Flame Retardancy of Biobased Composites—Research Development

Abstract

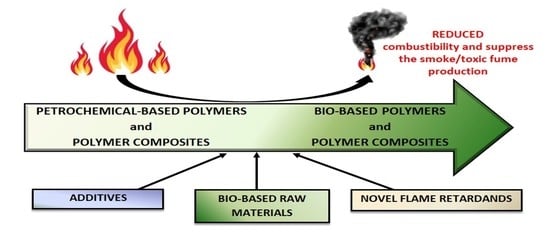

1. Introduction

2. Strategies of Polymer Flame Retardancy

3. Typical Flame Retardants for Polymer Materials

4. Flame Retardancy of Natural Fibers

5. Other Methods of Reducing the Flammability of Bio-Based Composites

5.1. PLA-Based Composites

5.2. PHA-Based Composites

5.3. Other Bio-Based Polymer Composites

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ramakrishna, S.; Huang, Z.M. Biocomposites. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Christian, S.J. Natural fibre-reinforced noncementitious composites (biocomposites). In Nonconventional and Vernacular Construction Materials; Woodhead Publishing: Cambridge, UK, 2016; pp. 111–126. [Google Scholar]

- Memmott, P.; Martin, D.; Amiralian, N. Nanotechnology and the Dreamtime knowledge of spinifex grass. In Green Composites; Woodhead Publishing: Duxford, UK, 2017; pp. 181–198. [Google Scholar]

- Alfred, R.; Choe, P. Biopolymers. In The Elements of Polymer Science and Engineering, 3rd ed.; Oxford Academic Press: Waltham, MA, USA; Oxford, UK, 2013; pp. 521–535. [Google Scholar]

- Graupner, N.; Herrmann, A.S.; Mussig, J. Natural and man-made cellulose fibre-reinforced poly (lactic acid)(PLA) composites: An overview about mechanical characteristics and application areas. Compos. A Appl. Sci. Manuf. 2009, 40, 810–821. [Google Scholar] [CrossRef]

- Davoodi, M.M.; Sapuan, S.M.; Ahmad, D.; Aidy, A.; Khalina, A.; Jonoobi, M. Concept selection of car bumper beam with developed hybrid bio-composite material. Mater. Des. 2011, 32, 4857–4865. [Google Scholar] [CrossRef]

- John, M.J.; Thomas, S. Biofibres and biocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar] [CrossRef]

- Van de Weyenberg, I.; Ivens, J.; De Coster, A.; Kino, B.; Baetens, E.; Verpoest, I. Influence of processing and chemical treatment of flax fibres on their composites. Compos. Sci. Tech. 2003, 63, 1241–1246. [Google Scholar] [CrossRef]

- Kalia, S.; Kaith, B.S. Cellulose fibers. In Bio- and Nano-Polymer Composites; Springer: Berlin, Germany, 2011. [Google Scholar]

- Dasari, A.; Yu, Z.-Z.; Cai, G.-P.; Mai, Y.-W. Recent developments in the fire retardancy of polymeric materials. Prog. Polym. Sci. 2013, 38, 1357–1387. [Google Scholar] [CrossRef]

- Reddy, M.M.; Vivekanandhan, S.; Misra, M.; Bhatia, S.K.; Mohanty, A.K. Biobased plastics and bionanocomposites: Current status and future opportunities. Prog. Polym. Sci. 2013, 38, 1653–1689. [Google Scholar] [CrossRef]

- Thomas, A.; Arun, M.; Moinuddin, K.; Joseph, P. Mechanistic Aspects of Condensed-and Gaseous-Phase Activities of Some Phosphorus-Containing Fire Retardants. Polymers 2020, 12, 1801. [Google Scholar] [CrossRef]

- Laoutid, F.; Bonnaud, L.; Alexandre, M.; Lopez-Cuesta, J.M.; Dubois, P. New prospects in flame retardant polymer materials: From fundamentals to nanocomposites. Mater. Sci. Eng. R Rep. 2009, 63, 100–125. [Google Scholar] [CrossRef]

- Jurkowski, B.; Jurkowska, B. Flame retardancy of polymeric materials. In Polymer Materials with Reduced Flammability; Scientific Publishing House of the Institute for Sustainable Technologies: Radom, Poland, 2012; pp. 19–174. [Google Scholar]

- Hull, T.R.; Stec, A.A. Polymers and fire. In Fire Retardancy of Polymers. New Strategies and Mechanisms; Hull, T.R., Kandola, B.K., Eds.; Royal Society of Chemistry: Cambridge, UK, 2009. [Google Scholar]

- Hamdani, S.; Longuet, C.; Perrin, D.; Lopez-Cuesta, J.M.; Ganachaud, F. Flame retardancy of silicone-based materials. Polym. Degrad. Stab. 2009, 94, 465–495. [Google Scholar] [CrossRef]

- Kiliaris, P.; Papaspyrides, C.D. Polymers on fire. In Polymer Green Flame Retardants; Elsevier: Amsterdam, The Netherlands, 2014; pp. 1–43. [Google Scholar]

- Rabek, J.F. Contemporary Knowledge about Polymers; PWN: Warsaw, Poland, 2008; pp. 517–518. [Google Scholar]

- Malucelli, G.; Carosio, F.; Alongi, J.; Fina, A.; Frache, A.; Camino, G. Materials engineering for surface-confined flame retardancy. Mater. Sci. Eng. R Rep. 2014, 84, 1–20. [Google Scholar] [CrossRef]

- Weil, E.D.; Levchik, S.V. Halogenated flame retardants. In Flame Retardants for Plastics and Textiles; Practical Applications; Hanser Publishers: Munich, Germany, 2016. [Google Scholar]

- Amrollahi, M.; Sadeghi, G.M.M. Evaluation of adhesion strength, flammability, and degradation of HBCD-containing polyurethane adhesives. J. Appl. Polym. Sci. 2008, 110, 3538–3543. [Google Scholar] [CrossRef]

- Chaudhary, B.; Barry, R.; Cheung, Y.; Ho, T.; Guest, M.; Stobby, W. Halogenated Fire-Retardant Compositions and Foams and Fabricated Articles Therefrom. U.S. Patent Application No. 09/728,145, 8 August 2002. [Google Scholar]

- Aslzadeh, M.M.; Abdouss, M.; Sadeghi, G.M. Preparation and characterization of new flame retardant polyurethane composite and nanocomposite. J. Appl. Polym. Sci. 2013, 127, 1683–1690. [Google Scholar] [CrossRef]

- Niroumand, J.S.; Peighambardoust, S.J.; Shenavar, A. Polystyrene-based composites and nanocomposites with reduced brominated-flame retardant. Iran. Polym. J. 2016, 25, 607–614. [Google Scholar] [CrossRef]

- Duan, H.; Yu, D.; Zuo, J.; Yang, B.; Zhang, Y.; Niu, Y. Characterization of brominated flame retardants in construction and demolition waste components: HBCD and PBDEs. Sci. Total Environ. 2016, 572, 77–85. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Jiang, H.; Ni, J.; Chen, J.; Zhou, H.; Wang, X.; Xin, F. Study on the effect of PolyFR and its FR system on the flame retardancy and foaming behavior of polystyrene. RSC Adv. 2019, 9, 192–205. [Google Scholar] [CrossRef]

- Kausar, A.; Rafique, I.; Anwar, Z.; Muhammad, B. Recent developments in different types of flame retardants and effect on fire retardancy of epoxy composite. Polym. Plast. Technol. Eng. 2016, 55, 1512–1535. [Google Scholar] [CrossRef]

- Samani, P.; van der Meer, Y. Life cycle assessment (LCA) studies on flame retardants: A systematic review. J. Clean. Prod. 2020, 274, 123259. [Google Scholar] [CrossRef]

- Rahman, F.; Langford, K.H.; Scrimshaw, M.D.; Lester, J.N. Polybrominated diphenyl ether (PBDE) flame retardants. Sci. Total Environ. 2001, 275, 1–17. [Google Scholar] [CrossRef]

- Ülker, O.C.; Ulker, O. Toxicity of formaldehyde, polybrominated diphenyl ethers (PBDEs) and phthalates in engineered wood products (EWPs) from the perspective of the green approach to materials: A review. BioResources 2019, 14, 7465–7493. [Google Scholar]

- Das, G.; Karak, N. Vegetable oil-based flame retardant epoxy/clay nanocomposites. Polym. Degrad. Stab. 2009, 94, 1948–1954. [Google Scholar] [CrossRef]

- Zhou, Q.; Wang, Y.; Xiao, J.; Zhan, Y. Preparation of magnetic core-shell Fe3O4@ polyaniline composite material and its application in adsorption and removal of tetrabromobisphenol A and decabromodiphenyl ether. Ecotoxicol. Environ. Saf. 2019, 183, 109471. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.; Wang, J.; Song, S.; Wang, Z.; Zhao, S. Antifouling and anticorrosion performance of the composite coating made of tetrabromobisphenol-A epoxy and polyaniline nanowires. Prog. Org. Coat. 2020, 148, 105888. [Google Scholar] [CrossRef]

- Zuiderveen, E.; Slootweg, J.C.; de Boer, J. Novel brominated flame retardants—A review of their occurrence in indoor air, dust, consumer goods and food. Chemosphere 2020, 255, 126816. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Wang, Y.Z. A review on flame retardant technology in China. Part I: Development of flame retardants. Polym. Adv. Technol. 2010, 21, 1–26. [Google Scholar] [CrossRef]

- Hussain, T.; Yousaf, A.M.; Ghori, M.U.; Khan, I.U.; Chohan, T.A.; Rizvi, S.A.; Shahzad, Y. Role of flame-retardants as EDCs in metabolic disorders. In Endocrine Disrupting Chemicals-Induced Metabolic Disorders and Treatment Strategies; Springer: Cham, Switzerland, 2020; pp. 221–238. [Google Scholar]

- Shaw, S.D.; Blum, A.; Weber, R.; Kannan, K.; Rich, D.; Lucas, D.; Koshland, C.P.; Dobraca, D.; Hanson, S.; Birnbaum, L.S. Halogenated flame retardants: Do the fire safety benefits justify the risks? Rev. Environ. Health 2010, 25, 261–305. [Google Scholar] [CrossRef]

- Wu, Z.; He, C.; Han, W.; Song, J.; Li, H.; Zhang, Y.; Jing, X.; Wu, W. Exposure pathways, levels and toxicity of polybrominated diphenyl ethers in humans: A review. Environ. Res. 2020, 187, 109531. [Google Scholar] [CrossRef]

- Wu, L.; Li, Y.; Ru, H.; Xie, H.; Yao, F.; Ni, Z.; Zhong, L. Parental exposure to 2, 2′, 4, 4′ 5-pentain polybrominated diphenyl ethers (BDE-99) causes thyroid disruption and developmental toxicity in zebrafish. Toxicol. Appl. Pharmacol. 2019, 372, 11–18. [Google Scholar] [CrossRef]

- Poston, R.G.; Saha, R.N. Epigenetic effects of polybrominated diphenyl ethers on human health. Int. J. Environ. Res. Public Health 2019, 16, 2703. [Google Scholar] [CrossRef]

- Suzuki, G.; Someya, M.; Takahashi, S.; Tanabe, S.; Sakai, S.I.; Takigami, H. Dioxin-like activity in Japanese indoor dusts evaluated by means of in vitro bioassay and instrumental analysis: Brominated dibenzofurans are an important contributor. Environ. Sci. Technol. 2010, 44, 8330–8336. [Google Scholar] [CrossRef]

- Levchik, S. Phosphorus-based FRs. In Non-Halogenated Flame Retardant Handbook; Morgan, A.B., Wilkie, C.A., Eds.; Scrivener Publishing: Beverly, MA, USA, 2014. [Google Scholar]

- Liu, H.; Shen, Y.; Du, B.; Fang, Z.; Wu, Y. Fabrication of dendrimer-like fullerene (C 60)-decorated oligomeric intumescent flame retardant for reducing the thermal oxidation and flammability of polypropylene nanocomposites. J. Mater. Chem. 2009, 19, 1305–1313. [Google Scholar]

- Guo, Z.; Zhao, L.; Fang, Z. The flame retardant and smoke suppression effect of fullerene by trapping radicals in decabromodiphenyl oxide/Sb2O3 flame-retarded high density polyethylene. Fire Mater. 2017, 41, 916–924. [Google Scholar] [CrossRef]

- Pan, Y.; Guo, Z.; Ran, S.; Fang, Z. Influence of fullerenes on the thermal and flame-retardant properties of polymeric materials. Appl. Polym. Sci. 2020, 137, 47538. [Google Scholar] [CrossRef]

- Beyer, G. Carbon nanotubes as flame retardants for polymers. Fire Mater. 2002, 26, 291–293. [Google Scholar] [CrossRef]

- Huang, G.; Wang, S.; Song, P.; Wu, C.; Chen, S.; Wang, X. Combination effect of carbon nanotubes with graphene on intumescent flame-retardant polypropylene nanocomposites. Compos. Part A Appl. Sci. Manuf. 2014, 59, 18–25. [Google Scholar] [CrossRef]

- Isitman, N.A.; Kaynak, C. Nanoclay and carbon nanotubes as potential synergists of an organophosphorus flame-retardant in poly (methyl methacrylate). Polym. Degrad. Stab. 2010, 95, 1523–1532. [Google Scholar] [CrossRef]

- Cai, H.; Peng, F.; Wang, Y.; Yi, J.; Cai, X.; Liu, H.; Kong, Q. Improving Flame Retardancy of Epoxy Resin Nanocomposites by Carbon Nanotubes Grafted CuAl-Layered Double Hydroxide Hybrid. J. Nanosci. Nanotechnol. 2020, 20, 6406–6412. [Google Scholar] [CrossRef]

- Dittrich, B.; Wartig, K.-A.; Hofmann, D.; Mülhaupt, R.; Schartel, B. Flame retardancy through carbon nanomaterials: Carbon black, multiwall nanotubes, expanded graphite, multi-layer graphene and graphene in polypropylene. Polym. Degrad. Stab. 2013, 98, 1495–1505. [Google Scholar] [CrossRef]

- Fukushima, K.; Murariu, M.; Camino, G.; Dubois, P. Effect of expanded graphite/layered-silicate clay on thermal, mechanical and fire retardant properties of poly (lactic acid). Polym. Degrad. Stab. 2010, 95, 1063–1076. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, M.; Zhou, Y.; Hu, L. The study of mechanical behavior and flame retardancy of castor oil phosphate-based rigid polyurethane foam composites containing expanded graphite and triethyl phosphate. Polym. Degrad. Stab. 2013, 98, 2784–2794. [Google Scholar] [CrossRef]

- Cheng, Z.; Liao, D.; Hu, X.; Li, W.; Xie, C.; Zhang, H.; Yang, W. Synergistic fire retardant effect between expandable graphite and ferrocene-based non-phosphorus polymer on polypropylene. Polym. Degrad. Stab. 2020, 178, 109201. [Google Scholar] [CrossRef]

- Franchini, E.; Galy, J.; Gérard, J.-F.; Tabuani, D.; Medici, A. Influence of POSS structure on the fire retardant properties of epoxy hybrid networks. Polym. Degrad. Stab. 2009, 94, 1728–1736. [Google Scholar] [CrossRef]

- Song, L.; Xuan, S.; Wang, X.; Hu, Y. Flame retardancy and thermal degradation behaviors of phosphate in combination with POSS in polylactide composites. Thermochim. Acta 2012, 527, 1–7. [Google Scholar] [CrossRef]

- Fina, A.; Abbenhuis, H.C.L.; Tabuani, D.; Camino, G. Metal functionalized POSS as fire retardants in polypropylene. Polym. Degrad. Stab. 2006, 91, 2275–2281. [Google Scholar] [CrossRef]

- Ye, X.; Li, J.; Zhang, W.; Yang, R.; Li, J. Fabrication of eco-friendly and multifunctional sodium-containing polyhedral oligomeric silsesquioxane and its flame retardancy on epoxy resin. Compos. B Eng. 2020, 191, 107961. [Google Scholar] [CrossRef]

- Szpilska, K.; Czaja, K.; Kudła, S. Thermal stability and flammability of polyolefin/halloysite nanotubes composites. Polymery 2015, 60, 671–750. [Google Scholar] [CrossRef]

- Jing, H.; Higaki, Y.; Ma, W.; Wu, H.; Yah, W.O.; Otsuka, H.; Lvov, Y.M.; Takahara, A. Internally modified halloysite nanotubes as inorganic nanocontainers for a flame retardant. Chem. Lett. 2013, 42, 121–123. [Google Scholar] [CrossRef]

- Goda, E.S.; Yoon, K.R.; El-sayed, S.H.; Hong, S.E. Halloysite nanotubes as smart flame retardant and economic reinforcing materials: A review. Thermochim. Acta 2018, 669, 173–184. [Google Scholar] [CrossRef]

- Su, X.; Li, D.; Tao, J.; Dai, Q. Synergistic effect of allophane with intumescent flame retardants on thermal behavior and fire retardancy of polypropylene. Polym. Bull. 2015, 72, 2089–2104. [Google Scholar] [CrossRef]

- Poncelet, O. Aluminosilicate Polymer as Fire Retardant. U.S. Patent 8,287,779, 16 October 2012. [Google Scholar]

- Wang, X.; Kalali, E.N.; Wan, J.-T.; Wang, D.-Y. Carbon-family materials for flame retardant polymeric materials. Prog. Polym. Sci. 2017, 69, 22–46. [Google Scholar] [CrossRef]

- Kim, N.K.; Dutta, S.; Bhattacharyya, D. Carbon-family materials for flame retardant polymeric materials. Compos. Sci. Technol. 2018, 162, 64–78. [Google Scholar] [CrossRef]

- Adeniyi, A.G.; Onifade, D.V.; Ighalo, J.O.; Adeoye, A.S. A review of coir fiber reinforced polymer composites. Compos. B Eng. 2019, 176, 107305. [Google Scholar] [CrossRef]

- Costes, L.; Laoutid, F.; Brohez, S.; Dubois, P. Bio-based flame retardants: When nature meets fire protection. Mater. Sci. Eng. R Rep. 2017, 117, 1–25. [Google Scholar] [CrossRef]

- Yiga, V.A.; Lubwama, M. Thermogravimetric analysis of agricultural residue carbonized briquettes for domestic and industrial applications. MRS Adv. 2020, 5, 1039–1048. [Google Scholar] [CrossRef]

- Samyn, F.; Vandewalle, M.; Bellayer, S.; Duquesne, S. Sol–Gel Treatments to Flame Retard PA11/Flax Composites. Fibers 2019, 7, 86. [Google Scholar] [CrossRef]

- Zhang, L.; Li, Z.; Pan, Y.T.; Yáñez, A.P.; Hu, S.; Zhang, X.Q.; Wang, R.; Wang, D.Y. Polydopamine induced natural fiber surface functionalization: A way towards flame retardancy of flax/poly (lactic acid) biocomposites. Compos. B Eng. 2018, 154, 56–63. [Google Scholar] [CrossRef]

- Xu, S.; Li, S.Y.; Zhang, M.; Zeng, H.Y.; Wu, K.; Tian, X.Y.; Chen, C.R.; Pan, Y. Fabrication of green alginate-based and layered double hydroxides flame retardant for enhancing the fire retardancy properties of polypropylene. Carbohydr. Polym. 2020, 234, 115891. [Google Scholar] [CrossRef]

- Boccarusso, L.; Carrino, L.; Durante, M.; Formisano, A.; Langella, A.; Minutolo, F.M.C. Hemp fabric/epoxy composites manufactured by infusion process: Improvement of fire properties promoted by ammonium polyphosphate. Compos. B Eng. 2016, 89, 117–126. [Google Scholar] [CrossRef]

- Yiga, V.A.; Lubwama, M.; Pagel, S.; Benz, J.; Olupot, P.W.; Bonten, C. Flame retardancy and thermal stability of agricultural residue fiber-reinforced polylactic acid: A Review. Polym. Compos. 2020. [Google Scholar] [CrossRef]

- Dashtizadeh, Z.; Abdan, K.; Jawaid, M.; Dashtizadeh, M. Thermal and Flammability Properties of Kenaf/Recycled Carbon Filled with Cardanol Hybrid Composites. Int. J. Polym. Sci. 2019, 2019, 9168342. [Google Scholar] [CrossRef]

- Netnapa, E.; Mariatti, M.; Hamid, Z.A.A.; Todo, M.; Banhan, L. Dielectric breakdown strength and flammability properties of flame retardant filler/PLLA-PLA microsphere/kenaf fiber composites. Procedia Chem. 2016, 19, 290–296. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, S.; Pan, Y.T.; Zhang, S.; Nie, S.; Wei, P.; Zhang, X.; Wang, R.; Wang, D.Y. Nickel metal–organic framework derived hierarchically Mesoporous nickel phosphate toward smoke suppression and mechanical enhancement of intumescent flame retardant wood Fiber/poly (lactic acid) composites. ACS Sustain. Chem. Eng. 2019, 7, 9272–9280. [Google Scholar] [CrossRef]

- Hapuarachchi, T.D.; Peijs, T. Multiwalled carbon nanotubes and sepiolite nanoclays as flame retardants for polylactide and its natural fibre reinforced composites. Compos. A Appl. Sci. Manuf. 2010, 41, 954–963. [Google Scholar] [CrossRef]

- Wang, X.; Hu, Y.; Song, L.; Xuan, S.; Xing, W.; Bai, Z.; Lu, H. Flame retardancy and thermal degradation of intumescent flame retardant poly (lactic acid)/starch biocomposites. Ind. Eng. Chem. Res. 2011, 50, 713–720. [Google Scholar] [CrossRef]

- Ran, G.; Liu, X.; Guo, J.; Sun, J.; Li, H.; Gu, X.; Zhang, S. Improving the flame retardancy and water resistance of polylactic acid by introducing polyborosiloxane microencapsulated ammonium polyphosphate. Compos. B Eng. 2019, 173, 106772. [Google Scholar] [CrossRef]

- Shumao, L.; Jie, R.; Hua, Y.; Tao, Y.; Weizhong, Y. Influence of ammonium polyphosphate on the flame retardancy and mechanical properties of ramie fiber-reinforced poly(lactic acid) biocomposites. Polym. Int. 2010, 59, 242–248. [Google Scholar] [CrossRef]

- Kozłowski, R.; Władyka-Przybylak, M. Flammability and fire resistance of composites reinforced by natural fibers. Polym. Adv. Technol. 2008, 19, 446–453. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T. A review of natural fiber composites: Properties, modification and processing techniques, characterization, applications. J. Mater. Sci. 2020, 55, 829–892. [Google Scholar] [CrossRef]

- Moussa, M.; El Hage, R.; Sonnier, R.; Chrusciel, L.; Ziegler-Devin, I.; Brosse, N. Toward the cottonization of hemp fibers by steam explosion. Flame-retardant fibers. Ind. Crops Prod. 2020, 151, 112242. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, L.; Liu, Y.; Zhang, G.; Zhu, P. Characterization and functional assessment of alginate fibers prepared by metal-calcium ion complex coagulation bath. Carbohydr. Polym. 2020, 232, 115693. [Google Scholar] [CrossRef]

- Tian, G.; Ji, Q.; Xu, D.; Tan, L.; Quan, F.; Xia, Y. The effect of zinc ion content on flame retardance and thermal degradation of alginate fibers. Fibers Polym. 2013, 14, 767–771. [Google Scholar] [CrossRef]

- Xu, P.; Shao, P.; Zhang, Q.; Cheng, W.; Li, Z.; Li, Q. A novel inherently flame-retardant composite based on zinc alginate/nano-Cu2O. Polymers 2019, 11, 1575. [Google Scholar] [CrossRef] [PubMed]

- Carosio, F.; Di Blasio, A.; Alongi, J.; Malucelli, G. Green DNA-based flame retardant coatings assembled through layer by layer. Polymer 2013, 54, 5148–5153. [Google Scholar] [CrossRef]

- Alongi, J.; Carletto, R.A.; Di Blasio, A.; Cuttica, F.; Carosio, F.; Bosco, F.; Malucelli, G. Intrinsic intumescent-like flame retardant properties of DNA-treated cotton fabrics. Carbohydr. Polym. 2013, 96, 296–304. [Google Scholar] [CrossRef] [PubMed]

- Alongi, J.; Carletto, R.A.; Di Blasio, A.; Carosio, F.; Bosco, F.; Malucelli, G. DNA: A novel, green, natural flame retardant and suppressant for cotton. J. Mater. Chem. A 2013, 1, 4779–4785. [Google Scholar] [CrossRef]

- Gallo, E.; Sanchez-Olivares, G.; Schartel, B. Flame retardancy of starch-based biocomposites-aluminum hydroxide-coconut fiber synergy. Polymery 2013, 58, 395–402. [Google Scholar] [CrossRef]

- Chen, D.; Li, J.; Ren, J. Combustion properties and transference behavior of ultrafine microencapsulated ammonium polyphosphate in ramie fabric-reinforced poly (L-lactic acid) biocomposites. Polym. Int. 2011, 60, 599–606. [Google Scholar] [CrossRef]

- Schartel, B.; Braun, U.; Schwarz, U.; Reinemann, S. Fire retardancy of polypropylene/flax blends. Polymer 2003, 44, 6241–6250. [Google Scholar] [CrossRef]

- Mazela, B.; Batista, A.; Grześkowiak, W. Expandable Graphite as a Fire Retardant for Cellulosic Materials-A Review. Forests 2020, 11, 755. [Google Scholar] [CrossRef]

- He, L.; Zhou, X.; Cai, W.; Xiao, Y.; Chu, F.; Mu, X.; Fu, X.; Hu, Y.; Song, L. Electrochemical exfoliation and functionalization of black phosphorene to enhance mechanical properties and flame retardancy of waterborne polyurethane. Compos. B Eng. 2020, 202, 108446. [Google Scholar] [CrossRef]

- Kodali, D.; Uddin, M.J.; Moura, E.A.; Rangari, V.K. Mechanical and Thermal Properties of Modified Georgian and Brazilian Clay Infused Biobased Epoxy Nanocomposites. Mat. Chem. Phys. 2020, 257, 123821. [Google Scholar] [CrossRef]

- Yu, T.; Jiang, N.; Li, Y. Functionalized multi-walled carbon nanotube for improving the flame retardancy of ramie/poly (lactic acid) composite. Compos. Sci. Technol. 2014, 104, 26–33. [Google Scholar] [CrossRef]

- Wang, X.; Hu, Y.; Song, L.; Xing, W.; Lu, H. Preparation, flame retardancy, and thermal degradation of epoxy thermosets modified with phosphorous/nitrogen-containing glycidyl derivative. Polym. Adv. Technol. 2012, 23, 190–197. [Google Scholar] [CrossRef]

- Murariu, M.; Dechief, A.L.; Bonnaud, L.; Gallos, A.; Fontaine, G.; Bourbigot, S.; Dubois, P. The production and properties of polylactide composites filled with expanded graphite. Polym. Degrad. Stab. 2010, 95, 889–900. [Google Scholar] [CrossRef]

- Tshai, K.Y. Advancement in flame retardancy of natural fibre reinforced composites with macro to nanoscale particulates additives. In Interfaces in Particle and Fibre Reinforced Composites; Series in Composites Science and Engineering; Woodhead Publishing: Cambridge, UK, 2020; pp. 311–342. [Google Scholar]

- Kuan, C.F.; Yen, W.H.; Chen, C.H.; Yuen, S.M.; Kuan, H.C.; Chiang, C.L. Synthesis, characterization, flame retardance and thermal properties of halogen-free expandable graphite/PMMA composites prepared from sol–gel method. Polym. Degrad. Stab. 2008, 93, 1357–1363. [Google Scholar] [CrossRef]

- Han, Z.; Dong, L.; Li, Y.; Zhao, H. A comparative study on the synergistic effect of expandable graphite with APP and IFR in polyethylene. J. Fire Sci. 2007, 25, 79–91. [Google Scholar] [CrossRef]

- Cheng, X.W.; Guan, J.P.; Tang, R.C.; Liu, K.Q. Phytic acid as a bio-based phosphorus flame retardant for poly (lactic acid) nonwoven fabric. J. Clean. Prod. 2016, 124, 114–119. [Google Scholar] [CrossRef]

- Zhang, J.; Fleury, E.; Chen, Y.; Brook, M.A. Flame retardant lignin-based silicone composites. RSC Adv. 2015, 5, 103907–103914. [Google Scholar] [CrossRef]

- Zhang, R.; Xiao, X.; Tai, Q.; Huang, H.; Hu, Y. Modification of lignin and its application as char agent in intumescent flame-retardant poly (lactic acid). Polym. Eng. Sci. 2012, 52, 2620–2626. [Google Scholar] [CrossRef]

- Ferry, L.; Dorez, G.; Taguet, A.; Otazaghine, B.; Lopez-Cuesta, J.M. Chemical modification of lignin by phosphorus molecules to improve the fire behavior of polybutylene succinate. Polym. Degrad. Stab. 2015, 113, 135–143. [Google Scholar] [CrossRef]

- Prieur, B.; Meub, M.; Wittemann, M.; Klein, R.; Bellayer, S.; Fontaine, G.; Bourbigot, S. Phosphorylation of lignin to flame retard acrylonitrile butadiene styrene (ABS). Polym. Degrad. Stab. 2016, 127, 32–43. [Google Scholar] [CrossRef]

- Zhang, R.; Xiao, X.; Tai, Q.; Huang, H.; Yang, J.; Hu, Y. The effect of different organic modified montmorillonites (OMMTs) on the thermal properties and flammability of PLA/MCAPP/lignin systems. J. Appl. Polym. Sci. 2013, 127, 4967–4973. [Google Scholar] [CrossRef]

- Costes, L.; Laoutid, F.; Brohez, S.; Delvosalle, C.; Dubois, P. Phytic acid–lignin combination: A simple and efficient route for enhancing thermal and flame retardant properties of polylactide. Eur. Polym. J. 2017, 94, 270–285. [Google Scholar] [CrossRef]

- Jin, X.; Cui, S.; Sun, S.; Gu, X.; Li, H.; Liu, X.; Sun, J.; Bourbigot, S.; Zhang, S. The preparation of a bio-polyelectrolytes based core-shell structure and its application in flame retardant polylactic acid composites. Compos. A Appl. Sci. Manuf. 2019, 124, 105485. [Google Scholar] [CrossRef]

- Nassar, M.; Hiraishi, N.; Tamura, Y.; Otsuki, M.; Aoki, K.; Tagami, J. Phytic acid: An alternative root canal chelating agent. J. Endod. 2015, 41, 242–247. [Google Scholar] [CrossRef]

- Bocz, K.; Szolnoki, B.; Marosi, A.; Tábi, T.; Wladyka-Przybylak, M.; Marosi, G. Flax fibre reinforced PLA/TPS biocomposites flame retarded with multifunctional additive system. Polym. Degrad. Stab. 2014, 106, 63–73. [Google Scholar] [CrossRef]

- Battegazzore, D.; Frache, A.; Carosio, F. Layer-by-Layer nanostructured interphase produces mechanically strong and flame retardant bio-composites. Compos. B Eng. 2020, 200, 108310. [Google Scholar] [CrossRef]

- Gallo, E.; Schartel, B.; Acierno, D.; Russo, P.J.E.P.J. Flame retardant biocomposites: Synergism between phosphinate and nanometric metal oxides. Eur. Polym. J. 2011, 47, 1390–1401. [Google Scholar] [CrossRef]

- Jiang, L.; Wolcott, M.P.; Zhang, J. Study of biodegradable polylactide/poly (butylene adipate-co-terephthalate) blends. Biomacromolecules 2006, 7, 199–207. [Google Scholar] [CrossRef]

- Gallo, E.; Schartel, B.; Acierno, D.; Cimino, F.; Russo, P. Tailoring the flame retardant and mechanical performances of natural fiber-reinforced biopolymer by multi-component laminate. Compos. B Eng. 2013, 44, 112–119. [Google Scholar] [CrossRef]

- Martino, L.; Basilissi, L.; Farina, H.; Ortenzi, M.A.; Zini, E.; Di Silvestro, G.; Scandola, M. Bio-based polyamide 11: Synthesis, rheology and solid-state properties of star structures. Eur. Polym. J. 2014, 59, 69–77. [Google Scholar] [CrossRef]

- Nuzzo, A.; Bilotti, E.; Peijs, T.; Acierno, D.; Filippone, G. Nanoparticle-induced co-continuity in immiscible polymer blends—A comparative study on bio-based PLA-PA11 blends filled with organoclay, sepiolite, and carbon nanotubes. Polymer 2014, 55, 4908–4919. [Google Scholar] [CrossRef]

- Benobeidallah, B.; Benhamida, A.; Kaci, M.; Lopez-Cuesta, J.M. Combined effect of palygorskite and melamine polyphosphate on flame retardancy properties of polyamide 11 nanocomposites. Appl. Clay Sci. 2020, 198, 105837. [Google Scholar] [CrossRef]

- Hao, A.; Wong, I.; Wu, H.; Lisco, B.; Ong, B.; Sallean, A.; Butler, S.; Londa, M.; Koo, J.H. Mechanical, thermal, and flame-retardant performance of polyamide 11–halloysite nanotube nanocomposites. J. Mater. Sci. 2015, 50, 157–167. [Google Scholar] [CrossRef]

- Mandlekar, N.; Malucelli, G.; Cayla, A.; Rault, F.; Giraud, S.; Salaün, F.; Guan, J. Fire retardant action of zinc phosphinate and polyamide 11 blend containing lignin as a carbon source. J. Polym. Degrad. Stab. 2018, 153, 63–74. [Google Scholar] [CrossRef]

- Modesti, M.; Lorenzetti, A. Halogen-free flame retardants for polymeric foams. Polym. Degrad. Stab. 2002, 78, 167–173. [Google Scholar] [CrossRef]

- Hu, X.M.; Wang, D.M. Enhanced fire behavior of rigid polyurethane foam by intumescent flame retardants. J. Appl. Polym. Sci. 2013, 129, 238–246. [Google Scholar] [CrossRef]

- Green, J. A review of phosphorus-containing flame retardants. J. Fire Sci. 1992, 10, 470–487. [Google Scholar] [CrossRef]

- Bhoyate, S.; Ionescu, M.; Kahol, P.K.; Gupta, R.K. Sustainable flame-retardant polyurethanes using renewable resources. Ind. Crops Prod. 2018, 123, 480–488. [Google Scholar] [CrossRef]

- Abdullah, N.M.; Rus, A.Z.M.; Abdullah, M.F.L. Synergistic influence of graphite on biopolymer composites properties. J. Teknol. 2015, 77, 11–19. [Google Scholar] [CrossRef][Green Version]

- Guler, T.; Tayfun, U.; Bayramli, E.; Dogan, M. Effect of expandable graphite on flame retardant, thermal and mechanical properties of thermoplastic polyurethane composites filled with huntite & hydromagnesite mineral. Thermochim. Acta 2017, 647, 70–80. [Google Scholar]

- Gama, N.; Costa, L.C.; Amaral, V.; Ferreira, A.; Barros-Timmons, A. Insights into the physical properties of biobased polyurethane/expanded graphite composite foams. Compos. Sci. Technol. 2017, 138, 24–31. [Google Scholar] [CrossRef]

- Kurańska, M.; Cabulis, U.; Auguścik, M.; Prociak, A.; Ryszkowska, J.; Kirpluks, M. Bio-based polyurethane-polyisocyanurate composites with an intumescent flame retardant. Polym. Degrad. Stab. 2016, 127, 11–19. [Google Scholar] [CrossRef]

- Gao, L.; Zheng, G.; Zhou, Y.; Hu, L.; Feng, G.; Zhang, M. Synergistic effect of expandable graphite, diethyl ethylphosphonate and organically-modified layered double hydroxide on flame retardancy and fire behavior of polyisocyanurate-polyurethane foam nanocomposite. Polym. Degrad. Stab. 2014, 101, 92–101. [Google Scholar] [CrossRef]

- Khalili, P.; Tshai, K.Y.; Kong, I. Natural fiber reinforced expandable graphite filled composites: Evaluation of the flame retardancy, thermal and mechanical performances. Compos. Appl. Sci. Manuf. 2017, 100, 194–205. [Google Scholar] [CrossRef]

- Khalili, P.; Tshai, K.Y.; Hui, D.; Kong, I. Synergistic of ammonium polyphosphate and alumina trihydrate as fire retardants for natural fiber reinforced epoxy composite. Compos. B Eng. 2017, 114, 101–110. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Z.; Zhang, L.; Molleja, J.G.; Wang, D.Y. Bimetallic metal-organic frameworks and graphene oxide nano-hybrids for enhanced fire retardant epoxy composites: A novel carbonization mechanism. Carbon 2019, 153, 407–416. [Google Scholar] [CrossRef]

- Song, K.; Wang, Y.; Ruan, F.; Yang, W.; Liu, J. Synthesis of a Novel Spirocyclic Inflatable Flame Retardant and Its Application in Epoxy Composites. Polymers 2020, 12, 2534. [Google Scholar] [CrossRef]

- Nie, S.; Jin, D.; Xu, Y.; Han, C.; Dong, X.; Yang, J.N. Effect of a flower-like nickel phyllosilicate-containing iron on the thermal stability and flame retardancy of epoxy resin. J. Mater. Res. Technol. 2020, 9, 10189–10197. [Google Scholar] [CrossRef]

- Zabihi, O.; Ahmadi, M.; Khayyam, H.; Naebe, M. Fish DNA-modified clays: Towards highly flame retardant polymer nanocomposite with improved interfacial and mechanical performance. Sci. Rep. 2016, 6, 38194. [Google Scholar] [CrossRef]

- Weng, Z.; Senthil, T.; Zhuo, D.; Song, L.; Wu, L. Flame retardancy and thermal properties of organoclay and phosphorous compound synergistically modified epoxy resin. J. Appl. Polym. Sci. 2016, 133, 43367. [Google Scholar] [CrossRef]

- Wan, J.; Gan, B.; Li, C.; Molina-Aldareguia, J.; Kalali, E.N.; Wang, X.; Wang, D.Y. A sustainable, eugenol-derived epoxy resin with high biobased content, modulus, hardness and low flammability: Synthesis, curing kinetics and structure–property relationship. Chem. Eng. J. 2016, 284, 1080–1093. [Google Scholar] [CrossRef]

- Wan, J.; Gan, B.; Li, C.; Molina-Aldareguia, J.; Li, Z.; Wang, X.; Wang, D.-Y. A novel biobased epoxy resin with high mechanical stiffness and low flammability: Synthesis, characterization and properties. J. Mater. Chem. A 2015, 3, 21907–21921. [Google Scholar] [CrossRef]

- Faye, I.; Decostanzi, M.; Ecochard, Y.; Caillol, S. Eugenol bio-based epoxy thermosets: From cloves to applied materials. Green Chem. 2017, 19, 5236–5242. [Google Scholar] [CrossRef]

- Li, C.; Fan, H.; Aziz, T.; Bittencourt, C.; Wu, L.; Wang, D.-Y.; Dubois, P. Biobased epoxy resin with low electrical permissivity and flame retardancy: From environmental friendly high-throughput synthesis to properties. ACS Sustain. Chem. Eng. 2018, 6, 8856–8867. [Google Scholar] [CrossRef]

- Wang, S.; Ma, S.; Xu, C.; Liu, Y.; Dai, J.; Wang, Z.; Liu, X.; Chen, J.; Shen, X.; Wei, J.; et al. Vanillin-derived high-performance flame retardant epoxy resins: Facile synthesis and properties. Macromolecules 2017, 50, 1892–1901. [Google Scholar] [CrossRef]

- Xu, X.; Wang, S.; Ma, S.; Yuan, W.; Li, Q.; Feng, J.; Zhu, J. Vanillin-derived phosphorus-containing compounds and ammonium polyphosphate as green fire-resistant systems for epoxy resins with balanced properties. Polym. Adv. Technol. 2019, 30, 264–278. [Google Scholar] [CrossRef]

- Ecochard, Y.; Decostanzi, M.; Negrell, C.; Sonnier, R.; Caillol, S. Cardanol and eugenol based flame retardant epoxy monomers for thermostable networks. Molecules 2019, 24, 1818. [Google Scholar] [CrossRef]

- Guo, W.; Wang, X.; Gangireddy, C.S.R.; Wang, J.; Pan, Y.; Xing, W.; Song, L.; Hu, Y. Cardanol derived benzoxazine in combination with boron-doped graphene toward simultaneously improved toughening and flame retardant epoxy composites. Compos. Part A Appl. Sci. Manuf. 2019, 116, 13–23. [Google Scholar] [CrossRef]

- Thenmozhi, S.; Murugavel, S.C. Investigation on mechanical, thermal, and flame retardant properties of particulate SiO2 reinforced cardanol based composites. Polym. Compos. 2020, 41, 1118–1134. [Google Scholar] [CrossRef]

| Halogen FR | Name | Structure | LOI (%) | Ref. |

|---|---|---|---|---|

| Bromine-containing flame retardants | Hexabromocyclododecane (HBCD) |  | 20.2 —MDI/ BDO/HTPB composite 28.3 —PS680/HCFC/HFC blends | [21,22,23,24,25,26] |

| Tetrabromophthalic anhydride (TBPA) |  | 31.5 —wool/malonic acid | [27] | |

| Polybrominated diphenyl ether (PBDE) |  | 26.7 —tin(II)tungstates/PS | [28,29,30] | |

| Tetrabromobisphenol-A (TBBPA) |  | 45.0 —epoxy resin/5 wt.% MMT nanoclay | [31,32,33,34] | |

| Chlorine-containing flame retardants | 1,4-di(2-hydroxyethoxy)-2,3,5,6-tetrachlorobenzene (TCHQD) |  | 25.0 —unsaturated polyesters | [35,36] |

| 1,4-di(ethoxycarbonyl-methoxy)-2,3,5,6-tetrachlorobenzene (TCHQA) |  | 27.0 —unsaturated polyesters | [35,36] |

| Composite | Remarks | Ref. |

|---|---|---|

| PLA/kenaf fibers/recycled carbon with a cashew nut shell liquid | - cardanol improved the thermal stability of kenaf; - the thermal stability of final composite was additionally improved by hybridization with recycled carbon (the flammability UL 90 HB test determines the flame retardancy property of all specimens) | [73] |

| PLA/kenaf fibers/phosphorus-based non-halogenated flame retardant (NP-100) | Addition of NP-100 flame retardant filler into the PLLA-PLA microsphere/KF composites: - improved the flammability; - decreased the flexural strength and modulus of the composites (NP-100 affects to the presence of void in the microstructure of composite). | [74] |

| PLA/wood fiber/mesoporous nickel phosphate | Ni-PO (when 5 wt.% ammonium polyphosphate was substituted by nickel phosphate) effects: - the reduction of the total smoke release amount of Wood Fiber-PLA composite by 43%; - gradually improved mechanical properties with the increasing loading amount of Ni-PO. | [75] |

| PLA/hemp/sepiolite nanoclay/ multiwalled nanotubes | Combining the flame retarding potential of carbon nanotubes and nanoclay resulted in enhanced flame retardancy of composite (ternary nanocomposite based on sepiolite and MWNTs—58% drop in pHRR, introduction of non-woven hemp fibre—45% reduction in pHRR, and 25% reduction in pHRR upon the introduction of hemp fiber into the PLA nanocomposite system; pHRRPLA = 485 kW/m2, pHRRPLA with hemp = 361 kW/m2, pHRRPLA ternary nanocomposite = 265 kW/m2 and pHRRPLA ternary nanocomposite with hemp = 340 kW/m2, respectively). | [76] |

| PLA/starch/ microencapsulated ammonium polyphosphate | - Microencapsulated ammonium polyphosphate within the PLA/starch biocomposites improves flame retardancy of composite and restrain the reaction between ammonium polyphosphate and starch during processing of PLA (composite PLA/starch/ microencapsulated ammonium polyphosphate: pHRR = 97 W/g; THR = 6.8 kJ/g and max HRR temp. = 365 °C compared to: 398 W/g; 13.9 kJ/g and 375 °C obtained for pure PLA). - Composites containing 30% microencapsulated ammonium polyphosphate reach UL-94 V0 with a LOI value of 41.0. The incorporation of IFR into PLA decreased the pHRR and THR of the composites. | [77] |

| PLA/ammonium polyphosphate (APP) microencapsulated/ polysiloxane/polyborosiloxane | The microencapsulation of ammonium polyphosphate resulted in: - improved compatibility of APP with PLA, resulting in better mechanical properties, enhanced flame retardancy (PLA composite containing 5%APP: pHHR = 512 kW/m2; time to ignition = 35 s and THR = 66 MJ/m2 compared to: 556; 39 and 78 obtained for pure PLA, respectively) and improved water resistance of the composite; - composite with BSi-APP exhibit the best flame retardancy (pHHR = 458 kW/m2; time to ignition = 33 s and THR = 57 MJ/m2 resulting from the formation of Si-O-C, Si-O-B, and B-O-P in the enhanced char residue) among the three tested FRs (APP, Si-APP and BSi-APP) to PLA under the same loading | [78] |

| Ramie fibers/ammonium polyphosphate | The ammonium polyphosphate: - effectively improves flame retardancy (UL94 test and LOI) due to increased char residue at high temperature; - however, disturbs the compatibility between PLA and fibers (worse dynamic mechanical properties and mechanical properties). | [79] |

| Composite | Remarks | Ref. |

|---|---|---|

| Epoxy/pulverized oil palm empty fruit bunch/expandable graphite | Increasing the amount of expandable graphite fillers in the composites: - significantly improved the fire resistivity and thermal properties; - however, reduced mechanical properties. | [129] |

| Epoxy/palm empty fruit bunch fiber/ATH/APP hybrid system | - An addition of APP enhanced the flame-resistant properties of the composite (reduced total flame time and zero drip). - The 10 wt.% ATH and 5 wt.% APP hybrid showed the most promising flame retardancy with a self-extinguishing property as well as the lowest gross heat and greatest char residue. - In order to create an acceptable FR-based systems, ATH required a greater concentration, but at the same time increasing ATH concentration resulted in deterioration of mechanical properties. | [130] |

| Epoxy/bimetallic metal-organic framework (MOF)/graphene oxide (GO) nano-hybrids (MOF@GO) with intumescent fire retardants (IFR) | - EP/0.5MOF@GO-9.5IFR composite exhibited a 41% decrease in peak heat release rate, 30% decrease in total smoke production compared with EP/10IFR and self-extinction behavior in the UL-94 test due to the barrier effect of highly reinforced carbonaceous char. - The intumescent epoxy composites exhibited enhanced mechanical performances (a 11% increase in tensile strength) due to improved interaction between the fillers and matrix. | [131] |

| Epoxy/eiphenylimidazole spirocyclic pentaerythritol bisphosphonate (PIPC) | PIPC was prepared via the substitution reaction between previously synthesized intermediate SPDPC (3,9-dichloro-2,4,8,10-tetraoxa-3,9-diphosphaspiro-(5,5)undecane-3,9-dioxide) and 2-phenylimidazole. An addition of PIPC: - slightly impacted the mechanical properties of epoxy composites with a low loading - in amount of 5 wt.% resulted in LOI of 29.7% and a V-0 rating in the UL 94 Test, decrease in pHRR (by 41.15%) and THR (by 21.64%). | [132] |

| Epoxy/flower-like nickel phyllosilicate (Ni-PS) | Fe/Ni-PS (4.0 wt.%) resulted in: LOI of 28.9 and ability of self-extinguishing with the total burning time of 12.0 s, passing the V-1 rating in UL-94 test, reduction pHRR by 20.1% and THR by 4.7 % compared to those of pure EP. | [133] |

| Epoxy/fish DNA-modified clays | Contribution of DNA molecules results in improvement of thermal stability and fire resistance of epoxy-clay nanocomposites (due to formation of condensed char layers during combustion caused by the release of effective suppressant agents during the decomposition of DNA structures). | [134] |

| Epoxy/DOPO/organoclay | A synergistic flame retardant effect DOPO and organoclay on epoxy composites (2.0 wt.% phosphorus and 4.0 wt.% organoclay) resulted in decrease of pHRR by 40% and smoke production rate by 46% when compared to neat epoxy resin (the single use of 2.0 wt.% phosphorus decreased the pHRR only to 59% of that of neat EP resin). | [135] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sienkiewicz, A.; Czub, P. Flame Retardancy of Biobased Composites—Research Development. Materials 2020, 13, 5253. https://doi.org/10.3390/ma13225253

Sienkiewicz A, Czub P. Flame Retardancy of Biobased Composites—Research Development. Materials. 2020; 13(22):5253. https://doi.org/10.3390/ma13225253

Chicago/Turabian StyleSienkiewicz, Anna, and Piotr Czub. 2020. "Flame Retardancy of Biobased Composites—Research Development" Materials 13, no. 22: 5253. https://doi.org/10.3390/ma13225253

APA StyleSienkiewicz, A., & Czub, P. (2020). Flame Retardancy of Biobased Composites—Research Development. Materials, 13(22), 5253. https://doi.org/10.3390/ma13225253