Low-Cycle Fatigue Behavior of the Novel Steel and 30SiMn2MoV Steel at 700 °C

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. High Temperature Tensile Properties

3.2. Cyclic Stress Response Behavior

3.3. Cyclic Stress–Strain Behavior

3.4. Masing Analysis

3.5. Low Cycle Fatigue Life

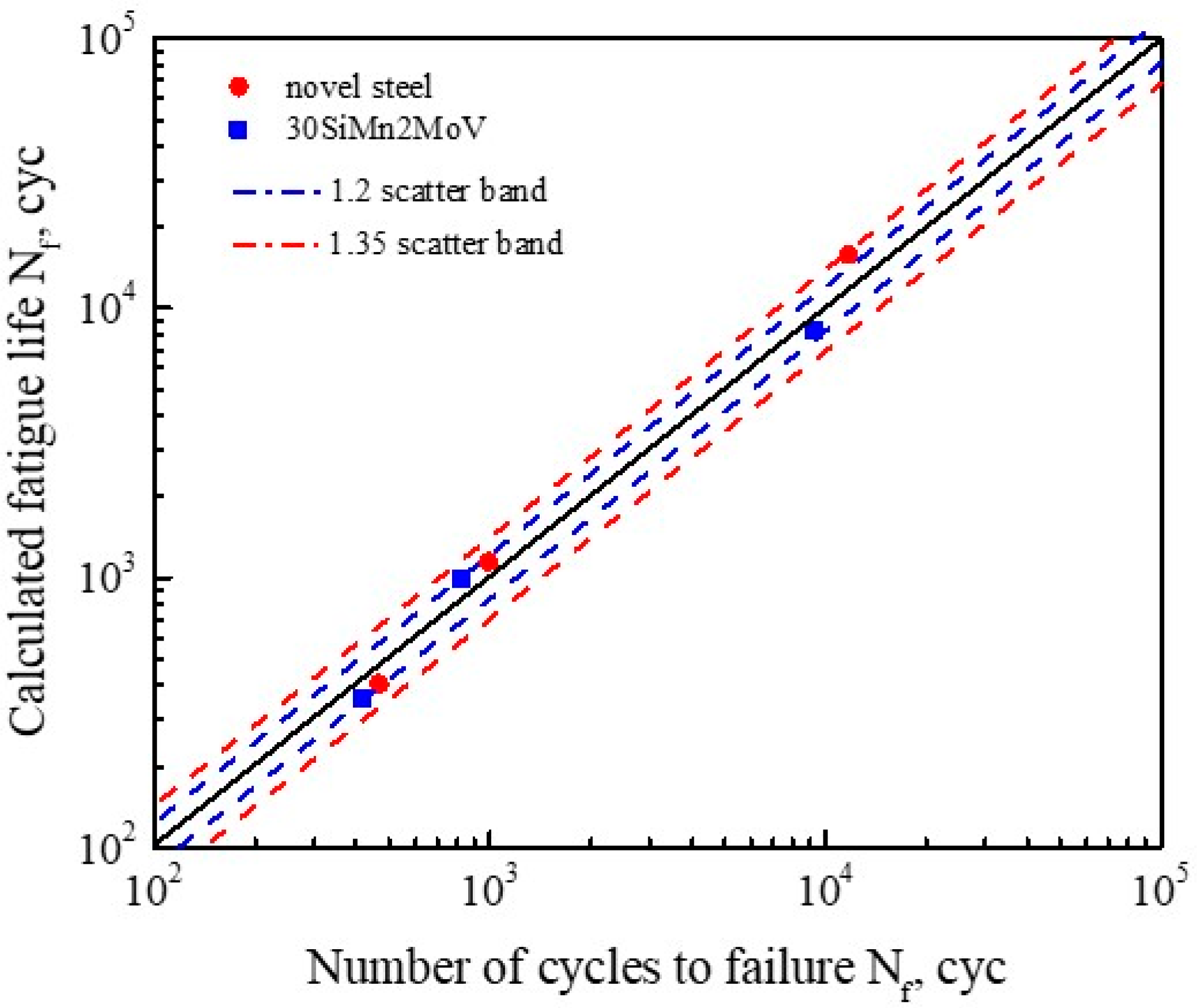

3.6. Energy–Life Prediction Models

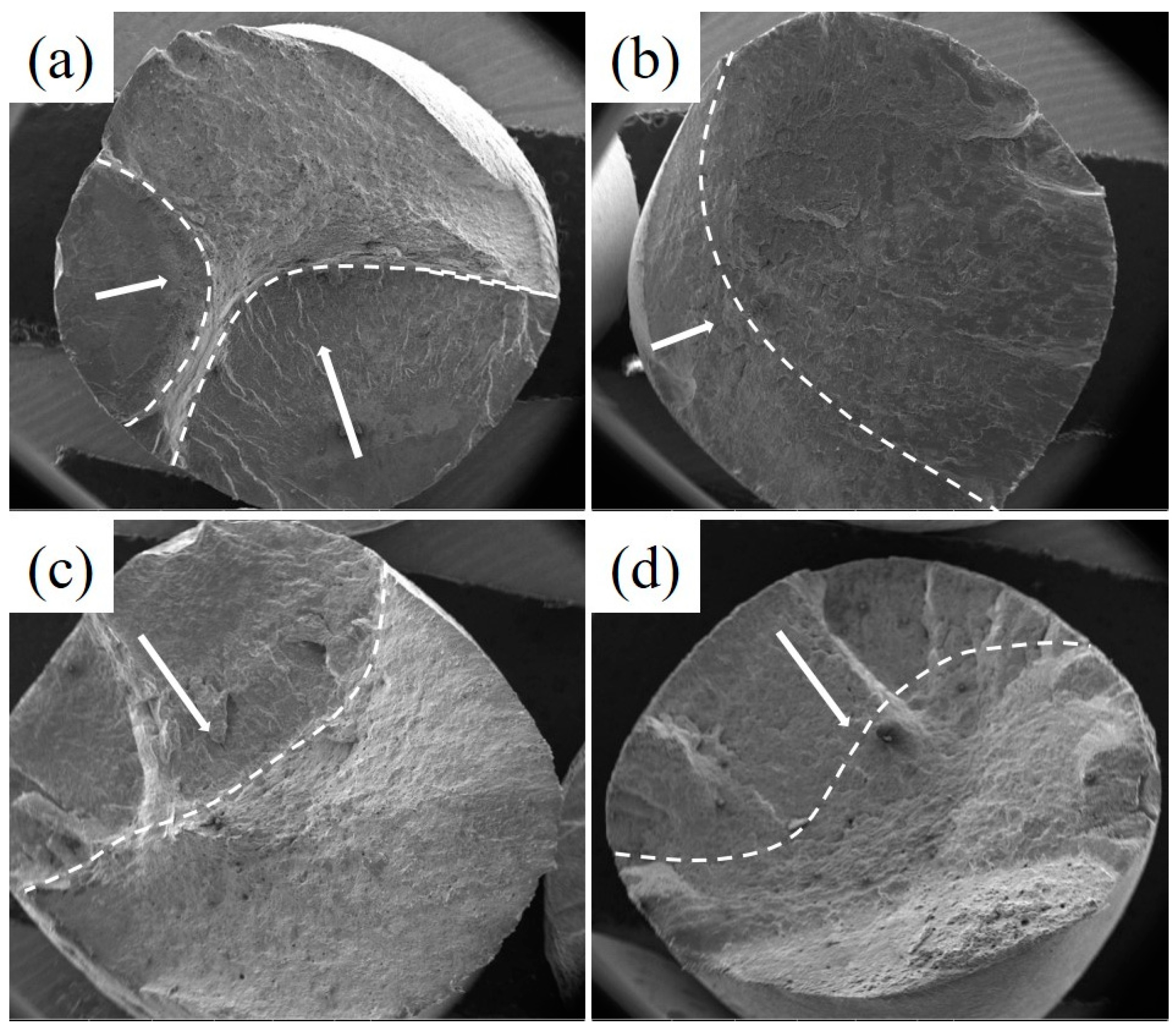

3.7. Fatigue Fracture Morphology

3.8. TEM Observation of Fatigue Microstructure

4. Discussion

5. Conclusions

- The novel steel and 30SiMn2MoV steel all show cyclic softening during the LCF testing at 700 °C. The cyclic stress–strain equation and strain fatigue life equation of both steels at 700 °C were obtained in this paper.

- The fatigue life of the two steels decreased obviously with strain amplitude increasing from 0.2% to 0.6%, and the novel steel had a higher fatigue life under the same strain amplitude. According to the hysteresis loops under different strain amplitudes, both steels demonstrated non-Masing behavior. The prediction of the fatigue life was in good agreement with the plastic strain energy density model, and the novel steel had better fatigue resistance than the 30SiMn2MoV steel.

- Fatigue cracks in the novel steel and 30SiMn2MoV steel predominantly initiate on the surface of the samples. The failure mode of the 30SiMn2MoV steel was a mixed mode of intergranular fracture and transgranular fracture; however, the failure mode of the novel steel was intergranular fracture.

- The novel steel had better fatigue performance at 700 °C. At low strain amplitude and high strain amplitude, the fatigue performance depended on the carbide morphology and martensitic lath characteristics in the material, respectively.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Balla, J.; Jankovych, R.; Beer, S.; Krist, Z.; Kovarik, M.; Prochazka, S. Technical Diagnostics of Tank Cannon Smooth Barrel Bore and Ramming Device. Def. Sci. J. 2015, 65, 356. [Google Scholar] [CrossRef] [Green Version]

- Wu, B.; Liu, B.-J.; Zheng, J.; Wang, T.; Chen, R.-G.; Chen, X.-L.; Zhang, K.-S.; Zou, Z.-Q. Strain-based health monitoring and remaining life prediction of large caliber gun barrel. Measurement 2018, 122, 297–311. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, C.L.; Zhao, Z.; Li, A.P.; Xu, X.L.; Shi, W.B. Low cycle fatigue behaviour of a Cr–Mo–V matrix-type high-speed steel used for cold forging. Mater. Des. 2013, 44, 612–621. [Google Scholar] [CrossRef]

- Li, Z.; Han, J.; Li, W.; Pan, L. Low cycle fatigue behavior of Cr–Mo–V low alloy steel used for railway brake discs. Mater. Des. 2014, 56, 146–157. [Google Scholar] [CrossRef]

- Wei, W.; Feng, Y.; Han, L.; Zhang, Q.; Zhang, J. Cyclic hardening and dynamic strain aging during low-cycle fatigue of Cr-Mo tempered martensitic steel at elevated temperatures. Mater. Sci. Eng. A 2018, 734, 20–26. [Google Scholar] [CrossRef]

- Verma, P.; Srinivas, N.S.; Singh, V. Low cycle fatigue behavior of modified 9Cr-1Mo steel at 300 °C. Mater. Sci. Eng. A 2018, 715, 17–24. [Google Scholar] [CrossRef]

- Mrozinski, S.; Egner, H.; Piotrowski, M. Effects of fatigue testing on low-cycle properties of P91 steel. Int. J. Fatigue 2019, 120, 65–72. [Google Scholar] [CrossRef]

- Şentürk, A.; Işık, H.; Evci, C. Thermo-mechanically coupled thermal and stress analysis of interior ballistics problem. Int. J. Therm. Sci. 2016, 104, 39–53. [Google Scholar] [CrossRef]

- Shan, Y.H.; Nie, Z.G.; Shan, S.Q.; Tan, L.D. Correlations between Gun-Barrels Temperature Rising and Shooting Specifications. Appl. Mech. Mater. 2015, 775, 115–118. [Google Scholar] [CrossRef]

- Wang, M.; Dong, H.; Wang, Q.; Fan, C. Low cycle fatigue behavior of high strength gun steels. J. Univ. Sci. Technol. B 2004, 11, 268–272. [Google Scholar]

- Gao, C.; Ren, T.; Liu, M. Low-cycle fatigue characteristics of Cr18Mn18N0.6 austenitic steel under strain controlled condition at 100 °C. Int. J. Fatigue 2019, 118, 35–43. [Google Scholar] [CrossRef]

- American Society of Testing Materials; Basquin, O.H. The Exponential Law of Endurance Tests; American Society of Testing Materials: West Conshohocken, PN, USA, 1910; Volume 10, pp. 10–625. [Google Scholar]

- Manson, S.S. Behavior of Materials under Conditions of Thermal Stress. In Heat Transfer Symposium; University of Michigan Engineering Research Institute: Ann Arbor, MI, USA, 1953; pp. 9–75. [Google Scholar]

- Coffin, L.F., Jr. A Study of the Effects of Cyclic Thermal Stresses on a Ductile Metal; Transactions of the ASME: Niskayuna, NY, USA, June 1954; Volume 76, pp. 931–950. [Google Scholar]

- Coffin, L.F. Fatigue at High Temperature. Advances in Research on the Strength & Fracture of Materials; Elsevier Inc.: Waterloo, ON, Canada, 1978; pp. 263–292. [Google Scholar]

- Song, W.; Liu, X.; Berto, F.; Razavi, S. Low-Cycle Fatigue Behavior of 10CrNi3MoV High Strength Steel and Its Undermatched Welds. Materials 2018, 11, 661. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Eswara Prasad, N.; Vogt, D.; Bidlingmaier, T.; Wanner, A.; Arzt, E. High temperature, low cycle fatigue behaviour of an aluminium alloy (Al-12Si-CuMgNi). Mater. Sci. Eng. A 2000, 276, 283–287. [Google Scholar] [CrossRef]

- Lefebvre, D.; Ellyin, F. Cyclic response and inelastic strain energy in low cycle fatigue. Int. J. Fatigue 1984, 6, 9–15. [Google Scholar] [CrossRef]

- Kong, W.-W.; Yuan, C.; Zhang, B.-N.; Qin, H.-Y.; Zhao, G.-P. Investigation on low-cycle fatigue behaviors of wrought superalloy GH4742 at room-temperature and 700 °C. Mater. Sci. Eng. A 2019, 751, 226–236. [Google Scholar] [CrossRef]

- Kaae, J. High-temperature low-cycle fatigue of Alloy 800H. Int. J. Fatigue 2009, 31, 332–340. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, J.; Yao, Z.; Xie, G.; Lian, Y.; Ma, M.; Zhao, C.; Huang, J. Design for Novel Hot-Work Die Steel by Thermodynamic Calculation and Microstructural Examination. Metals 2019, 9, 805. [Google Scholar] [CrossRef] [Green Version]

- Liang, Y.; Manninen, T.; Zhao, O.; Walport, F.; Gardner, L. Elevated temperature material properties of a new high-chromium austenitic stainless steel. J. Constr. Steel Res. 2019, 152, 261–273. [Google Scholar] [CrossRef] [Green Version]

- Unigovski, Y.B.; Grinberg, A.; Gutman, E.M. Low-cycle Fatigue of the Light Advanced Materials. Procedia Eng. 2013, 66, 713–722. [Google Scholar] [CrossRef] [Green Version]

- Peng, F.; Xu, Y.; Gu, X.; Wang, Y.; Liu, X.; Li, J. The relationships of microstructure-mechanical properties in quenching and partitioning (Q&P) steel accompanied with microalloyed carbide precipitation. Mater. Sci. Eng. A 2018, 723, 247–258. [Google Scholar] [CrossRef]

- Ueki, S.; Mine, Y.; Takashima, K. Microstructure-sensitive fatigue crack growth in lath martensite of low carbon steel. Mater. Sci. Eng. A 2020, 773, 138830. [Google Scholar] [CrossRef]

| Steel | C (%) | Si (%) | Mn (%) | Cr (%) | Mo (%) | W (%) | Ni (%) | V (%) |

|---|---|---|---|---|---|---|---|---|

| Novel Steel | 0.25- 0.28 | – | – | 2.50- 2.80 | 1.60- 1.90 | 0.20- 0.60 | 0.50- 0.80 | 0.20- 0.50 |

| 30SiMn2MoV | 0.27- 0.32 | 0.40- 0.60 | 1.60- 1.85 | 0.10- 0.25 | 0.40- 0.60 | – | 0.10- 0.25 | 0.15- 0.25 |

| Steel | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Reduction (%) |

|---|---|---|---|---|

| Novel Steel | 452 | 350 | 30 | 82.4 |

| 30SiMn2MoV | 240 | 119 | 42 | 82 |

| Material | ||

|---|---|---|

| Novel Steel | 283.23 | 0.1158 |

| 30SiMn2MoV | 189.08 | 0.0709 |

| Material | ||||

|---|---|---|---|---|

| Novel Steel | 0.2 | 0.14465 | 0.0555 | 23,462 |

| 0.4 | 0.17125 | 0.229 | 1980 | |

| 0.6 | 0.19075 | 0.409 | 936 | |

| 30SiMn2MoV | 0.2 | 0.1146 | 0.0855 | 18,604 |

| 0.4 | 0.1349 | 0.265 | 1634 | |

| 0.6 | 0.14225 | 0.4575 | 832 |

| Material | b | c | ||

|---|---|---|---|---|

| Novel Steel | 0.3299 | 11.12 | −0.0859 | −0.5323 |

| 30SiMn2MoV | 0.2134 | 9.7629 | −0.0594 | −0.4669 |

| Material | ||

|---|---|---|

| Novel Steel | 370.06 | −0.692 |

| 30SiMn2MoV | 265.33 | −0.678 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, C.; Zhang, J.; Fu, J.; Lian, Y.; Zhang, Z.; Zhang, C.; Huang, J. Low-Cycle Fatigue Behavior of the Novel Steel and 30SiMn2MoV Steel at 700 °C. Materials 2020, 13, 5753. https://doi.org/10.3390/ma13245753

Zhao C, Zhang J, Fu J, Lian Y, Zhang Z, Zhang C, Huang J. Low-Cycle Fatigue Behavior of the Novel Steel and 30SiMn2MoV Steel at 700 °C. Materials. 2020; 13(24):5753. https://doi.org/10.3390/ma13245753

Chicago/Turabian StyleZhao, Chao, Jin Zhang, Jiawei Fu, Yong Lian, Zunjun Zhang, Cheng Zhang, and Jinfeng Huang. 2020. "Low-Cycle Fatigue Behavior of the Novel Steel and 30SiMn2MoV Steel at 700 °C" Materials 13, no. 24: 5753. https://doi.org/10.3390/ma13245753