Modification of Structural Properties Using Process Parameters and Surface Treatment of Monolithic and Thin-Walled Parts Obtained by Selective Laser Melting

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

2.2. Additive Manufacturing Process

2.3. Material Properties Analysis

3. Results and Discussion

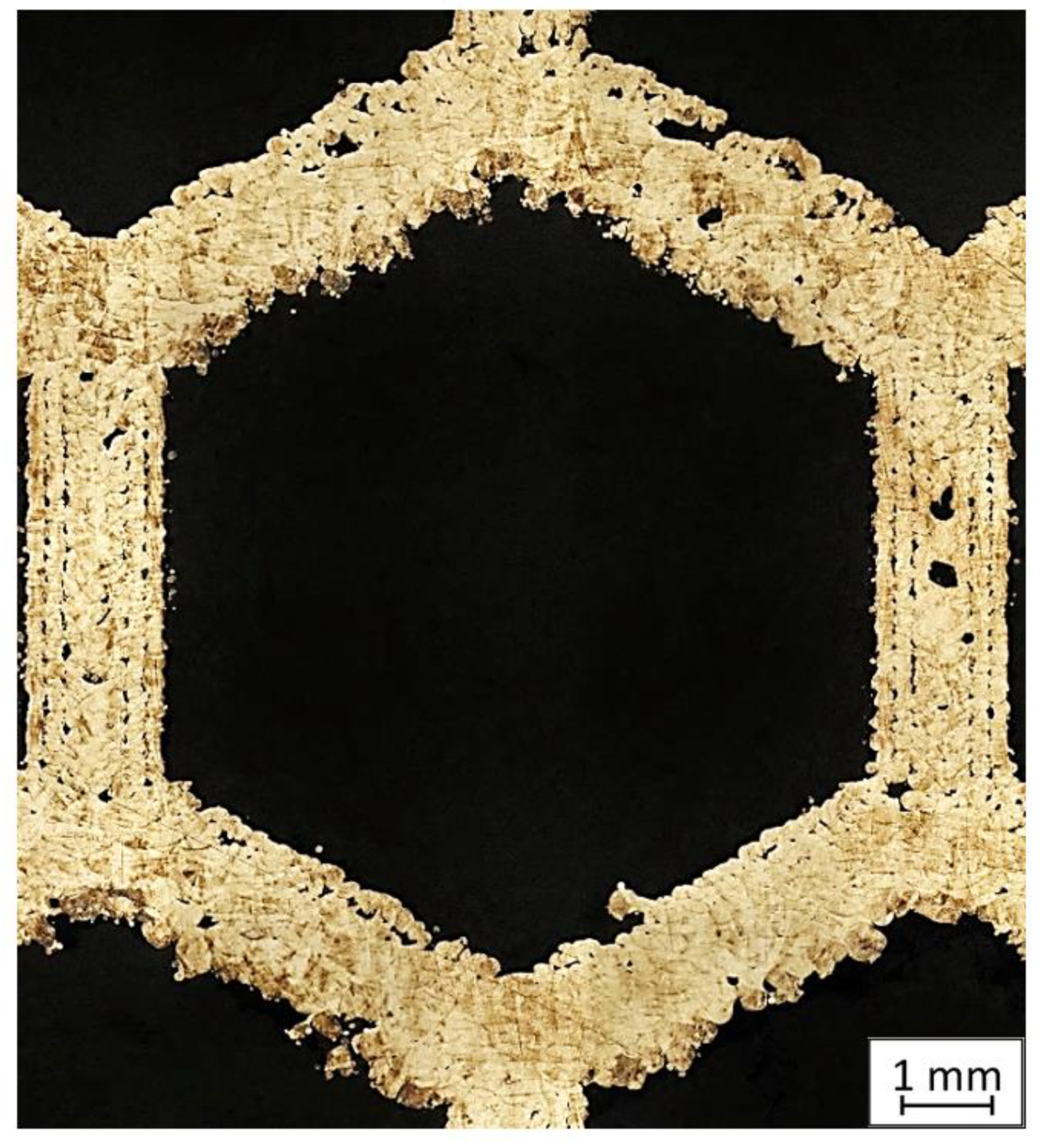

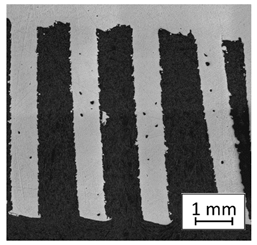

3.1. Porosity Analysis

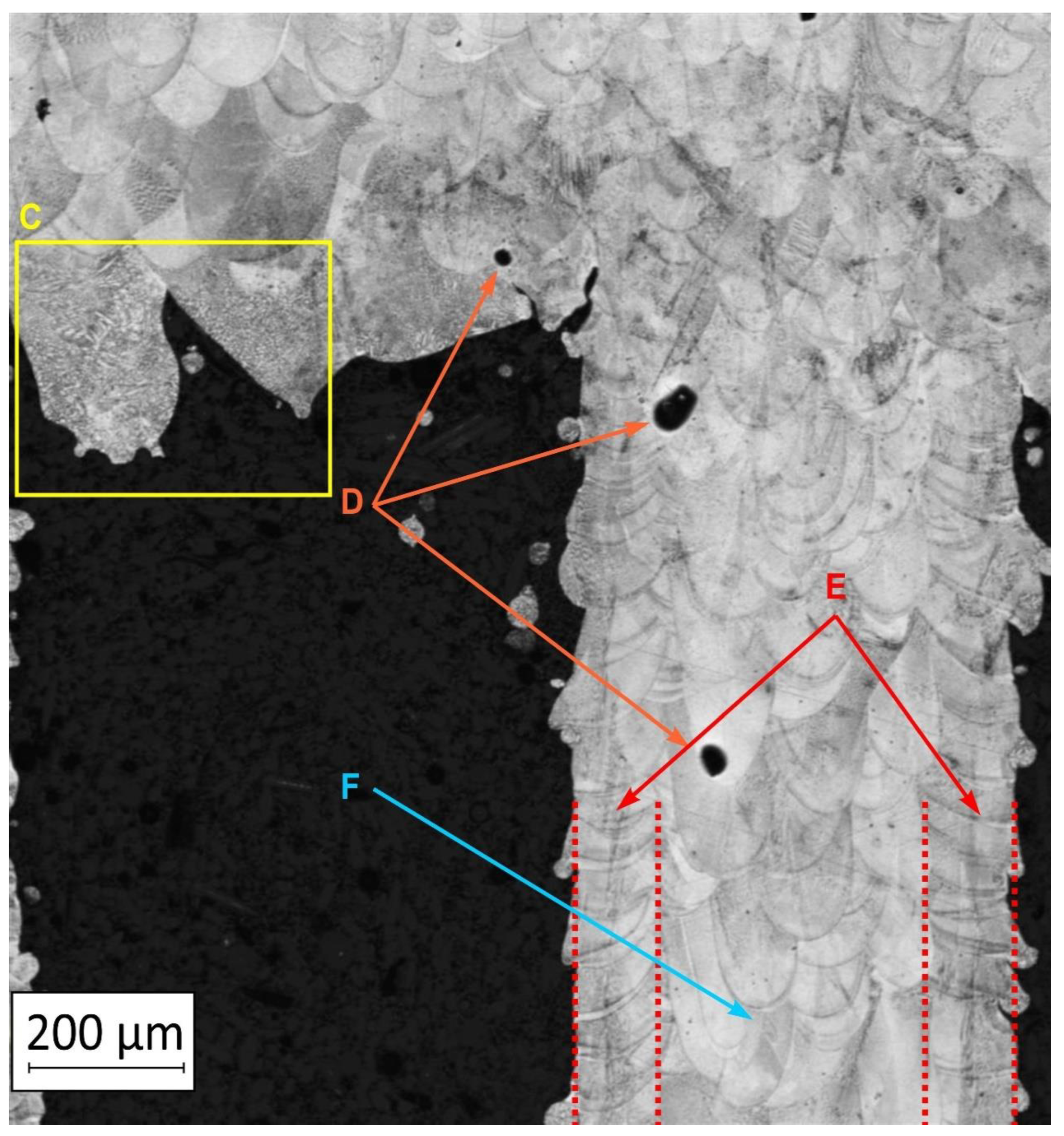

3.2. Microstructural Analysis

3.3. Surface Roughness Analysis

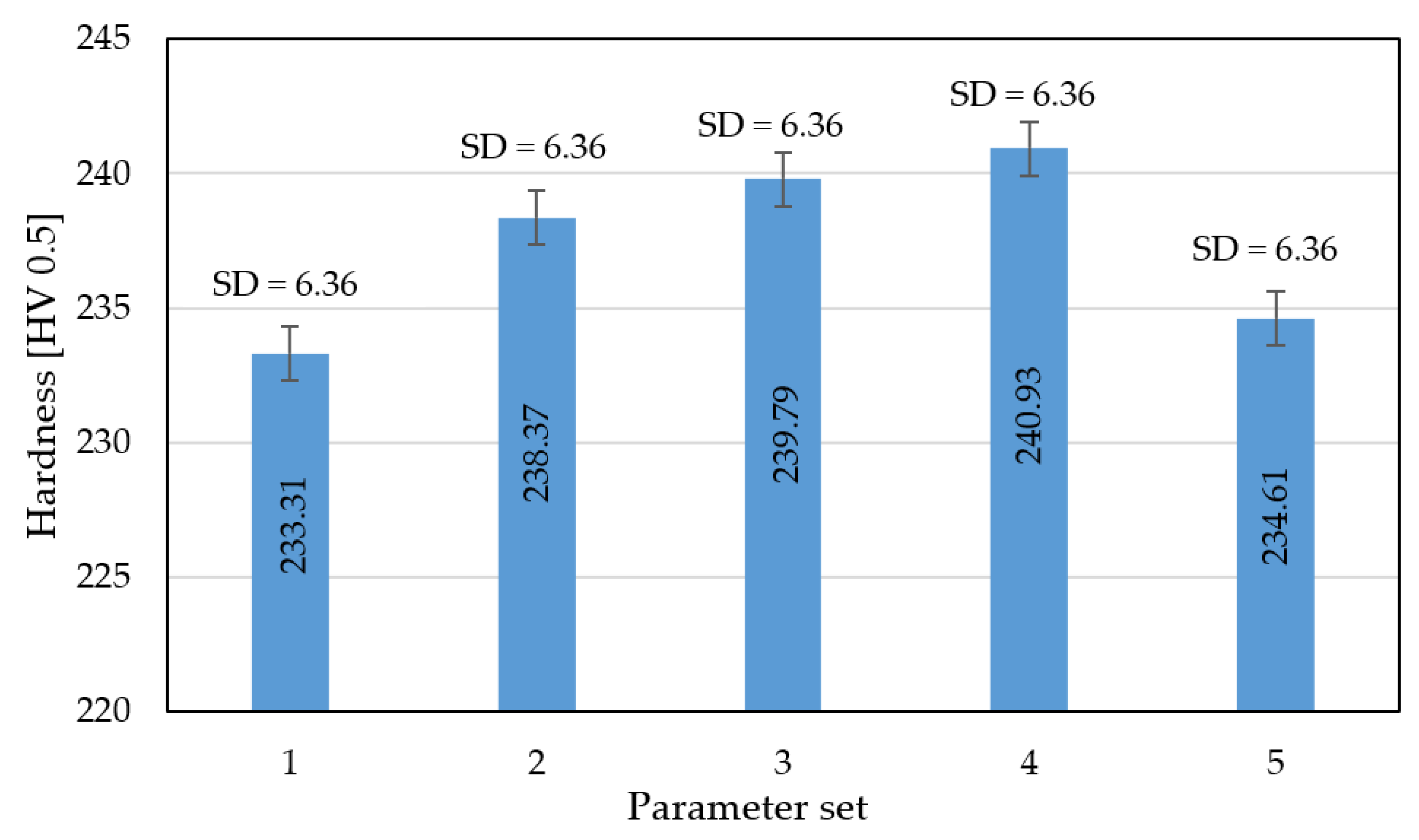

3.4. Hardness Analysis

3.5. Surface Treatment

4. Conclusions

- An energy density increase of 56% caused almost an 85% decrease in porosity and a 45% increase in surface roughness. Additionally, manufacturing using parameters with lower energy density led to a slight increase in the measured hardness.

- Using higher energy density during the SLM process reduced the layered structure effect and slightly increased surface roughness with the growth of the material solidification.

- For thin-walled structures, using a higher amount of energy density than would be used for monolithic parts is suggested to obtain better structural properties. This kind of modification has to be limited by process technological windows specific to each material.

- Surface treatment allowed for a 70–90% roughness reduction. In the case of electropolishing, it was very important to ensure a stable surface roughness value before the treatment in order to avoid structural heterogeneity generation after polishing.

Author Contributions

Funding

Conflicts of Interest

References

- du Plessis, A.; Broeckhoven, C.; Yadroitsava, I.; Yadroitsev, I.; Hands, C.H.; Kunju, R.; Bhate, D. Beautiful and Functional: A Review of Biomimetic Design in Additive Manufacturing. Addit. Manuf. 2019, 27, 408–427. [Google Scholar] [CrossRef]

- Sienkiewicz, J.; Płatek, P.; Jiang, F.; Sun, X.; Rusinek, A. Investigations on the Mechanical Response of Gradient Lattice Structures Manufactured via SLM. Metals 2020, 10, 213. [Google Scholar] [CrossRef]

- Eliaz, N.; Foucks, N.; Geva, D.; Oren, S.; Shriki, N.; Vaknin, D.; Fishman, D.; Levi, O. Alloy 4047 Either Manufactured or Repaired by Laser Engineered Net Shaping (LENS). Materials 2020, 13, 4171. [Google Scholar] [CrossRef]

- Mooney, B.; Kourousis, K.I. A Review of Factors Affecting the Mechanical A Review of of Maraging Factors Affecting Properties of Powder Bed Fusion. Metals 2020, 10, 1273. [Google Scholar] [CrossRef]

- Śniezek, L.; Grzelak, K.; Torzewski, J.; Kluczyński, J. Study of the mechanical properties components made by SLM additive technology. In Proceedings of the 11th International Conference on Intelligent Technologies in Logistics and Mechatronics Systems, ITELMS, Panevezys, Lithuania, 28–29 April 2016; pp. 145–153. [Google Scholar]

- Kluczyński, J.; Śniezek, L.; Grzelak, K.; Torzewski, J.; Szachogłuchowicz, I.; Wachowski, M.; Łuszczek, J. Crack growth behavior of additively manufactured 316L steel-influence of build orientation and heat treatment. Materials 2020, 13, 3259. [Google Scholar] [CrossRef]

- Kluczyński, J.; Śnieżek, L.; Grzelak, K.; Janiszewski, J.; Płatek, P.; Torzewski, J.; Szachogłuchowicz, I.; Gocman, K. Influence of Selective Laser Melting Technological Parameters on the Mechanical Properties of Additively Manufactured Elements Using 316L Austenitic Steel. Materials 2020, 13, 1449. [Google Scholar] [CrossRef]

- Kluczyński, J.; Śnieżek, L.; Kravcov, A.; Grzelak, K.; Svoboda, P.; Szachogłuchowicz, I.; Franek, O.; Morozov, N.; Torzewski, J.; Kubeček, P. The Examination of Restrained Joints Created in the Process of Multi-Material FFF Additive Manufacturing Technology. Materials 2020, 13, 903. [Google Scholar] [CrossRef] [PubMed]

- Kluczyński, J.; Sniezek, L.; Grzelak, K.; Torzewski, J. The influence of layer re-melting on tensile and fatigue strength of selective laser melted 316L steel. In Proceedings of the 12th International Conference on Intelligent Technologies in Logistics and Mechatronics Systems, ITELMS, Panevezys, Lithuania, 26–27 April 2018; pp. 115–123. [Google Scholar]

- Kluczyński, J.; Śniezek, L.; Grzelak, K.; Oziebło, A.; Perkowski, K.; Torzewski, J.; Szachogłuchowicz, I.; Gocman, K.; Wachowski, M.; Kania, B. Comparison of different heat treatment processes of selective laser melted 316L steel based on analysis of mechanical properties. Materials 2020, 13, 3805. [Google Scholar] [CrossRef]

- Kucewicz, M.; Baranowski, P.; Małachowski, J.; Popławski, A.; Płatek, P. Modelling, and characterization of 3D printed cellular structures. Mater. Des. 2018, 142, 177–189. [Google Scholar] [CrossRef]

- Antolak-Dudka, A.; Płatek, P.; Durejko, T.; Baranowski, P.; Małachowski, J.; Sarzyński, M.; Czujko, T. Static and dynamic loading behavior of Ti6Al4V honeycomb structures manufactured by Laser Engineered Net Shaping (LENSTM) technology. Materials 2019, 12, 1225. [Google Scholar] [CrossRef] [PubMed]

- Kucewicz, M.; Baranowski, P.; Stankiewicz, M.; Konarzewski, M.; Płatek, P.; Małachowski, J. Modelling and testing of 3D printed cellular structures under quasi-static and dynamic conditions. Thin-Walled Struct. 2019, 145, 106385. [Google Scholar] [CrossRef]

- Malachowski, J.; Damaziak, K.; Platek, P.; Sarzynski, M.; Kupidura, P.; Wozniak, R.; Zahor, M. Numerical and experimental failure analysis of rifle extractor. Eng. Fail. Anal. 2016, 62, 112–127. [Google Scholar] [CrossRef]

- Leordean, D.; Dudescu, C.; Marcu, T.; Berce, P.; Balc, N. Customized implants with specific properties, made by selective laser melting. Rapid Prototyp. J. 2015, 21, 98–104. [Google Scholar] [CrossRef]

- Subramaniam, A.; Danivas, V.; Mahavir Agarwal, S.; Kalmady, S.; Shivakumar, V.; Amaresha, A.C.; Bose, A.; Narayanaswamy, J.C.; Varambally, S.; Hutton, S.B.; et al. Clinical correlates of saccadic eye movement in antipsychotic-naïve schizophrenia. Psychiatry Res. 2018, 259, 154–159. [Google Scholar] [CrossRef] [PubMed]

- Jia, D.; Li, F.; Zhang, Y. 3D-printing process design of lattice compressor impeller based on residual stress and deformation. Sci. Rep. 2020, 10, 600. [Google Scholar] [CrossRef]

- Rokicki, P.; Kozik, B.; Budzik, G.; Dziubek, T.; Bernaczek, J.; Przeszlowski, L.; Markowska, O.; Sobolewski, B.; Rzucidlo, A. Manufacturing of aircraft engine transmission gear with SLS (DMLS) method. Aircr. Eng. Aerosp. Technol. 2016, 88, 397–403. [Google Scholar] [CrossRef]

- Platek, P.; Damaziak, K.; Malachowski, J.; Kupidura, P.; Wozniak, R.; Zahor, M. Numerical study of modular 5.56 mm standard assault rifle referring to dynamic characteristics. Def. Sci. J. 2015, 65, 431–437. [Google Scholar] [CrossRef]

- García-Dominguez, A.; Claver, J.; Sebastián, M.A. Optimization Methodology for Additive Manufacturing of Customized Parts by Fused Deposition Modeling (FDM). Application to a Shoe Heel. Polymers 2020, 12, 2119. [Google Scholar] [CrossRef]

- Alfaify, A.; Saleh, M.; Abdullah, F.M. Design for Additive Manufacturing: A Systematic Review. Sustainability 2020, 12, 7936. [Google Scholar] [CrossRef]

- Gusarov, A.V.; Yadroitsev, I.; Bertrand, P.; Smurov, I. Heat transfer modelling and stability analysis of selective laser melting. Appl. Surf. Sci. 2007, 254, 975–979. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, Y.; Mai, S.; Wang, D.; Song, C. Investigation into spatter behavior during selective laser melting of AISI 316L stainless steel powder. Mater. Des. 2015, 87, 797–806. [Google Scholar] [CrossRef]

- Matthews, M.J.; Guss, G.; Khairallah, S.A.; Rubenchik, A.M.; Depond, P.J.; King, W.E. Denudation of metal powder layers in laser powder bed fusion processes. Acta Mater. 2016, 114, 33–42. [Google Scholar] [CrossRef]

- Kluczyński, J.; Śniezek, L.; Grzelak, K.; Mierzyński, J. The influence of exposure energy density on porosity and microhardness of the SLM additive manufactured elements. Materials 2018, 11, 2304. [Google Scholar] [CrossRef] [PubMed]

- Jaskari, M.; Mäkikangas, J.; Järvenpää, A.; Mäntyjärvi, K.; Karjalainen, P. Effect of High Porosity on Bending Fatigue Properties of 3D Printed AISI 316L Steel. Procedia Manuf. 2019, 36, 33–41. [Google Scholar] [CrossRef]

- Cherry, J.A.; Davies, H.M.; Mehmood, S.; Lavery, N.P.; Brown, S.G.R.; Sienz, J. Investigation into the effect of process parameters on microstructural and physical properties of 316L stainless steel parts by selective laser melting. Int. J. Adv. Manuf. Technol. 2014, 76, 869–879. [Google Scholar] [CrossRef]

- Tucho, W.M.; Lysne, V.H.; Austbø, H.; Sjolyst-Kverneland, A.; Hansen, V. Investigation of effects of process parameters on microstructure and hardness of SLM manufactured SS316L. J. Alloys Compd. 2018, 740, 910–925. [Google Scholar] [CrossRef]

- Wang, D.; Liu, Y.; Yang, Y.; Xiao, D. Theoretical and experimental study on surface roughness of 316L stainless steel metal parts obtained through selective laser melting. Rapid Prototyp. J. 2016, 22, 706–716. [Google Scholar] [CrossRef]

- Stern, F.; Kleinhorst, J.; Tenkamp, J.; Walther, F. Investigation of the anisotropic cyclic damage behavior of selective laser melted AISI 316L stainless steel. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 2422–2430. [Google Scholar] [CrossRef]

- Zhang, M.; Sun, C.N.; Zhang, X.; Wei, J.; Hardacre, D.; Li, H. Predictive models for fatigue property of laser powder bed fusion stainless steel 316L. Mater. Des. 2018, 145, 42–54. [Google Scholar] [CrossRef]

- Fatemi, A.; Molaei, R.; Phan, N. Multiaxial fatigue of additive manufactured metals: Performance, analysis, and applications. Int. J. Fatigue 2020, 134, 105479. [Google Scholar] [CrossRef]

- Criales, L.E.; Arısoy, Y.M.; Lane, B.; Moylan, S.; Donmez, A.; Özel, T. Laser powder bed fusion of nickel alloy 625: Experimental investigations of effects of process parameters on melt pool size and shape with spatter analysis. Int. J. Mach. Tools Manuf. 2017, 121, 22–36. [Google Scholar] [CrossRef]

- Simson, T.; Emmel, A.; Dwars, A.; Böhm, J. Residual stress measurements on AISI 316L samples manufactured by selective laser melting. Addit. Manuf. 2017, 17, 183–189. [Google Scholar] [CrossRef]

| C | Mn | Si | P | S | N | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|---|

| weight (%) | ||||||||

| max. 0.03 | max. | max. | max. | max. | max. | 16.00–18.00 | 2.00–3.00 | 10.00–14.00 |

| 2.00 | 0.75 | 0.04 | 0.03 | 0.10 | ||||

| Type of Parameter | Value |

|---|---|

| Density ( | 7.9 |

| Thermal conductivity ( | 15 |

| Tensile strength in horizontal orientation (MPa) | 651 |

| Tensile strength in vertical orientation (MPa) | 640 |

| Offset yield strength in horizontal orientation (MPa) | 546 |

| Offset yield strength in vertical orientation (MPa) | 529 |

| Elongation at break in horizontal orientation (%) | 41 |

| Elongation at break in vertical orientation (%) | 43 |

| Parameter Set | LP (W) | ev (mm/s) | hd (mm) | lt (mm) | ρE (J/mm3) |

|---|---|---|---|---|---|

| 1 | 191 | 700 | 0.12 | 0.05 | 45.48 |

| 2 | 233 | 700 | 0.12 | 0.05 | 55.48 |

| 3 | 275 | 700 | 0.12 | 0.05 | 65.48 |

| 4 | 317 | 700 | 0.12 | 0.05 | 75.48 |

| 5 | 359 | 700 | 0.12 | 0.05 | 85.48 |

| Parameters Set | ||||

|---|---|---|---|---|

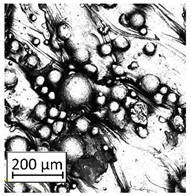

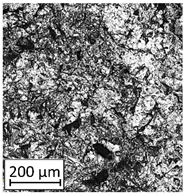

| Value of Registered Porosity (%) | Registered and Merged Image | Porosity of Reference Monolithic Samples (%) | ||

| Parameter set | 1 | 0.68 |  | 0.59 |

| 2 | 0.63 |  | 0.12 | |

| 3 | 0.62 |  | 0.10 | |

| 4 | 0.56 |  | 0.03 | |

| 5 | 0.09 |  | 0.04 | |

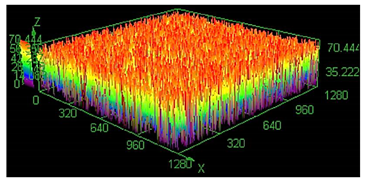

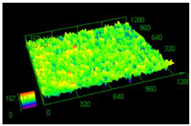

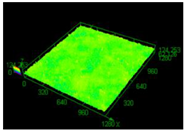

| Parameters Set | |||

|---|---|---|---|

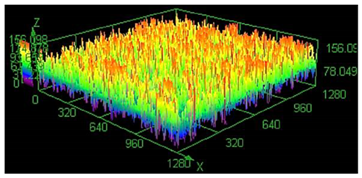

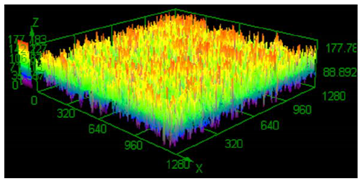

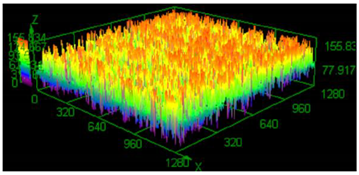

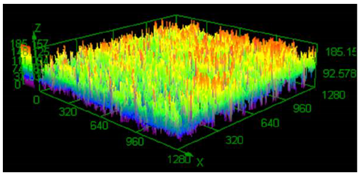

| Value of Registered Surface Roughness Ra (µm)/Rz (µm) | Registered Roughness Values Map | ||

| Parameter set | 1 | 12.56/71.60 |  |

| 2 | 16.36/168.80 |  | |

| 3 | 19.54/182.05 |  | |

| 4 | 18.43/166.05 |  | |

| 5 | 19.71/219.82 |  | |

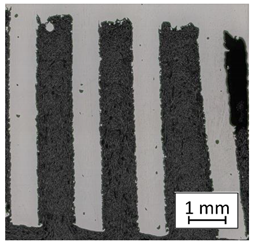

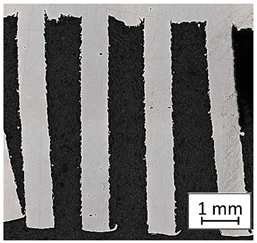

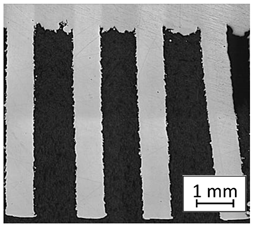

| As-Built | Sanded | Electropolished | |

|---|---|---|---|

| Surface image |  |  |  |

| Roughness values map |  |  |  |

| Registered roughness value Ra (µm) | 13.641 | 3.950 | 1.316 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grzelak, K.; Kluczyński, J.; Szachogłuchowicz, I.; Łuszczek, J.; Śnieżek, L.; Torzewski, J. Modification of Structural Properties Using Process Parameters and Surface Treatment of Monolithic and Thin-Walled Parts Obtained by Selective Laser Melting. Materials 2020, 13, 5662. https://doi.org/10.3390/ma13245662

Grzelak K, Kluczyński J, Szachogłuchowicz I, Łuszczek J, Śnieżek L, Torzewski J. Modification of Structural Properties Using Process Parameters and Surface Treatment of Monolithic and Thin-Walled Parts Obtained by Selective Laser Melting. Materials. 2020; 13(24):5662. https://doi.org/10.3390/ma13245662

Chicago/Turabian StyleGrzelak, Krzysztof, Janusz Kluczyński, Ireneusz Szachogłuchowicz, Jakub Łuszczek, Lucjan Śnieżek, and Janusz Torzewski. 2020. "Modification of Structural Properties Using Process Parameters and Surface Treatment of Monolithic and Thin-Walled Parts Obtained by Selective Laser Melting" Materials 13, no. 24: 5662. https://doi.org/10.3390/ma13245662

APA StyleGrzelak, K., Kluczyński, J., Szachogłuchowicz, I., Łuszczek, J., Śnieżek, L., & Torzewski, J. (2020). Modification of Structural Properties Using Process Parameters and Surface Treatment of Monolithic and Thin-Walled Parts Obtained by Selective Laser Melting. Materials, 13(24), 5662. https://doi.org/10.3390/ma13245662