Microstructure and Properties of Inconel 625 Fabricated Using Two Types of Laser Metal Deposition Methods

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

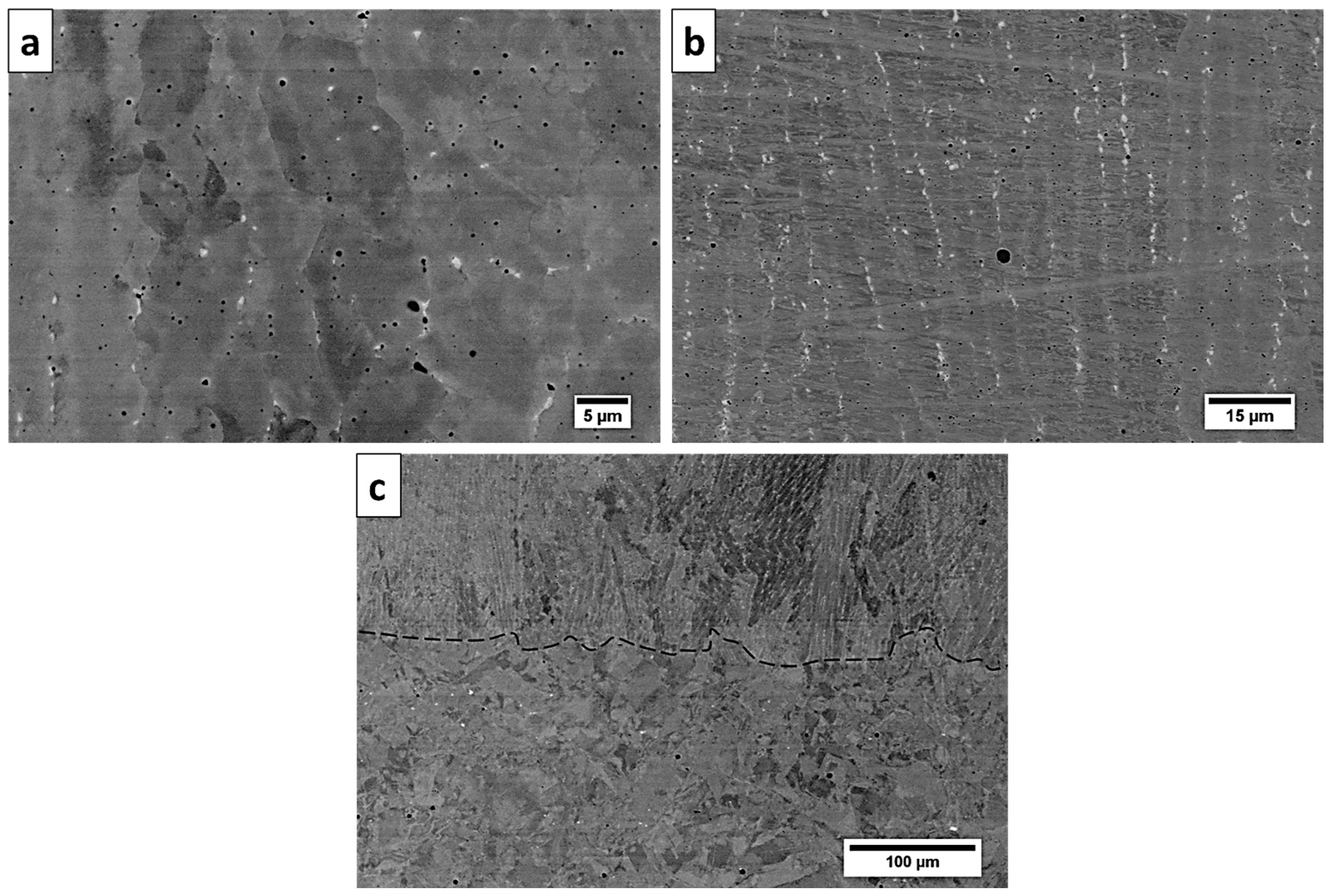

3.1. Substrate Material Characterization

3.2. Microstructure of Inconel 625 Deposited by CO2 Laser

3.3. Microstructure of Inconel 625 Deposited Using LENS Technique

3.4. Mechanical Properties of Inconel 625 Deposited Using High-Power CO2 Laser and LENS Technique

4. Conclusions

- A comparison of two types of direct deposition systems, one with a high-power CO2 laser (2200 W) that transported the powder through helium gas to the laser beam focal point and injected it into the melt pool and the other with a LENS system of a lower power (400 W) and processed in the chamber under a purified argon atmosphere, was performed in view of differences in resulting microstructure and mechanical properties. The high-power laser application resulted in a strong <100> build texture, while, at a low power, the Goss component {011} <100> increased. This orientation was accompanied by an increased number of low-angle grain boundaries.

- Due to the higher cooling rate of the melt pool during the LENS process, the obtained samples showed higher yield strengths, ultimate tensile strengths, and a lower plasticity than the samples fabricated by the high-power CO2 laser deposition due to a higher supersaturation of alloying elements and solid solution strengthening mechanism in addition to precipitate hardening. Moreover, a higher average microhardness (by approximately 55 HV0.1) for the LENS-deposited Inconel 625 samples was observed.

- Both types of deposited materials had dendritic microstructures with Ti-, Mo-, and Nb-rich zones at cell boundaries, where numerous precipitates were also observed. The elongated grains in the build directions were larger than those in the substrate and had a length that reached 1 mm. The average size was 95 μm compared to 31 μm for the substrate. The low-power laser caused similar sizes for the deposited grains elongated in the <100> growth direction, but they were inclined with respect to the substrate by 45°.

- The main precipitates identified using SEM EDS and STEM microanalysis were Nb2C and NbC carbides with a high percentage of Mo, Cr, and Ti. The microanalysis results also suggested the presence of titanium carbides. In addition, the results of the EDS analysis suggested the presence of intermetallic compounds, such as Nb3Ni and NbNiCr. The latter was identified using electron diffraction.

Author Contributions

Funding

Conflicts of Interest

References

- Trosch, T.; Strößner, J.; Völkl, R.; Glatzel, U. Microstructure and mechanical properties of selective laser melted Inconel 718 compared to forging and casting. Mater. Lett. 2016, 164, 428–431. [Google Scholar] [CrossRef]

- Li, C.; White, R.; Fang, X.; Weaver, M.; Guo, Y. Microstructure evolution characteristics of Inconel 625 alloy from selective laser melting to heat treatment. Mater. Sci. Eng. A 2017, 705, 20–31. [Google Scholar] [CrossRef]

- Kreitcberg, A.; Brailovski, V.; Turenne, S. Effect of heat treatment and hot isostatic pressing on the microstructure and mechanical properties of Inconel 625 alloy processed by laser powder bed fusion. Mater. Sci. Eng. A 2017, 689, 1–10. [Google Scholar] [CrossRef]

- Li, S.; Wei, Q.; Shi, Y.; Zhu, Z.; Zhang, D. Microstructure characteristics of Inconel 625 superalloy manufactured by selective laser melting. J. Mater. Sci. Technol. 2015, 31, 946–952. [Google Scholar] [CrossRef]

- Lass, E.A.; Stoudt, M.R.; Williams, M.E.; Katz, M.B.; Levine, L.E.; Phan, T.Q.; Gnaeupel-Herold, T.H.; Ng, D.S. Formation of the Ni3Nb δ-phase in stress-relieved Inconel 625 produced via laser powder-bed fusion additive manufacturing. Met. Mater. Trans. A 2017, 48, 5547–5558. [Google Scholar] [CrossRef] [Green Version]

- Marchese, G.; Colera, X.G.; Calignano, F.; Lorusso, M.; Biamino, S.; Minetola, P.; Manfredi, D. Characterization and comparison of Inconel 625 processed by selective laser melting and laser metal deposition. Adv. Eng. Mater. 2016, 19, 1–9. [Google Scholar] [CrossRef]

- Xu, F.; Lv, Y.; Xu, B.; Liu, Y.; Shu, F.; He, P. Effect of deposition strategy on the microstructure and mechanical properties of Inconel 625 superalloy fabricated by pulsed plasma arc deposition. Mater. Des. 2013, 45, 446–455. [Google Scholar] [CrossRef]

- Cardozo, E.P.; Ríos, S.; Ganguly, S.; D’Oliveira, A.S.C. Correction to: Assessment of the effect of different forms of Inconel 625 alloy feedstock in Plasma Transferred Arc (PTA) additive manufacturing. Int. J. Adv. Manuf. Technol. 2018, 98, 1695–1705. [Google Scholar] [CrossRef]

- Tian, Y.; Ouyang, B.; Gontcharov, A.; Gauvin, R.; Lowden, P.; Brochu, M. Microstructure evolution of Inconel 625 with 0.4 wt% boron modification during gas tungsten arc deposition. J. Alloy Compd. 2017, 694, 429–438. [Google Scholar] [CrossRef]

- Tanvir, A.N.M.; Ahsan, R.U.; Ji, C.; Hawkins, W.; Bates, B.; Kim, D.B. Heat treatment effects on Inconel 625 components fabricated by wire + arc additive manufacturing (WAAM)—Part 1: Microstructural characterization. Int. J. Adv. Manuf. Technol. 2019, 103, 3785–3798. [Google Scholar] [CrossRef]

- Jurić, I.; Garašić, I.; Bušić, M.; Kožuh, Z. Influence of shielding gas composition on structure and mechanical properties of wire and arc additive manufactured Inconel 625. JOM 2018, 71, 703–708. [Google Scholar] [CrossRef]

- Murr, L.E.; Martinez, E.; Gaytan, S.M.; Ramirez, D.A.; Machado, B.I.; Shindo, P.W.; Martinez, J.L.; Medina, F.; Wooten, J.; Ciscel, D.; et al. Microstructural architecture, microstructures, and mechanical properties for a nickel-base superalloy fabricated by electron beam melting. Met. Mater. Trans. A 2011, 42, 3491–3508. [Google Scholar] [CrossRef] [Green Version]

- Dinda, G.; Dasgupta, A.; Mazumder, J. Laser aided direct metal deposition of Inconel 625 superalloy: Microstructural evolution and thermal stability. Mater. Sci. Eng. A 2009, 509, 98–104. [Google Scholar] [CrossRef]

- Ma, D.; Stoica, A.D.; Wang, Z.; Beese, A.M. Crystallographic texture in an additively manufactured nickel-base superalloy. Mater. Sci. Eng. A 2017, 684, 47–53. [Google Scholar] [CrossRef] [Green Version]

- Popovich, V.A.; Borisov, E.V.; Popovich, A.A.; Sufiiarov, V.S.; Masaylo, D.V.; Alzina, L. Functionally graded Inconel 718 processed by additive manufacturing: Crystallographic texture, anisotropy of microstructure and mechanical properties. Mater. Des. 2017, 114, 441–449. [Google Scholar] [CrossRef]

- Shen, M.Y.; Tian, X.J.; Liu, N.; Tang, H.B.; Cheng, X. Microstructure and fracture behavior of TiC particles reinforced Inconel 625 composites prepared by laser additive manufacturing. J. Alloy Compd. 2018, 734, 188–195. [Google Scholar] [CrossRef]

- Mostafaei, A.; Behnamian, Y.; Krimer, Y.L.; Stevens, E.; Luo, J.L.; Chmielus, M. Effect of solutionizing and aging on the microstructure and mechanical properties of powder bed binder jet printed nickel-based superalloy 625. Mater. Des. 2016, 111, 482–491. [Google Scholar] [CrossRef]

- Fullen, M.D.; Schneider, J.A. Effects of varying heat treatments on the microstructure and mechanical properties of blown powder Inconel 625. JOM 2019, 71, 1127–1133. [Google Scholar] [CrossRef]

- Amato, K.; Hernandez, J.; Murr, L.E.; Martinez, E.; Gaytan, S.M.; Shindo, P.W.; Collins, S. Comparison of microstructures and properties for a Ni-base superalloy (Alloy 625) fabricated by electron beam melting. J. Mater. Sci. Res. 2012, 1, 3. [Google Scholar] [CrossRef]

- Rai, S.K.; Kumar, A.; Shankar, V.; Jayakumar, T.; Rao, K.B.S.; Raj, B. Characterization of microstructures in Inconel 625 using X-ray diffraction peak broadening and lattice parameter measurements. Scr. Mater. 2004, 51, 59–63. [Google Scholar] [CrossRef]

- Lindwall, G.; Campbell, C.E.; Lass, E.A.; Zhang, F.; Stoudt, M.R.; Allen, A.J.; Levine, L.E. Simulation of TTT curves for additively manufactured Inconel 625. Met. Mater. Trans. A 2018, 50, 457–467. [Google Scholar] [CrossRef] [Green Version]

- Fujishima, M.; Oda, Y.; Ashida, R.; Takezawa, K.; Kondo, M. Study on factors for pores and cladding shape in the deposition processes of Inconel 625 by the directed energy deposition (DED) method. CIRP J. Manuf. Sci. Technol. 2017, 19, 200–204. [Google Scholar] [CrossRef]

- Brown, C.U.; Jacob, G.; Stoudt, M.; Moylan, S.; Slotwinski, J.; Donmez, A. Interlaboratory Study for Nickel Alloy 625 Made by Laser Powder Bed Fusion to Quantify Mechanical Property Variability. J. Mater. Eng. Perform. 2016, 25, 3390–3397. [Google Scholar] [CrossRef]

- Hutsaylyuk, V.; Student, M.; Posuvailo, V.; Student, O.; Sirak, Y.; Hvozdets’Kyi, V.; Maruschak, P.; Veselivska, H. The properties of oxide-ceramic layers with Cu and Ni inclusions synthesizing by PEO method on top of the gas-spraying coatings on aluminium alloys. Vacuum 2020, 179, 109514. [Google Scholar] [CrossRef]

- Pleass, C.; Jothi, S. Influence of powder characteristics and additive manufacturing process parameters on the microstructure and mechanical behaviour of Inconel 625 fabricated by Selective Laser Melting. Addit. Manuf. 2018, 24, 419–431. [Google Scholar] [CrossRef]

- Kreitcberg, A.; Brailovski, V.; Turenne, S. Elevated temperature mechanical behavior of IN625 alloy processed by laser powder-bed fusion. Mater. Sci. Eng. A 2017, 700, 540–553. [Google Scholar] [CrossRef]

- Sateesh, N.; Kumar, G.M.; Prasad, K.; Srinivasa, C.K.; Vinod, A. Microstructure and mechanical characterization of laser sintered Inconel-625 superalloy. Procedia Mater. Sci. 2014, 5, 772–779. [Google Scholar] [CrossRef]

- Leary, M.; Mazur, M.; Williams, H.; Yang, E.; Alghamdi, A.; Lozanovski, B.; Zhang, X.; Shidid, D.; Farahbod-Sternahl, L.; Witt, G.; et al. Inconel 625 lattice structures manufactured by selective laser melting (SLM): Mechanical properties, deformation and failure modes. Mater. Des. 2018, 157, 179–199. [Google Scholar] [CrossRef]

- Dubiel, B.; Sieniawski, J. Precipitates in additively manufactured Inconel 625 superalloy. Materials 2019, 12, 1144. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Chou, K. Electron Backscatter diffraction analysis of Inconel 718 parts fabricated by selective laser melting additive manufacturing. JOM 2016, 69, 402–408. [Google Scholar] [CrossRef]

- Robichaud, J.; Vincent, T.; Schultheis, B.; Chaudhary, A. Integrated computational materials engineering to predict melt-pool dimensions and 3D grain structures for selective laser melting of Inconel 625. Integrating Mater. Manuf. Innov. 2019, 8, 305–317. [Google Scholar] [CrossRef]

- Tian, Y.; McAllister, D.; Colijn, H.; Mills, M.; Farson, D.F.; Nordin, M.; Babu, S.S. Rationalization of Microstructure Heterogeneity in INCONEL 718 Builds Made by the Direct Laser Additive Manufacturing Process. Met. Mater. Trans. A 2014, 45, 4470–4483. [Google Scholar] [CrossRef]

| Chemical Composition (at.%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ni | Cr | Nb | Mo | Si | Mn | Fe | Co | Al | Ti | C |

| 58.0 | 21.6 | 3.6 | 1.7 | 0.5 | 0.5 | 4.9 | 1.0 | 0.4 | 0.4 | 0.1 |

| No | Chemical Composition (at.%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Ni | Cr | Nb | Mo | Si | Fe | Al | Ti | C | |

| 1 | 3.1 | 1.3 | 52.2 | 1.7 | 0.6 | – | 0.2 | 3.8 | 37.0 |

| 2 | 4.4 | 2.1 | 49.2 | 1.4 | 0.6 | – | 0.2 | 4.9 | 37.3 |

| 3 | 2.1 | 3.2 | 19.9 | 0.3 | – | – | – | 74.5 | – |

| Area | 63.0 | 25.0 | 1.7 | 4.1 | 0.3 | 5.2 | 0.3 | 0.4 | – |

| No | Chemical Composition (at.%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Ni | Cr | Nb | Mo | Si | Fe | Al | Ti | C | |

| 1 | 41.8 | 21.7 | 13.9 | 8.8 | 4.0 | 0.8 | 0.1 | 0.2 | 8.7 |

| 2 | 35.5 | 21.1 | 19.0 | 8.4 | 3.7 | 0.4 | 0.2 | 0.3 | 11.4 |

| 3 | 45.1 | 24.0 | 15.4 | 10.1 | 4.5 | 0.6 | 0.3 | – | – |

| Area 1 | 62.8 | 22.6 | 1.1 | 3.5 | 0.6 | 1.1 | 0.2 | – | 7.6 |

| Area 2 | 63.2 | 23.2 | 1.3 | 3.7 | 0.7 | 1.1 | 0.1 | 0.1 | 6.6 |

| No | Chemical Composition (at.%) | ||||

|---|---|---|---|---|---|

| Ni | Cr | Nb | Mo | C | |

| 1 | 1.8 | 4.7 | 66.8 | 2.3 | 24.3 |

| 2 | 56.0 | 15.7 | 2.0 | 5.3 | 20.9 |

| No | Chemical Composition (at.%) | ||||||

|---|---|---|---|---|---|---|---|

| Ni | Cr | Nb | Mo | Fe | Ti | C | |

| 1 | 1.4 | 2.0 | 6.7 | – | 0.5 | 47.9 | 40.5 |

| 2 | 1.2 | 0.7 | 30.6 | – | 0.3 | 3.4 | 60.8 |

| 4 | 8.5 | 4.4 | 32.3 | – | 0.9 | 4.8 | 48.9 |

| 5 | 2.6 | 3.1 | 7.1 | 0.5 | 0.8 | 50.0 | 35.5 |

| Area | 61.8 | 26.0 | 1.7 | 4.0 | 4.1 | 0.3 | – |

| No | Chemical Composition (at.%) | |||||

|---|---|---|---|---|---|---|

| Ni | Cr | Nb | Mo | Fe | C | |

| 1 | 3.3 | 11.4 | 79.7 | 5.5 | – | – |

| 2 | 34.7 | 15.6 | 26.3 | 18.7 | 2.6 | 1.7 |

| 3 | 10.8 | 20.5 | 2.3 | 6.4 | 2.7 | 18.0 |

| No | Chemical Composition (at.%) | |||||

|---|---|---|---|---|---|---|

| Ni | Cr | Nb | Mo | Fe | C | |

| 1 | 39.5 | 17.6 | 79.7 | 13.9 | – | 11.9 |

| 2 | 58.3 | 24.4 | 3.0 | 7.4 | 6.9 | – |

| 3 | 55.4 | – | 36.5 | 6.7 | – | 1.4 |

| 4 | 47.6 | 21.2 | 11.0 | 9.7 | 3.9 | 6.4 |

| Fabrication Method | YS (MPa) | UTS (MPa) | Elongation (%) | Microhardness (HV0.1) | Cooling Rate (s−1) |

|---|---|---|---|---|---|

| CO2 laser | 472 ± 1 | 868 ± 3 | 42 ± 4 | 261 ± 6 | 1.5 × 103 |

| LENS | 524 ± 13 | 944 ± 12 | 35 ± 4 | 316 ± 5 | 1.7 × 104 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dutkiewicz, J.; Rogal, Ł.; Kalita, D.; Berent, K.; Antoszewski, B.; Danielewski, H.; Węglowski, M.S.; Łazińska, M.; Durejko, T.; Czujko, T. Microstructure and Properties of Inconel 625 Fabricated Using Two Types of Laser Metal Deposition Methods. Materials 2020, 13, 5050. https://doi.org/10.3390/ma13215050

Dutkiewicz J, Rogal Ł, Kalita D, Berent K, Antoszewski B, Danielewski H, Węglowski MS, Łazińska M, Durejko T, Czujko T. Microstructure and Properties of Inconel 625 Fabricated Using Two Types of Laser Metal Deposition Methods. Materials. 2020; 13(21):5050. https://doi.org/10.3390/ma13215050

Chicago/Turabian StyleDutkiewicz, Jan, Łukasz Rogal, Damian Kalita, Katarzyna Berent, Bogdan Antoszewski, Hubert Danielewski, Marek St. Węglowski, Magdalena Łazińska, Tomasz Durejko, and Tomasz Czujko. 2020. "Microstructure and Properties of Inconel 625 Fabricated Using Two Types of Laser Metal Deposition Methods" Materials 13, no. 21: 5050. https://doi.org/10.3390/ma13215050

APA StyleDutkiewicz, J., Rogal, Ł., Kalita, D., Berent, K., Antoszewski, B., Danielewski, H., Węglowski, M. S., Łazińska, M., Durejko, T., & Czujko, T. (2020). Microstructure and Properties of Inconel 625 Fabricated Using Two Types of Laser Metal Deposition Methods. Materials, 13(21), 5050. https://doi.org/10.3390/ma13215050