The Effect of MWCNTs Filler on the Absorbing Properties of OPEFB/PLA Composites Using Microstrip Line at Microwave Frequency

Abstract

:1. Introduction

2. Experimental

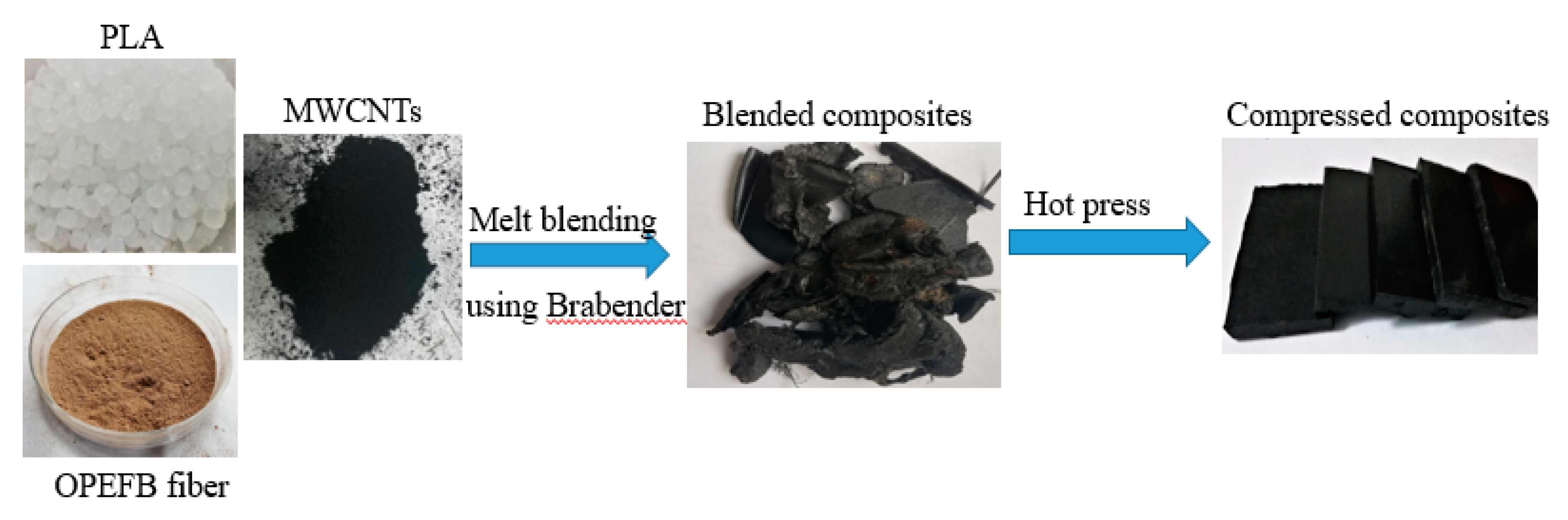

2.1. OPEFB/PLA/MWCNTs Composites Preparation

2.2. Dielectric Properties Measurement

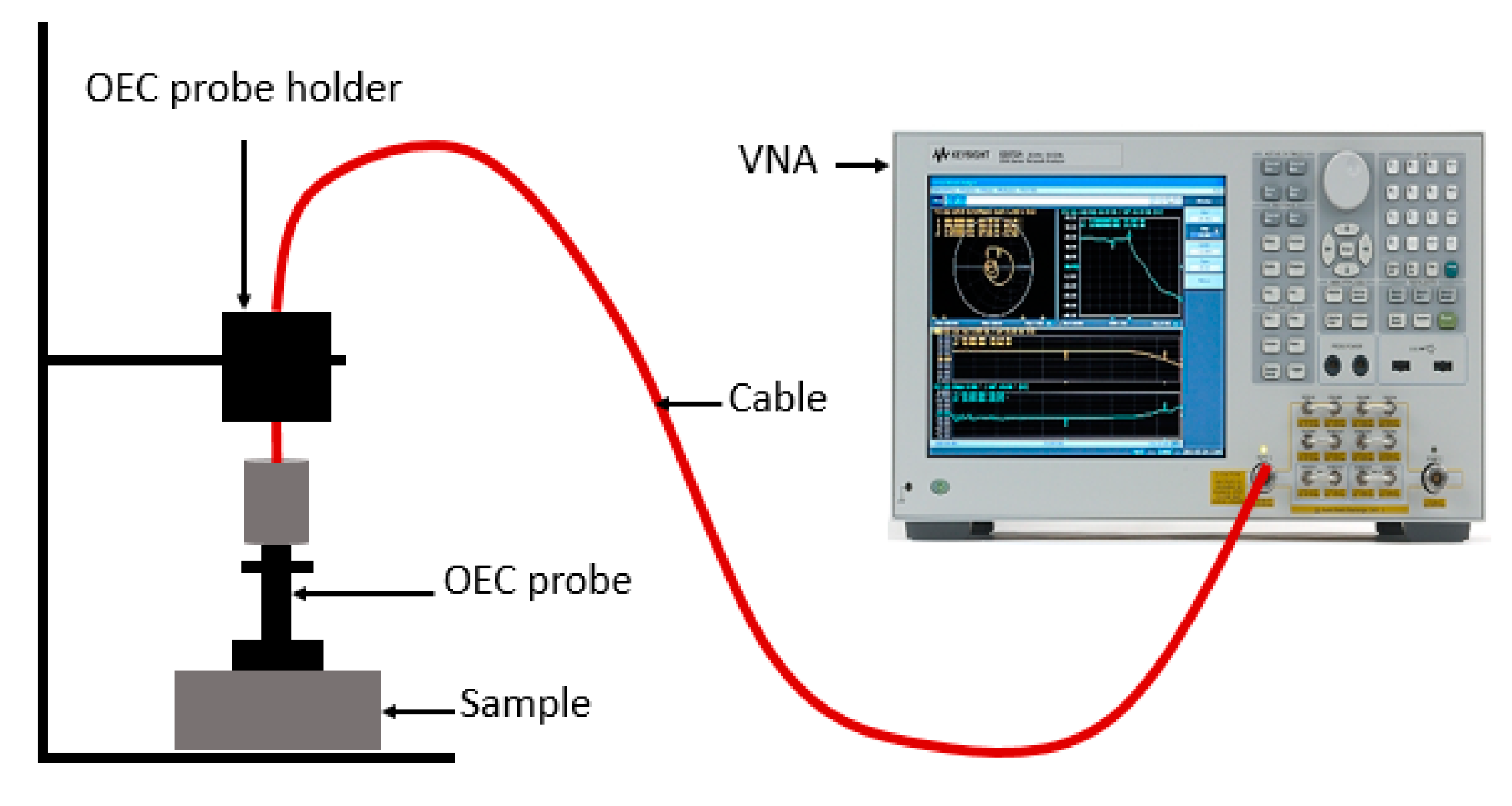

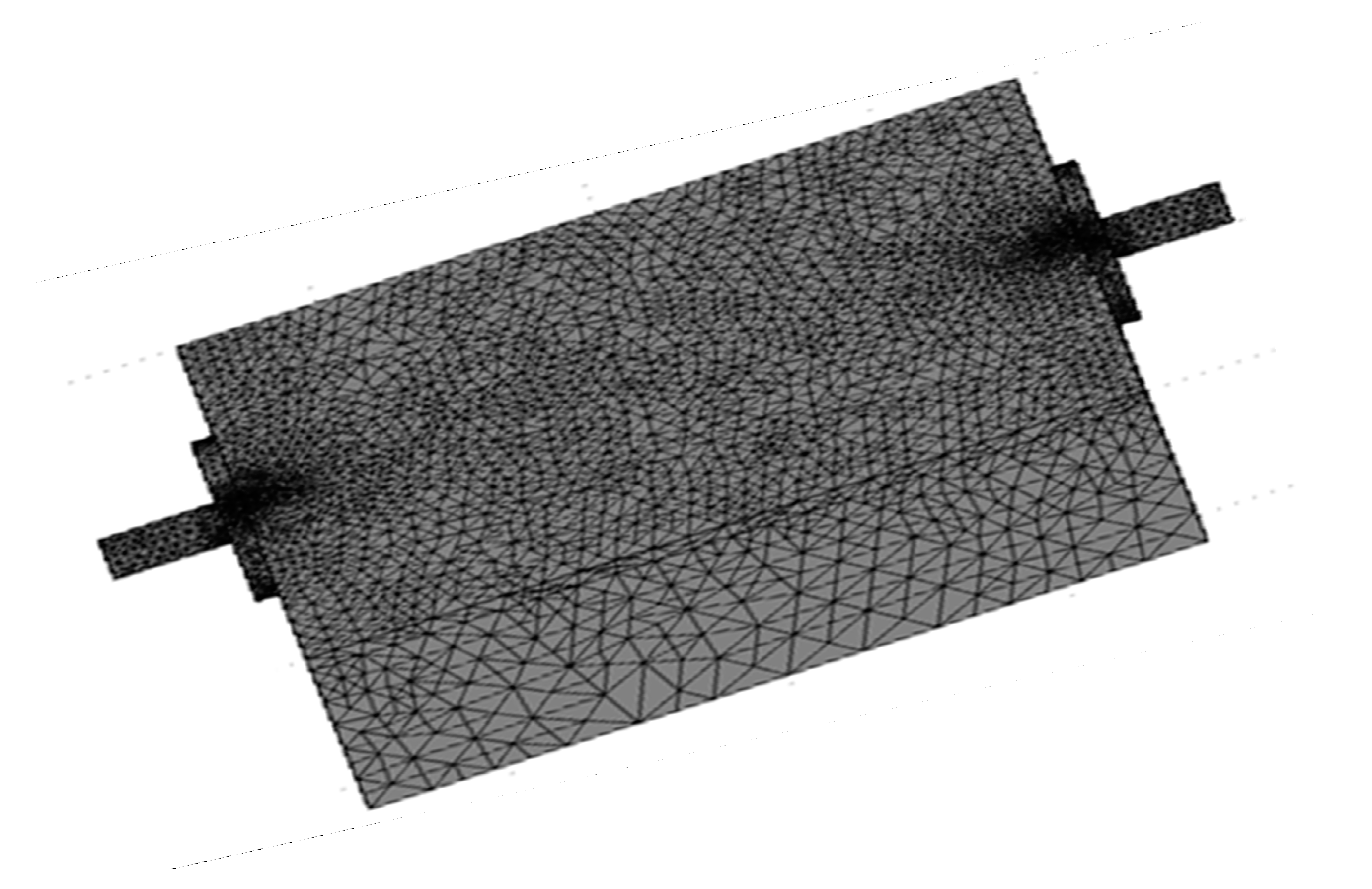

2.3. Measurement of Scattering Parameters (S-Parameters)

2.4. Characterization

3. Results and Discussion

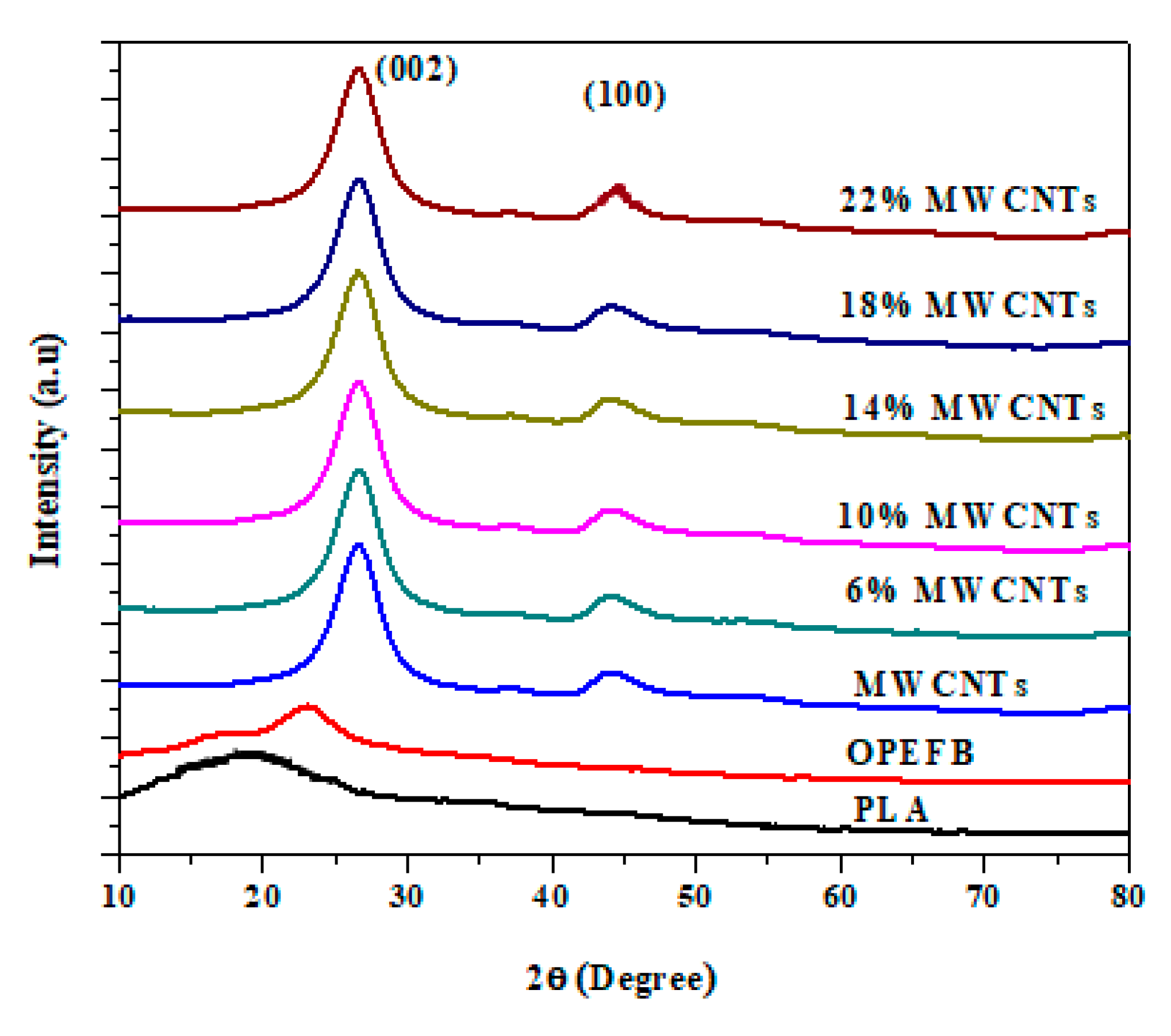

3.1. X-Ray Diffraction (XRD) Analysis

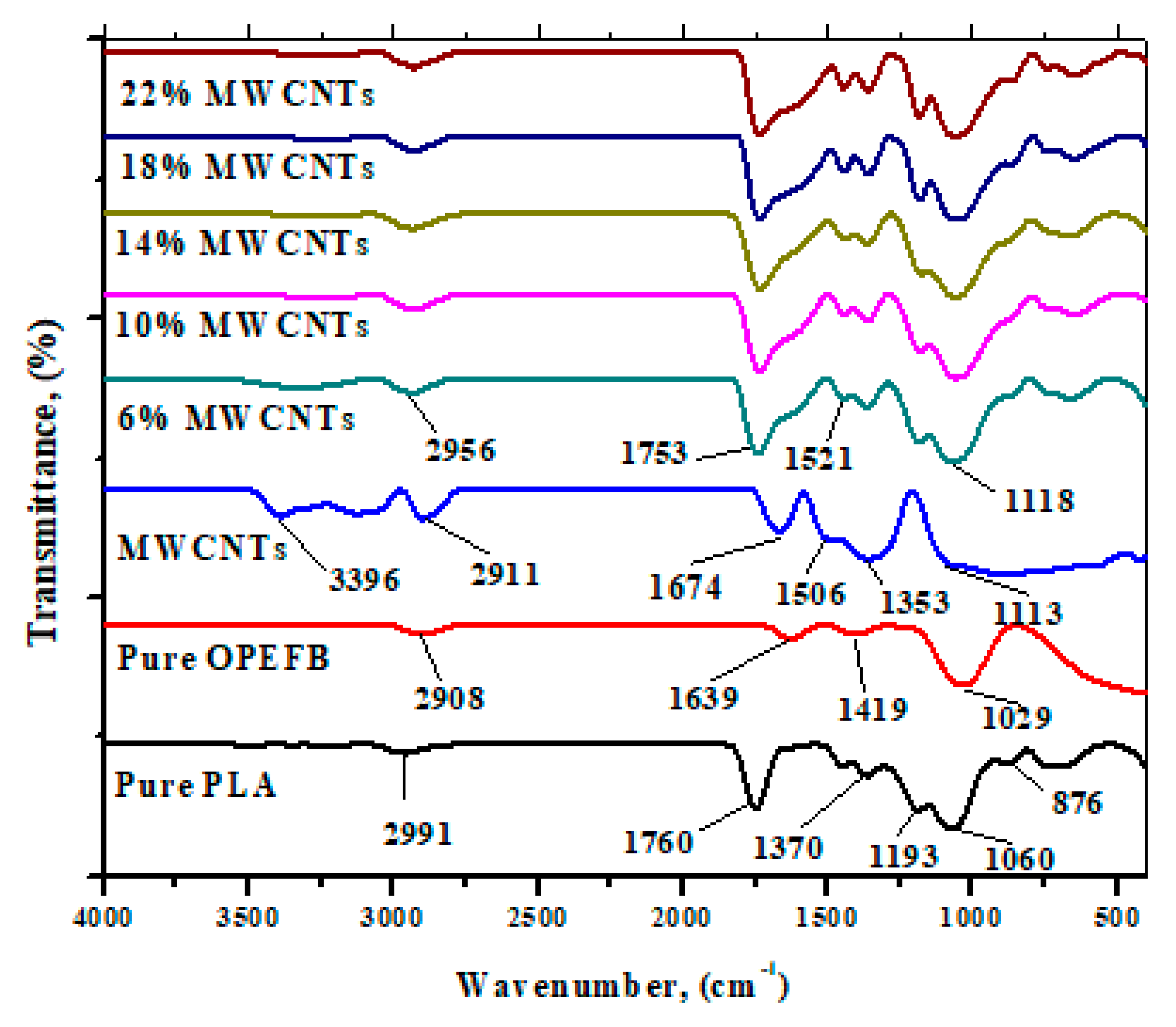

3.2. Fourier Transform Infrared (FTIR) Analysis

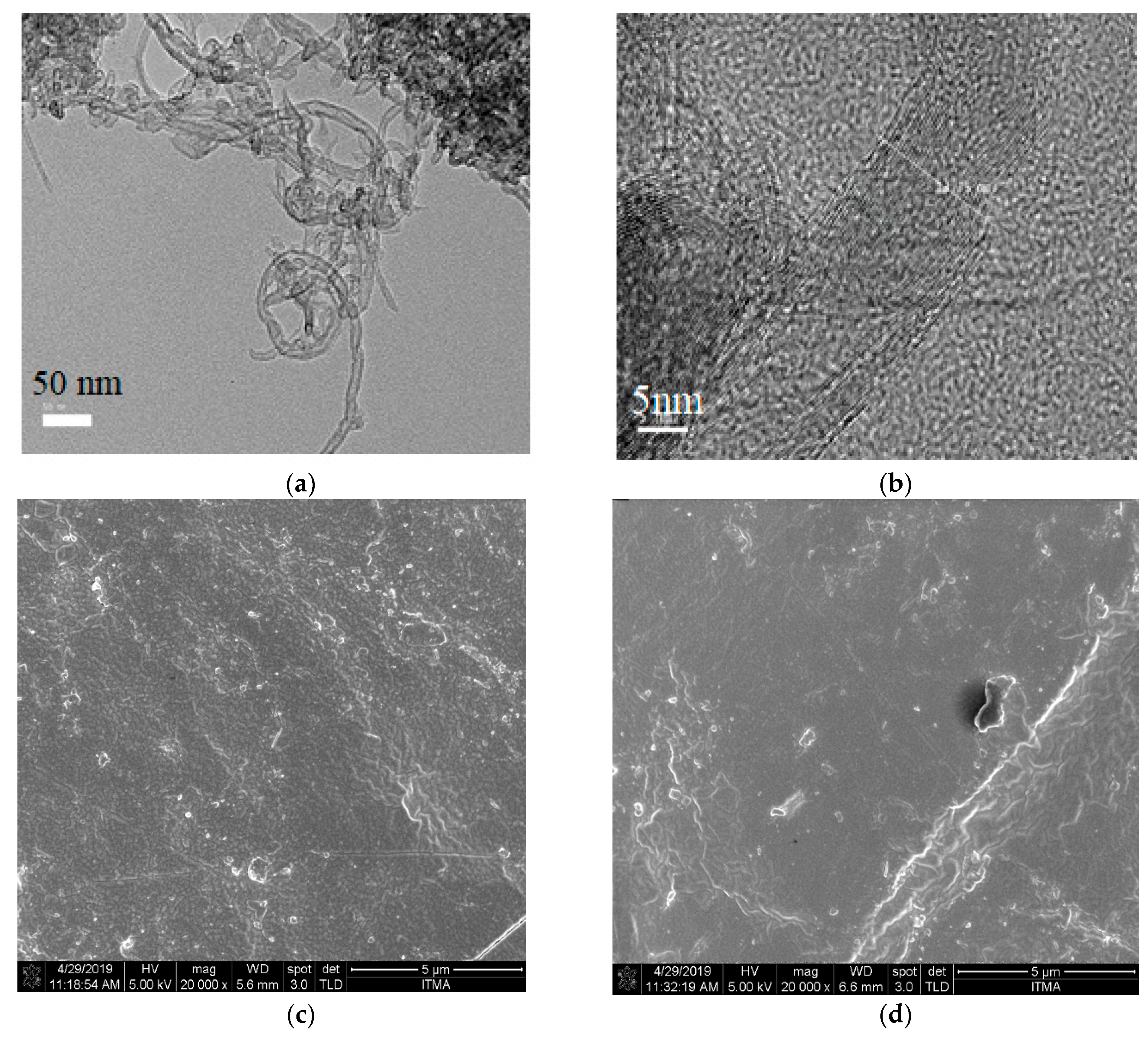

3.3. TEM and FE-SEM Analysis

3.4. Dielectric Properties Analysis

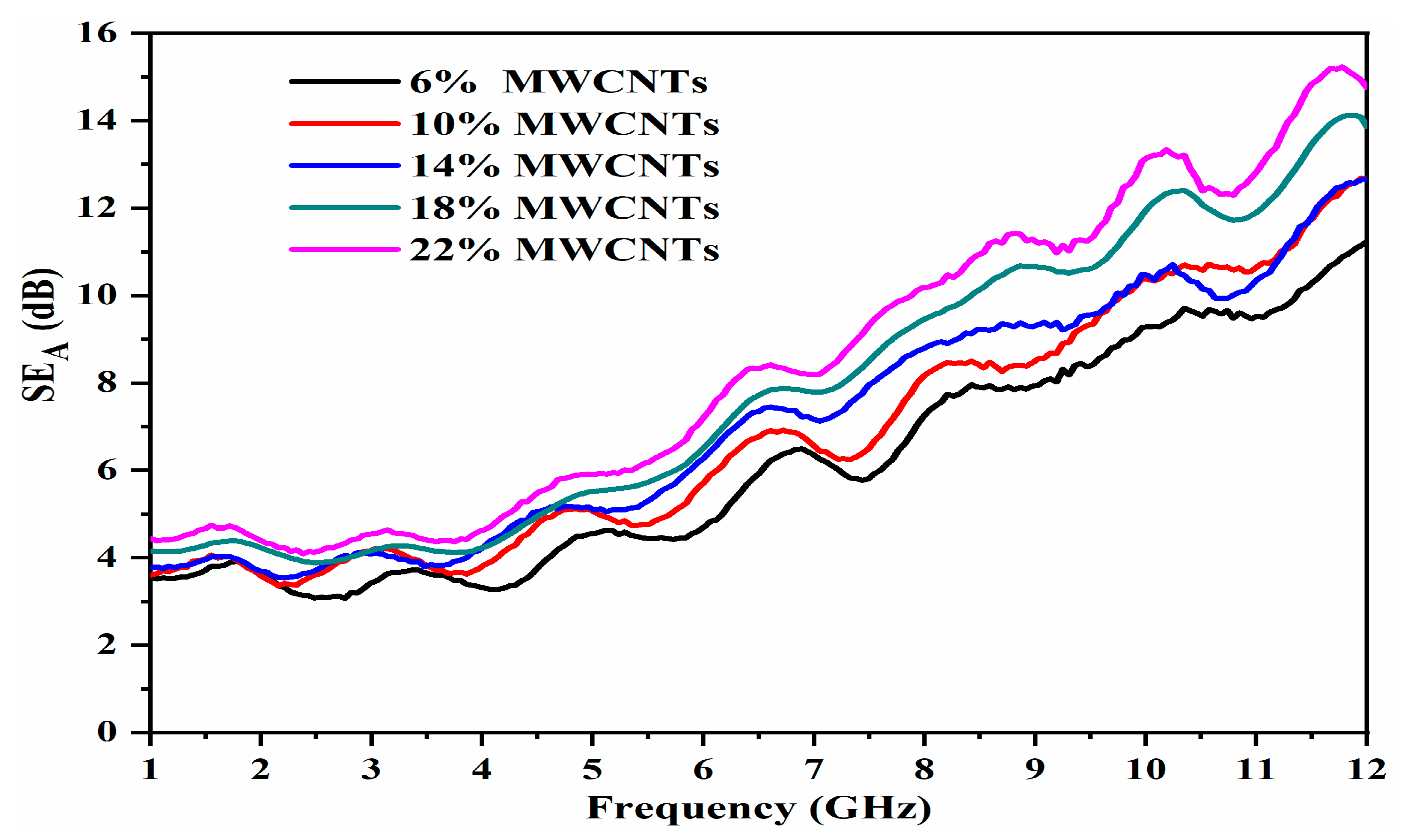

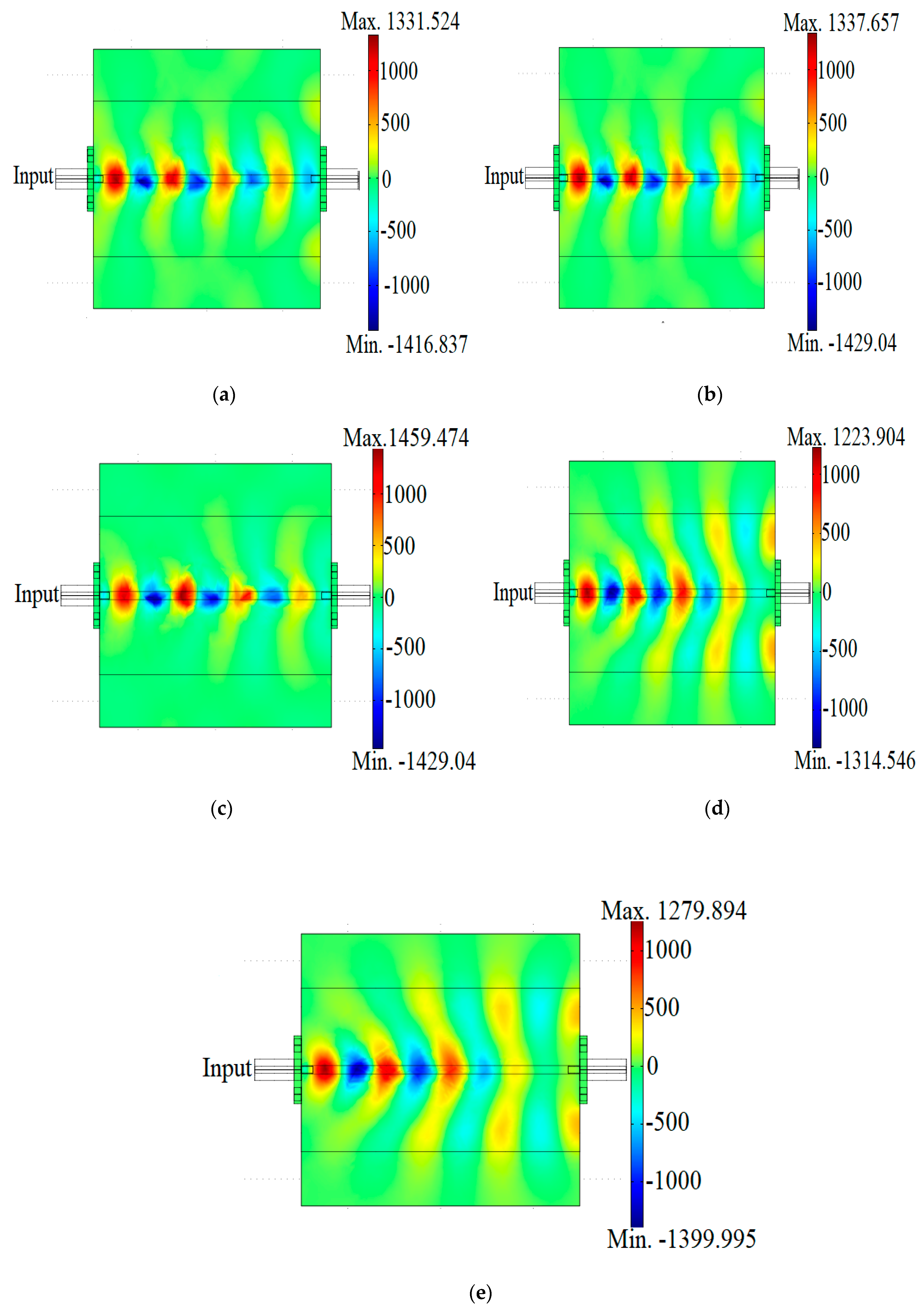

3.5. Microwave-Absorbing Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mishra, R.R.; Sharma, A.K. Microwave-material interaction phenomena: Heating mechanisms, challenges and opportunities in material processing. Compos. Part A Appl. Sci. Manuf. 2016, 81, 78–97. [Google Scholar] [CrossRef]

- Tang, H.; Jian, X.; Wu, B.; Liu, S.; Jiang, Z.; Chen, X.; Lv, W.; He, W.; Tian, W.; Wei, Y.; et al. Fe3C/helical carbon nanotube hybrid: Facile synthesis and spin-induced enhancement in microwave-absorbing properties. Compos. Part B Eng. 2016, 107, 51–58. [Google Scholar] [CrossRef]

- Bibi, M.; Abbas, S.M.; Ahmad, N.; Muhammad, B.; Iqbal, Z.; Rana, U.A.; Khan, S.U.-D. Microwaves absorbing characteristics of metal ferrite/multiwall carbon nanotubes nanocomposites in X-band. Compos. Part B: Eng. 2017, 114, 139–148. [Google Scholar] [CrossRef]

- Zeng, Z.; Chen, M.; Jin, H.; Li, W.; Xue, X.; Zhou, L.; Pei, Y.; Zhang, H.; Zhang, Z. Thin and flexible multi-walled carbon nanotube/waterborne polyurethane composites with high-performance electromagnetic interference shielding. Carbon 2016, 96, 768–777. [Google Scholar] [CrossRef]

- Jia, L.-C.; Yan, D.-X.; Cui, C.-H.; Jiang, X.; Ji, X.; Li, Z.-M. Electrically conductive and electromagnetic interference shielding of polyethylene composites with devisable carbon nanotube networks. J. Mater. Chem. C 2015, 3, 9369–9378. [Google Scholar] [CrossRef]

- Ravindren, R.; Mondal, S.; Nath, K.; Das, N.C. Synergistic effect of double percolated co-supportive MWCNT-CB conductive network for high-performance EMI shielding application. Polym. Adv. Technol. 2019, 30, 1506–1517. [Google Scholar] [CrossRef]

- Gahlout, P.; Choudhary, V. EMI shielding response of polypyrrole-MWCNT/polyurethane composites. Synth. Met. 2020, 266, 116414. [Google Scholar] [CrossRef]

- Nam, Y.-W.; Choi, J.-H.; Huh, J.-M.; Lee, W.-J.; Kim, C.-G. Thin broadband microwave absorber with conductive and magnetic materials coated on a glass fabric. J. Compos. Mater. 2017, 52, 1413–1420. [Google Scholar] [CrossRef]

- Nagasree, P.S.; Ramji, K.; Murthy, K.K.; Naidu, M.K.; Haritha, T. Fibre Reinforced Polymer (FRP) Nanocomposites for Radar Absorption Application in the X-Band. In Advances in Design, Simulation and Manufacturing III; Springer: Singapore, 2020; pp. 409–418. [Google Scholar]

- Wang, G.; Wang, L.; Mark, L.H.; Shaayegan, V.; Wang, G.; Li, H.; Zhao, G.; Park, C.B. Ultralow-Threshold and Lightweight Biodegradable Porous PLA/MWCNT with Segregated Conductive Networks for High-Performance Thermal Insulation and Electromagnetic Interference Shielding Applications. ACS Appl. Mater. Interfaces 2017, 10, 1195–1203. [Google Scholar] [CrossRef]

- Chaudhary, A.; Kumar, R.; Teotia, S.; Dhawan, S.K.; Dhakate, S.R.; Kumari, S. Integration of MCMBs/MWCNTs with Fe3 O4 in a flexible and lightweight composite paper for promising EMI shielding applications. J. Mater. Chem. C 2017, 5, 322–332. [Google Scholar] [CrossRef]

- Abdalhadi, D.M.; Abbas, Z.; Ahmad, A.F.; Matori, K.; Esa, F. Controlling the Properties of OPEFB/PLA Polymer Composite by Using Fe2O3 for Microwave Applications. Fibers Polym. 2018, 19, 1513–1521. [Google Scholar] [CrossRef]

- Abdul, P.M.; Jahim, J.M.; Harun, S.; Markom, M.; Lutpi, N.A.; Hassan, O.; Balan, V.; Dale, B.E.; Nor, M.T.M. Effects of changes in chemical and structural characteristics of ammonia fiber expansion (AFEX) pretreated oil palm empty fruit bunch fiber on enzymatic saccharification and fermentability for biohydrogen. Bioresour. Technol. 2016, 211, 200–208. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, A.F.; Abbas, Z.; Obaiys, S.J.; Abdalhadi, D.M. Improvement of dielectric, magnetic and thermal properties of OPEFB fiber-polycaprolactone composite by adding Ni-Zn ferrite. Polymers 2017, 9, 12. [Google Scholar] [CrossRef] [Green Version]

- Dike, A.S. Improvement of mechanical and physical performance of poly (lactic acid) biocomposites by application of surface silanization for huntite-hydromagnesite mineral. J. Thermoplast. Compos. Mater. 2020, 0892705720930776. [Google Scholar] [CrossRef]

- Yan, L.; Kasal, B.; Huang, L. A review of recent research on the use of cellulosic fibers, their fiber fabric reinforced cementitious, geo-polymer and polymer composites in civil engineering. Compos. Part B Eng. 2016, 92, 94–132. [Google Scholar] [CrossRef]

- Kjelgard, K.G.; Wisland, D.T.; Lande, T.S. 3D Printed Wideband Microwave Absorbers using Composite Graphite/PLA Filament. In Proceedings of the 2018 48th European Microwave Conference (EuMC), Madrid, Spain, 23–27 September 2018; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2018; pp. 859–862. [Google Scholar]

- Bychanok, D.; Angelova, P.; Paddubskaya, A.; Meisak, D.; Shashkova, L.; Demidenko, M.; Plyushch, A.; Ivanov, E.; Krastev, R.; Kotsilkova, R.; et al. Terahertz absorption in graphite nanoplatelets/polylactic acid composites. J. Phys. D Appl. Phys. 2018, 51, 145307. [Google Scholar] [CrossRef]

- Mensah, E.E.; Abbas, Z.; Azis, R.S.; Khamis, A. Enhancement of Complex Permittivity and Attenuation Properties of Recycled Hematite (α-Fe2O3) Using Nanoparticles Prepared via Ball Milling Technique. Materials 2019, 12, 1696. [Google Scholar] [CrossRef] [Green Version]

- Challabi, A.J.H.; Chieng, B.W.; Ibrahim, N.A.; Ariffin, H.; Zainuddin, N. Effect of Superheated Steam Treatment on the Mechanical Properties and Dimensional Stability of PALF/PLA Biocomposite. Polymers 2019, 11, 482. [Google Scholar] [CrossRef] [Green Version]

- Harun, N.A.F.; Baharuddin, A.S.; Zainudin, M.H.M.; Bahrin, E.K.; Naim, M.N.; Zakaria, R. Cellulase Production from Treated Oil Palm Empty Fruit Bunch Degradation by Locally Isolated Thermobifida fusca. Bioresources 2012, 8, 676–687. [Google Scholar]

- Ali, E.; Yong, C.K.; Ching, Y.C.; Chuah, C.H.; Liou, N.-S. Effect of Single and Double Stage Chemically Treated Kenaf Fibers on Mechanical Properties of Polyvinyl Alcohol Film. Bioresources 2014, 10, 822–838. [Google Scholar] [CrossRef] [Green Version]

- Huang, L.; Liu, X.; Yu, R. Enhanced microwave absorption properties of rod-shaped Fe2O3/Fe3O4/MWCNTs composites. Prog. Nat. Sci. Mater. Int. 2018, 28, 288–295. [Google Scholar] [CrossRef]

- Maleknejad, Z.; Gheisari, K.; Raouf, A.H. Structure, Microstructure, Magnetic, Electromagnetic, and Dielectric Properties of Nanostructured Mn–Zn Ferrite Synthesized by Microwave-Induced Urea–Nitrate Process. J. Supercond. Nov. Magn. 2016, 29, 2523–2534. [Google Scholar] [CrossRef]

- Qing, Y.; Wang, X.; Zhou, Y.; Huang, Z.; Luo, F.; Zhou, W. Enhanced microwave absorption of multi-walled carbon nanotubes/epoxy composites incorporated with ceramic particles. Compos. Sci. Technol. 2014, 102, 161–168. [Google Scholar] [CrossRef]

- Mensah, E.E.; Abbas, Z.; Azis, R.S.; Ibrahim, N.A.; Khamis, A. Complex Permittivity and Microwave Absorption Properties of OPEFB Fiber-Polycaprolactone Composites Filled with Recycled Hematite (α-Fe2O3) Nanoparticles. Polymers 2019, 11, 918. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gao, W.; Zheng, Y.; Shen, J.; Guo, S. Electrical Properties of Polypropylene-Based Composites Controlled by Multilayered Distribution of Conductive Particles. ACS Appl. Mater. Interfaces 2015, 7, 1541–1549. [Google Scholar] [CrossRef]

| OPEFB | PLA | MWCNTs | Total Mass (g) | |||

|---|---|---|---|---|---|---|

| Weight (%) | Mass (g) | Weight (%) | Mass (g) | Weight (%) | Mass (g) | |

| 28.2 | 14.1 | 65.8 | 32.9 | 6 | 3 | 50.0 |

| 27.0 | 13.5 | 63.0 | 31.5 | 10 | 5 | 50.0 |

| 25.8 | 12.9 | 60.2 | 30.1 | 14 | 7 | 50.0 |

| 24.6 | 12.3 | 57.4 | 38.7 | 18 | 9 | 50.0 |

| 23.4 | 11.7 | 54.6 | 27.3 | 22 | 11 | 50.0 |

| MWCNTs (wt.%) | 8 GHz | 9.5 GHz | 10.5 GHz | 11.7 GHz |

|---|---|---|---|---|

| 6 | 7.4 | 8.4 | 9.5 | 10.9 |

| 10 | 8.2 | 9.3 | 10.6 | 12.4 |

| 14 | 8.8 | 9.5 | 10.1 | 12.5 |

| 18 | 9.5 | 10.6 | 12.1 | 14.1 |

| 22 | 10.2 | 11.3 | 12.3 | 15.2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ibrahim Lakin, I.; Abbas, Z.; Azis, R.S.; Ibrahim, N.A.; Abd Rahman, M.A. The Effect of MWCNTs Filler on the Absorbing Properties of OPEFB/PLA Composites Using Microstrip Line at Microwave Frequency. Materials 2020, 13, 4581. https://doi.org/10.3390/ma13204581

Ibrahim Lakin I, Abbas Z, Azis RS, Ibrahim NA, Abd Rahman MA. The Effect of MWCNTs Filler on the Absorbing Properties of OPEFB/PLA Composites Using Microstrip Line at Microwave Frequency. Materials. 2020; 13(20):4581. https://doi.org/10.3390/ma13204581

Chicago/Turabian StyleIbrahim Lakin, Ismail, Zulkifly Abbas, Rabaah Syahidah Azis, Nor Azowa Ibrahim, and Mohd Amiruddin Abd Rahman. 2020. "The Effect of MWCNTs Filler on the Absorbing Properties of OPEFB/PLA Composites Using Microstrip Line at Microwave Frequency" Materials 13, no. 20: 4581. https://doi.org/10.3390/ma13204581