The Use of De-Vulcanized Recycled Rubber in the Modification of Road Bitumen

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Bitumen Modification

2.3. Methods Used in the Characterization of Bitumen Properties

2.3.1. Penetration at 25 °C

2.3.2. Softening Point

2.3.3. Fraass Breaking Point

2.3.4. Softening Point SPR&B Increase

2.3.5. Elastic Recovery at 25 °C

2.3.6. Stability

2.3.7. The Mass Change after RTFOT

2.3.8. Cohesion Energies and Maximal Tensile Force

2.3.9. Differential Scanning Calorimetry (DSC)

2.3.10. Solid Residue

3. Results and Discussion

4. Conclusions

5. Patents

Author Contributions

Funding

Conflicts of Interest

References

- Polacco, G.; Berlincioni, S.; Biondi, D.; Stastna, J.; Zanzotto, L. Asphalt modification with different polyethylene-based polymers. Eur. Polym. J. 2005, 41, 2831–2844. [Google Scholar] [CrossRef]

- Ajideh, H.; Rangel, A.; Bahia, H. Can chemical modification of paving asphalts be equated to polymer modification? A laboratory study. Transport. Res. Rec. 2004, 1875, 56–69. [Google Scholar] [CrossRef]

- Becker, Y.; Müller, A.J.; Rodriguez, Y. Use of rheological compatibility criteria to study SBS modified asphalts. J. Appl. Polym. Sci. 2003, 90, 1772–1782. [Google Scholar]

- Tapkin, S.; Özcan, Ş. Determination of the Optimal Polypropylene Fiber Addition to the Dense Bituminous Mixtures by the Aid of Mechanical and Optical Means. Balt. J. Road Bridge. E 2012, 7, 22–29. [Google Scholar] [CrossRef]

- Slavgorodskaya, O.I.; Bondaletov, V.G.; Ustimenko, Y.P. Bitumen Modification. Adv. Mater. Res. 2014, 880, 3–6. [Google Scholar] [CrossRef]

- Alataş, T.; Yilmaz, M. Effects of different polymers on mechanical properties of bituminous binders and hot mixtures. Constr. Build. Mater. 2013, 42, 161–167. [Google Scholar] [CrossRef]

- Zhu, J.; Birgisson, B.; Kringos, N. Polymer modification of bitumen: Advances and challenges. Europ. Polym. J. 2014, 54, 18–38. [Google Scholar] [CrossRef]

- Jeong, K.D.; Lee, S.J.; Amirkhanian, S.N.; Kim, K.W. Interaction effects of crumb rubber modified asphalt binders. Constr. Build. Mater. 2010, 24, 824–831. [Google Scholar] [CrossRef]

- Hamida, A.; Abdelrahman, M. Monitoring separation tendency of partial asphalt replacement by crumb rubber modifier and quayule resin. Constr. Build. Mater. 2020, 251, 118967. [Google Scholar] [CrossRef]

- Mashaan, N.S.; Ali, A.H.; Karim, M.R.; Abdelaziz, M. An overview of crumb rubber modified. Int. J. Phys. Sci. 2012, 7, 166–170. [Google Scholar]

- Willis, J.R.; Turner, P.; Plemmons, C.; Rodezno, C.; Rosenmayer, T.; Daranga, C.; Carlson, D. Effect of rubber characteristics on asphalt binder properties. Road Mater. Pavement Des. 2013, 14, 214–230. [Google Scholar] [CrossRef]

- Lo Presti, D. Recycled tyre rubber modified bitumens for road asphalt mixtures: A literature review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Rodriguez-Alloza, A.M.; Gallego, J. Mechanical performance of asphalt rubber mixtures with warm mix asphalt additives. Mater. Struct. 2017, 50, 147. [Google Scholar] [CrossRef]

- Wang, X. Study of Rubber Asphalt Modification Mechanism. Adv. Mater. Res. 2011, 194–196, 844–847. [Google Scholar] [CrossRef]

- Wang, H.; Liu, X.; Apostolidis, P.; Scarpas, T. Review of warm mix rubberized asphalt concrete: Towards a sustainable paving technology. J. Clean. Prod. 2018, 177, 302–314. [Google Scholar] [CrossRef]

- Rodríguez-Fernández, I.; Cavalli, M.C.; Poulikakos, L.; Bueno, M. Recyclability of asphalt mixtures with crumb rubber incorporated by dry process: A laboratory investigation. Materials 2020, 13, 2870. [Google Scholar] [CrossRef]

- Thodesen, C.; Biro, S.; Kay, J. Evaluation of current modified asphalt binders using the multiple stress creep recovery test. Proceedings of AR2009 Conference, Nanjing, China, 24–25 August 2009. [Google Scholar]

- Pouranian, M.R.; Shishehbor, M. Sustainability assessment of green asphalt mixtures: A review. Environments 2019, 6, 73. [Google Scholar] [CrossRef]

- Pouranian, M.R.; Notani, M.A.; Tabesh, M.T.; Nazeri, B.; Shishehbor, M. Rheological and environmental characteristics of crumb rubber asphalt binders containing non-foaming warm mix asphalt additives. Constr. Build. Mater. 2020, 238, 117707. [Google Scholar] [CrossRef]

- Seghar, S.; Asaro, L.; Rolland-Monnet, M.; Aϊt Hocine, N. Thermo-mechanical devulcanization and recycling of rubber industry waste. Resour. Conserv. Recycl. 2019, 144, 180–186. [Google Scholar] [CrossRef]

- Błażejowski, J.; Gawdzik, B.; Matynia, T. Effect of recycled rubber on the properties of road bitumen. J. Chem. 2018, 2018, 8759549. [Google Scholar] [CrossRef]

- Gaweł, I.; Kalabińska, M.; Piłat, J. Asfalty Drogowe; Wydawnictwa Komunikacji i Łączności: Warsaw, Poland, 2014; p. 158. [Google Scholar]

- Saiwari, S.; Dierkes, W.K.; Noordermeer, J.W.M.; Blume, A. Best Practice for the Devulcanization of Sulfur-cured SBR Rubber. In Proceedings of the International Rubber Conference, Nürnberg, Germany, 29 June–2 July 2015; pp. 1–17. [Google Scholar]

- Gawdzik, B.; Matynia, T. Method of Modifying Road Bitumens. Polish Patent 229418, 10 July 2018. [Google Scholar]

- Coomarasamy, A.; Manolis, S.; Hesp, S. High temperature performance of scrap tire rubber modified asphalt concrete. Prepr. Am. Chem. Soc. Fuel Chem. Div. 1996, 41, 1322–1326. [Google Scholar]

- Porto, M.; Caputo, P.; Loise, V.; Eskandarsefat, S.; Teltayev, B.; Rossi, C.O. Bitumen and bitumen modification: A review on latest advances. Appl. Sci. 2019, 9, 742. [Google Scholar] [CrossRef]

- Zhu, J.; Balieu, R.; Lu, X.; Kringos, N. Characterization and Modelling of Phase Separation in Polymer Modified Bitumen. Ann. Transact. Nordic Rheol. Soc. 2016, 24, 59–61. [Google Scholar]

- Soesen, H.L.X.; Laukkanen, O.L. Oxidation of bitumen: Molecular characterization and influence on rheological properties. Rheol. Acta 2016, 55, 315–326. [Google Scholar] [CrossRef]

- Xie, J.; Yang, Y.; Lv, S.; Peng, X.; Zhang, Y. Investigation on Preparation Process and Storage Stability of Modified Asphalt Binder by Grafting Activated Crumb Rubber. Materials 2019, 12, 2014. [Google Scholar] [CrossRef] [PubMed]

- Ehinola, O.A.; Falode, O.A.; Jonathan, G. Softening point and penetration index of bitumen from parts of Southwestern Nigeria. Nafta 2012, 63, 319–323. [Google Scholar]

- Hofford, S. Survey of fatigue resistance quantification of asphalt mixture. Int. J. Adv. App. Sci. 2015, 2, 42–49. [Google Scholar]

- Tan, Y.; Guo, M. Using surface free energy method to study the cohesion and adhesion of asphalt mastic. Constr. Build. Mater. 2013, 47, 254–260. [Google Scholar] [CrossRef]

| Sample No. | Modifiers (%) | Modification Time (h) | Residue after Devulcanization (%) | ||

|---|---|---|---|---|---|

| Rubber 0.4 | SBS | Donor S | |||

| 1 | 10 | 2 | 0.07 | 2 | 5.6 |

| 2 | 15 | 2 | 0.07 | 2 | 12.7 |

| 3 | 10 | 2 | 0.07 | 4 | 5.2 |

| 4 | 15 | 2 | 0.07 | 4 | 9.0 |

| 5 | 10 | 2 | 0.07 | 8 | 5.0 |

| 6 | 15 | 2 | 0.07 | 8 | 6.4 |

| 7 | - | 2 | 0.07 | 8 | - |

| Sample No. | Modifiers (%) | Modification Time (h) | Residue after Devulcanization (%) | ||

|---|---|---|---|---|---|

| Rubber 0.4 | SBS | Donor S | |||

| 8 | 10 | 2 | 0.07 | 2 | 3.6 |

| 9 | 15 | 2 | 0.07 | 2 | 5.0 |

| 10 | 10 | 2 | 0.07 | 4 | 4.0 |

| 11 | 15 | 2 | 0.07 | 4 | 5.0 |

| 12 | 10 | 2 | 0.07 | 8 | 3.3 |

| 13 | 15 | 2 | 0.07 | 8 | 4.5 |

| Property | Sample No. | ||||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | |

| penetration at 25 °C (0.1 mm) | 50.4 | 50.6 | 50.0 | 54.0 | 47.0 | 64.0 | 502 |

| softening point (R&B) (°C) | 65.9 | 64.4 | 64.0 | 73.8 | 626 | 70.0 | 57.0 |

| penetration index | 1.9 | 2.3 | 1.7 | 2.6 | 1.4 | 2.5 | - |

| Fraass breaking point (°C) | −17 | −18 | −18 | −18 | −18 | −16 | −14 |

| elastic recovery at 25 °C (%) | 75.0 | 80.0 | 75.0 | 76.3 | 76.0 | 76.1 | 58.8 |

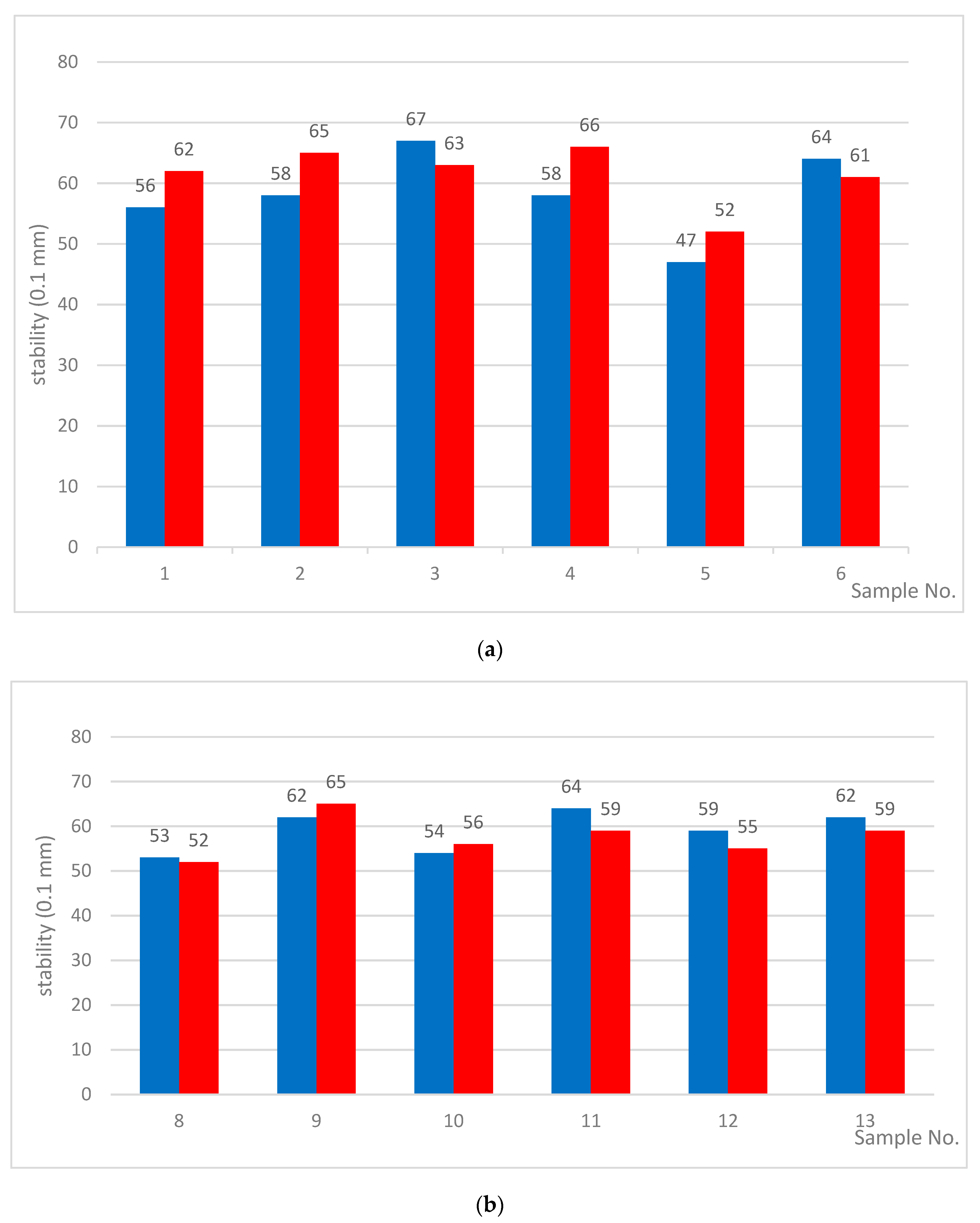

| stability (values of penetration top/penetration bottom) (0.1 mm) | 56/62 | 58/65 | 69/63 | 58/66 | 47/52 | 64/61 | - |

| delta penetration (difference between top and bottom of the tube) (0.1 mm) | 4 | 7 | 6 | 8 | 5 | 3 | - |

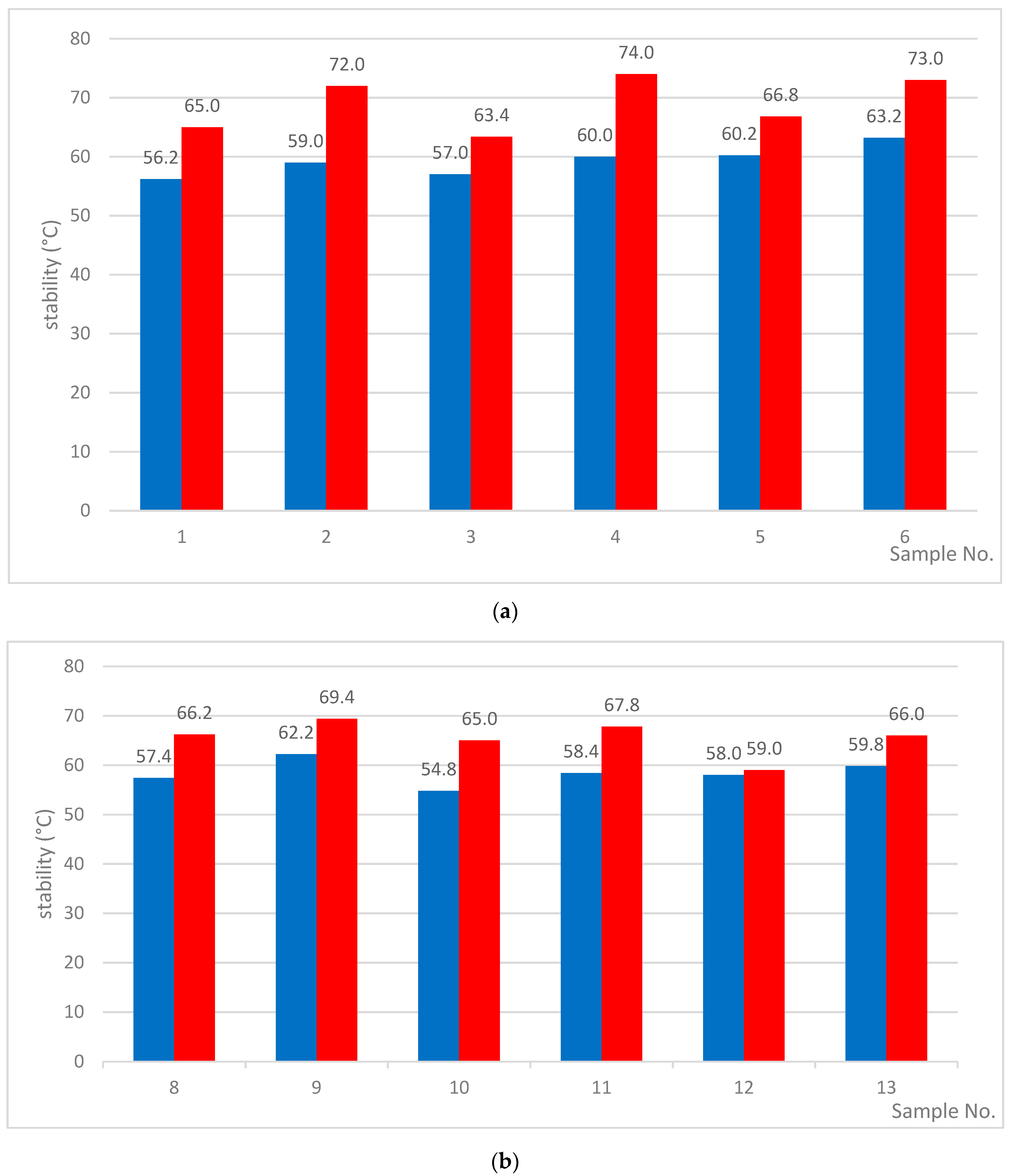

| stability (R&B top/R&B bottom) | 56.2/65.0 | 59.0/72.0 | 57.0/63.4 | 60.0/74.0 | 60.2/66.8 | 63.2/73.0 | - |

| delta R&B (°C) | 8.8 | 13.0 | 6.4 | 14.0 | 6.6 | 9.8 | - |

| softening point after RTFOT (°C) | 66.0 | 70.2 | 65.6 | 76.6 | 66.8 | 70.4 | - |

| increasing of softening point R&B after RTFOT (°C) | 0.1 | 5.8 | 1.6 | 2.8 | 4.2 | 0.4 | - |

| mass change after RTFOT (%) | +0.02 | −0.10 | −0.05 | −0.04 | +0.04 | +0.09 | - |

| cohesion energy at 5 °C (J/cm2) | 4.8 | breaking | 4.8 | breaking | 4.8 | 4.3 | - |

| cohesion energy at 10 °C (J/cm2) | 2.6 | 1.9 | 2.5 | 2.0 | 2.6 | 2.4 | - |

| maximal tensile force at 5 °C (N) | 54.3 | 39.5 | 32.0 | 9.6 | 59.0 | 32.4 | - |

| maximal tensile force at 10 °C (N) | 26.8 | 18.8 | 16.0 | 6.6 | 30.0 | 18.0 | - |

| Property | Sample No. | |||||

|---|---|---|---|---|---|---|

| 8 | 9 | 10 | 11 | 12 | 13 | |

| penetration at 25 °C (0.1 mm) | 53.8 | 61.0 | 50.3 | 59.5 | 50.1 | 57.8 |

| softening point (R&B) (°C) | 60.8 | 71.0 | 59.4 | 64.0 | 59.0 | 59.2 |

| penetration index | 1.4 | 1.7 | 0.9 | 1.7 | 0.6 | 1.2 |

| Fraass breaking point (°C) | −18 | −20 | −18 | −18 | −19 | −18 |

| elastic recovery at 25 °C (%) | 74.8 | 78.9 | 78.2 | 71.3 | 76.6 | 75.0 |

| stability (values of penetration top/penetration bottom) (0.1 mm) | 53/52 | 6/65 | 54/56 | 64/59 | 59/55 | 62/59 |

| delta penetration (difference between top and bottom of the tube) (0.1 mm) | 1 | 3 | 2 | 5 | 4 | 3 |

| stability (R&B top/R&B bottom) | 57.4/66.2 | 62.2/69.4 | 54.8/65.0 | 58.4/67.8 | 58.0/59.0 | 59.8/66.0 |

| delta R&B (°C) | 8.8 | 7.2 | 10.2 | 9.4 | 1.0 | 6.2 |

| softening point after RTFOT (°C) | 64.4 | 73.7 | 66.4 | 70.2 | 58.0 | 66.4 |

| increasing of softening point R&B after RTFOT (°C) | 3.6 | 2.7 | 7.2 | 6.2 | 7.6 | 5.8 |

| mass change after RTFOT (%) | −0.07 | −0.11 | −0.10 | −0.15 | −0.02 | −0.04 |

| cohesion energy at 5 °C (J/cm2) | 3.5 | 3.0 | 3.7 | 2.5 | 3.6 | 2.7 |

| cohesion energy at 10 °C (J/cm2) | 2.1 | 1.4 | 1.9 | 1.4 | 1.9 | 1.5 |

| maximal tensile force at 5 °C (N) | 53.0 | 30.5 | 52.6 | 37.5 | 54.0 | 37.0 |

| maximal tensile force at 10 °C (N) | 26.0 | 15.9 | 25.0 | 18.0 | 25.0 | 17.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gawdzik, B.; Matynia, T.; Błażejowski, K. The Use of De-Vulcanized Recycled Rubber in the Modification of Road Bitumen. Materials 2020, 13, 4864. https://doi.org/10.3390/ma13214864

Gawdzik B, Matynia T, Błażejowski K. The Use of De-Vulcanized Recycled Rubber in the Modification of Road Bitumen. Materials. 2020; 13(21):4864. https://doi.org/10.3390/ma13214864

Chicago/Turabian StyleGawdzik, Barbara, Tadeusz Matynia, and Krzysztof Błażejowski. 2020. "The Use of De-Vulcanized Recycled Rubber in the Modification of Road Bitumen" Materials 13, no. 21: 4864. https://doi.org/10.3390/ma13214864

APA StyleGawdzik, B., Matynia, T., & Błażejowski, K. (2020). The Use of De-Vulcanized Recycled Rubber in the Modification of Road Bitumen. Materials, 13(21), 4864. https://doi.org/10.3390/ma13214864