Determination of Local Strain Distribution at the Level of the Constituents of Particle Reinforced Composite: An Experimental and Numerical Study

Abstract

1. Introduction

2. Materials and Methods

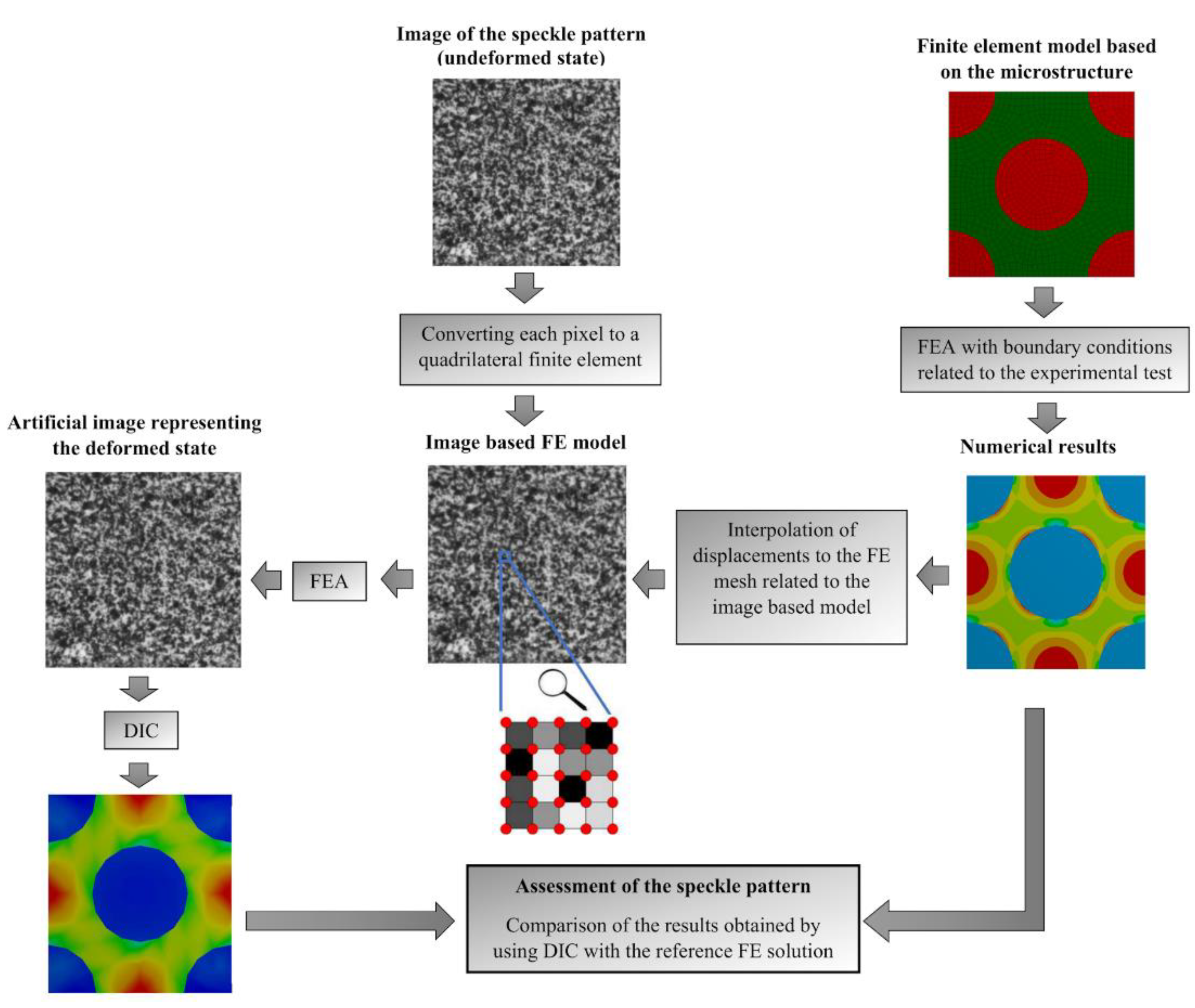

2.1. Method of Assessment of the Speckle Pattern

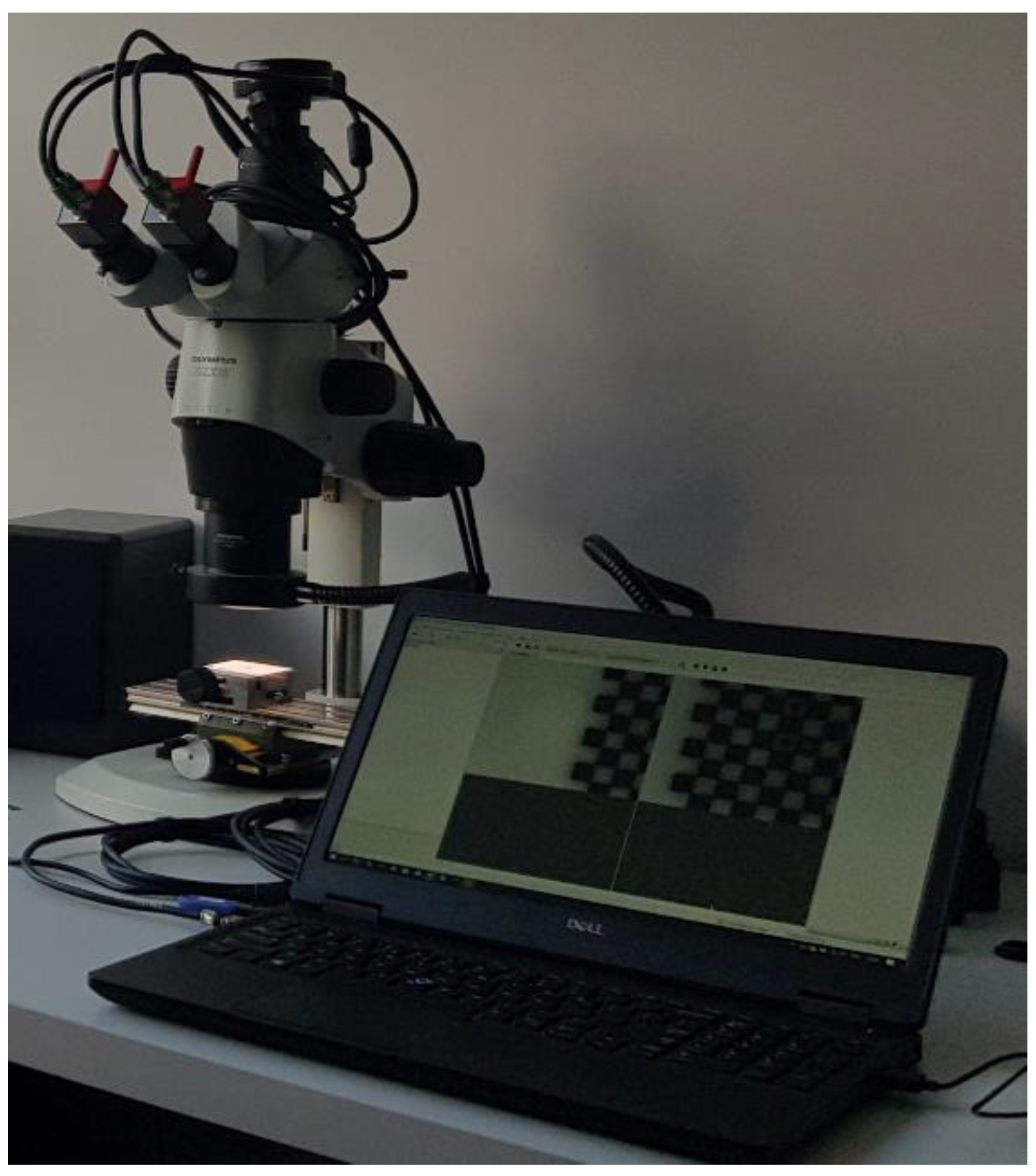

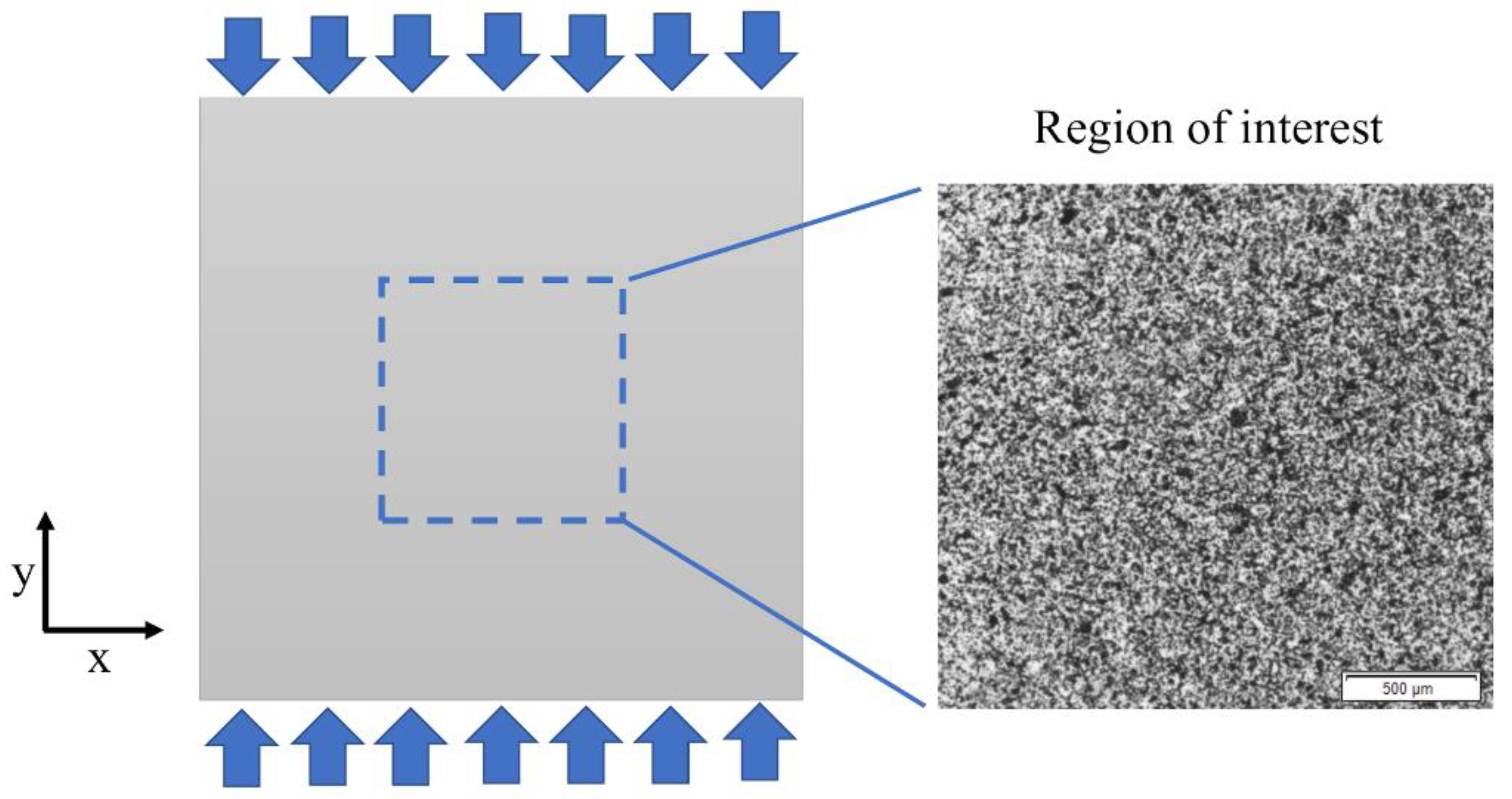

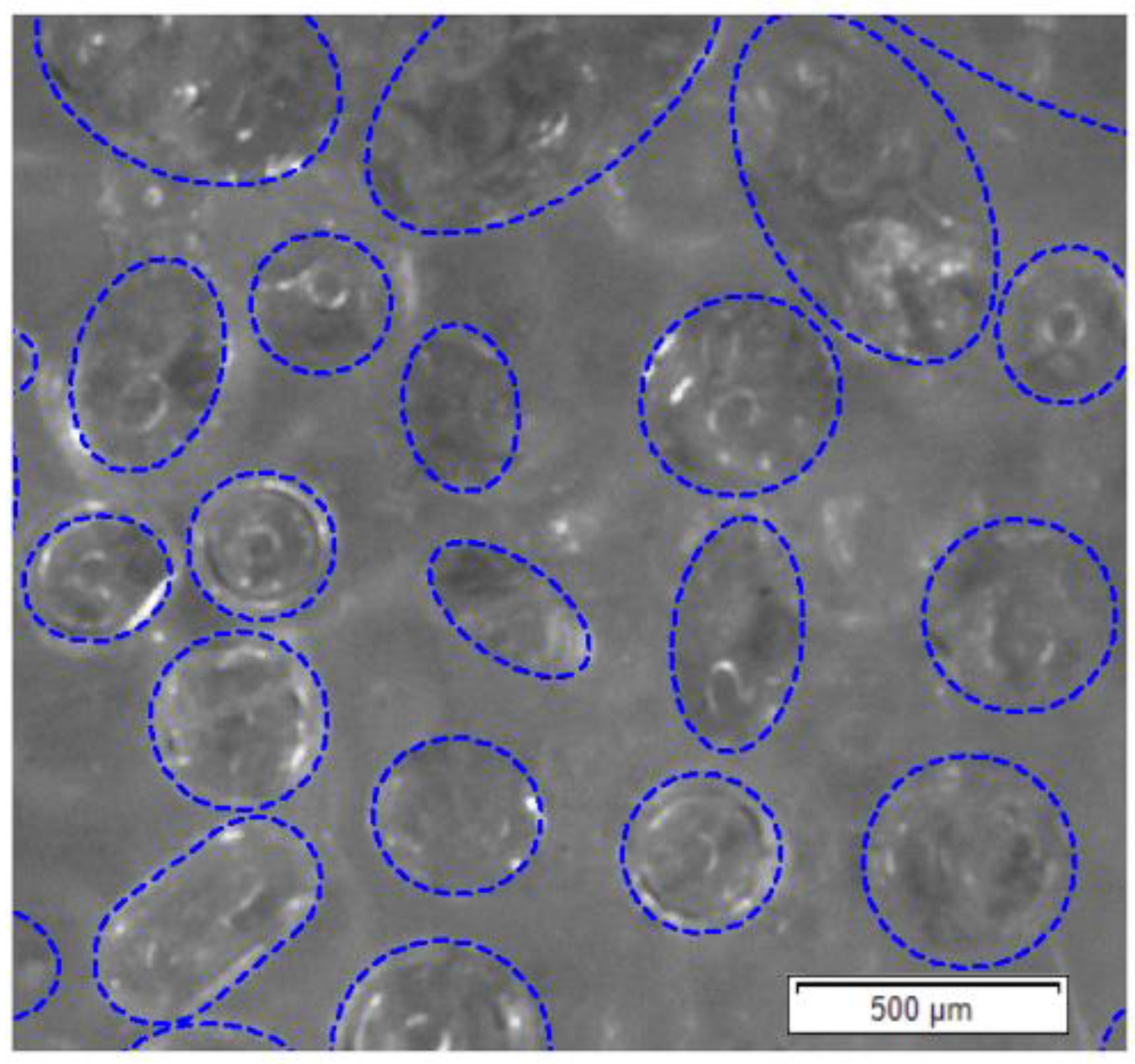

2.2. Experimental Test

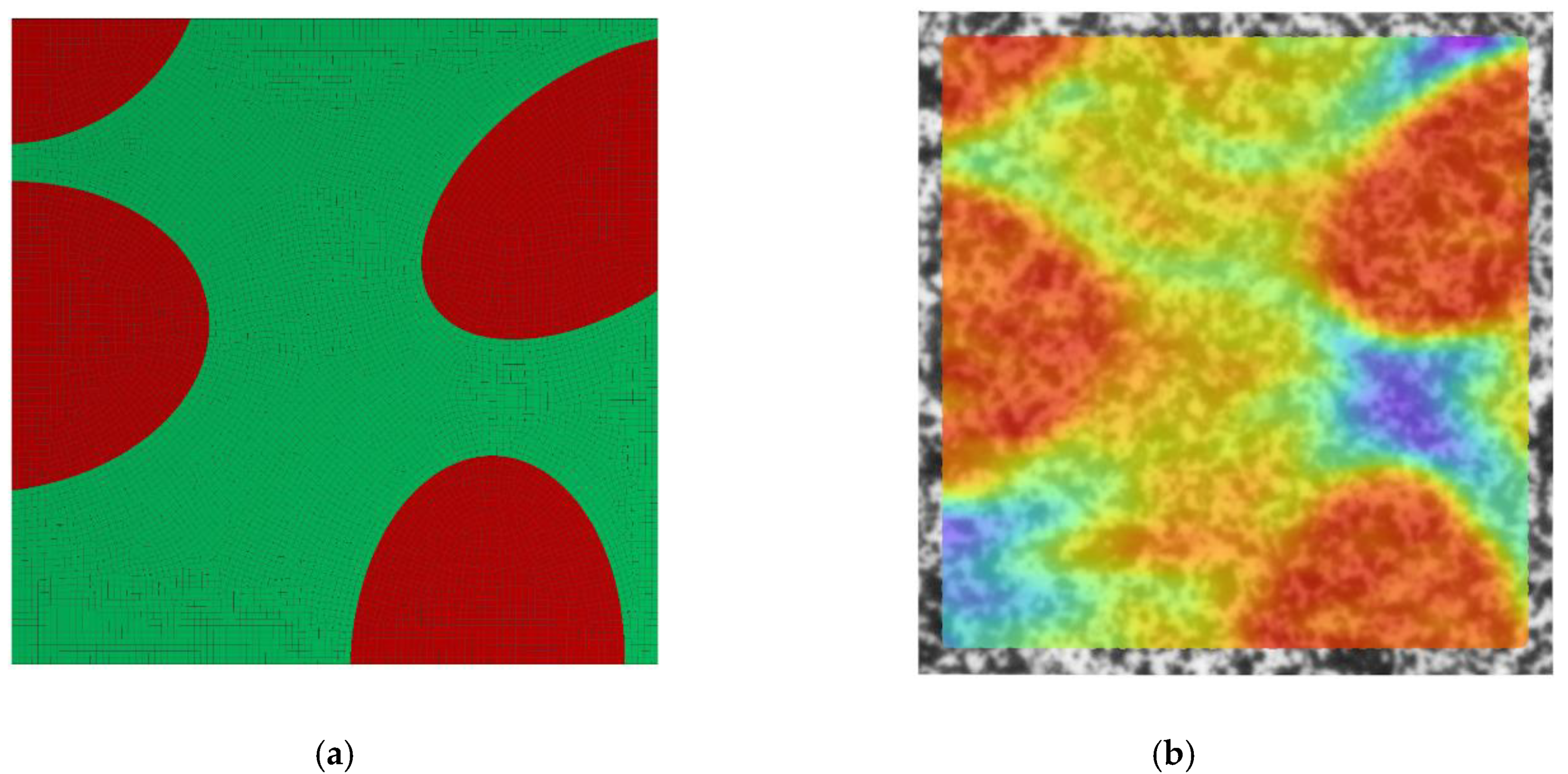

2.3. Numerical Modeling

3. Results and Discussion

3.1. Testing of the Speckle Pattern

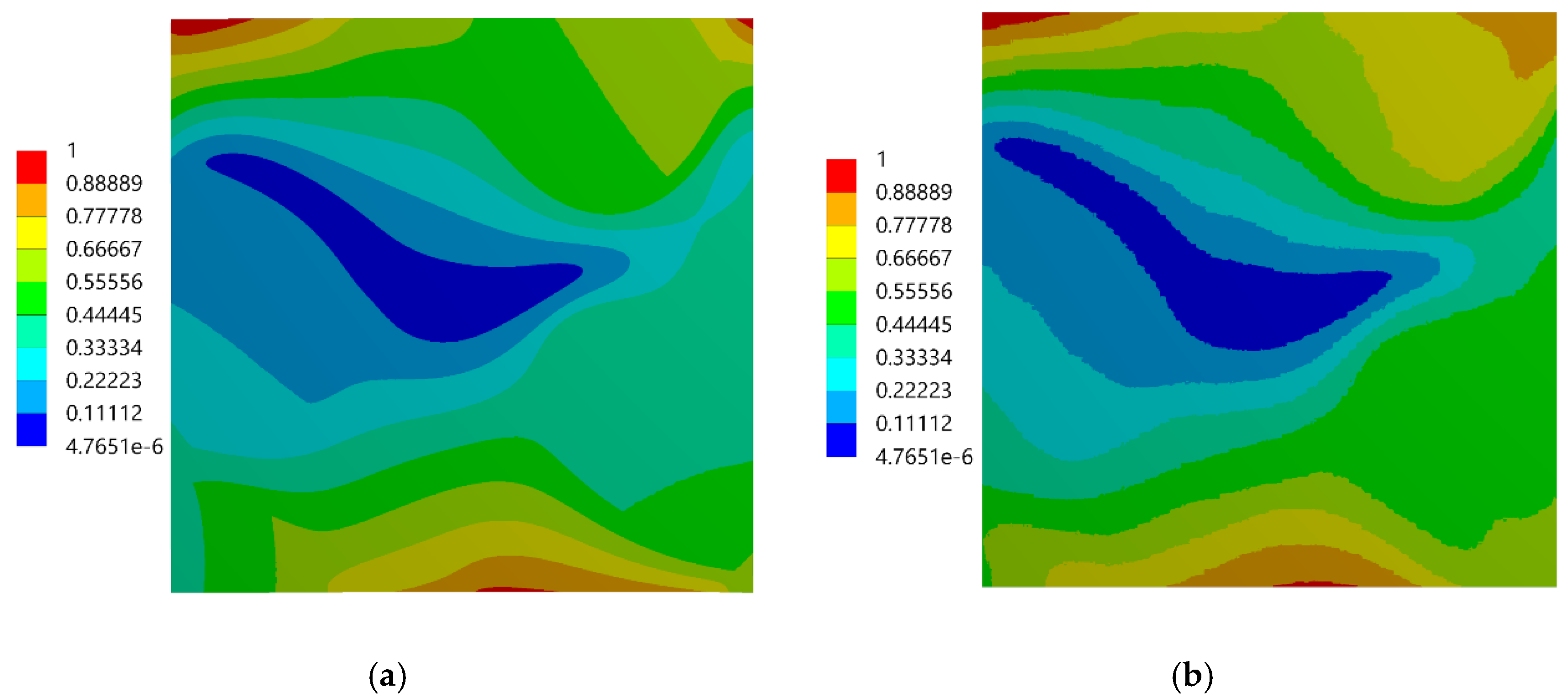

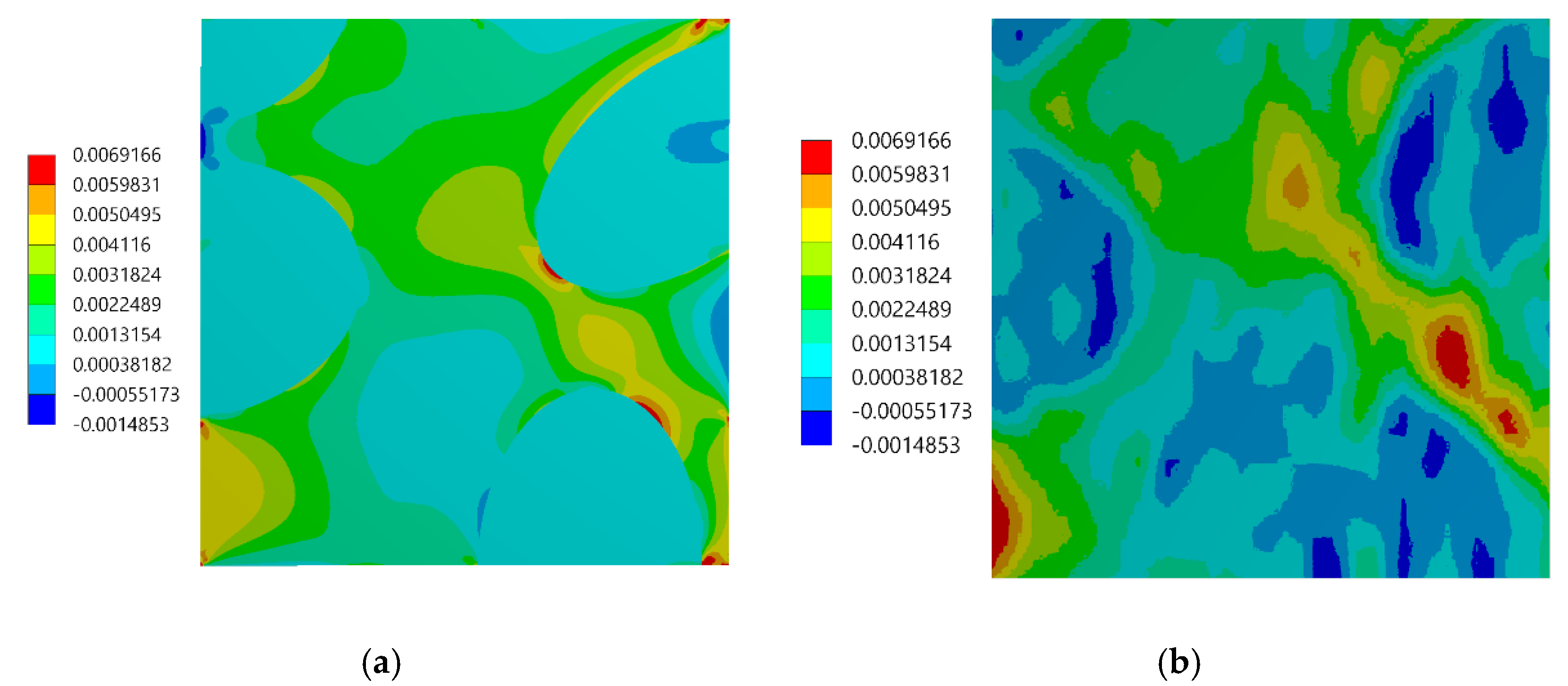

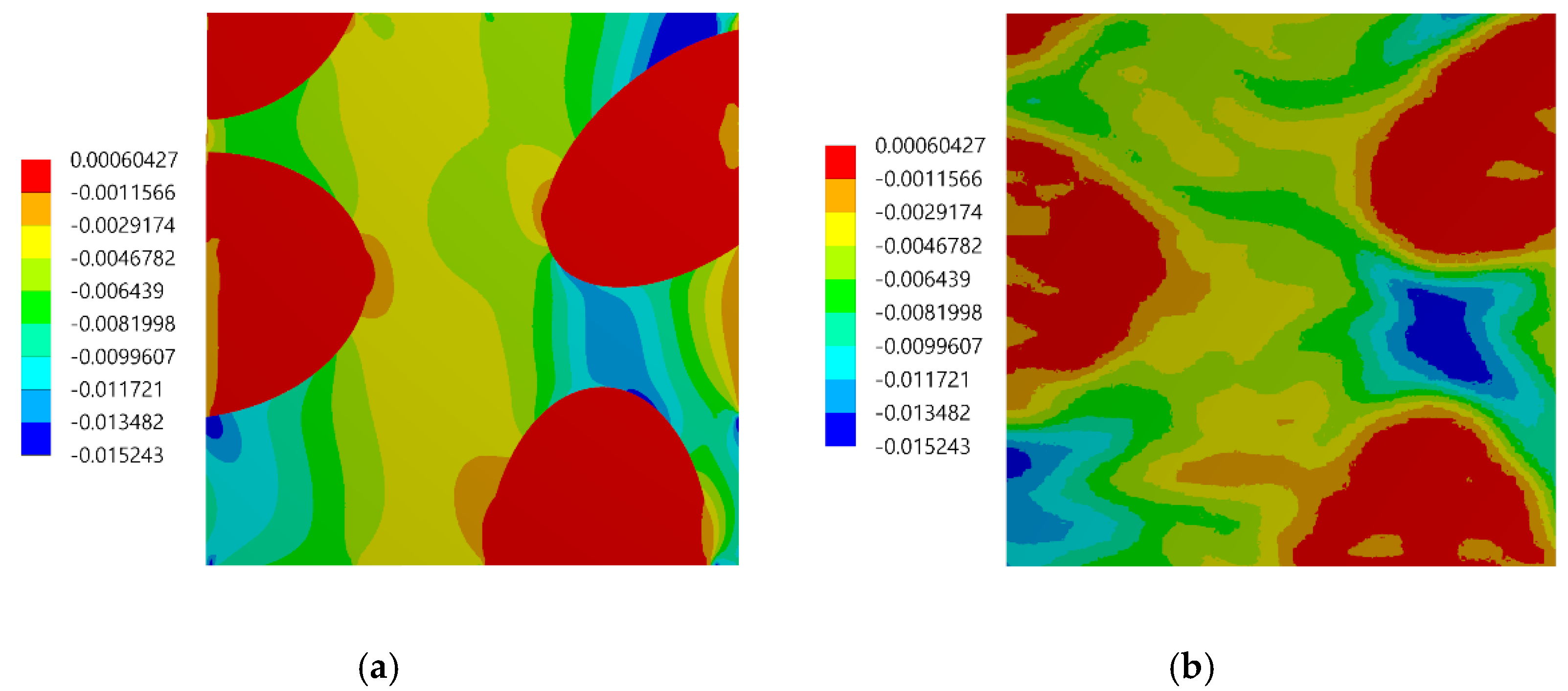

3.2. Experimental versus Numerical Results

4. Conclusions

- The proposed method for the assessment of the speckle pattern made it possible to verify that the speckle pattern prepared on the surface of the specimen was applicable for measuring a local strain at the level of constituents of composite by using the DIC method. Moreover, it made it possible to predict how much the strain distributions obtained by the DIC were smoothed out by performing a comparison with the “accurate” reference solution.

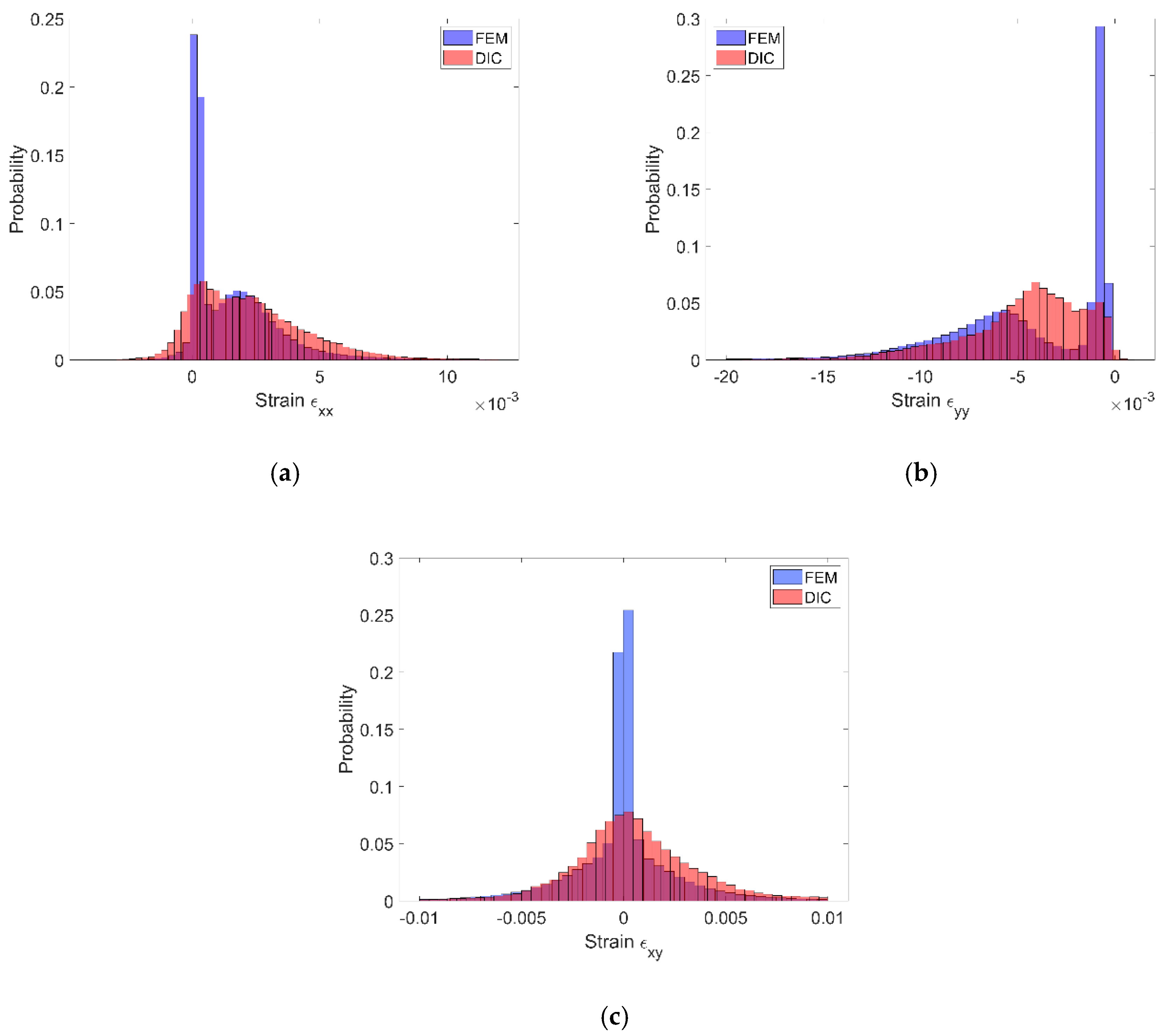

- Good agreement between the local strain distributions determined experimentally by using the DIC and numerically by using FEA based on the RVE model has been noticed. The agreement between the results was good, despite the simplifications related to the geometrical model of the microstructure (RVE).

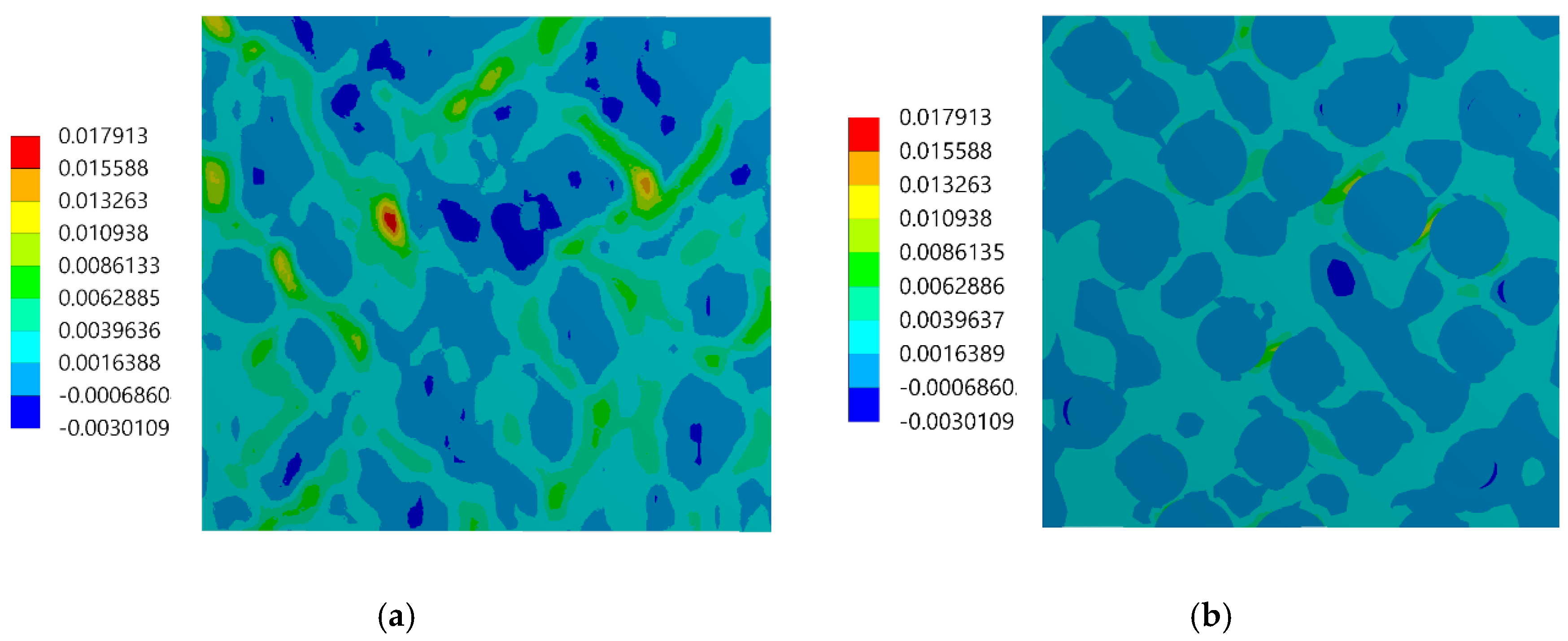

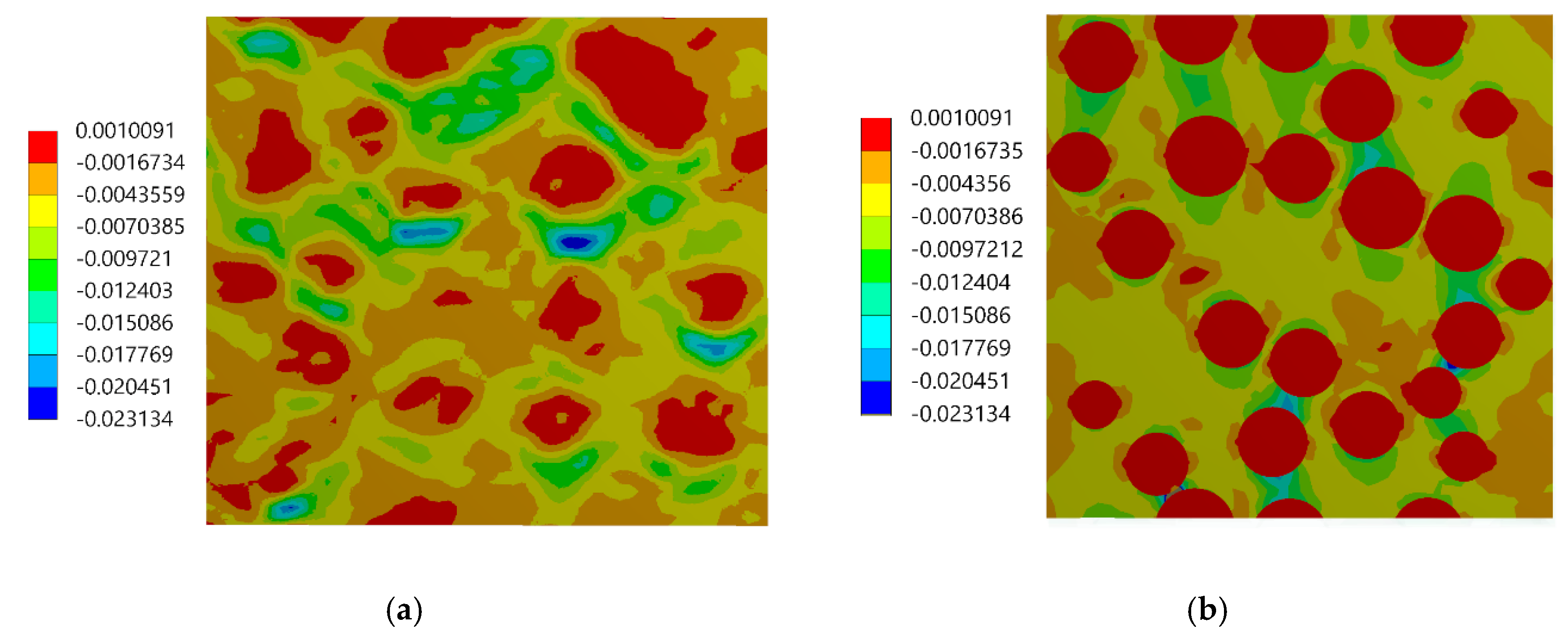

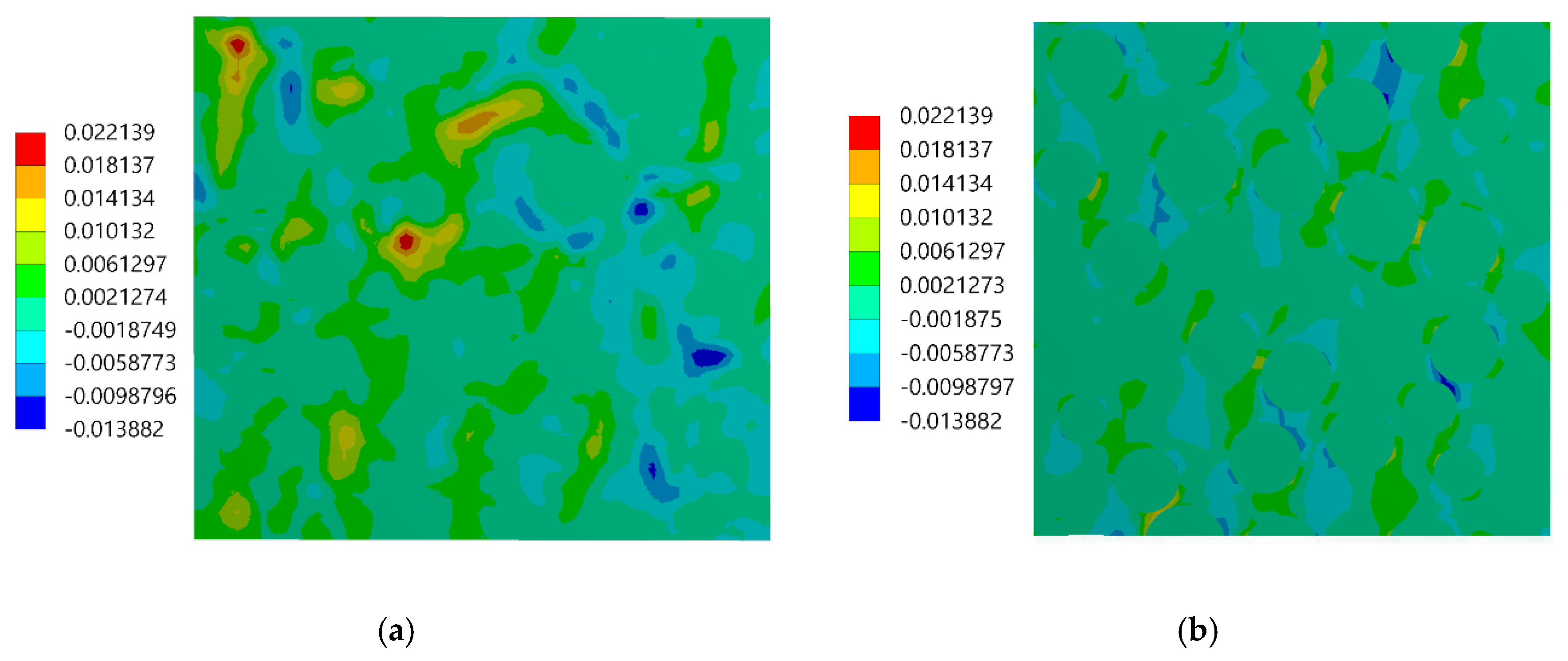

- The main difference in the full-field strains obtained experimentally and numerically was related to the region of the phase boundaries: the strain jumps between the phases are visible in the case of the numerical result, while they are smoothed out in the case of the experimental results.

- The normal elastic strain distributions had a bimodal character due to strain partitioning between the matrix and reinforcing particles. The bimodality has been revealed by both experimental and numerical results although the bimodality is much more pronounced in the numerical case. The shear strain distributions have got symmetric unimodal shape. The widths of the strain distributions are similar for both methods.

Author Contributions

Funding

Conflicts of Interest

References

- Klein, S.; Weber, S.; Theisen, W. Investigation of heat transfer in a copper-infiltrated tool steel based on measurement, microtomography, and numerical simulation. Mater. Des. 2018, 156, 42–51. [Google Scholar] [CrossRef]

- Basista, M.; Węglewski, W.; Bochenek, K.; Poniżnik, Z.; Nowak, Z. Micro-CT Finite Element Analysis of Thermal Residual Stresses and Fracture in Metal-Ceramic Composites. Adv. Eng. Mater. 2017, 19, 1600725. [Google Scholar] [CrossRef]

- Gao, X.; Luo, P.; Fang, G.; Zhang, S.; Song, Y. Micro-XCT-based finite element method for predicting the elastic modulus of needle carbon-fiber-reinforced ceramic matrix composites. Sci. Eng. Compos. Mater. 2017, 24, 1–11. [Google Scholar] [CrossRef]

- Huang, J.; Krabbenhoft, K.; Lyamin, A.V. Statistical homogenization of elastic properties of cement paste based on X-ray microtomography images. Int. J. Solids Struct. 2013, 50, 699–709. [Google Scholar] [CrossRef]

- Sasagawa, T.; Tanaka, M.; Omote, R.; Balzani, D. Construction of statistically similar representative volume elements for discontinuous fiber composites. Compos. Struct. 2018, 203, 193–203. [Google Scholar] [CrossRef]

- Ogierman, W.; Kokot, G. Generation of representative volume elements of heterogeneous materials with distributed orientations of inclusions. Compos. Struct. 2018, 201, 636–646. [Google Scholar] [CrossRef]

- Kamiński, M. Boundary element method homogenization of the periodic linear elastic fiber composites. Eng. Anal. Bound. Elem. 1999, 23, 815–823. [Google Scholar] [CrossRef]

- Chen, X.; Papathanasiou, T.D. Interface stress distributions in transversely loaded continuous fiber composites: Parallel computation in multi-fiber RVEs using the boundary element method. Compos. Sci. Technol. 2004, 64, 1101–1114. [Google Scholar] [CrossRef]

- Fedeliński, P.; Górski, G.; Czyż, T.; Dziatkiewicz, G.; Ptaszny, J. Analysis of effective properties of materials by using the boundary element method. Arch. Mech. 2014, 66, 19–35. [Google Scholar]

- Ptaszny, J.; Hatłas, M. Evaluation of the FMBEM efficiency in the analysis of porous structures. Eng. Comput. (Swansea Wales) 2018, 35, 843–866. [Google Scholar] [CrossRef]

- Moulinec, H.; Suquet, P. A numerical method for computing the overall response of nonlinear composites with complex microstructure. Comput. Methods Appl. Mech. Eng. 1998, 157, 69–94. [Google Scholar] [CrossRef]

- Lebensohn, R.A.; Kanjarla, A.K.; Eisenlohr, P. An elasto-viscoplastic formulation based on fast Fourier transforms for the prediction of micromechanical fields in polycrystalline materials. Int. J. Plast. 2012, 32–33, 59–69. [Google Scholar] [CrossRef]

- Lucarini, S.; Segurado, J. DBFFT: A displacement based FFT approach for non-linear homogenization of the mechanical behavior. Int. J. Eng. Sci. 2019, 144, 103131. [Google Scholar] [CrossRef]

- Rasool, A.; Böhm, H.J. Effects of particle shape on the macroscopic and microscopic linear behaviors of particle reinforced composites. Int. J. Eng. Sci. 2012, 58, 21–34. [Google Scholar] [CrossRef]

- Majewski, M.; Holobut, P.; Kursa, M.; Kowalczyk-Gajewska, K. Packing and size effects in elastic-plastic particulate composites: Micromechanical modelling and numerical verification. Int. J. Eng. Sci. 2020, 151, 103271. [Google Scholar] [CrossRef]

- Ma, S.; Zhuang, X.; Wang, X. 3D micromechanical simulation of the mechanical behavior of an in-situ Al3Ti/A356 composite. Compos. Part B Eng. 2019, 176, 107115. [Google Scholar] [CrossRef]

- Segurado, J.; González, C.; LLorca, J. A numerical investigation of the effect of particle clustering on the mechanical properties of composites. Acta Mater. 2003, 51, 2355–2369. [Google Scholar] [CrossRef]

- Zhang, J.F.; Zhang, X.X.; Wang, Q.Z.; Xiao, B.L.; Ma, Z.Y. Simulations of deformation and damage processes of SiCp/Al composites during tension. J. Mater. Sci. Technol. 2018, 34, 627–634. [Google Scholar] [CrossRef]

- Ogierman, W.; Grzegorzek, W. The influence of the WC-Co composite microstructure model on stress field heterogeneity at the microstructure level : FEM based study. Sci. Eng. Compos. Mater. 2019, 26, 134–146. [Google Scholar] [CrossRef]

- Fathi, A.; Keller, J.H.; Altstaedt, V. Full-field shear analyses of sandwich core materials using Digital Image Correlation (DIC). Compos. Part B Eng. 2015, 70, 156–166. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C.; Pappalettera, G. Digital image correlation comparison of damaged and undamaged aeronautical CFRPs during compression tests. Materials (Basel) 2019, 12, 249. [Google Scholar] [CrossRef] [PubMed]

- Barile, C.; Casavola, C.; Pappalettera, G.; Vimalathithan, P.K. Characterization of adhesive bonded CFRP laminates using full-field digital image stereo-correlation and finite element analysis. Compos. Sci. Technol. 2019, 169, 16–25. [Google Scholar] [CrossRef]

- Xu, D.; Cerbu, C.; Wang, H.; Rosca, I.C. Analysis of the hybrid composite materials reinforced with natural fibers considering digital image correlation (DIC) measurements. Mech. Mater. 2019, 135, 46–56. [Google Scholar] [CrossRef]

- Ji, X.; Hao, Z.; Su, L.; He, T.; Liu, L. Characterizing the constitutive response of plain-woven fibre reinforced aerogel matrix composites using digital image correlation. Compos. Struct. 2020, 234, 111652. [Google Scholar] [CrossRef]

- Cuadrado, M.; Pernas-Sánchez, J.; Artero-Guerrero, J.A.; Varas, D. Model updating of uncertain parameters of carbon/epoxy composite plates using digital image correlation for full-field vibration measurement. Measurement 2020, 159, 107783. [Google Scholar] [CrossRef]

- Kötter, B.; Karsten, J.; Körbelin, J.; Fiedler, B. Cfrp thin-ply fibre metal laminates: Influences of ply thickness and metal layers on open hole tension and compression properties. Materials (Basel) 2020, 13, 910. [Google Scholar] [CrossRef]

- Azadi, M.; Saeedi, M.; Mokhtarishirazabad, M.; Lopez-Crespo, P. Effects of loading rate on crack growth behavior in carbon fiber reinforced polymer composites using digital image correlation technique. Compos. Part B Eng. 2019, 175, 107161. [Google Scholar] [CrossRef]

- Berfield, T.A.; Patel, J.K.; Shimmin, R.G.; Braun, P.V.; Lambros, J.; Sottos, N.R. Micro-and nanoscale deformation measurement of surface and internal planes via digital image correlation. Exp. Mech. 2007, 47, 51–62. [Google Scholar] [CrossRef]

- Canal, L.P.; González, C.; Molina-Aldareguía, J.M.; Segurado, J.; Llorca, J. Application of digital image correlation at the microscale in fiber-reinforced composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1630–1638. [Google Scholar] [CrossRef]

- Mehdikhani, M.; Aravand, M.; Sabuncuoglu, B.; Callens, M.G.; Lomov, S.V.; Gorbatikh, L. Full-field strain measurements at the micro-scale in fiber-reinforced composites using digital image correlation. Compos. Struct. 2016, 140, 192–201. [Google Scholar] [CrossRef]

- Mehdikhani, M.; Steensels, E.; Standaert, A.; Vallons, K.A.M.; Gorbatikh, L.; Lomov, S.V. Multi-scale digital image correlation for detection and quantification of matrix cracks in carbon fiber composite laminates in the absence and presence of voids controlled by the cure cycle. Compos. Part B Eng. 2018, 154, 138–147. [Google Scholar] [CrossRef]

- Orell, O.; Vuorinen, J.; Jokinen, J.; Kettunen, H.; Hytönen, P.; Turunen, J.; Kanerva, M. Characterization of elastic constants of anisotropic composites in compression using digital image correlation. Compos. Struct. 2018, 185, 176–185. [Google Scholar] [CrossRef]

- Koohbor, B.; Ravindran, S.; Kidane, A. Meso-scale strain localization and failure response of an orthotropic woven glass-fiber reinforced composite. Compos. Part B Eng. 2015, 78, 308–318. [Google Scholar] [CrossRef]

- Anzelotti, G.; Nicoletto, G.; Riva, E. Mesomechanic strain analysis of twill-weave composite lamina under unidirectional in-plane tension. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1294–1301. [Google Scholar] [CrossRef]

- Hadjem-Hamouche, Z.; Derrien, K.; Héripré, E.; Chevalier, J.P. In-situ experimental and numerical studies of the damage evolution and fracture in a Fe-TiB2 composite. Mater. Sci. Eng. A 2018, 724, 594–605. [Google Scholar] [CrossRef]

- Herrera-Solaz, V.; Patriarca, L.; Foletti, S.; Segurado, J.; Niffenegger, M. Microstructure-based modelling and Digital Image Correlation measurement of strain fields in austenitic stainless steel 316L during tension loading. Mater. Sci. Eng. A 2019, 751, 99–106. [Google Scholar] [CrossRef]

- Ghadbeigi, H.; Pinna, C.; Celotto, S. Quantitative Strain Analysis of the Large Deformation at the Scale of Microstructure: Comparison between Digital Image Correlation and Microgrid Techniques. Exp. Mech. 2012, 52, 1483–1492. [Google Scholar] [CrossRef]

- Ghadbeigi, H.; Pinna, C.; Celotto, S.; Yates, J.R. Local plastic strain evolution in a high strength dual-phase steel. Mater. Sci. Eng. A 2010, 527, 5026–5032. [Google Scholar] [CrossRef]

- Joo, S.H.; Lee, J.K.; Koo, J.M.; Lee, S.; Suh, D.W.; Kim, H.S. Method for measuring nanoscale local strain in a dual phase steel using digital image correlation with nanodot patterns. Scr. Mater. 2013, 68, 245–248. [Google Scholar] [CrossRef]

- Ogierman, W.; Kokot, G. Analysis of strain field heterogeneity at the microstructure level and inverse identification of composite constituents by means of digital image correlation. Materials (Basel) 2020, 13, 287. [Google Scholar] [CrossRef]

- International Digital Image Correlation Society. A Good Practices Guide for Digital Image Correlation; Jones, E.M.C., Iadicola, M.A., Eds.; International Digital Image Correlation Society: Portland, OR, USA, 2018. [Google Scholar] [CrossRef]

- Zheng, Y.; Fish, J. Toward realization of computational homogenization in practice. Int. J. Numer. Methods Eng. 2008, 73, 361–380. [Google Scholar] [CrossRef]

- Pierard, O.; González, C.; Segurado, J.; LLorca, J.; Doghri, I. Micromechanics of elasto-plastic materials reinforced with ellipsoidal inclusions. Int. J. Solids Struct. 2007, 44, 6945–6962. [Google Scholar] [CrossRef]

- Brault, R.; Germaneau, A.; Dupré, J.C.; Doumalin, P.; Mistou, S.; Fazzini, M. In-situ Analysis of Laminated Composite Materials by X-ray Micro-Computed Tomography and Digital Volume Correlation. Exp. Mech. 2013, 53, 1143–1151. [Google Scholar] [CrossRef]

- Morgeneyer, T.F.; Taillandier-Thomas, T.; Helfen, L.; Baumbach, T.; Sinclair, I.; Roux, S.; Hild, F. In situ 3-D observation of early strain localization during failure of thin Al alloy (2198) sheet. Acta Mater. 2014, 69, 78–91. [Google Scholar] [CrossRef]

- Xu, F. Quantitative characterization of deformation and damage process by digital volume correlation: A review. Theor. Appl. Mech. Lett. 2018, 8, 83–96. [Google Scholar] [CrossRef]

- Schöberl, E.; Breite, C.; Melnikov, A.; Swolfs, Y.; Mavrogordato, M.N.; Sinclair, I.; Spearing, S.M. Fibre-direction strain measurement in a composite ply under quasi-static tensile loading using Digital Volume Correlation and in situ Synchrotron Radiation Computed Tomography. Compos. Part A Appl. Sci. Manuf. 2020, 137, 105935. [Google Scholar] [CrossRef]

- Hong, S.; Liu, P.; Zhang, J.; Kuang, C.; Dong, B.; Luo, Q.; Liu, W. Interior fracture analysis of rubber-cement composites based on X-ray computed tomography and digital volume correlation. Constr. Build. Mater. 2020, 259, 119833. [Google Scholar] [CrossRef]

- Schadler, L.S.; Laird, C.; Melanitis, N.; Galiotis, C.; Figueroa, J.C. Interfacial studies on carbon/thermoplastic model composites using laser Raman spectroscopy. J. Mater. Sci. 1992, 27, 1663–1671. [Google Scholar] [CrossRef]

- Amer, M.S.; Schadler, L.S. Stress concentration phenomenon in graphite/epoxy composites: Tension/compression effects. Compos. Sci. Technol. 1997, 57, 1129–1137. [Google Scholar] [CrossRef]

- Young, R.J. Analysis of composites using Raman and fluorescence microscopy—A review. J. Microsc. 1997, 185, 199–205. [Google Scholar] [CrossRef]

- Arjyal, B.P.; Tarantili, P.A.; Andreopoulos, A.G.; Galiotis, C. Surface and Bulk Stress/Strain Measurements In Composite Laminates With A Fibre-Optic Raman Probe. Compos. Part A Appl. Sci. Manuf. 1999, 30, 1187–1195. [Google Scholar] [CrossRef]

- Puech, P.; Pinel, S.; Jasinevicius, R.G.; Pizani, P.S. Mapping the three-dimensional strain field around a microindentation on silicon using polishing and Raman spectroscopy. J. Appl. Phys. 2000, 88, 4582–4585. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ogierman, W.; Kokot, G. Determination of Local Strain Distribution at the Level of the Constituents of Particle Reinforced Composite: An Experimental and Numerical Study. Materials 2020, 13, 3889. https://doi.org/10.3390/ma13173889

Ogierman W, Kokot G. Determination of Local Strain Distribution at the Level of the Constituents of Particle Reinforced Composite: An Experimental and Numerical Study. Materials. 2020; 13(17):3889. https://doi.org/10.3390/ma13173889

Chicago/Turabian StyleOgierman, Witold, and Grzegorz Kokot. 2020. "Determination of Local Strain Distribution at the Level of the Constituents of Particle Reinforced Composite: An Experimental and Numerical Study" Materials 13, no. 17: 3889. https://doi.org/10.3390/ma13173889

APA StyleOgierman, W., & Kokot, G. (2020). Determination of Local Strain Distribution at the Level of the Constituents of Particle Reinforced Composite: An Experimental and Numerical Study. Materials, 13(17), 3889. https://doi.org/10.3390/ma13173889