New Findings in the Field of Thermal Drilling of Aluminum Alloys

Abstract

:1. Introduction

- The material types and properties to be joined;

- The geometry of the joint;

- The required functions that the joint has to fulfil;

- The production conditions of future joining.

- Design for disassembly;

- Material and energy saving;

- Reuse of materials;

- Recycling of materials;

- Fuel economy regulation.

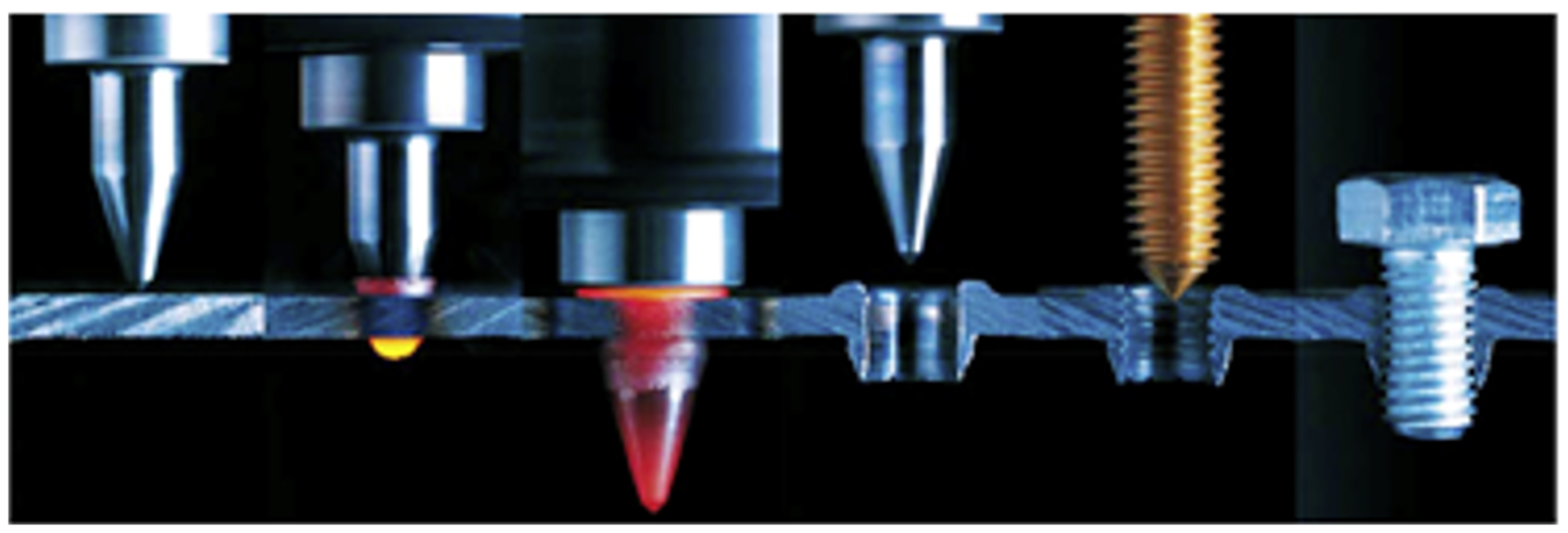

2. Friction Drilling Method

- Made by cutting, the thread is obtained as in many other machining operations by chip removal.

- Threads production is achieved by forming or tapping operations. The threads may be produced by the cold forming operation, which involves rolling, deformation of the raw material under cold working conditions, and tapping, in order to achieve a good joint of similar strength to conventional drilling, but simultaneously avoiding the use of nuts (and even screws) in some cases.

3. Experimental Method and Details

- Drill 1: type—Flowdrill short, diameter Ø 7.3 mm (M8).

- Drill 2: type—Flowdrill short, with a milling cutter of Ø 7.3 mm (M8) and lubrication paste Flowdrill type FDKS.

- Forming tap M8; rpm during tapping: 600–680 min−1; lubrication oil Flowdrill type FTMZ.

3.1. Experimental Setup

- Visual evaluation of the testing samples;

- Metallographic and microscopy evaluation.

3.1.1. Visual Evaluation

3.1.2. Metallographic and Microscopy Evaluation

3.1.3. Hardness Test

4. Discussion

5. Conclusions

- Reduction of the number of required technological operations and simplified process for preparing collars, bushings and holes.

- Use of material with various thicknesses and types for creating joints.

- Possibility to use mixed materials with various chemical and mechanical properties.

- Reduction of the amount additional materials such as nuts, welding electrodes, etc.

- The short production time of 2–6 s depends on the thickness and type of the used material.

- Increase in the usable thickness of the material by the creation of bushing by up to three times in comparison with the original thickness of the base material.

- The thermal drilling operation reduces or even completely removes waste material (chips) from the production. Material from the drilling holes is transported into collar and bushing.

- By rolled threads in the bushing or by removal of the collar from the upper joining place, it increases the variability in the use of joints.

- Reduction of the number of required pieces of equipment for manual and/or automated production.

- The possibilities that chipless technology offers, i.e., energy saving, low cost, simplification of forming and cutting technological operations and undemanding for special equipment and without negative environmental impacts, are important factors from the environmental perspective.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wood, K.L. Design for assembly techniques in reverse engineering and Redesign. ASME Design Theory and Methodology. In Proceedings of the ASME Design Theory and Methodology Conference, DETC/DTM-1517, Irvine, CA, USA, 18–22 August 1996; pp. 1–28. [Google Scholar]

- Cataloque Material Thermdrill: The Thermdrill® Method Solves an Old Problem. 2019. Available online: http://thermdrill.com/threaded-bushing-flowing-drill-instead-of-rivet-nut/ (accessed on 14 June 2019).

- Bahador, A.; Hamzah, E.; Mamat, M.F. Effect of filler metals on the mechanical properties of dissimilar welding of stainless steel 316L and carbon steel A516 GR 70. J. Teknol. 2015, 75, 61–65. [Google Scholar] [CrossRef] [Green Version]

- LeBacq, C.; Brechet, Y.; Shercliff, H.R.; Jeggy, T.; Salvo, L. Selection of joining methods in mechanical design. Mater. Des. 2002, 23, 405–416. [Google Scholar] [CrossRef]

- Nong, N.; Keju, O.; Zhang, Y.; Qiao, Z.; Changcheng, T.; Feipeng, L. Research on press joining technology for automotive metallic sheets. J. Mater. Process. Technol. 2003, 137, 159–163. [Google Scholar] [CrossRef]

- Sobotova, L.; Kralikova, R.; Badida, M. The Analysis of Chosen Material Properties at Thermal Drilling. Key Eng. Mater. 2015, 635, 35–40. [Google Scholar] [CrossRef]

- Pedreschi, R.F.; Sinha, B.P.; Davies, R. Advanced connection techniques for cold—Formed steel structures. J. Struct. Eng. 1997, 123, 138–144. [Google Scholar] [CrossRef]

- Bustilloa, A.; Urbikain, G.; Perezc, J.M.; Pereirab, O.M.; Lopez de Lacalleb, L.N. Smart optimization of a friction-drilling process based on boosting ensembles. J. Manuf. Syst. 2018, 48, 108–121. [Google Scholar] [CrossRef]

- Miller, S.F. Experimental Analysis and Numerical Modeling of the Friction Drilling Process. Ph.D. Thesis, The University of Michigan, Ann Arbor, MI, USA, 2006; p. 126. [Google Scholar]

- Mishra, R.S.; Mahoney, M.W. Friction Stir Welding and Processing, 1st ed.; ASM International: Materials Park, OH, USA, 2007; pp. 1–78. [Google Scholar]

- Pereira, O.; Martín-Alfonso, J.E.; Rodríguez, A.; Calleja, A.; Fernández-Valdivielso, A.; López de Lacalle, L.N. Sustainability analysis of lubricant oils for minimum quantity lubrication based on their tribo-rheological performance. J. Clean. Prod. 2017, 164, 1419–1429. [Google Scholar] [CrossRef]

- Mathew, N.T.; Vijayaraghavan, L. Environmentally friendly drilling of intermetallic titanium aluminide at different aspect ratio. J. Clean. Prod. 2017, 141, 439–452. [Google Scholar] [CrossRef]

- Miller, S.F.; Blau, P.; Shih, A.J. Microstructural Alterations Associated with Friction Drilling of Steel, Aluminum, and Titanium. J. Mater. Eng. Perform. 2005, 14, 647–653. [Google Scholar] [CrossRef]

- Miller, S.F.; Wang, H.; Li, R.; Shih, A.J. Experimental and numerical analysis of the friction drilling process. ASME J. Manuf. Sci. Eng. 2006, 128, 803–810. [Google Scholar] [CrossRef]

- Honda to Release All- New Fit and Fit Hybrid in Japan—All-New Fit and Fit Hybrid Achieve Class-Leading Fuel Economy. Available online: http://world.honda.com/news/2013/4130218eng.html (accessed on 25 September 2019).

- EJOT®—The Self-Piercing and Extruding Screw for High- Strength Sheet Joints. Available online: www.ejot.com (accessed on 14 June 2019).

- Eliseeva, A.A.; Fortunaa, S.V.; Kolubaev, E.A.; Kalashnikova, T.A. Microstructure modification of 2024 aluminum alloy produced by friction drilling. Mater. Sci. Eng. 2017, 691, 121–125. [Google Scholar] [CrossRef]

- Pantawane, P.D.; Ahuja, B.B. Experimental investigations and multi-objective optimization of friction drilling process on AISI 1015. Int. J. Appl. Eng. Res. Dindigul 2011, 2, 448–461. [Google Scholar]

- Ahn, D.G.; Jung, G.W. Influence of process parameters on drilling characteristics of Al 1050 sheet with thickness of 0.2 mm using pulsed Nd:YAG laser. Trans. Nonferrous Met. Soc. China 2009, 19, 157–163. [Google Scholar] [CrossRef]

- Miller, S.F.; Tao, J.; Shih, A.J. Friction drilling of cast metals. Int. J. Mach. Tools Manuf. 2006, 46, 1526–1535. [Google Scholar] [CrossRef]

- Miller, S.F.; Shih, A.J. Tool wear in friction drilling. Int. J. Mach. Tools Manuf. 2007, 47, 1636–1645. [Google Scholar] [CrossRef]

- Cebeli, O.; Zulkuf, D. Investigate the Friction Drilling of Aluminium Alloys according to the Thermal Conductivity. TEM J. 2013, 2, 93–101. [Google Scholar]

- Formdrill. Available online: http://www.formdrill.eu (accessed on 15 September 2019).

- Dehghan, S.; Ismail, M.I.S.; Ariffin, M.K.A.; Baharutin, B.T.H.T. Measurement and analysis of thrust force and torque in friction drilling of difficult-to-machine materials. J. Adv. Technol. 2019, 105, 2749–2769. [Google Scholar] [CrossRef]

- Raju, B.P.; Swamy, M.K. Finite Element Simulation of a Friction Drilling process using Deform-3D. Int. J. Eng. Res. Appl. (IJERA) 2012, 2, 716–721. [Google Scholar]

- Pereira, O.; Urbikaín, G.; Rodríguez, A.; Calleja, A.; Ayesta, I.; López de Lacalle, L.N. Process performance and life cycle assessment of friction drilling on dual-phase steel. J. Clean. Prod. 2019, 213, 1147–1156. [Google Scholar] [CrossRef]

- Miller, S.F.; Shih, A.J. Thermo-Mechanical Finite Element Modelling of the Friction Drilling. J. Manuf. Sci. Eng. 2007, 129, 531–538. [Google Scholar] [CrossRef]

- Urbikain, G.; Perez, J.M.; Lopez de Lacalle, L.N.; Andueza, A. Combination of friction drilling and form tapping processes on dissimilar materials for making nutless joints. J. Eng. Manuf. 2016, 232, 1007–1020. [Google Scholar] [CrossRef]

- Sobotova, L. Joining of materials by Flowdrill method. In PRO-TECH-MA ‘07; Politechnika Rzeszowska: Rzeszów, Poland, 2007; pp. 198–204. [Google Scholar]

- Matysiak, W.; Bernat, L. Shaping the edges using Flowdrill technology. Metalurgija 2015, 54, 235–238. [Google Scholar]

- Folea, M.; Schlegel, D.; Gete, E.; Langlade, C.; Roman, A. Preliminary tests on flowdrilling of maraging steels. Acad. J. Manuf. Eng. 2012, 10, 42–47. [Google Scholar]

- Sobotová, L.; Badida, M. The New Knowledge of Environmentally Friendly Joints Made by Thermal Drilling. Mater. Sci. Forum 2015, 818, 212–215. [Google Scholar]

- Matysiak, W.; Bartkowski, D.; Frackowiak, P. Microstructure, microhardness and general characterisation of sintered tools using for flanging of hole edge by Flowdrill technology. IOP Conf. Ser. Mater. Sci. Eng. 2018, 393, 012094. [Google Scholar] [CrossRef]

- El-Bahloul, S.A.; El-Shourbagy, H.E.; Elmidany, T.T.M. Effect of tool Geometry, feed rate, and rotational speed of thermal friction drilling process on AISI 304 stainless steel. Bull. Fac. Eng. Mansoura Univ. 2016, 41, 9–15. [Google Scholar] [CrossRef]

- Sobotova, L.; Spisak, E. Progressive technologies in joining of materials. In Progressive Technologies and Materials. 3-A, Technologies; OWPR Rzeszow: Rzeszów, Poland, 2009; pp. 61–67. [Google Scholar]

- Aluminium and Aluminium Alloys-Extruded Rod/Bar, Tube and Profiles–Part 2: Mechanical Properties; DIN EN 755-2; DIN Deutsches Institut für Normung e. V.: Berlin, Germany, 2016.

- Metallic and Other Inorganic Coatings. Definitions and Conventions Concerning Appearance; STN EN ISO 16348; The European Committee for Standardization: Brussels, Belgium, 2003.

- Metallic Materials–Vickers Hardness Test—Part 1: Test Method; I.S. EN ISO 6507-1; The European Committee for Standardization: Brussels, Belgium, 2018.

- Metallic Materials–Vickers Hardness Test–Part 3: Calibration of Reference Blocks; STN EN ISO 6507-3; The European Committee for Standardization: Brussels, Belgium, 2018.

| Chemical Element | Al | Fe | Cu | Si | Mg | Other Elements |

|---|---|---|---|---|---|---|

| Content (%) | 98.8 | 0.1 | 0.1 | 0.3 | 0.4 | 0.3 |

| Tested Sample | Rm * (MPa) | A80 * (%) |

|---|---|---|

| AlMgSi | 120–215 | 6–14 |

| Measuring Place | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Microhardness Sample 1 | 68.08 | 66.3 | 64.5 | 63.6 | 63.1 | 64.2 | 65.4 | 65.8 | 66.3 | 69.2 |

| Microhardness Sample 2 | 73.5 | - | 62.8 | 53.4 | 53.4 | 62.8 | - | - | - | 76.5 |

| Microhardness Sample 3 | 62.6 | - | 56.9 | 45.6 | 45.7 | 60.1 | - | - | - | 62.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sobotova, L.; Badida, M.; Moravec, M.; Badidova, A.; Maslejova, A. New Findings in the Field of Thermal Drilling of Aluminum Alloys. Materials 2020, 13, 5007. https://doi.org/10.3390/ma13215007

Sobotova L, Badida M, Moravec M, Badidova A, Maslejova A. New Findings in the Field of Thermal Drilling of Aluminum Alloys. Materials. 2020; 13(21):5007. https://doi.org/10.3390/ma13215007

Chicago/Turabian StyleSobotova, Lydia, Miroslav Badida, Marek Moravec, Anna Badidova, and Alica Maslejova. 2020. "New Findings in the Field of Thermal Drilling of Aluminum Alloys" Materials 13, no. 21: 5007. https://doi.org/10.3390/ma13215007