The Influence of Laser Surface Remelting on the Tribological Behavior of the ECAP-Processed AZ61 Mg Alloy and AZ61–Al2O3 Metal Matrix Composite

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

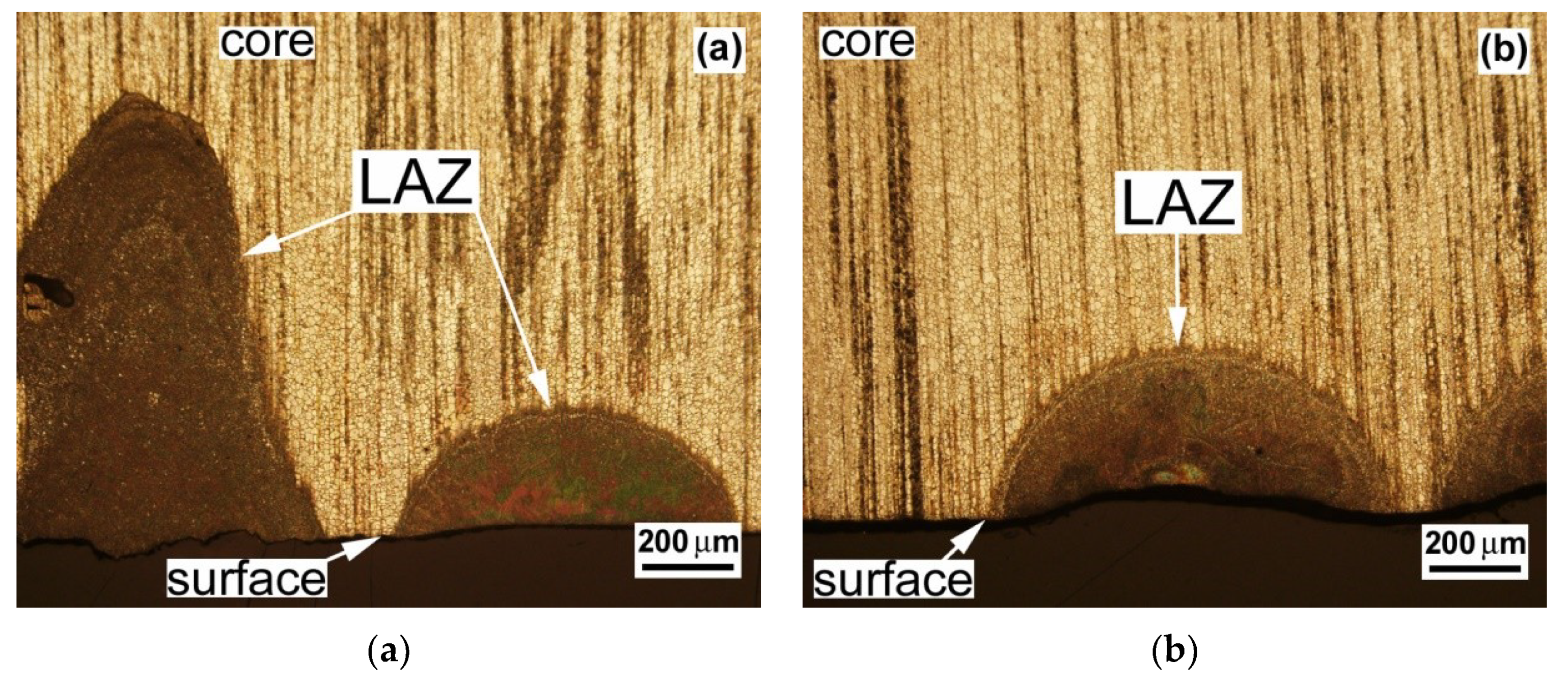

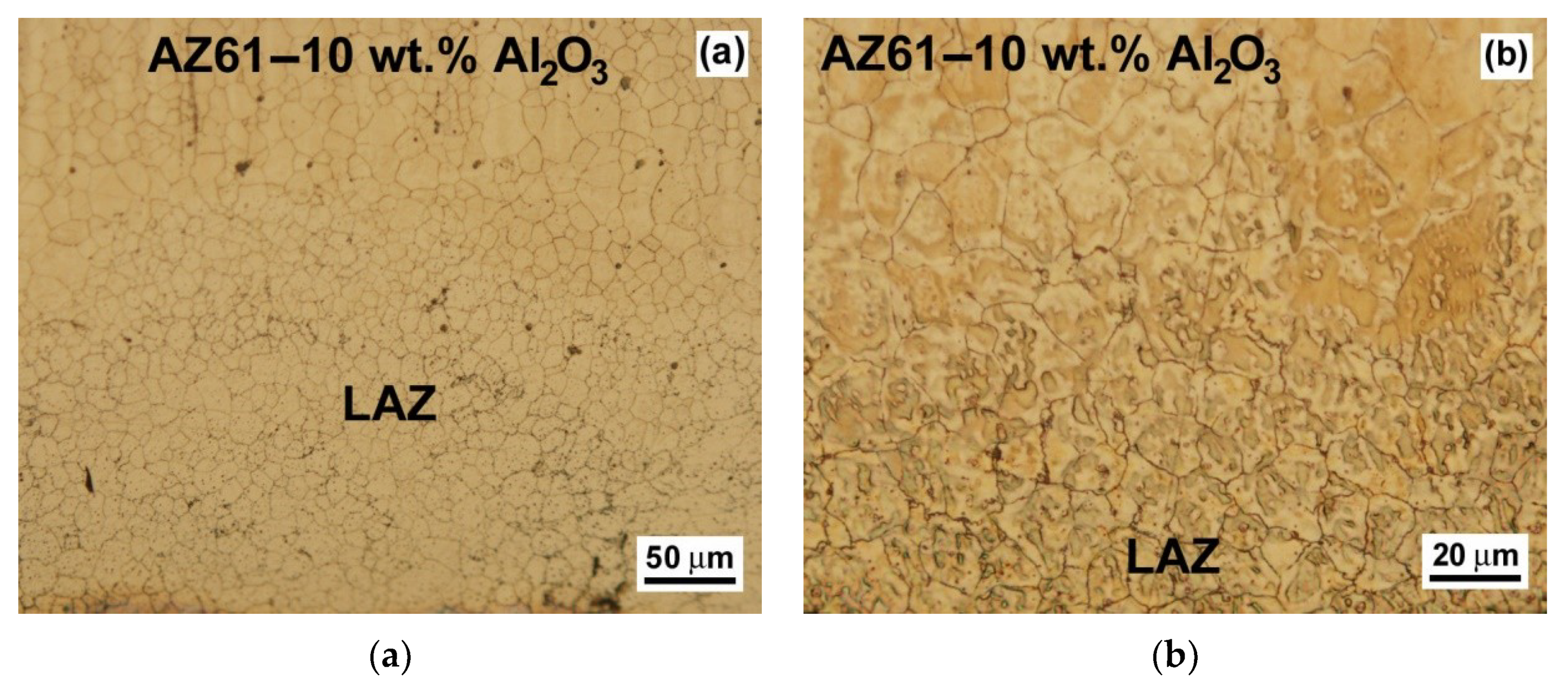

3.1. Microstructural Observations

3.2. Nanoindentation Measurements

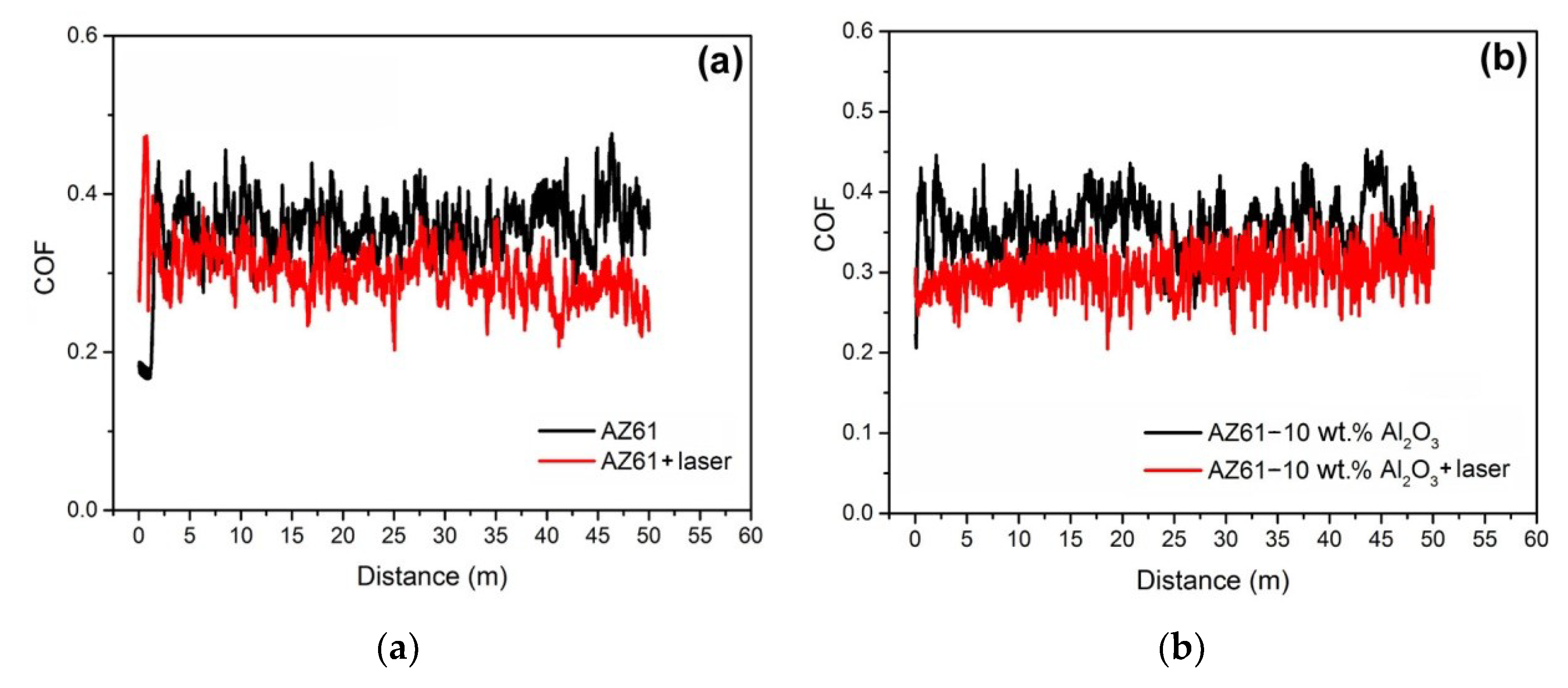

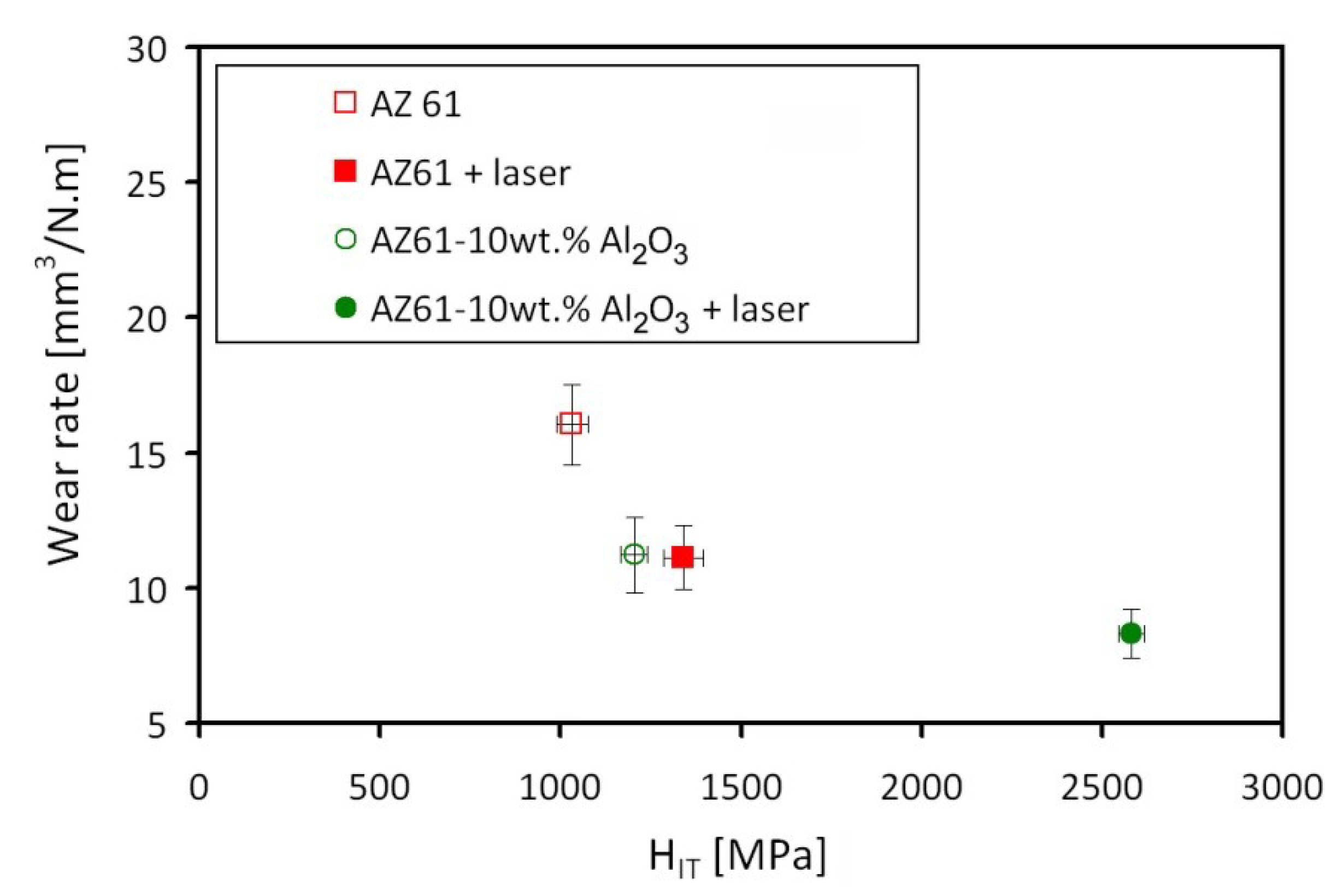

3.3. Friction and Wear Behavior

4. Conclusions

- The ECAP-processed AZ61 alloy and its derived AZ61–10 wt.% Al2O3 nanocomposite exhibited after the application of laser surface remelting significant microstructural differences within their laser-affected zones (LAZs). Whereas the LAZ microstructure of the AZ61 alloy had a typical dendritic character, the LAZ of the AZ61–10 wt.% Al2O3 nanocomposite showed a clearly recrystallized grain structure. The LAZs created by using optimized laser remelting conditions did not exhibit any serious metallurgical defects such as cracks, porosity, or ablation.

- The nanoindentation measurements revealed that the addition of Al2O3 nanoparticles into the AZ61 alloy and the application of laser surface remelting led to considerable improvements in their studied nanoindentation characteristics. Whereas the nanohardness of the AZ61 alloy increased by about 30% after the laser treatment, the nanohardness of the AZ61–10 wt.% Al2O3 nanocomposite increased more than twice after the laser surface remelting, compared to its laser untreated material state. The effect of laser surface treatment on the elasticity modulus was less pronounced. It increased by about 17% and 53% for the laser treated AZ61 alloy and the AZ61–10 wt.% Al2O3 nanocomposite, respectively.

- The results of the tribological tests indicated similar values for the average coefficient of friction (COF) for the ECAP-processed AZ61 alloy and the AZ61–10 wt.% Al2O3 nanocomposite, which were 0.352 and 0.355, respectively. The additional laser surface remelting led to a clear decrease in the average COF values for both the ECAP-processed AZ61 alloy and the AZ61–10 wt.% Al2O3 nanocomposite, which were 0.302 and 0.3, respectively. Thus, it can be concluded that, unlike the laser treatment, the addition of Al2O3 nanoparticles had quite an insignificant effect on the COF behavior in the individual material states under consideration.

- The observed effect of laser surface treatment on the lowering of the average COF values for both the ECAP-processed AZ61 alloy and the AZ61–10 wt.% Al2O3 nanocomposite was also acting synergically on the lowering of their specific wear rates. Whereas the incorporation of Al2O3 nanoparticles within the AZ61–10 wt.% Al2O3 nanocomposite led to about a 30% decrease in the specific wear rate compared to the AZ61 alloy, the additional laser surface remelting of the AZ61–10 wt.% Al2O3 nanocomposite led to a wear rate reduction of about 48%, compared to the laser untreated AZ61 base material.

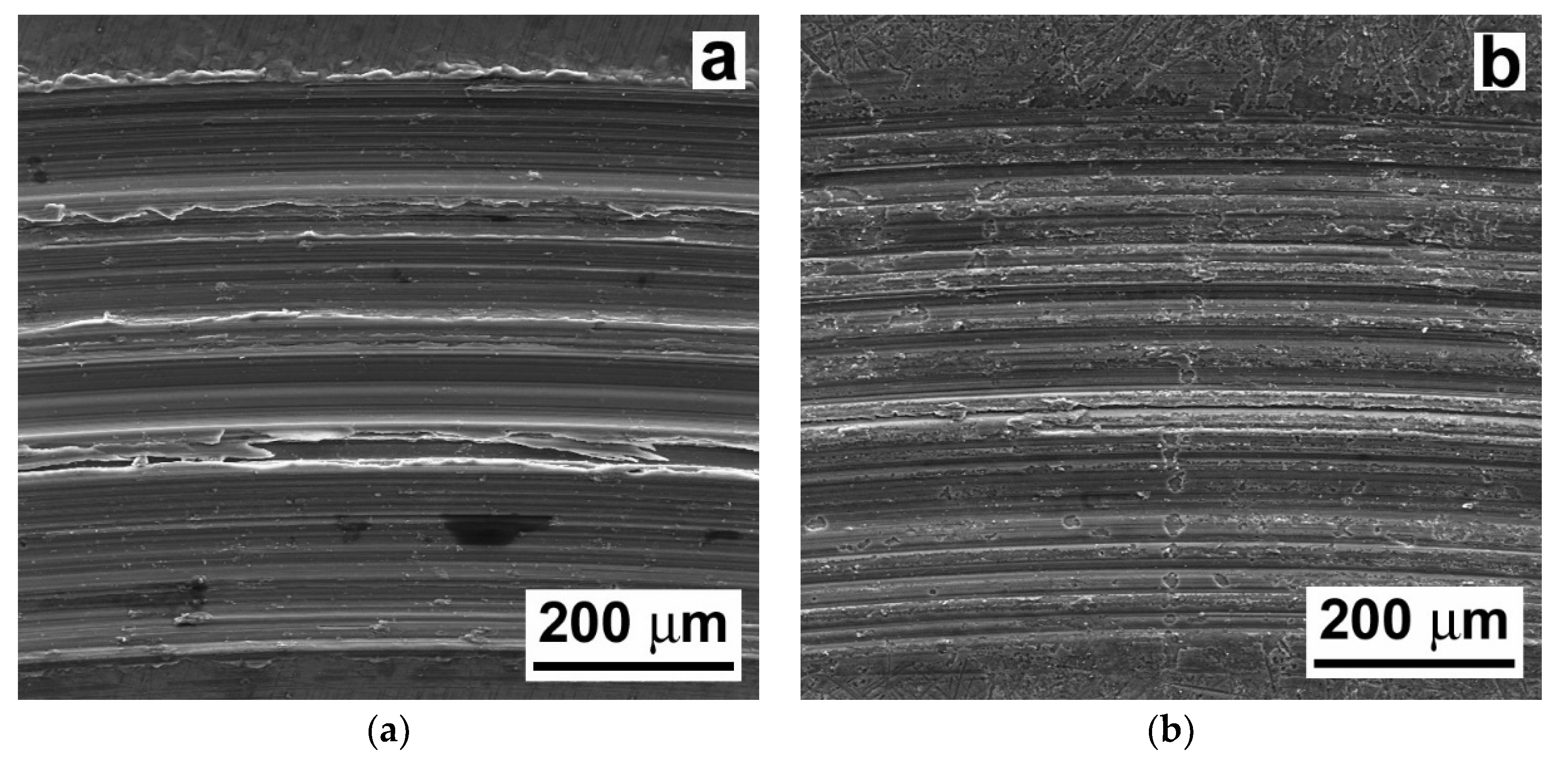

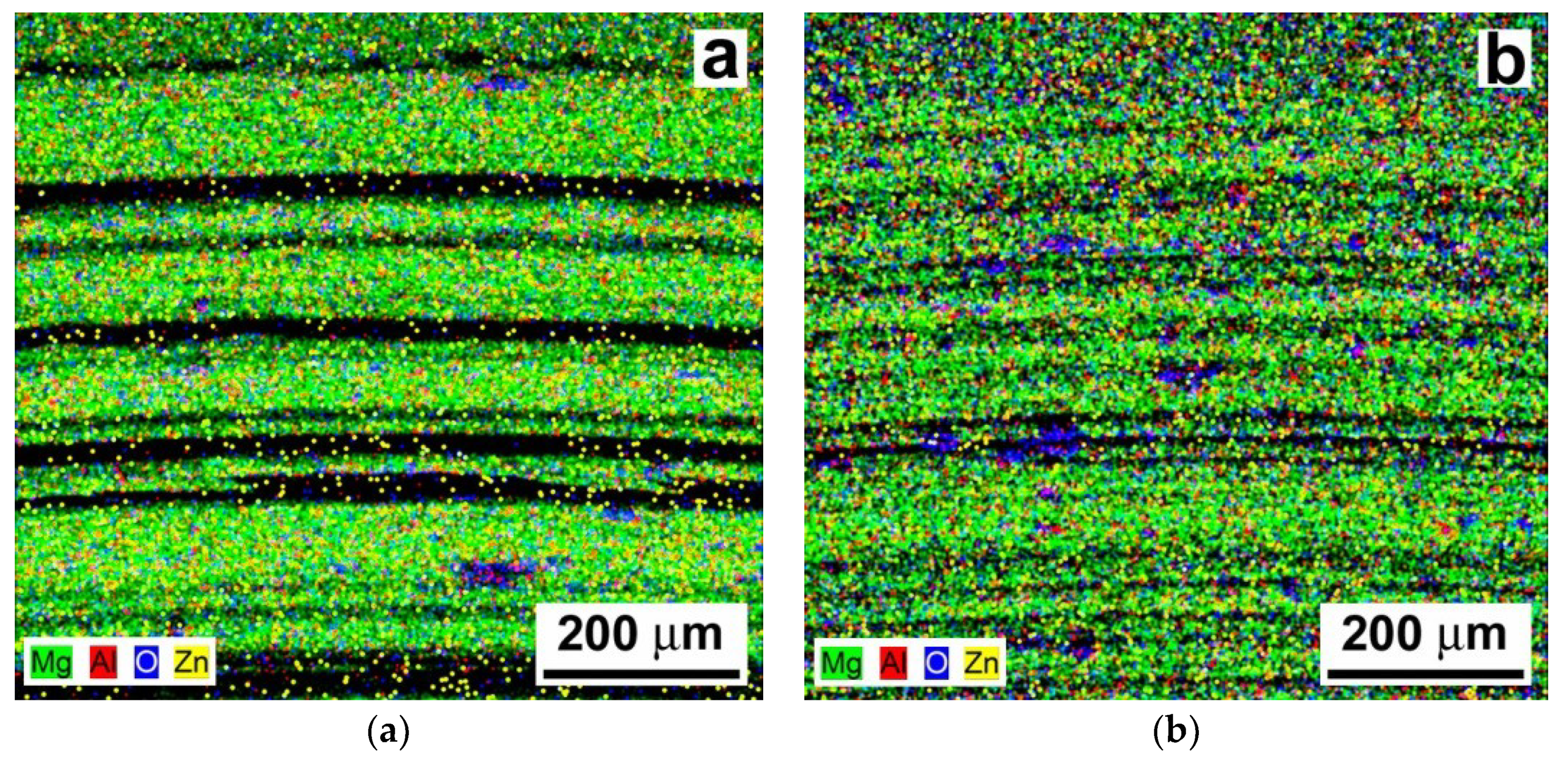

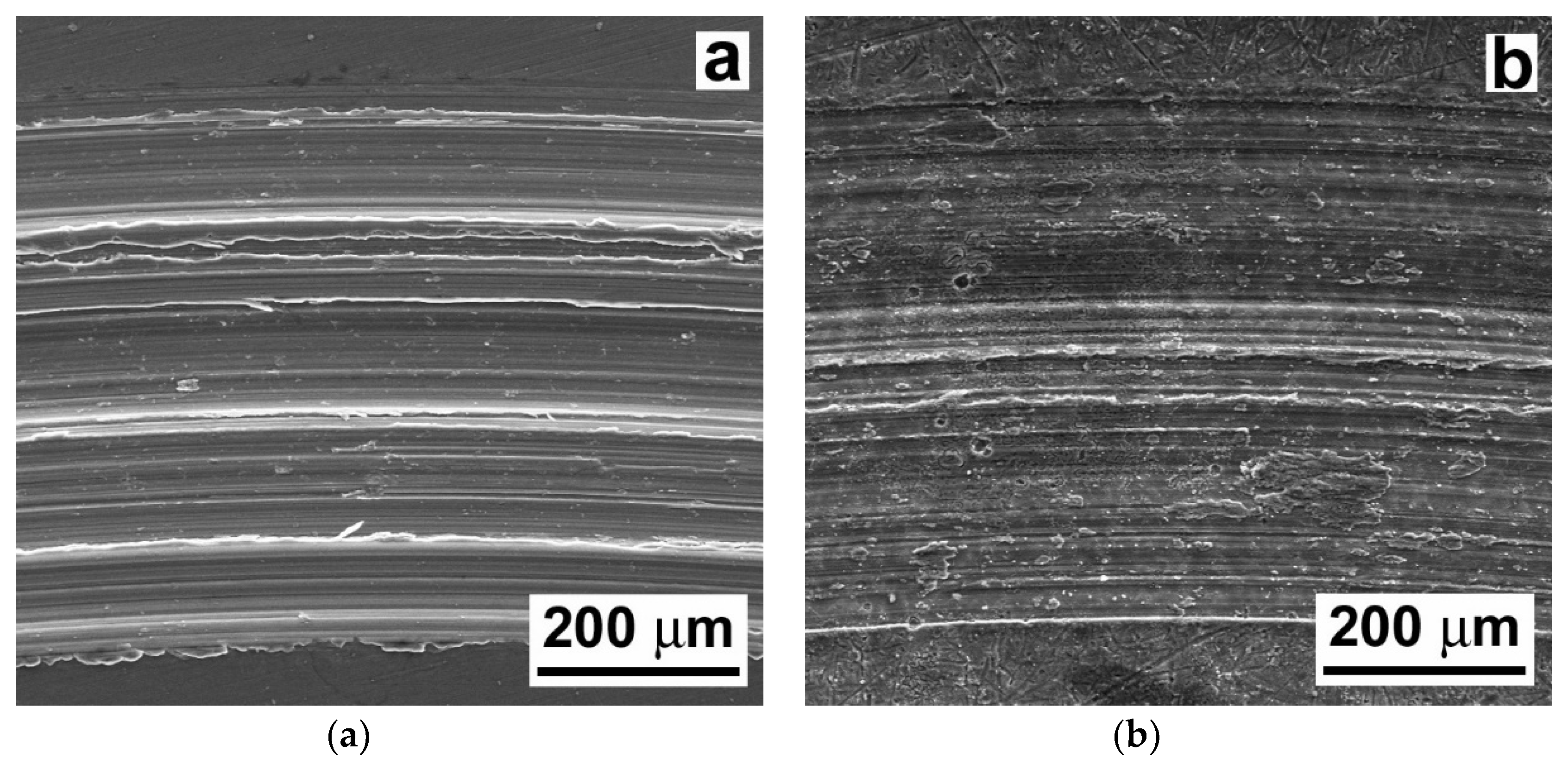

- The microstructural variations related to the individual materials (i.e., AZ61 alloy and AZ61–10 wt. % Al2O3 nanocomposite) and their specific material states (i.e., either the laser untreated or laser treated) were clearly reflected by variations in their wear types and corresponding wear micromechanisms. Significant size differences in the individual morphological features (i.e., abrasion grooves, wear debris, plastically deformed areas) within the wear tracks were noticeable between the laser untreated and laser treated material states. Whereas the dominant wear type of the AZ61 alloy was abrasion and tribological laser remelting induced oxidation, the wear of the AZ61–10 wt.% Al2O3 nanocomposite included additionally occurring adhesion.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Thirugnanasambandham, T.; Chandradass, J.; Baskara Sethupathi, P.; Leenus Jesu Martin, M. Experimental study of wear characteristics of Al2O3 reinforced magnesium based metal matrix composites. Mater. Today-Proc. 2019, 14, 211–218. [Google Scholar] [CrossRef]

- Du, X.; Du, W.; Wang, Z.; Liu, K.; Li, S. Ultra-high strengthening efficiency of graphene nanoplatelets reinforced magnesium matrix composites. Mater. Sci. Eng. A 2018, 711, 633–642. [Google Scholar] [CrossRef]

- Giannopoulou, D.; Dieringa, H.; Bohlen, J. Influence of AlN nanoparticle addition on microstructure and mechanical properties of extruded pure magnesium and an aluminum-free Mg-Zn-Y alloy. Metals 2019, 9, 667. [Google Scholar] [CrossRef]

- John Iruthaya Raj, M.; Manisekar, K.; Gupta, M. Mechanical and wear properties of Mg/Mo nanocomposites. Kovove Mater. 2019, 57, 237–246. [Google Scholar] [CrossRef]

- Xie, Z.; Guo, F.; Huang, X.; Li, K.; Chen, Q.; Chen, Y.; Gong, F. Understanding the anti-wear mechanism of SiCp/WE43 magnesium matrix composite. Vacuum 2020, 172, 109049. [Google Scholar] [CrossRef]

- Prasadh, S.; Ratheesh, V.; Manakari, V.; Parande, G.; Gupta, M.; Wong, R. The potential of magnesium based materials in mandibular reconstruction. Metals 2019, 9, 302. [Google Scholar] [CrossRef]

- Tjong, S.C. Recent progress in the development and properties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphene nanosheets. Mater. Sci. Eng. R 2013, 74, 281–350. [Google Scholar] [CrossRef]

- Dieringa, H. Processing of magnesium-based metal matrix nanocomposites by ultrasound-assisted particle dispersion: A review. Metals 2018, 8, 431. [Google Scholar] [CrossRef]

- Dinaharan, I.; Vettivel, S.C.; Balakrishnan, M.; Akinlabi, E.T. Influence of processing route on microstructure and wear resistance of fly ash reinforced AZ31 magnesium matrix composites. J. Magnes. Alloy. 2019, 7, 155–165. [Google Scholar] [CrossRef]

- Hvizdoš, P.; Besterci, M.; Ballóková, B.; Huang, S.J.; Lin, P.C. Tribological behaviour and mechanical properties of copper and magnesium based composites treated by severe plastic deformation. Int. J. Mater. Prod. Tec. 2015, 50, 80–100. [Google Scholar] [CrossRef]

- Gleiter, H. Nanostructured Materials. Adv. Mater. 1992, 4, 474–481. [Google Scholar] [CrossRef]

- Azushima, A.; Kopp, R.; Korhonen, A.; Yang, D.Y.; Micari, F.; Lahoti, G.D.; Groche, P.; Yanagimoto, J.; Tsuji, N.; Rosochowski, A.; et al. Severe plastic deformation (SPD) processes for metals. CIRP Ann. Manuf. Technol. 2008, 57, 716–735. [Google Scholar] [CrossRef]

- Trojanová, Z.; Halmešová, K.; Drozd, Z.; Šíma, V.; Lukáč, P.; Džugan, J.; Minárik, P. Thermal conductivity of an AZ31 sheet after accumulative roll bonding. Crystals 2018, 8, 278. [Google Scholar] [CrossRef]

- Avvari, M.; Narendranath, S.; Able, M. Microstructure evolution in AZ61 alloy processed by equal channel angular pressing. Adv. Mech. Eng. 2016, 8, 1–9. [Google Scholar] [CrossRef]

- Molnár, P.; Jäger, A. Multi-temperature equal channel angular pressing of Mg-3 wt%Al-1 wt%Zn alloy. Philos. Mag. 2013, 97, 3612–3626. [Google Scholar] [CrossRef]

- Dobeš, F.; Dymáček, P.; Besterci, M. Estimation of the mechanical properties of aluminium and an aluminium composite after equal channel angular pressing by means of the small punch test. Mater. Sci. Eng. A 2015, 626, 313–321. [Google Scholar] [CrossRef]

- Besterci, M.; Nagy, Š.; Huang, S.; Velgosová, O.; Sulleiová, K.; Kulu, P. Fracture description of AZ61 Mg-Al2O3 materials studied by “in situ tensile test in SEM”. Key Eng. Mat. 2016, 674, 165–172. [Google Scholar] [CrossRef]

- Dutta Majumdar, J.; Galun, R.; Mordike, B.L.; Ramesh Chandra, B.; Manna, I. Laser composite surfacing of a magnesium alloy with chromium carbide. Lasers Eng. 2006, 16, 349–359. [Google Scholar]

- Biswas, A.; Mordike, B.L.; Manna, I.; Majumdar, J.D. Studies on laser surface melting of Al-11% Si alloy. Lasers Eng. 2008, 18, 95–105. [Google Scholar]

- Šebek, M.; Falat, L.; Orečný, M.; Petryshynets, I.; Kováč, F.; Černík, M. Abrasive wear resistance of modified X37CrMoV5-1 hot work tool steel after conventional and laser heat treatment. Int. J. Mater. Res. 2018, 109, 460–468. [Google Scholar] [CrossRef]

- Du, F.; Li, C.; Mi, Z.; Shen, Y.; Huang, R.; Han, X.; Dong, Y.; Xu, J. Anti-wear property of aluminum–silicon alloy treated by chemical etching, mechanical honing and laser finishing. Materials 2019, 12, 1273. [Google Scholar] [CrossRef] [PubMed]

- Dobrzański, L.A.; Domagała, J.; Tański, T.; Klimpel, A.; Janicki, D. Laser surface treatment of cast magnesium alloys. Arch. Mater. Sci. Eng. 2009, 35, 101–106. [Google Scholar]

- Besterci, M.; Nagy, Š.; Huang, S.-J.; Velgosová, O.; Sülleiová, K.; Lin, P.-C. Influence of Al2O3 particles weight fraction on fracture mechanism of AZ61 Mg-Al2O3 system studied by in situ tensile test in SEM. Acta Phys. Pol. A 2016, 129, 138–141. [Google Scholar] [CrossRef]

- Besterci, M.; Sülleiová, K.; Velgosová, O.; Balloková, B.; Huang, S.-J. Superplastic behaviour of AZ61-F magnesium composite materials. High Temp. Mater. Proc. 2017, 36, 279–283. [Google Scholar] [CrossRef]

- Besterci, M.; Sulleiova, K.; Ballokova, B.; Nagy, S.; Velgosova, O.; Huang, S.J. Phases analysis and impact of phases on fracture mechanism of AZ61-SiC composite. Materialwiss. Werkst. 2019, 50, 1242–1249. [Google Scholar] [CrossRef]

- El-Morsy, A.; Ismail, A.; Waly, M. Microstructural and mechanical properties evolution of magnesium AZ61 alloy processed through a combination of extrusion and thermomechanical processes. Mater. Sci. Eng. A 2008, 486, 528–533. [Google Scholar] [CrossRef]

- Ballóková, B.; Jakubéczyová, D. Fracture analysis and mechanical properties of magnesium based composites. Mater. Sci. Forum 2017, 891, 526–532. [Google Scholar] [CrossRef]

- Zhao, X.; Li, S.; Yan, F.; Zhang, Z.; Wu, Y. Microstructure evolution and mechanical properties of AZ80 Mg alloy during annular channel angular extrusion process and heat treatment. Materials 2019, 12, 4223. [Google Scholar] [CrossRef]

- Huang, S.-J.; Lin, P.-C.; Ballóková, B.; Hvizdoš, P.; Besterci, M. Tribological behaviour and local mechanical properties of magnesium-alumina composites. Kovove Mater. 2014, 52, 313–319. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- ASTM G 99 – 95a standard: Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus; ASTM: West Conshohocken, PA, USA, 2000.

- Bimla Mardi, K.; Mallick, A.; Rai Dixit, A.; Gupta, M. Enhancing compressive response of Mg-6Al alloy using Al2O3 nanoparticles. Kovove Mater. 2018, 56, 183–190. [Google Scholar] [CrossRef]

- Besterci, M.; Sülleiová, K. Theoretical-experimental possibillities of microstructure quantification of dispersion strengthened materials. Acta Metall. Slovaca 2019, 25, 65–72. [Google Scholar] [CrossRef]

- Dutta Majumdar, J.; Galun, R.; Mordike, B.L.; Manna, I. Effect of laser surface melting on corrosion and wear resistance of a commercial magnesium alloy. Mater. Sci. Eng. A 2003, 361, 119–129. [Google Scholar] [CrossRef]

- Yan, H.; Wan, J.; Nie, Q. Wear behavior of extruded nano-SiCp reinforced AZ61 magnesium matrix composites. Adv. Mech. Eng. 2013, 2013, 489528. [Google Scholar] [CrossRef]

- Cao, L.; Wang, Y.; Yao, C.K. The wear properties of an SiC-whisker-reinforced aluminium composite. Wear 1990, 140, 273–277. [Google Scholar] [CrossRef]

- Wang, A.; Rack, H.J. Transition wear behavior of SiC-particulate- and SiC-whisker-reinforced 7091 Al metal matrix composites. Mater. Sci. Eng. A 1991, 147, 211–224. [Google Scholar] [CrossRef]

- Wei, T.Z.; Shamsuri, S.R.B.; Yee, C.S.; Rashid, M.W.A.; Ahsan, Q. Effect of sliding velocity on wear behavior of magnesium composite reinforced with SiC and MWCNT. Procedia Eng. 2013, 68, 703–709. [Google Scholar] [CrossRef]

| Elements | Al | Mn | Zn | Si | Fe | Cu | Ni | Mg |

|---|---|---|---|---|---|---|---|---|

| (wt.%) | 5.95 | 0.26 | 0.64 | 0.009 | 0.005 | 0.0008 | 0.0007 | balance |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ballóková, B.; Falat, L.; Puchý, V.; Molčanová, Z.; Besterci, M.; Džunda, R.; Abbas, A.; Huang, S.-J. The Influence of Laser Surface Remelting on the Tribological Behavior of the ECAP-Processed AZ61 Mg Alloy and AZ61–Al2O3 Metal Matrix Composite. Materials 2020, 13, 2688. https://doi.org/10.3390/ma13122688

Ballóková B, Falat L, Puchý V, Molčanová Z, Besterci M, Džunda R, Abbas A, Huang S-J. The Influence of Laser Surface Remelting on the Tribological Behavior of the ECAP-Processed AZ61 Mg Alloy and AZ61–Al2O3 Metal Matrix Composite. Materials. 2020; 13(12):2688. https://doi.org/10.3390/ma13122688

Chicago/Turabian StyleBallóková, Beáta, Ladislav Falat, Viktor Puchý, Zuzana Molčanová, Michal Besterci, Róbert Džunda, Aqeel Abbas, and Song-Jeng Huang. 2020. "The Influence of Laser Surface Remelting on the Tribological Behavior of the ECAP-Processed AZ61 Mg Alloy and AZ61–Al2O3 Metal Matrix Composite" Materials 13, no. 12: 2688. https://doi.org/10.3390/ma13122688

APA StyleBallóková, B., Falat, L., Puchý, V., Molčanová, Z., Besterci, M., Džunda, R., Abbas, A., & Huang, S.-J. (2020). The Influence of Laser Surface Remelting on the Tribological Behavior of the ECAP-Processed AZ61 Mg Alloy and AZ61–Al2O3 Metal Matrix Composite. Materials, 13(12), 2688. https://doi.org/10.3390/ma13122688