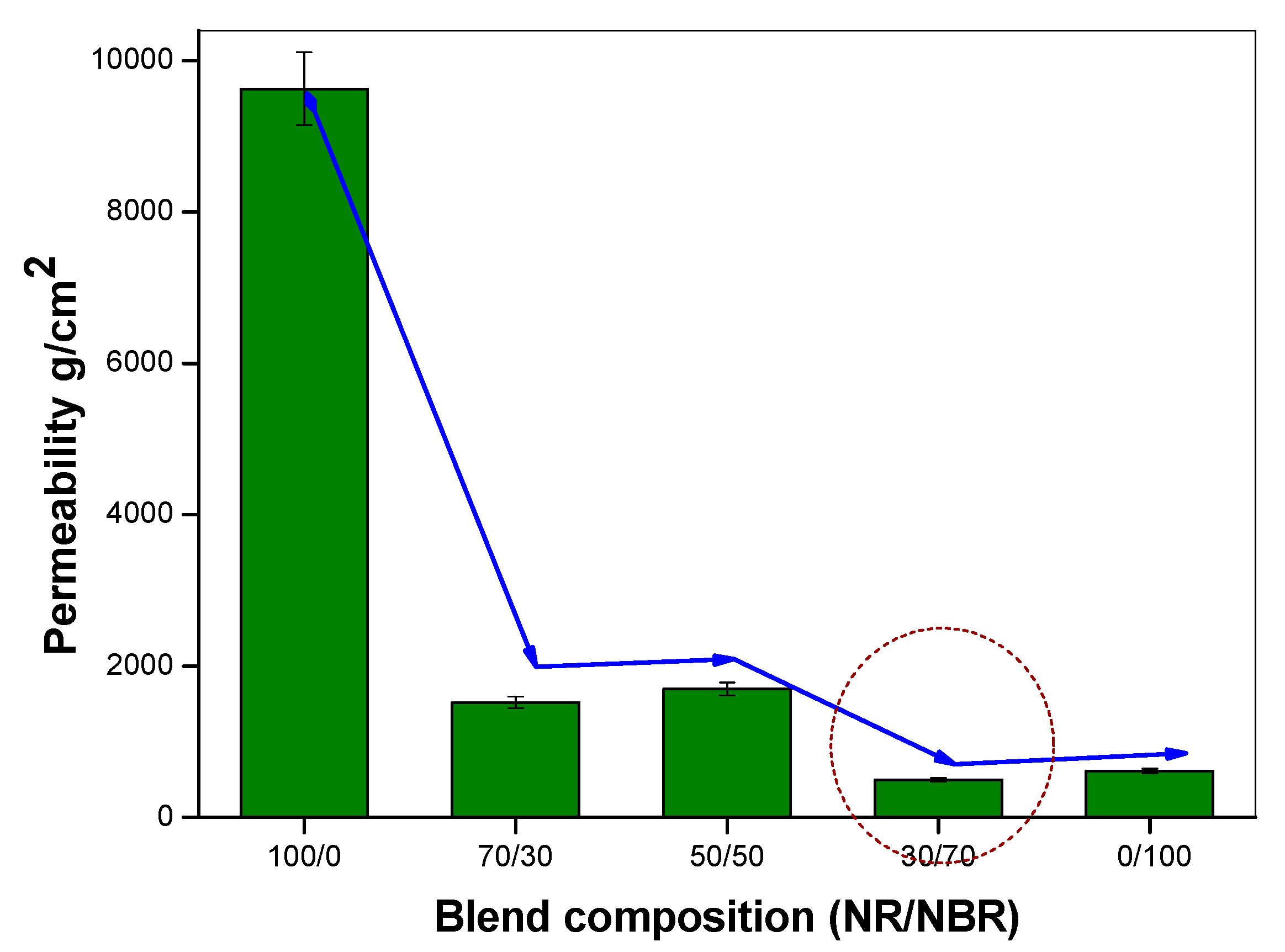

3.1. Effect of NR/NBR Blend Composition on Oxygen Permeability

3.2. Effect of Filler Loading on Oxygen Permeability

3.3. Effect of the Gas Nature

3.4. Rheological Properties of NR/NBR Blend Nanocomposites

3.5. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Adrees, M.; Iqbal, S.S.; Ahmad, A.; Jamshaid, F.; Haider, B.; Khan, M.H.; Khan, R.; Butt, M.T.Z.; Bahadar, A. Characterization of novel polydimethylsiloxane (PDMS) and copolymer polyvinyl chloride-co-vinyl acetate (PVCA) enhanced polymer blend membranes for CO2 separation. Polym. Test. 2019, 80, 106163. [Google Scholar] [CrossRef]

- Matavos-Aramyan, S.; Jazebizadeh, M.H.; Babaei, S. Investigating CO2, O2 and N2 permeation properties of two new types of nanocomposite membranes: Polyurethane/silica and polyesterurethane/silica. Nano-Struct. Nano-Objects 2020, 21, 100414. [Google Scholar] [CrossRef]

- Zembouai, I.; Kaci, M.; Bruzaud, S.; Benhamida, A.; Corre, Y.M.; Grohens, Y. A study of morphological, thermal, rheological and barrier properties of Poly (3-hydroxybutyrate-Co-3-Hydroxyvalerate)/polylactide blends prepared by melt mixing. Polym. Test. 2013, 32, 842–851. [Google Scholar] [CrossRef]

- Lafitte, G.; Espuche, E.; Gérard, J.F. Polyamide 11/poly (hydroxy amino ether) blends: Influence of the blend composition and morphology on the barrier and mechanical properties. Eur. Polym. J. 2011, 47, 1994–2002. [Google Scholar] [CrossRef]

- Subramanian, P.M.; Mehra, V. Laminar morphology in polymer blends: Structure and properties. Polym. Eng. Sci. 1987, 27, 663–668. [Google Scholar] [CrossRef]

- Subramanian, P.M.; Koros, W.J. (Eds.) Polymer Blends: Morphology and Solvent Barriers, Ch. 13 in Barrier Properties of Polymers. Am. Chem. Soc. 1990, 252, 265. [Google Scholar] [CrossRef] [Green Version]

- Rooj, S.; Das, A.; Thakur, V.; Mahaling, R.N.; Bhowmick, A.K.; Heinrich, G. Preparation and properties of natural nanocomposites based on natural rubber and naturally occurring halloysite nanotubes. Mater. Des. 2010, 31, 2151–2156. [Google Scholar] [CrossRef]

- Boonprasith, P.; Wootthikanokkhan, J.; Nimitsiriwat, N. Mechanical, thermal, and barrier properties of nanocomposites based on poly (butylene succinate)/thermoplastic starch blends containing different types of clay. J. Appl. Polym. Sci. 2013, 130, 1114–1123. [Google Scholar] [CrossRef]

- Boudenne, A.; Mamunya, Y.; Levchenko, V.; Garnier, B.; Lebedev, E. Improvement of thermal and electrical properties of Silicone–Ni composites using magnetic field. Eur. Polym. J. 2015, 63, 11–19. [Google Scholar] [CrossRef]

- Kratochvíla, J.; Boudenne, A.; Krupa, I. Effect of filler size on thermophysical and electrical behavior of nanocomposites based on expanded graphite nanoparticles filled in low-density polyethylene matrix. Polym. Compos. 2013, 34, 149–155. [Google Scholar] [CrossRef]

- Tlili, R.; Boudenne, A.; Cecen, V.; Ibos, L.; Krupa, I.; Candau, Y. Thermophysical and electrical properties of nanocomposites based on ethylene–vinylacetate copolymer (EVA) filled with expanded and unexpanded graphite. Int. J. Thermophys. 2010, 31, 936–948. [Google Scholar] [CrossRef]

- Frounchi, M.; Dadbin, S.; Salehpour, Z.; Noferesti, M. Gas barrier properties of PP/EPDM blend nanocomposites. J. Membr. Sci. 2006, 282, 142–148. [Google Scholar] [CrossRef]

- Yeh, J.T.; Fan-Chiang, C.C.; Yang, S.S. Effects of composition of modified polyamide on barrier properties of polyethylene/modified polyamide blends. J. Appl. Polym. Sci. 1997, 64, 1531–1540. [Google Scholar] [CrossRef]

- Yeh, J.T.; Chang, C.J.; Tsai, F.C.; Chen, K.N.; Huang, K.S. Oxygen barrier and blending properties of blown films of blends of modified polyamide and polyamide-6 clay mineral nanocomposites. Appl. Clay Sci. 2009, 45, 1–7. [Google Scholar] [CrossRef]

- Ghanbari, A.; Heuzey, M.C.; Carreau, P.J.; Ton-That, M.T. Morphological and rheological properties of PET/clay nanocomposites. Rheol. Acta 2013, 52, 59–74. [Google Scholar] [CrossRef]

- Bitinis, N.; Verdejo, R.; Maya, E.M.; Espuche, E.; Cassagnau, P.; Lopez-Manchado, M.A. Physicochemical properties of organoclay filled polylactic acid/natural rubber blend bionanocomposites. Compos. Sci. Technol. 2012, 72, 305–313. [Google Scholar] [CrossRef]

- Kuriakose, B.; De, S.K. Studies on the melt flow behavior of thermoplastic elastomers from polypropylene—natural rubber blends. Polym. Eng. Sci. 1985, 25, 630–634. [Google Scholar] [CrossRef]

- Meares, P. The diffusion of gases through polyvinyl acetate1. J. Am. Chem. Soc. 1954, 76, 3415–3422. [Google Scholar] [CrossRef]

- Alentiev, A.Y.; Yampolskii, Y.P. Meares equation and the role of cohesion energy density in diffusion in polymers. J. Membr. Sci. 2002, 206, 291–306. [Google Scholar] [CrossRef]

- Kubica, P.; Wolinska-Grabczyk, A. Correlation between cohesive energy density, fractional free volume, and gas transport properties of poly (ethylene-co-vinyl acetate) materials. Int. J. Polym. Sci. 2015, 2015, 861979. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.H.; Haile, M.; Park, Y.T.; Malek, F.A.; Grunlan, J.C. Super gas barrier of all-polymer multilayer thin films. Macromolecules 2011, 44, 1450–1459. [Google Scholar] [CrossRef]

- Studymate. Available online: https://www.studymateonline.com/media/filer_public/65/6e/656ed9e6-5f92-45ff-9382-3ce08b07ada6/ch_1_11th_some_basic_concept.pdf (accessed on 3 March 2020).

- Mehio, N.; Dai, S.; Jiang, D.E. Quantum mechanical basis for kinetic diameters of small gaseous molecules. J. Phys. Chem. A 2014, 118, 1150–1154. [Google Scholar] [CrossRef] [PubMed]

- Chaix, E.; Guillaume, C.; Guillard, V. Oxygen and carbon dioxide solubility and diffusivity in solid food matrices: A review of past and current knowledge. Compr. Rev. Food Sci. Food Saf. 2014, 13, 261–286. [Google Scholar] [CrossRef]

- Cassagnau, P. Melt rheology of organoclay and fumed silica nanocomposites. Polymer 2008, 49, 2183–2196. [Google Scholar] [CrossRef] [Green Version]

- Meera, A.P. Effect of Spherical and Layered Type Fillers on the Morphology and Physico Mechanical Properties of Natural Rubber Nanocomposites. Ph.D. Thesis, Mahatma Gandhi University, Kottayam, Kerala, India, March 2010. [Google Scholar]

- Maria, H.J.; Lyczko, N.; Nzihou, A.; Joseph, K.; Mathew, C.; Thomas, S. Stress relaxation behavior of organically modified montmorillonite filled natural rubber/nitrile rubber nanocomposites. Appl. Clay Sci. 2014, 87, 120–128. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Mistretta, M.C.; Morreale, M. Recycling and thermomechanical degradation of LDPE/modified clay nanocomposites. Macromol. Mater. Eng. 2014, 299, 96–103. [Google Scholar] [CrossRef]

- Srivastava, S.K.; Mishra, Y.K. Nanocarbon reinforced rubber nanocomposites: Detailed insights about mechanical, dynamical mechanical properties, Payne, and Mullin effects. Nanomaterials 2018, 8, 945. [Google Scholar] [CrossRef] [Green Version]

| Materials | Curing Agents Parts Per Hundred (phr) of Rubber (in the Order of Mixing) |

|---|---|

| Zinc oxide | 2.5 |

| Stearic acid | 1.5 |

| CBS(N-cyclohexyl-benzothiazyl sulphonamide) | 1.3 |

| TMTD(tetra methyl thiuram disulphide) | 0.2 |

| Sulphur | 2.25 |

| Blends NR/NBR | Nanocomposites Nanoclay (phr) | ||||

|---|---|---|---|---|---|

| 0 | 1 | 2 | 5 | 10 | |

| 100/0 | 100/0 (0) | 100/0 (1) | 100/0 (2) | 100/0 (5) | 100/0 (10) |

| 70/30 | 70/30 (0) | 70/30 (1) | 70/30 (2) | 70/30 (5) | 70/30 (10) |

| 50/50 | 50/50 (0) | 50/50 (1) | 50/50 (2) | 50/50 (5) | 50/50 (10) |

| 30/70 | 30/70 (0) | 30/70 (1) | 30/70 (2) | 30/70 (5) | 30/70 (10) |

| 0/100 | 0/100 (0) | 0/100 (1) | 0/100 (2) | 0/100 (5) | 0/100 (10) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maria, H.J.; Thomas, M.G.; Morreale, M.; La Mantia, F.P.; Nzihou, A.; Joseph, K.; Rouxel, D.; Fernandes, S.C.M.; Kalarikkal, N.; Thomas, S. Gas Barrier, Rheological and Mechanical Properties of Immiscible Natural Rubber/Acrylonitrile Butadiene Rubber/Organoclay (NR/NBR/Organoclay) Blend Nanocomposites. Materials 2020, 13, 2654. https://doi.org/10.3390/ma13112654

Maria HJ, Thomas MG, Morreale M, La Mantia FP, Nzihou A, Joseph K, Rouxel D, Fernandes SCM, Kalarikkal N, Thomas S. Gas Barrier, Rheological and Mechanical Properties of Immiscible Natural Rubber/Acrylonitrile Butadiene Rubber/Organoclay (NR/NBR/Organoclay) Blend Nanocomposites. Materials. 2020; 13(11):2654. https://doi.org/10.3390/ma13112654

Chicago/Turabian StyleMaria, Hanna J., Martin George Thomas, Marco Morreale, Francesco Paolo La Mantia, Ange Nzihou, Kuruvilla Joseph, Didier Rouxel, Susana C. M. Fernandes, Nandakumar Kalarikkal, and Sabu Thomas. 2020. "Gas Barrier, Rheological and Mechanical Properties of Immiscible Natural Rubber/Acrylonitrile Butadiene Rubber/Organoclay (NR/NBR/Organoclay) Blend Nanocomposites" Materials 13, no. 11: 2654. https://doi.org/10.3390/ma13112654

APA StyleMaria, H. J., Thomas, M. G., Morreale, M., La Mantia, F. P., Nzihou, A., Joseph, K., Rouxel, D., Fernandes, S. C. M., Kalarikkal, N., & Thomas, S. (2020). Gas Barrier, Rheological and Mechanical Properties of Immiscible Natural Rubber/Acrylonitrile Butadiene Rubber/Organoclay (NR/NBR/Organoclay) Blend Nanocomposites. Materials, 13(11), 2654. https://doi.org/10.3390/ma13112654