Flexural Properties of Renewable Coir Fiber Reinforced Magnesium Phosphate Cement, Considering Fiber Length

Abstract

:1. Introduction

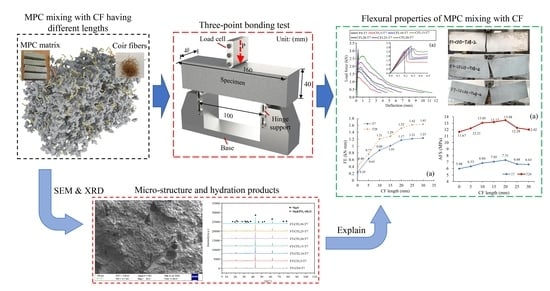

2. Experimental Program

2.1. Raw Material and Mix Design

2.2. Test Specimens

2.3. Test Method

3. Results and Discussions

3.1. Failure Process and Modes

3.2. L-D Curves

3.3. Flexural Strength

3.4. Flexural Toughness

3.5. Microstructure Analysis

4. Conclusions

- (1)

- CF length presents similar effects on the flexural performances of MPC at different curing ages. However, specimens at the curing age of 28 days exhibit higher flexural strength, stiffness, and flexural toughness than specimens at the curing age of 7 days.

- (2)

- The flexural strength of MPC can be improved by increasing the CF length within a certain length range, but begins to decrease when CF is longer than 20 mm (in this study). However, further tests are needed to capture a more precise threshold of CF length.

- (3)

- Longer CF is more beneficial to the improvement of MPC ductility, but reduces MPC stiffness continuously. In addition, MPC performance displays a secondary rise after its softening first as CF length increases.

- (4)

- CF contributes to improving MPC toughness. However, this improvement slows down after CF is longer than a threshold. In this study, the threshold is 20 mm for T7 and 25 mm for T28. Moreover, overlong CF has slight extra help in strengthening MPC’s crack-resistance in its elastic stage than CF with the threshold length.

- (5)

- Longer CF reduces the amount of MKP and degrades the compactness of MPC matrix.

- (6)

- The threshold of CF length suggested in this study may change with the scaling of specimens, which will be investigated in further tests.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Haque, M.A.; Chen, B. Research progresses on magnesium phosphate cement: A review. Constr. Build. Mater. 2019, 211, 885–898. [Google Scholar] [CrossRef]

- Yang, N.; Shi, C.; Yang, J.; Chang, Y. Research Progresses in Magnesium Phosphate Cement–Based Materials. J. Mater. Civ. Eng. 2014, 26, 04014071. [Google Scholar] [CrossRef]

- Li, Y.; Li, Y.; Shi, T.; Li, J. Experimental study on mechanical properties and fracture toughness of magnesium phosphate cement. Constr. Build. Mater. 2015, 96, 346–352. [Google Scholar] [CrossRef]

- Fang, Y.; Chen, B.; Oderji, S.Y. Experimental research on magnesium phosphate cement mortar reinforced by glass fiber. Constr. Build. Mater. 2018, 188, 729–736. [Google Scholar] [CrossRef]

- Fang, Y.; Cui, P.; Ding, Z.; Zhu, J.-X. Properties of a magnesium phosphate cement-based fire-retardant coating containing glass fiber or glass fiber powder. Constr. Build. Mater. 2018, 162, 553–560. [Google Scholar] [CrossRef]

- Ahmad, M.R.; Chen, B. Effect of silica fume and basalt fiber on the mechanical properties and microstructure of magnesium phosphate cement (MPC) mortar. Constr. Build. Mater. 2018, 190, 466–478. [Google Scholar] [CrossRef]

- Haque, M.A.; Chen, B.; Ahmad, M.R.; Shah, S.F.A. Evaluating the physical and strength properties of fibre reinforced magnesium phosphate cement mortar considering mass loss. Constr. Build. Mater. 2019, 217, 427–440. [Google Scholar] [CrossRef]

- Feng, H.; Chen, G.; Gao, D.; Zhao, K.; Zhang, C. Mechanical Properties of Steel Fiber-Reinforced Magnesium Phosphate Cement Mortar. Adv. Civ. Eng. 2018, 2018, 1–11. [Google Scholar] [CrossRef]

- Reis, J. Fracture and flexural characterization of natural fiber-reinforced polymer concrete. Constr. Build. Mater. 2006, 20, 673–678. [Google Scholar] [CrossRef]

- Sekar, A.; Kandasamy, G. Optimization of Coconut Fiber in Coconut Shell Concrete and Its Mechanical and Bond Properties. Materials 2018, 11, 1726. [Google Scholar] [CrossRef] [Green Version]

- Thanushan, K.; Yogananth, Y.; Sangeeth, P.; Coonghe, J.G.; Sathiparan, N. Strength and Durability Characteristics of Coconut Fibre Reinforced Earth Cement Blocks. J. Nat. Fibers 2019, 1–16. [Google Scholar] [CrossRef]

- Li, Z.; Wang, L.; Wang, X. Flexural characteristics of coir fiber reinforced cementitious composites. Fibers Polym. 2006, 7, 286–294. [Google Scholar] [CrossRef] [Green Version]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Silva, G.G.; De Souza, D.A.; Machado, J.C.; Hourston, D.J. Mechanical and thermal characterization of native brazilian coir fiber. J. Appl. Polym. Sci. 2000, 76, 1197–1206. [Google Scholar] [CrossRef]

- Sagar, B.S.V.; Varun, C.S.; Divyaprabandha, K.; Raju, L.S.; Jyothi, Y. Fabrication and characterization of foam coir concrete. Int. Conf. Renew. Energy Res. Educ. 2018, 1992, 040010. [Google Scholar] [CrossRef]

- Abdullah, A.; Jamaludin, S.B.; Noor, M.M.; Hussin, K. Mechanical properties and fracture behaviour of coconut fibre-based green composites. Rom. J. Mater. 2011, 41, 262–268. [Google Scholar]

- Zhang, L.; Geng, T.; Liu, Z.; Zhang, W.; Shang, Q. Effect of silica fume and calcium carbonate whisker on interfacial behavior of near-surface-mounted FRP with magnesium phosphate cement. Arch. Civ. Mech. Eng. 2019, 20, 2. [Google Scholar] [CrossRef]

- Zhang, L.W.; Liu, Z.Q.; Geng, T.; Zhang, W.H.; Shang, Q.H.; Deng, Y.G. Study on performances on green and ecological concrete of near surface mounted (nsm) with mpc adhesive based on ecological theory. Feb Fresenius Environ. Bull. 2020, 29, 3840–3852. [Google Scholar]

- Geng, T.; Jiang, Z.; Li, J.; Zhang, L. Effect of fiber type on mechanical properties of magnesium phosphate cements. In Sustainable Buildings and Structures: Building a Sustainable Tomorrow. In Proceedings of the 2nd International Conference in Sutainable Buildings and Structures (ICSBS 2019), Suzhou, China, 25–27 October 2019; CRC Press: Boca Raton, FL, USA, 2019; p. 221. [Google Scholar]

- CNIS. GB/T 17671-Method of Testing Cements-Determination of Strength; China National Standards: Beijing, China, 1999. [Google Scholar]

- ASTM C1609-10. Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete; American Society for Testing and Materials, ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- ASTMC293-10. Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Center-Point Loading); American Society for Testing and Materials, ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- Chen, G.; Yang, H.; Lin, C.; Chen, J.; He, Y.; Zhang, H. Fracture behaviour of steel fibre reinforced recycled aggregate concrete after exposure to elevated temperatures. Constr. Build. Mater. 2016, 128, 272–286. [Google Scholar] [CrossRef]

- Ding, Z.; Dong, B.; Xing, F.; Han, N.; Li, Z. Cementing mechanism of potassium phosphate based magnesium phosphate cement. Ceram. Int. 2012, 38, 6281–6288. [Google Scholar] [CrossRef]

- Xu, B.; Lothenbach, B.; Leemann, A.; Winnefeld, F. Reaction mechanism of magnesium potassium phosphate cement with high magnesium-to-phosphate ratio. Cem. Concr. Res. 2018, 108, 140–151. [Google Scholar] [CrossRef]

| MgO | KH2PO4 | Borax | FA | Water |

|---|---|---|---|---|

| 1171.87 | 797.26 | 117.18 | 295.31 | 328.3 |

| Compositions | MgO | Al2O3 | Fe2O3 | CaO | SiO2 | LOI |

| Weight Percent (%) | 96.25 | 0.29 | 1.09 | 1.18 | 1.16 | 0.03 |

| Compositions | SiO2 | Al2O3 | Fe2O3 | CaO | TiO2 | MgO | SO3 | LOI |

| Weight Percent (%) | 56.74 | 24.58 | 6.55 | 4.87 | 1.86 | 3.3 | 0.8 | 1.3 |

| Diameter (µm) | Density (kg/m3) | Tensile Strength (MPa) | Elasticity Modulus (GPa) | Elongation (%) |

|---|---|---|---|---|

| 150–350 | 1200 | 112–146 | 2.3–3.4 | 14–28 |

| Group | Set | Specimen Number | Curing Age (Day) | CF | ||

|---|---|---|---|---|---|---|

| L1 (mm) | VC2 (%) | Mass (g) | ||||

| T7 | CF0-T7 | FT-CF0-T7-1 | 7 | 0 | 0 | 0 |

| FT-CF0-T7-2 | ||||||

| FT-CF0-T7-3 | ||||||

| CF5-T7 | FT-CFL5-T7-1 | 5 | 3 | 9 | ||

| FT-CFL5-T7-2 | ||||||

| FT-CFL5-T7-3 | ||||||

| CF10-T7 | FT-CFL10-T7-1 | 10 | ||||

| FT-CFL10-T7-2 | ||||||

| FT-CFL10-T7-3 | ||||||

| CF15-T7 | FT-CFL15-T7-1 | 15 | ||||

| FT-CFL15-T7-2 | ||||||

| FT-CFL15-T7-3 | ||||||

| CF20-T7 | FT-CFL20-T7-1 | 20 | ||||

| FT-CFL20-T7-2 | ||||||

| FT-CFL20-T7-3 | ||||||

| CF25-T7 | FT-CFL25-T7-1 | 25 | ||||

| FT-CFL25-T7-2 | ||||||

| FT-CFL25-T7-3 | ||||||

| CF30-T7 | FT-CFL30-T7-1 | 30 | ||||

| FT-CFL30-T7-2 | ||||||

| FT-CFL30-T7-3 | ||||||

| T28 | CF0-T28 | FT-CF0-T28-1 | 28 | 0 | 0 | 0 |

| FT-CF0-T28-2 | ||||||

| FT-CF0-T28-3 | ||||||

| CF5-T28 | FT-CFL5-T28-1 | 5 | 3 | 9 | ||

| FT-CFL5-T28-2 | ||||||

| FT-CFL5-T28-3 | ||||||

| CF10-T28 | FT-CFL10-T28-1 | 10 | ||||

| FT-CFL10-T28-2 | ||||||

| FT-CFL10-T28-3 | ||||||

| CF15-T28 | FT-CFL15-T28-1 | 15 | ||||

| FT-CFL15-T28-2 | ||||||

| FT-CFL15-T28-3 | ||||||

| CF20-T28 | FT-CFL20-T28-1 | 20 | ||||

| FT-CFL20-T28-2 | ||||||

| FT-CFL20-T28-3 | ||||||

| CF25-T28 | FT-CFL25-T28-1 | 25 | ||||

| FT-CFL25-T28-2 | ||||||

| FT-CFL25-T28-3 | ||||||

| CF30-T28 | FT-CFL30-T28-1 | 30 | ||||

| FT-CFL30-T28-2 | ||||||

| FT-CFL30-T28-3 | ||||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Jiang, Z.; Wu, H.; Zhang, W.; Lai, Y.; Zheng, W.; Li, J. Flexural Properties of Renewable Coir Fiber Reinforced Magnesium Phosphate Cement, Considering Fiber Length. Materials 2020, 13, 3692. https://doi.org/10.3390/ma13173692

Zhang L, Jiang Z, Wu H, Zhang W, Lai Y, Zheng W, Li J. Flexural Properties of Renewable Coir Fiber Reinforced Magnesium Phosphate Cement, Considering Fiber Length. Materials. 2020; 13(17):3692. https://doi.org/10.3390/ma13173692

Chicago/Turabian StyleZhang, Liwen, Zuqian Jiang, Hui Wu, Wenhua Zhang, Yushan Lai, Weile Zheng, and Jing Li. 2020. "Flexural Properties of Renewable Coir Fiber Reinforced Magnesium Phosphate Cement, Considering Fiber Length" Materials 13, no. 17: 3692. https://doi.org/10.3390/ma13173692

APA StyleZhang, L., Jiang, Z., Wu, H., Zhang, W., Lai, Y., Zheng, W., & Li, J. (2020). Flexural Properties of Renewable Coir Fiber Reinforced Magnesium Phosphate Cement, Considering Fiber Length. Materials, 13(17), 3692. https://doi.org/10.3390/ma13173692