A New Test Method for Evaluation of Solidification Cracking Susceptibility of Stainless Steel during Laser Welding

Abstract

:1. Introduction

2. Materials and Experiment

2.1. Materials

2.2. Experiment

3. Results and Discussion

3.1. Principle of the New Test Method—“Trapezoidal hot” Cracking Test

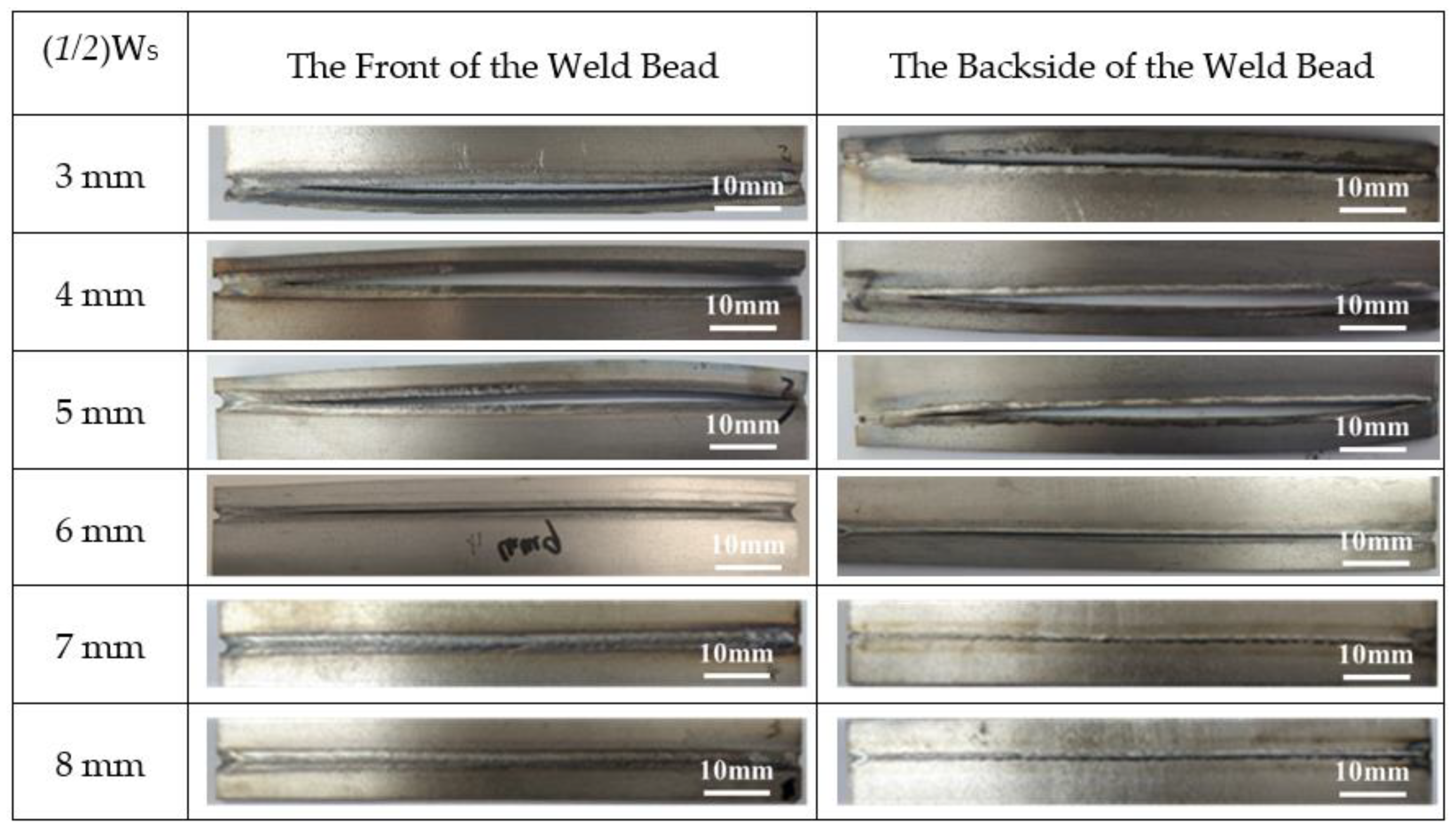

3.2. Development of the “Trapezoidal hot” Cracking Test

3.3. The Effect of the Chemical Composition on the Solidification Cracking Susceptibility of Stainless Steel During Laser Welding at a Welding Speed of 1.0 m/min

3.4. The Effect of Laser Welding Speed on the Solidification Cracking Susceptibility of Stainless Steel

4. Conclusions

- (1)

- The new test method called the “Trapezoidal hot”cracking test was developed to evaluate the solidification cracking susceptibility using the solidification cracking rate which was the ratio of the solidification cracking length to the weld bead length under the suitable values of WS and WF.

- (2)

- The sequence of the solidification cracking susceptibility was as follows: SUS310 > SUS316 > SUS304 during laser welding at a welding speed of 1.0 m/min; because the fully austenitic structure appeared in the weld joint of SUS310 stainless steel, and the ferrite and austenitic mixed structures were produced in SUS316 and SUS304 stainless steel, the latter had relatively more ferrite.

- (3)

- With the increase in welding speed from 1.0 to 2.0 m/min, the solidification cracking susceptibilities of SUS310 and SUS304 stainless steels tended to decrease and increase during laser welding, respectively. This is due to the grain refinement for the former and a decrease in the amount of ferrite for the latter.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Acherjee, B. Hybrid laser arc welding: State-of-art review. Opt. Laser Technol. 2018, 99, 60–71. [Google Scholar] [CrossRef]

- Chen, X.; Lei, Z.; Chen, Y.; Jiang, M.; Tian, Z.; Bi, J.; Lin, S. Microstructure and mechanical properties of laser welded Al-Si coated hot-press-forming steel joints. Materials 2019, 12, 3294. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.K.; Park, S.H.; Kang, C.Y. Effect of plasma current on surface defects of plasma-MIG welding in cryogenic aluminum alloys. J. Mater. Process. Technol. 2015, 223, 203–215. [Google Scholar] [CrossRef]

- Abe, D.; Matsuzaka, F.; Murakami, Y.; Matsuoka, T.; Yamaoka, H. Determining the BTR by conducting a Trans-Varestraint test using a high-speed camera and two-color pyrometry. Weld. World 2018, 62, 1237–1246. [Google Scholar] [CrossRef] [Green Version]

- Alvarez, P.; Vázquez, L.; Ruiz, N.; Rodríguez, P.; Magaña, A.; Niklas, A.; Santos, F. Comparison of hot cracking susceptibility of TIG and laser beam welded alloy 718 by Varestraint testing. Metals 2019, 9, 985. [Google Scholar] [CrossRef] [Green Version]

- Statharas, D.; Atkinson, H.; Thornton, R.; Marsden, J.; Dong, H.; Wen, S. Getting the strain under control: Trans-Varestraint tests for hot cracking susceptibility. Metall. Mater. Trans. A 2019, 50, 1748–1762. [Google Scholar] [CrossRef] [Green Version]

- Goodwin, M. Development of a new hot-cracking test—the Sigmajig. Weld. J. 1987, 66, 33–38. [Google Scholar]

- Mossman, M.; Lippold, J. Weldability testing of dissimilar combinations of 5000- and 6000-series aluminum alloys. Weld. J. 2002, 81, 188–194. [Google Scholar]

- Fukuhisa, M.; Hiroji, N.; Shogo, T.; Hiroaki, K.; Yoshioki, H. Measuring of critical strain for initiation of solidification crack by Rapid tensile cracking test investigation on weld solidification cracking by MISO technique (Report II). Q. J. Jpn. Weld. Soc. 1988, 6, 401–405. [Google Scholar]

- Fukuhisa, M.; Hiroji, N.; Shogo, T.; Kazuhiko, S. Behaviors of solidification front, initiation and propagation of bolidification crack investigation of weld solidification cracking by MISO technique (Report 1). Q. J. Jpn. Weld. Soc. 1988, 6, 394–400. [Google Scholar]

- Katoh, M.; Nishio, K.; Mukae, S. A comparison of the conventional and reverse Houldcroft type hot cracking tests in a5052 aluminum alloy sheet. Q. J. Jpn. Weld. Soc. 1994, 12, 179–185. [Google Scholar] [CrossRef]

- Pereita, M.; Taniguchi, C.; Brandi, D.; Machida, S. Analysis of solidification cracks in welds of Al-Mg-Si a6351 type alloy welded by high frequency pulsed TIG process. Q. J. Jpn. Weld. Soc. 1994, 12, 342–350. [Google Scholar] [CrossRef]

- Adamiec, J.; Kierzek, A. Hot cracking of ZRE1 alloy in constant joint stiffness condition. Arch. Foundry Eng. 2010, 10, 151–156. [Google Scholar]

- Klimpel, A.; Mazur, M.; Bulski, Z. Zirconium and the occurrence of weld cracking during the welding of GA8 magnesium alloy castings. Weld. Int. 2003, 17, 94–97. [Google Scholar] [CrossRef]

- David, A.; Woodhouse, J. Weldability test for thin sheet materials. Weld. J. 1987, 66, 129–134. [Google Scholar]

- Nelson, T.; Lippold, J.; Lin, W. Evaluation of the circular patch test for assessing weld solidification cracking, part i - development of a test method. Weld. J. 1997, 76, 110–119. [Google Scholar]

- Shinozaki, K.; Yamamoto, M.; Kawasaki, A.; Tamura, T.; Wen, P. Development of evaluation method for solidification cracking susceptibility of Inconel600/SUS347 dissimilar laser weld metal by in-situ observation. Mater. Sci. Forum 2009, 580–582, 49–52. [Google Scholar] [CrossRef]

- Shinozaki, K.; Wen, P.; Yamamoto, M.; Kadoi, K.; Kohno, Y.; Komori, T. Effect of grain size on solidification cracking susceptibility of type 347 stainless steel during laser welding. Trans. JWRI 2010, 39, 136–138. [Google Scholar] [CrossRef] [Green Version]

- Kadoi, K.; Fujinaga, A.; Yamamoto, M.; Shinozaki, K. The effect of welding conditions on solidification cracking susceptibility of type 310S stainless steel during laser welding using an in-situ observation technique. Weld. World 2013, 57, 383–390. [Google Scholar] [CrossRef] [Green Version]

- Chun, J.; Baba, H.; Nishimoto, K.; Saida, K. Development of laser beam welding Trans-Varestraint test for assessment of solidification cracking susceptibility in laser welds(Article). Met. Mater. Int. 2015, 21, 543–553. [Google Scholar] [CrossRef]

- Dan, W.; Shuntaro, S.; Kota, K.; Kenji, S.; Motomichi, Y. Investigation of evaluation method for hot cracking susceptibility of 310S stainless steel during laser welding using Trans-Varestraint test. Q. J. Jpn. Weld. Soc. 2015, 33, 39–43. [Google Scholar]

- Dan, W.; Kota, K.; Kenji, S.; Motomichi, Y. Evaluation of solidification cracking susceptibility for austenitic stainless steel during laser Trans-varestraint test using two-dimensional temperature measurement. ISIJ Int. 2016, 56, 2022–2028. [Google Scholar]

- Zhai, Y.; Huang, J.; Li, M.; Chen, J.; Yang, M.; Zhao, Y. Research on high speed high power CO(2) laser welding of 6061-T6 aluminum with filler wire. Zhongguo Jiguang (Chinese J. Lasers) 2011, 38, 0503001. [Google Scholar]

- Fukuhisa, M.; Nakata, K. A new test specimen for self-restraint solidification crack susceptibility test of electron-beam welding bead: Fan-shaped cracking test(Materials, Metallurgy & Weldability). Trans. JWRI 1982, 11, 87–94. [Google Scholar]

- Reddy, G.; Mukhopadhyay, K.; Rao, A. Influence of scandium on weldability of 7010 aluminium alloy. Sci. Technol. Weld. Joi. 2013, 10, 432–441. [Google Scholar] [CrossRef]

- Li, J.; Li, H.; Liang, Y.; Liu, P.; Yang, L. The microstructure and mechanical properties of multi-strand, composite welding-wire welded joints of high nitrogen austenitic stainless steel. Materials 2019, 12, 2944. [Google Scholar] [CrossRef] [Green Version]

- Bermejo, M.; Debroy, T.; Hurtig, K.; Karlsson, L. Towards a map of solidification cracking risk in laser welding of austenitic stainless steels. In Proceedings of the 15th Nordic Laser Materials Processing Conference, Lappeenranta, Finland, 25–28 August 2015. [Google Scholar]

- Lippold, J.; Kotecki, J. Welding Metallurgy and Weldability of Stainless Steels; John Wiley & Sons, Inc.: Hoboken, NJ., USA, 2005; pp. 174–175. [Google Scholar]

- Flemings, M. Solidification Processing; McGraw-Hill: New York, NY, USA, 1974; Volume 75, pp. 219–224. [Google Scholar]

- Kou, S. Welding Metallurgy; Wiley-Interscience: Hoboken, NJ, USA, 2003; p. 284. [Google Scholar]

- Agarwal, G.; Kumar, A.; Richardson, M.; Hermans, M. Evaluation of solidification cracking susceptibility during laser welding in advanced high strength automotive steels. Mater. Des. 2019, 183, 1–12. [Google Scholar] [CrossRef]

| Materials | C | Si | Mn | P | S | Cr | Ni | Mo | Cu | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| SUS310 | 0.07 | 0.40 | 0.95 | 0.015 | 0.014 | 24.7 | 20.3 | 0.12 | 0.10 | Bal. |

| SUS316 | 0.06 | 0.26 | 1.12 | 0.015 | 0.019 | 16.7 | 10.2 | 2.11 | 0.09 | Bal. |

| SUS304 | 0.04 | 0.32 | 1.04 | 0.015 | 0.016 | 18.3 | 8.1 | 0.01 | 0.02 | Bal. |

| Welding Speed, m/min | 1.0 | 1.5 | 2.0 |

|---|---|---|---|

| Laser power, kW | 1.8 | 2.3 | 2.8 |

| Laser spot size, mm | 0.6 (Just focus) | ||

| Laser irradiation angle, deg | 10 | ||

| Ar shielding gas, L/min | 20 (Front and backside) | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Xiong, L.; Wang, D.; Ma, Q.; Hu, Y.; Hu, G.; Lei, Y. A New Test Method for Evaluation of Solidification Cracking Susceptibility of Stainless Steel during Laser Welding. Materials 2020, 13, 3178. https://doi.org/10.3390/ma13143178

Wang W, Xiong L, Wang D, Ma Q, Hu Y, Hu G, Lei Y. A New Test Method for Evaluation of Solidification Cracking Susceptibility of Stainless Steel during Laser Welding. Materials. 2020; 13(14):3178. https://doi.org/10.3390/ma13143178

Chicago/Turabian StyleWang, Wenbin, Li Xiong, Dan Wang, Qin Ma, Yan Hu, Guanzhi Hu, and Yucheng Lei. 2020. "A New Test Method for Evaluation of Solidification Cracking Susceptibility of Stainless Steel during Laser Welding" Materials 13, no. 14: 3178. https://doi.org/10.3390/ma13143178

APA StyleWang, W., Xiong, L., Wang, D., Ma, Q., Hu, Y., Hu, G., & Lei, Y. (2020). A New Test Method for Evaluation of Solidification Cracking Susceptibility of Stainless Steel during Laser Welding. Materials, 13(14), 3178. https://doi.org/10.3390/ma13143178