A Preliminary Characterisation of Innovative Semi-Flexible Composite Pavement Comprising Geopolymer Grout and Reclaimed Asphalt Planings

Abstract

1. Introduction

2. SFC Pavement Materials

2.1. Open-Graded Aggregate Skeleton

2.2. Geopolymer Grouts

3. Experimental Programme

3.1. Geopolymer Grout Mix Design

3.2. Geopolymer Grout Characterisation

3.3. SFC Characterisation

4. Results and Discussions

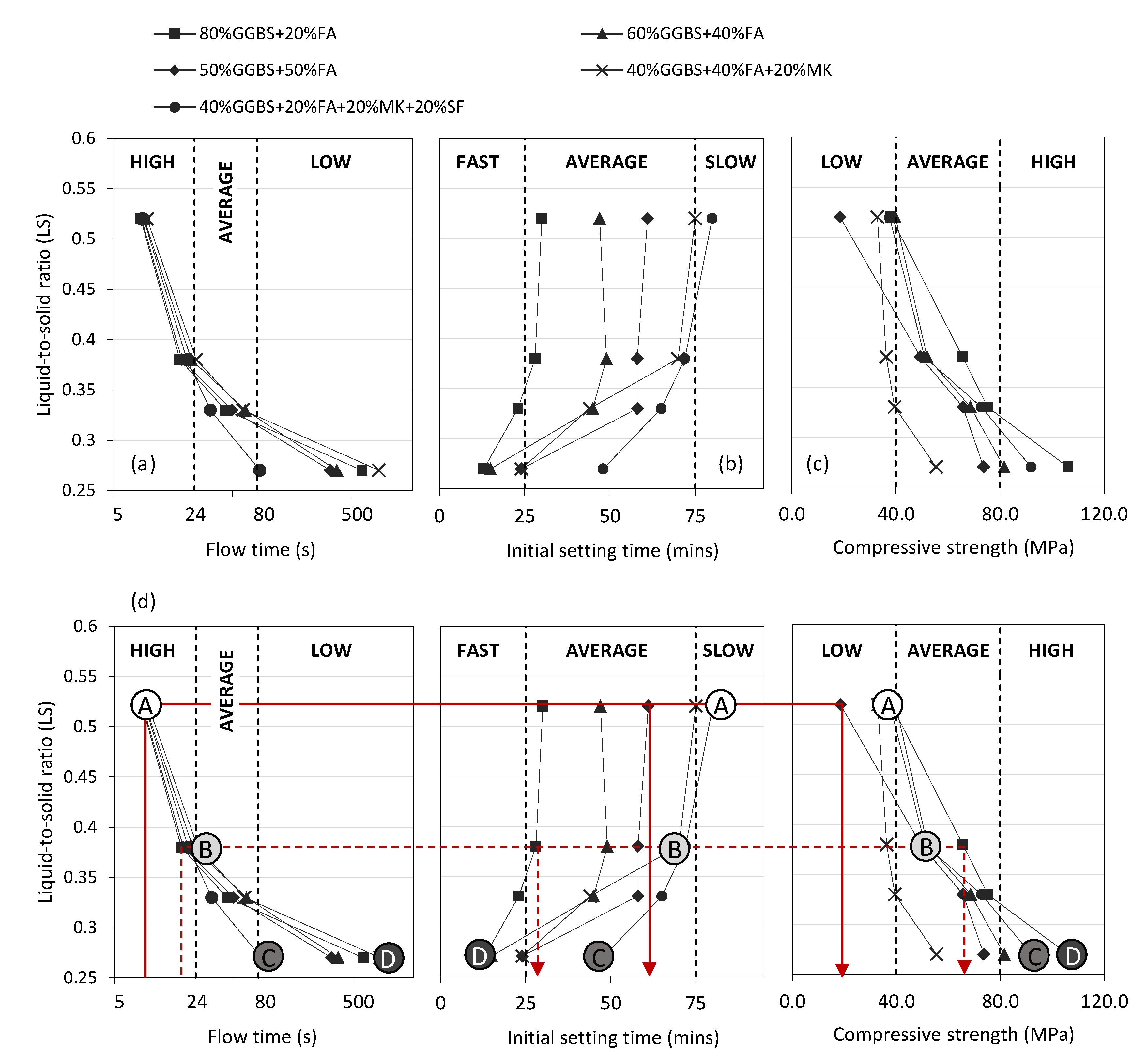

4.1. Geopolymer Grout Characterisation

- Flow time (s): High (<24); Average (24–80); Low (>80);

- Setting time (mins): Fast (<25); Average (25–75); Slow (>75);

- 28-day strength (MPa): Low (<40); Average (40–80); High (>80).

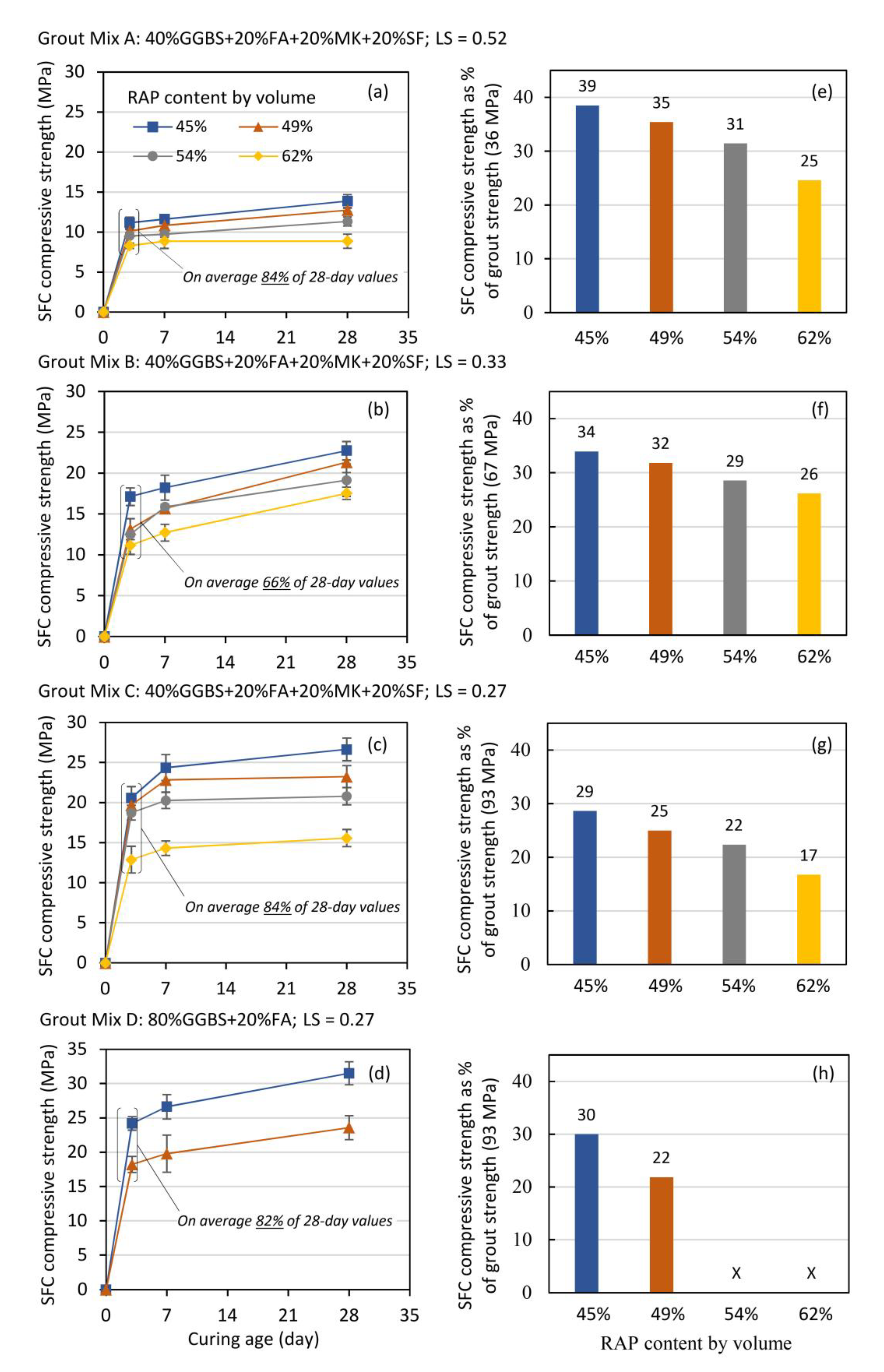

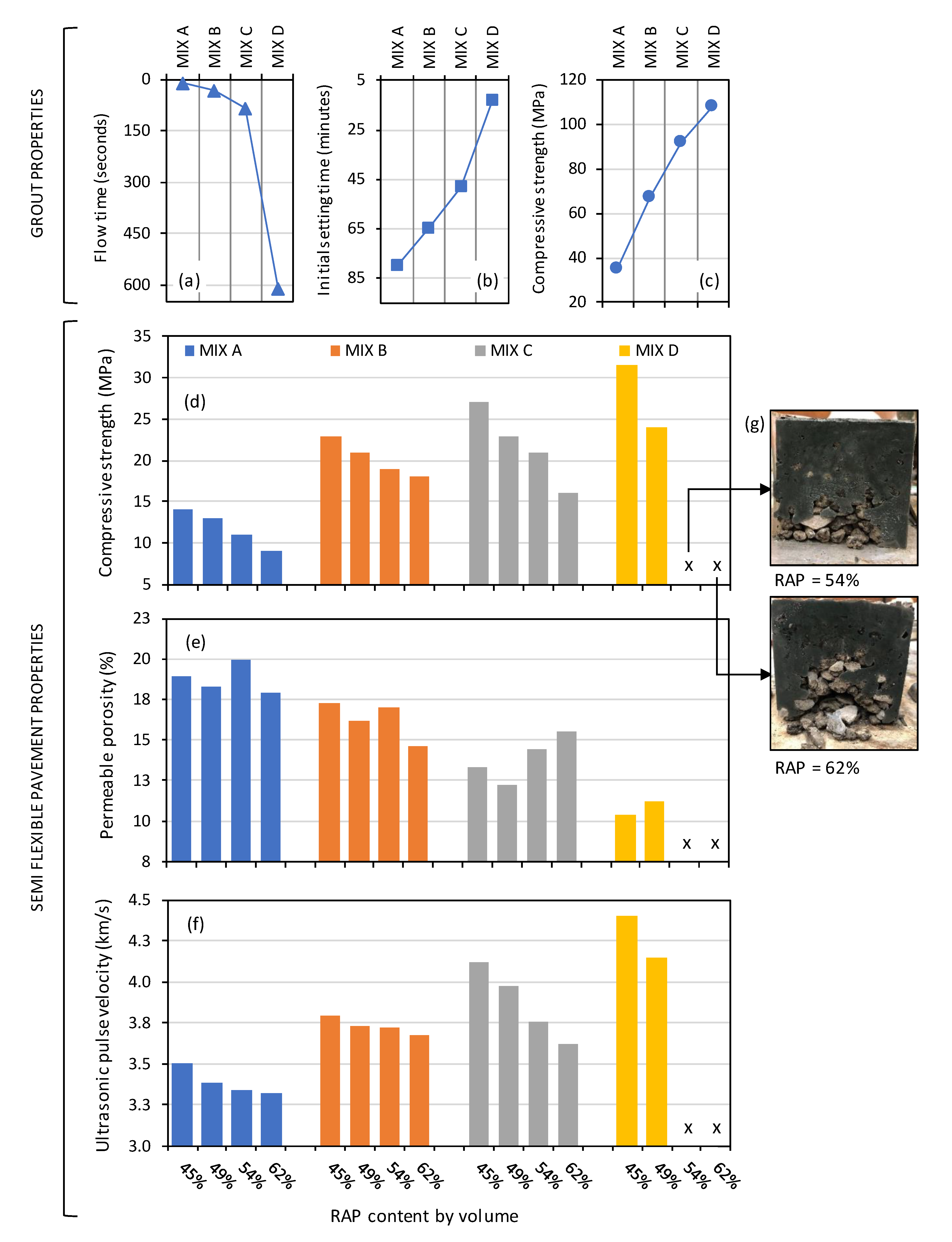

4.2. SFC Characterisation

- Mix A (‘High’|‘Slow’|‘Low’)

- Mix B (‘Average’|‘Average’|‘Average’)

- Mix C (‘Low’|‘Average’|‘High’)

- Mix D (‘Low’|‘Fast’|‘High’)

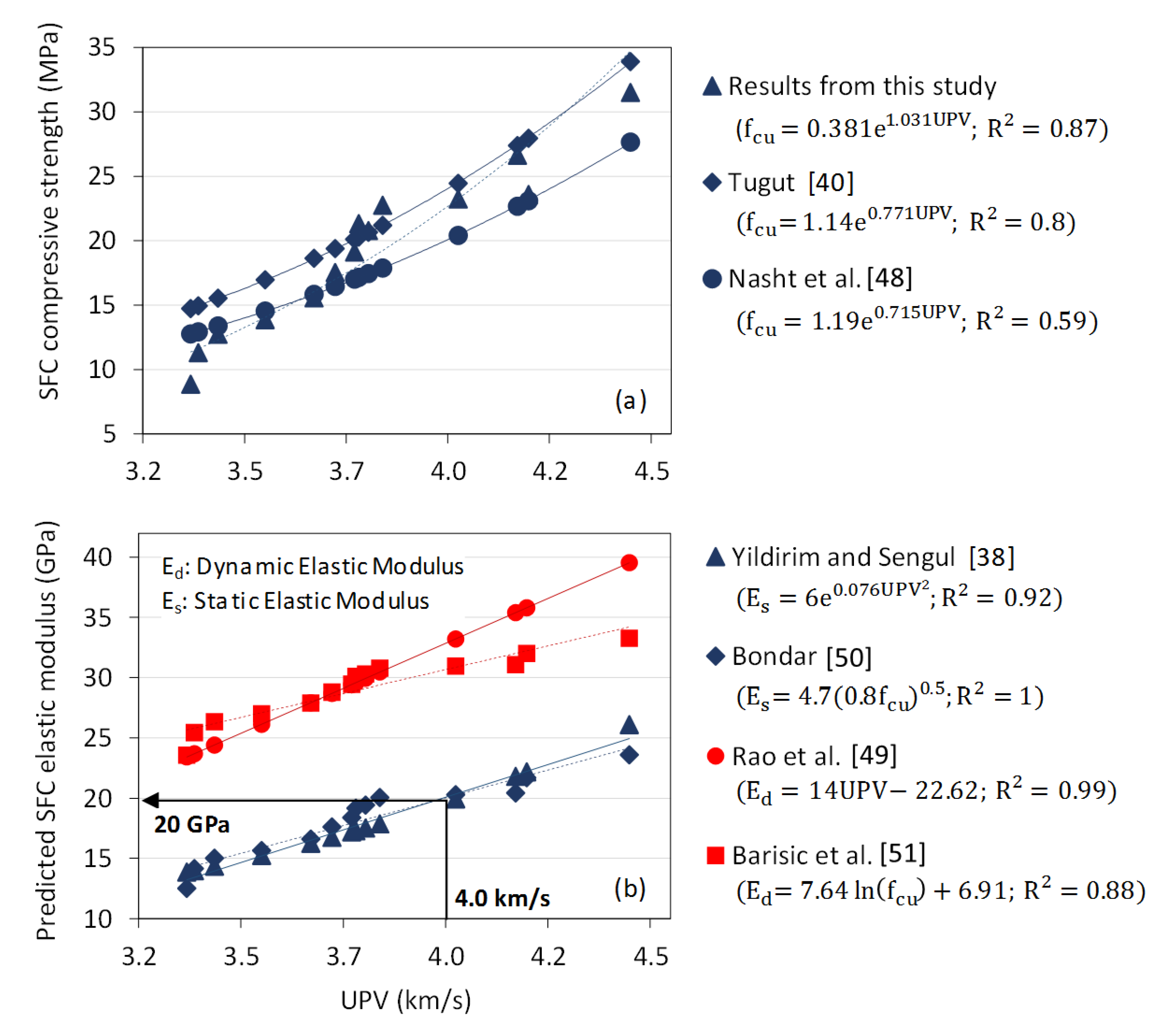

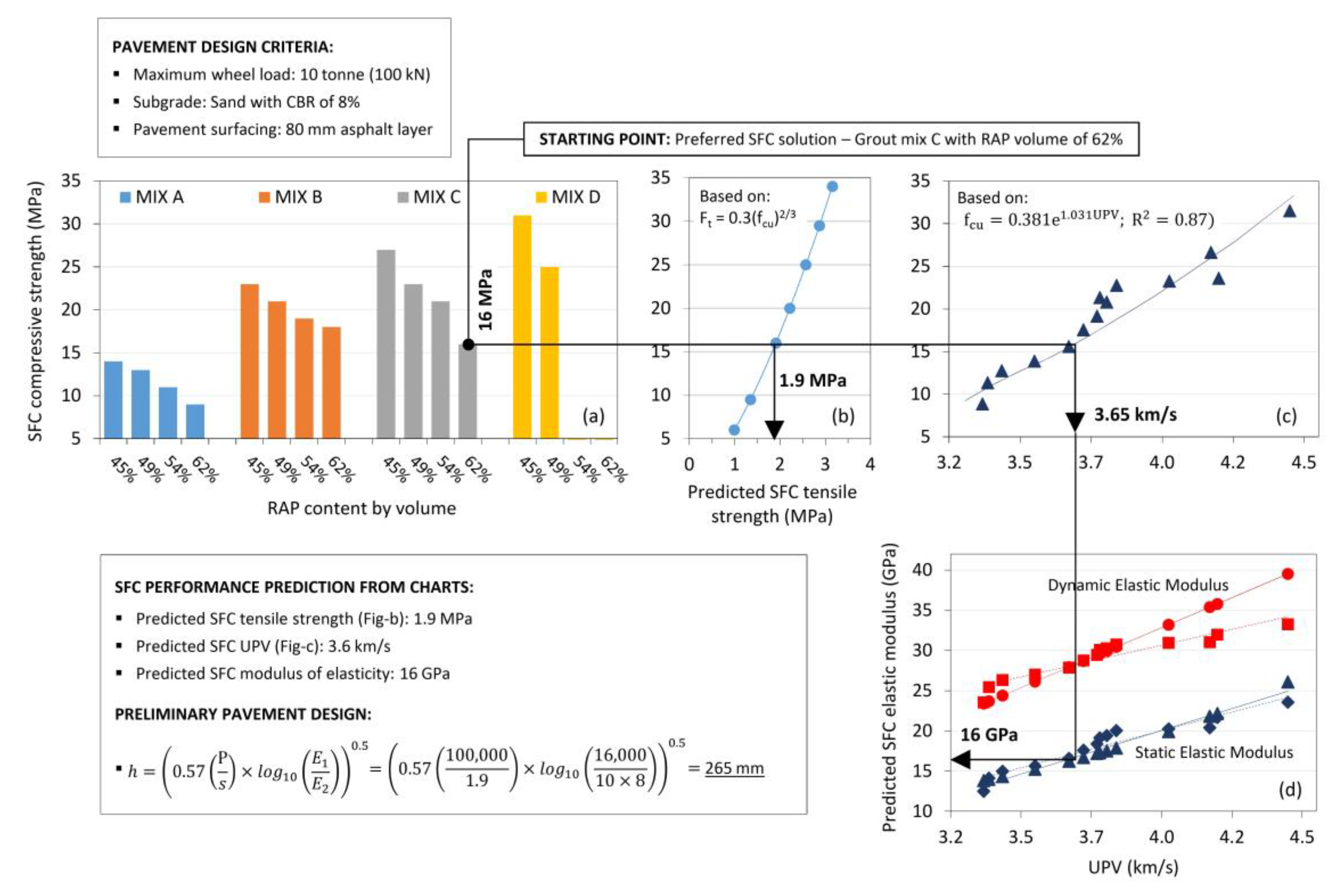

4.3. SFC Performance Predictions

4.4. Preliminary Design for Industrial Hardstanding Application

5. Conclusions

- To facilitate the manufacture of SFC suitable for a broad range of practical applications, a diverse suite of 20 geopolymer grouts was initially produced using binder combinations GGBS + FA, GGBS + FA + MK, and GGBS + FA + MK + SF with liquid-to-solid (LS) ratios ranging from 0.27–0.52. The grouts had a wide range of performance in terms of flow (9–609 s), initial setting time (13–80 min), and compressive strength (19–108 MPa).

- A suite of 16 SFC mixtures was assessed based on four grout mixes chosen based on contrasting performance classifications. Each grout type was used to impregnate RAP skeletons with solids contents ranging from 45–62% by volume, resulting in corresponding wide ranges of SFC performance in terms of compressive strength (9–32 MPa), permeable porosity (10–20%), and ultrasonic pulse velocity (3.32–4.40 km/s). SFC performance was influenced by both grout properties and RAP content, with increasing performance values generally associated with decreasing RAP contents combined with highly flowable, high strength grout. All but two of the SFC mixtures considered, yielded viable pavement material solutions. Despite having the highest compressive strength (108 MPa), use of grout mix D was not practically possible with solid RAP contents of 54 and 62% by volume, owing to its relatively ‘slow’ flowability (609 s) and ‘fast’ setting time (13 min) resulting in incomplete RAP penetration.

- A strong correlation between ultrasonic pulse velocity and compressive strength was found for the range of SFCs considered (R2 = 0.87). Given the similarity between this relationship and those established for conventional Portland cement-based materials, published relationships relating UPV and elastic modulus for the latter were adopted to enable preliminary pavement designs incorporating SFC layers. An example for SFC use as an industrial hardstanding sub-base layer was presented. For a maximum wheel load of 10 tonnes, subgrade CBR of 8% and 80 mm-thick asphalt surfacing, the resultant SFC thickness requirement is 265 mm. For a hardstanding area of 100 m2, this equates to the consumption of approximately 35 tonnes of RAP and 15 tonnes of geopolymer-based product; thereby presenting a potentially economic and environmentally responsible pavement solution.

- The behaviour of SFC conformed with the mechanical performance levels required by the Design Manual for Roads and Bridges (DMRB): Volume 7–Section 2 [45] for base layer made of hydraulically bound material (HBM) in accordance with BS 9227:2019 [46]. As such, this initial investigation has successfully proven the potential suitability of this material.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- European Environment Agency. Environmental Pressures from European Consumption and Production—A Study in Integrated Environmental and Economic Analysis; European Environment Agency: Brussel, Belgium, 2013. [Google Scholar]

- Karim, M.R.; Zain, M.F.M.; Jamil, M.; Lai, F.C.; Islam, M.N. Use of wastes in construction industries as an energy saving approach. Energy Procedia 2011, 12, 915–919. [Google Scholar] [CrossRef]

- Mahamadu, A.M.; Baffour Awuah, K.; Booth, C.A. Sustainability of Construction Materials; Woodhead Publishing: Cambridge, UK, 2016; pp. 13–31. [Google Scholar] [CrossRef]

- Mallick, R.B.; Bergendahl, J. A laboratory study on CO2 emission from asphalt binder and its reduction with the use of warm mix asphalt. Int. J. Sustain. Eng. 2009, 2, 275–283. [Google Scholar] [CrossRef]

- Pimraksa, K.; Chindaprasirt, P.; Sanjayan, J.; Ling, T.C. Alternative cementitious materials and their composites. Adv. Mater. Sci. Eng. 2018, 20148, 5074636. [Google Scholar] [CrossRef]

- Copeland, A. Reclaimed Asphalt Pavement in Asphalt Mixtures: State of the Practice; Federal Highway Administration: McLean, VA, USA, 2011; Publication No. FHWA-HRT-11-021. [Google Scholar]

- Lo Presti, D.; Khan, R.; Abdul Hassan, N.; Airey, G.; Collop, A. Laboratory mix design of asphalt mixture containing reclaimed material. Adv. Mater. Sci. Eng. 2014, 2014, 507082. [Google Scholar] [CrossRef]

- Hettiarachchi, C.; Hou, X.; Wang, J.; Xiao, F. A comprehensive review on the utilization of reclaimed asphalt material with warm mix asphalt technology. Constr. Build. Mater. 2019, 227, 117096. [Google Scholar] [CrossRef]

- Afonso, M.L.; Dinis-Almeida, M.; Pereira-De-Oliveira, L.A.; Castro-Gomes, J.; Zoorob, S.E. Development of a semi-flexible heavy duty pavement surfacing incorporating recycled and waste aggregates—Preliminary study. Constr. Build. Mater. 2016, 102, 155–161. [Google Scholar] [CrossRef]

- Hoyos, L.R.; Puppala, A.J.; Ordonez, C.A. Characterization of cement-fiber-treated reclaimed asphalt pavement aggregates: Preliminary investigation. J. Mater. Civ. Eng. 2011, 23, 977–989. [Google Scholar] [CrossRef]

- Arulrajah, A.; Piratheepan, J.; Disfani, M.M. Reclaimed asphalt pavement and recycled concrete aggregate blends in pavement subbases: Laboratory and field evaluation. J. Mater. Civ. Eng. 2014, 26, 349–357. [Google Scholar] [CrossRef]

- Huang, B.; Kingery, W.; Zhang, Z.; Zuo, G. Laboratory study of fatigue characteristics of HMA surface mixtures containing RAP. In Proceedings of the 83rd Annual Meeting of the Transportation Research Board, Washington, DC, USA, 11–15 January 2014. [Google Scholar]

- Xiao, F.; Amirkhanian, S.N.; Wu, B. Fatigue and stiffness evaluations of reclaimed asphalt pavement in hot mix asphalt mixtures. J. Test. Eval. 2011, 39, 102699. [Google Scholar]

- Hossiney, N.; Wang, G.; Tia, M.; Bergin, M. Evaluation of concrete containing reclaimed asphalt pavements for use in concrete pavement. In Proceedings of the TRB 87th Annual Meeting, Washington, DC, USA, 13–17 January 2008; pp. 1–13. [Google Scholar]

- Ricci, R. Laboratory Study of Grouted Macadams Impregnated with Mine Waste Geopolymeric Binder. Ph.D. Thesis, Universita di Bologna, Bologna, Italy, 2012. [Google Scholar]

- Huang, B.; Shu, X.; Burdette, E.G. Mechanical properties of concrete containing recycled asphalt pavements. Mag. Concr. Res. 2006, 58, 313–320. [Google Scholar] [CrossRef]

- Kowalski, K.J.; Król, J.; Radziszewski, P.; Casado, R.; Blanco, V.; Pérez, D. Eco-friendly materials for a new concept of asphalt pavement. Transp. Res. Procedia 2016, 14, 3582–3591. [Google Scholar] [CrossRef]

- Qingjun, D.; Mingyu, Z.; Fan, S.; Xiaoqiang, Z. Mechanical behavior and failure mechanism of recycled semi-flexible pavement material. J. Wuhan Univ. Technol. 2015, 30, 981–988. [Google Scholar]

- Luo, S.; Yang, X.; Zhong, K.; Yin, J. Open-graded asphalt concrete grouted by latex modified cement mortar. Road Mater. Pavement Des. 2018, 10, 61–77. [Google Scholar] [CrossRef]

- Anderton, G.L. Engineering Properties of Resin Modified Pavement (RMP) for Mechanistic Design. US Army Corps of Engineers, Engineer Research and Development Center. Ph.D. Thesis, The University of Texas, Austin, TX, USA, 2000. [Google Scholar]

- Hossiney, N.; Tia, M.; Bergin, M.J. Concrete containing RAP for use in concrete pavement. Int. J. Pavement Res. Technol. 2010, 3, 251–258. [Google Scholar]

- Li, G.; Zhao, Y.; Pang, S.; Huang, W. Experimental study of cement-asphalt emulsion composite. Cem. Concr. Res. 1998, 28, 635–641. [Google Scholar] [CrossRef]

- Densit. Technical Data Sheet: Densiphalt-Semi Flexible and Joint Free Topping Where Durability and Wear Resistance Are High Priorities, ITW Performance Polymers; Densit: Aalborg, Denmark, 2018. [Google Scholar]

- Trimurtiningrum, R.; Ekaputri, J.J. Geopolymer grout material. Mater. Sci. Forum 2016, 841, 40–47. [Google Scholar] [CrossRef]

- Huseien, G.F.; Mirza, J.; Ismail, M.; Ghoshal, S.K.; Ariffin, M.A.M. Effect of metakaolin replaced granulated blast furnace slag on fresh and early strength properties of geopolymer mortar. Ain. Shams. Eng. J. 2016, 9, 1557–1566. [Google Scholar] [CrossRef]

- Hadi, M.N.S.; Farhan, N.A.; Sheikh, M.N. Design of geopolymer concrete with GGBFS at ambient curing condition using Taguchi method. Constr. Build. Mater. 2017, 140, 424–431. [Google Scholar] [CrossRef]

- Bosque, I.F.; Zhu, W.; Howind, T.; Matías, A.; Sánchez de Rojas, M.I.; Medina, C. Properties of interfacial transition zones (ITZs) in concrete containing recycled mixed aggregate. Cem. Concr. Compos. 2017, 81, 25–34. [Google Scholar] [CrossRef]

- Hu, J.; Stroeven, P. Properties of the interfacial transition zone in model concrete. Interface. Sci. 2004, 12, 389–397. [Google Scholar] [CrossRef]

- Wilkinson, A. The Use of Geopolymer Cement for Road Surface Applications. Ph.D. Thesis, Ulster University, Ulster, UK, 2017. [Google Scholar]

- Sinsiri, T.; Chindaprasirt, P.; Jaturapitakkul, C. Influence of fly ash fineness and shape on the porosity and permeability of blended cement pastes. Int. J. Miner. Metall. Mater. 2010, 17, 683–690. [Google Scholar] [CrossRef]

- Oakes, L.; Wilkinson, A.; Magee, B. Preliminary mix design procedure for alkali activated cement mortars based on metakaolin and industrial waste products activated with potasium silicate. In Proceedings of the 42nd International Conference on Advanced Ceramics and Composites: Ceramic Engineering and Science Proceedings; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2019; Volume 39, pp. 209–223. [Google Scholar]

- American Society for Testing and Materials. ASTM C939-02. Standard Test Method for Flow of Grout for Preplaced-Aggregate Concrete (Flow Cone Method); American Society for Testing and Materials: West Conshohocken, PA, USA, 2010. [Google Scholar]

- British Standards. BS EN 480-22006. Admixtures for Concrete, Mortar and Grout. Test Methods. Part 2: Determination of Setting Time; Comite Europeen de Normalisation: Brussels, Belgium, 2006.

- British Standards. BS EN 1015-11. Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. Part 11 Determ Flexural Compressive Strength Hardened Mortar; Comite Europeen de Normalisation: Brussels, Belgium, 1999.

- American Society for Testing and Materials. ASTM C1202-12. Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration; American Society for Testing and Materials: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Safiuddin, M.; Hearn, N. Comparison of ASTM saturation techniques for measuring the permeable porosity of concrete. Cem. Concr. Res. 2005, 35, 1008–1013. [Google Scholar] [CrossRef]

- Panzera, T.H.; Christoforo, A.L.; Ribeiro Borges, P.H.; Bowen, C.R. Advances in Composite Materials-Analysis of Natural and Man-Made Materials; BoD–Books on Demand: Norderstedt, Germany, 2011. [Google Scholar] [CrossRef]

- Yildirim, H.; Sengul, O. Modulus of elasticity of substandard and normal concretes. Constr. Build Mater. 2011, 25, 1645–1652. [Google Scholar] [CrossRef]

- Trtnik, G.; Turk, G.; Kavčič, F.; Bosiljkov, V.B. Possibilities of using the ultrasonic wave transmission method to estimate initial setting time of cement paste. Cem. Concr. Res. 2008, 38, 1336–1342. [Google Scholar] [CrossRef]

- Turgut, P. Evaluation of the ultrasonic pulse velocity data coming on field. In Proceedings of the 4th International Conference on NDE in Relation to Structural Integrity for Nuclear and Pressurised Components, London, UK, 6–8 December 2004. [Google Scholar]

- Bureau of Indian Standards. Indian Standard: Part 1; IS 13311. Non-Destructive Testing of Concrete—Part 1: Ultrasonic Pulse Velocity; Bureau of Indian Standards: New Delhi, India, 1996. [Google Scholar]

- British Standards. BS EN 12504-4. Testing Concrete. Determination of Ultrasonic Pulse Velocity; Comite Europeen de Normalisation: Brussels, Belgium, 2004.

- An, J.; Nam, B.; Youn, H. Investigation on the Effect of Recycled Asphalt Shingle (RAS) in Portland Cement Mortar. Sustainability 2016, 8, 384. [Google Scholar] [CrossRef]

- Topçu, I.B.; Uygunoglu, T. Sustainability of Using Waste Rubber in Concrete, 2nd ed.; Woodhead Publishing Series in Civil and Structural Engineering: Cambridge, UK, 2016; pp. 597–623. [Google Scholar] [CrossRef]

- Design Manual for Roads and Bridges; HD 26/06. Pavement Design and Maintenance—Pavement Design and Construction—Part 3: Pavement Design; The Stationery Office Ltd.: London, UK, 2006.

- British Standards. BS 9227:2019. Hydraulically Bound Materials for Civil Engineering Purposes—Specification for Production and Installation in Pavements; Comite Europeen de Normalisation: Brussels, Belgium, 2019.

- Samantasinghar, S.; Singh, S.P. Fresh and Hardened Properties of Fly Ash– Slag Blended Geopolymer Paste and Mortar. Int. J. Concr. Struct. Mater. 2019, 13, 47. [Google Scholar] [CrossRef]

- Nash’t, I.H.; Saeed, H.A.; Sadoon, A.A. Finding an Unified Relationship between Crushing Strength of Concrete and Non-destructive Tests. In Proceedings of the 3rd MENDT, Manama, Bahrain, 27–30 November 2005; Volume 7, pp. 27–30. [Google Scholar]

- Rao, S.K.; Sravana, P.; Rao, T.C. Experimental studies in Ultrasonic Pulse Velocity of roller compacted concrete pavement containing fly ash and M-sand. Int. J. Pavement Res. Technol. 2016, 9, 289–301. [Google Scholar] [CrossRef]

- Bondar, D. Alkali Activation of Iranian Natural Pozzolans for Producing Geopolymer Cement and Concrete. Ph.D. Thesis, University of Sheffield, Sheffield, UK, 2009. [Google Scholar]

- Barišić, I.; Dimter, S.; Rukavina, T. Elastic properties of cement-stabilised mixes with steel slag. Int. J. Pavement Eng. 2015, 17, 753–762. [Google Scholar] [CrossRef]

- British Standards. BS EN 14227-1:2013. Hydraulically Bound Mixtures—Specifications. Part 1: Cement Bound Granular Mixtures; Comite Europeen de Normalisation: Brussels, Belgium, 2013.

- British Standards. BS EN 14227-2:2013. Hydraulically Bound Mixtures—Specifications. Part 2: Slag Bound Granular Mixtures; Comite Europeen de Normalisation: Brussels, Belgium, 2013.

- British Standards. BS EN 14227-3:2013. Hydraulically bound mixtures—Specifications. Part 3: Fly Ash Bound Granular Mixtures; Comite Europeen de Normalisation: Brussels, Belgium, 2013.

- Williams, R.T. Cement-Treated Pavements: Materials, Design, and Construction; Elsevier Pub. Co.: New York, NY, USA, 1986; pp. 684–717. [Google Scholar]

- British Standards. BS EN 1992-1-1:2004. Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings; Comite Europeen de Normalisation: Brussels, Belgium, 2014.

| Properties | RAP |

|---|---|

| Compacted bulk density (g/cm3) | 1.39 |

| Loose bulk density (g/cm3) | 1.25 |

| Specific density (g/cm3) | 2.53 |

| Water absorption (%) | 1.03 |

| Moisture content (%) | 0.31 |

| Aggregate impact value (%) | 5.10 |

| Material | Chemical Composition (% by Mass) | Particle Size 1 (μm) | Specific Gravity (g/cm3) | |||||

|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | CaO | Fe2O3 | D(10) | D(50) | D(90) | ||

| FA | 57 | 24 | 3.9 | 6 | 2.9 | 18.8 | 124.6 | 2.7 |

| GGBS | 36.5 | 10.4 | 42.4 | 0 | 1.1 | 5.3 | 22.5 | 2.85 |

| MK | 55 | 40 | 0.3 | 1.4 | 0.9 | 2.7 | 8.2 | 2.6 |

| SF | 96 | 0.8 | 0.5 | 0.8 | 0.1 | 0.15 | 0.4 | 2.2 |

| Binder Combinations | Geopolymer Powder Contents (% by Mass of Total Binder) | Liquid-to-Solid Ratios (LS) | |||

|---|---|---|---|---|---|

| GGBS | FA | MK | SF | ||

| GGBS + FA | 80 | 20 | 0 | 0 | 0.27, 0.33, 0.38, 0.52 |

| 60 | 40 | 0 | 0 | ||

| 50 | 50 | 0 | 0 | ||

| GGBS + FA + MK | 40 | 40 | 20 | 0 | |

| GGBS + FA + MK + SF | 40 | 20 | 20 | 20 | |

| MIX | GGBS/FA/MK/SF Binder Composition (%) | LS | Grout Properties | Grout Performance Summary: Flowability|Setting Time|Strength 1 | ||

|---|---|---|---|---|---|---|

| Flow (s) | Setting Time (mins) | Strength (MPa) | ||||

| A | 40/20/20/20 | 0.52 | 9.0 | 80 | 36.0 | ‘High’|‘Slow’|‘Low’ |

| B | 40/20/20/20 | 0.33 | 32.6 | 65 | 67.0 | ‘Average’|‘Average’|‘Average’ |

| C | 40/20/20/20 | 0.27 | 84.8 | 48 | 93.0 | ‘Low’|‘Average’|‘High’ |

| D | 80/20/0/0 | 0.27 | 608.6 | 13 | 108.0 | ‘Low’|‘Fast’|‘High’ |

| Flow Time (s): | >80 | 24–80 | <24 |

| Flowability: | ‘Low’ | ‘Average’ | ‘High’ |

| Initial setting time (mins): | >75 | 25–75 | <25 |

| Setting time: | ‘Slow’ | ‘Average’ | ‘Fast’ |

| 28-day compressive strength (MPa): | <40 | 40–80 | >80 |

| Strength: | ‘Low’ | ‘Average’ | ‘High’ |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huynh, A.T.; Magee, B.; Woodward, D. A Preliminary Characterisation of Innovative Semi-Flexible Composite Pavement Comprising Geopolymer Grout and Reclaimed Asphalt Planings. Materials 2020, 13, 3644. https://doi.org/10.3390/ma13163644

Huynh AT, Magee B, Woodward D. A Preliminary Characterisation of Innovative Semi-Flexible Composite Pavement Comprising Geopolymer Grout and Reclaimed Asphalt Planings. Materials. 2020; 13(16):3644. https://doi.org/10.3390/ma13163644

Chicago/Turabian StyleHuynh, An Thao, Bryan Magee, and David Woodward. 2020. "A Preliminary Characterisation of Innovative Semi-Flexible Composite Pavement Comprising Geopolymer Grout and Reclaimed Asphalt Planings" Materials 13, no. 16: 3644. https://doi.org/10.3390/ma13163644

APA StyleHuynh, A. T., Magee, B., & Woodward, D. (2020). A Preliminary Characterisation of Innovative Semi-Flexible Composite Pavement Comprising Geopolymer Grout and Reclaimed Asphalt Planings. Materials, 13(16), 3644. https://doi.org/10.3390/ma13163644