Rigid Polyurethane Foams Based on Bio-Polyol and Additionally Reinforced with Silanized and Acetylated Walnut Shells for the Synthesis of Environmentally Friendly Insulating Materials

Abstract

:1. Introduction

2. Experimental Section

2.1. Chemicals and Materials

2.2. Methods

2.2.1. Pre-Treatment of WS with an Alkali Solution

2.2.2. Silanization of WS

2.2.3. Acetylation of WS

2.2.4. PUR Foams Preparation

2.3. Test Methods

3. Results and Discussion

3.1. Characterization of WS-Based Polyol

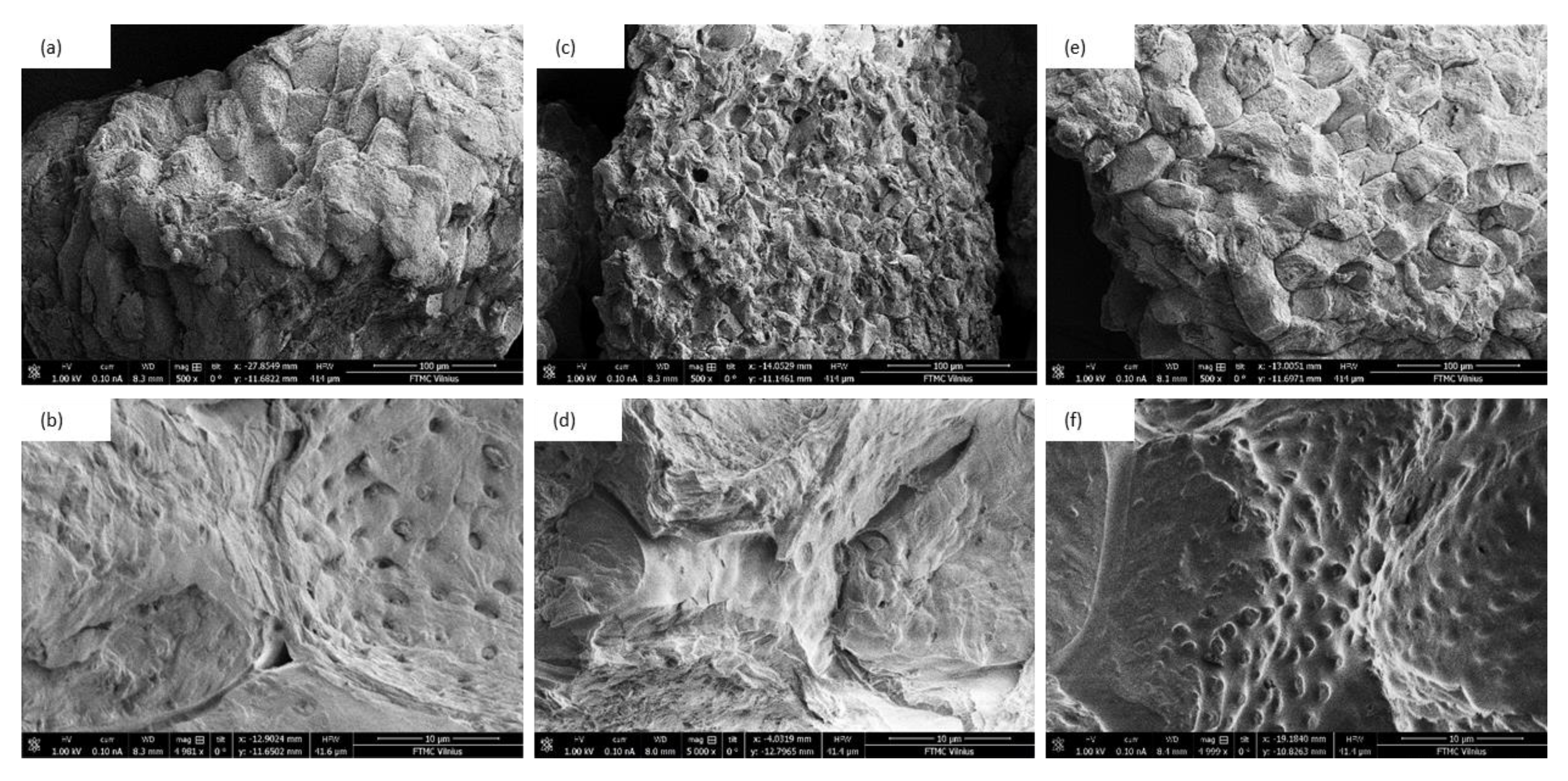

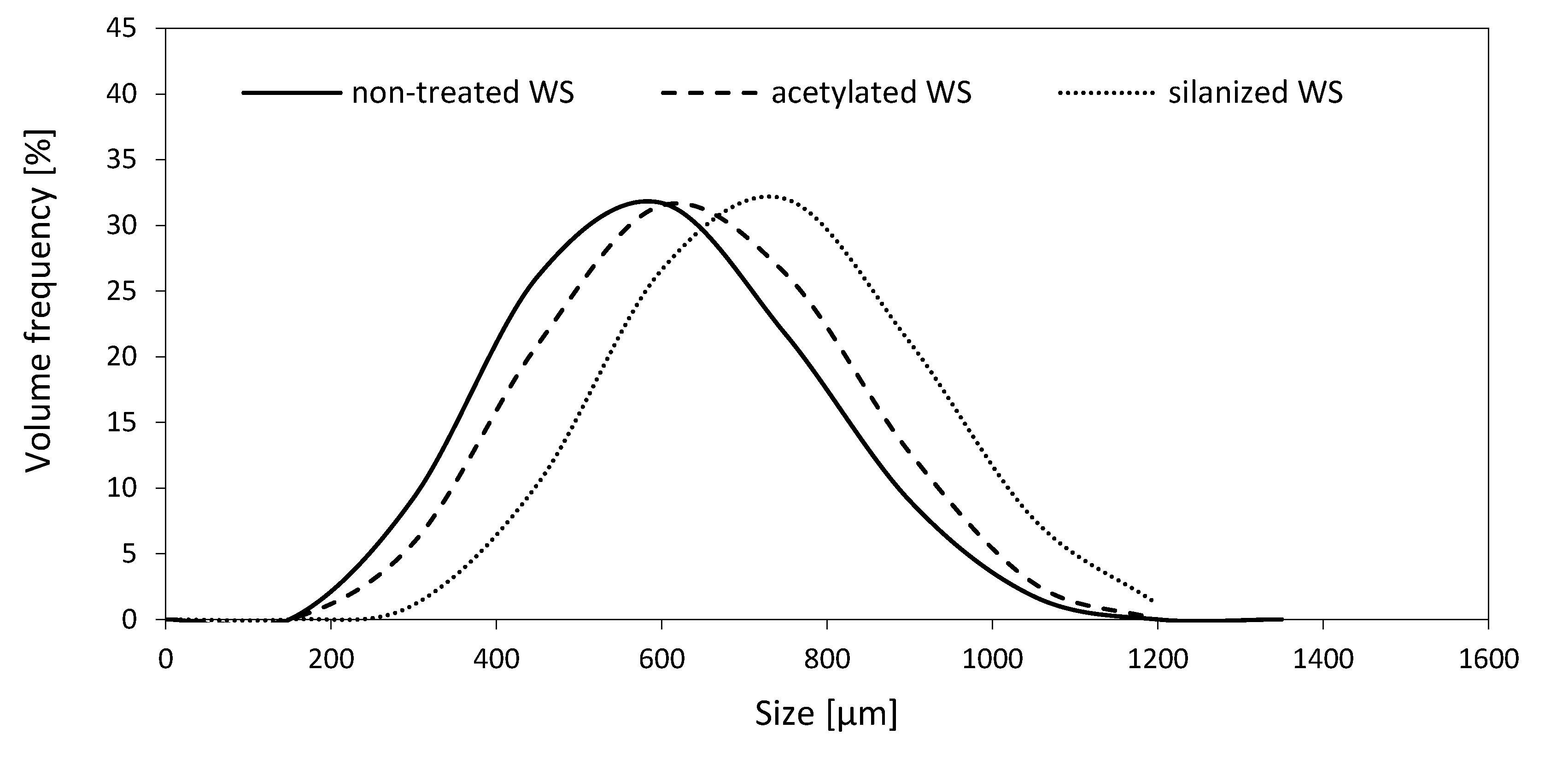

3.2. Characterization of WS Filler

3.3. Foaming Kinetic

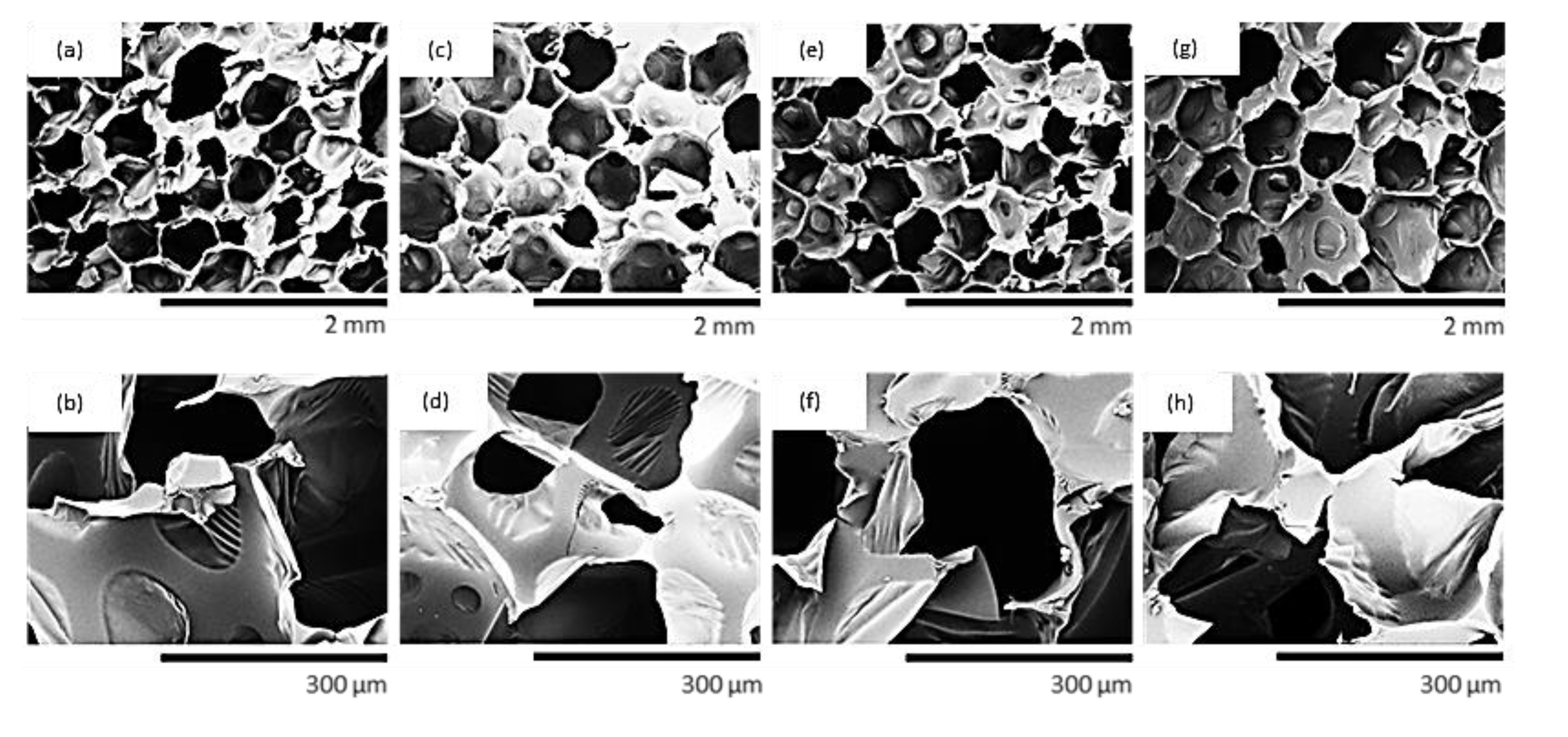

3.4. Cellular Structure and Thermal Conductivity

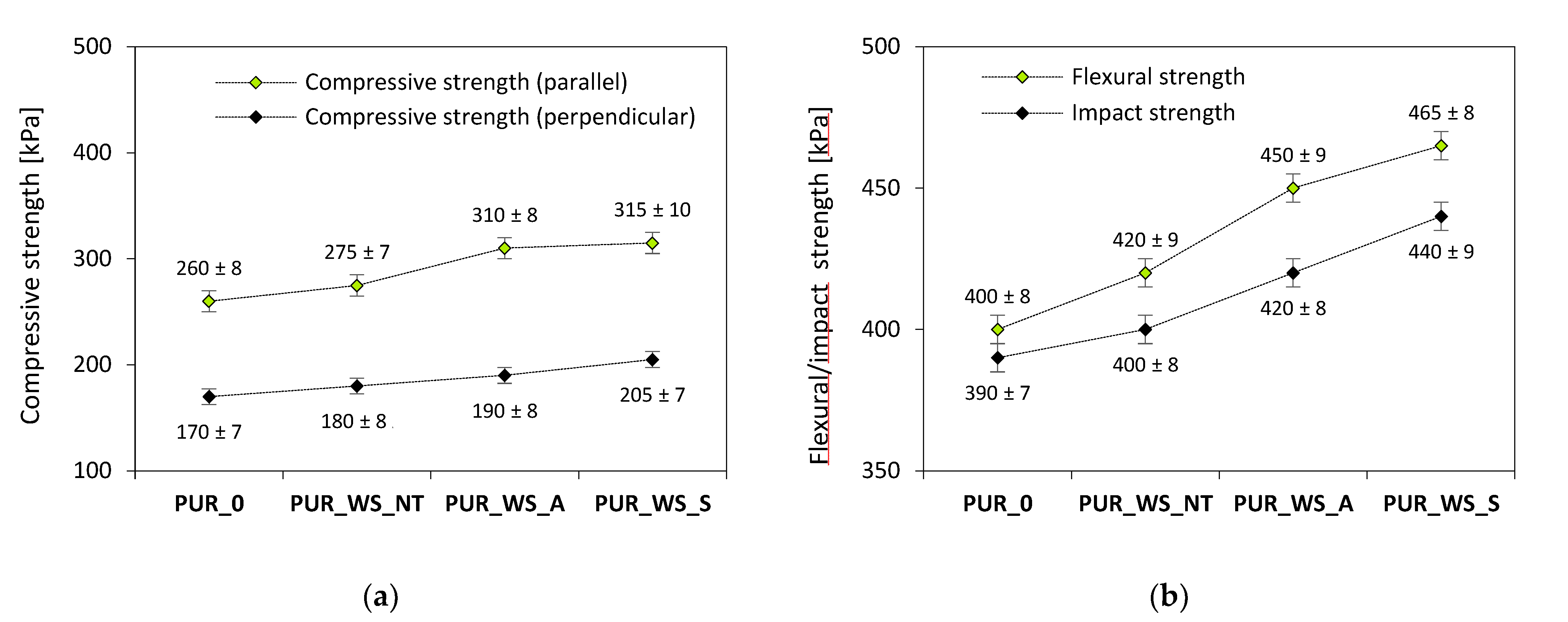

3.5. Mechanical Characteristics

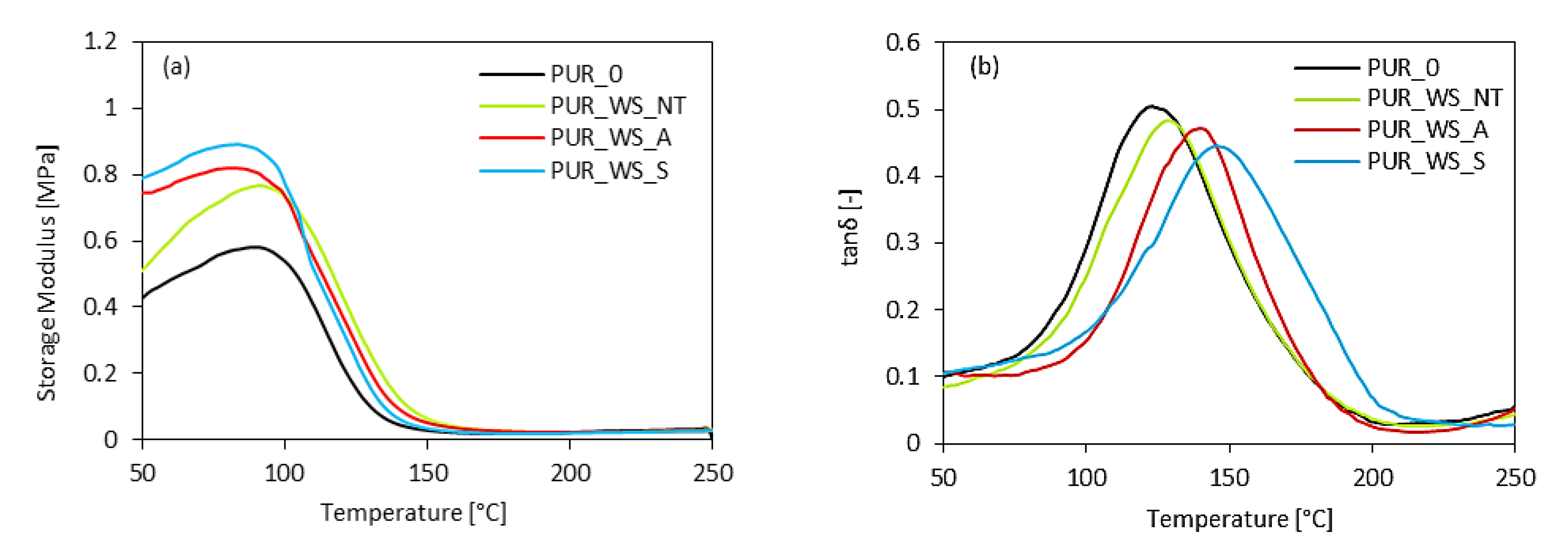

3.6. DMA Results

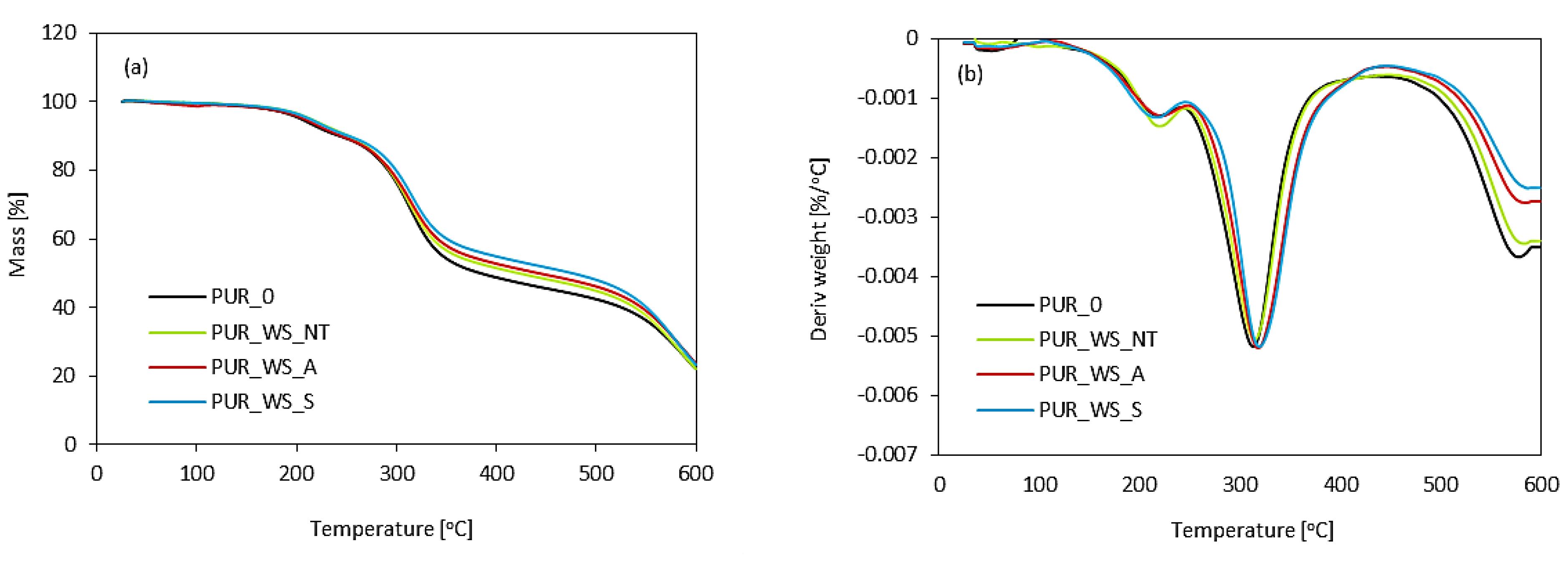

3.7. Thermal Stability

4. Conclusion

Author Contributions

Funding

Conflicts of Interest

References

- KAIRYTĖ, A.; Kizinievič, O.; Kizinievič, V.; Kremensas, A. Synthesis of biomass-derived bottom waste ash based rigid biopolyurethane composite foams: Rheological behaviour, structure and performance characteristics. Compos. Part A Appl. Sci. Manuf. 2019, 117, 193–201. [Google Scholar] [CrossRef]

- KAIRYTĖ, A.; Vaitkus, S.; Vėjelis, S.; Girskas, G.; Balčiūnas, G. Rapeseed-based polyols and paper production waste sludge in polyurethane foam: Physical properties and their prediction models. Ind. Crop. Prod. 2018, 112, 119–129. [Google Scholar] [CrossRef]

- KAIRYTĖ, A.; Vėjelis, S. Evaluation of forming mixture composition impact on properties of water blown rigid polyurethane (PUR) foam from rapeseed oil polyol. Ind. Crop. Prod. 2015, 66, 210–215. [Google Scholar] [CrossRef]

- Prociak, A.; Szczepkowski, L.; Ryszkowska, J.; Kurańska, M.; Auguścik, M.; Malewska, E.; Gloc, M.; Michałowski, S. Influence of Chemical Structure of Petrochemical Polyol on Properties of Bio-polyurethane Foams. J. Polym. Environ. 2019, 27, 2360–2368. [Google Scholar] [CrossRef] [Green Version]

- Kurańska, M.; Polaczek, K.; Auguścik-Królikowska, M.; Prociak, A.; Ryszkowska, J. Open-cell rigid polyurethane bio-foams based on modified used cooking oil. Polymer 2020, 190, 122164. [Google Scholar] [CrossRef]

- Kurańska, M.; Pinto, J.; Salach, K.; Barreiro, M.F.; Prociak, A. Synthesis of thermal insulating polyurethane foams from lignin and rapeseed based polyols: A comparative study. Ind. Crop. Prod. 2020, 143, 111882. [Google Scholar] [CrossRef]

- Borowicz, M.; Paciorek-Sadowska, J.; Lubczak, J.; Czupryński, B. Biodegradable, Flame-Retardant, and Bio-Based Rigid Polyurethane/Polyisocyanurate Foams for Thermal Insulation Application. Polymer 2019, 11, 1816. [Google Scholar] [CrossRef] [Green Version]

- Soares, B.; Gama, N.V.; Freire, C.S.; Barros-Timmons, A.; Brandão, I.; Silva, R.; Neto, C.P.; Ferreira, A. Spent coffee grounds as a renewable source for ecopolyols production. J. Chem. Technol. Biotechnol. 2014, 90, 1480–1488. [Google Scholar] [CrossRef]

- Kang, J.; Chen, W.; Yao, Y.; Jin, Y.; Cheng, X.; Lü, Q. Optimisation of Bio-polyol Production from Cassava Residue Using Ethylene Glycol as the Liquefaction Reagent. J. Wuhan Univ. Technol. Sci. Ed. 2019, 34, 945–949. [Google Scholar] [CrossRef]

- Huang, G.; Wang, P. Effects of preparation conditions on properties of rigid polyurethane foam composites based on liquefied bagasse and jute fibre. Polym. Test. 2017, 60, 266–273. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; KAIRYTĖ, A. Application of Walnut Shells-Derived Biopolyol in the Synthesis of Rigid Polyurethane Foams. Materials 2020, 13, 2687. [Google Scholar] [CrossRef] [PubMed]

- Sarsari, N.A.; Pourmousa, S.; Tajdini, A. Physical and Mechanical Properties of Walnut Shell Flour-Filled Thermoplastic Starch Composites. Bioresour. 2016, 11, 6968–6983. [Google Scholar] [CrossRef] [Green Version]

- Ayrilmis, N.; Kaymakci, A.; Özdemir, F. Physical, mechanical, and thermal properties of polypropylene composites filled with walnut shell flour. J. Ind. Eng. Chem. 2013, 19, 908–914. [Google Scholar] [CrossRef]

- Barczewski, M.; Salasinska, K.; Kloziński, A.; Skórczewska, K.; Szulc, J.; Piasecki, A. Application of the Basalt Powder as a Filler for Polypropylene Composites With Improved Thermo-Mechanical Stability and Reduced Flammability. Polym. Eng. Sci. 2018, 59, E71–E79. [Google Scholar] [CrossRef]

- Barczewski, M.; Mysiukiewicz, O.; Matykiewicz, D.; Kloziński, A.; Andrzejewski, J.; Piasecki, A. Synergistic effect of different basalt fillers and annealing on the structure and properties of polylactide composites. Polym. Test. 2020, 89, 106628. [Google Scholar] [CrossRef]

- Barczewski, M.; Kurańska, M.; Sałasińska, K.; Michałowski, S.; Prociak, A.; Uram, K.; Lewandowski, K. Rigid polyurethane foams modified with thermoset polyester-glass fiber composite waste. Polym. Test. 2020, 81, 106190. [Google Scholar] [CrossRef]

- Zhou, X.; Sethi, J.; Geng, S.; Berglund, L.; Frisk, N.; Aitomäki, Y.; Sain, M.; Oksman, K. Dispersion and reinforcing effect of carrot nanofibers on biopolyurethane foams. Mater. Des. 2016, 110, 526–531. [Google Scholar] [CrossRef]

- KAIRYTĖ, A.; Kirpluks, M.; Ivdre, A.; Cabulis, U.; Vėjelis, S.; Balčiūnas, G. Paper waste sludge enhanced eco-efficient polyurethane foam composites: Physical-mechanical properties and microstructure. Polym. Compos. 2016, 39, 1852–1860. [Google Scholar] [CrossRef]

- Paciorek-Sadowska, J.; Borowicz, M.; Isbrandt, M.; Czupryński, B.; Apiecionek, L. The Use of Waste from the Production of Rapeseed Oil for Obtaining of New Polyurethane Composites. Polymer. 2019, 11, 1431. [Google Scholar] [CrossRef] [Green Version]

- Pappu, A.; Patil, V.; Jain, S.; Mahindrakar, A.; Haque, R.; Thakur, V. Advances in industrial prospective of cellulosic macromolecules enriched banana biofibre resources: A review. Int. J. Boil. Macromol. 2015, 79, 449–458. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.‑P.; Sain, M. Progress Report on Natural Fiber Reinforced Composites. Macromol. Mater. Eng. 2013, 299, 9–26. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.‑P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Lopes, F.P.D.; Barbosa, A.P.; Bevitori, A.B.; Da Silva, I.L.A.; Da Costa, L.L. Natural Lignocellulosic Fibers as Engineering Materials—An Overview. Met. Mater. Trans. A 2011, 42, 2963–2974. [Google Scholar] [CrossRef] [Green Version]

- Cichosz, S.; Masek, A. Thermal Behavior of Green Cellulose-Filled Thermoplastic Elastomer Polymer Blends. Molecules 2020, 25, 1279. [Google Scholar] [CrossRef] [Green Version]

- Cichosz, S.; Masek, A. Drying of the Natural Fibers as A Solvent-Free Way to Improve the Cellulose-Filled Polymer Composite Performance. Polymer 2020, 12, 484. [Google Scholar] [CrossRef] [Green Version]

- Septevani, A.A.; Evans, D.A.; Annamalai, P.K.; Martin, D.J. The use of cellulose nanocrystals to enhance the thermal insulation properties and sustainability of rigid polyurethane foam. Ind. Crop. Prod. 2017, 107, 114–121. [Google Scholar] [CrossRef]

- Hayati, A.N.; Evans, D.A.C.; Laycock, B.; Martin, D.J.; Annamalai, P.K. A simple methodology for improving the performance and sustainability of rigid polyurethane foam by incorporating industrial lignin. Ind. Crop. Prod. 2018, 117, 149–158. [Google Scholar] [CrossRef]

- Zakaria, S.; Hamzah, H.; Murshidi, J.A.; Deraman, M. Chemical modification on lignocellulosic polymeric oil palm empty fruit bunch for advanced material. Adv. Polym. Technol. 2001, 20, 289–295. [Google Scholar] [CrossRef]

- Wolski, K.; Cichosz, S.; Masek, A. Surface hydrophobisation of lignocellulosic waste for the preparation of biothermoelastoplastic composites. Eur. Polym. J. 2019, 118, 481–491. [Google Scholar] [CrossRef]

- Cichosz, S.; Masek, A. Cellulose Fibers Hydrophobization via a Hybrid Chemical Modification. Polymer 2019, 11, 1174. [Google Scholar] [CrossRef] [Green Version]

- Cichosz, S.; Masek, A. Superiority of Cellulose Non-Solvent Chemical Modification over Solvent-Involving Treatment: Application in Polymer Composite (part II). Materials 2020, 13, 2901. [Google Scholar] [CrossRef] [PubMed]

- Borysiak, S. Fundamental studies on lignocellulose/polypropylene composites: Effects of wood treatment on the transcrystalline morphology and mechanical properties. J. Appl. Polym. Sci. 2012, 127, 1309–1322. [Google Scholar] [CrossRef]

- Neto, J.S.S.; Lima, R.D.A.A.; Cavalcanti, D.; Souza, J.P.B.; Aguiar, R.A.A.; Banea, M.D. Effect of chemical treatment on the thermal properties of hybrid natural fiber-reinforced composites. J. Appl. Polym. Sci. 2018, 136, 1–13. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Compos. Part B Eng. 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Liu, Y.; Xie, J.; Wu, N.; Wang, L.; Ma, Y.; Tong, J. Influence of silane treatment on the mechanical, tribological and morphological properties of corn stalk fiber reinforced polymer composites. Tribol. Int. 2019, 131, 398–405. [Google Scholar] [CrossRef]

- ISO 2555-Plastics—Resins in the liquid state or as emulsions or dispersions-Determination of apparent viscosity by the Brookfield Test method; International Organization for Standardization: Geneva, Switzerland, 1989.

- ISO 845-Cellular plastics and rubbers—Determination of apparent density; International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 844-Preview Rigid cellular plastics—Determination of compression properties; International Organization for Standardization: Geneva, Switzerland, 2014.

- ISO 178-Plastics—Determination of flexural properties; International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 180-Plastics—Determination of Izod impact strength; International Organization for Standardization: Geneva, Switzerland, 2019.

- Kolev, T.M.; Velcheva, E.A.; Stamboliyska, B.; Spiteller, M. DFT and experimental studies of the structure and vibrational spectra of curcumin. Int. J. Quantum Chem. 2005, 102, 1069–1079. [Google Scholar] [CrossRef]

- Al-Oweini, R.; El-Rassy, H. Synthesis and characterization by FTIR spectroscopy of silica aerogels prepared using several Si(OR)4 and R′′Si(OR′)3 precursors. J. Mol. Struct. 2009, 919, 140–145. [Google Scholar] [CrossRef]

- Wang, X.; Xu, S.; Tan, Y.; Du, J.; Wang, J. Synthesis and characterization of a porous and hydrophobic cellulose-based composite for efficient and fast oil–water separation. Carbohydr. Polym. 2016, 140, 188–194. [Google Scholar] [CrossRef]

- Tang, L.; Huang, B.; Yang, N.; Li, T.; Lu, Q.; Lin, W.; Chen, X. Organic solvent-free and efficient manufacture of functionalized cellulose nanocrystals via one-pot tandem reactions. Green Chem. 2013, 15, 2369–2373. [Google Scholar] [CrossRef]

- Adebajo, M.; Frost, R.L. Infrared and 13C MAS nuclear magnetic resonance spectroscopic study of acetylation of cotton. Spectrochim. Acta Part A: Mol. Biomol. Spectrosc. 2004, 60, 449–453. [Google Scholar] [CrossRef] [Green Version]

- Adebajo, M.; Frost, R.L. Acetylation of raw cotton for oil spill cleanup application: An FTIR and 13C MAS NMR spectroscopic investigation. Spectrochim. Acta Part A: Mol. Biomol. Spectrosc. 2004, 60, 2315–2321. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Frisoni, G.; Baiardo, M.; Scandola, M.; Lednická, D.; Cnockaert, M.C.; Mergaert, J.; Swings, J. Natural cellulose fibers: Heterogeneous acetylation kinetics and biodegradation behavior. Biomacromolecules 2001, 2, 476–482. [Google Scholar] [CrossRef] [PubMed]

- Rambabu, N.; Panthapulakkal, S.; Sain, M.; Dalai, A.K. Production of nanocellulose fibers from pinecone biomass: Evaluation and optimization of chemical and mechanical treatment conditions on mechanical properties of nanocellulose films. Ind. Crop. Prod. 2016, 83, 746–754. [Google Scholar] [CrossRef]

- Manimaran, P.; Senthamaraikannan, P.; Sanjay, M.; Marichelvam, M.; Jawaid, M. Study on characterization of Furcraea foetida new natural fiber as composite reinforcement for lightweight applications. Carbohydr. Polym. 2018, 181, 650–658. [Google Scholar] [CrossRef]

- Manimaran, P.; Saravanan, S.; Sanjay, M.; Siengchin, S.; Jawaid, M.; Khan, A. Characterization of new cellulosic fiber: Dracaena reflexa as a reinforcement for polymer composite structures. J. Mater. Res. Technol. 2019, 8, 1952–1963. [Google Scholar] [CrossRef]

- Negawo, T.A.; Polat, Y.; Buyuknalcaci, F.N.; Kilic, A.; Saba, N.; Jawaid, M. Mechanical, morphological, structural and dynamic mechanical properties of alkali treated Ensete stem fibers reinforced unsaturated polyester composites. Compos. Struct. 2019, 207, 589–597. [Google Scholar] [CrossRef]

- Yaghoubi, A.; Nikje, M.M.A. Silanization of multi-walled carbon nanotubes and the study of its effects on the properties of polyurethane rigid foam nanocomposites. Compos. Part A Appl. Sci. Manuf. 2018, 109, 338–344. [Google Scholar] [CrossRef]

- Sawpan, M.A.; Pickering, K.; Fernyhough, A. Effect of various chemical treatments on the fibre structure and tensile properties of industrial hemp fibres. Compos. Part A: Appl. Sci. Manuf. 2011, 42, 888–895. [Google Scholar] [CrossRef] [Green Version]

- Amin, K.N.M. Cellulose nanocrystals reinforced thermoplastic polyurethane nanocomposites. Master’s Thesis, University of Queensland Library, Brisbane, QL, Australia, 2016. [Google Scholar]

- Ma, S.-R.; Shi, L.; Feng, X.; Yu, W.-J.; Lü, B. Graft modification of ZnO nanoparticles with silane coupling agent KH570 in mixed solvent. J. Shanghai Univ. Engl. Ed. 2008, 12, 278–282. [Google Scholar] [CrossRef]

- Marcovich, N.; Kurańska, M.; Prociak, A.; Malewska, E.; Kulpa, K. Open cell semi-rigid polyurethane foams synthesized using palm oil-based bio-polyol. Ind. Crop. Prod. 2017, 102, 88–96. [Google Scholar] [CrossRef]

- Cinelli, P.; Anguillesi, I.; Lazzeri, A. Green synthesis of flexible polyurethane foams from liquefied lignin. Eur. Polym. J. 2013, 49, 1174–1184. [Google Scholar] [CrossRef]

- Kurańska, M.; Aleksander, P.; Mikelis, K.; Ugis, C. Porous polyurethane composites based on bio-components. Compos. Sci. Technol. 2013, 75, 70–76. [Google Scholar] [CrossRef]

- Santiago-Calvo, M.; Tirado-Mediavilla, J.; Ruiz-Herrero, J.L.; Rodriguez-Perez, M.A.; Villafañe, F. The effects of functional nanofillers on the reaction kinetics, microstructure, thermal and mechanical properties of water blown rigid polyurethane foams. Polymer 2018, 150, 138–149. [Google Scholar] [CrossRef]

- Sung, G.; Kim, J.H. Influence of filler surface characteristics on morphological, physical, acoustic properties of polyurethane composite foams filled with inorganic fillers. Compos. Sci. Technol. 2017, 146, 147–154. [Google Scholar] [CrossRef]

- Modesti, M.; Lorenzetti, A.; Besco, S. Influence of nanofillers on thermal insulating properties of polyurethane nanocomposites foams. Polym. Eng. Sci. 2007, 47, 1351–1358. [Google Scholar] [CrossRef]

- Kurańska, M.; Barczewski, M.; Uram, K.; Lewandowski, K.; Prociak, A.; Michałowski, S. Basalt waste management in the production of highly effective porous polyurethane composites for thermal insulating applications. Polym. Test. 2019, 76, 90–100. [Google Scholar] [CrossRef]

- Formela, K.; Hejna, A.; Zedler, Ł.; Przybysz, M.; Ryl, J.; Saeb, M.R.; Przybysz, Ł. Structural, thermal and physico-mechanical properties of polyurethane/brewers’ spent grain composite foams modified with ground tire rubber. Ind. Crop. Prod. 2017, 108, 844–852. [Google Scholar] [CrossRef]

- Yang, S.; Wang, J.; Huo, S.; Wang, M.; Wang, J.; Zhang, B. Synergistic flame-retardant effect of expandable graphite and phosphorus-containing compounds for epoxy resin: Strong bonding of different carbon residues. Polym. Degrad. Stab. 2016, 128, 89–98. [Google Scholar] [CrossRef]

- KAIRYTĖ, A.; Vaitkus, S.; Vėjelis, S. Titanate-Based Surface Modification of Paper Waste Particles and its Impact on Rigid Polyurethane Foam Properties. Key Eng. Mater. 2016, 721, 58–62. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Pospiech, P.; Strzelec, K. Effects of Chemically Treated Eucalyptus Fibers on Mechanical, Thermal and Insulating Properties of Polyurethane Composite Foams. Materials 2020, 13, 1781. [Google Scholar] [CrossRef] [Green Version]

- Członka, S.; Strąkowska, A.; KAIRYTĖ, A. Effect of walnut shells and silanized walnut shells on the mechanical and thermal properties of rigid polyurethane foams. Polym. Test. 2020, 87, 106534. [Google Scholar] [CrossRef]

- Ciobanu, C.; Ungureanu, M.; Ignat, L.; Popa, V.; Ungureanu, D. Properties of lignin–polyurethane films prepared by casting method. Ind. Crop. Prod. 2004, 20, 231–241. [Google Scholar] [CrossRef]

- Ciecierska, E.; Jurczyk-Kowalska, M.; Bazarnik, P.; Gloc, M.; Kulesza, M.; Kowalski, M.; Krauze, S.; Lewandowska, M. Flammability, mechanical properties and structure of rigid polyurethane foams with different types of carbon reinforcing materials. Compos. Struct. 2016, 140, 67–76. [Google Scholar] [CrossRef]

- Gu, R.; Konar, S.; Sain, M. Preparation and Characterization of Sustainable Polyurethane Foams from Soybean Oils. J. Am. Oil Chem. Soc. 2012, 89, 2103–2111. [Google Scholar] [CrossRef]

- Xue, B.; Wen, J.-L.; Sun, S.-L. Producing Lignin-Based Polyols through Microwave-Assisted Liquefaction for Rigid Polyurethane Foam Production. Materials 2015, 8, 586–599. [Google Scholar] [CrossRef] [Green Version]

- Gómez-Fernández, S.; Ugarte, L.; Calvo-Correas, T.; Peña-Rodríguez, C.; Corcuera, M.A.; Eceiza, A. Properties of flexible polyurethane foams containing isocyanate functionalized kraft lignin. Ind. Crop. Prod. 2017, 100, 51–64. [Google Scholar] [CrossRef]

- Hu, S.; Li, Y. Two-step sequential liquefaction of lignocellulosic biomass by crude glycerol for the production of polyols and polyurethane foams. Bioresour. Technol. 2014, 161, 410–415. [Google Scholar] [CrossRef]

- Luo, X.; Xiao, Y.; Wu, Q.; Zeng, J. Development of high-performance biodegradable rigid polyurethane foams using all bioresource-based polyols: Lignin and soy oil-derived polyols. Int. J. Boil. Macromol. 2018, 115, 786–791. [Google Scholar] [CrossRef]

- Mahmood, N.; Yuan, Z.; Schmidt, J.; Xu, C. (Charles) Preparation of bio-based rigid polyurethane foam using hydrolytically depolymerized Kraft lignin via direct replacement or oxypropylation. Eur. Polym. J. 2015, 68, 1–9. [Google Scholar] [CrossRef]

| Component | PUR_0 | PUR_WS_NT | PUR_WS_A | PUR_WS_S |

|---|---|---|---|---|

| Amount, parts by STEPANPOL PS-2352 weight [pbw] | ||||

| STEPANPOL PS-2352 | 80 | 80 | 80 | 80 |

| WS-based polyol | 20 | 20 | 20 | 20 |

| PUROCYN B | 160 | 160 | 160 | 160 |

| Kosmos 75 | 6 | 6 | 6 | 6 |

| Kosmos 33 | 0.8 | 0.8 | 0.8 | 0.8 |

| Tegostab B8513 | 2.5 | 2.5 | 2.5 | 2.5 |

| Water | 0.5 | 0.5 | 0.5 | 0.5 |

| Pentane/cyclopentane | 11 | 11 | 11 | 11 |

| Non-treated WS | 0 | 2 | 0 | 0 |

| Acetylated WS | 0 | 0 | 2 | 0 |

| Silanized WS | 0 | 0 | 0 | 2 |

| Component | Viscosity [mPa s] | Molecular Weight (Mw) [Da] | Hydroxyl Number [mg KOH/g] |

|---|---|---|---|

| WS-based polyol | 2550 | 420 | 340 |

| STEPANPOL PS-2352 | 2000-4500 | 468 | 230–250 |

| Sample | Dynamic Viscosity η [mPa·s] | |||

|---|---|---|---|---|

| 0.5 rpm | 5 rpm | 10 rpm | 100 rpm | |

| PUR_0 | 840 ± 10 | 520 ± 8 | 470 ± 9 | 230 ± 7 |

| PUR_WS_NT | 1700 ± 12 | 1200 ± 10 | 750 ± 9 | 450 ± 8 |

| PUR_WS_A | 1900 ± 11 | 1300 ± 10 | 1050 ± 10 | 580 ± 8 |

| PUR_WS_S | 2050 ± 10 | 1450 ± 12 | 1200 ± 11 | 650 ± 7 |

| Sample | Cream Time [s] | Expansion Time [s] | Tack-Free Time [s] |

|---|---|---|---|

| PUR_0 | 56 ± 3 | 419 ± 8 | 340 ± 7 |

| PUR_WS_NT | 60 ± 1 | 495 ± 9 | 375 ± 8 |

| PUR_WS_A | 59 ± 2 | 510 ± 6 | 365 ± 9 |

| PUR_WS_S | 59 ± 3 | 515 ± 8 | 370 ± 8 |

| Sample | Cell Size [µm] | Apparent Density [kg m−3] | Closed-Cell Content [%] | Thermal Conductivity [W m−1 K−1] |

|---|---|---|---|---|

| PUR_0 | 410 ± 9 | 38 ± 1 | 86.4 ± 0.6 | 0.0251 ± 0.0008 |

| PUR_WS_NT | 380 ± 9 | 42 ± 2 | 83.1 ± 1.1 | 0.0302 ± 0.0007 |

| PUR_WS_A | 360 ± 8 | 40 ± 3 | 85.9 ± 1.1 | 0.0293 ± 0.0009 |

| PUR_WS_S | 355 ± 8 | 39 ± 2 | 86.0 ± 0.8 | 0.0284 ± 0.0009 |

| Sample | Tmax [°C] | Residue at 450 °C | Residue at 600 °C | DTG [%/min] | ||

|---|---|---|---|---|---|---|

| 1st Stage | 2nd Stage | 3rd Stage | ||||

| PUR_0 | 218 | 315 | 581 | 48.1 | 21.9 | 0.0057 |

| PUR_WS_NT | 219 | 317 | 587 | 49.8 | 23.1 | 0.0055 |

| PUR_WS_A | 224 | 323 | 585 | 50.2 | 25.5 | 0.0056 |

| PUR_WS_S | 225 | 325 | 591 | 51.5 | 24.7 | 0.0056 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Członka, S.; Strąkowska, A. Rigid Polyurethane Foams Based on Bio-Polyol and Additionally Reinforced with Silanized and Acetylated Walnut Shells for the Synthesis of Environmentally Friendly Insulating Materials. Materials 2020, 13, 3245. https://doi.org/10.3390/ma13153245

Członka S, Strąkowska A. Rigid Polyurethane Foams Based on Bio-Polyol and Additionally Reinforced with Silanized and Acetylated Walnut Shells for the Synthesis of Environmentally Friendly Insulating Materials. Materials. 2020; 13(15):3245. https://doi.org/10.3390/ma13153245

Chicago/Turabian StyleCzłonka, Sylwia, and Anna Strąkowska. 2020. "Rigid Polyurethane Foams Based on Bio-Polyol and Additionally Reinforced with Silanized and Acetylated Walnut Shells for the Synthesis of Environmentally Friendly Insulating Materials" Materials 13, no. 15: 3245. https://doi.org/10.3390/ma13153245

APA StyleCzłonka, S., & Strąkowska, A. (2020). Rigid Polyurethane Foams Based on Bio-Polyol and Additionally Reinforced with Silanized and Acetylated Walnut Shells for the Synthesis of Environmentally Friendly Insulating Materials. Materials, 13(15), 3245. https://doi.org/10.3390/ma13153245