Influence of Microstructure and Chemical Composition on Microhardness and Wear Properties of Laser Borided Monel 400

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Laser Heat Treatment

2.3. Samples Preparation

2.4. Microstructure and Chemical Composition

2.5. Microhardness Testing

2.6. Wear Test

2.7. Depth of Friction Zone and Mass Loss

3. Results and Discussion

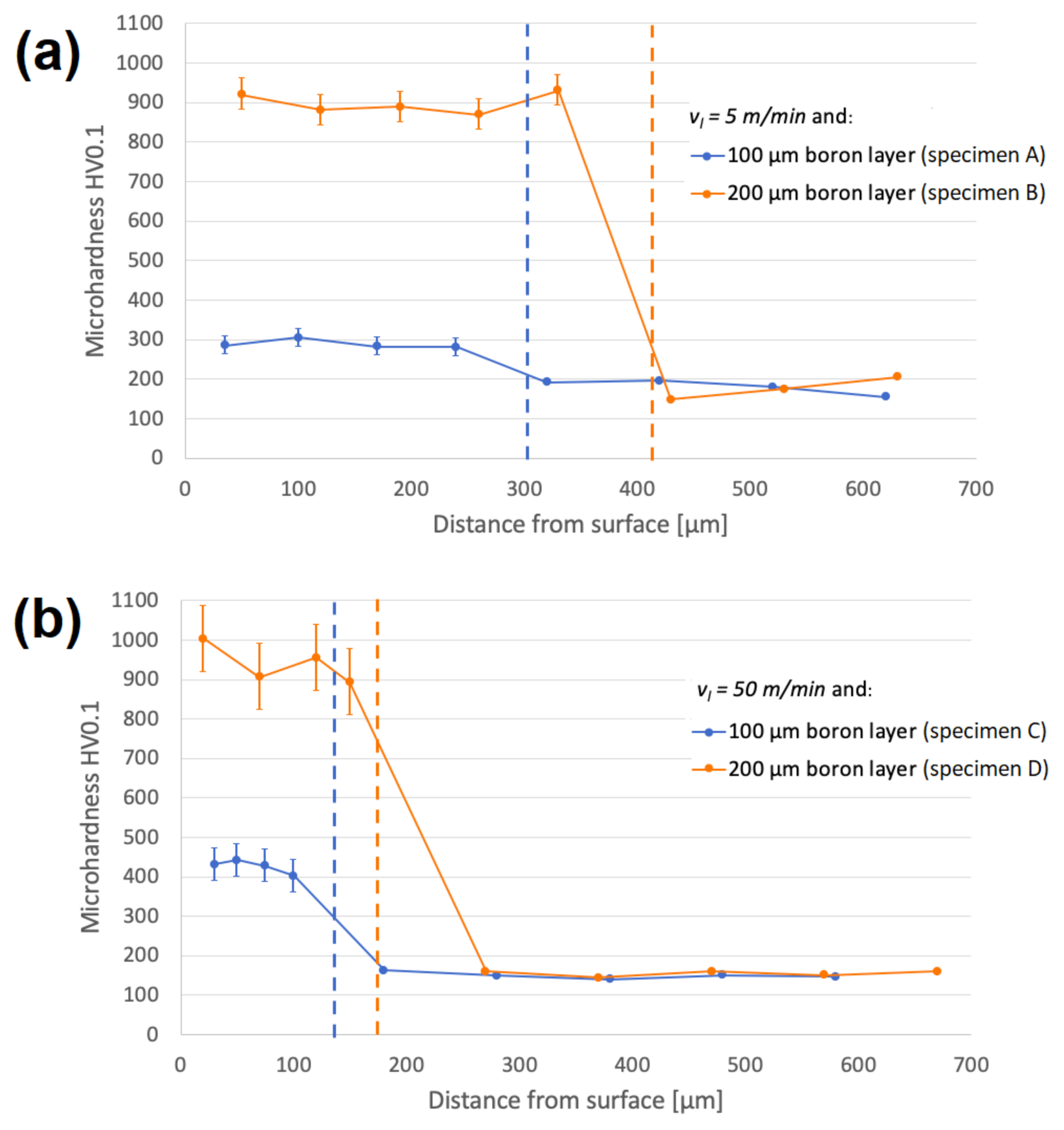

3.1. Microstructural Characterization and Microhardness

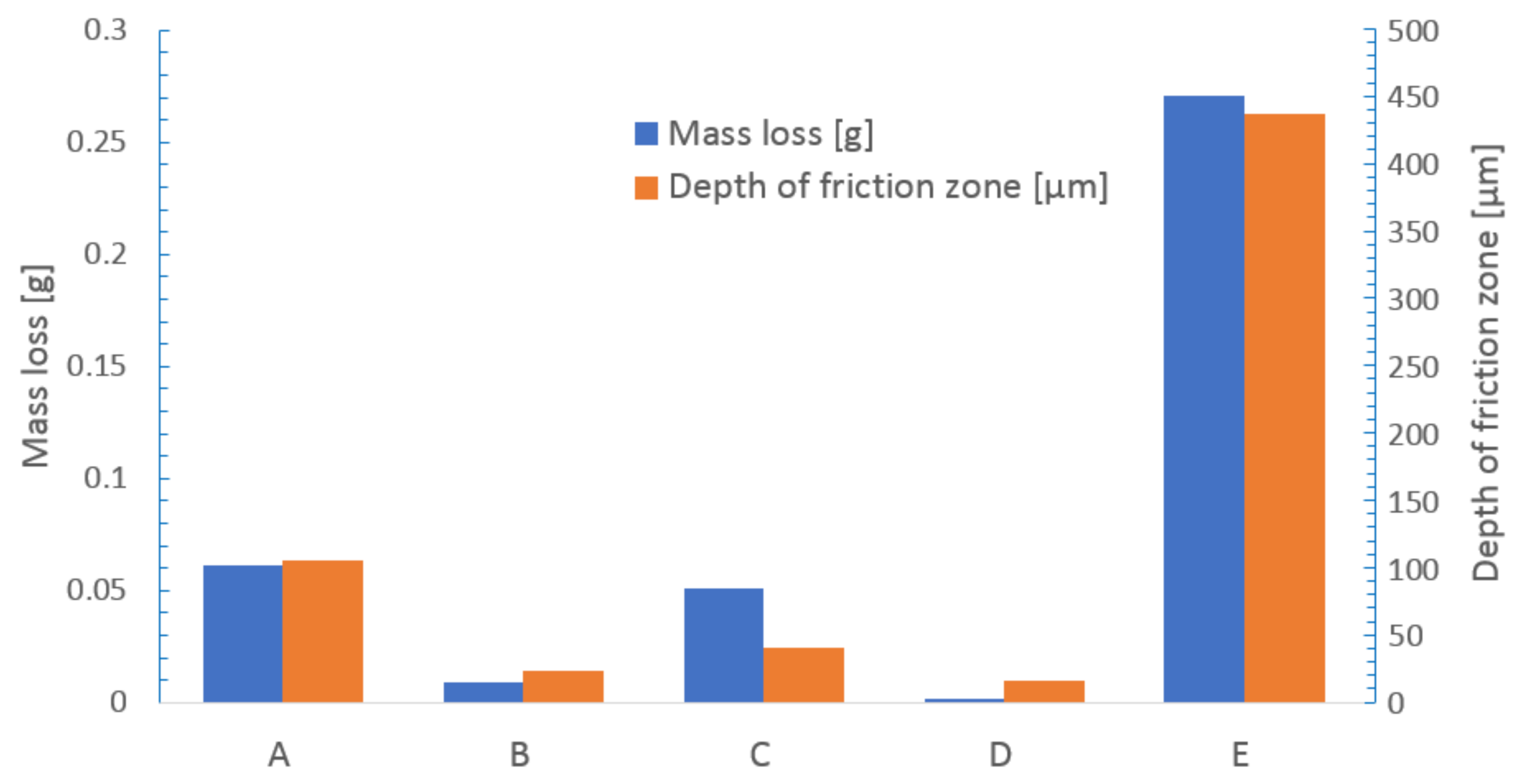

3.2. Wear Analysis

4. Conclusions

- (1)

- Laser alloying with boron is an effective method for improving wear resistance of Monel 400 and level of this enhancement is strongly dependent on microhardness of obtained layers and hence on the laser boriding parameters. This fact confirms that laser boriding can be implemented to increase hardness and wear properties of this specific Ni-Cu alloy, as it is for other nickel-based metals.

- (2)

- Wear resistance, both in terms of depth of friction zone and mass loss after the wear test, improves with increasing initial boron content and laser beam scanning velocity during the laser boriding process. In this study, the highest wear resistance was observed for surface alloyed with initial boron layer 200 µm thick using laser beam scanning velocity equal to 50 m/min.

- (3)

- The improvement of wear resistance achieved by laser alloying Monel 400 with boron is quantitatively larger than increase of microhardness in each examined case. For example, microhardness of surface laser borided with 100 µm thick initial boron layer using laser beam scanning velocity equal to 50 m/min almost doubles while mass loss during the wear test decreases about five times in comparison with untreated Monel 400.

- (4)

- In conditions chosen for this examination, mechanism of wear evolves from severe abrasive and adhesive on surface alloyed with initial boron layer 100 µm thick using laser beam scanning velocity 5 m/min to insignificant abrasive wear of surface re-melted with 200 µm boron layer and laser beam scanning velocity equal to 50 m/min. Thus, increasing boron content and laser beam scanning velocity leads to reduction of adhesive wear on alloyed surfaces.

Author Contributions

Funding

Conflicts of Interest

References

- Hajkowski, J.; Popielarski, P.; Ignaszak, Z. Cellular Automation Finite Element Method Applied for Microstructure Prediction of Aluminium Casting Treated by Laser Beam. Arch. Foundry Eng. 2019, 19, 111–118. [Google Scholar] [CrossRef]

- Chwalczuk, T.; Przestacki, D.; Szablewski, P.; Felusiak, A. Microstructure characterisation of Inconel 718 after laser assisted turning. MATEC Web Conf. 2018, 188, 02004. [Google Scholar] [CrossRef]

- Przestacki, D.; Kukliński, M.; Bartkowska, A. Influence of laser heat treatment on microstructure and properties of surface layer of Waspaloy aimed for laser-assisted machining. Int. J. Adv. Manuf. Technol. 2017, 93, 3111–3123. [Google Scholar] [CrossRef]

- Nakata, K.; Tomoto, K.; Matsuda, F. Laser Boronizing of Copper Alloy. Trans. JWRI 1996, 25, 37–41. [Google Scholar]

- Zhang, C.; Wu, C.; Zhang, S.; Jia, Y.; Guan, M.; Tan, J.; Lin, B. Laser cladding of NiCrSiB on Monel 400 to enhance cavitation erosion and corrosion resistance. Rare Met. 2016, 1–9. [Google Scholar] [CrossRef]

- Kukliński, M.; Bartkowska, A.; Przestacki, D. Microstructure and selected properties of Monel 400 alloy after laser heat treatment and laser boriding using diode laser. Int. J. Adv. Manuf. Technol. 2018, 98, 3005–3017. [Google Scholar] [CrossRef]

- Żórawski, W.; Chatys, R.; Radek, N.; Borowiecka-Jamrozek, J. Plasma sprayed composite coatings with reduced friction coefficient. Surf. Coat. Technol. 2018, 202, 4578–4582. [Google Scholar] [CrossRef]

- High-Performance Alloys for Resistance to Aqueous Corrosion. Available online: http://www.parrinst.com/wp-content/uploads/downloads/2011/07/Parr_Inconel-Incoloy-Monel-Nickel-Corrosion-Info.pdf (accessed on 16 October 2020).

- Dutta, R.S. Corrosion aspects of Ni-Cr-Fe based and Ni-Cu based steam generator tube materials. J. Nucl. Mater. 2009, 393, 343–349. [Google Scholar] [CrossRef]

- Shoemaker, L.E. A Century of Monel Metal: 1906–2006. JOM 2006, 58, 22–26. [Google Scholar] [CrossRef]

- Monel-alloy-400. Available online: http://www.specialmetals.com/assets/smc/documents/alloys/monel/monel-alloy-400.pdf (accessed on 16 October 2020).

- Wiciak-Pikuła, M.; Felusiak-Czyryca, A.; Twardowski, P. Tool Wear Prediction Based on Artificial Neural Network during Aluminum Matrix Composite Milling. Sensors 2020, 20, 5798. [Google Scholar] [CrossRef]

- Bill, R.C. Study of fretting wear in titanium, monel-400, and cobalt-25 percent molybdenum using scanning electron microscopy. ASLE Trans 1973, 16, 286–290. [Google Scholar] [CrossRef]

- Esgin, U.; Özyürek, D.; Kaya, H. An investigation of wear behaviors of different Monel alloys produced by powder metallurgy. AIP Conf. Proc. 2016, 1727, 020008. [Google Scholar]

- Ma, F.; Zeng, Z.; Gao, Y. Tribocorrosion and the surface repassivation behavior of Monel 400 alloy in artificial seawater. Ind. Lubr. Tribol. 2018, 70, 1331–1340. [Google Scholar] [CrossRef]

- Waliszyn, A.; Adamkiewicz, A. Studies on resistance to erosion of nickel and its alloys to be used in elements of fluid-flow machines. Eksploatacja i Niezawodnosc 2019, 21, 692–696. [Google Scholar] [CrossRef]

- Ueda, N.; Mizukoshi, T.; Demizu, K.; Sone, T.; Ikenaga, A.; Kawamoto, M. Boriding of nickel by the powder-pack method. Surf. Coat. Technol. 2000, 126, 25–30. [Google Scholar] [CrossRef]

- Anthymidis, K.G.; Zinoviadis, P.; Roussos, D.; Tsipas, D.N. Boriding of nickel in a fluidized bed reactor. Mater. Res. Bull. 2002, 37, 515–522. [Google Scholar] [CrossRef]

- Petrova, R.S.; Suwattananont, N.; Samardzic, V. The Effect of Boronizing on Metallic Alloys for Automotive Applications. J. Mater. Eng. Perform. 2008, 17, 340–345. [Google Scholar] [CrossRef]

- Sista, V.; Kahvecioglu, O.; Kartal, G.; Zeng, Q.Z.; Kim, J.H.; Eryilmaz, O.L.; Erdemir, A. Evaluation of electrochemical boriding of Inconel 600. Surf. Coat. Technol. 2013, 215, 452–459. [Google Scholar] [CrossRef]

- Gunen, A.; Kanca, E. Microstructure and Mechanical Properties of Borided Inconel 625 Superalloy. Materia 2017, 22, 11829. [Google Scholar] [CrossRef]

- Gunen, A.; Kanca, E.; Cakir, H.; Karakas, M.; Gok, M.; Kucuk, Y.; Demir, M. Effect of borotitanizing on microstructure and wear behavior of Inconel 625. Surf. Coat. Technol. 2017, 311, 374–382. [Google Scholar] [CrossRef]

- Campos-Silva, I.; Contla-Pacheco, A.D.; Figueroa-López, U.; Martínez-Trinidad, J.; Garduño-Alva, A.; Ortega-Avilés, M. Sliding wear resistance of nickel boride layers on an Inconel 718 superalloy. Surf. Coat. Technol. 2019, 378, 124862. [Google Scholar] [CrossRef]

- Gheisari, R.; Polycarpou, A.A. Tribology of Selected Hard Coatings for Oil and Gas Applications Up to 450 °C. Tribol. Lett. 2019, 67, 51. [Google Scholar] [CrossRef]

- Krelling, A.P.; Melo, F.S.; Almeida, E.A.S.; Da Costa, C.E.; Milan, J.C.G. Microstructure and properties of borided Monel 400 alloy. Mater. Res. Express 2019, 6, 106410. [Google Scholar] [CrossRef]

- Morimoto, J.; Ozaki, T.; Kubohori, T.; Morimoto, S.; Abe, N.; Tsukamoto, M. Some properties of boronized layers on steels with direct diode laser. Vacuum 2009, 83, 185–189. [Google Scholar] [CrossRef]

- Safonov, A.N. Special features of boronizing iron and steel using a continuous-wave CO2 laser. Met. Sci. Heat Treat. 1998, 40, 6–10. [Google Scholar] [CrossRef]

- Bartkowska, A.; Bartkowski, D.; Popławski, M.; Piasecki, A.; Przestacki, D.; Miklaszewski, A. Microstructure, Microhardness, Corrosion Resistance and Chemical Composition of Mo, B and Mo-B Coatings Produced Using Laser Processing. Materials 2020, 13, 3249. [Google Scholar] [CrossRef]

- Tian, Y.S.; Zhang, Q.Y.; Wang, D.Y.; Chen, C.Z. Analysis of the growth morphology of TiB and the microstructure refinement of the coatings fabricated on Ti-6Al-4V by laser boronizing. Cryst. Growth Des. 2008, 8, 700–703. [Google Scholar] [CrossRef]

- Kulka, M. Current Trends in Boriding, 1st ed.; Springer: Cham, Switzerland, 2018. [Google Scholar]

- Kukliński, M.; Bartkowska, A.; Przestacki, D. Laser Alloying Monel 400 with Amorphous Boron to Obtain Hard Coatings. Materials 2019, 12, 3494. [Google Scholar] [CrossRef]

- Bartkowski, D.; Kinal, G. Microstructure and wear resistance of Stellite-6/WC MMC coatings produced by laser cladding using Yb:YAG disk laser. Int. J. Refract. Hard Met. 2016, 58, 157–164. [Google Scholar] [CrossRef]

| Cu [%] | Si [%] | Fe [%] | Mn [%] | C [%] | S [%] | Ni |

|---|---|---|---|---|---|---|

| 31 | 0.5 | 2.5 | 2.0 | 0.3 | 0.024 | bal. |

| C [%] | Si [%] | Mn [%] | Cr [%] | Mo [%] | Cu [%] | Al [%] | P [%] | S [%] | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 1.00 | 0.25 | 0.35 | 1.45 | 0.1 | 0.3 | 0.05 | 0.025 | 0.015 | bal. |

| P [W] | q [kW/cm2] | tb [µm] | vl [m/min] | dl [mm] | f [mm] | Symbol of Specimen |

|---|---|---|---|---|---|---|

| 1400 | 178.3 | 100 | 5 | 1 | 0.5 | A |

| 1400 | 178.3 | 200 | 5 | 1 | 0.5 | B |

| 1400 | 178.3 | 100 | 50 | 1 | 0.5 | C |

| 1400 | 178.3 | 200 | 50 | 1 | 0.5 | D |

| - | - | - | - | - | - | E |

| Symbol | A1 | A2 | A3 | A4 | B1 | B2 | B3 | B4 | C1 | C2 |

| Ni [Wt%] | 30.4 | 26.9 | 59.7 | 42.9 | 37.1 | 38.1 | 57.0 | 58.2 | 19.3 | 19.9 |

| Cu [Wt%] | 18.2 | 16.9 | 35.3 | 53.4 | 7.6 | 7.3 | 33.9 | 33.0 | 16.4 | 0.8 |

| Fe [Wt%] | 20.1 | 21.6 | 3.1 | 2.2 | 28.7 | 26.9 | 6.4 | 6.5 | 25.6 | 44.7 |

| O [Wt%] | 31.3 | 34.7 | 1.8 | 1.5 | 26.6 | 27.7 | 2.3 | 2.2 | 38.8 | 34.6 |

| Symbol | C3 | C4 | D1 | D2 | D3 | D4 | E1 | E2 | E3 | E4 |

| Ni [Wt%] | 58.3 | 59.9 | 49.4 | 41.3 | 60.5 | 62.7 | 61.1 | 63.2 | 64.1 | 63.5 |

| Cu [Wt%] | 30.0 | 32.2 | 23.3 | 45.0 | 36.0 | 34.0 | 33.1 | 33.7 | 30.7 | 31.5 |

| Fe [Wt%] | 8.4 | 3.7 | 4.6 | 1.8 | 2.1 | 2.3 | 2.7 | 2.4 | 4.0 | 2.2 |

| O [Wt%] | 3.4 | 4.1 | 22.6 | 11.9 | 1.4 | 1.0 | 3.1 | 0.7 | 1.3 | 2.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kukliński, M.; Bartkowska, A.; Przestacki, D.; Kinal, G. Influence of Microstructure and Chemical Composition on Microhardness and Wear Properties of Laser Borided Monel 400. Materials 2020, 13, 5757. https://doi.org/10.3390/ma13245757

Kukliński M, Bartkowska A, Przestacki D, Kinal G. Influence of Microstructure and Chemical Composition on Microhardness and Wear Properties of Laser Borided Monel 400. Materials. 2020; 13(24):5757. https://doi.org/10.3390/ma13245757

Chicago/Turabian StyleKukliński, Mateusz, Aneta Bartkowska, Damian Przestacki, and Grzegorz Kinal. 2020. "Influence of Microstructure and Chemical Composition on Microhardness and Wear Properties of Laser Borided Monel 400" Materials 13, no. 24: 5757. https://doi.org/10.3390/ma13245757

APA StyleKukliński, M., Bartkowska, A., Przestacki, D., & Kinal, G. (2020). Influence of Microstructure and Chemical Composition on Microhardness and Wear Properties of Laser Borided Monel 400. Materials, 13(24), 5757. https://doi.org/10.3390/ma13245757