Systematic Review on the Effects, Roles and Methods of Magnetic Particle Coatings in Magnetorheological Materials

Abstract

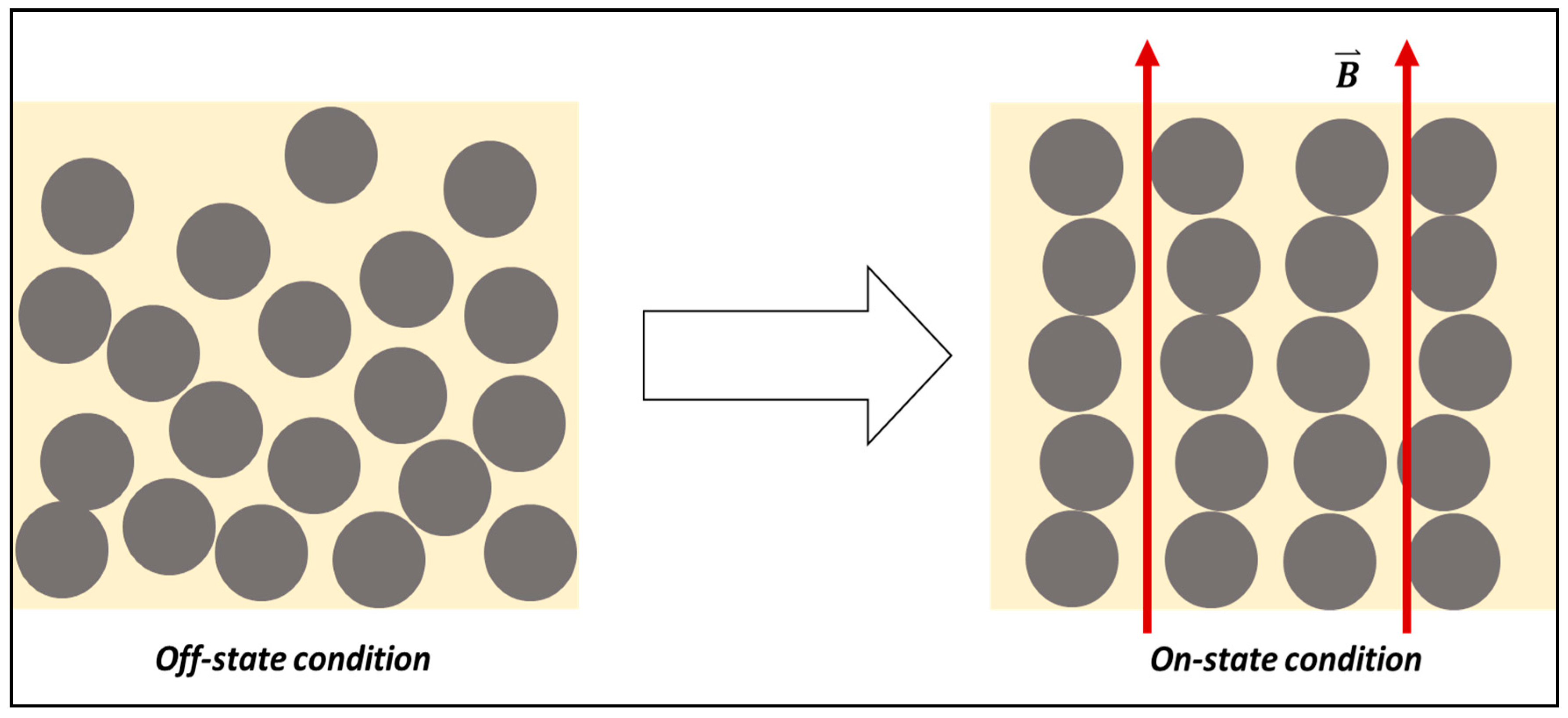

1. Introduction

2. Problems in MR Materials

3. Particle Coating in MR Materials

3.1. Sedimentation Stability

3.2. Tribology Properties

3.3. Oxidation

3.4. Electromagnetic Shielding

4. Coating Methods

4.1. Atom Transfer Radical Polymerization (ATRP)

4.2. Chemical Oxidative Polymerization

4.3. Dispersion Polymerization

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ladipo, I.L.; Fadly, J.; Faris, W.F. Characterization of Magnetorheological Elastomer (MRE) Engine Mounts. Mater. Today Proc. 2016, 3, 411–418. [Google Scholar] [CrossRef]

- Wang, D.M.; Hou, Y.F.; Tian, Z.Z. A novel high-torque magnetorheological brake with a water cooling method for heat dissipation. Smart Mater. Struct. 2013, 22, 025019. [Google Scholar] [CrossRef]

- Karakoc, K.; Park, E.J.; Suleman, A. Design considerations for an automotive magnetorheological brake. Mechatronics 2008, 18, 434–447. [Google Scholar] [CrossRef]

- Nguyen, P.-B.; Do, X.-P.; Jeon, J.; Choi, S.-B.; Liu, Y.D.; Choi, H.J. Brake performance of core–shell structured carbonyl iron/silica based magnetorheological suspension. J. Magn. Magn. Mater. 2014, 367, 69–74. [Google Scholar] [CrossRef]

- Chen, D.; Yu, M.; Zhu, M.; Qi, S.; Fu, J. Carbonyl iron powder surface modification of magnetorheological elastomers for vibration absorbing application. Smart Mater. Struct. 2016, 25, 115005. [Google Scholar] [CrossRef]

- Deng, H.-X.; Gong, X.-L.; Wang, L.-H. Development of an adaptive tuned vibration absorber with magnetorheological elastomer. Smart Mater. Struct. 2006, 15, N111–N116. [Google Scholar] [CrossRef]

- Deng, H.-X.; Gong, X. Application of magnetorheological elastomer to vibration absorber. Commun. Nonlinear Sci. Numer. Simul. 2008, 13, 1938–1947. [Google Scholar] [CrossRef]

- Du, G.; Chen, X. MEMS magnetometer based on magnetorheological elastomer. Measurement 2012, 45, 54–58. [Google Scholar] [CrossRef]

- Ge, L.; Gong, X.; Wang, Y.; Xuan, S. The conductive three dimensional topological structure enhanced magnetorheological elastomer towards a strain sensor. Compos. Sci. Technol. 2016, 135, 92–99. [Google Scholar] [CrossRef]

- Hu, T.; Xuan, S.; Ding, L.; Gong, X. Stretchable and magneto-sensitive strain sensor based on silver nanowire-polyurethane sponge enhanced magnetorheological elastomer. Mater. Des. 2018, 156, 528–537. [Google Scholar] [CrossRef]

- Skalski, P.; Kalita, K. Implementation of magnetorheological elastomers in transport. Trans. Inst. Aviat. 2016, 245, 189–198. [Google Scholar] [CrossRef]

- Atabay, E.; Ozkol, I. Application of a magnetorheological damper modeled using the current–dependent Bouc–Wen model for shimmy suppression in a torsional nose landing gear with and without freeplay. J. Vib. Control. 2014, 20, 1622–1644. [Google Scholar] [CrossRef]

- Yang, J.; Sun, S.-S.; Tian, T.; Li, W.; Du, H.; Alici, G.; Nakano, M. Development of a novel multi-layer MRE isolator for suppression of building vibrations under seismic events. Mech. Syst. Signal. Process. 2016, 70, 811–820. [Google Scholar] [CrossRef]

- Coyle, S.; Majidi, C.; LeDuc, P.R.; Hsia, K.J. Bio-inspired soft robotics: Material selection, actuation, and design. Extreme Mech. Lett. 2018, 22, 51–59. [Google Scholar] [CrossRef]

- Park, J.; Yoon, G.-H.; Kang, J.-W.; Choi, S.-B. Design and control of a prosthetic leg for above-knee amputees operated in semi-active and active modes. Smart Mater. Struct. 2016, 25, 085009. [Google Scholar] [CrossRef]

- Rabinow, J. The Magnetic Fluid Clutch. AIEE Trans. 1948, 67, 1308–1315. [Google Scholar]

- Plachy, T.; Kutalkova, E.; Sedlacik, M.; Vesel, A.; Masar, M.; Kuritka, I. Impact of corrosion process of carbonyl iron particles on magnetorheological behavior of their suspensions. J. Ind. Eng. Chem. 2018, 66, 362–369. [Google Scholar] [CrossRef]

- Zhang, P.; Dong, Y.Z.; Choi, H.J.; Lee, C.-H. Tribological and rheological tests of core-shell typed carbonyl iron/polystyrene particle-based magnetorheological fluid. J. Ind. Eng. Chem. 2018, 68, 342–349. [Google Scholar] [CrossRef]

- Lee, J.H.; Choi, H.J. Synthesis of core-shell formed carbonyl iron/polydiphenylamine particles and their rheological response under applied magnetic fields. Colloid Polym. Sci. 2018, 296, 1857–1865. [Google Scholar] [CrossRef]

- Cvek, M.; Mrlik, M.; Mosnacek, J.; Babayan, V.A.; Kuceková, Z.; Humpolíček, P.; Pavlinek, V. The chemical stability and cytotoxicity of carbonyl iron particles grafted with poly(glycidyl methacrylate) and the magnetorheological activity of their suspensions. RSC Adv. 2015, 5, 72816–72824. [Google Scholar] [CrossRef]

- Tian, T.; Nakano, M. Fabrication and characterisation of anisotropic magnetorheological elastomer with 45° iron particle alignment at various silicone oil concentrations. J. Intell. Mater. Syst. Struct. 2018, 29, 151–159. [Google Scholar] [CrossRef]

- Liu, J.; Wang, X.; Tang, X.; Hong, R.; Wang, Y.; Feng, W. Preparation and characterization of carbonyl iron/strontium hexaferrite magnetorheological fluids. Particuology 2015, 22, 134–144. [Google Scholar] [CrossRef]

- Lanzetta, M.; Iagnemma, K. Gripping by controllable wet adhesion using a magnetorheological fluid. CIRP Ann. 2013, 62, 21–25. [Google Scholar] [CrossRef]

- Bramantya, M.A.; Sawada, T. The influence of magnetic field swept rate on the ultrasonic propagation velocity of magnetorheological fluids. J. Magn. Magn. Mater. 2011, 323, 1330–1333. [Google Scholar] [CrossRef]

- Mazlan, S.A.; Issa, A.; Chowdhury, H.; Olabi, A. Magnetic circuit design for the squeeze mode experiments on magnetorheological fluids. Mater. Des. 2009, 30, 1985–1993. [Google Scholar] [CrossRef]

- Hu, Z.; Yan, H.; Qiu, H.; Zhang, P.; Liu, Q. Friction and wear of magnetorheological fluid under magnetic field. Wear 2012, 278, 48–52. [Google Scholar] [CrossRef]

- Park, B.J.; Kim, M.S.; Choi, H.J. Fabrication and magnetorheological property of core/shell structured magnetic composite particle encapsulated with cross-linked poly(methyl methacrylate). Mater. Lett. 2009, 63, 2178–2180. [Google Scholar] [CrossRef]

- Agirre-Olabide, I.; Kuzhir, P.; Elejabarrieta, M. Linear magneto-viscoelastic model based on magnetic permeability components for anisotropic magnetorheological elastomers. J. Magn. Magn. Mater. 2018, 446, 155–161. [Google Scholar] [CrossRef]

- Kwon, S.H.; An, J.S.; Choi, S.Y.; Chung, K.H.; Choi, H.J. Poly(glycidyl methacrylate) Coated Soft-Magnetic Carbonyl Iron/Silicone Rubber Composite Elastomer and Its Magnetorheology. Macromol. Res. 2019, 27, 448–453. [Google Scholar] [CrossRef]

- Guan, X.; Dong, X.; Ou, J. Magnetostrictive effect of magnetorheological elastomer. J. Magn. Magn. Mater. 2008, 320, 158–163. [Google Scholar] [CrossRef]

- Khairi, M.H.A.; Mazlan, S.A.; Ubaidillah, U.; Ahmad, S.H.; Choi, S.-B.; Aziz, S.A.A.; Yunus, N.A. The field-dependent complex modulus of magnetorheological elastomers consisting of sucrose acetate isobutyrate ester. J. Intell. Mater. Syst. Struct. 2017, 28, 1993–2004. [Google Scholar] [CrossRef]

- Hapipi, N.; Aziz, S.A.A.; Mazlan, S.A.; Choi, S.B.; Mohamad, N.; Khairi, M.H.A.; Fatah, A.Y.A. The field-dependent rheological properties of plate-like carbonyl iron particle-based magnetorheological elastomers. Results Phys. 2019, 12, 2146–2154. [Google Scholar] [CrossRef]

- Agirre-Olabide, I.; Elejabarrieta, M.J. A new magneto-dynamic compression technique for magnetorheological elastomers at high frequencies. Polym. Test. 2018, 66, 114–121. [Google Scholar] [CrossRef]

- Jung, H.S.; Kwon, S.H.; Choi, H.J.; Jung, J.H.; Gil Kim, Y. Magnetic carbonyl iron/natural rubber composite elastomer and its magnetorheology. Compos. Struct. 2016, 136, 106–112. [Google Scholar] [CrossRef]

- Khimi, S.; Syamsinar, S.; Najwa, T. Effect of Carbon Black on Self-healing Efficiency of Natural Rubber. Mater. Today Proc. 2019, 17, 1064–1071. [Google Scholar] [CrossRef]

- Yu, M.; Zhu, M.; Fu, J.; Yang, P.A.; Qi, S. A dimorphic magnetorheological elastomer incorporated with Fe nano-flakes modified carbonyl iron particles: Preparation and characterization. Smart Mater. Struct. 2015, 24, 115021. [Google Scholar] [CrossRef]

- Bica, I.; Anitas, E.M.; Averis, L.M.E.; Kwon, S.H.; Choi, H.J. Magnetostrictive and viscoelastic characteristics of polyurethane-based magnetorheological elastomer. J. Ind. Eng. Chem. 2019, 73, 128–133. [Google Scholar] [CrossRef]

- Bandarian, M.; Shojaei, A.; Rashidi, A.M. Thermal, mechanical and acoustic damping properties of flexible open-cell polyurethane/multi-walled carbon nanotube foams: Effect of surface functionality of nanotubes. Polym. Int. 2011, 60, 475–482. [Google Scholar] [CrossRef]

- Sung, G.; Kim, J.W.; Kim, J.H. Fabrication of polyurethane composite foams with magnesium hydroxide filler for improved sound absorption. J. Ind. Eng. Chem. 2016, 44, 99–104. [Google Scholar] [CrossRef]

- Baferani, A.H.; Katbab, A.; Ohadi, A. The role of sonication time upon acoustic wave absorption efficiency, microstructure, and viscoelastic behavior of flexible polyurethane/CNT nanocomposite foam. Eur. Polym. J. 2017, 90, 383–391. [Google Scholar] [CrossRef]

- Muhazeli, N.S.; Nordin, N.A.; Mazlan, S.A.; Rizuan, N.; Aziz, S.A.A.; Fatah, A.Y.A.; Ibrahim, Z.; Ubaidillah, U.; Choi, S.-B. Characterization of morphological and rheological properties of rigid magnetorheological foams via in situ fabrication method. J. Mater. Sci. 2019, 54, 13821–13833. [Google Scholar] [CrossRef]

- Xu, J.; Wang, P.; Pang, H.; Wang, Y.; Wu, J.; Xuan, S.; Gong, X. The dynamic mechanical properties of magnetorheological plastomers under high strain rate. Compos. Sci. Technol. 2018, 159, 50–58. [Google Scholar] [CrossRef]

- Zhao, W.; Pang, H.; Gong, X. Novel Magnetorheological Plastomer Filled with NdFeB Particles: Preparation, Characterization, and Magnetic–Mechanic Coupling Properties. Ind. Eng. Chem. Res. 2017, 56, 8857–8863. [Google Scholar] [CrossRef]

- Hapipi, N.M.; Mazlan, S.A.; Ubaidillah, U.; Aziz, S.A.A.; Khairi, M.H.A.; Nordin, N.A.; Nazmi, N. Solvent Dependence of the Rheological Properties in Hydrogel Magnetorheological Plastomer. Int. J. Mol. Sci. 2020, 21, 1793. [Google Scholar] [CrossRef]

- Wu, J.; Gong, X.; Fan, Y.; Xia, H. Physically crosslinked poly(vinyl alcohol) hydrogels with magnetic field controlled modulus. Soft Matter 2011, 7, 6205–6212. [Google Scholar] [CrossRef]

- Qi, S.; Fu, J.; Xie, Y.; Li, Y.; Gan, R.; Yu, M. Versatile magnetorheological plastomer with 3D printability, switchable mechanics, shape memory, and self-healing capacity. Compos. Sci. Technol. 2019, 183, 107817. [Google Scholar] [CrossRef]

- Sutrisno, J.; Fuchs, A.; Sahin, H.; Gordaninejad, F. Surface coated iron particles via atom transfer radical polymerization for thermal-oxidatively stable high viscosity magnetorheological fluid. J. Appl. Polym. Sci. 2013, 128, 470–480. [Google Scholar] [CrossRef]

- Hu, B.; Fuchs, A.; Huseyin, S.; Gordaninejad, F.; Evrensel, C. Atom transfer radical polymerized MR fluids. Polymer 2006, 47, 7653–7663. [Google Scholar] [CrossRef]

- Quan, X.; Chuah, W.; Seo, Y.; Choi, H.J. Core-Shell Structured Polystyrene Coated Carbonyl Iron Microspheres and their Magnetorheology. IEEE Trans. Magn. 2014, 50, 1–4. [Google Scholar] [CrossRef]

- Min, T.H.; Choi, H.J.; Kim, N.-H.; Park, K.; You, C.-Y. Effects of surface treatment on magnetic carbonyl iron/polyaniline microspheres and their magnetorheological study. Colloids Surf. A Physicochem. Eng. Asp. 2017, 531, 48–55. [Google Scholar] [CrossRef]

- Salzman, S.; Romanofsky, H.J.; Jacobs, S.D.; Lambropoulos, J.C. Surface–texture evolution of different chemical-vapor-deposited zinc sulfide flats polished with various magnetorheological fluids. Precis. Eng. 2016, 43, 257–261. [Google Scholar] [CrossRef]

- Saraswathamma, K.; Jha, S.; Rao, P.V. Rheological behaviour of Magnetorheological polishing fluid for Si polishing. Mater. Today Proc. 2017, 4, 1478–1491. [Google Scholar] [CrossRef]

- Paswan, S.K.; Bedi, T.S.; Singh, A.K. Modeling and simulation of surface roughness in magnetorheological fluid based honing process. Wear 2017, 376–377, 1207–1221. [Google Scholar] [CrossRef]

- Lee, J.-W.; Hong, K.-P.; Kwon, S.H.; Choi, H.J.; Cho, M.-W. Suspension Rheology and Magnetorheological Finishing Characteristics of Biopolymer-Coated Carbonyliron Particles. Ind. Eng. Chem. Res. 2017, 56, 2416–2424. [Google Scholar] [CrossRef]

- Zhang, P.; Lee, K.; Lee, C.-H. Fretting friction and wear characteristics of magnetorheological fluid under different magnetic field strengths. J. Magn. Magn. Mater. 2017, 421, 13–18. [Google Scholar] [CrossRef]

- Bombard, A.J.F.; De Vicente, J. Boundary lubrication of magnetorheological fluids in PTFE/steel point contacts. Wear 2012, 296, 484–490. [Google Scholar] [CrossRef]

- Lee, J.W.; Hong, K.P.; Cho, M.W.; Kwon, S.H.; Choi, H.J. Polishing characteristics of optical glass using PMMA-coated carbonyl-iron-based magnetorheological fluid. Smart Mater. Struct. 2015, 24, 065002. [Google Scholar] [CrossRef]

- Hong, K.P.; Song, K.H.; Cho, M.-W.; Kwon, S.H.; Choi, H.J. Magnetorheological properties and polishing characteristics of silica-coated carbonyl iron magnetorheological fluid. J. Intell. Mater. Syst. Struct. 2018, 29, 137–146. [Google Scholar] [CrossRef]

- Xu, Z.; Wang, Q.; Zhu, K.; Jiang, S.; Wu, H.; Yi, L. Preparation and characterization of magnetorheological elastic polishing composites. J. Intell. Mater. Syst. Struct. 2019, 30, 1481–1492. [Google Scholar] [CrossRef]

- Yavas, D.; Yu, T.; Bastawros, A.F. Experimental Feasibility Study of Tunable-Stiffness Polishing Wheel via Integration of Magneto-Rheological Elastomers. In Mechanics of Composite and Multi-Functional Materials; Singh, R., Slipher, G., Eds.; Springer International Publishing: Cham, Switzerland, 2020; Volume 5, pp. 85–91. [Google Scholar]

- Lokander, M.; Reitberger, T.; Stenberg, B. Oxidation of natural rubber-based magnetorheological elastomers. Polym. Degrad. Stab. 2004, 86, 467–471. [Google Scholar] [CrossRef]

- Ulicny, J.C.; Balogh, M.P.; Potter, N.M.; Waldo, R.A. Magnetorheological fluid durability test—Iron analysis. Mater. Sci. Eng. A 2007, 443, 16–24. [Google Scholar] [CrossRef]

- Burhannuddin, N.L.; Nordin, N.A.; Mazlan, S.A.; Aziz, S.A.A.; Choi, S.-B.; Kuwano, N.; Nazmi, N.; Johari, N. Effects of corrosion rate of the magnetic particles on the field-dependentmaterial characteristics of silicone based magnetorheological elastomers. Smart Mater. Struct. 2020, 29, 087003. [Google Scholar] [CrossRef]

- Utami, D.; Mazlan, S.A.; Imaduddin, F.; Nordin, N.A.; Bahiuddin, I.; Aziz, S.A.A.; Mohamad, N.; Choi, S.-B. Material Characterization of a Magnetorheological Fluid Subjected to Long-Term Operation in Damper. Materials 2018, 11, 2195. [Google Scholar] [CrossRef] [PubMed]

- Shafrir, S.N.; Romanofsky, H.J.; Skarlinski, M.; Wang, M.; Miao, C. Zirconia Coated Carbonyl Iron Particle-Based Magnetorheological Fluid for Polishing. Appl. Opt. 2009, 48, 6797–6810. [Google Scholar] [CrossRef] [PubMed]

- Behrooz, M.; Sutrisno, J.; Zhang, L.; Fuchs, A.; Gordaninejad, F. Behavior of magnetorheological elastomers with coated particles. Smart Mater. Struct. 2015, 24, 35026. [Google Scholar] [CrossRef]

- Perales-Martínez, I.A.; Palacios-Pineda, L.M.; Lozano-Sánchez, L.M.; Martínez-Romero, O.; Puente-Cordova, J.G.; Elías-Zúñiga, A. Enhancement of a magnetorheological PDMS elastomer with carbonyl iron particles. Polym. Test. 2017, 57, 78–86. [Google Scholar] [CrossRef]

- Sedlacik, M.; Mrlik, M.; Babayan, V.; Pavlinek, V. Magnetorheological elastomers with efficient electromagnetic shielding. Compos. Struct. 2016, 135, 199–204. [Google Scholar] [CrossRef]

- Yu, M.; Qi, S.; Fu, J.; Zhu, M.; Chen, D. Understanding the reinforcing behaviors of polyaniline-modified carbonyl iron particles in magnetorheological elastomer based on polyurethane/epoxy resin IPNs matrix. Compos. Sci. Technol. 2017, 139, 36–46. [Google Scholar] [CrossRef]

- Cvek, M.; Mrlík, M.; Ilcíková, M.; Mosnáček, J.; Münster, L.; Pavlínek, V. Synthesis of Silicone Elastomers Containing Silyl-Based Polymer-Grafted Carbonyl Iron Particles: An Efficient Way to Improve Magnetorheological, Damping, and Sensing Performances. Macromolecules 2017, 50, 2189–2200. [Google Scholar] [CrossRef]

- Wang, J.-S.; Matyjaszewski, K. “Living”/Controlled Radical Polymerization. Transition-Metal-Catalyzed Atom Transfer Radical Polymerization in the Presence of a Conventional Radical Initiator. Macromolecules 1995, 28, 7572–7573. [Google Scholar] [CrossRef]

- Matyjaszewski, K.; Xia, J. Atom Transfer Radical Polymerization. Chem. Rev. 2001, 101, 2921–2990. [Google Scholar] [CrossRef] [PubMed]

- Król, P.; Chmielarz, P. Recent advances in ATRP methods in relation to the synthesis of copolymer coating materials. Prog. Org. Coat. 2014, 77, 913–948. [Google Scholar] [CrossRef]

- Matyjaszewski, K. Overview: Fundamentals of Controlled/Living Radical Polymerization; American Chemical Society: Washington, DC, USA, 1998; pp. 2–30. [Google Scholar]

- Morick, J.; Buback, M.; Matyjaszewski, K. Activation—Deactivation Equilibrium of Atom Transfer Radical Polymerization of Styrene up to High Pressure. Macromol. Chem. Phys. 2011, 212, 2423–2428. [Google Scholar] [CrossRef]

- Fuchs, A.; Sutrisno, J.; Gordaninejad, F.; Caglar, M.B.; Yanming, L. Surface polymerization of iron particles for magnetorheological elastomers. J. Appl. Polym. Sci. 2010, 117, 934–942. [Google Scholar] [CrossRef]

- Li, Y.; Li, Q.; Zhang, C.; Cai, P.; Bai, N.; Xu, X. Intelligent self-healing superhydrophobic modification of cotton fabrics via surface-initiated ARGET ATRP of styrene. Chem. Eng. J. 2017, 323, 134–142. [Google Scholar] [CrossRef]

- Parida, D.; Serra, C.A.; Gómez, R.I.; Garg, D.K.; Hoarau, Y.; Bouquey, M.; Muller, R. Atom Transfer Radical Polymerization in Continuous Microflow: Effect of Process Parameters. J. Flow Chem. 2014, 4, 92–96. [Google Scholar] [CrossRef]

- Monge, S.; Darcos, V.; Haddleton, D.M. Effect of DMSO used as solvent in copper mediated living radical polymerization. J. Polym. Sci. Part. A Polym. Chem. 2004, 42, 6299–6308. [Google Scholar] [CrossRef]

- Cvek, M.; Mrlik, M.; Sevcik, J.; Sedlacik, M. Tailoring Performance, Damping, and Surface Properties of Magnetorheological Elastomers via Particle-Grafting Technology. Polymers 2018, 10, 1411. [Google Scholar] [CrossRef]

- Bondarev, D.; Borská, K.; Šoral, M.; Moravčíková, D.; Mosnáček, J. Simple tertiary amines as promotors in oxygen tolerant photochemically induced ATRP of acrylates. Polymer 2019, 161, 122–127. [Google Scholar] [CrossRef]

- Khezri, K.; Fazli, Y. Evaluation of the effect of hydrophobically modified silica aerogel on the ARGET ATRP of styrene and butyl acrylate. Microporous Mesoporous Mater. 2019, 280, 236–242. [Google Scholar] [CrossRef]

- Zaborniak, I.; Chmielarz, P.; Martinez, M.R.; Wolski, K.; Wang, Z.; Matyjaszewski, K. Synthesis of high molecular weight poly(n-butyl acrylate) macromolecules via seATRP: From polymer stars to molecular bottlebrushes. Eur. Polym. J. 2020, 126, 109566. [Google Scholar] [CrossRef]

- Trevisanello, E.; De Bon, F.; Daniel, G.; Lorandi, F.; Durante, C.; Isse, A.A.; Gennaro, A. Electrochemically mediated atom transfer radical polymerization of acrylonitrile and poly(acrylonitrile-b-butyl acrylate) copolymer as a precursor for N-doped mesoporous carbons. Electrochim. Acta 2018, 285, 344–354. [Google Scholar] [CrossRef]

- Wang, G.; Wang, Z.; Lee, B.; Yuan, R.; Lu, Z.; Yan, J.; Pan, X.; Song, Y.; Bockstaller, M.R.; Matyjaszewski, K. Polymerization-induced self-assembly of acrylonitrile via ICAR ATRP. Polymer 2017, 129, 57–67. [Google Scholar] [CrossRef]

- Chmielarz, P.; Park, S.; Simakova, A.; Matyjaszewski, K. Electrochemically mediated ATRP of acrylamides in water. Polymer 2015, 60, 302–307. [Google Scholar] [CrossRef]

- Ma, Y.; Cai, M.; He, L.; Luo, X. Enhanced protein retention on poly(caprolactone) via surface initiated polymerization of acrylamide. Appl. Surf. Sci. 2016, 360, 20–27. [Google Scholar] [CrossRef]

- Matyjaszewski, K.; Coca, S.; Gaynor, S.G.; Wei, M.; Woodworth, B.E. Controlled radical polymerisation in the presence of oxygen. Macromolecules 1998, 31, 5967–5969. [Google Scholar] [CrossRef]

- Horn, M.; Matyjaszewski, K. Solvent Effects on the Activation Rate Constant in Atom Transfer Radical Polymerization. Macromolecules 2013, 46, 3350–3357. [Google Scholar] [CrossRef]

- París, R.; De La Fuente, J.L. Solvent effect on the atom transfer radical polymerization of allyl methacrylate. J. Polym. Sci. Part. A Polym. Chem. 2005, 43, 6247–6261. [Google Scholar] [CrossRef]

- Zhu, K.; Zhu, Z.; Zhou, H.; Zhang, J.; Liu, S. Precisely installing gold nanoparticles at the core/shell interface of micellar assemblies of triblock copolymers. Chin. Chem. Lett. 2017, 28, 1276–1284. [Google Scholar] [CrossRef]

- Cvek, M.; Mrlik, M.; Ilcíková, M.; Plachy, T.; Sedlacik, M.; Mosnacek, J.; Pavlinek, V. A facile controllable coating of carbonyl iron particles with poly(glycidyl methacrylate): A tool for adjusting MR response and stability properties. J. Mater. Chem. C 2015, 3, 4646–4656. [Google Scholar] [CrossRef]

- Eyiler, E.; Walters, K.B. Magnetic iron oxide nanoparticles grafted with poly(itaconic acid)-block-poly(N-isopropylacrylamide). Colloids Surf. A Physicochem. Eng. Asp. 2014, 444, 321–325. [Google Scholar] [CrossRef]

- Sapurina, I.Y.; Shishov, M.A. Oxidative Polymerization of Aniline: Molecular Synthesis of Polyaniline and the Formation of Supramolecular Structures. New Polym. Spec. Appl. 2012, 740, 272. [Google Scholar] [CrossRef]

- Higashimura, H.; Kobayashi, S. Oxidative Polymerization. In Encyclopedia of Polymer Science and Technology; Wiley-Interscience: New York, NY, USA, 2016; pp. 1–37. [Google Scholar] [CrossRef]

- Jamari, S.K.M.; Kasi, R.; Ismail, L.; Nor, N.A.M.; Subramanian, R.R.; Subramaniam, T.R.; Vengadaesvaran, B.; Arof, A.K.M. Studies on anticorrosion properties of polyaniline-TiO2 blended with acrylic-silicone coating using electrochemical impedance spectroscopy. Pigment. Resin Technol. 2016, 45, 18–23. [Google Scholar] [CrossRef]

- Kalendova, A.; Veselý, D.; Stejskal, J. Organic coatings containing polyaniline and inorganic pigments as corrosion inhibitors. Prog. Org. Coat. 2008, 62, 105–116. [Google Scholar] [CrossRef]

- He, Z.; Fang, Y.; Wang, X.; Pang, H. Microwave absorption properties of PANI/CIP/Fe3O4 composites. Synth. Met. 2011, 161, 420–425. [Google Scholar] [CrossRef]

- Fan, M.; He, Z.; Pang, H. Microwave absorption enhancement of CIP/PANI composites. Synth. Met. 2013, 166, 1–6. [Google Scholar] [CrossRef]

- Lin, K.-Y.; Hu, L.-W.; Chen, K.-L.; Siao, M.-D.; Ji, W.-F.; Yang, C.-C.; Yeh, J.-M.; Chiu, K.-C. Characterization of polyaniline synthesized from chemical oxidative polymerization at various polymerization temperatures. Eur. Polym. J. 2017, 88, 311–319. [Google Scholar] [CrossRef]

- Amer, I.; Young, D.A. Chemically oxidative polymerization of aromatic diamines: The first use of aluminium-triflate as a co-catalyst. Polymer 2013, 54, 505–512. [Google Scholar] [CrossRef]

- Kong, H.; Song, J.; Jang, J. One-step fabrication of magnetic γ-Fe2O3/polyrhodanine nanoparticles using in situ chemical oxidation polymerization and their antibacterial properties. Chem. Commun. 2010, 46, 6735. [Google Scholar] [CrossRef]

- Yuan, G.; Wang, H. Facile synthesis and performance of polypyrrole-coated sulfur nanocomposite as cathode materials for lithium/sulfur batteries. J. Energy Chem. 2014, 23, 657–661. [Google Scholar] [CrossRef]

- Bai, R.; Zhang, X. Polypyrrole-Coated Granules for Humic Acid Removal. J. Colloid Interface Sci. 2001, 243, 52–60. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Q.; Liu, P. Poly(1,5-diaminoanthraquinone) coated carbon cloth composites as flexible electrode with extraordinary cycling stability for symmetric solid-state supercapacitors. J. Colloid Interface Sci. 2019, 546, 60–69. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Li, R.R.; Zhou, X.Z.; Li, J.; Lei, Z. Polythiophene-coated nano-silicon composite anodes with enhanced performance for lithium-ion batteries. J. Solid State Electrochem. 2016, 20, 1331–1336. [Google Scholar] [CrossRef]

- Slomkowski, S.; Alemán, J.V.; Gilbert, R.G.; Hess, M.; Horie, K.; Jones, R.G.; Kubisa, P.; Meisel, I.; Mormann, W.; Penczek, S.; et al. Terminology of polymers and polymerization processes in dispersed systems (IUPAC Recommendations 2011). Pure Appl. Chem. 2011, 83, 2229–2259. [Google Scholar] [CrossRef]

- Kawaguchi, S.; Ito, K. Dispersion polymerization. In Polymer Particles; Springer: Berlin/Heidelberg, Germany, 2005; Volume 175, pp. 299–328. [Google Scholar]

- Fang, F.F.; Liu, Y.D.; Choi, H.J. Carbon nanotube coated magnetic carbonyl iron microspheres prepared by solvent casting method and their magneto-responsive characteristics. Colloids Surf. A Physicochem. Eng. Asp. 2012, 412, 47–56. [Google Scholar] [CrossRef]

- Kim, J.H.; Fang, F.F.; Choi, H.J.; Seo, Y. Magnetic composites of conducting polyaniline/nano-sized magnetite and their magnetorheology. Mater. Lett. 2008, 62, 2897–2899. [Google Scholar] [CrossRef]

| Monomers | Initiators | Catalysts | Solvents | Remarks | Ref. |

|---|---|---|---|---|---|

| Glycidyl methacrylate | BiBB EBiB | CuBr PMDETA (L) | THF Anisole Acetone Ethanol | APTES was used as a coupling agent during surface treatment. CIP was pre-treated with HCl. | [20,92] |

| Butyl acrylate | CTCS | CuBr CuBr2 Sparteine (L) | THF Toluene | [48] | |

| Fluorinated styrene | CTCS | CuBr CuBr2 Sparteine (L) | Toluene Octyl pyrrolidone | [47,76] | |

| 2-hydroxyethyl methacrylate Chlorotrimethyl-silane | BiBB EBiB | CuBr PMDETA (L) | Dichloro-methane Anisole | APTES used as a linker of BiBB Et3N used to trap hydrogen chloride | [70,80] |

| Polymerized Polymers | Substrates | Findings | Ref. |

|---|---|---|---|

| Polypyrrole | Sulfur nano-sphere | For rechargeable lithium/sulfur batteries application

| [103] |

| Polypyrrole | Glass beads | For water treatment application

| [104] |

| Poly(1,5-diaminoanthra-quinone) | Carbon cloth | For supercapacitor application

| [105] |

| Polythiophene | Nano-silicon | For lithium batteries application

| [106] |

| Polyrhodanine | γ-Fe2O3 nano-particles | For antibacterial application

| [102] |

| Coating Methods | Ref. | Storage Modulus | Loss Modulus/Factor | MR Effect | Chemical Stability | Thermal Stability | Sedimentation Stability | Magnetic Saturation | Other Characteristics |

|---|---|---|---|---|---|---|---|---|---|

| ATRP | [92] | ↑ | ↑ | ↑ | ↑ | ↑ | 7.02–9.47 emu/g ↓ | ||

| [76] | ↑ | ↑ | ↑ | ||||||

| [47] | ↑ | ↑ | |||||||

| [70] | ↓ | ↑ | ↑ | ↑ | ↑ | 6.2% ↓ (~10 emu/g) | ↑ hydrophobicity ↑ magnetostriction | ||

| [20] | ↓ | ↑ | 9–14 emu/g ↓ | ↑ cytotoxicity ↓ yield stress | |||||

| [80] | ↓ | ↑ | ↑ | ↑ | ↑ | ~20 emu/g ↓ | ↑ roughness | ||

| COP | [50] | ↑ | ↓ | TGA: ~90wt% at 800 °C ↑ | ↑ | 59 emu/g ↓ | |||

| [110] | 42 emu/g ↓ | No comparison for other parameters | |||||||

| [69] | ↑ | ↓ (strain sweep) ↑ (frequency sweep) | 31.5 emu/g ↓ | ↑ hydrophobicity | |||||

| Dispersion polymerization | [29] | ↑ | ↓ | ↓ | 45 emu/g ↓ | ||||

| [18] | ↓ | ↑ | 36 emu/g ↓ | ↓ yield stress ↓ shear viscosity ↑ friction resistance | |||||

| [57] | ↑ | ↑ | ↓ yield stress ↓ shear stress ↑ material removal depth | ||||||

| [49] | 10 emu/g ↓ | ↑ dispersion stability ≈ shear stress | |||||||

| [27] | ↑ | 24 emu/g ↓ | ↓ shear stress ↓ shear viscosity |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jamari, S.K.M.; Nordin, N.A.; Ubaidillah; Aziz, S.A.A.; Nazmi, N.; Mazlan, S.A. Systematic Review on the Effects, Roles and Methods of Magnetic Particle Coatings in Magnetorheological Materials. Materials 2020, 13, 5317. https://doi.org/10.3390/ma13235317

Jamari SKM, Nordin NA, Ubaidillah, Aziz SAA, Nazmi N, Mazlan SA. Systematic Review on the Effects, Roles and Methods of Magnetic Particle Coatings in Magnetorheological Materials. Materials. 2020; 13(23):5317. https://doi.org/10.3390/ma13235317

Chicago/Turabian StyleJamari, Siti Khumaira Mohd, Nur Azmah Nordin, Ubaidillah, Siti Aishah Abdul Aziz, Nurhazimah Nazmi, and Saiful Amri Mazlan. 2020. "Systematic Review on the Effects, Roles and Methods of Magnetic Particle Coatings in Magnetorheological Materials" Materials 13, no. 23: 5317. https://doi.org/10.3390/ma13235317

APA StyleJamari, S. K. M., Nordin, N. A., Ubaidillah, Aziz, S. A. A., Nazmi, N., & Mazlan, S. A. (2020). Systematic Review on the Effects, Roles and Methods of Magnetic Particle Coatings in Magnetorheological Materials. Materials, 13(23), 5317. https://doi.org/10.3390/ma13235317