Study of Structural and Optoelectronic Properties of Thin Films Made of a Few Layered WS2 Flakes

Abstract

:1. Introduction

2. Materials and Methods

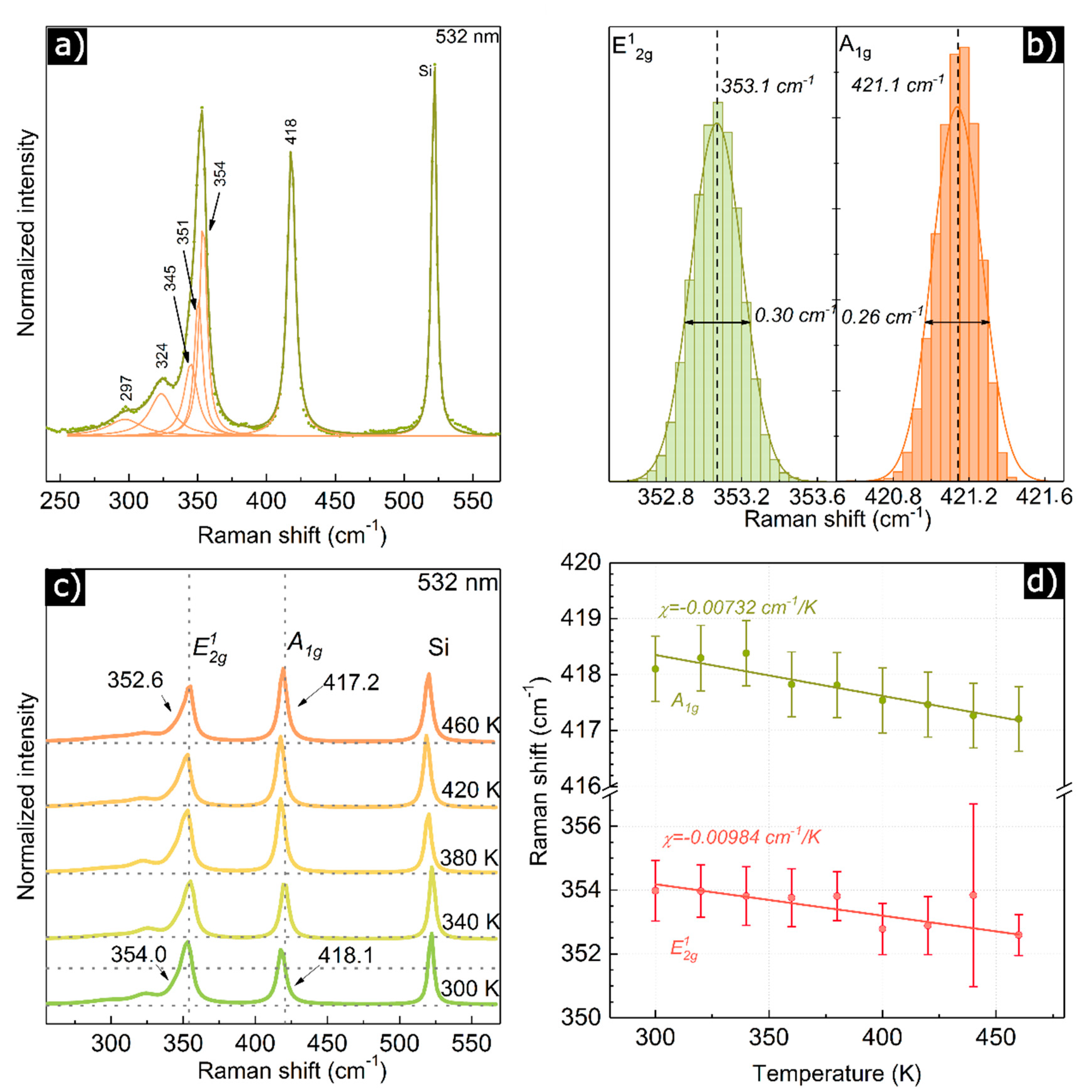

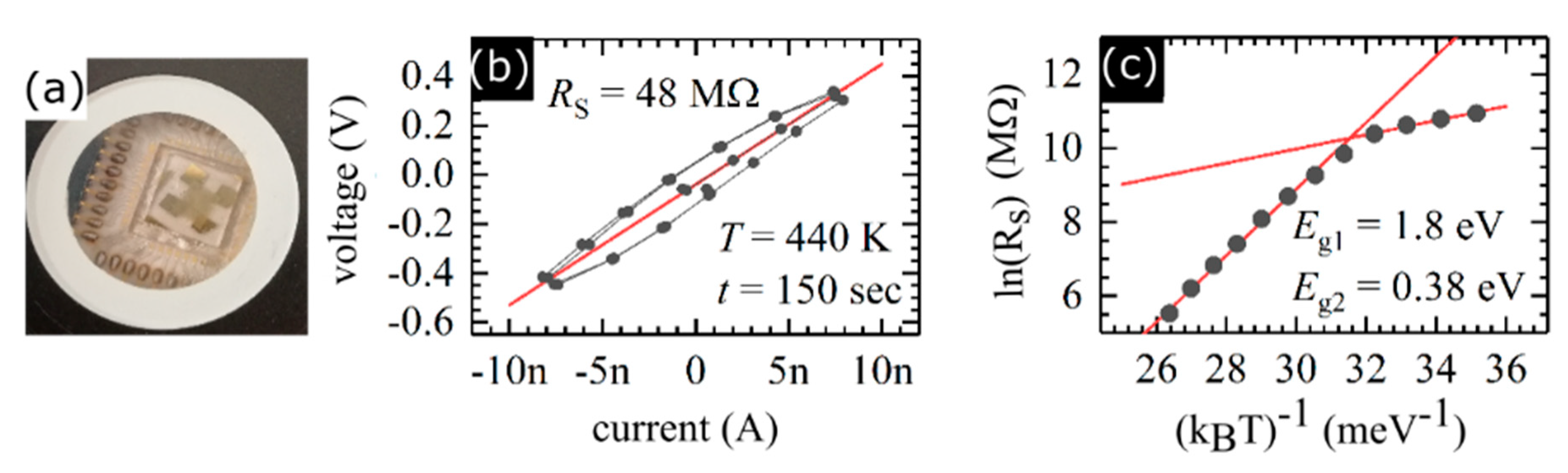

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Novoselov, K.S.; Mishchenko, A.; Carvalho, A.; Neto, A.H.C. 2D materials and van der Waals heterostructures. Science 2016, 353, aac9439. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Miró, P.; Audiffred, M.; Heine, T. An atlas of two-dimensional materials. Chem. Soc. Rev. 2014, 43, 6537–6554. [Google Scholar] [CrossRef] [PubMed]

- Lin, Z.; McCreary, A.; Briggs, N.; Subramanian, S.; Zhang, K.; Sun, Y.; Li, X.; Borys, N.J.; Yuan, H.; Fullerton-Shirey, S.K.; et al. 2D materials advances: From large scale synthesis and controlled heterostructures to improved characterization techniques, defects and applications. 2D Mater. 2016, 3, 042001. [Google Scholar] [CrossRef]

- Huo, C.; Yan, Z.; Song, X.; Zeng, H. 2D materials via liquid exfoliation: A review on fabrication and applications. Sci. Bull. 2015, 60, 1994–2008. [Google Scholar] [CrossRef]

- Zhao, W.; Ghorannevis, Z.; Chua, L.; Toh, M.; Kloc, C.; Tan, P.-H.; Eda, G. Evolution of electronic structure in atomically thin sheets of WS2 and WSe2. ACS Nano 2013, 7, 791–797. [Google Scholar] [CrossRef] [Green Version]

- Peimyoo, N.; Shang, J.; Yang, W.; Wang, Y.; Cong, C.; Yu, T. Thermal conductivity determination of suspended mono-and bilayer WS2 by Raman spectroscopy. Nano Res. 2015, 8, 1210–1221. [Google Scholar] [CrossRef]

- Higgs, C.F.; Heshmat, C.A.; Heshmat, H. Comparative evaluation of MoS2 and WS2 as powder lubricants in high speed, multi-pad journal bearings. J. Tribol. 1999, 121, 625–630. [Google Scholar] [CrossRef]

- Torres-Torres, C.; Perea-López, N.; Elías, A.L.; Gutiérrez, H.R.; Cullen, D.A.; Berkdemir, A.; López-Urías, F.; Terrones, M.; Terrones, M. Third order nonlinear optical response exhibited by mono-and few-layers of WS2. 2D Mater. 2016, 3, 21005. [Google Scholar] [CrossRef]

- Ovchinnikov, D.; Allain, A.; Huang, Y.-S.; Dumcenco, D.; Kis, A. Electrical transport properties of single-layer WS2. ACS Nano 2014, 8, 8174–8181. [Google Scholar] [CrossRef]

- Yang, L.; Majumdar, K.; Liu, H.; Du, Y.; Wu, H.; Hatzistergos, M.; Hung, P.Y.; Tieckelmann, R.; Tsai, W.; Hobbs, C.; et al. Chloride molecular doping technique on 2D materials: WS2 and MoS2. Nano Lett. 2014, 14, 6275–6280. [Google Scholar] [CrossRef] [Green Version]

- Li, S.; Wang, S.; Tang, D.-M.; Zhao, W.; Xu, H.; Chu, L.; Bando, Y.; Golberg, D.; Eda, G. Halide-assisted atmospheric pressure growth of large WSe2 and WS2 monolayer crystals. Appl. Mater. Today 2015, 1, 60–66. [Google Scholar] [CrossRef] [Green Version]

- Hwang, W.S.; Remskar, M.; Yan, R.; Protasenko, V.; Tahy, K.; Chae, S.D.; Zhao, P.; Konar, A.; Xing, H.G.; Seabaugh, A.; et al. Transistors with chemically synthesized layered semiconductor WS2 exhibiting 105 room temperature modulation and ambipolar behavior. Appl. Phys. Lett. 2012, 101, 013107. [Google Scholar] [CrossRef] [Green Version]

- Coleman, J.N.; Lotya, M.; O’Neill, A.; Bergin, S.D.; King, P.J.; Khan, U.; Young, K.; Gaucher, A.; De, S.; Smith, R.J.; et al. Two-dimensional nanosheets produced by liquid exfoliation of layered materials. Science 2011, 331, 568–571. [Google Scholar] [CrossRef] [Green Version]

- Ueberricke, L.; Coleman, J.N.; Backes, C. Robustness of size selection and spectroscopic size, thickness and monolayer metrics of liquid-exfoliated WS2. Phys. Status Solidi (B) 2017, 254, 1700443. [Google Scholar] [CrossRef]

- Han, G.-Q.; Liu, Y.; Hu, W.-H.; Dong, B.; Li, X.; Chai, Y.-M.; Liu, Y.-Q.; Liu, C. WS2 nanosheets based on liquid exfoliation as effective electrocatalysts for hydrogen evolution reaction. Mater. Chem. Phys. 2015, 167, 271–277. [Google Scholar] [CrossRef]

- Vega-Mayoral, V.; Backes, C.; Hanlon, D.; Khan, U.; Gholamvand, Z.; O’Brien, M.; Duesberg, G.S.; Gadermaier, C.; Coleman, J.N. Photoluminescence from liquid-exfoliated WS2 monomers in poly (vinyl alcohol) polymer composites. Adv. Funct. Mater. 2015, 26, 1028–1039. [Google Scholar] [CrossRef]

- Hai, X.; Chang, K.; Pang, H.; Li, M.; Li, P.; Liu, H.; Shi, L.; Ye, J. Engineering the edges of MoS2 (WS2) crystals for direct exfoliation into monolayers in polar micromolecular solvents. J. Am. Chem. Soc. 2016, 138, 14962–14969. [Google Scholar] [CrossRef]

- Sajedi-Moghaddam, A.; Saievar-Iranizad, E.; Saiever-Iranized, E. High-yield exfoliation of tungsten disulphide nanosheets by rational mixing of low-boiling-point solvents. Mater. Res. Express 2018, 5, 015045. [Google Scholar] [CrossRef]

- Mao, X.; Xu, Y.; Xue, Q.; Wang, W.; Gao, D. Ferromagnetism in exfoliated tungsten disulfide nanosheets. Nanoscale Res. Lett. 2013, 8, 430. [Google Scholar] [CrossRef] [Green Version]

- Jha, R.K.; Guha, P.K. Liquid exfoliated pristine WS2 nanosheets for ultrasensitive and highly stable chemiresistive humidity sensors. Nanotechnology 2016, 27, 475503. [Google Scholar] [CrossRef]

- Güler, Ö.; Tekeli, M.; Taşkın, M.; Güler, S.H.; Yahia, I. The production of graphene by direct liquid phase exfoliation of graphite at moderate sonication power by using low boiling liquid media: The effect of liquid media on yield and optimization. Ceram. Int. 2020, 47, 521–533. [Google Scholar] [CrossRef]

- Manna, K.; Hsieh, C.-Y.; Lo, S.-C.; Li, Y.-S.; Huang, H.-N.; Chiang, W.-H. Graphene and graphene-analogue nanosheets produced by efficient water-assisted liquid exfoliation of layered materials. Carbon 2016, 105, 551–555. [Google Scholar] [CrossRef]

- Nicolosi, V.; Chhowalla, M.; Kanatzidis, M.G.; Strano, M.S.; Coleman, J.N. Liquid exfoliation of layered materials. Science 2013, 340, 1226419. [Google Scholar] [CrossRef] [Green Version]

- Lu, C.; Quan, C.; Si, K.; Xu, X.; He, C.; Zhao, Q.; Zhan, Y.; Xu, X. Charge transfer in graphene/WS2 enhancing the saturable absorption in mixed heterostructure films. Appl. Surf. Sci. 2019, 479, 1161–1168. [Google Scholar] [CrossRef]

- Ellmer, K.; Stock, C.; Diesner, K.; Sieber, I. Deposition of c⊥-oriented tungsten disulfide (WS2) films by reactive DC magnetron sputtering from a W-target in Ar/H2S. J. Cryst. Growth 1997, 182, 389–393. [Google Scholar] [CrossRef]

- Hernandez, Y.; Nicolosi, V.; Lotya, M.; Blighe, F.M.; Sun, Z.; De, S.; McGovern, I.T.; Holland, B.; Byrne, M.; Gun’Ko, Y.K.; et al. High-yield production of graphene by liquid-phase exfoliation of graphite. Nat. Nanotechnol. 2008, 3, 563–568. [Google Scholar] [CrossRef] [Green Version]

- Wu, Z. Transparent, conductive carbon nanotube films. Science 2004, 305, 1273–1276. [Google Scholar] [CrossRef]

- Gertych, A.P.; Łapińska, A.; Czerniak-Łosiewicz, K.; Dużyńska, A.; Zdrojek, M.; Judek, J. Thermal properties of thin films made from MoS2 nanoflakes and probed via statistical optothermal Raman method. Sci. Rep. 2019, 9, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Berkdemir, A.; Gutiérrez, H.R.; Mendez, A.R.B.; Perea-López, N.; Elías, A.L.; Chia, C.-I.; Wang, B.; Crespi, V.H.; López-Urías, F.; Charlier, J.-C.; et al. Identification of individual and few layers of WS2 using Raman spectroscopy. Sci. Rep. 2013, 3, 1755. [Google Scholar] [CrossRef] [Green Version]

- Terrones, H.; Del Corro, E.; Feng, S.; Poumirol, J.M.; Rhodes, D.; Smirnov, D.; Pradhan, N.R.; Lin, Z.; Nguyen, M.A.T.; Elías, A.L.; et al. New first order raman-active modes in few layered transition metal dichalcogenides. Sci. Rep. 2014, 4, 4215. [Google Scholar] [CrossRef]

- Zhao, W.; Nevis, Z.G.; Amara, K.K.; Pang, J.R.; Toh, M.; Zhang, X.; Kloc, C.; Tan, P.H.; Eda, G. Lattice dynamics in mono-and few-layer sheets of WS2 and WSe2. Nanoscale 2013, 5, 9677–9683. [Google Scholar] [CrossRef] [Green Version]

- Peimyoo, N.; Shang, J.; Cong, C.; Shen, X.; Wu, X.; Yeow, E.K.L.; Yu, T. Nonblinking, intense two-dimensional light emitter: Monolayer WS2 triangles. ACS Nano 2013, 7, 10985–10994. [Google Scholar] [CrossRef]

- Łapińska, A.; Taube, A.; Wąsik, M.; Żukowska, G.Z.; Duzynska, A.; Judek, J.; Zdrojek, M. Raman spectroscopy of layered lead tin disulfide (PbSnS2) thin films. J. Raman Spectrosc. 2017, 48, 479–484. [Google Scholar] [CrossRef]

- Taube, A.; Judek, J.; Łapińska, A.; Zdrojek, M. Temperature-dependent thermal properties of supported MoS2 monolayers. ACS Appl. Mater. Interfaces 2015, 7, 5061–5065. [Google Scholar] [CrossRef]

- Taube, A.; Lapińska, A.; Judek, J.; Zdrojek, M. Temperature dependence of Raman shifts in layered ReSe2 and SnSe2 semiconductor nanosheets. Appl. Phys. Lett. 2015, 107, 013105. [Google Scholar]

- Li, J.; Han, J.; Li, H.; Fan, X.; Huang, K. Large-area, flexible broadband photodetector based on WS2 nanosheets films. Mater. Sci. Semicond. Process. 2020, 107, 104804. [Google Scholar] [CrossRef]

- Hankare, P.P.; Manikshete, A.H.; Sathe, D.J.; Chate, P.A.; Patil, A.A.; Garadkar, K.M. WS2 thin films: Opto-electronic characterization. J. Alloy. Compd. 2019, 479, 657. [Google Scholar] [CrossRef]

- Hankare, P.; Chate, P. Growth and characterization of WS2 thin films deposited by dip method. Mater. Chem. Phys. 2009, 117, 347–349. [Google Scholar] [CrossRef]

- Vega-Mayoral, V.; Vella, D.; Borzda, T.; Prijatelj, M.; Tempra, I.; Pogna, E.A.A.; Conte, S.D.; Topolovsek, P.; Vujicic, N.; Cerullo, G.; et al. Exciton and charge carrier dynamics in few-layer WS2. Nanoscale 2016, 8, 5428–5434. [Google Scholar] [CrossRef]

- Zhang, S.; Dong, N.; McEvoy, N.; O’Brien, M.; Winters, S.; Berner, N.C.; Yim, C.; Li, Y.; Zhang, X.; Chen, Z.; et al. Direct observation of degenerate two-photon absorption and its saturation in WS2 and MoS2 monolayer and few-layer films. ACS Nano 2015, 9, 7142–7150. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Łapińska, A.; Kuźniewicz, M.; Gertych, A.P.; Czerniak-Łosiewicz, K.; Żerańska-Chudek, K.; Wróblewska, A.; Świniarski, M.; Dużyńska, A.; Judek, J.; Zdrojek, M. Study of Structural and Optoelectronic Properties of Thin Films Made of a Few Layered WS2 Flakes. Materials 2020, 13, 5315. https://doi.org/10.3390/ma13235315

Łapińska A, Kuźniewicz M, Gertych AP, Czerniak-Łosiewicz K, Żerańska-Chudek K, Wróblewska A, Świniarski M, Dużyńska A, Judek J, Zdrojek M. Study of Structural and Optoelectronic Properties of Thin Films Made of a Few Layered WS2 Flakes. Materials. 2020; 13(23):5315. https://doi.org/10.3390/ma13235315

Chicago/Turabian StyleŁapińska, Anna, Michał Kuźniewicz, Arkadiusz P. Gertych, Karolina Czerniak-Łosiewicz, Klaudia Żerańska-Chudek, Anna Wróblewska, Michał Świniarski, Anna Dużyńska, Jarosław Judek, and Mariusz Zdrojek. 2020. "Study of Structural and Optoelectronic Properties of Thin Films Made of a Few Layered WS2 Flakes" Materials 13, no. 23: 5315. https://doi.org/10.3390/ma13235315