1. Introduction

There are many ancient wood structures in China, which present China’s material and spiritual civilization. However, due to the impact of the natural environment and human factors, the wood components of ancient wood structures are easily cracked, deformed, decayed and moth-eaten. In order to preserve most of original material, the lap joint is commonly used to replace the damaged part of a wood component. The core principle of architectural heritage protection is authenticity and integrity [

1]. During the restoration of the ancient wood structures, the intervention on the original building should be minimized, the original material of the building should be kept as much as possible, and the value of cultural relics of the building should be protected as much as possible [

2]. Partial component replacement with a lap joint is consistent with modern conservation principles of minimum intervention [

3].

Arciszewska-Kedzior et al. and Hasníková et al. used a lapped scarf joint with inclined faces and wood dowels to repair the beam-end in historical timber beams, and investigated the mechanical behavior of the lapped scarf joint by an experimental and numerical model [

4,

5]. Li et al. used self-tapping wood screws to reinforce the lap joint in a spliced beam [

6]. Sangree et al. examined the behavior of a halved and tabled traditional timber scarf joint [

7,

8]. Jensen et al. studied the shear strength of beam spliced joints with glued-in rods [

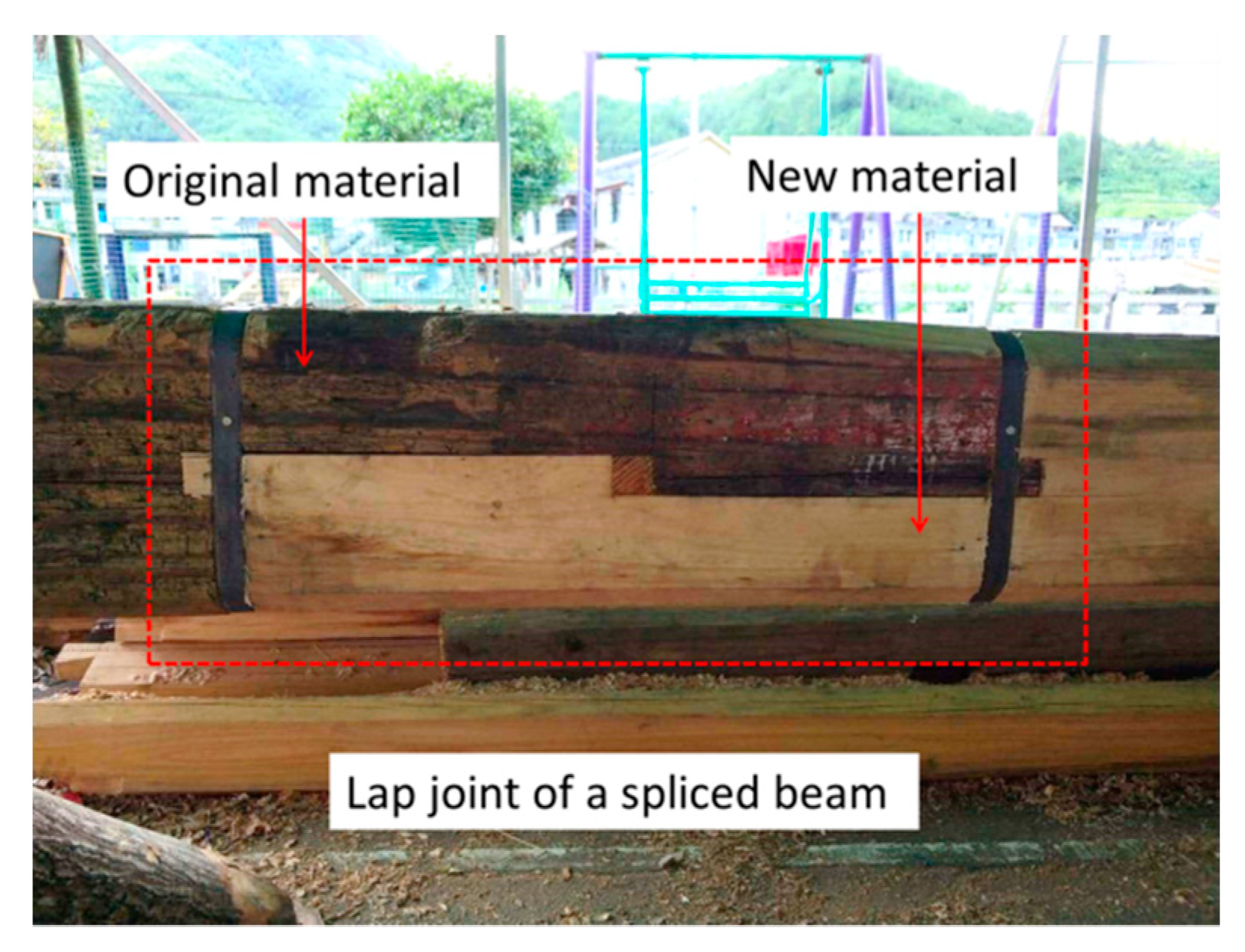

9]. In China, when the bottom of a column in an ancient wood structure is seriously decayed, the decayed portion is replaced with a new portion (

Figure 1), and the new portion is connected with the rest of the column by a lap joint [

10]. This type of lap joint was also planned to be used for the restoration of the timber arch lounge bridges in China (

Figure 2). The main bearing structure of the timber arch lounge bridge is a woven arch, which is composed of round wood components, and these round wood components need to bear loads such as the structure’s own weight and pedestrian loads [

11,

12]. However, the bearing capacity of an unreinforced lap joint could not reach the bearing capacity of the intact beam, which made it unsafe to be used in some load-bearing members.

Fiber-reinforced polymer (FRP) composite materials are well-known for possessing outstanding specific stiffness and strength, and FRP composite materials are widely used in the aviation industry, automobile industry and construction industry [

13,

14,

15,

16,

17,

18]. In terms of reinforcement and repair of wooden structures, steel materials and composite materials are widely used to reinforce the wood components. Many scholars used carbon fiber-reinforced polymer (CFRP) bars, CFRP sheets, steel bars or glass fiber-reinforced polymer (GFRP) to strengthen glulam beams [

19,

20,

21,

22,

23]. Steel materials are increasingly being replaced by composite materials due to the advantages of light weight, high strength and corrosion resistance of composite materials [

24,

25,

26]. Dewey et al. used CFRP strips and GFRP bars to strengthen the deteriorated timber bridge girders, and the results showed that the moment capacity and ductility of the repaired members were enhanced [

27]. Svecova and Eden used GFRP bars to strengthen timber stringers. Strengthening timber stringers with GFRP reinforcement increased the ultimate strength of the stringers and reduced their variability [

28]. Borri et al. performed a study on the reinforcement of existing wood elements under bending loads through the use of FRP materials [

29]. Bergner et al. used carbon fiber and basalt fiber rovings to reinforce spruce wood specimens, and two methods (vacuum infusion process and TowPregs) were developed to manufacture the composites [

30]. Qin performed an excellent study on using GFRP to strengthen spliced wood beams with lap joints, and studied the bending strength and shear strength of reinforced spliced beams by experiments [

31]. Steel jackets and CFRPs were used to reinforce splice-jointed timber columns [

32,

33,

34].

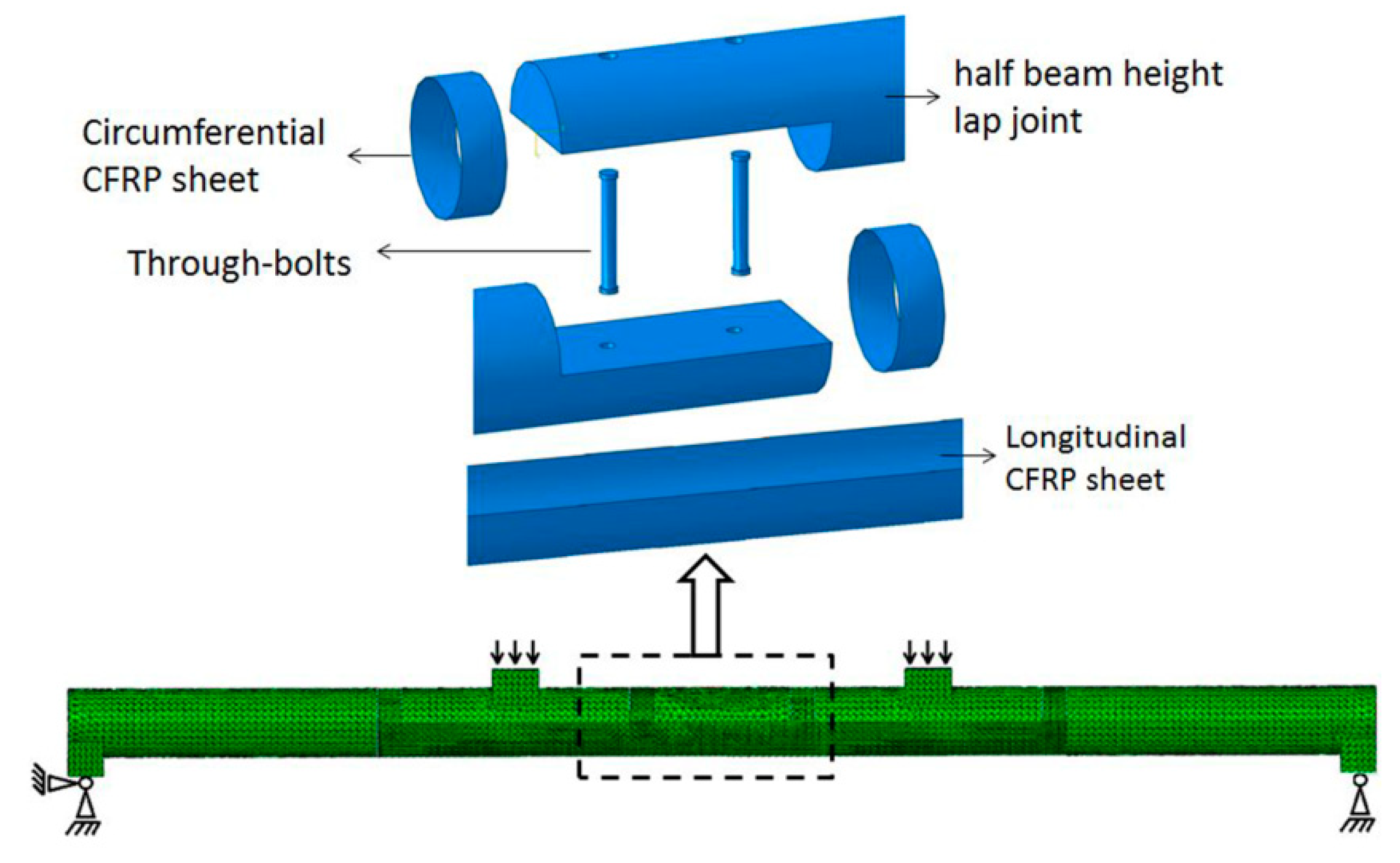

This paper studies the mechanical behavior of the half beam height lap joint reinforced with CFRP sheets, CFRP bars or steel bars. Two research methods, experimental and numerical analysis, were used in this paper. Intact beams and spliced beams with strengthening lap joints were tested to analyze the bearing capacity, stiffness and failure modes. The parameters that influence the mechanical behavior of the lap joint such as the reinforcement ratio and bond length of CFRP sheets will be discussed. The stress distribution and deformation of the lap joint reinforced by CFRP sheets will be studied by numerical analysis. Finally, a proposal for repairing wood beams with the lap joint is proposed.

4. Discussion

Reinforced spliced beams with lap joints were tested in this paper. The test results show that the effect of reinforcement with CFRP sheets is better than the effect of reinforcement with CFRP bars or steel bars. The reason is that the bond strength between the CFRP sheets and wood is better than the bond strength between the CFRP bars and wood. The ultimate load value of beam B6 was about 111.5 percent of the ultimate load value of beam B0, and the ultimate load value of beam S2 was about 99 percent of the ultimate load value of beam S0. This shows that by affixing a sufficient thickness of longitudinal CFRP sheet at the bottom of the lap joint and providing reliable adhesion between the longitudinal CFRP sheet and the wood, the flexural load-bearing capacity of the beam with a lap joint can exceed the load-bearing capacity of the intact beam.

This paper used the finite element method to simulate the spliced beam reinforced by CFRP sheets, and a correlation between numerical results and experimental results is herein discussed. As shown in

Figure 12, the differences between the numerical and experimental results are small. The differences in the stiffness between numerical and experimental values are of 20% and 18% for the reinforced beams with two layers of CFRP sheets and one layer of CFRP sheets, respectively. Taking into account the inevitable deviations between the numerical model and the specimens, the relative error of finite elemental models is low. The numerical model can be used to predict the stiffness of the specimens in the elastic stage. In addition, the finite elemental model can be used to analyze the structural behavior of the reinforced lap joints and explain some experimental results.

The ultimate load value of beam B4 increased by about 61.5 percent compared to that of beam B3, and the ultimate load value of beam B6 increased by about 131.2 percent compared to that of beam B5. Comparison between the ultimate load values of beam B3 and beam B4 or beam B5 and beam B6 showed that increasing the thickness of the longitudinal CFRP sheet could significantly increase the bearing capacity of the lap joints. As shown in

Figure 7, the stiffness of beams B4 and B6 are greater than the stiffness of beams B3 and B5. The stiffness of the beam also increased as the thickness of the longitudinal CFRP sheet increased. The reason why the stiffness and bearing capacity of the specimens reinforced with two layers of CFRP sheets are increased is that increasing the thickness of the CFRP sheet reduces the deformation of the lap joint and improves its mechanical properties. As seen in

Figure 14, the seam in the lower half of the lap joint will separate. The numerical results showed that the seam deformation of the lap joint reinforced with one layer of a CFRP sheet (Δ1) was larger than that of the lap joint reinforced with two layers of CFRP sheets (Δ2). The seam deformation would weaken the integrity of the lap joint, which was not conducive to the bearing capacity of the joint. On the one hand, the depth of the compression zone of the lap joint will decrease as the thickness of the CFRP sheet decreases. As seen in

Figure 15 and

Figure 16, both numerical results and experimental results show that the depth of the compression zone of the specimen reinforced with one layer of CFRP sheet is smaller than that of the specimen reinforced with two layers of CFRP sheets. On the other hand, under the same load, the stress and strain of the specimens will increase as the thickness of the CFRP sheet decreases. As seen in

Figure 16, in the case of similar loads, the maximum tensile strain and maximum compressive strain of beam B5 are both larger than the beam B6. The numerical results also show the same pattern (

Figure 13).

The numerical results can also be used to explain why beams B3 and B5 failed due to the compressive failure of the wood on the top surface while beams B4 and B6 failed due to the bond failure between the CFRP sheet and the wood. As discussed above, the specimens reinforced with one layer of a CFRP sheet have greater stress and smaller depth of the compression zone. The smaller depth of the compression zone and greater stress make the upper section prone to compressive failure, which can explain why beams B3 and B5 failed due to the compressive failure. When reinforced with two layers of CFRP sheets, the depth of the compression zone of wood increases and the cross-sectional area involved in compression also increases, which can provide a resistance greater than the bonding force and make bonding failure occur before compression failure.

In addition, the location of the maximum stress in the numerical models and the location of the failure in experiments are highly consistent, which reveals that the numerical models also can be used to predict possible failure modes.

Figure 17 shows the comparison between the stress contour and the failure modes of the specimens. According to the stress contour, the maximum compression stress occurred around the bolt hole. Beams B3 and B5 failed due to the compressive failure of wood near the bolt hole where the compressive stress is the largest. The maximum tension stress occurred on the longitudinal CFRP sheet near the seam of the lap joint, so the bond failure between the CFRP sheet and wood happened first near the seam of the lap joint. The rupture of longitudinal CFRP sheet also occurred near the seam of the lap joint where the tension stress is the largest. Although the finite elemental model in this study cannot simulate the failure mode, it can better predict the location and form of the failure.