Influence of Aluminum Surface Treatment on Tensile and Fatigue Behavior of Thermoplastic-Based Hybrid Laminates

Abstract

:1. Introduction

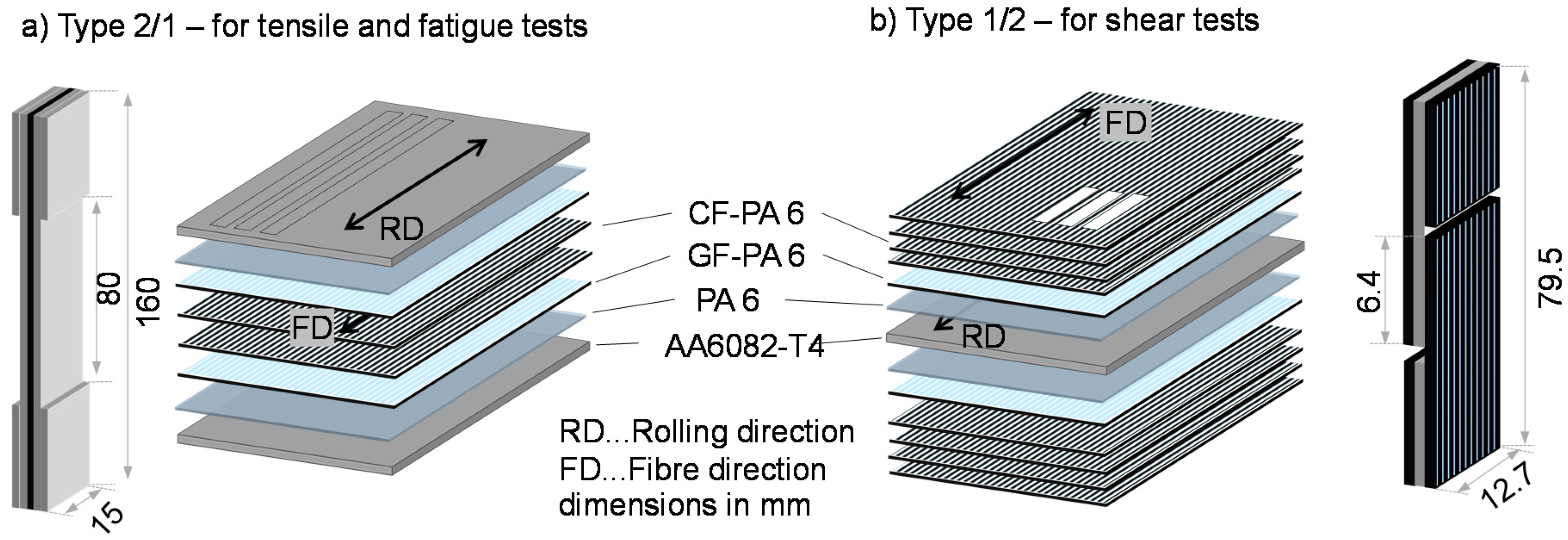

2. Materials and Methods

2.1. Materials and Manufacturing

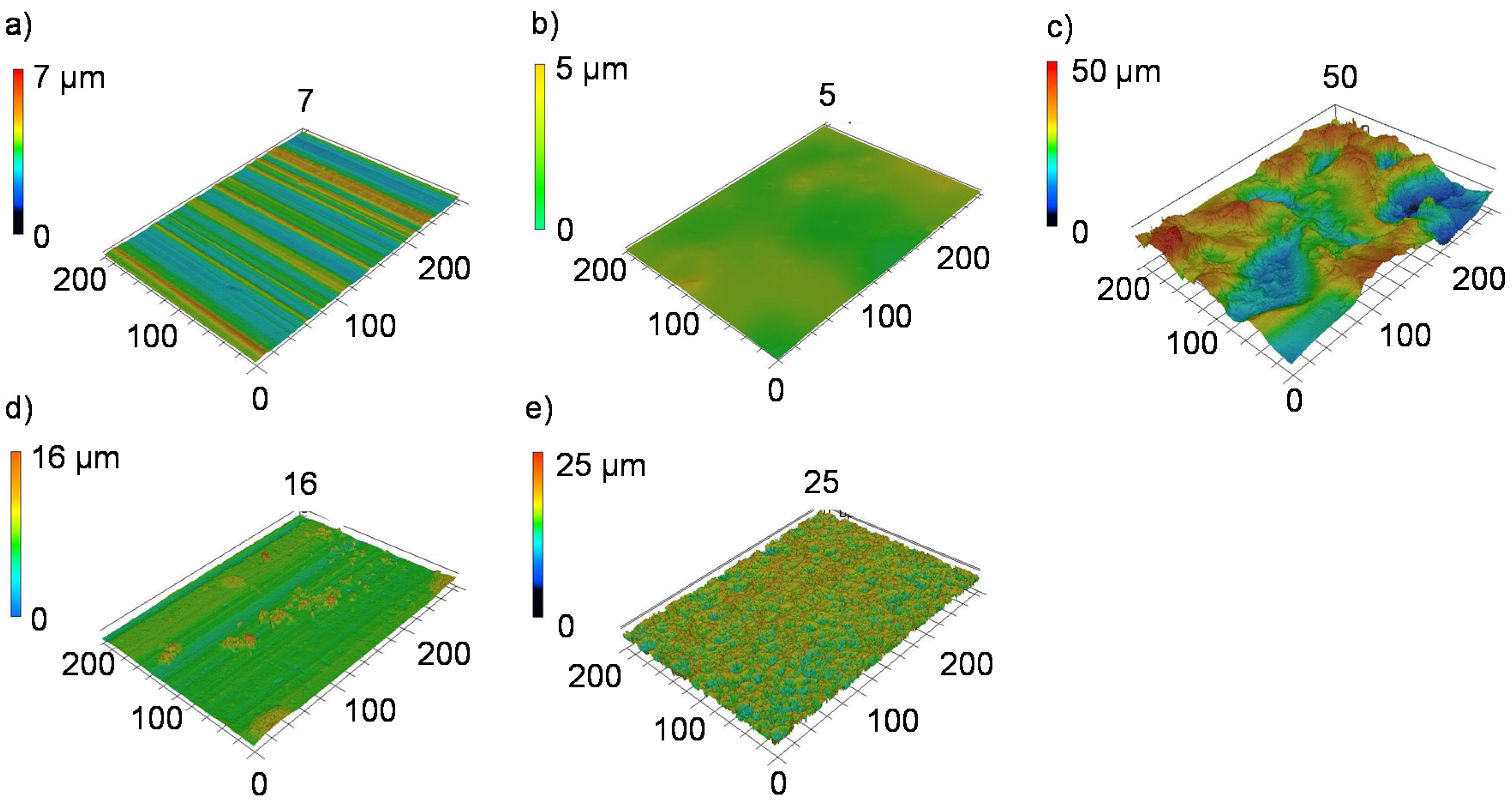

2.2. Aluminum Surface Treatments

- (I).

- Adhesion promoter: After phosphating (see III), the co-polyamide VESTAMELT (Evonik Resource Efficiency GmbH, Marl, Germany) was applied evenly to the sheet as a powder utilizing an electrostatic spray coating and then melted in an oven at 200 °C. This forms a uniform glassy adhesion film with an approximate thickness of 75 µm.

- (II).

- Mechanical blasting: The sheets were blasted manually with a pressure of 1 bar on both sides by using high-grade Al2O3 with a grain size F24 (600–850 µm) in a working distance of 100 mm. The blasting material is applied at an angle of 90° to the surface. The duration for blasting a sheet of 260 × 260 mm2 on both sides is 170 s (8 cm2/s).

- (III).

- Phosphating: The phosphating was carried out using the Bonderite M-ZN process from Henkel. By dipping the sheets in a zinc phosphate solution, a conversion layer of small crystalline zinc-phosphatic mangan will be formed, which typically improves the adhesion of the lacquer.

- (IV).

- Anodizing: After a pretreatment by etching the sheets in 10% sodium hydroxide and subsequent pickling, a 15 µm thick layer of Al2O3 was formed under direct current in sulfuric acid.

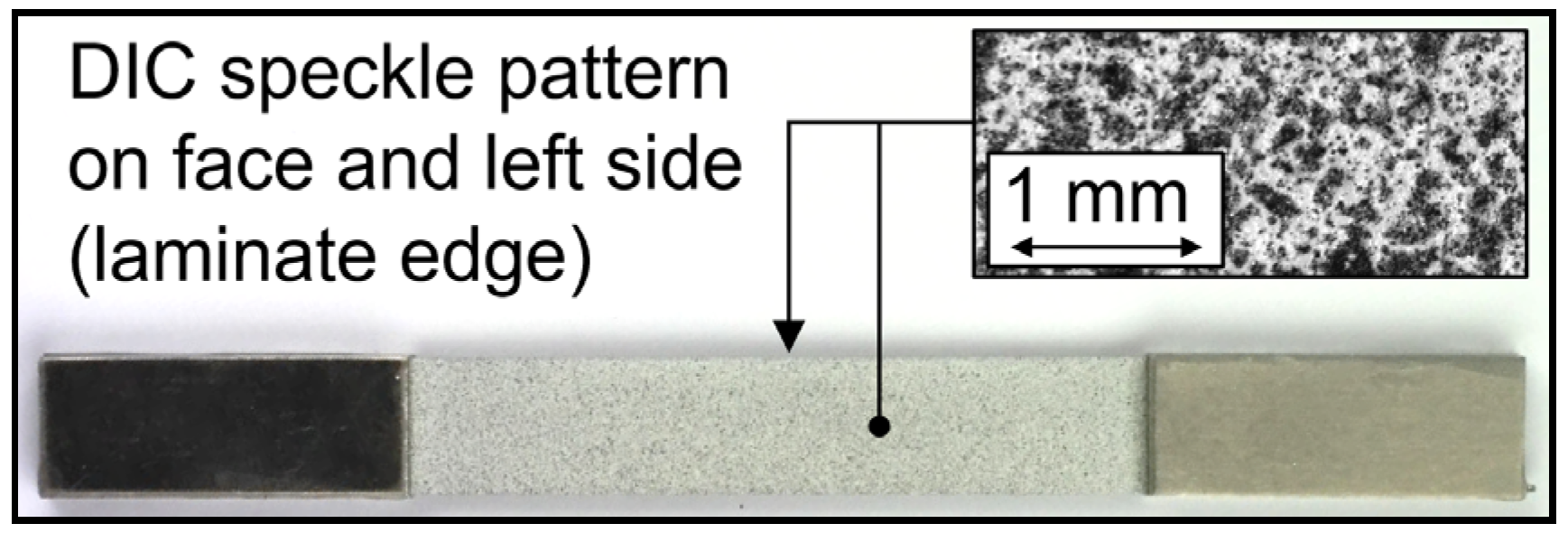

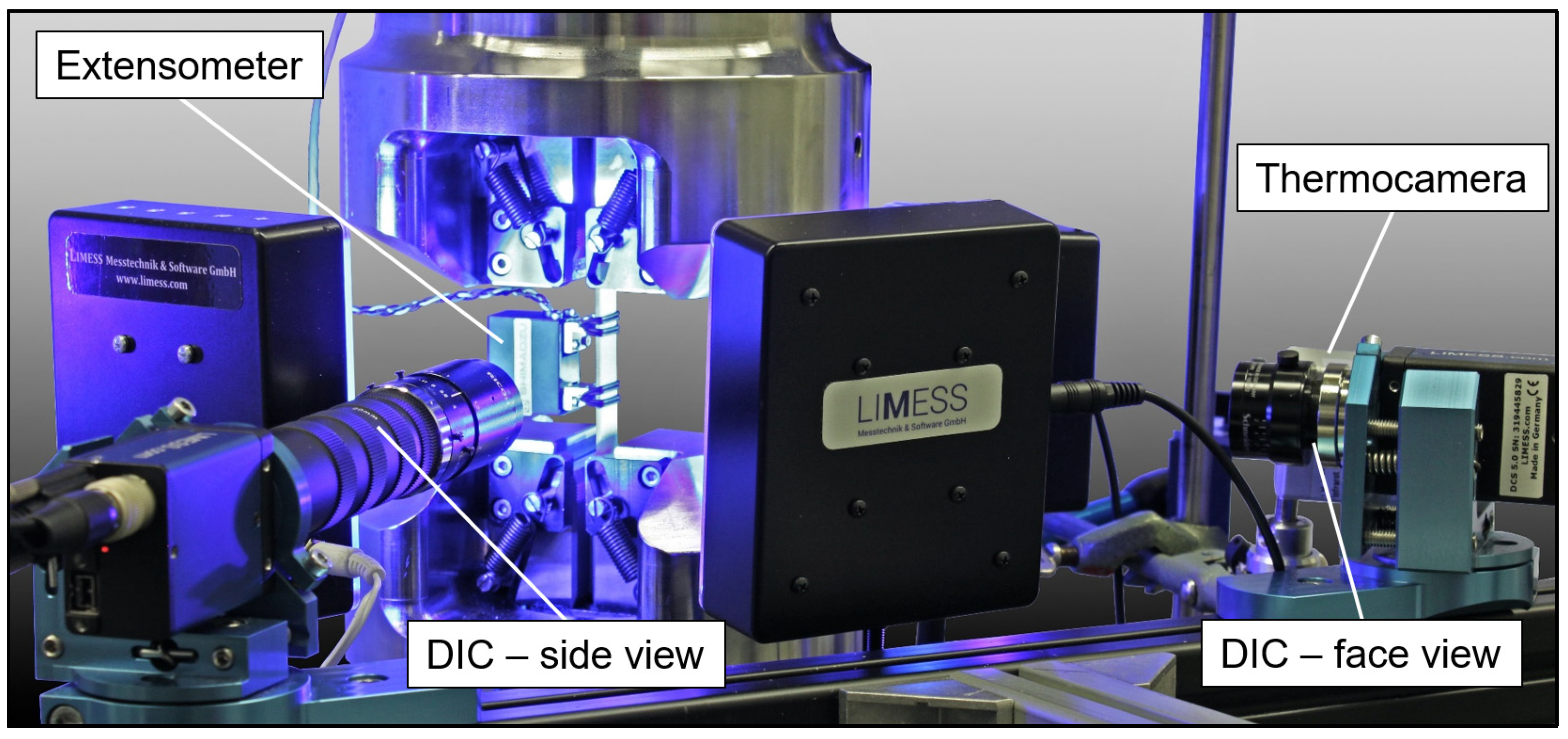

2.3. Chracterization and Testing Methodes

2.3.1. Aluminum Roughness and Laminate Microstructure

2.3.2. Quasistatic Properties

2.3.3. Cyclic Properties

3. Results and Discussion

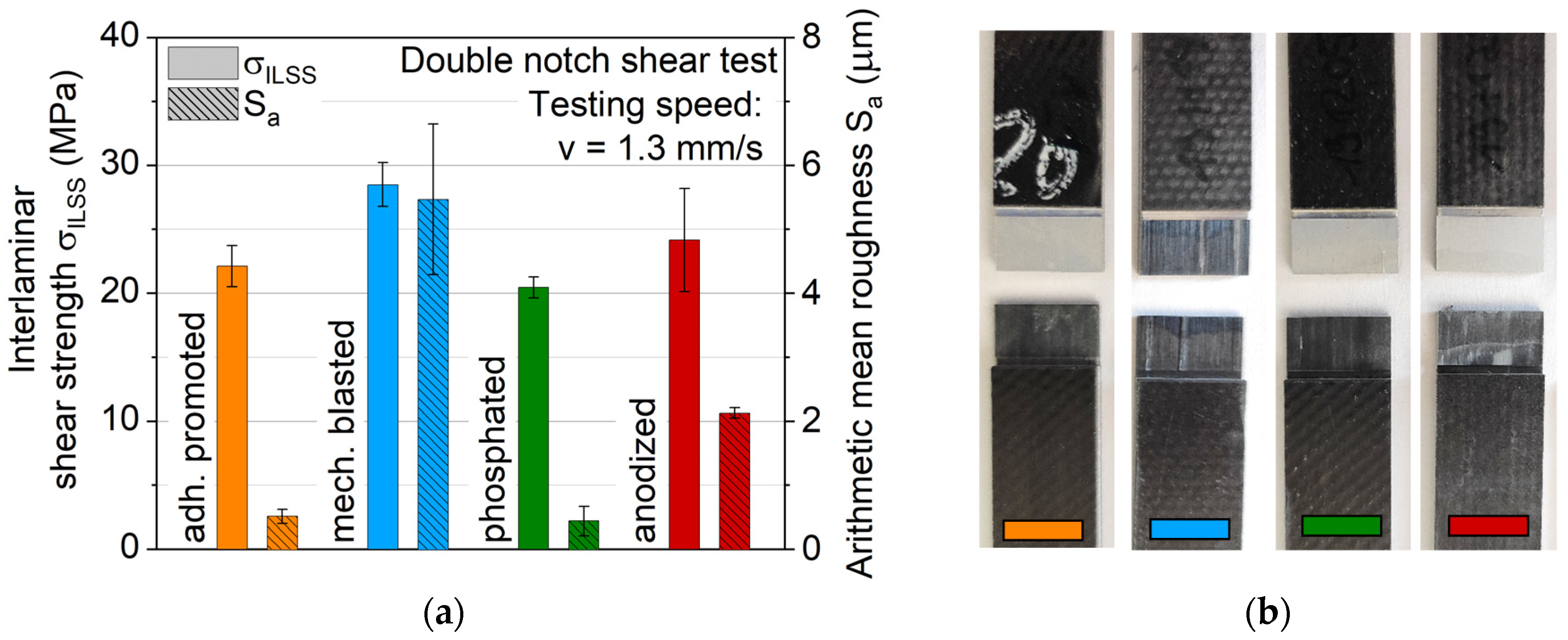

3.1. Aluminum Roughness and Laminate Microstructure

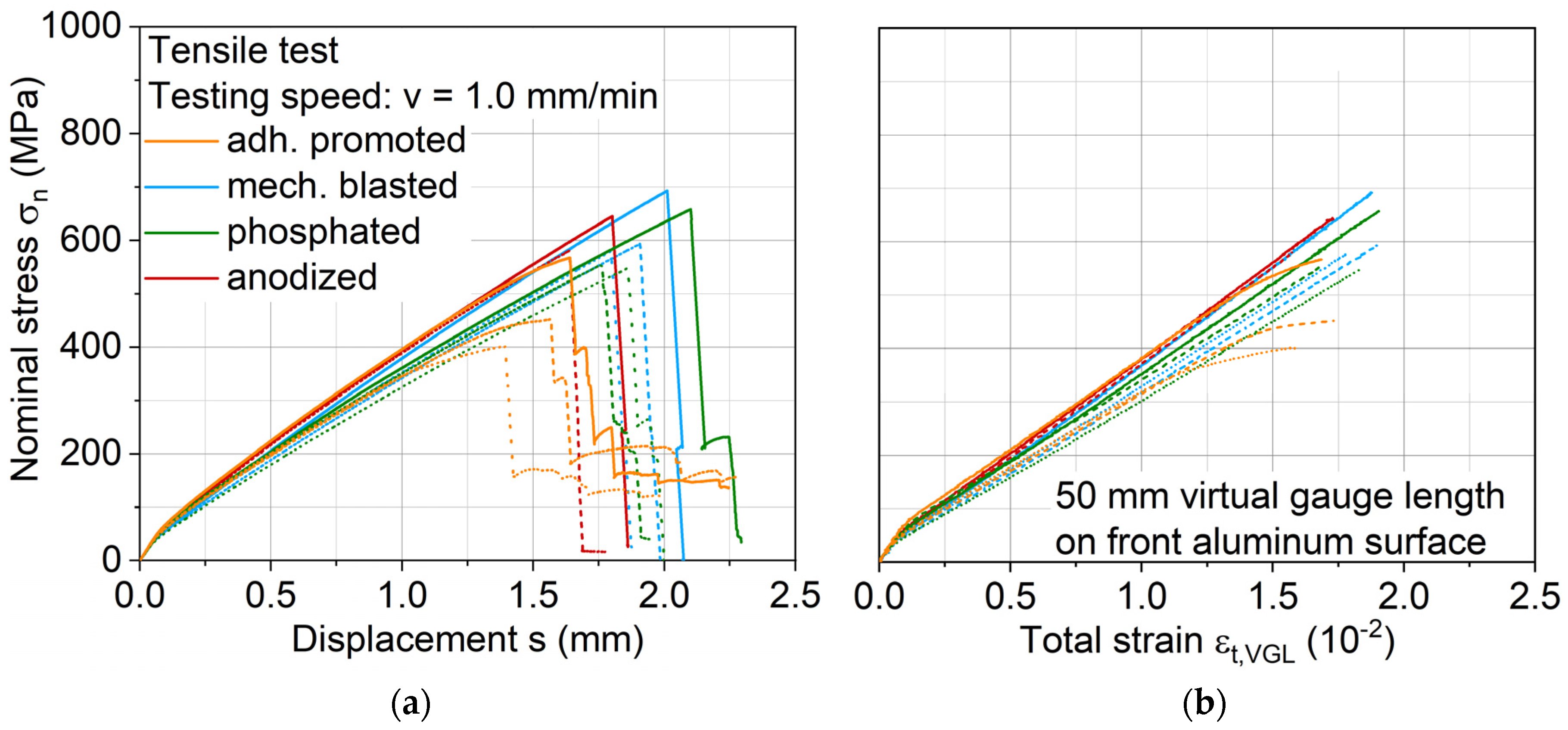

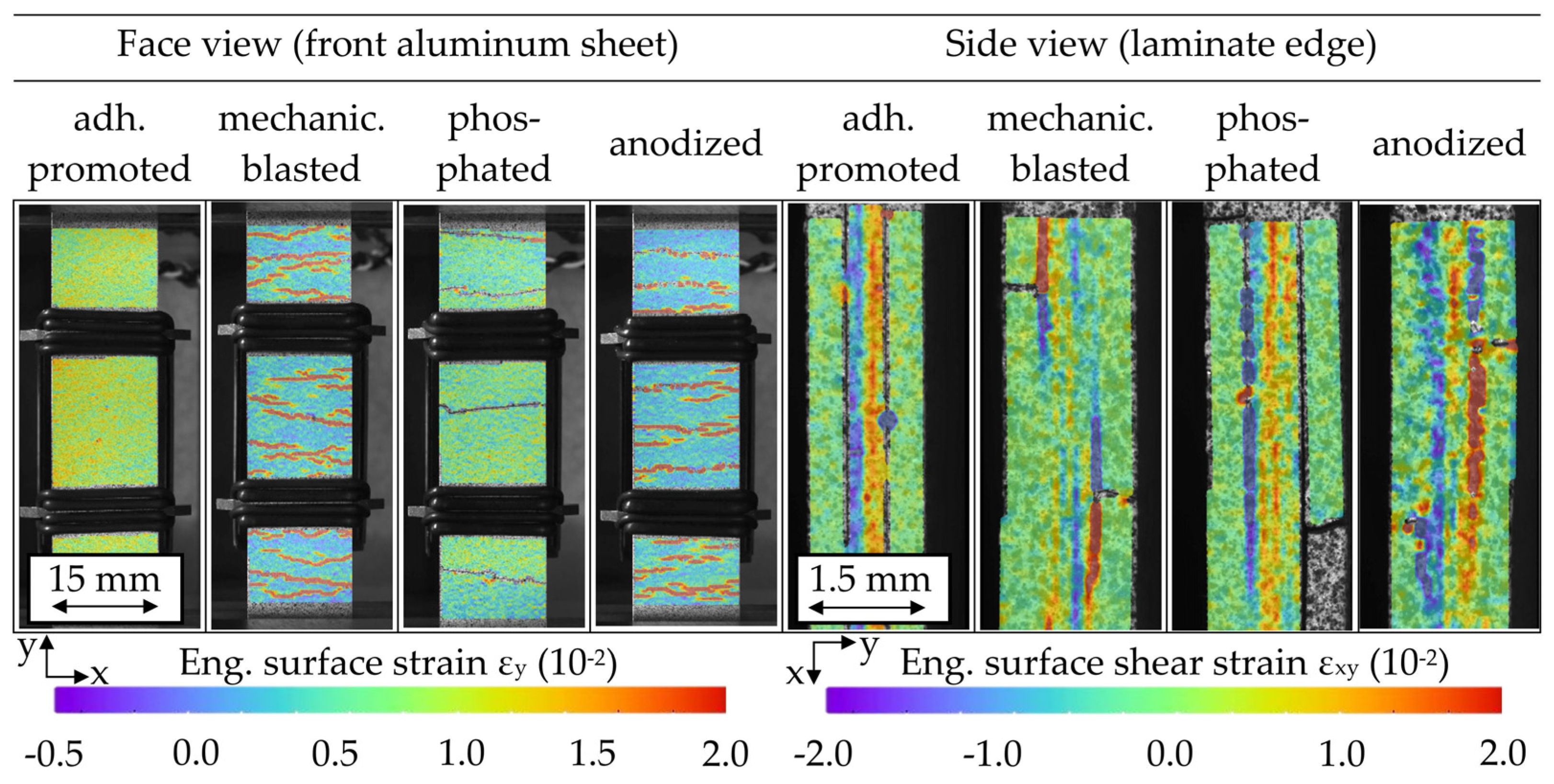

3.2. Quasistatic Properties

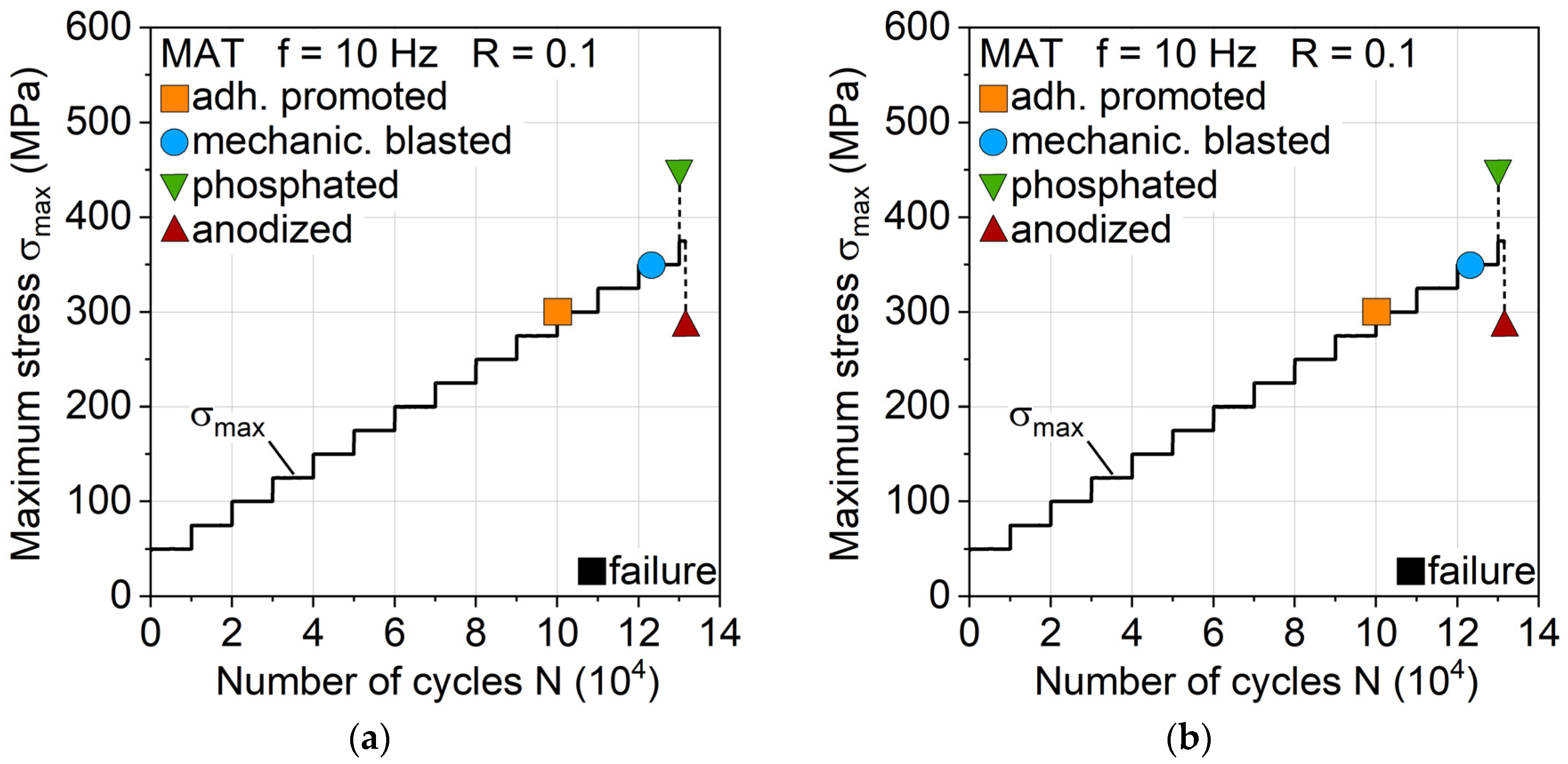

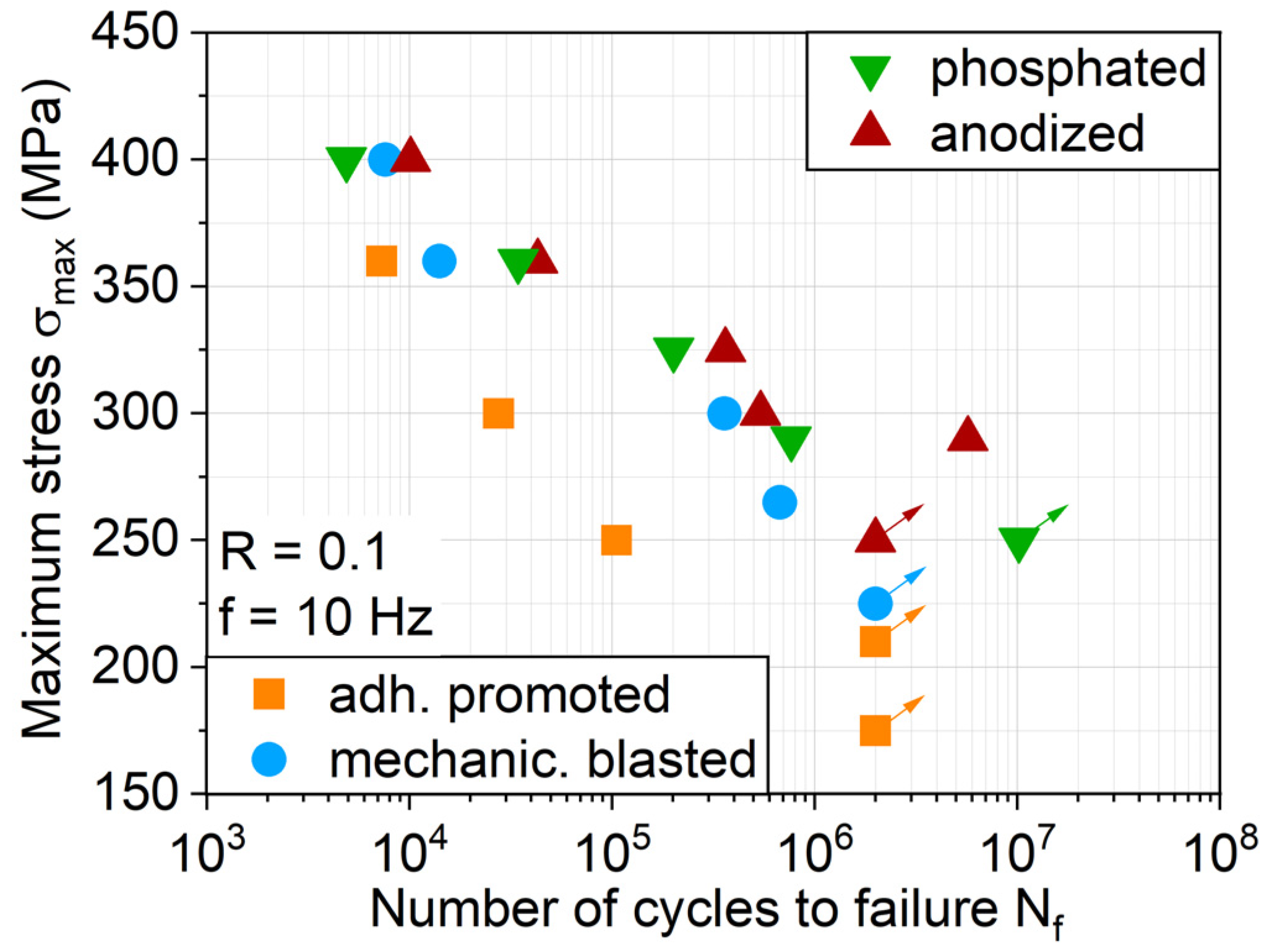

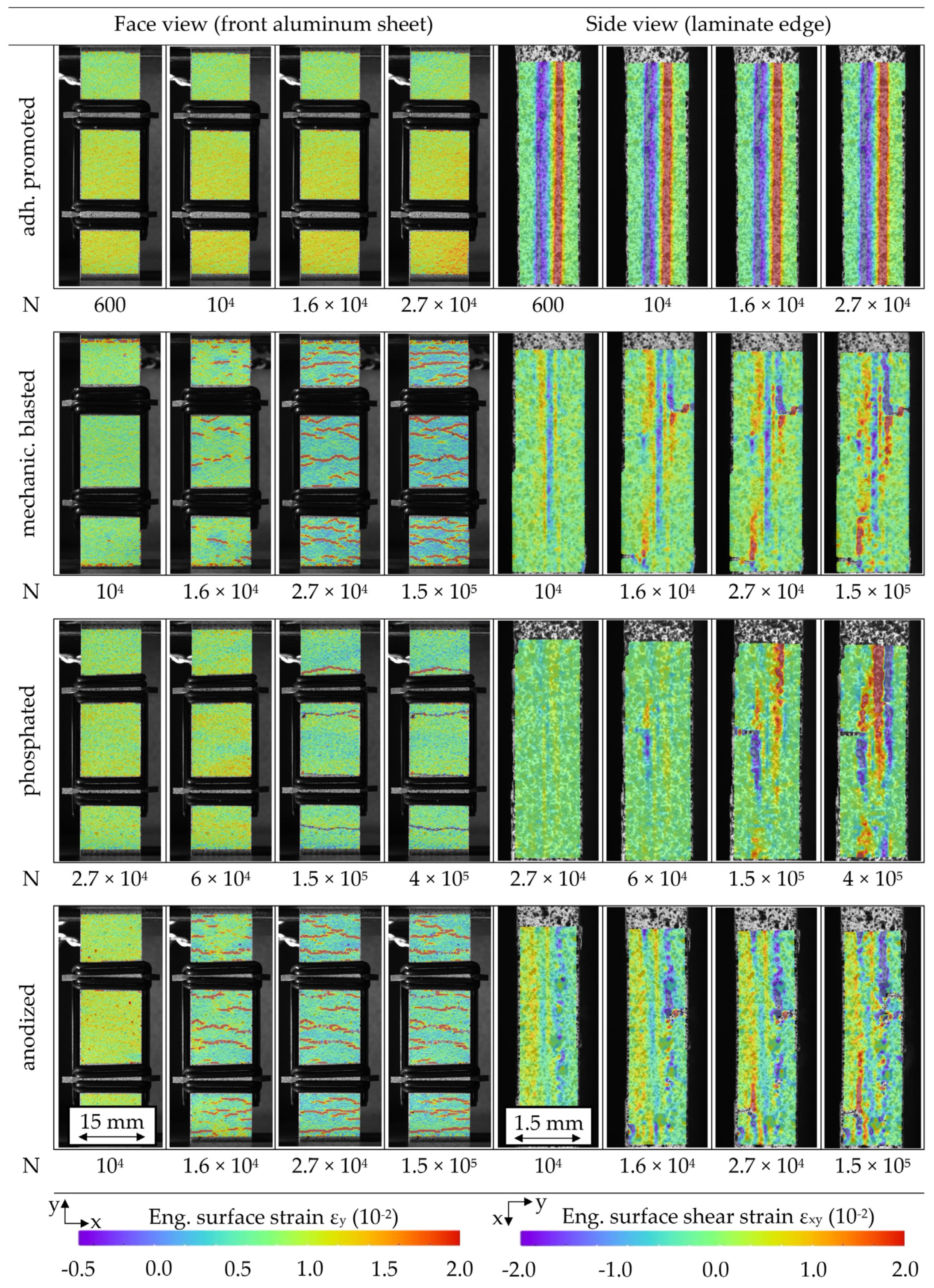

3.3. Cyclic Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Vermeeren, C.A.J.R. An historic overview of the development of fibre metal laminates. Appl. Compos. Mater. 2003, 10, 189–205. [Google Scholar] [CrossRef]

- Sinmazçelik, T.; Avcu, E.; Bora, M.Ö.; Çoban, O. A review: Fibre metal laminates, background, bonding types and applied test methods. Mater. Des. 2011, 32, 3671–3685. [Google Scholar] [CrossRef]

- Alderliesten, R.; Homan, J. Fatigue and damage tolerance issues of Glare in aircraft structures. Int. J. Fatigue 2006, 28, 1116–1123. [Google Scholar] [CrossRef]

- Mukesh, A.M.; Hynes, N.R.J. Mechanical properties and applications of fibre metal laminates. AIP Conf. Proc. 2019, 2142, 100002. [Google Scholar]

- Böhm, M.; Głowacka, K. Fatigue Life Estimation with Mean Stress Effect Compensation for Lightweight Structures-The Case of GLARE 2 Composite. Polymer (Basel) 2020, 12, 251. [Google Scholar] [CrossRef] [Green Version]

- Vlot, A.; Gunnink, J.W. (Eds.) Fibre Metal Laminates. An Introduction; Springer: Dordrecht, The Netherlands, 2001; ISBN 978-94-010-0995-9. [Google Scholar]

- Shim, D.J.; Alderliesten, R.C.; Spearing, S.M.; Burianek, D.A. Fatigue crack growth prediction in GLARE hybrid laminates. Compos. Sci. Technol. 2003, 63, 1759–1767. [Google Scholar] [CrossRef]

- Khan, S.U.; Alderliesten, R.C.; Benedictus, R. Delamination in Fiber Metal Laminates (GLARE) during fatigue crack growth under variable amplitude loading. Int. J. Fatigue 2011, 33, 1292–1303. [Google Scholar] [CrossRef]

- Alderliesten, R. Analytical prediction model for fatigue crack propagation and delamination growth in Glare. Int. J. Fatigue 2007, 29, 628–646. [Google Scholar] [CrossRef]

- Reyes, V.G.; Cantwell, W.J. The mechanical properties of fibre-metal laminates based on glass fibre reinforced polypropylene. Compos. Sci. Technol. 2000, 60, 1085–1094. [Google Scholar] [CrossRef]

- Wielage, B.; Nestler, D.; Steger, H.; Kroll, L.; Tröltzsch, J.; Nendel, S. CAPAAL and CAPET–new materials of high-strength, high-stiff hybrid laminates. In Integrated Systems, Design and Technology 2010; Springer: Berlin/Heidelberg, Germany, 2011; ISBN 978-3-642-17384-4. [Google Scholar]

- Zopp, C.; Nestler, D.; Tröltzsch, J.; Trautmann, M.; Nendel, S.; Wagner, G.; Nendel, W.; Kroll, L. CATPUAL —An Innovative and High-Performance Hybrid Laminate with Carbon Fibre-Reinforced Thermoplastic Polyurethane. KEM 2017, 742, 294–301. [Google Scholar] [CrossRef]

- Sexton, A.; Cantwell, W.; Kalyanasundaram, S. Stretch forming studies on a fibre metal laminate based on a self-reinforcing polypropylene composite. Compos. Struct. 2012, 94, 431–437. [Google Scholar] [CrossRef]

- Zanjani, N.A.; Sexton, A.; Kalyanasundaram, S. Induced forming modes in a pre-consolidated woven polypropylene composite during stretch forming process at room temperature: I. Experimental studies. Compos. Part A Appl. Sci. Manuf. 2015, 68, 251–263. [Google Scholar] [CrossRef]

- Nestler, D.; Trautmann, M.; Zopp, C.; Tröltzsch, J.; Osiecki, T.; Nendel, S.; Wagner, G.; Kroll, L. Continuous Film Stacking and Thermoforming Process for Hybrid CFRP/aluminum Laminates. Procedia Cirp 2017, 66, 107–112. [Google Scholar] [CrossRef]

- AL-Obaidi, A.; Graf, A.; Kräusel, V.; Trautmann, M. Heat supported single point incremental forming of hybrid laminates for orthopedic applications. Procedia Manuf. 2019, 29, 21–27. [Google Scholar] [CrossRef]

- Zopp, C.; Dittes, A.; Nestler, D.; Scharf, I.; Kroll, L.; Lampke, T. Quasi-static and fatigue bending behavior of a continuous fiber-reinforced thermoplastic/metal laminate. Compos. Part B Eng. 2019, 174, 107043. [Google Scholar] [CrossRef]

- Gonzalez-Canche, N.G.; Flores-Johnson, E.A.; Cortes, P.; Carrillo, J.G. Evaluation of surface treatments on 5052-H32 aluminum alloy for enhancing the interfacial adhesion of thermoplastic-based fiber metal laminates. Int. J. Adhes. Adhes. 2018, 82, 90–99. [Google Scholar] [CrossRef]

- Zhu, W.; Xiao, H.; Wang, J.; Fu, C. Characterization and properties of AA6061-based fiber metal laminates with different aluminum-surface pretreatments. Compos. Struct. 2019, 227, 111321. [Google Scholar] [CrossRef]

- Santhanakrishnan Balakrishnan, V.; Obrosov, A.; Kuke, F.; Seidlitz, H.; Weiß, S. Influence of metal surface preparation on the flexural strength and impact damage behaviour of thermoplastic FRP reinforced metal laminate made by press forming. Compos. Part B Eng. 2019, 173, 106883. [Google Scholar] [CrossRef]

- Park, S.Y.; Choi, W.J.; Choi, H.S.; Kwon, H. Effects of surface pre-treatment and void content on GLARE laminate process characteristics. J. Mater. Process. Technol. 2010, 210, 1008–1016. [Google Scholar] [CrossRef]

- Nestler, D.; Trautmann, M.; Nendel, S.; Wagner, G.; Kroll, L. Innovative hybrid laminates of aluminium alloy foils and fibre-reinforced thermoplastic layers. Materialwissenschaft und Werkstofftechnik 2016, 47, 1121–1131. [Google Scholar] [CrossRef]

- Bosbach, B.; Baytekin-Gerngross, M.; Heyden, E.; Gerngross, M.-D.; Carstensen, J.; Adelung, R.; Fiedler, B. Reaching maximum inter-laminar properties in GFRP/nanoscale sculptured aluminium ply laminates. Compos. Sci. Technol. 2018, 167, 32–41. [Google Scholar] [CrossRef]

- Gunnink, J.W.; Vlot, A.; de Vries, T.J.; van der Hoeven, W. Glare technology development 1997-2000. Appl. Compos. Mater. 2002, 9, 201–219. [Google Scholar] [CrossRef]

- Hausmann, J.; Naghipour, P.; Schulze, K. Analytical and Numerical Residual Stress Models for Fiber Metal Laminates—Comparison and Application. Procedia Mater. Sci. 2013, 2, 68–73. [Google Scholar] [CrossRef] [Green Version]

- Walther, F. Microstructure-Oriented Fatigue Assessment of Construction Materials and Joints Using Short-Time Load Increase Procedure. MP 2014, 56, 519–527. [Google Scholar] [CrossRef]

- Mrzljak, S.; Huelsbusch, D.; Walther, F. Damage initiation and propagation in glass-fiber-reinforced polyurethane during cyclic loading analyzed by in situ computed tomography. In Proceedings of the 7th International Conference on Fatigue of Composites, Vicenza, Italy, 4–6 July 2018. [Google Scholar]

| Surface Treatment AA6082-T4 | Arithmetic Mean Sa in µm | Root Mean Squared Sq in µm | Skewness Ssk |  |

| Untreated | 0.55 ± 0.12 | 0.66 ± 0.01 | 0.6 ± 0.1 | |

| Adhesion promoted | 0.49 ± 0.16 | 0.59 ± 0.18 | 0.5 ± 0.5 | |

| Mechanically blasted | 5.74 ± 1.18 | 6.88 ± 1.13 | −0.2 ± 0.4 | |

| Phosphated | 0.67 ± 0.15 | 0.95 ± 0.24 | 1.3 ± 0.8 | |

| Anodized | 2.13 ± 0.13 | 2.39 ± 0.10 | −0.4 ± 0.1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mrzljak, S.; Trautmann, M.; Wagner, G.; Walther, F. Influence of Aluminum Surface Treatment on Tensile and Fatigue Behavior of Thermoplastic-Based Hybrid Laminates. Materials 2020, 13, 3080. https://doi.org/10.3390/ma13143080

Mrzljak S, Trautmann M, Wagner G, Walther F. Influence of Aluminum Surface Treatment on Tensile and Fatigue Behavior of Thermoplastic-Based Hybrid Laminates. Materials. 2020; 13(14):3080. https://doi.org/10.3390/ma13143080

Chicago/Turabian StyleMrzljak, Selim, Maik Trautmann, Guntram Wagner, and Frank Walther. 2020. "Influence of Aluminum Surface Treatment on Tensile and Fatigue Behavior of Thermoplastic-Based Hybrid Laminates" Materials 13, no. 14: 3080. https://doi.org/10.3390/ma13143080

APA StyleMrzljak, S., Trautmann, M., Wagner, G., & Walther, F. (2020). Influence of Aluminum Surface Treatment on Tensile and Fatigue Behavior of Thermoplastic-Based Hybrid Laminates. Materials, 13(14), 3080. https://doi.org/10.3390/ma13143080