Monotonic and Fatigue Behavior of EBM Manufactured Ti-6Al-4V Solid Samples: Experimental, Analytical and Numerical Investigations

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Design and Manufacturing

2.2. Experimental Set-Up

2.3. Analytical and Numerical Models

2.3.1. Analytical Monotonic Stress-Strain Relation

2.3.2. Numerical Damage Model

2.3.3. Cyclic Behavior

3. Results and Discussion

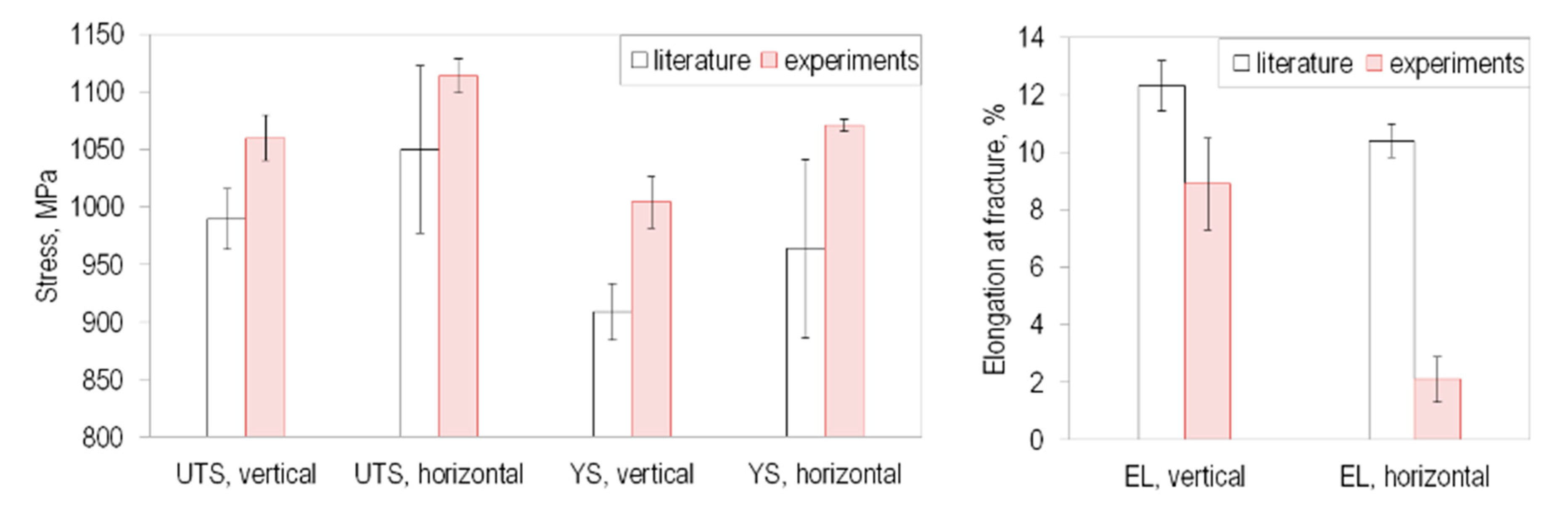

3.1. Tensile Properties

3.1.1. Stress-Strain Characteristics

3.1.2. Fracture Surfaces

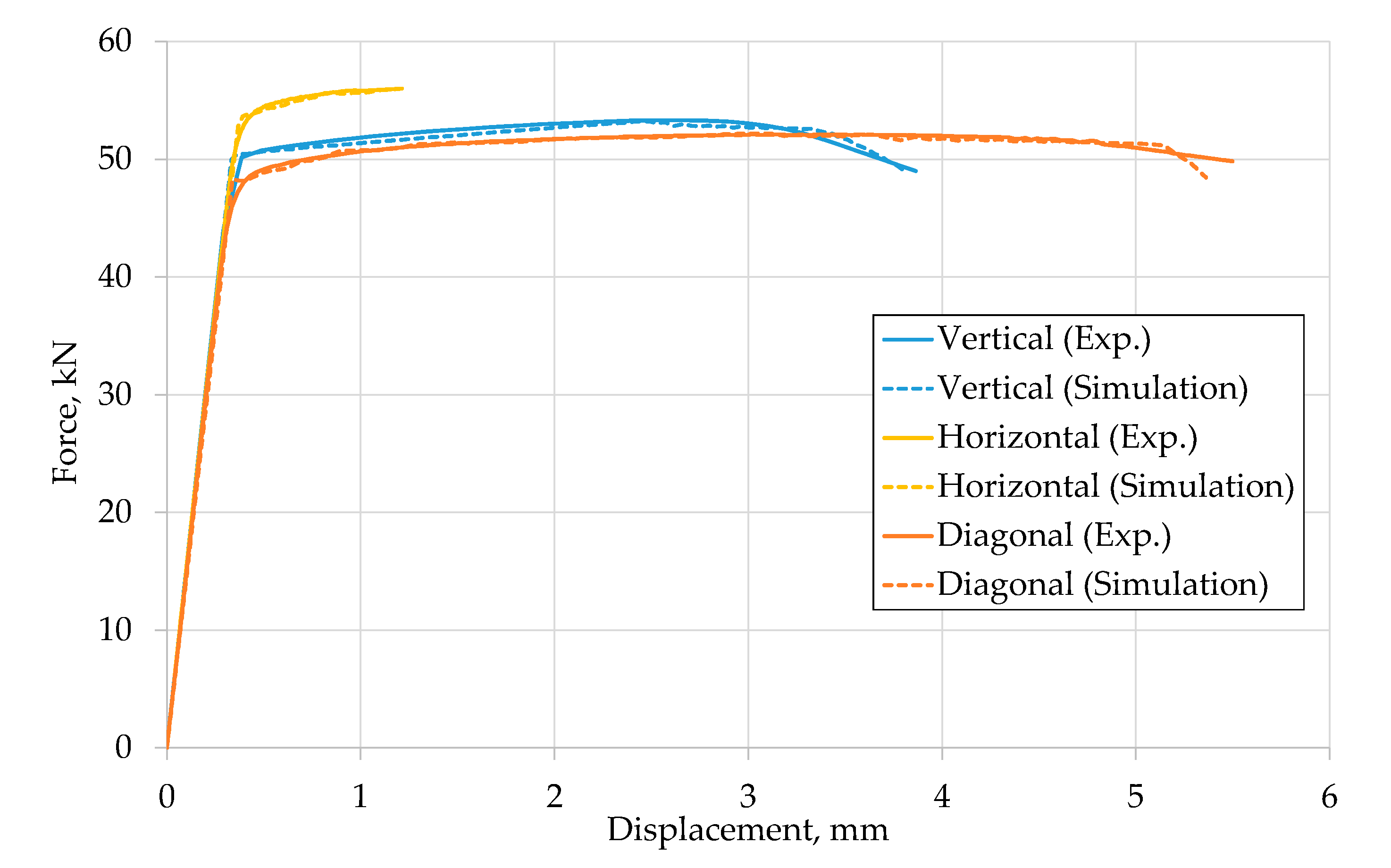

3.1.3. Damage and Failure Model

3.2. Fatigue Performance

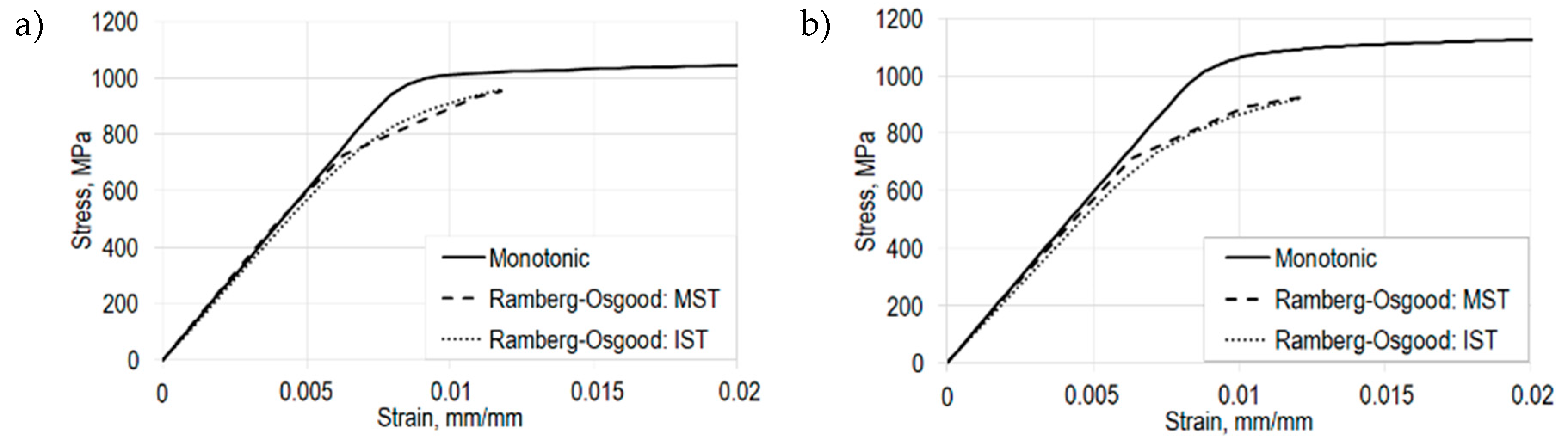

3.2.1. Cyclic Stress-Strain Curves

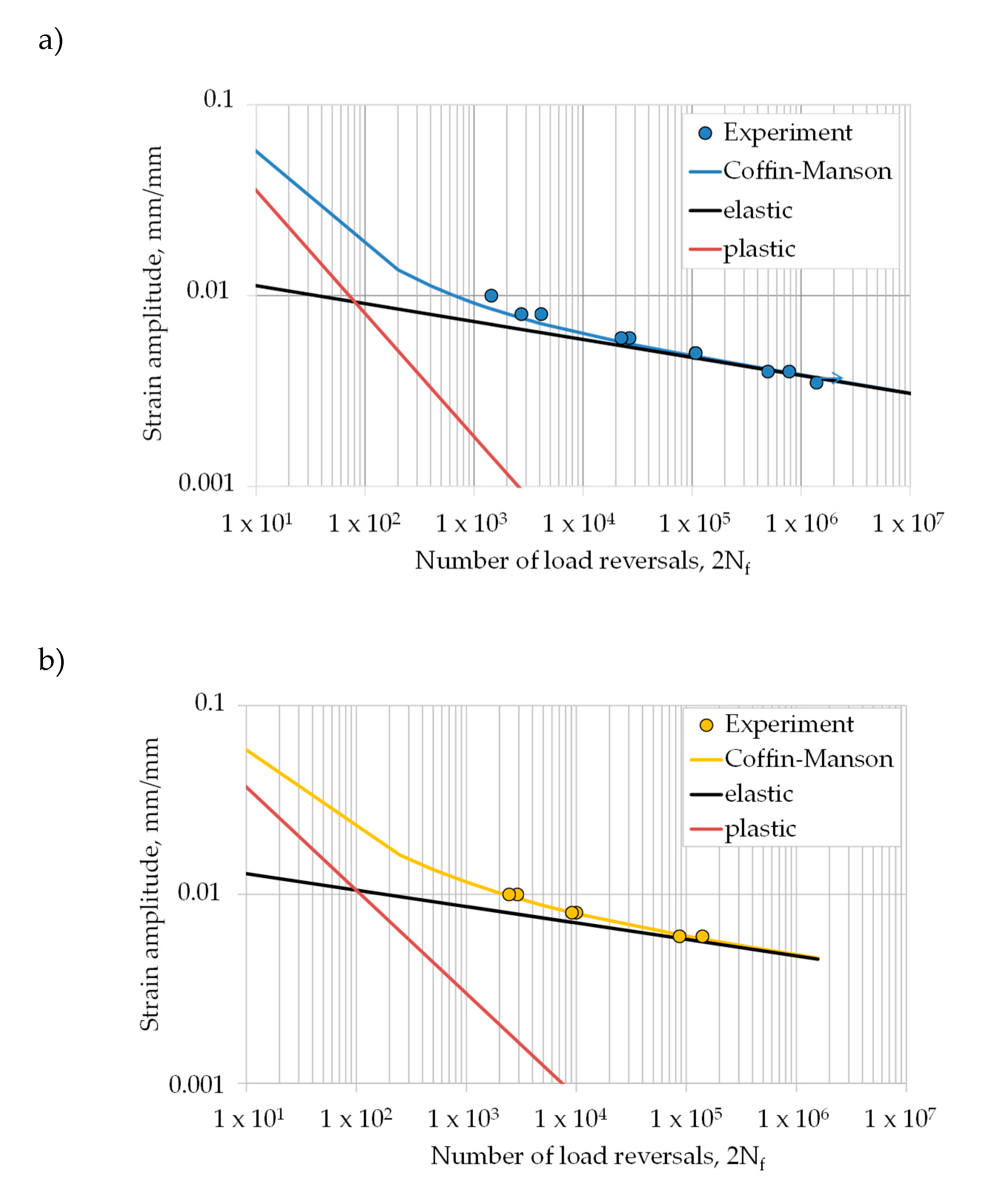

3.2.2. Strain-Life Curves

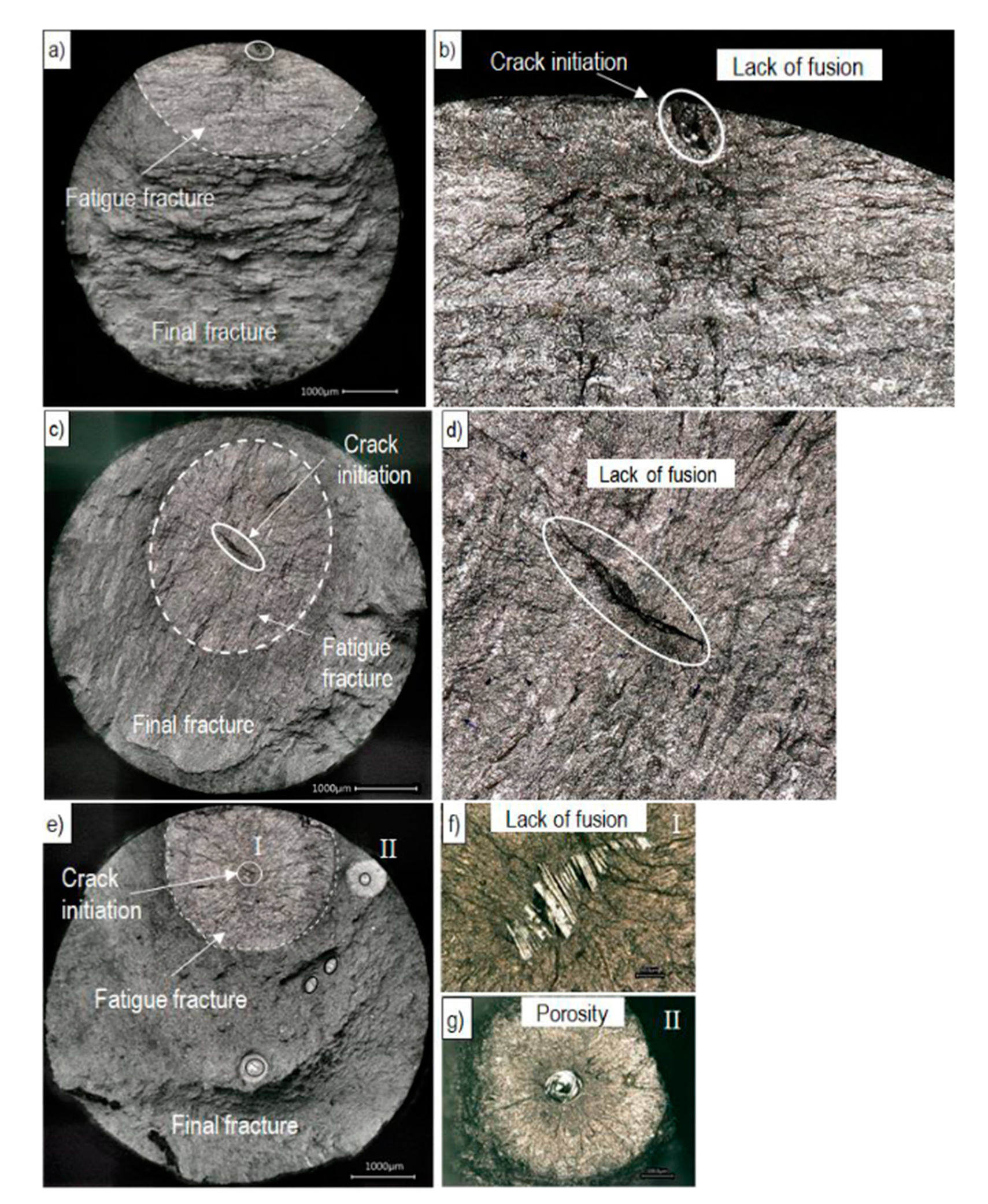

3.2.3. Fractography Analysis

4. Summary and Conclusions

- The comparison of the experimental monotonic tensile test results with literature data shows that many influencing factors must be taken into account when evaluating the results. Even if the trend of the influence of the build direction is qualitatively verified, the quantitative values are influenced individually by each process. It is absolutely necessary to consider process conditions, e.g., process machine, process parameters and build direction.

- For the description of the material behavior in the case of large plastic deformations, e.g., in damage models, the build direction must be taken into account, since it has a significant influence on the ductility.

- The Johnson–Cook failure model, including the damage initiation and damage evolution law, is a suitable model to describe the EBM Ti-6Al-4V material behavior until failure.

- While the defect size influences the elongation at fracture, it is not solely responsible for the elongation. For example, the build direction and the resulting size, shape and location of defects in relation to the load direction should also be considered.

- To determine the cyclic stress–strain curve, multiple step tests and incremental step tests were performed. It could be observed that plasticization played an important role.

- The strain-life curves of EBM Ti-6Al-4V can be described using the Coffin–Manson approach. The results show that a horizontal build direction leads to longer lifetimes compared to the vertical build direction.

- In addition, Murakami´s approach was adapted to the strain-life approach, taking the defect size and position into account. These results suggest that the defects are the main influencing factor on the fatigue lifetime, rather than changes in the bulk material behavior.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Singh, R.; Lee, P.D.; Dashwood, R.J.; Lindley, T.C. Titanium foams for biomedical applications: A review. Mater. Technol. 2010, 25, 127–136. [Google Scholar] [CrossRef]

- Avila, J.; Bose, S.; Bandyopadhyay, A. Additive Manufacturing of Titanium and Titanium Alloys for Biomedical Applications. In Titanium in Medical and Dental Applications; Elsevier: Amsterdam, The Netherlands, 2018; pp. 325–343. [Google Scholar]

- Yuan, L.; Ding, S.; Wen, C. Additive manufacturing technology for porous metal implant applications and triple minimal surface structures: A review. Bioact. Mater. 2019, 4, 56–70. [Google Scholar] [CrossRef]

- Chern, A.H.; Nandwana, P.; Yuan, T.; Kirka, M.M.; Dehoff, R.; Liaw, P.K.; Duty, C. A review on the fatigue behavior of Ti-6Al-4V fabricated by electron beam melting additive manufacturing. Int. J. Fatigue 2019, 119, 173–184. [Google Scholar] [CrossRef]

- Fousová, M.; Vojtěch, D.; Doubrava, K.; Daniel, M.; Lin, C.-F. Influence of Inherent Surface and Internal Defects on Mechanical Properties of Additively Manufactured Ti6Al4V Alloy: Comparison between Selective Laser Melting and Electron Beam Melting. Materials 2018, 11, 537. [Google Scholar] [CrossRef] [Green Version]

- Greitemeier, D.; Palm, F.; Syassen, F.; Melz, T. Fatigue performance of additive manufactured TiAl6V4 using electron and laser beam melting. Int. J. Fatigue 2017, 94, 211–217. [Google Scholar] [CrossRef]

- Günther, J.; Leuders, S.; Tröster, T.; Weidner, A.; Biermann, H.; Niendorf, T. Fatigue Behavior of Ti-6al-4v Additively Manufactured by Selective Laser and Electron Beam Melting—On The Impact of the Chemical Composition, Process-Induced Porosity and Surface Roughness. In DVM-report vol. 2 (2017); pp. 89–98. Available online: https://www.researchgate.net/profile/Johannes_Guenther4/publication/321309470_Fatigue_behavior_of_Ti-6Al-4V_additively_manufactured_by_selective_laser_and_electron_beam_melting_-_On_the_impact_of_the_chemical_composition_process-induced_porosity_and_surface_roughness/links/5a2a4abc0f7e9b63e535696f/Fatigue-behavior-of-Ti-6Al-4V-additively-manufactured-by-selective-laser-and-electron-beam-melting-On-the-impact-of-the-chemical-composition-process-induced-porosity-and-surface-roughness.pdf (accessed on 12 August 2020).

- Hrabe, N.; Gnäupel-Herold, T.; Quinn, T. Fatigue properties of a titanium alloy (Ti–6Al–4V) fabricated via electron beam melting (EBM): Effects of internal defects and residual stress. Int. J. Fatigue 2017, 94, 202–210. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Molaei, R.; Fatemi, A.; Sanaei, N.; Pegues, J.; Shamsaei, N.; Shao, S.; Li, P.; Warner, D.; Phan, N. Fatigue of additive manufactured Ti-6Al-4V, Part II: The relationship between microstructure, material cyclic properties, and component performance. Int. J. Fatigue 2020, 132, 105363. [Google Scholar] [CrossRef]

- Chern, A.H.; Nandwana, P.; McDaniels, R.; Dehoff, R.R.; Liaw, P.K.; Tryon, R.; Duty, C.E. Build orientation, surface roughness, and scan path influence on the microstructure, mechanical properties, and flexural fatigue behavior of Ti–6Al–4V fabricated by electron beam melting. Mater. Sci. Eng. A 2020, 772, 138740. [Google Scholar] [CrossRef]

- Hrabe, N.; Quinn, T. Effects of processing on microstructure and mechanical properties of a titanium alloy (Ti–6Al–4V) fabricated using electron beam melting (EBM), part 1: Distance from build plate and part size. Mater. Sci. Eng. A 2013, 573, 271–277. [Google Scholar] [CrossRef]

- Seifi, M.; Dahar, M.; Aman, R.; Harrysson, O.; Beuth, J.; Lewandowski, J.J. Evaluation of Orientation Dependence of Fracture Toughness and Fatigue Crack Propagation Behavior of As-Deposited ARCAM EBM Ti-6Al-4V. JOM 2015, 67, 597–607. [Google Scholar] [CrossRef]

- Kahlin, M.; Ansell, H.; Moverare, J. Fatigue behaviour of additive manufactured Ti6Al4V, with as-built surfaces, exposed to variable amplitude loading. Int. J. Fatigue 2017, 103, 353–362. [Google Scholar] [CrossRef] [Green Version]

- Zhai, Y.; Galarraga, H.; Lados, D.A. Microstructure, static properties, and fatigue crack growth mechanisms in Ti-6Al-4V fabricated by additive manufacturing: LENS and EBM. Eng. Fail. Anal. 2016, 69, 3–14. [Google Scholar] [CrossRef]

- Günther, J.; Krewerth, D.; Lippmann, T.; Leuders, S.; Tröster, T.; Weidner, A.; Biermann, H.; Niendorf, T. Fatigue life of additively manufactured Ti–6Al–4V in the very high cycle fatigue regime. Int. J. Fatigue 2017, 94, 236–245. [Google Scholar] [CrossRef]

- Chastand, V.; Quaegebeur, P.; Maia, W.; Charkaluk, E. Comparative study of fatigue properties of Ti-6Al-4V specimens built by electron beam melting (EBM) and selective laser melting (SLM). Mater. Charact. 2018, 143, 76–81. [Google Scholar] [CrossRef]

- Seifi, M.; Salem, A.; Satko, D.; Shaffer, J.; Lewandowski, J.J. Defect distribution and microstructure heterogeneity effects on fracture resistance and fatigue behavior of EBM Ti–6Al–4V. Int. J. Fatigue 2017, 94, 263–287. [Google Scholar] [CrossRef]

- Fatemi, A.; Molaei, R.; Simsiriwong, J.; Sanaei, N.; Pegues, J.; Torries, B.; Phan, N.; Shamsaei, N. Fatigue behaviour of additive manufactured materials: An overview of some recent experimental studies on Ti-6Al-4V considering various processing and loading direction effects. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 991–1009. [Google Scholar] [CrossRef]

- Persenot, T.; Burr, A.; Martin, G.; Buffiere, J.-Y.; Dendievel, R.; Maire, E. Effect of build orientation on the fatigue properties of as-built Electron Beam Melted Ti-6Al-4V alloy. Int. J. Fatigue 2019, 118, 65–76. [Google Scholar] [CrossRef]

- Benedetti, M.; Fontanari, V.; Bandini, M.; Zanini, F.; Carmignato, S. Low- and high-cycle fatigue resistance of Ti-6Al-4V ELI additively manufactured via selective laser melting: Mean stress and defect sensitivity. Int. J. Fatigue 2018, 107, 96–109. [Google Scholar] [CrossRef]

- Romano, S.; Brückner-Foit, A.; Brandão, A.; Gumpinger, J.; Ghidini, T.; Beretta, S. Fatigue properties of AlSi10Mg obtained by additive manufacturing: Defect-based modelling and prediction of fatigue strength. Eng. Fract. Mech. 2018, 187, 165–189. [Google Scholar] [CrossRef]

- Zhang, J.; Fatemi, A. Surface roughness effect on multiaxial fatigue behavior of additive manufactured metals and its modeling. Theor. Appl. Fract. Mech. 2019, 103, 102260. [Google Scholar] [CrossRef]

- Debroy, T.; Wei, H.; Zuback, J.; Mukherjee, T.; Elmer, J.; Milewski, J.; Beese, A.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Svensson, M. Material properties of ebm-manufactured ti6al4v & ti6al4v eli under raw and hip conditions; Arcam AB: Mölnlycke, Sweden, 2009. [Google Scholar]

- Rafi, H.K.; Karthik, N.V.; Gong, H.; Starr, T.L.; Stucker, B.E. Microstructures and Mechanical Properties of Ti6Al4V Parts Fabricated by Selective Laser Melting and Electron Beam Melting. J. Mater. Eng. Perform. 2013, 22, 3872–3883. [Google Scholar] [CrossRef]

- Zhao, X.; Li, S.; Zhang, M.; Liu, Y.; Sercombe, T.B.; Wang, S.; Hao, Y.; Yang, R.; Murr, L.E. Comparison of the microstructures and mechanical properties of Ti–6Al–4V fabricated by selective laser melting and electron beam melting. Mater. Des. 2016, 95, 21–31. [Google Scholar] [CrossRef]

- Arrieta, E.; Haque, M.; Mireles, J.; Stewart, C.M.; Carrasco, C.; Wicker, R.B. Mechanical Behavior of Differently Oriented Electron Beam Melting Ti–6Al–4V Components Using Digital Image Correlation. J. Eng. Mater. Technol. 2018, 141, 011004. [Google Scholar] [CrossRef] [Green Version]

- Gonzalez, F.J.Q.; Nuño, N. Finite element modeling of manufacturing irregularities of porous materials. Biomater. Biomech. Bioeng. 2016, 3, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Xiao, L.; Song, W.; Wang, C.; Tang, H.; Fan, Q.; Liu, N.; Wang, J. Mechanical properties of open-cell rhombic dodecahedron titanium alloy lattice structure manufactured using electron beam melting under dynamic loading. Int. J. Impact Eng. 2017, 100, 75–89. [Google Scholar] [CrossRef]

- Metallic materials—Tensile testing—Part 1: Method of test at room temperature (ISO 6892-1:2016); BSI Standards Publication: London, UK, 2016; Available online: https://www.3ppars.com/WebsiteImages/download/5249022041.PDF (accessed on 16 October 2016).

- Standard Test Method for Strain-Controlled Fatigue Testing (E606/E606M); ASTM International: West Conshohocken, PA, USA, 2012.

- Datasheet, Ti6Al4V ELI Titanium Alloy; Arcam AB: Mölndal, Sweden; Available online: https://de.scribd.com/document/437741282/Arcam-Ti6Al4V-ELI-Titanium-Alloy-pdf (accessed on 5 February 2020).

- Mabrouki, T.; Girardin, F.; Asad, M.; Rigal, J.-F. Numerical and experimental study of dry cutting for an aeronautic aluminium alloy (A2024-T351). Int. J. Mach. Tools Manuf. 2008, 48, 1187–1197. [Google Scholar] [CrossRef]

- Abaqus Abaqus 6.14: Analysis User’s Guide. Available online: http://abaqus.software.polimi.it/v6.14/books/usb/default.htm (accessed on 1 March 2018).

- Capelli, C. Failure Modeling of Titanium 6Al-4V and Aluminum 2024-T3 With the Johnson-Cook Material Model; National Technical Information Service (NTIS): Springfield, VA, USA, 2003. Available online: http://www.tc.faa.gov/its/worldpac/techrpt/ar03-57.pdf (accessed on 6 March 2018).

- Kadkhodapour, J.; Montazerian, H.; Darabi, A.C.; Zargarian, A.; Schmauder, S. The relationships between deformation mechanisms and mechanical properties of additively manufactured porous biomaterials. J. Mech. Behav. Biomed. Mater. 2017, 70, 28–42. [Google Scholar] [CrossRef]

- Ramberg, W.; Osgood, W.R. Description of Stress-Strain Curves by Three Parameters. Technical Note No. 902; National Advisory Committee for Aeronautics: 1943. Available online: http://www.apesolutions.com/spd/public/NACA-TN902.pdf (accessed on 19 June 2019).

- Manson, S.S. Fatigue: A complex subject—Some simple approximations. Exp. Mech. 1965, 5, 193–226. [Google Scholar] [CrossRef]

- Coffin, L.F., Jr. A study of the effects of cyclic thermal stresses on a ductile metal. Trans. ASME 1954, 76, 931–950. [Google Scholar]

- Morrow, J. Cyclic Plastic Strain Energy and Fatigue of Metals. In Internal Friction, Damping, and Cyclic Plasticity; ASTM International: West Conshohocken, PA, USA, 1965; pp. 45–87. [Google Scholar] [CrossRef]

- Haibach, E. Betriebsfestigkeit; Springer-Verlag Berlin Heidelberg: Heidelberg, Germany, 2006. [Google Scholar] [CrossRef]

- Edwards, P.; O’Conner, A.; Ramulu, M. Electron Beam Additive Manufacturing of Titanium Components: Properties and Performance. J. Manuf. Sci. Eng. 2013, 135, 061016. [Google Scholar] [CrossRef]

- Galarraga, H.; Lados, D.A.; Dehoff, R.; Kirka, M.M.; Nandwana, P. Effects of the microstructure and porosity on properties of Ti-6Al-4V ELI alloy fabricated by electron beam melting (EBM). Addit. Manuf. 2016, 10, 47–57. [Google Scholar] [CrossRef] [Green Version]

- Kirchner, A.; Klöden, B.; Luft, J.; Weißgärber, T.; Kieback, B. Process window for electron beam melting of Ti-6Al-4V. Powder Met. 2015, 58, 246–249. [Google Scholar] [CrossRef]

- Sun, Y.Y.; Gulizia, S.; Oh, C.H.; Fraser, D.; Leary, M.; Yang, Y.F.; Qian, M. The Influence of As-Built Surface Conditions on Mechanical Properties of Ti-6Al-4V Additively Manufactured by Selective Electron Beam Melting. JOM 2016, 68, 791–798. [Google Scholar] [CrossRef]

- Smith, R.W.; Hirschberg, M.H.; Manson, S. Fatigue Behavior of Materials under Strain Cycling in Low and Intermediate Life Range; National Aeronautics and Space Administration Washington: Cleveland, OH, USA, 1963. [Google Scholar]

| (%) | |||||||

|---|---|---|---|---|---|---|---|

| Ti | Al | V | C | Fe | O | N | H |

| Balance | 6.0 | 4.0 | 0.03 | 0.1 | 0.1 | 0.01 | <0.003 |

| Build Direction | Tensile Test | Multiple Step Test | Incremental Step Test | Strain-Life Test | |||

|---|---|---|---|---|---|---|---|

| Number | Number | Strain Amplitudes | Number | Strain Amplitudes | Number | Strain Amplitudes | |

| Vertical | 8 | 4 | 0.2–1.2% | 1 | 0.1–1.2% | 14 | 0.3–1% |

| Diagonal | 3 | / | / | / | / | / | / |

| Horizontal | 3 | 2 | 0.2–1.2% | 1 | 0.1–1.2% | 6 | 0.4–1% |

| Build Direction | Young’s Modulus, GPa | Yield Strength, MPa | Ultimate Tensile Strength, MPa | Elongation at Fracture, % |

|---|---|---|---|---|

| Vertical | 118 ± 1.3 | 1004 ± 22 | 1060 ± 20 | 8.9 ± 1.6 |

| Diagonal | 114 ± 0.4 | 957 ± 5 | 1037 ± 4 | 13.1 ± 1.3 |

| Horizontal | 115 ± 0.3 | 1071 ± 5 | 1114 ± 15 | 2.1 ± 0.8 |

| Build Direction | e(1), % | εf, % |

|---|---|---|

| Vertical | 35.3 ± 5.5 | 37.7 ± 4.5 |

| Diagonal | 32.8 ± 3.1 | 29.9 ± 2.1 |

| Horizontal | / | 10.2 ± 3.6 |

| Vertical | Diagonal | Horizontal | |

|---|---|---|---|

| 0.04 | 0.08 | 0.02 | |

| 0.025 | 0.04 | 0.01 | |

| −2.5 | 1.5 | 3.5 |

| Vertical | Diagonal | Horizontal | |||

|---|---|---|---|---|---|

| D | D | D | |||

| 0 | 0 | 0 | 0 | 0 | 0 |

| 0.007 | 0.005 | 0.007 | 0.005 | 1 | 0.0006 |

| 0.011 | 0.02 | 0.011 | 0.04 | ||

| 0.15 | 0.05 | 0.15 | 0.055 | ||

| 1 | 0.06 | 1 | 0.06 | ||

| MST—Ascending | MST—Descending | IST | |||||

|---|---|---|---|---|---|---|---|

| Tensile | Compr. | Tensile | Compr. | Tensile | Compr. | ||

| K’, MPa | vertical | 1023 ± 60 | 1090 ± 42 | 1648 ± 99 | 1578 ± 127 | 1700 | 1660 |

| horizontal | 1020 ± 28 | 1010 ± 0 | 1400 ± 28 | 1750 ± 113 | 1710 | 1700 | |

| n’ | vertical | 0.012 ± 0.01 | 0.011 ± 0.003 | 0.1 ± 0.01 | 0.077 ± 0.01 | 0.098 | 0.081 |

| horizontal | 0.017 ± 0.005 | 0.007 ± 0 | 0.075 ± 0.004 | 0.106 ± 0.01 | 0.11 | 0.095 | |

| E, GPa | vertical | 122.6 ± 2.8 | 119.9 ± 3.3 | 114.2 ± 2.2 | 117.6 ± 4.4 | 114.6 | 116.9 |

| horizontal | 119.9 ± 1.9 | 118.2 ± 2.3 | 110.6 ± 0.5 | 116.5 ± 0.8 | 108.8 | 109.4 | |

| b | c | |||

|---|---|---|---|---|

| vertical | 1722 | −0.094 | 0.1575 | −0.645 |

| horizontal | 1935 | −0.087 | 0.13 | −0.546 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Radlof, W.; Benz, C.; Heyer, H.; Sander, M. Monotonic and Fatigue Behavior of EBM Manufactured Ti-6Al-4V Solid Samples: Experimental, Analytical and Numerical Investigations. Materials 2020, 13, 4642. https://doi.org/10.3390/ma13204642

Radlof W, Benz C, Heyer H, Sander M. Monotonic and Fatigue Behavior of EBM Manufactured Ti-6Al-4V Solid Samples: Experimental, Analytical and Numerical Investigations. Materials. 2020; 13(20):4642. https://doi.org/10.3390/ma13204642

Chicago/Turabian StyleRadlof, Wiebke, Christopher Benz, Horst Heyer, and Manuela Sander. 2020. "Monotonic and Fatigue Behavior of EBM Manufactured Ti-6Al-4V Solid Samples: Experimental, Analytical and Numerical Investigations" Materials 13, no. 20: 4642. https://doi.org/10.3390/ma13204642

APA StyleRadlof, W., Benz, C., Heyer, H., & Sander, M. (2020). Monotonic and Fatigue Behavior of EBM Manufactured Ti-6Al-4V Solid Samples: Experimental, Analytical and Numerical Investigations. Materials, 13(20), 4642. https://doi.org/10.3390/ma13204642