Analytical Model for Springback Prediction of CuZn20 Foil Considering Size Effects: Weakening versus Strengthening

Abstract

1. Introduction

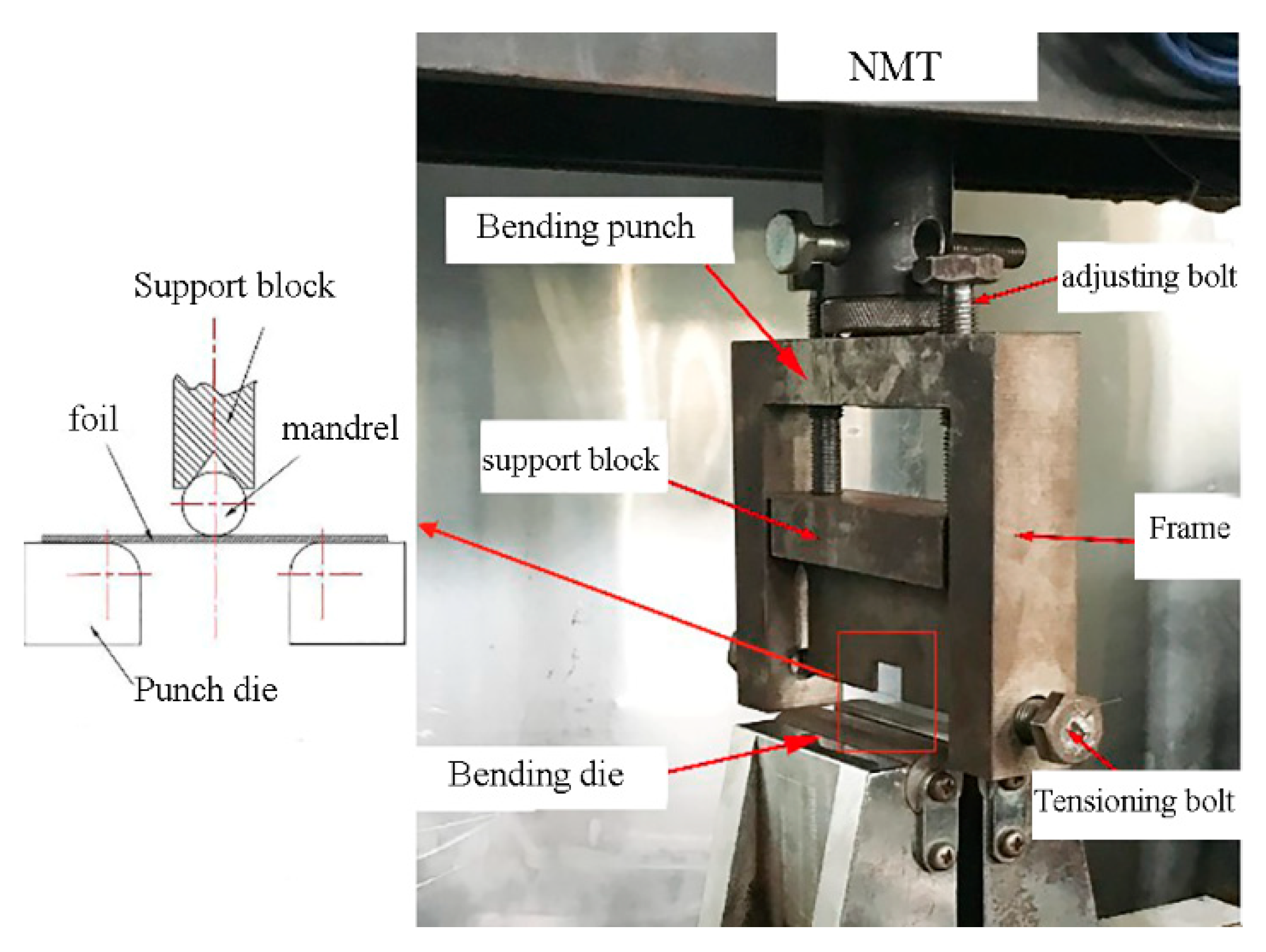

2. Materials and Methods

3. Results and Discussion

4. Analytical Model

4.1. Expression of Strain Gradient as a Nonlocal Integral of Strain

4.2. Material Hardening Behavior under Strain Gradient

4.3. Mechanical Analysis of Foil Bend Forming

4.3.1. Equivalent Strain and Equivalent Strain Gradient

4.3.2. Stress Analysis

4.3.3. Bending Moment Calculation

4.3.4. Springback Calculation

4.4. Application and Discussion

- (1)

- Classical bend forming theory (calculation with , the mechanical properties of foils are represented by that of the 400 μm thick foils);

- (2)

- Surface grain theory (calculation with , the mechanical properties of foils are shown in Figure 5);

- (3)

- Strain gradient theory (calculation with , ω = 1 in );

- (4)

- The analytical model (calculation with , ω is calculated as Equation (9) in ).

5. Conclusions

- (1)

- With the decrease of the foil thickness, the springback of foils shows two contradictory trends that are divided by a critical thickness, and the springback angle is the minimum at the critical thickness.

- (2)

- An analytical model based on Taylor-based nonlocal theory of plasticity is developed, in which the drastic increases of both the proportion of surface grains and the strain gradient are taken into account. Moreover, the influence of strain gradient in the model is modified by considering the blocking effect of the grain-boundary region on geometrically necessary dislocations.

- (3)

- The springback angle of foils is jointly determined by the decrement angle caused by surface grains and the increment angle caused by the strain gradient. The appearance of springback trend is ultimately determined by the intrinsic competition between the weakening and strengthening contributions resulting from size effects.

- (4)

- The relative error of the predicted springback angle by the model is less than 15%.

Author Contributions

Funding

Conflicts of Interest

References

- Feng, F.; Li, J.; Chen, R.; Peng, Y.; Su, H.; Zhang, Q.; Huang, P.; Zheng, Z. Effect of Die Geometry on the Formability of 5052 Aluminum Alloy in Electromagnetic Impaction Deformation. Materials 2018, 11, 1379. [Google Scholar] [CrossRef]

- Fu, M.W.; Chan, W.L. Geometry and grain size effects on the fracture behavior of sheet metal in micro-scale plastic deformation. Mater. Des. 2011, 32, 4738–4746. [Google Scholar] [CrossRef]

- Xue, S.; Wang, C.; Chen, P.; Xu, Z.; Cheng, L.; Guo, B.; Shan, D. Investigation of Electrically-Assisted Rolling Process of Corrugated Surface Microstructure with T2 Copper Foil. Materials 2019, 12, 4144. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.; Tong, G.Q.; Chen, F.; Wang, Q.; Wang, S. Grain size effect on springback behavior in bending of Ti-2.5Al-1.5Mn foils. J. Mater. Process. Technol. 2015, 224, 11–17. [Google Scholar] [CrossRef]

- Wang, C.J.; Shan, D.B.; Zhou, J.; Guo, B.; Sun, L.N. Size effects of the cavity dimension on the microforming ability during coining process. J. Mater. Process. Technol. 2007, 187–188, 256–259. [Google Scholar] [CrossRef]

- Geiger, M.; Geißdörfer, S.; Engel, U. Mesoscopic model: Advanced simulation of microforming processes. Prod. Eng. 2007, 1, 79–84. [Google Scholar] [CrossRef]

- Chan, W.L.; Fu, M.W. Experimental studies and numerical modeling of the specimen and grain size effects on the flow stress of sheet metal in microforming. Mater. Sci. Eng. A 2011, 528, 7674–7683. [Google Scholar] [CrossRef]

- Gao, H.; Huang, Y. Geometrically necessary dislocation and size-dependent plasticity. Scr. Mater. 2003, 48, 113–118. [Google Scholar] [CrossRef]

- Fleck, N.A.; Muller, G.M.; Ashby, M.F.; Hutchinson, J.W. Strain gradient plasticity: Theory and experiment. Acta Metall. Mater. 1994, 42, 475–487. [Google Scholar] [CrossRef]

- Stölken, J.S.; Evans, A.G. A microbend test method for measuring the plasticity length scale. Acta Mater. 1998, 46, 5109–5115. [Google Scholar] [CrossRef]

- Li, H.; Dong, X.; Shen, Y.; Diehl, A.; Hagenah, H.; Engel, U.; Merklein, M. Size effect on springback behavior due to plastic strain gradient hardening in microbending process of pure aluminum foils. Mater. Sci. Eng. A 2010, 527, 4497–4504. [Google Scholar] [CrossRef]

- Liu, J.G.; Fu, M.W.; Lu, J.; Chan, W.L. Influence of size effect on the springback of sheet metal foils in micro-bending. Comput. Mater. Sci. 2011, 50, 2604–2614. [Google Scholar] [CrossRef]

- Fleck, N.A.; Hutchinson, J.W. A phenomenological theory for strain gradient effects in plasticity. J. Mech. Phys. Solids 1993, 41, 1825–1857. [Google Scholar] [CrossRef]

- Borst, R.; Mühlhaus, H.-B. Gradient-dependent plasticity: Formulation and algorithmic aspects. Int. J. Numer. Methods Eng. 1992, 35, 521–539. [Google Scholar] [CrossRef]

- Nix, W.D.; Gao, H. Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids 1998, 46, 411–425. [Google Scholar] [CrossRef]

- Gao, H.; Huang, Y. Taylor-based nonlocal theory of plasticity. Int. J. Solids Struct. 2001, 38, 2615–2637. [Google Scholar] [CrossRef]

- Gao, H.; Huang, Y.; Nix, W.D. Modeling Plasticity at the Micrometer Scale. Naturwissenschaften 1999, 86, 507–515. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.-W.; Cao, Z.-Y.; Lu, J.-B.; Zhang, Y.-J.; Liu, W.; Yin, Z. Size effects on springback behavior of H80 foils. Rare Met. 2018, 37, 1082–1090. [Google Scholar] [CrossRef]

- Gao, H.; Huang, Y.-S.; Nix, W.D.; Hutchinson, J. Mechanism-based strain gradient plasticity—I. Theory. J. Mech. Phys. Solids 1999, 47, 1239–1263. [Google Scholar] [CrossRef]

- Voyiadjis, G.Z.; Al-Rub, R.K.A. Gradient plasticity theory with a variable length scale parameter. Int. J. Solids Struct. 2005, 42, 3998–4029. [Google Scholar] [CrossRef]

- Fu, H.H.; Benson, D.J.; Meyers, M.A. Analytical and computational description of effect of grain size on yield stress of metals. Acta Mater. 2001, 49, 2567–2582. [Google Scholar] [CrossRef]

- Li, H.-Z.; Dong, X.-H.; Shen, Y.; Diehl, A.; Hagenah, H.; Engel, U.; Merklein, M. Microbending moment of brass foils based on strain gradient hardening model. J. Shanghai Jiaotong Univ. 2011, 45, 1668–1672. [Google Scholar]

| Young’s Modulus E | Shear Modulus G | Burger’s Vector b | Poisson’s Ratio γ |

|---|---|---|---|

| 91 GPa | 34.2 GPa | 3.6 × 10 −7 mm | 0.33 |

| Thickness (t, μm) | Annealing Conditions | Grain Size (d, μm) | Ps |

|---|---|---|---|

| 30 | 600 °C, 1 h | 34.2 ± 2.4 | 100% |

| 50 | 500 °C, 1 h | 35.3 ± 2.7 | 100% |

| 100 | 500 °C, 1 h | 33.8 ± 1.9 | 66.7% |

| 200 | 500 °C, 1.5 h | 36.2 ± 3.1 | 36.3% |

| 400 | 400 °C, 1 h | 34.6 ± 2.3 | 17.2% |

| Thickness t (μm) | Scaling Factor λ | Mandrel Diameter Dd (mm) | Die Diameter Dp (mm) | Clearance between Mandrel and Die C (mm) | Punch Speed v (mm/min) |

|---|---|---|---|---|---|

| 30 | 0.3 | 0.3 | 0.3 | 0.15 | 0.3 |

| 50 | 0.5 | 0.5 | 0.5 | 0.25 | 0.5 |

| 100 | 1 | 1 | 1 | 0.5 | 1 |

| 200 | 2 | 2 | 2 | 1 | 2 |

| 400 | 4 | 4 | 4 | 2 | 4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guan, X.; Ma, Z.; Wang, C.; He, H.; Zhang, Y.; Wang, X.; Zhang, W. Analytical Model for Springback Prediction of CuZn20 Foil Considering Size Effects: Weakening versus Strengthening. Materials 2020, 13, 4929. https://doi.org/10.3390/ma13214929

Guan X, Ma Z, Wang C, He H, Zhang Y, Wang X, Zhang W. Analytical Model for Springback Prediction of CuZn20 Foil Considering Size Effects: Weakening versus Strengthening. Materials. 2020; 13(21):4929. https://doi.org/10.3390/ma13214929

Chicago/Turabian StyleGuan, Xin, Zhenwu Ma, Chunju Wang, Haidong He, Yuanjing Zhang, Xinwei Wang, and Weiwei Zhang. 2020. "Analytical Model for Springback Prediction of CuZn20 Foil Considering Size Effects: Weakening versus Strengthening" Materials 13, no. 21: 4929. https://doi.org/10.3390/ma13214929

APA StyleGuan, X., Ma, Z., Wang, C., He, H., Zhang, Y., Wang, X., & Zhang, W. (2020). Analytical Model for Springback Prediction of CuZn20 Foil Considering Size Effects: Weakening versus Strengthening. Materials, 13(21), 4929. https://doi.org/10.3390/ma13214929