Research on the Bond Behavior of Preplaced Aggregate Concrete-Filled Steel Tube Columns

Abstract

:1. Introduction

2. Materials and Methods

2.1. Test Specimens

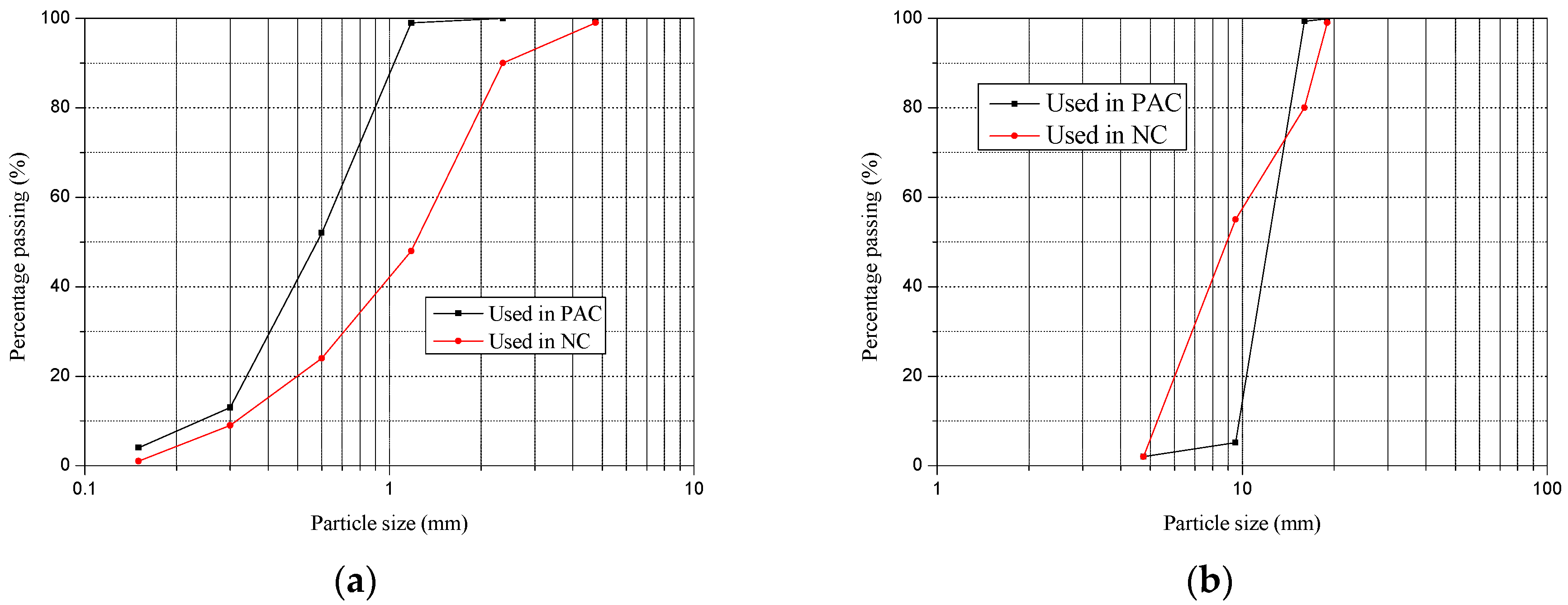

2.2. Material Properties and Concrete Proportions

2.2.1. Material Properties

2.2.2. Concrete Proportions

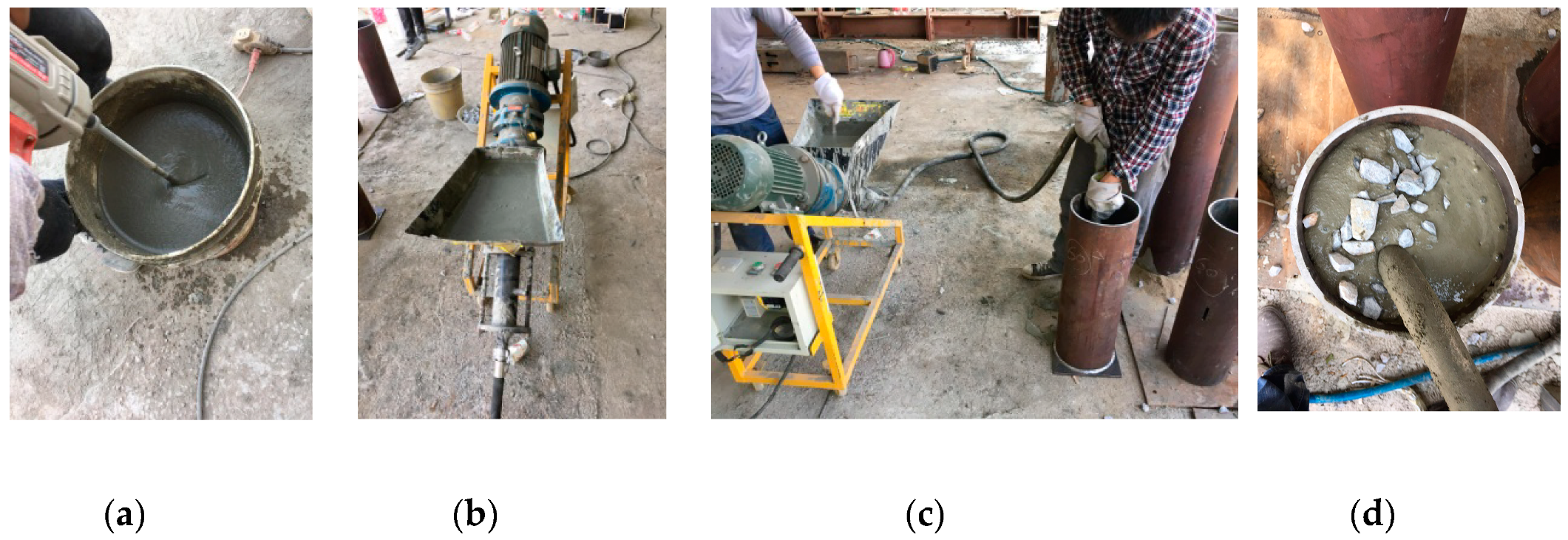

2.3. Preparation of Specimens

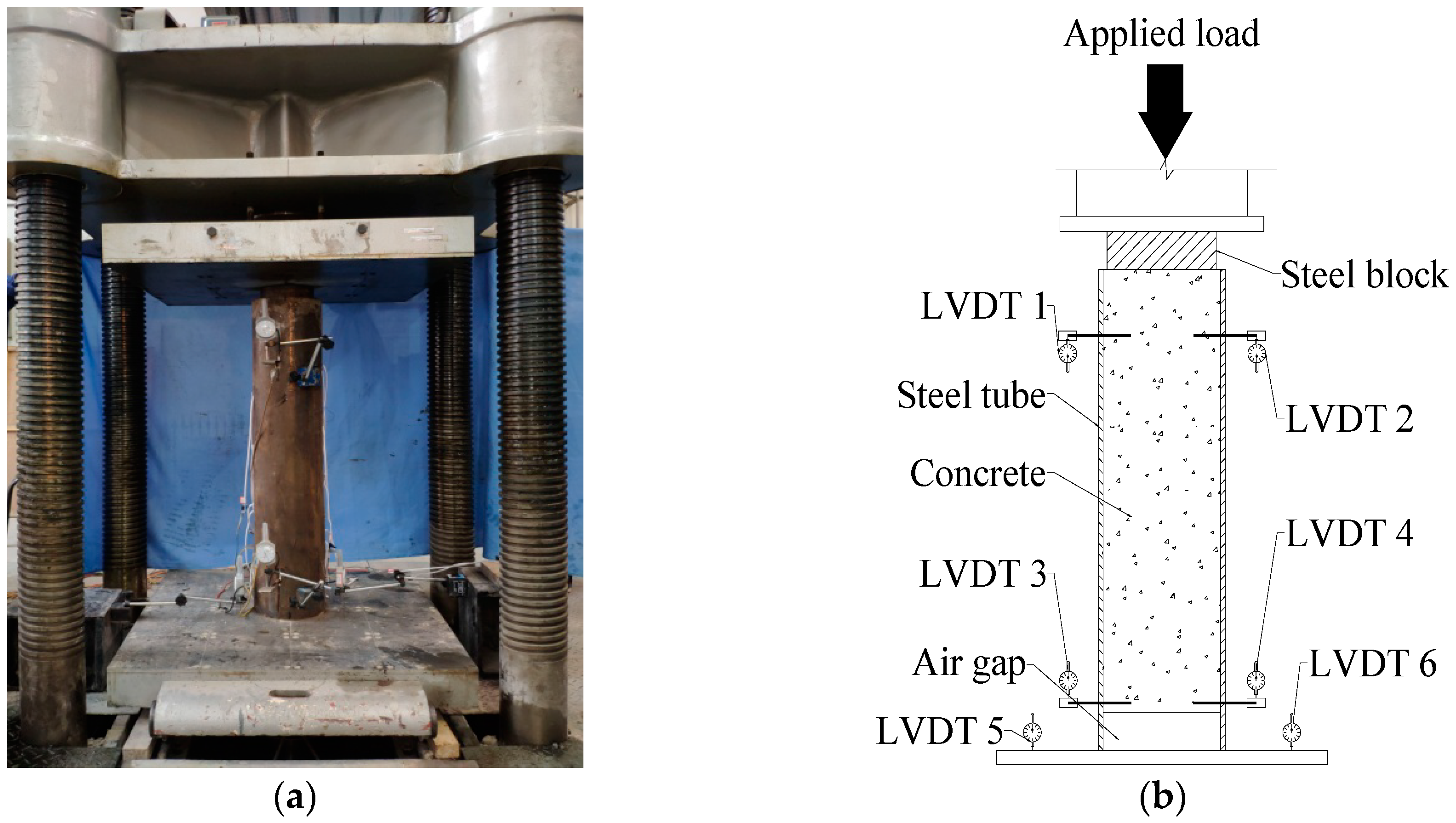

2.4. Experimental Setup

3. Results and Discussion

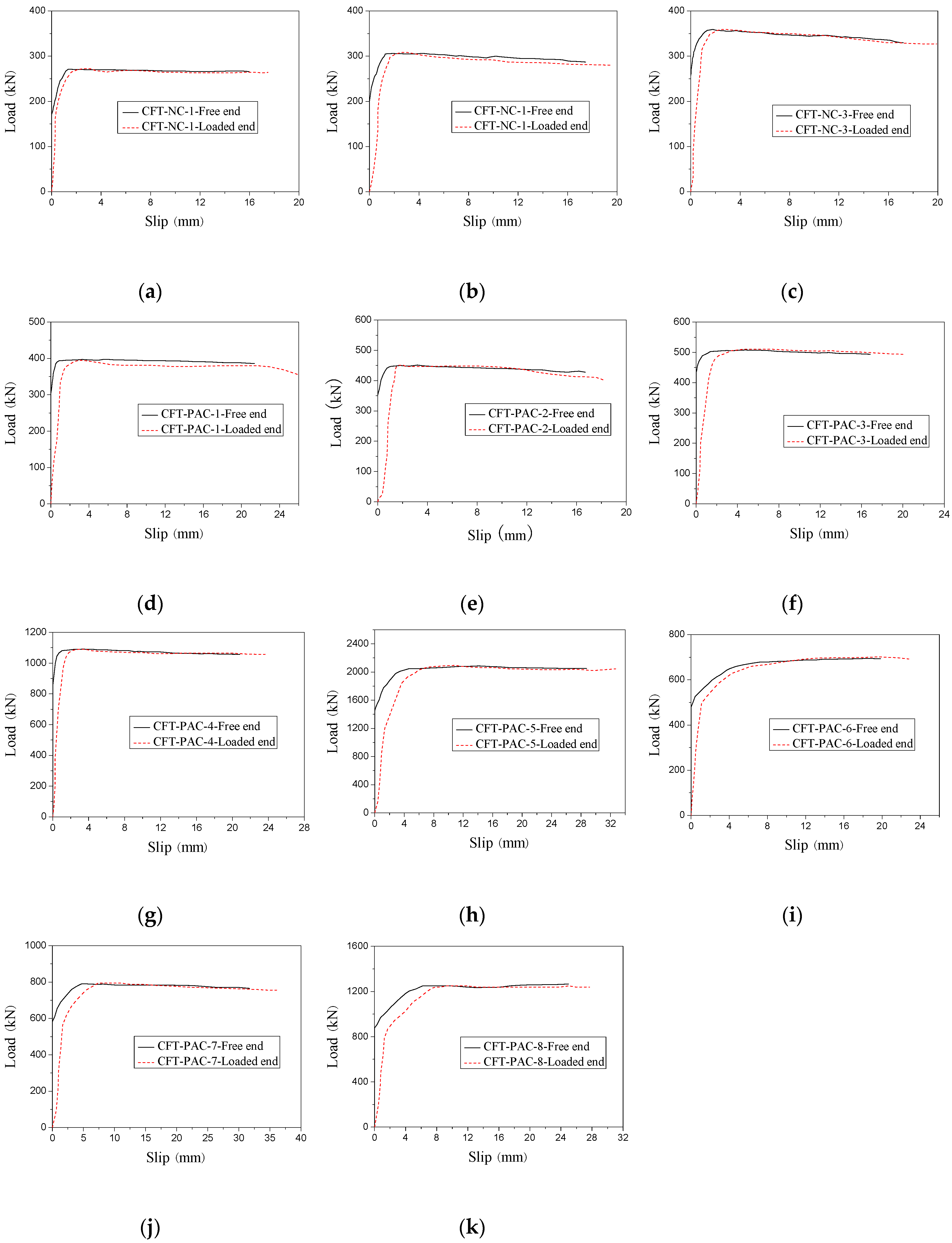

3.1. Load-slip Curves and Failure Modes

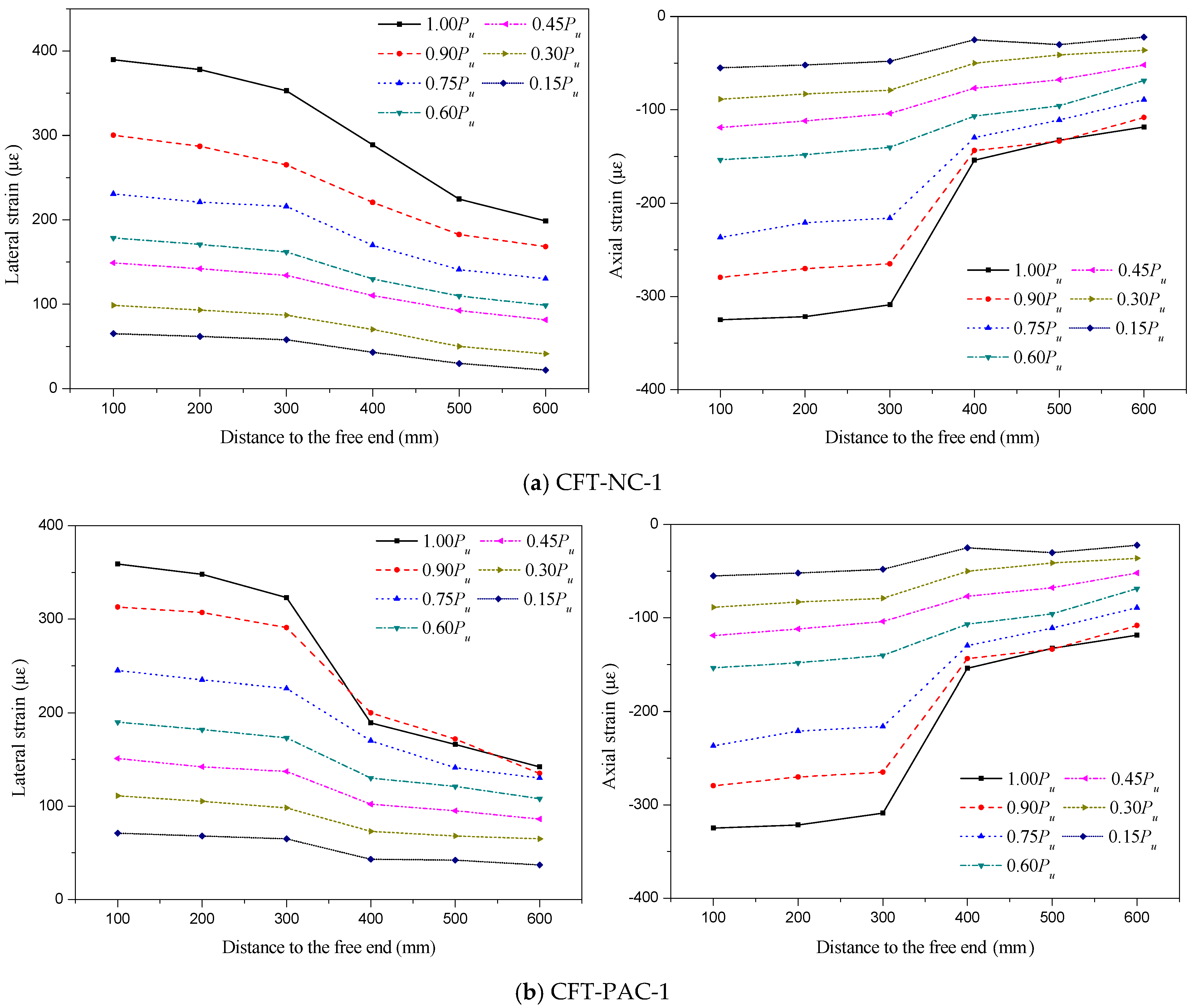

3.2. Axial and Lateral Strain Distributions

3.3. Influence of Different Parameters

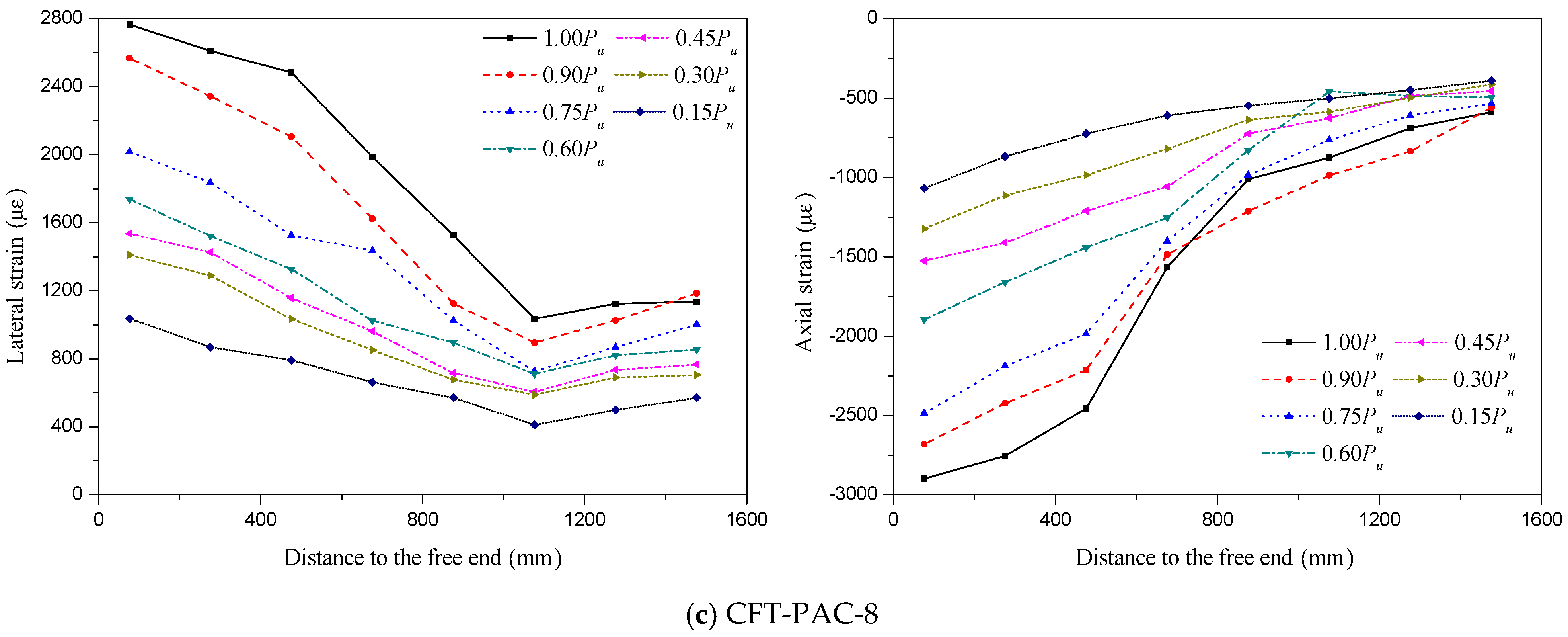

3.3.1. Effect of Concrete Strength and Concrete Type

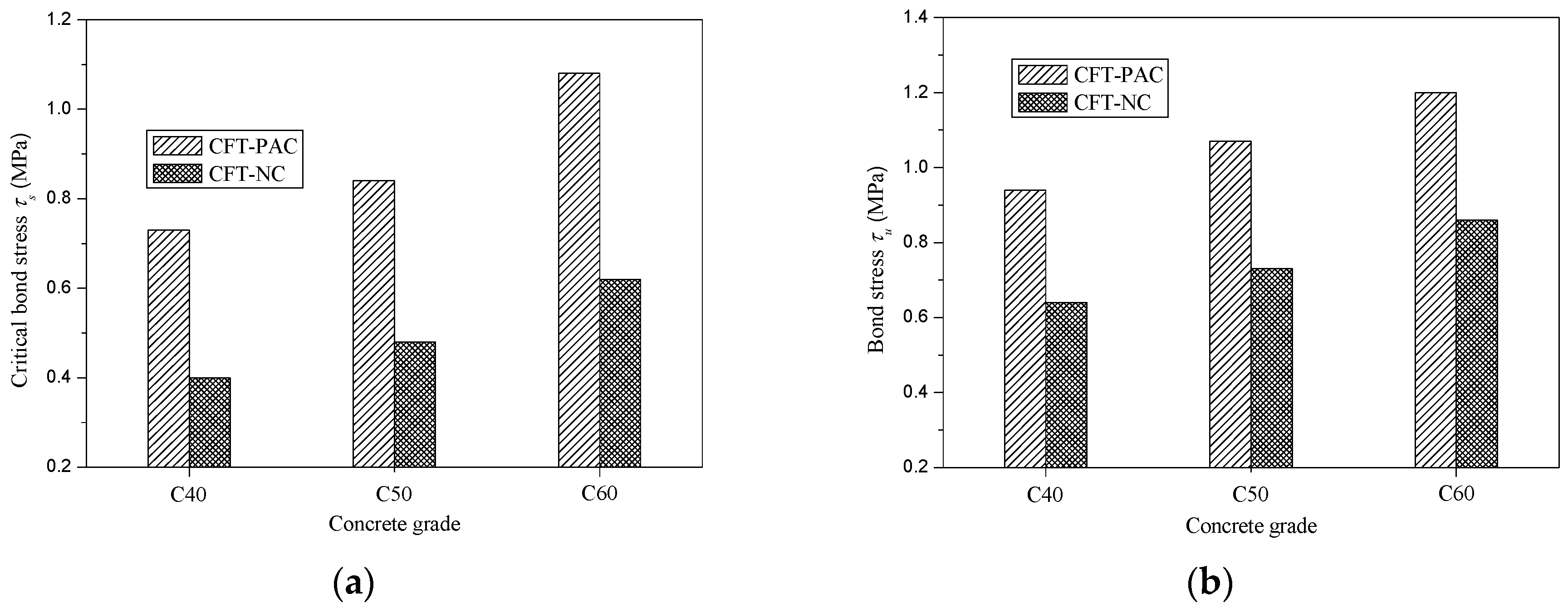

3.3.2. Effect of Cross-Section Geometry

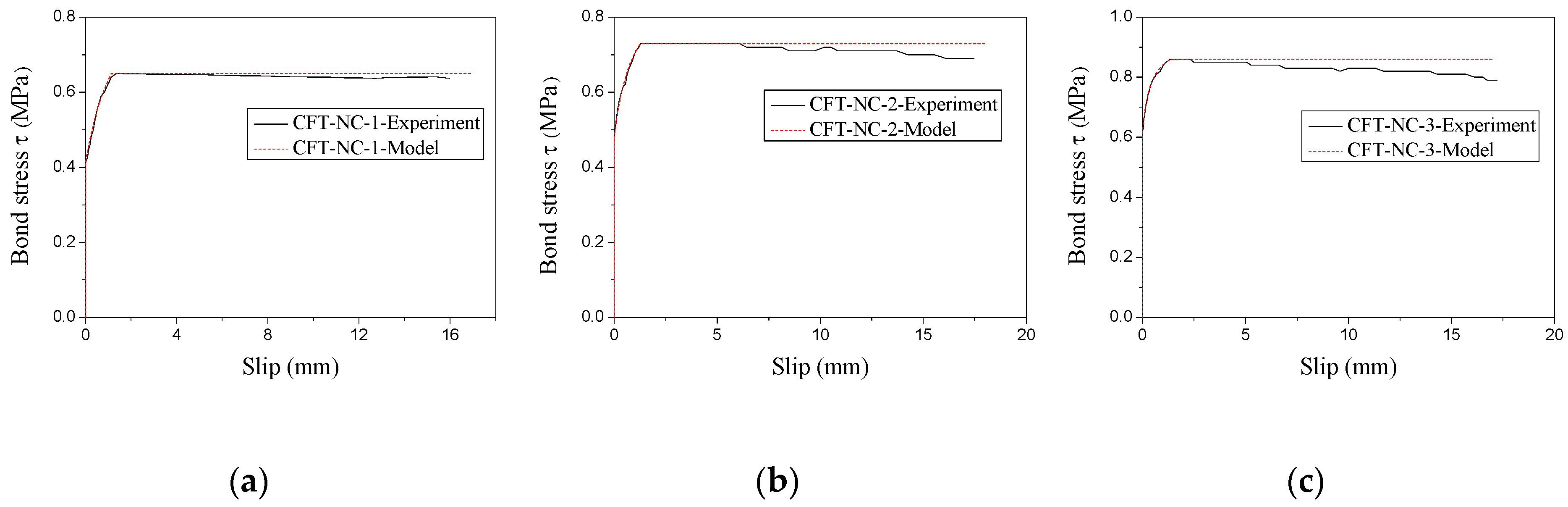

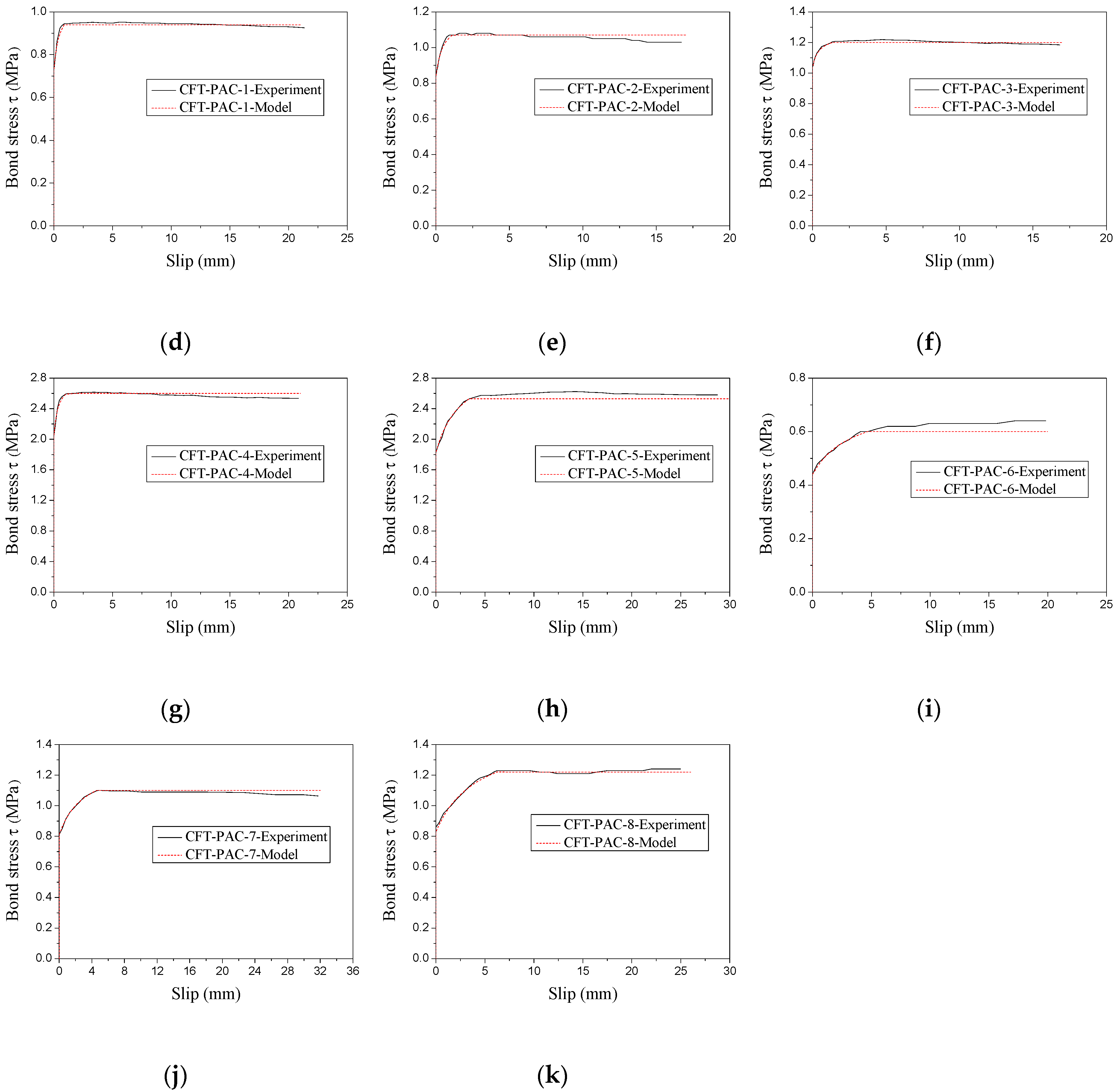

3.4. Bond Stress–Slip Relationship Model

4. Conclusions

- ➢

- The CTF-PAC columns had a similar load-slip curves with CFT columns filled with NC, manufactured sand concrete and recycled aggregate concrete. The bond stress of CFT-PAC was higher than that of PAC-NC at the same concrete strength.

- ➢

- The different influence factors had effect on critical bond strength, bond strength and slip corresponding to peak load of CFT-PAC: (i) the critical bond strength and bond strength of CFT-PAC columns increased with the compressive strength of PAC added; (ii) the L/D ratio had a slight effect on the bond strength of CFT-PAC, but slip corresponding to peak increased obviously with the L/D ratio; (iii) the D/t ratio increased from 27.4 to 37.4 led to a reduction of 2.3% in the bond stress of CFT-PAC, while the D/t ratio increased from 37.4 to 43.9 led to a reduction of 76.3% in bond of CFT-PAC.

- ➢

- The slip corresponding to the peak load of CFT-PAC increased almost linearly with the D/t ratio.

- ➢

- The proposed bond stress–slip relationship model was suitable to describe the bond stress–slip relationship of CFT-PAC. A further research on the influence factors of parameters τu, τs, Su and S0.5 was necessary to carried out to establish a prediction model for bond stress–slip relationship of CFT-PAC.

Author Contributions

Funding

Conflicts of Interest

References

- Lai, M.H.; Ho, J.C.M. Confinement effect of ring-confined concrete-filled-steel-tube columns under uni-axial load. Eng. Struct. 2014, 67, 123–141. [Google Scholar] [CrossRef]

- Milan, C.C.; Albareda-Valls, A.; Carreras, J.M. Evaluation of structural performance between active and passive preloading systems in circular concrete-filled steel tubes (CFST). Thin Wall. Struct. 2019, 194, 207–219. [Google Scholar] [CrossRef]

- Han, L.H.; Li, W.; Bjorhovde, R. Developments and advanced applications of concrete-filled steel tubular (CFST) structures: Members. J. Constr. Steel Res. 2014, 100, 211–228. [Google Scholar] [CrossRef]

- Wang, R.; Han, L.H.; Hou, C.C. Behavior of concrete filled steel tubular (CFST) members under lateral impact: Experiment and FEA model. J. Constr. Steel Res. 2013, 80, 188–201. [Google Scholar] [CrossRef]

- Roeder, C.W.; Lehman, D.E.; Bishop, E. Strength and Stiffness of Circular Concrete-Filled Tubes. J. Struct. Eng. ASCE 2010, 136, 1545–1553. [Google Scholar] [CrossRef]

- Yu, Z.W.; Ding, F.X.; Cai, C.S. Experimental behavior of circular concrete-filled steel tube stub columns. J. Constr. Steel Res. 2007, 63, 165–174. [Google Scholar] [CrossRef]

- Ellobody, E.; Young, B. Nonlinear analysis of concrete-filled steel SHS and RHS columns. Thin Wall. Struct. 2006, 44, 919–930. [Google Scholar] [CrossRef]

- Xu, W.; Han, L.H.; Li, W. Seismic performance of concrete-encased column base for hexagonal concrete-filled steel tube: Experimental study. J. Constr. Steel Res. 2016, 121, 352–369. [Google Scholar] [CrossRef]

- Li, Y.; Cai, C.C.; Liu, Y.; Chen, Y.J.; Liu, J.F. Dynamic analysis of a large span specially shaped hybrid girder bridge with concrete-filled steel tube arches. Eng. Struct. 2016, 106, 243–260. [Google Scholar] [CrossRef] [Green Version]

- Xin, L.F.; Li, X.Z.; Zhang, Z.T.; Zhao, L.F. Seismic behavior of long-span concrete-filled steel tubular arch bridge subjected to near-fault fling-step motions. Eng. Struct. 2019, 180, 148–159. [Google Scholar] [CrossRef]

- He, A.; Zhao, Q. Experimental and numerical investigations of concrete-filled stainless steel tube stub columns under axial partial compression. J. Constr. Steel Res. 2019, 158, 405–416. [Google Scholar] [CrossRef]

- Qiao, Q.Y.; Zhang, W.W.; Mou, B.; Cao, W.L. Seismic behavior of exposed concrete filled steel tube column bases with embedded reinforcing bars: Experimental investigation. Thin Wall. Struct. 2019, 136, 367–381. [Google Scholar] [CrossRef]

- Tian, H.W.; Zhou, Z.; Wei, Y.; Wang, Y.Q.; Lu, J.P. Experimental investigation on axial compressive behavior of ultra-high performance concrete (UHPC) filled glass FRP tubes. Constr. Build. Mater. 2017, 154, 644–657. [Google Scholar] [CrossRef]

- Yang, J.L.; Wang, J.Z.; Wang, X.P.; Cheng, L.; Wang, Z.R. Compressive Behavior of Circular Tubed Steel-Reinforced High-Strength Concrete Short Columns. J. Struct. Eng. 2019, 145, 1–17. [Google Scholar] [CrossRef]

- Abed, F.; AlHamaydeh, M.; Abdalla, S. Experimental and numerical investigations of the compressive behavior of concrete filled steel tubes (CFSTs). J. Constr. Steel Res. 2013, 80, 429–439. [Google Scholar] [CrossRef]

- Tao, Z.; Song, T.Y.; Uy, B.; Han, L.H. Bond behavior in concrete-filled steel tubes. J. Constr. Steel Res. 2016, 120, 81–93. [Google Scholar] [CrossRef]

- Chen, Y.; Feng, R.; Shao, Y.B.; Zhang, X.T. Bond-slip behaviour of concrete-filled stainless steel circular hollow section tubes. J. Constr. Steel Res. 2017, 130, 248–263. [Google Scholar] [CrossRef]

- Chen, Z.P.; Xu, J.J.; Liang, Y.; Su, Y.S. Bond behaviors of shape steel embedded in recycled aggregate concrete and recycled aggregate concrete filled in steel tubes. Steel Compos. Struct. 2014, 17, 929–949. [Google Scholar] [CrossRef]

- Abendeh, R.; Ahmad, H.S.; Hunaiti, Y.M. Experimental studies on the behavior of concrete-filled steel tubes incorporating crumb rubber. J. Constr. Steel Res. 2016, 122, 251–260. [Google Scholar] [CrossRef]

- Fang, S.; Liu, F.; Xiong, Z.; Fang, J.S.; Li, L.J. Seismic performance of recycled aggregate concrete-filled glass fibre-reinforced polymer-steel composite tube columns. Constr. Build. Mater. 2019, 225, 997–1010. [Google Scholar] [CrossRef]

- Xu, J.J.; Chen, Z.P.; Zhao, X.Y.; Demartino, C.; Ozbakkaloglu, T.; Xue, J.Y. Seismic performance of circular recycled aggregate concrete-filled steel tubular columns: FEM modelling and sensitivity analysis. Thin Wall. Struct. 2019, 141, 509–525. [Google Scholar] [CrossRef]

- Yu, M.; Wang, T.; Huang, W.J.; Yuan, H.X.; Ye, J.Q. Fire resistance of concrete-filled steel tube columns with preload. Part I: Experimental investigation. Compos. Struct. 2019, 223, 110994. [Google Scholar] [CrossRef]

- Wang, K.; Ben, Y. Fire resistance of concrete-filled high strength steel tubular columns. Thin Wall. Struct. 2013, 71, 46–56. [Google Scholar] [CrossRef] [Green Version]

- Ferdous, W.; Ngo, T.D.; Nguyen, K.T.Q.; Ghazlan, A.; Mendis, P.; Manalo, A. Effect of fire-retardant ceram powder on the properties of phenolic-based GFRP composites. Compos. B Eng. 2018, 155, 414–424. [Google Scholar] [CrossRef]

- Fu, Z.Q.; Ji, B.H.; Wu, D.Y.; Yu, Z.P. Behaviour of lightweight aggregate concrete-filled steel tube under horizontal cyclic load. Steel Compos. Struct. 2019, 32, 717–729. [Google Scholar]

- Fu, Z.Q.; Ji, B.H.; Lv, L.; Zhou, W.J. Behavior of lightweight aggregate concrete filled steel tubular slender columns under axial compression. Adv. Steel Constr. 2011, 7, 144–156. [Google Scholar]

- Han, L.H.; Hou, C.C.; Zhao, X.L.; Rasmussen, K.J.R. Behaviour of high-strength concrete filled steel tubes under transverse impact loading. J. Constr. Steel Res. 2014, 92, 25–39. [Google Scholar] [CrossRef]

- Ellobody, E.; Young, B.; Lam, D. Behaviour of normal and high strength concrete-filled compact steel tube circular stub columns. J. Constr. Steel Res. 2006, 62, 706–715. [Google Scholar] [CrossRef]

- Abdikarim, I.N.; Esra, M.G. Prediction model on compressive strength of recycled aggregate concrete filled steel tube columns. Compos. B 2019, 173, 106938. [Google Scholar]

- Lyu, W.Q.; Han, L.H. Investigation on bond strength between recycled aggregate concrete (RAC) and steel tube in RAC-filled steel tubes. J. Constr. Steel Res. 2019, 155, 438–459. [Google Scholar] [CrossRef]

- Tang, Y.C.; Li, L.J.; Feng, W.X.; Liu, F.; Liao, B. Seismic performance of recycled aggregate concrete–filled steel tube columns. J. Constr. Steel Res. 2017, 133, 112–124. [Google Scholar] [CrossRef]

- Li, W.G.; Luo, Z.Y.; Tao, Z.; Duan, W.H.; Shah, S.P. Mechanical behavior of recycled aggregate concrete-filled steel tube stub columns after exposure to elevated temperatures. Constr. Build. Mater. 2017, 146, 571–581. [Google Scholar] [CrossRef]

- Zhang, Y.R.; Wei, Y.; Bai, J.W.; Zhang, Y.X. Stress-strain model of an FRP-confined concrete filled steel tube under axial compression. Thin Wall. Struct. 2019, 142, 149–159. [Google Scholar] [CrossRef]

- Chen, P.; Wang, Y.Y.; Liu, C.Y. Confinement path-dependent analytical model for FRP-confined concrete and concrete-filled steel tube subjected to axial compression. Compos. Struct. 2018, 201, 234–247. [Google Scholar] [CrossRef]

- Nehdi, M.L.; Najjar, M.F.; Soliman, A.M.; Azabi, T.M. Novel eco-efficient Two-Stage Concrete incorporating high volume recycled content for sustainable pavement construction. Constr. Build. Mater. 2017, 146, 9–14. [Google Scholar] [CrossRef]

- Najjar, M.F.; Nehdi, M.L.; Soliman, A.M.; Azabi, T.M. Damage mechanisms of two-stage concrete exposed to chemical and physical sulfate attack. Constr. Build. Mater. 2017, 137, 141–152. [Google Scholar] [CrossRef]

- Najjar, M.F.; Soliman, A.M.; Nehdi, M.L. Critical overview of two-stage concrete: Properties and applications. Constr. Build. Mater. 2014, 62, 47–58. [Google Scholar] [CrossRef]

- Yoon, J.Y.; Kim, J.H. Mechanical properties of preplaced lightweight aggregates concrete. Constr. Build. Mater. 2019, 216, 440–449. [Google Scholar] [CrossRef]

- Coo, M.; Pheeraphan, T. Effect of sand, fly ash, and coarse aggregate gradation on preplaced aggregate concrete studied through factorial design. Constr. Build. Mater. 2015, 93, 812–821. [Google Scholar] [CrossRef]

- Abdelgader, H.S.; Górsk, J. Stress-Strain Relations and Modulus of Elasticity of Two-Stage Concrete. J. Mater. Civ. Eng. 2003, 15, 329–334. [Google Scholar] [CrossRef]

- Ferdous, W.; Bai, Y.; Almutairi, A.D.; Satasivam, S.; Jeske, J. Modular assembly of water-retaining walls using GFRP hollow profiles: Components and connection performance. Compos. Struct. 2018, 194, 1–11. [Google Scholar] [CrossRef]

- GB/T 228-2010. Metallic Materials-Tensile Testing at Ambient Temperature; China Architecture and Building Press: Beijing, China, 2010. (In Chinese) [Google Scholar]

- GB50081-2002. Standard for Test Method of Mechanical Properties on Ordinary Concrete; China Architecture and Building press: Beijing, China, 2003. (In Chinese) [Google Scholar]

- GB 175-2007. Common Portland Cement; China Standards Press: Beijing, China, 2007. (In Chinese) [Google Scholar]

- Guan, M.S.; Lai, Z.C.; Xiao, Q.; Du, H.B.; Zhang, K. Bond behavior of concrete-filled steel tube columns using manufactured sand (MS-CFT). Eng. Struct. 2019, 187, 199–208. [Google Scholar] [CrossRef]

- Xu, K.; Bi, L.; Chen, M. Experimental study on bond stress–slip constitutive relationship for CFST. J. Build. Struct. 2015, 36, 407–412. (In Chinese) [Google Scholar]

| Specimen ID | L (mm) | D (mm) | t (mm) | D/t | Concrete Grade |

|---|---|---|---|---|---|

| CFT-PAC-1 | 657 | 219 | 6 | 36.5 | C40 |

| CFT-PAC-2 | 657 | 219 | 6 | 36.5 | C50 |

| CFT-PAC-3 | 657 | 219 | 6 | 36.5 | C60 |

| CFT-PAC-4 | 657 | 219 | 8 | 27.4 | C40 |

| CFT-PAC-5 | 897 | 299 | 8 | 37.4 | C40 |

| CFT-PAC-6 | 1053 | 351 | 8 | 43.9 | C40 |

| CFT-PAC-7 | 1095 | 219 | 6 | 36.5 | C40 |

| CFT-PAC-8 | 1533 | 219 | 6 | 36.5 | C40 |

| CFT-NC-1 | 657 | 219 | 6 | 36.5 | C40 |

| CFT-NC-2 | 657 | 219 | 6 | 36.5 | C50 |

| CFT-NC-3 | 657 | 219 | 6 | 36.5 | C60 |

| Grade of Steel | D (mm) | t (mm) | fy (MPa) | fu (MPa) | Es (MPa) |

|---|---|---|---|---|---|

| Q235 | 219 | 6 | 340 | 510 | 2.05 × 105 |

| 8 | 332 | 492 | 2.08 × 105 | ||

| 299 | 8 | 341 | 503 | 2.06 × 105 | |

| 315 | 8 | 343 | 511 | 2.06 × 105 |

| Concrete Grade | Weight per Cubic Meter (kg/m3) | W/B | Elastic Modulus (GPa) | Cubic Compressive Strength (MPa) | ||||

|---|---|---|---|---|---|---|---|---|

| Cement | Sand | Coarse Aggregate | Water Reducer | Water | ||||

| C60 (PAC) | 385 | 578 | 1360 | 5.78 | 116 | 0.30 | 44.1 | 65.7 |

| C50 (PAC) | 330 | 660 | 1360 | 4.98 | 100 | 0.30 | 42.1 | 57.2 |

| C40 (PAC) | 310 | 620 | 1360 | 2.48 | 124 | 0.40 | 40.2 | 44.7 |

| C60 (NC) | 500 | 660 | 1080 | 7.50 | 160 | 0.32 | 38.3 | 67.1 |

| C50 (NC) | 470 | 580 | 1180 | 7.05 | 170 | 0.36 | 35.8 | 56.8 |

| C40 (NC) | 420 | 570 | 1270 | 4.20 | 185 | 0.44 | 34.1 | 46.4 |

| Chemical Analysis (%) | Cement |

|---|---|

| CaO | 60.32 |

| SiO2 | 22.34 |

| Al2O3 | 4.55 |

| Fe2O3 | 4.18 |

| MgO | 2.05 |

| SO3 | 2.87 |

| K2O | 0.51 |

| Na2O | 0.41 |

| Loss on ignition | 2.77 |

| Specific gravity | 3.13 |

| Fineness (m2/kg) | 334 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, J.; Zhou, T.; Du, Q.; Li, K.; Jin, L. Research on the Bond Behavior of Preplaced Aggregate Concrete-Filled Steel Tube Columns. Materials 2020, 13, 300. https://doi.org/10.3390/ma13020300

Lv J, Zhou T, Du Q, Li K, Jin L. Research on the Bond Behavior of Preplaced Aggregate Concrete-Filled Steel Tube Columns. Materials. 2020; 13(2):300. https://doi.org/10.3390/ma13020300

Chicago/Turabian StyleLv, Jing, Tianhua Zhou, Qiang Du, Kunlun Li, and Liangwei Jin. 2020. "Research on the Bond Behavior of Preplaced Aggregate Concrete-Filled Steel Tube Columns" Materials 13, no. 2: 300. https://doi.org/10.3390/ma13020300