Research on the Properties and Low Cycle Fatigue of Sc-Modified AA2519-T62 FSW Joint

Abstract

:1. Introduction

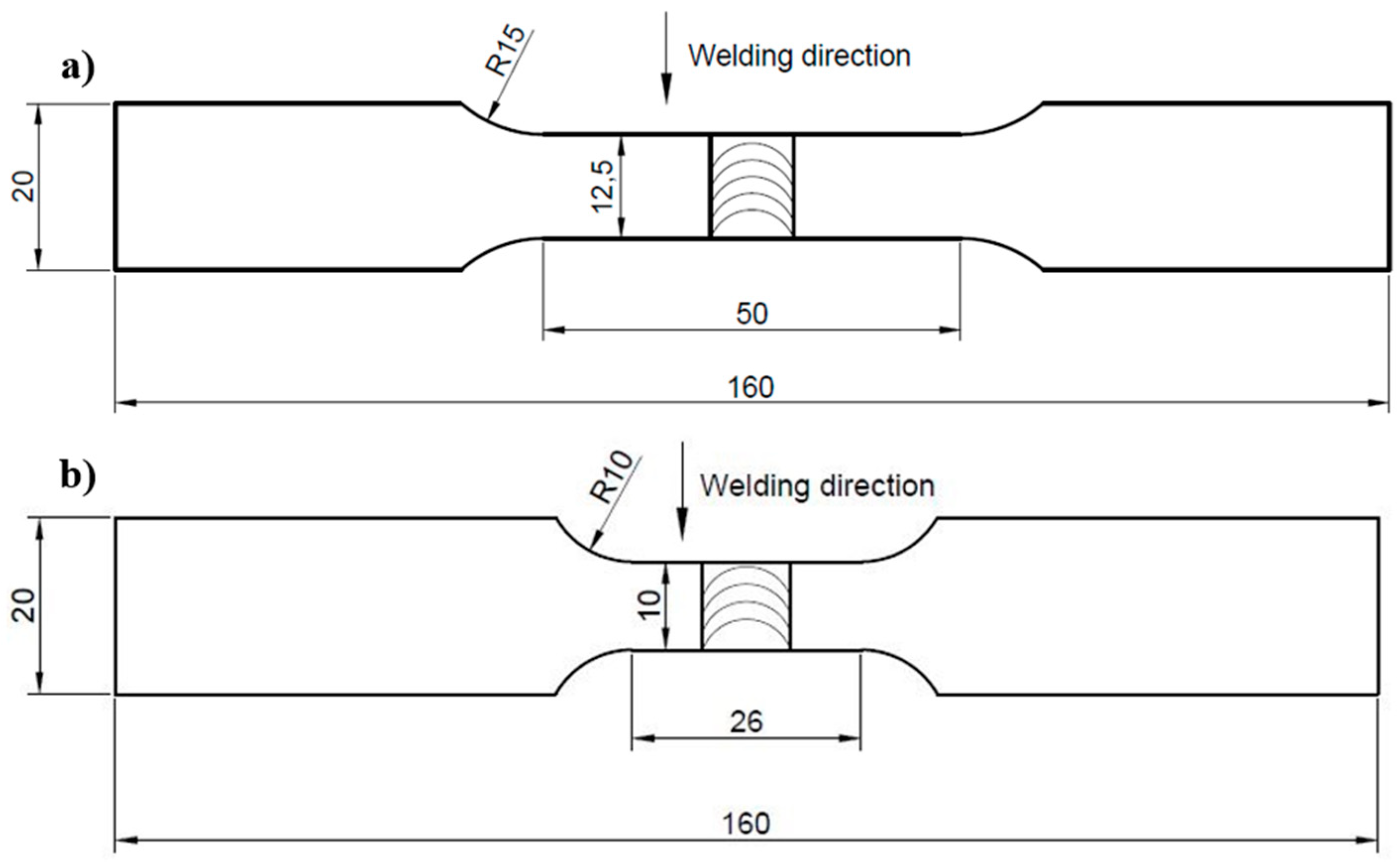

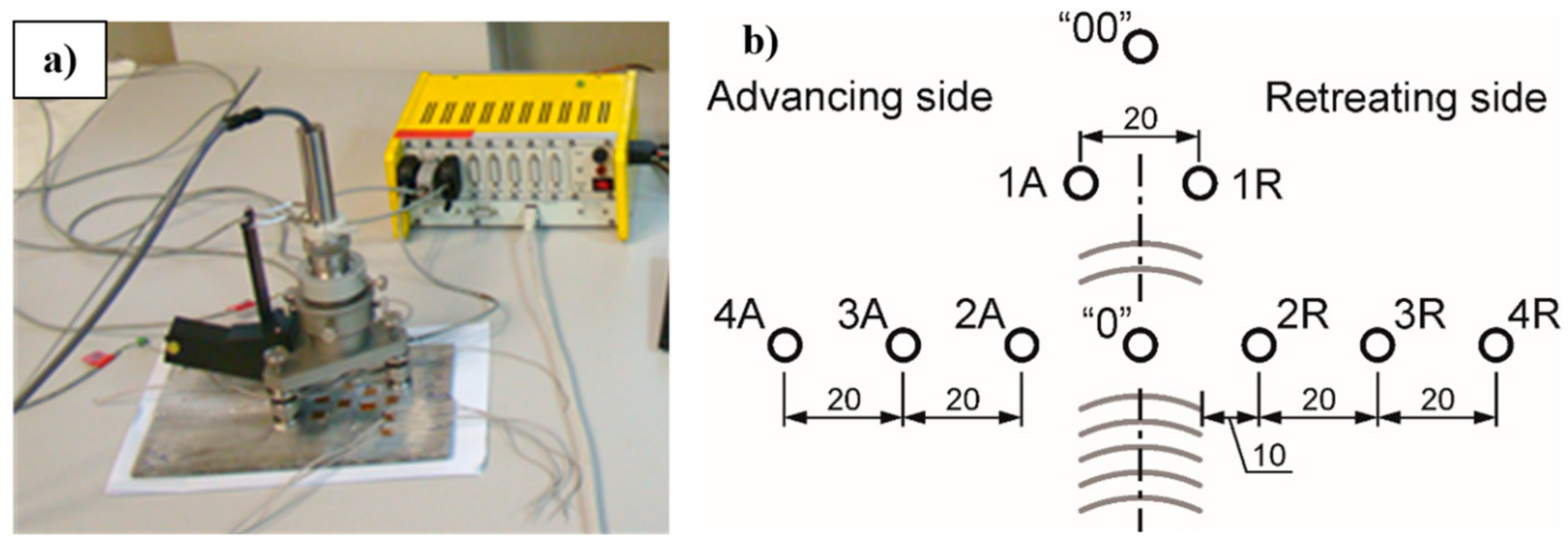

2. Material and Experimental Procedures

3. Results and Discussion

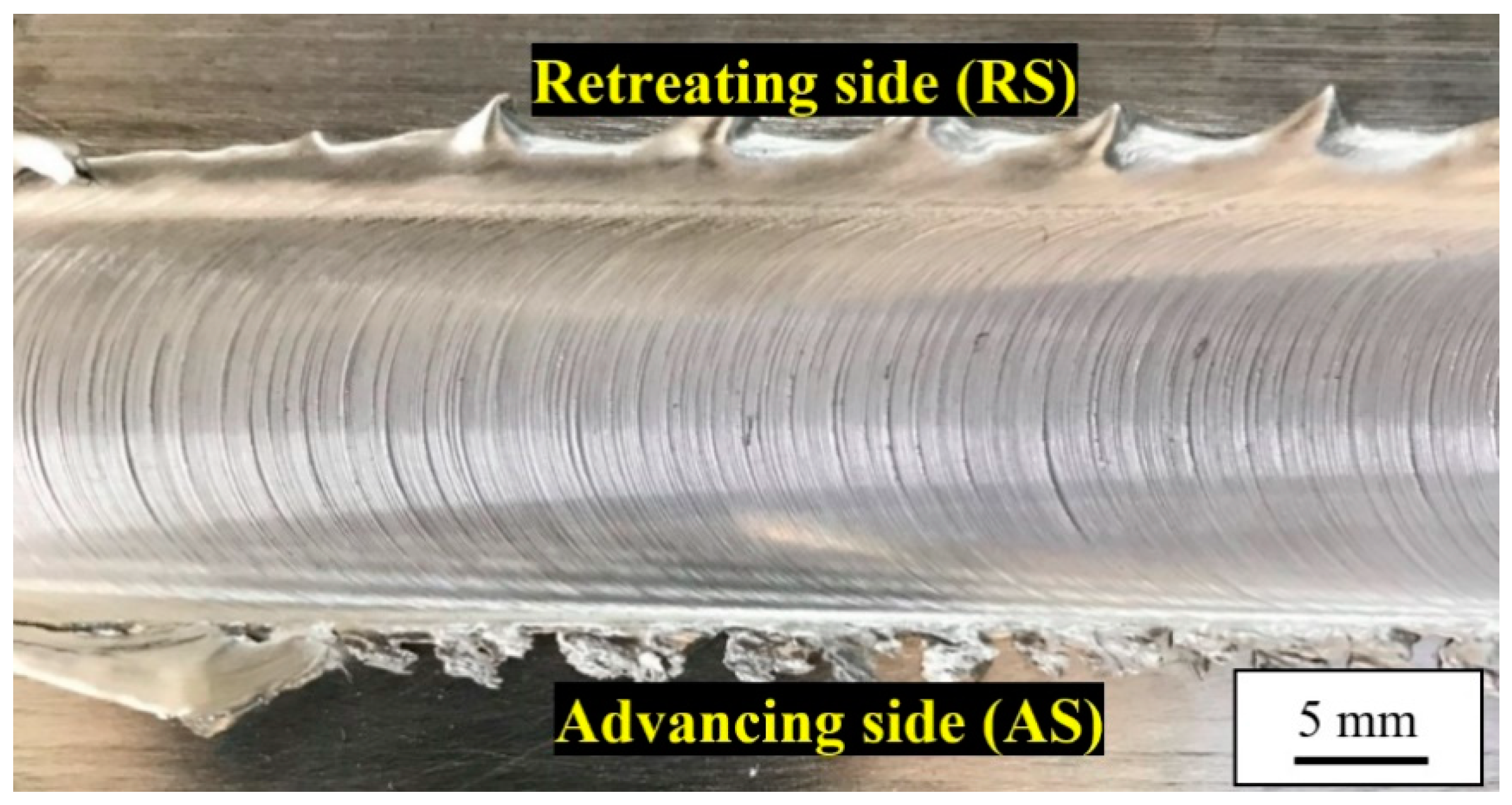

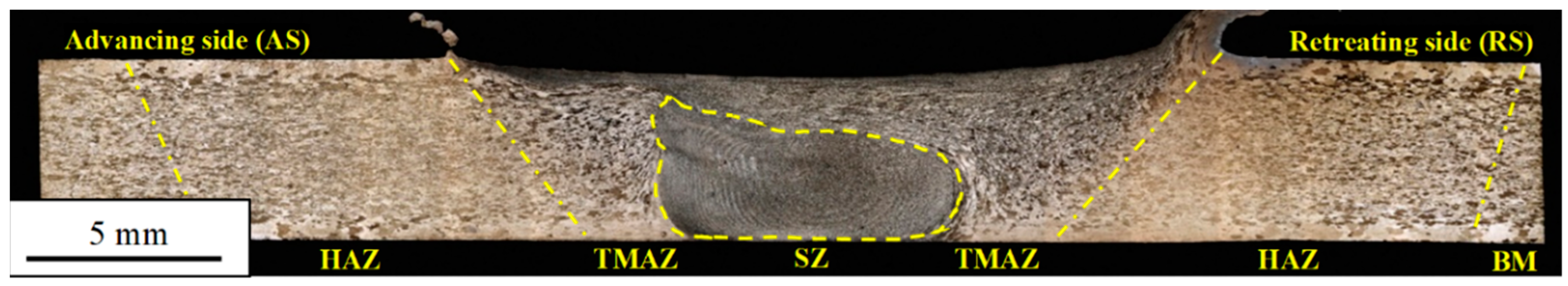

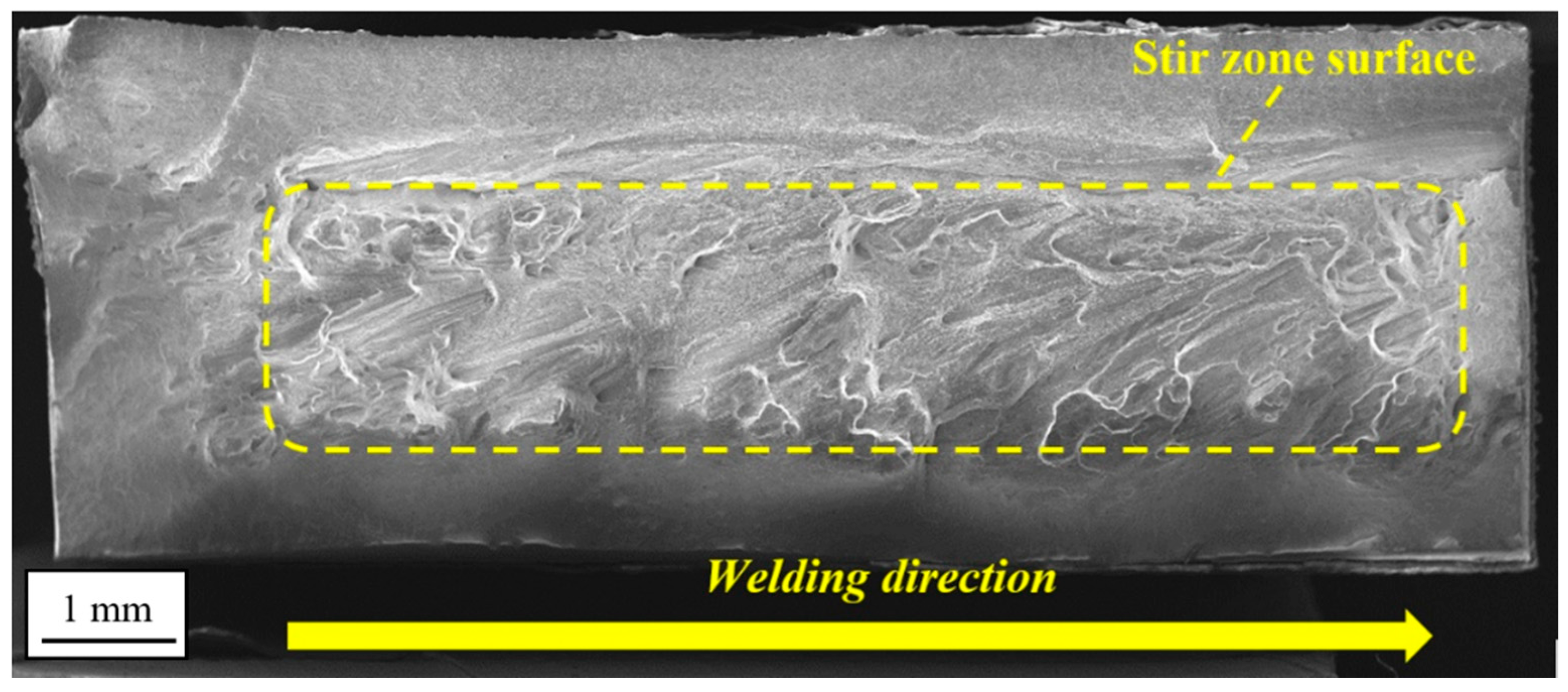

3.1. Macroscopic Observations

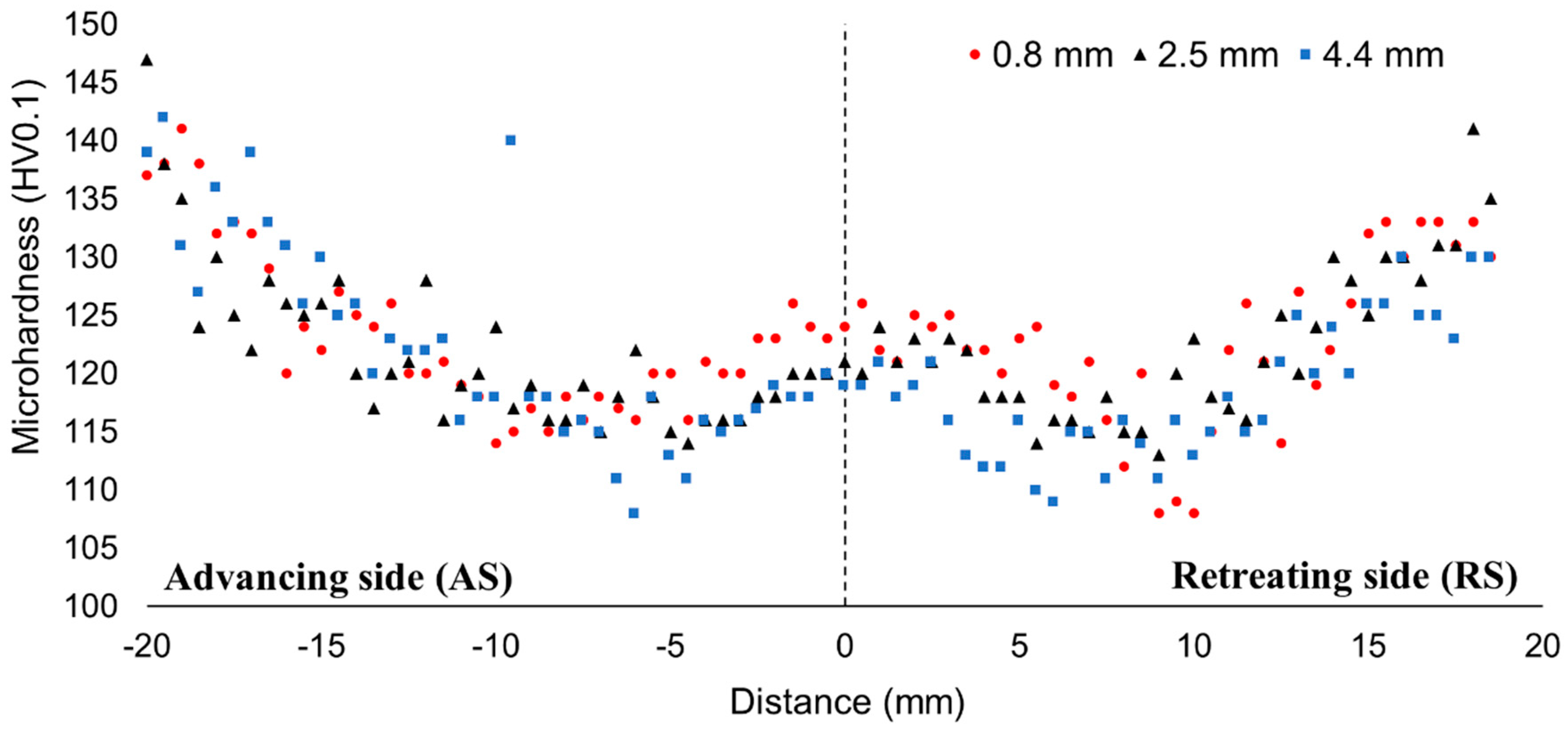

3.2. Microstructure Analysis and Microhardness Measurements

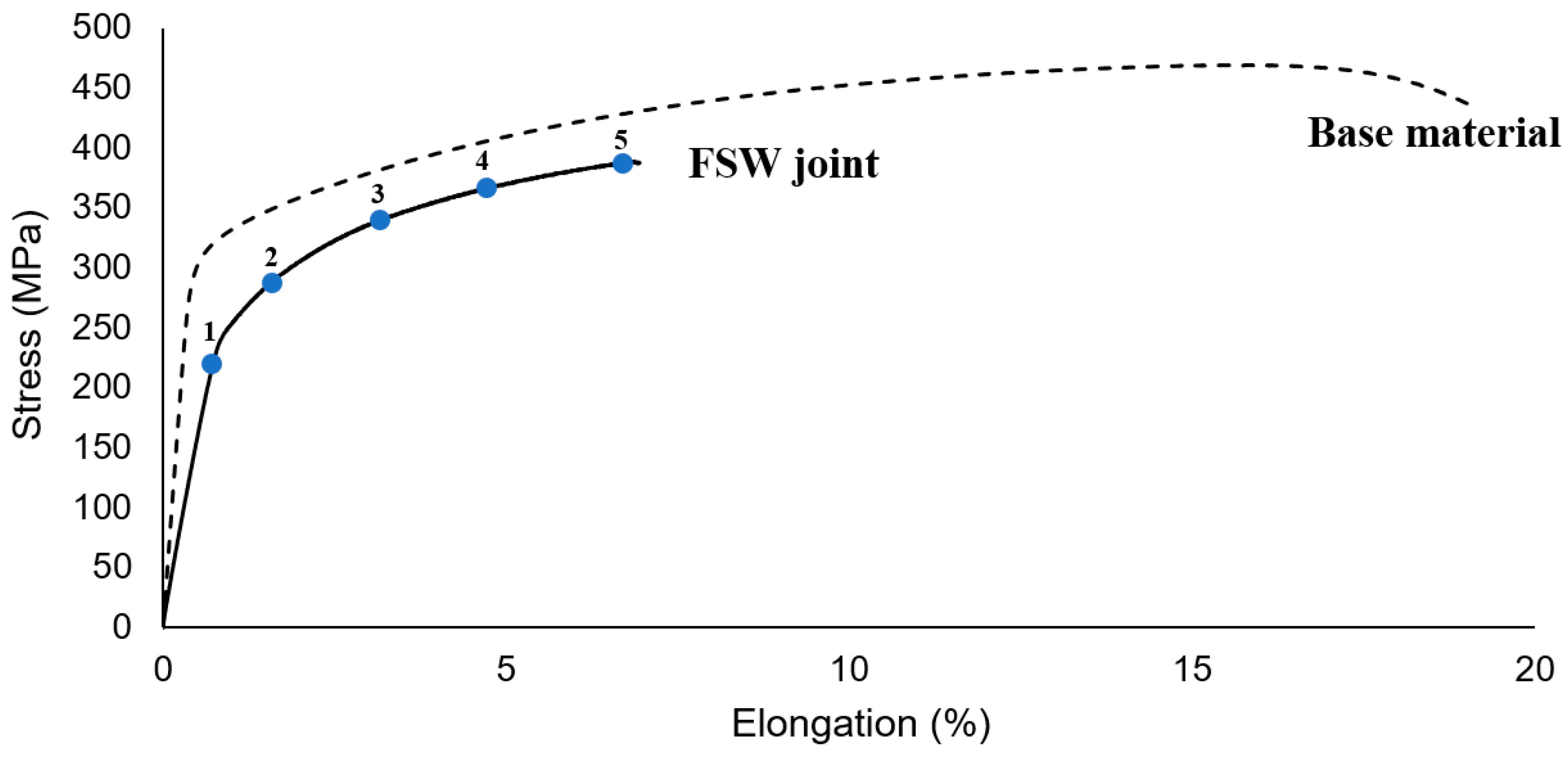

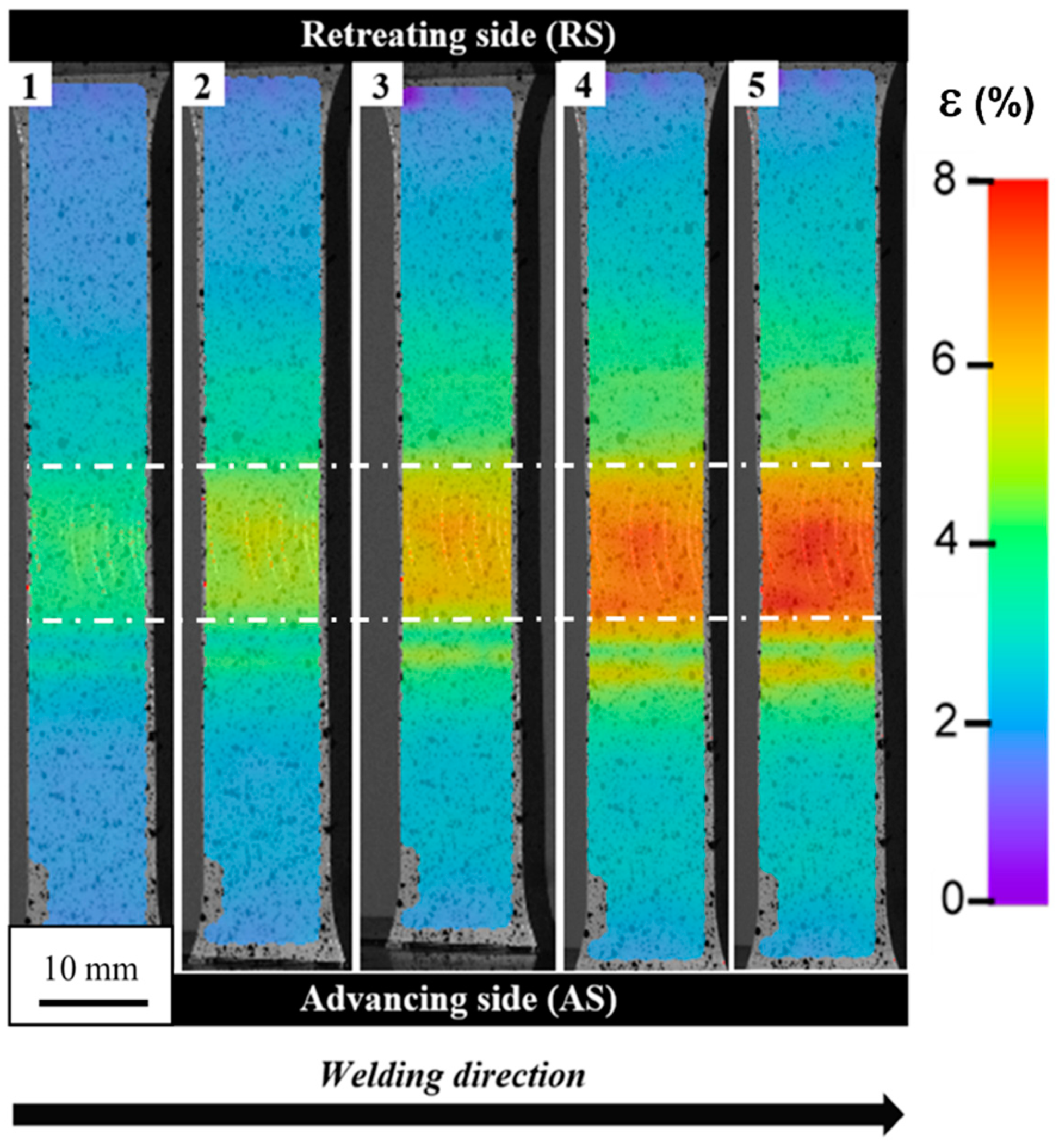

3.3. Tensile Test Results

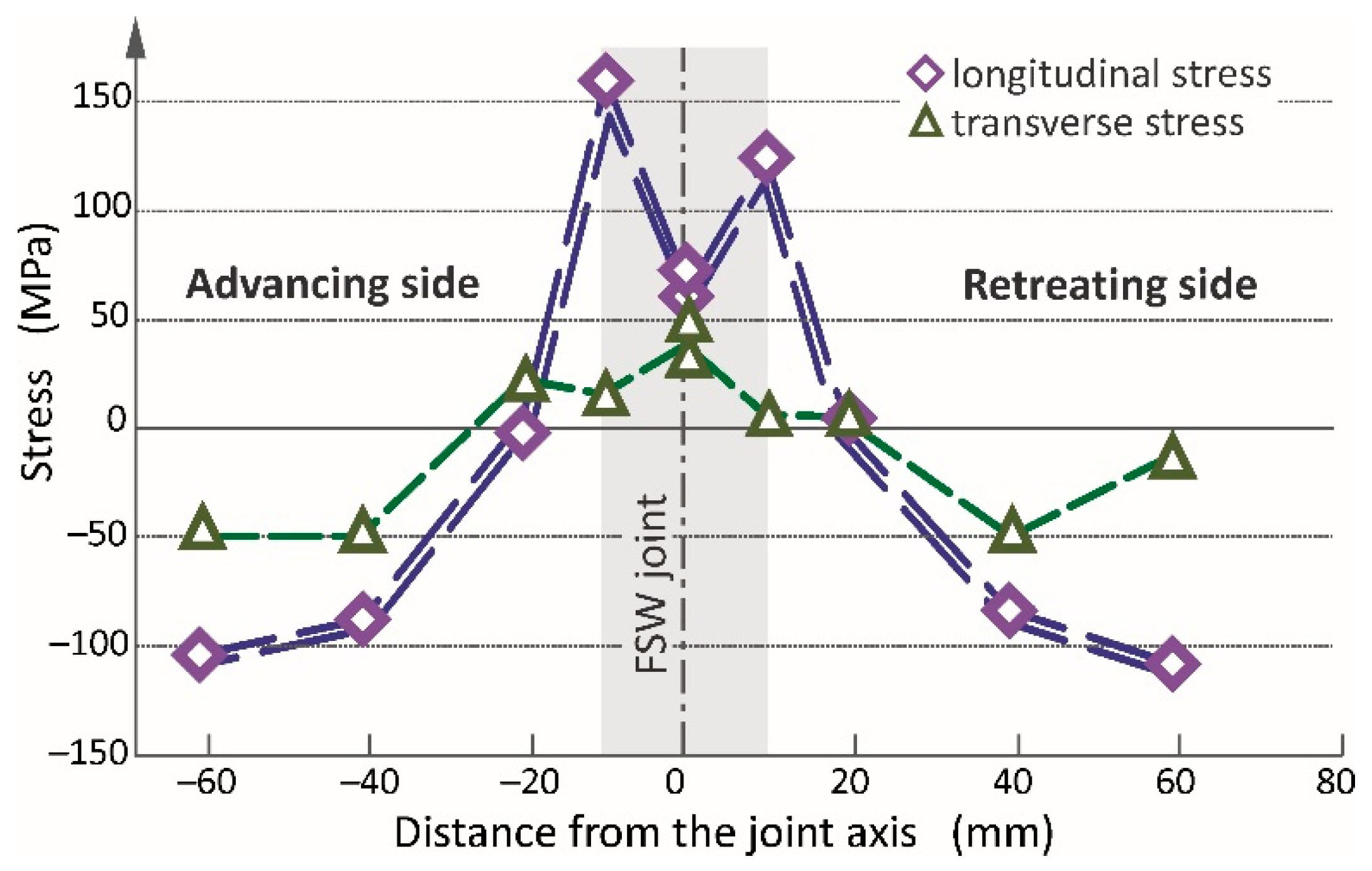

3.4. Residual Stress Measurements

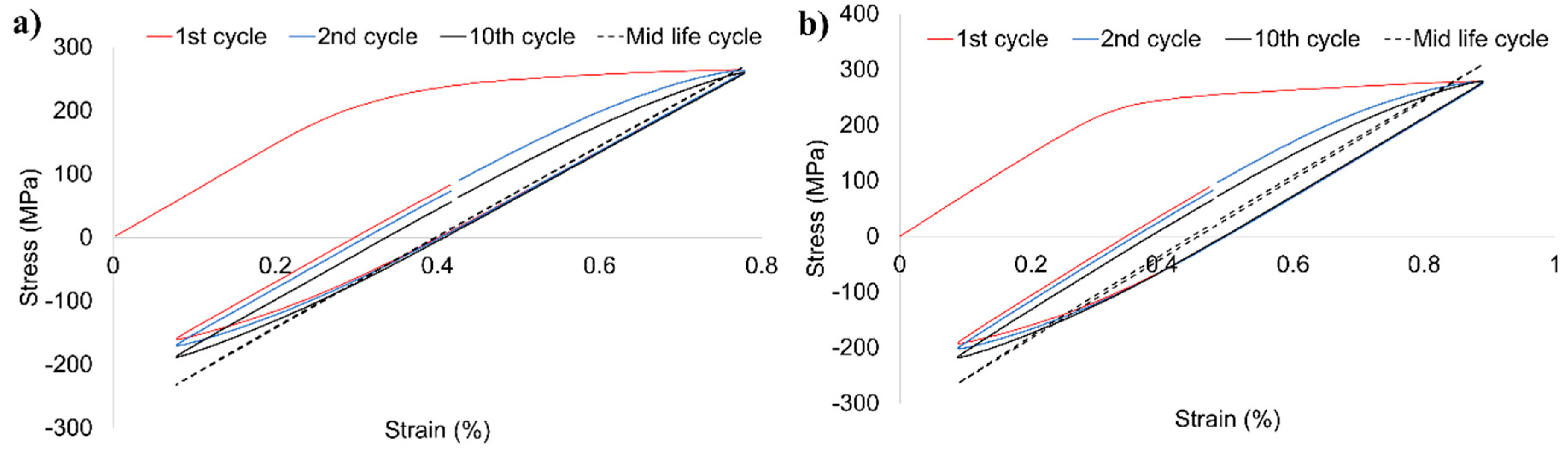

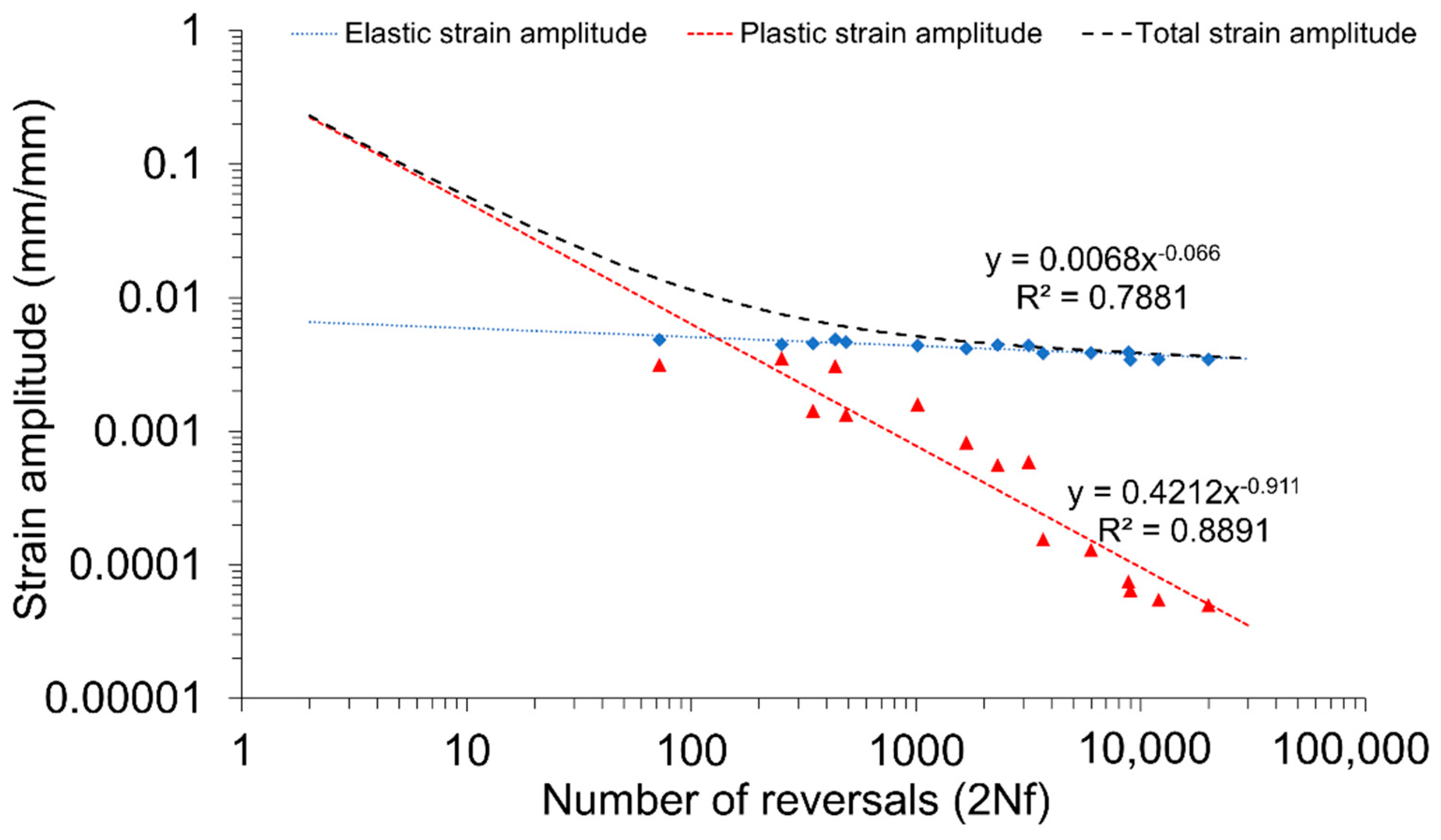

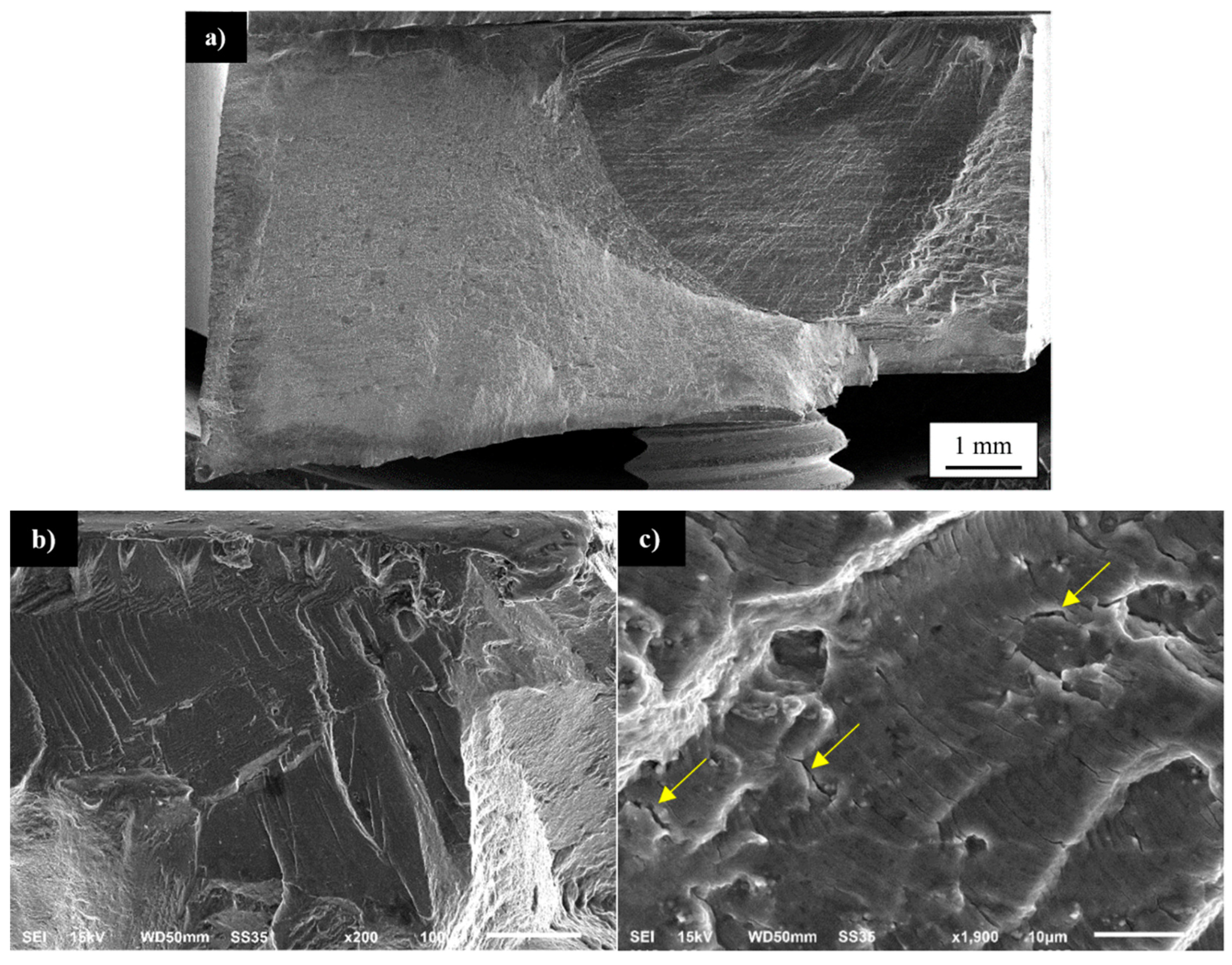

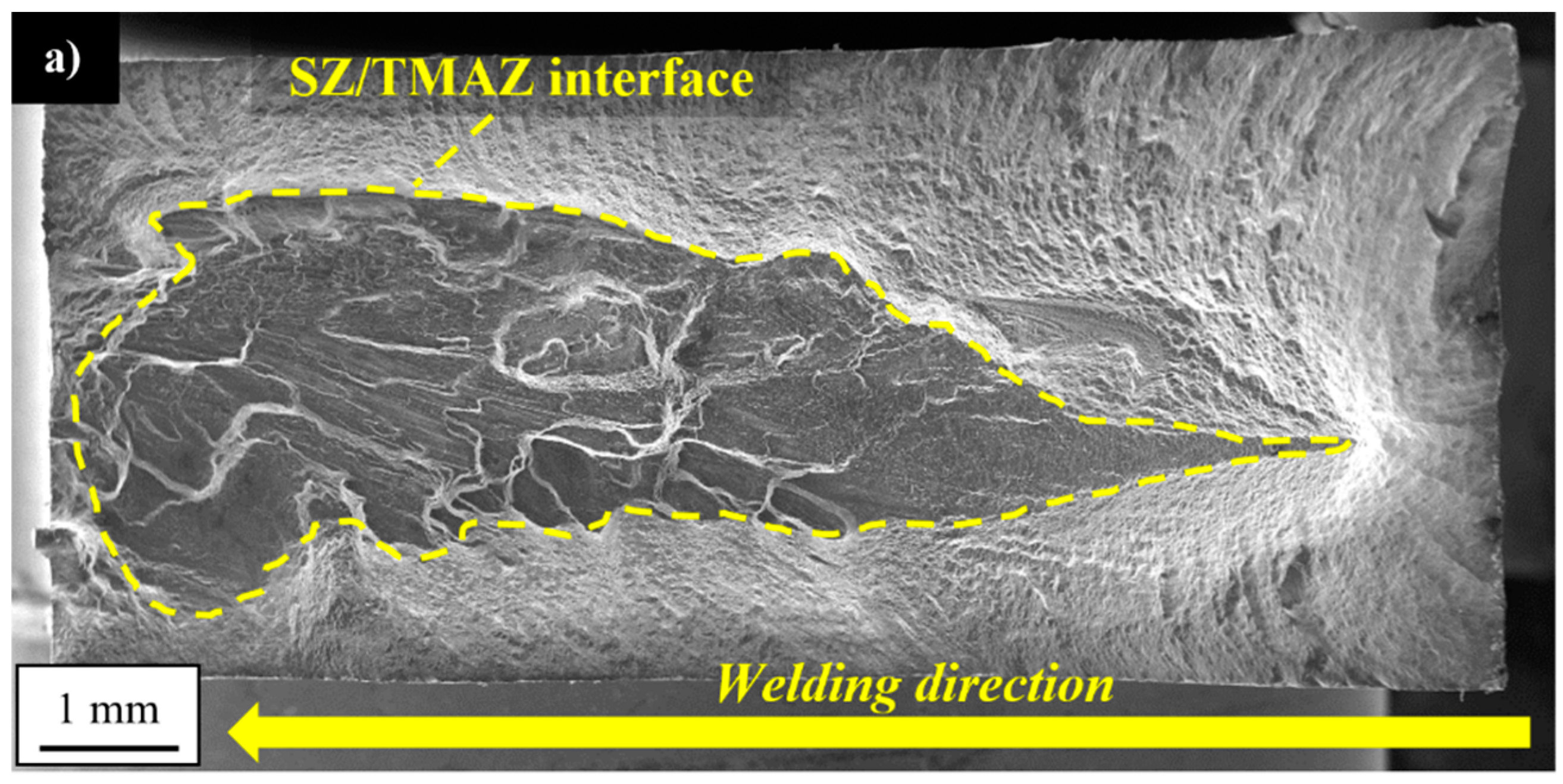

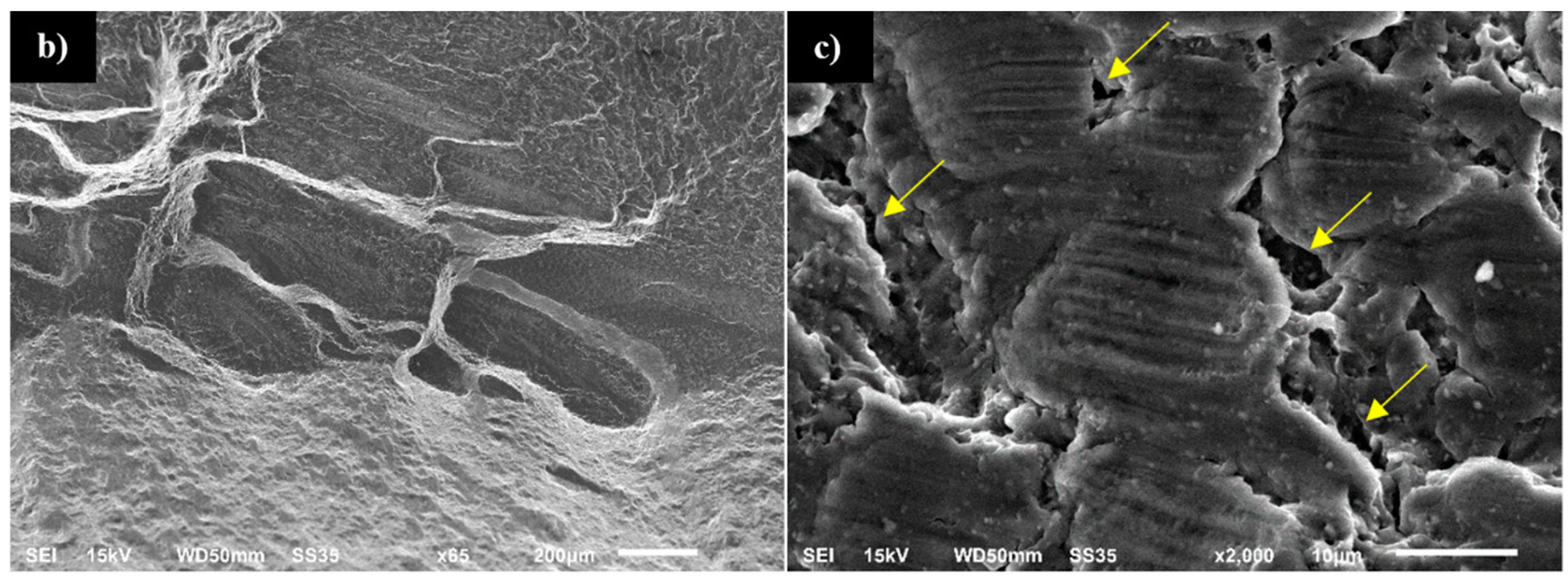

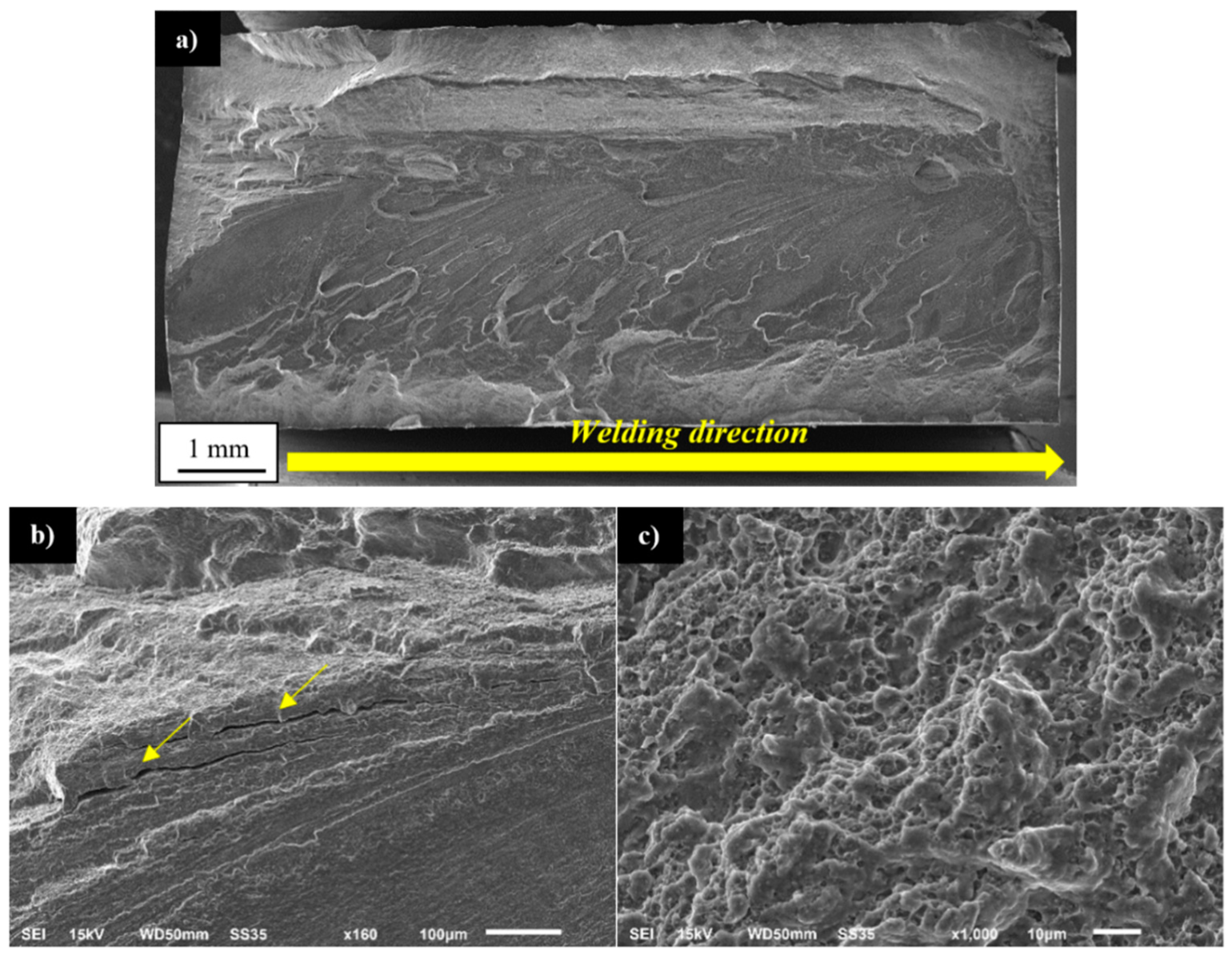

3.5. Low Cycle Fatigue Properties and Fracture Surface Observations

4. Conclusions

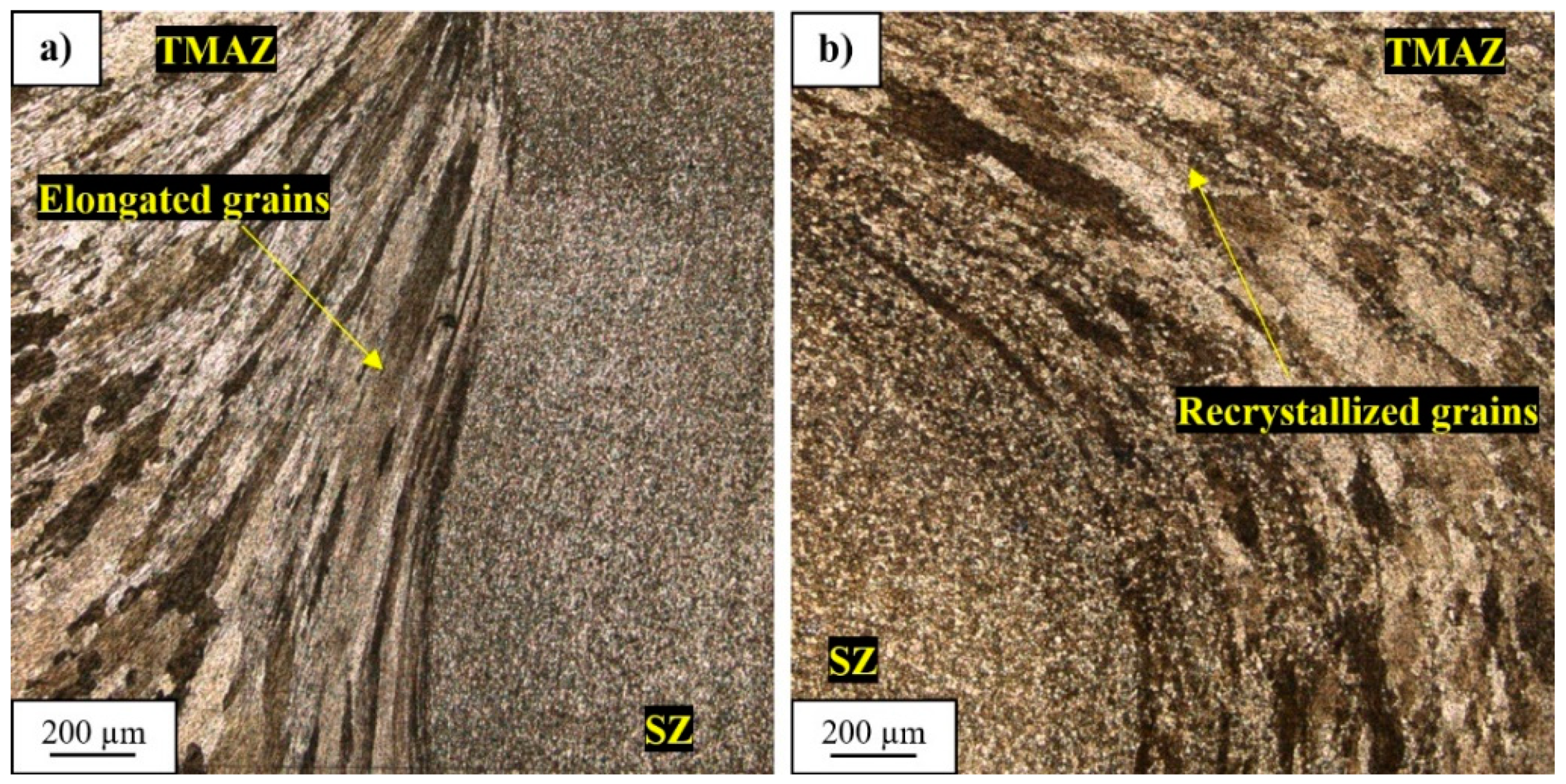

- The microstructure analysis of the obtained weld has revealed the differences in the boundaries between SZ and TMAZ on each side of the joint. On the advancing side, the severely deformed and elongated grains of TMAZ are adjoined to the dynamically recrystallized grains of SZ, while on the retreating side the boundary between SZ and TMAZ is not clear and TMAZ is characterized by partly recrystallized microstructure.

- The failure in the tensile test has occurred in the boundary of TMAZ/SZ on the advancing side of the weld with the registered value of 83% joint efficiency. The changes in strain distribution in the FSW joint zone on the local scale were successfully assessed by the DIC system.

- The residual stress measurements have revealed that the highest values of longitudinal stress are localized at the distance of 10 mm from the joint line with their values of 124 MPa (the retreating side) and 159 MPa (the advancing side).

- The cyclic hardening of AA2519-T62 FSW joints during the low-cycle fatigue process were revealed by a reduction of the width of hysteresis loops during the test, with the simultaneous increase in the range of stress values.

Author Contributions

Funding

Conflicts of Interest

References

- Çam, G.; Mistikoglu, S. Recent developments in friction stir welding of al-alloys. J. Mater. Eng. Perform. 2014, 23, 1936–1953. [Google Scholar] [CrossRef]

- Friction Stir Welding and Processing; Mishra, R.S.; Mahoney, M.W. (Eds.) ASM International: Materials Park, OH, USA, 2007; ISBN 978-0-87170-848-9. [Google Scholar]

- Ma, Z.Y.; Feng, A.H.; Chen, D.L.; Shen, J. Recent advances in friction stir welding/processing of aluminum alloys: Microstructural evolution and mechanical properties. Crit. Rev. Solid State Mater. Sci. 2018, 43, 269–333. [Google Scholar] [CrossRef]

- Olea, C.A.W.; Roldo, L.; Strohaecker, T.R.; Dos Santos, J.F. Friction stir welding of precipitate hardenable aluminium alloys: A review. Weld. World 2006, 50, 78–87. [Google Scholar] [CrossRef]

- Siddiquee, A.; Siddiquee, A.N.; Khan, Z.A.; Ubaid, M.; Bajaj, D.; Atif, M.; Khan, A. Microstructure evolution of friction stir welded dissimilar aerospace aluminium alloys. IOP Conf. Series: Mater. Sci. Eng. 2018, 404, 012002. [Google Scholar] [CrossRef]

- Lin, S.; Tang, J.; Liu, S.; Deng, Y.; Lin, H.; Ji, H.; Ye, L.; Zhang, X. Effect of travel speed on microstructure and mechanical properties of FSW joints for Al–Zn–Mg alloy. Materials 2019, 12, 4178. [Google Scholar] [CrossRef] [Green Version]

- Sato, Y.S.; Kokawa, H.; Kurihara, S. Systematic examination of precipitation phenomena associated with hardness and corrosion properties in friction stir welded aluminium alloy 2024. Weld. World 2011, 55, 39–47. [Google Scholar] [CrossRef]

- Fisher, J.J., Jr.; Kramer, L.S.; Pickens, J.R. Aluminum alloy 2519 in military vehicles. Adv. Mater. Process. 2002, 160, 43–46. [Google Scholar]

- Płonka, B.; Rajda, M.; Zamkotowicz, Z.; Żelechowski, J.; Remsak, K.; Korczak, P.; Szymański, W.; Sniezek, L. Studies of the AA2519 alloy hot rolling process and cladding with EN AW-1050A alloy. Arch. Met. Mater. 2016, 61, 381–388. [Google Scholar] [CrossRef]

- Owolabi, G.; Daramola, T.; Yilmaz, N.; Whitworth, H.; Zeytinchi, A. Mechanical Properties of Ultrafine Grain 2519 Aluminum Alloy. In TMS Annual Meeting & Exhibition, Proceedings of the 147th Annual Meeting & Exhibition Supplemental TMS, 11-15.03, Phoenix, Arizona, 11–15 March 2018; The Minerals, Metals & Materials Series; Springer International Publishing: Cham, Switzerland, 2018; pp. 943–950. ISBN 978-3-319-72525-3. [Google Scholar]

- Dorin, T.; Ramajayam, M.; Vahid, A.; Langan, T. Aluminium scandium alloys. In Fundamentals of Aluminium Metallurgy; Elsevier: Amsterdam, The Netherlands, 2018; pp. 439–494. ISBN 978-0-08-102063-0. [Google Scholar]

- Nokhrin, A.; Shadrina, I.; Chuvil’Deev, V.; Kopylov, V.I. Study of structure and mechanical properties of fine-grained aluminum alloys al-0.6wt.%Mg-Zr-Sc with ratio Zr:Sc = 1.5 obtained by cold drawing. Materials 2019, 12, 316. [Google Scholar] [CrossRef] [Green Version]

- Røyset, J. Scandium in aluminium alloys overview: Physical metallurgy, properties and applications. Metall. Sci. Technol. 2007, 25, 1–26. [Google Scholar]

- Du, Y.; Li, H.; Yang, L.; Luo, C. Accurate measurement of residual stresses of 2219-T87 aluminum alloy friction stir welding joints based on properties of joints. J. Mech. Sci. Technol. 2018, 32, 139–147. [Google Scholar] [CrossRef]

- Chen, Y.; Feng, J.; Liu, H. Precipitate evolution in friction stir welding of 2219-T6 aluminum alloys. Mater. Charact. 2009, 60, 476–481. [Google Scholar] [CrossRef]

- Sabari, S.S.; Malarvizhi, S.; Balasubramanian, V. Characteristics of FSW and UWFSW joints of AA2519-T87 aluminium alloy: Effect of tool rotation speed. J. Manuf. Process. 2016, 22, 278–289. [Google Scholar] [CrossRef]

- Liang, X.P.; Li, H.Z.; Li, Z.; Hong, T.; Ma, B.; Liu, S.D.; Liu, Y. Study on the microstructure in a friction stir welded 2519-T87 Al alloy. Mater. Des. 2012, 35, 603–608. [Google Scholar] [CrossRef]

- Ubaid, M.; Bajaj, D.; Mukhopadhyay, A.K.; Siddiquee, A.N. Friction stir welding of thick AA2519 alloy: Defect elimination, mechanical and micro-structural characterization. Met. Mater. Int. 2019, 1–20. [Google Scholar] [CrossRef]

- Lacki, P.; Adamus, K.; Winowiecka, J. The numerical simulation of aviation structure joined by FSW. Arch. Metall. Mater. 2019, 64, 387–392. [Google Scholar] [CrossRef]

- Mishra, A. Artificial intelligence algorithms for the analysis of mechanical property of friction stir welded joints by using python programming. Weld. Technol. Rev. 2020, 92, 7–16. [Google Scholar] [CrossRef]

- Nadeau, F.; Thériault, B.; Gagné, M.O. Machine learning models applied to friction stir welding defect index using multiple joint configurations and alloys. Proc. Inst. Mech. Eng. L 2020, 234, 752–765. [Google Scholar] [CrossRef]

- He, C.; Liu, Y.; Dong, J.; Wang, Q.; Wagner, D.R.; Bathias, C. Fatigue crack initiation behaviors throughout friction stir welded joints in AA7075-T6 in ultrasonic fatigue. Int. J. Fatigue 2015, 81, 171–178. [Google Scholar] [CrossRef]

- Panin, S.; Vlasov, I.; Sergeev, V.P.; Maruschak, P.; Sunder, R.; Ovechkin, B. Fatigue life improvement of 12Cr1MoV steel by irradiation with Zr+ ion beam. Int. J. Fatigue 2015, 76, 3–10. [Google Scholar] [CrossRef]

- Moreira, P.; De Figueiredo, M.; De Castro, P. Fatigue behaviour of FSW and MIG weldments for two aluminium alloys. Theor. Appl. Fract. Mech. 2007, 48, 169–177. [Google Scholar] [CrossRef]

- Maruschak, P.; Panin, S.; Ignatovich, S.; Zakiev, I.; Konovalenko, I.; Lytvynenko, I.; Sergeev, V. Influence of deformation process in material at multiple cracking and fragmentation of nanocoating. Theor. Appl. Fract. Mech. 2012, 57, 43–48. [Google Scholar] [CrossRef]

- Mierzyński, J.; Hutsaylyuk, V. Fatigue crack growth in the D16CzATW aluminium alloy in the presence of a calibrated hole under simple bending. Int. J. Fatigue 2012, 39, 54–60. [Google Scholar] [CrossRef]

- Viňáš, J.; Brezinová, J.; Maruschak, P.; Brezina, J. Structural and mechanical features of laser-welded joints of zinc-coated advanced steel sheets. Mater. Sci. 2019, 55, 46–51. [Google Scholar] [CrossRef]

- Wachowski, M.; Sniezek, L.; Szachogluchowicz, I.; Kosturek, R.; Płociński, T. Microstructure and fatigue life of Cp-Ti/316L bimetallic joints obtained by means of explosive welding. Bull. Pol. Acad. Tech. 2018, 66, 925–933. [Google Scholar] [CrossRef]

- Kurek, A.; Wachowski, M.; Niesłony, A.; Płociński, T.; Kurzydłowski, K.J. Fatigue tests and metallographic of explosively cladded steel-titanium bimetal. Arch. Met. Mater. 2014, 59, 1566–1570. [Google Scholar] [CrossRef] [Green Version]

- Xu, W.; Liu, J.H.; Chen, D.L.; Luan, G.H. Low-cycle fatigue of a friction stir welded 2219-T62 aluminum alloy at different welding parameters and cooling conditions. Int. J. Adv. Manuf. Technol. 2014, 74, 209–218. [Google Scholar] [CrossRef]

- Sun, G.; Chen, Y.; Chen, S.; Shang, D. Fatigue modeling and life prediction for friction stir welded joint based on microstructure and mechanical characterization. Int. J. Fatigue 2017, 98, 131–141. [Google Scholar] [CrossRef]

- Vuherer, T.; Kramberger, J.; Milčić, D.; Milčić, M.; Glodež, S. Fatigue behaviour of friction stir welded AA-2024 aluminium alloy sheets. IOP Conf. Ser. Mater. Sci. Eng. 2019, 659, 012032. [Google Scholar] [CrossRef]

- Kosturek, R.; Sniezek, L.; Wachowski, M.; Torzewski, J. The influence of post-weld heat treatment on the microstructure and fatigue properties of sc-modified AA2519 friction stir-welded joint. Materials 2019, 12, 583. [Google Scholar] [CrossRef] [Green Version]

- Kosturek, R.; Śnieżek, L.; Torzewski, J.; Wachowski, M. The influence of welding parameters on macrostructure and mechanical properties of Sc-modified AA2519-T62 FSW joints. Manuf. Rev. 2020, 7, 28. [Google Scholar] [CrossRef]

- Texier, D.; Atmani, F.; Bocher, P.; Nadeau, F.; Chen, J.; Zedan, Y.; Vanderesse, N.; Demers, V. Fatigue performances of FSW and GMAW aluminum alloys welded joints: Competition between microstructural and structural-contact-fretting crack initiation. Int. J. Fatigue 2018, 116, 220–233. [Google Scholar] [CrossRef] [Green Version]

- Torzewski, J.; Grzelak, K.; Wachowski, M.; Kosturek, R. Microstructure and low cycle fatigue properties of AA5083 H111 friction stir welded joint. Materials 2020, 13, 2381. [Google Scholar] [CrossRef]

- Kambouz, Y.; Benguediab, M.; Bouchouicha, B.; Mazari, M. Numerical study of the mechanical behavior and fatigue in a weld bead by friction stir for a 6082-T6 aluminum alloy. Mech. Mech. Eng. 2017, 61, 36–43. [Google Scholar] [CrossRef] [Green Version]

- ASTM E8/E8M-13a. Standard Test Methods for Tension Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- ASTM E837-13a. Standard Test Method for Determining Residual Stresses by the Hole-Drilling Strain-Gage Method; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Lee, H.S.; Lee, Y.R.; Min, K.J. Effects of friction stir welding speed on AA2195 alloy. MATEC Web Conf. 2016, 45, 01003. [Google Scholar] [CrossRef] [Green Version]

- Tufaro, L.; Manzoni, I.; Svoboda, H.G. Effect of heat input on AA5052 friction stir welds characteristics. Procedia Mater. Sci. 2015, 8, 914–923. [Google Scholar] [CrossRef] [Green Version]

- Sun, P.Y.; Zhu, Z.K.; Su, C.Y.; Lu, L.; Zhou, C.Y.; He, X.H. Experimental characterisation of mechanical behaviour for a TA2 welded joint using digital image correlation. Opt. Lasers Eng. 2019, 115, 161–171. [Google Scholar] [CrossRef]

- Kubit, A.; Bucior, M.; Kluz, R.; Święch, Ł.; Ochał, K. Application of the 3D digital image correlation to the analysis of deformation of joints welded with the FSW method after shot peening. Adv. Mater. Sci. 2019, 19, 57–66. [Google Scholar] [CrossRef] [Green Version]

- TN-503. Measurement of Residual Stresses by the Blind Hole-drilling Method; Measurements Group Inc.: Raleigh, NC, USA, 2020. [Google Scholar]

- Zapata, J.; Del Toro, M.A.; Lopez, D.O. Residual stresses in friction stir dissimilar welding of aluminum alloys. J. Mater. Process. Technol. 2016, 229, 121–127. [Google Scholar] [CrossRef]

- Sadeghi, S.; Najafabadi, M.A.; Javadi, Y.; Mohammadisefat, M. Using ultrasonic waves and finite element method to evaluate through-thickness residual stresses distribution in the friction stir welding of aluminum plates. Mater. Des. 2013, 52, 870–880. [Google Scholar] [CrossRef]

- Jimenez-Mena, N.; Sapanathan, T.; Drezet, J.-M.; Pirling, T.; Jacques, P.; Simar, A. Residual stresses of friction melt bonded aluminum/steel joints determined by neutron diffraction. J. Mater. Process. Technol. 2018, 266, 651–661. [Google Scholar] [CrossRef]

- Sun, T.; Roy, M.; Strong, D.; Withers, P.J.; Prangnell, P.B. Comparison of residual stress distributions in conventional and stationary shoulder high-strength aluminum alloy friction stir welds. J. Mater. Process. Technol. 2017, 242, 92–100. [Google Scholar] [CrossRef] [Green Version]

- Sonne, M.R.; Tutum, C.C.; Hattel, J.H.; Simar, A.; De Meester, B. The effect of hardening laws and thermal softening on modeling residual stresses in FSW of aluminum alloy 2024-T3. J. Mater. Process. Technol. 2013, 213, 477–486. [Google Scholar] [CrossRef]

- Buglioni, L.; Tufaro, L.; Svoboda, H.G. Thermal cycles and residual stresses in FSW of aluminum alloys: Experimental measurements and numerical models. Procedia Mater. Sci. 2015, 9, 87–96. [Google Scholar] [CrossRef] [Green Version]

- Preston, R.; Shercliff, H.; Withers, P.J.; Smith, S. Physically-based constitutive modelling of residual stress development in welding of aluminium alloy 2024. Acta Mater. 2004, 52, 4973–4983. [Google Scholar] [CrossRef]

- Kosturek, R.; Sniezek, L.; Torzewski, J.; Wachowski, M. Low cycle fatigue properties of Sc-modified AA2519-T62 extrusion. Materials 2020, 13, 220. [Google Scholar] [CrossRef] [Green Version]

- Kłysz, S.; Goss, C. Zagadnienia niskocyklowego zmęczenia metali. Res. Works Air Force Inst. Technol. 2003, 17, 53–69. [Google Scholar]

- Szachogluchowicz, I.; Sniezek, L.; Hutsaylyuk, V. Low cycle fatigue properties of AA2519–Ti6Al4V laminate bonded by explosion welding. Eng. Fail. Anal. 2016, 69, 77–87. [Google Scholar] [CrossRef]

- Sun, G.Q.; Guo, Y.; Han, X.; Shang, D.G.; Chen, S. Fatigue modeling containing hardening particles and grain orientation for aluminum alloy FSW joints. Materials 2019, 12, 2024. [Google Scholar] [CrossRef] [Green Version]

- Ribeiro, A.S.; de Jesus, A.M.; Feup, I. Fatigue behaviour of welded joints made of 6061-T651 aluminium alloy. In Aluminium Alloys, Theory and Applications; Kvackaj, T., Ed.; InTech: London, UK, 2011; ISBN 978-953-307-244-9. [Google Scholar]

- Cisko, A.R.; Jordon, J.; Avery, D.Z.; Liu, T.; Brewer, L.N.; Allison, P.G.; Carino, R.L.; Hammi, Y.; Rushing, T.W.; Garcia, L. Experiments and modeling of fatigue behavior of friction stir welded aluminum lithium alloy. Metals 2019, 9, 293. [Google Scholar] [CrossRef] [Green Version]

| Fe | Si | Cu | Zn | Ti | Mn | Mg | Ni | Zr | Sc | V | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.11 | 0.08 | 6.32 | 0.05 | 0.08 | 0.17 | 0.33 | 0.02 | 0.19 | 0.16 | 0.10 | Base |

| Young Modulus (E) | Yield Strength (Re0.2) | Tensile Strength (Rm) | Elongation (A) |

|---|---|---|---|

| 78 GPa | 312 MPa | 469 MPa | 19% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kosturek, R.; Śnieżek, L.; Torzewski, J.; Ślęzak, T.; Wachowski, M.; Szachogłuchowicz, I. Research on the Properties and Low Cycle Fatigue of Sc-Modified AA2519-T62 FSW Joint. Materials 2020, 13, 5226. https://doi.org/10.3390/ma13225226

Kosturek R, Śnieżek L, Torzewski J, Ślęzak T, Wachowski M, Szachogłuchowicz I. Research on the Properties and Low Cycle Fatigue of Sc-Modified AA2519-T62 FSW Joint. Materials. 2020; 13(22):5226. https://doi.org/10.3390/ma13225226

Chicago/Turabian StyleKosturek, Robert, Lucjan Śnieżek, Janusz Torzewski, Tomasz Ślęzak, Marcin Wachowski, and Ireneusz Szachogłuchowicz. 2020. "Research on the Properties and Low Cycle Fatigue of Sc-Modified AA2519-T62 FSW Joint" Materials 13, no. 22: 5226. https://doi.org/10.3390/ma13225226

APA StyleKosturek, R., Śnieżek, L., Torzewski, J., Ślęzak, T., Wachowski, M., & Szachogłuchowicz, I. (2020). Research on the Properties and Low Cycle Fatigue of Sc-Modified AA2519-T62 FSW Joint. Materials, 13(22), 5226. https://doi.org/10.3390/ma13225226