Polish Transition towards Circular Economy: Materials Management and Implications for the Construction Sector

Abstract

1. Introduction

2. Materials and Methods

3. Polish Legislation versus EU Measures

4. Circular Economy Roadmap

- Analysis of potential and legislative changes proposed to increase the economic use of incineration by-products. Over 78% of electrical energy in Poland is generated from lignite and hard coal. During incineration of these raw materials, however, gases and incineration by-products are generated, including ash, slag and dust. Incineration by-products are the source of many minerals whose potential is not fully exploited. Owing to their binding characteristics, they can be used for the production of construction materials, mainly cement and concrete (as Portland cement substitute), and in road and underground construction as an ingredient of embankments and other structural layers [36,37].

- Creating a platform dedicated to secondary raw materials, aimed at market actors, providing information about supply and demand, and trade.

- Extended producer responsibility (EPR), encouraging producers to design and make products with extended service life, and imposing the obligation to collect and manage waste from the same products as the ones launched.

- Identification of the environmental impact of products and services using, for example, the Life Cycle Assessment (LCA), Product Environmental Footprint (PEF) and Organization Environmental Footprint (OEF) methods [38].

- Identification of all streams of municipal waste, including post-consumer waste, previously not recorded but having an economic impact. This measure can be particularly useful in the context of the classification of waste (effective until 2018) generated during minor repairs, construction and demolition works by individuals, incorporating construction and demolition waste into the stream of municipal waste.

- Changes in public procurement law, which would generate demand for products and services according to CE business models and increasing the share of green public procurement.

- Analysis of the possibilities to implement reporting and inspection reliefs guidelines for entities that observe environmental standards, such as the EU Eco label and EMAS, and entities entered in the Polish Register of Cleaner Production and Responsible Entrepreneurship.

- The systematic assessment of the Polish economy transformation towards CE and the impact of the new economy model on the social and economic development of Poland will be carried out with two sets of indicators developed by state administration bodies in cooperation with public sector institutions and industry representatives as part of the “otoGOZ” programme [30].

5. The Construction Sector in the Context of the Domestic Materials Economy

6. Construction and Demolition Waste in Domestic Waste Management

7. Obstacles on the Road of Polish Construction to CE

7.1. Disturbance of Relational and Logistic Systems

7.2. Market Barriers

7.3. Technological Context

7.4. Social Aspects

8. Conclusions

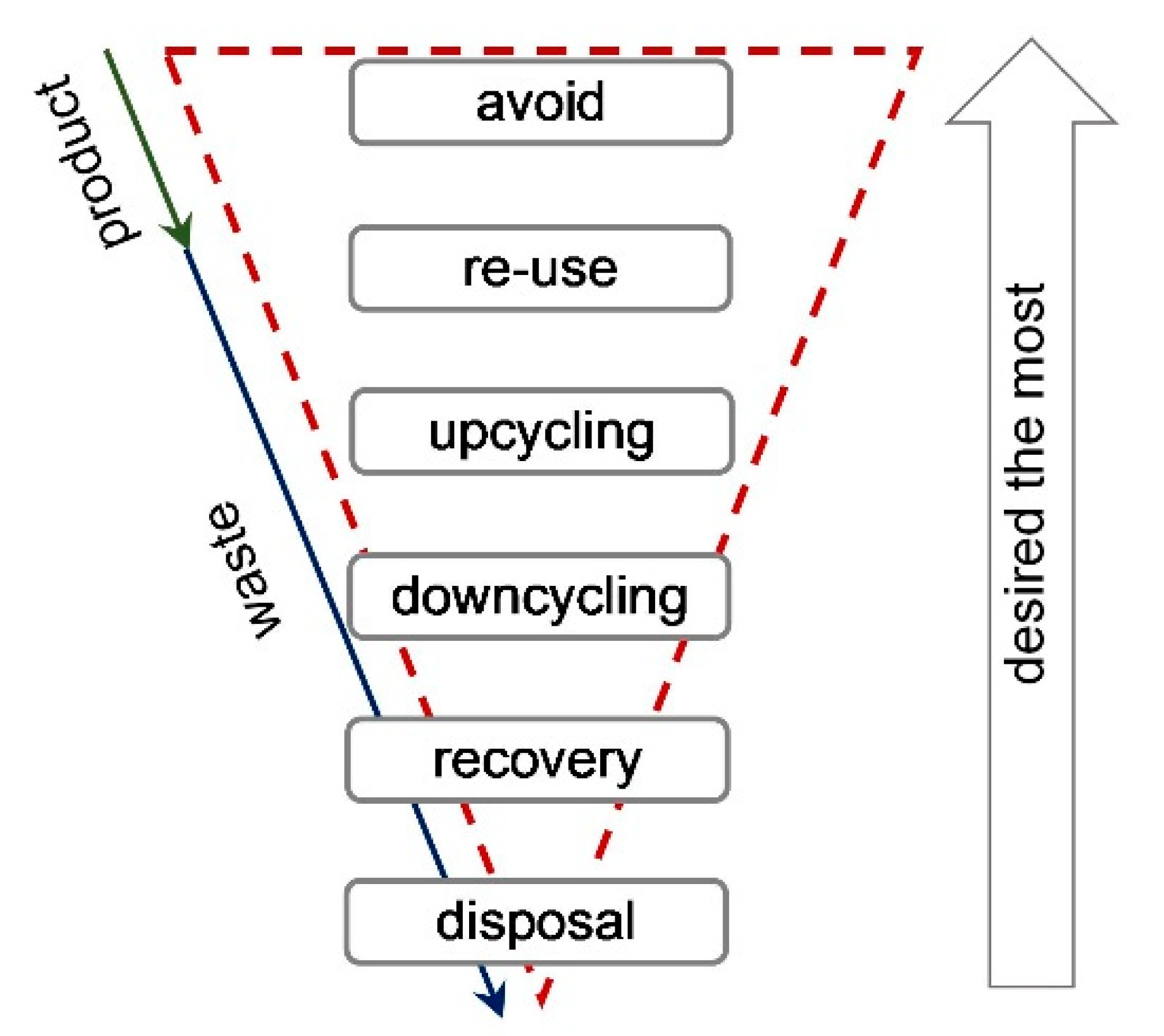

- Circular economy solutions help to maintain the added value of products and eliminate waste. The possibility of the reuse of natural resources after the end of a product’s life cycle supports their effective maintenance in economic circulation and, hence, limits their negative environmental impact [43,44,45].

- The effective implementation of CE assumptions requires changes across the whole of the value chain, from the stage of design and new business model development to innovative methods of waste collection and processing, and the development of new consumer habits. It also entails the need to reorganize the system and introduce numerous economic, organizational, social and political innovations.

- Regardless of the acquired strategy, some elements of linearity will not be fully eliminated, mainly because of the need to use resources that have not been used previously or the generation of unavoidable residual waste.

- Poland’s transition to the CE model implies the need to develop product and service innovations, the development of new business models, organizational charts and, most importantly, to increase social awareness. In order to maximize the benefits of transformation and theoretical elimination of the risks related to CE, the changes being implemented should also be coordinated on a legislative, organizational and business level. In construction, it is important to develop instruments that allow an overlap between investor and user goals.

- The promotion of circular solutions by authorities should go along with considerations for technological constraints and the provision of maximum support for the development of product and service innovations, including consumer safety.

- It is also important to remember that regardless of the refinement of the implemented solutions and their expected engineering effectiveness, the end user will ultimately remain the final judge of the efficiency of any changes. Society’s response can either impede or trigger the implementation of CE solutions. The conclusions drawn from the survey reveal that Polish society is aware of the need to protect the natural environment, but that certain CE aspects have not yet been fully discovered, despite information frequently shared in the media. Therefore, it can be expected that increased efforts in educating society on the consequences of environmental overexploitation and the long-term benefits of CE solutions can be key in the effective economic transformation of Poland.

- In addition to the obvious environmental and economic benefits resulting from the implementation of the CE model, one should remember that social benefits, including the trend of creating new jobs, is forecast in many analyses [16,68,69]. Nevertheless, the real impact of actions taken should be should be systematically monitored. In consequence, detailed analysis of associated changes occurring in the particular branches of the economy with the special emphasis on the construction sector and the whole supply chain can be proposed as evident continuation of this research. The global dimension of the transformation should be also considered since it directly impacts on the international politics of Poland.

Funding

Acknowledgments

Conflicts of Interest

Abbreviation

| CE | Circular Economy |

| CDW | construction and demolition waste |

| CO2 | carbon dioxide |

| EOD | Earth Overshoot Day |

| EU | European Union |

| GDP | Gross Domestic Product |

| LCA | Life Cycle Assessment |

| LCC | Life Cycle Cost |

| OECD | Organization for Economic Cooperation and Development |

| OEF | Organization Environmental Footprint |

| PEF | Product Environmental Footprint |

| PSZOK | Municipal Selective Waste Collection Points (in Polish: Punkt Selektywnej Zbiórki Odpadów) |

References

- McDonough, W.; Braungart, M. Cradle to Cradle: Remaking the Way We Make Thing, 1st ed.; North Point Press: New York, NY, USA, 2003. [Google Scholar]

- Ellen MacArthur Foundation. Growth within: A Circular Economy Vision for a Competitive Europe; Ellen MacArthur Foundation: Cowes, UK, 2015. [Google Scholar]

- European Comission. Closing the Loop—An EU Action Plan for the Circular Economy COM(2015)614 Final. 2015. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:8a8ef5e8-99a0-11e5-b3b7-01aa75ed71a1.0012.02/DOC_1&format=PDF (accessed on 21 April 2020).

- Worldometers. Available online: https://www.worldometers.info/world-population/ (accessed on 17 April 2020).

- Earth Overshoot Day. Available online: https://www.overshootday.org/newsroom/country-overshoot-days/ (accessed on 3 May 2020).

- Mayer, A.; Haas, W.; Wiedenhofer, D.; Krausmann, F.; Nuss, P.; Blengini, G.A. Measuring Progress towards a Circular Economy: A Monitoring Framework for Economy-wide Material Loop Closing in the EU28. J. Ind. Ecol. 2019, 23, 62–76. [Google Scholar] [CrossRef] [PubMed]

- OECD. Available online: https://www.oecd.org/ (accessed on 1 June 2020).

- Eurostat. Available online: https://ec.europa.eu/eurostat (accessed on 21 April 2020).

- Statistics Poland. Materials Management in 2018; Statistics Poland: Warsaw, Poland, 2019. [Google Scholar]

- Statistics Poland. Construction and Assembly Production in 2018; Statistics Poland: Warsaw, Poland, 2019. [Google Scholar]

- Benachio, G.L.F.; Freitas, M.d.C.D.; Tavares, S.F. Circular economy in the construction industry: A systematic literature review. J. Clean. Prod. 2020, 260, 121046. [Google Scholar] [CrossRef]

- Clark, G. Evolution of the global sustainable consumption and production policy and the United Nations Environment Programme’s (UNEP) supporting activities. J. Clean. Prod. 2007, 15, 492–498. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Circular Academy. Available online: http://www.circular.academy/circular-economy-some-definitions/ (accessed on 19 September 2019).

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Morseletto, P. Targets for a circular economy. Resour. Conserv. Recycl. 2020, 153, 104553. [Google Scholar] [CrossRef]

- European Comission. Towards a Circular Economy: Closing the Loop of the Products Lifecycle. Available online: https://ec.europa.eu/commission/priorities/jobs-growth-and-investment/towards-circular-economy_en (accessed on 17 April 2020).

- European Comission. Regulation No 305/2011 Laying Down Harmonised Conditions for the Marketing of Construction Products; European Comission: Brussel, Belgium, 2011. [Google Scholar]

- European Comission. Circular Economy Package. Available online: https://ec.europa.eu/commission/publications/documents-strategy-plastics-circular-economy_en (accessed on 17 April 2020).

- European Comission. Implementation of the Circular Economy Action Plan; European Comission: Brussel, Belgium, 2019. [Google Scholar]

- Single Market for Green Products Initiative (SMGP). Available online: https://ec.europa.eu/environment/eussd/smgp/ (accessed on 17 April 2020).

- European Comission. The Use of Common Methods to Measure and Communicate the Life Cycle Environmental Performance of Products and Organisations (2013/179/EU); European Comission: Brussel, Belgium, 2013. [Google Scholar]

- Institute for Environment and Sustainability. Product Environmental Footprint (PEF) Guide. Available online: https://ec.europa.eu/environment/archives/eussd/pdf/Draft%20Product%20Environmental%20Footprint%20Guide%20for%20invited%20stakeholder%20meeting.pdf (accessed on 10 April 2020).

- Institute for Environment and Sustainability. Organisation Environmental Footprint (OEF) Guide. Available online: https://ec.europa.eu/environment/eussd/pdf/footprint/OEF%20Guide_final_July%202012_clean%20version.pdf (accessed on 10 April 2020).

- The EU Environmental Footprint Pilots. Available online: https://ec.europa.eu/environment/eussd/smgp/ef_pilots.htm (accessed on 17 April 2020).

- European Comission. Monitoring Framework for the Circular Economy COM(2018) 29 Final. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1516265440535&uri=SWD:2018:17:FIN (accessed on 16 April 2020).

- Ministerstwo Rozwoju i Finansów. Strategia na rzecz Odpowiedzialnego Rozwoju do Roku 2020 (z perspektywą do 2030 r.). 2017. Available online: http://gamma.infor.pl/zalaczniki/mpo/2017/044/mpo.2017.044.260.0001.pdf (accessed on 17 April 2020).

- Ministerstwo Rozwoju Regionalnego. Strategia Rozwoju Kraju 2020. 2012. Available online: https://bip.kprm.gov.pl/download/75/43055/Strategia2020.pdf (accessed on 18 April 2020).

- Ministerstwo Rozwoju. Mapa Drogowa Transformacji w Kierunku Gospodarki o Obiegu Zamkniętym. 2019. Available online: https://www.gov.pl/web/rozwoj-praca-technologia/rada-ministrow-przyjela-projekt-mapy-drogowej-goz (accessed on 1 April 2020).

- R2π. Available online: http://www.r2piproject.eu/ (accessed on 20 April 2020).

- Gospostrateg “oto-GOZ”. Available online: https://archiwum.mpit.gov.pl/strony/zadania/zrownowazony-rozwoj/gospodarka-o-obiegu-zamknietym/gospostrateg-oto-goz/ (accessed on 20 April 2020).

- Green Economy. Available online: https://www.gridw.pl/zielona-gospodarka (accessed on 18 April 2020).

- Cleaner Production. Available online: https://www.cp.org.pl/ (accessed on 18 April 2020).

- Sustainable Development. Available online: http://www.un.org.pl/ (accessed on 18 April 2020).

- Low-Carbon Economy. Available online: http://gospodarkaniskoemisyjna.pl/ (accessed on 18 April 2020).

- Ellen MacArthur Foundation. Towards the Circular Economy: Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2013. [Google Scholar]

- Rajczyk, K. Popioły Lotne z Kotłów Fluidalnych i Możliwości ich Uszlachetniania; Instytut Materiałów Ceramicznych i Budowlanych: Opole, Poland, 2012. [Google Scholar]

- Rosiek, J. The implementation of Circular Economy Concept in the Polish Coal Combustion Products Sector—Selected problems. Econ. Environ. Stud. 2018, 18, 353–373. [Google Scholar] [CrossRef]

- Sameer, H.; Weber, V.; Mostert, C.; Bringezu, S.; Fehling, E.; Wetzel, A. Environmental Assessment of Ultra-High-Performance Concrete Using Carbon, Material, and Water Footprint. Materials 2019, 12, 851. [Google Scholar] [CrossRef] [PubMed]

- Statistics Poland. Quarterly National Accounts of Gross Domestic Product 2014–2018; Statistics Poland: Warszawa, Poland, 2018. [Google Scholar]

- Statistics Poland. Available online: https://stat.gov.pl (accessed on 26 April 2020).

- Macuk, R. Transformacja Energetyczna w Polsce. Available online: https://forum-energii.eu/public/upload/files/Transformacja%20energetyczna%20w%20Polsce.%20Edycja%202020.pdf (accessed on 29 April 2020).

- Statistics Poland. Statistical Yearbook of Industry—Poland; Statistics Poland: Warsaw, Poland, 2020. [Google Scholar]

- Maraveas, C. Production of Sustainable Construction Materials Using Agro-Wastes. Materials 2020, 13, 262. [Google Scholar] [CrossRef] [PubMed]

- Ling, T.; Lu, Y.; Zhang, Z.; Li, C.; Oeser, M. Value-Added Application of Waste Rubber and Waste Plastic in Asphalt Binder as a Multifunctional Additive. Materials 2019, 12, 1280. [Google Scholar] [CrossRef] [PubMed]

- Hýsek, Š.; Neuberger, P.; Sikora, A.; Schönfelder, O.; Ditommaso, G. Waste Utilization: Insulation Panel from Recycled Polyurethane Particles and Wheat Husks. Materials 2019, 12, 3075. [Google Scholar] [CrossRef] [PubMed]

- Innowo. Budownictwo w Obiegu Zamkniętym w Praktyce. 2019. Available online: https://innowo.org/userfiles/publikacje/Budownictwo%20w%20obiegu%20zamkni%C4%99tym%20w%20praktyce_raport.pdf (accessed on 18 April 2020).

- Rozporządzenie Ministra Klimatu z 2 Grudnia 2020 r. W Sprawie Katalogu Odpadów. 2020. Available online: http://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20200000010/O/D20200010.pdf (accessed on 29 April 2020).

- Statistics Poland. Environment 2019; Statistics Poland: Warszawa, Poland, 2019. [Google Scholar]

- Ustawa z Dnia 7 Lipca 1994 r.—Prawo Budowlane (Dz.U. 1994 nr 89 poz. 414). 1994. Available online: http://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20102431623/U/D20101623Lj.pdf (accessed on 17 April 2020).

- European Commission. Directive 2018/851 on Waste; European Commission: Brussel, Belgium, 2018. [Google Scholar]

- European Commission. Directive 2008/98 on Waste and Repealing Certain Directives; European Commission: Brussel, Belgium, 2008. [Google Scholar]

- López Ruiz, L.A.; Roca Ramón, X.; Gassó Domingo, S. The circular economy in the construction and demolition waste sector—A review and an integrative model approach. J. Clean. Prod. 2020, 248, 119238. [Google Scholar] [CrossRef]

- Rahman, M.A.; Imteaz, M.; Arulrajah, A.; Disfani, M.M. Suitability of recycled construction and demolition aggregates as alternative pipe backfilling materials. J. Clean. Prod. 2014, 66, 75–84. [Google Scholar] [CrossRef]

- Ekoportal. Available online: http://ecoportal.com.pl/ (accessed on 24 April 2020).

- PolyStyreneLoop. Available online: https://polystyreneloop.eu/ (accessed on 24 April 2020).

- Synthos, S.A. Available online: https://www.synthosgroup.com/relacje-inwestorskie/gospodarka-obiegu-zamknietego/aktualnosc/synthos-z-certyfikatem-unep-grid (accessed on 24 April 2020).

- European Commission. Directive 2018/852 on Packaging and Packaging Waste; European Commission: Brussel, Belgium, 2018. [Google Scholar]

- European Commission. Directive 2018/850 on the Landfill of Waste; European Commission: Brussel, Belgium, 2018. [Google Scholar]

- European Commission. Directive 2018/849 on Batteries and Accumulators and Waste Batteries and Accumulators; European Commission: Brussel, Belgium, 2018. [Google Scholar]

- McKinsey. Reinventing Construction: A Route to Higher Productivity; McKinsey: New York, NY, USA, 2017. [Google Scholar]

- European Comission. COM(2008) 400 Final. 2008. Available online: https://www.eumonitor.eu/9353000/1/j9vvik7m1c3gyxp/vikqhmp71bv0#p4 (accessed on 24 April 2020).

- ozporządzenie Ministra Inwestycji i Rozwoju z Dnia 11 Lipca 2018 r. w Sprawie Metody Kalkulacji Kosztów Cyklu Życia Budynków Oraz Sposobu Przedstawiania Informacji o Tych Kosztach (Dz.U. 2018 poz. 1357). 2016. Available online: https://www.uzp.gov.pl/__data/assets/pdf_file/0024/37167/Rozporzadzenie-z-dn.-11.07.2018-r.-w-spr.-kosztow-cyklu-zycia-budynkow.pdf (accessed on 30 April 2020).

- Urząd Zamówień Publicznych. Stan Zrównoważonych Zamówień Publicznych w 2017 Roku; Urząd Zamówień Publicznych: Warszawa, Poland, 2018. [Google Scholar]

- Oyedele, L.O.; Ajayi, S.O.; Kadiri, K.O. Use of recycled products in UK construction industry: An empirical investigation into critical impediments and strategies for improvement. Resour. Conserv. Recycl. 2014, 93, 23–31. [Google Scholar] [CrossRef]

- Blaisi, N.I. Construction and demolition waste management in Saudi Arabia: Current practice and roadmap for sustainable management. J. Clean. Prod. 2019, 221, 167–175. [Google Scholar] [CrossRef]

- Rodríguez, G.; Medina, C.; Alegre, F.J.; Asensio, E.; Sánchez de Rojas, M.I. Assessment of Construction and Demolition Waste plant management in Spain: In pursuit of sustainability and eco-efficiency. J. Clean. Prod. 2015, 90, 16–24. [Google Scholar] [CrossRef]

- Chen, X.; Lu, W. Identifying factors influencing demolition waste generation in Hong Kong. J. Clean. Prod. 2017, 141, 799–811. [Google Scholar] [CrossRef]

- Stahel, W.R. The circular economy. Nat. Comment 2016, 531, 435–438. [Google Scholar] [CrossRef] [PubMed]

- Ellen MacArthur Foundation. Towards the Circular Economy: Opportunities for the Consumer Goods Sector; Ellen MacArthur Foundation: Cowes, UK, 2013; Volume 2. [Google Scholar]

| No. | Question | Answer |

|---|---|---|

| 1. | Gender | (a) Female; (b) Male; (c) Other |

| 2. | Education | (a) Higher; (b) Secondary; (c) Primary; (d) Other |

| 3. | Age | (a) Between 20–39; (b) Between 40–59; (c) Above 60 |

| 4. | Links with the construction sector | (a) Professional; (b) Employment in the construction sector; (c) People from the closest environment work in the construction sector; (d) No links; (e) Others |

| 5. | How do you rate your knowledge and/or experience in the field of construction? | Scale from 1 to 5 |

| 6. | Have you ever participated in planning or carrying out construction works (e.g., supervising the renovation of an apartment, construction of a single-family house or elements of small architecture)? | (a) Yes; (b) Yes, I currently participate; (c) No, never |

| 7. | How do you rate the need to protect the natural environment? | Scale from 1 to 5 |

| 8. | Please, assess your level of knowledge of the following terms: (1) sustainable development, (2) environmental protection, (3) sustainable development, (4) selective waste collection, (5) recycling, (4) Circular Economy | (a) I have very little information; (b) I have basic knowledge; (c) I know this topic quite well |

| 9. | Which factors determine your choice when purchasing building materials? | (a) Proven solutions; (b) Innovative solutions; (c) Environmentally friendly solutions; (d) Best value for money; (e) Products of popular manufacturers; (f) Products of Polish manufacturers |

| 10. | Please indicate 2 criteria that will determine your choice when purchasing gypsum plasterboards | (a) Price, (b) Dimension, (c) The origin of the plaster, (d) Manufacturer, (e) Availability of the product, (f) Other (please specify) |

| 11. | Imagine you are supervising the construction of your own house on the property with a building to be demolish. When ordering the demolition service of this building, you will decide to: | (a) Basic service providing removal of CDW waste; (b) Premium service that ensures maximal re-use and recycling of construction and demolition waste (CDW) waste (ca. 20% more expensive than a)); (c) I prefer premium service to protect environment, but construction of the house is expensive so I will choose basic service; (d) It makes no difference to me, the most important thing is that the service should be provided immediately; (e) Other (please specify) |

| Aspect | Component | Share |

|---|---|---|

| Construction and assembly works | Specialized works | 43.3% |

| Construction of buildings | 31.9% | |

| Construction of civil engineering structures | 24.8% | |

| Costs covered by medium and large enterprises (>9 employees) | Purchase of materials | 46.5% |

| Direct remuneration | 14.1% | |

| Other direct costs | 11.5% | |

| Other | 27.9% | |

| Exported construction works | Construction companies | 89.7% |

| Non-construction companies | 10.3% | |

| Construction works export countries (enterprises >9 employees) | Germany | 48.6% |

| Sweden | 8.5% | |

| Belgium | 7.5% | |

| Netherlands | 4.5% | |

| Austria | 4.2% | |

| Other countries | 26.7% |

| Category of Products | Production in Bln EUR * | Number of Entities * | Representatives of the Category | Energy Consumed in kWh ** | Share of Total Cost in % *** | ||

|---|---|---|---|---|---|---|---|

| Materials and Energy | External Services | Wages and Salaries | |||||

| Products of wood, cork, straw and wicker | 1.0 | 2152 | sawmilling and planing | 8.7 | 59.0 | 13.4 | 15.9 |

| wood, cork, straw products | 11.1 | 65.7 | 12.7 | 11.7 | |||

| Chemicals and chemical products | 15.5 | 710 | paints, varnishes and similar coatings, printing ink and mastics | 1.6 | 67.8 | 11.7 | 11.4 |

| Rubber and plastic products | 22.4 | 2366 | rubber products | 5.9 | 64.3 | 13.1 | 13 |

| plastic products | 6.8 | 66.0 | 11.7 | 12.7 | |||

| Other non-metallic mineral products | 14.1 | 1498 | glass and glass products | 11.8 | 55.2 | 16.6 | 15.6 |

| refractory products | 4.7 | 66.6 | 12.8 | 12.3 | |||

| clay building materials | 16.4 | 53.1 | 14.4 | 15.2 | |||

| cement, lime and plaster | 31.4 | 44.2 | 30.4 | 9.2 | |||

| articles of concrete, cement and plaster | 3.5 | 53.4 | 21.7 | 14.0 | |||

| abrasive products and non-metallic mineral products | 13.0 | 59.1 | 18.7 | 12.0 | |||

| Basic metals | 13.5 | 437 | pig iron, ferroalloys, steel and metallurgical products | 18.5 | 77.6 | 11.8 | 5.1 |

| tubes, pipes, hollow profiles and related steel fittings | 6.1 | 76.9 | 8.1 | 8.7 | |||

| Metal products | 28.7 | 5300 | structural metal products | 2.3 | 54.3 | 18.3 | 17.6 |

| Specification | Waste Generated in 2018 | Waste Landfilled | |||||

|---|---|---|---|---|---|---|---|

| Grand Total | Recovered | Disposed 1 | Transferred to Other Recipients 2 | Temporarily Stored | |||

| Total | Of Which Landfilled 1 | ||||||

| In Thousand Tonnes | |||||||

| Total | 115,339 | 58,429 | 54,636 | 49,046 | 1006 | 1267 | 1,760,072 |

| Mining and quarrying | 61,364 | 24,141 | 36,905 | 36,865 | 24 | 294 | 812,316 |

| Manufacturing | 26,117 | 19,485 | 5561 | 3051 | 444 | 627 | 266,359 |

| Electricity, gas, steam and air conditioning supplies | 18,341 | 8829 | 9171 | 8984 | 153 | 189 | 304,676 |

| Water supply; sewerage waste management and remediation | 5174 | 2147 | 2885 | 58 | 33 | 109 | 362,453 |

| Construction | 3774 | 3388 | 17 | 6 | 333 | 36 | ─ |

| Other sections | 569 | 439 | 97 | 83 | 19 | 13 | 14,268 |

| Aspect | I have Very Little Information | I have Basic Knowledge | I Know this Topic Quite Well | Total Number of Votes |

|---|---|---|---|---|

| Sustainable construction in general | 102 | 162 | 42 | 306 |

| Environmental protection in general | 8 | 76 | 222 | 306 |

| Sustainable development | 121 | 119 | 61 | 301 |

| Selective collection of waste | 21 | 165 | 118 | 304 |

| Recycling | 13 | 173 | 117 | 303 |

| Circular Economy | 136 | 117 | 45 | 298 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tomaszewska, J. Polish Transition towards Circular Economy: Materials Management and Implications for the Construction Sector. Materials 2020, 13, 5228. https://doi.org/10.3390/ma13225228

Tomaszewska J. Polish Transition towards Circular Economy: Materials Management and Implications for the Construction Sector. Materials. 2020; 13(22):5228. https://doi.org/10.3390/ma13225228

Chicago/Turabian StyleTomaszewska, Justyna. 2020. "Polish Transition towards Circular Economy: Materials Management and Implications for the Construction Sector" Materials 13, no. 22: 5228. https://doi.org/10.3390/ma13225228

APA StyleTomaszewska, J. (2020). Polish Transition towards Circular Economy: Materials Management and Implications for the Construction Sector. Materials, 13(22), 5228. https://doi.org/10.3390/ma13225228