Eco-UHPC as Repair Material—Bond Strength, Interfacial Transition Zone and Effects of Formwork Type

Abstract

:1. Introduction

2. Experimental Setup

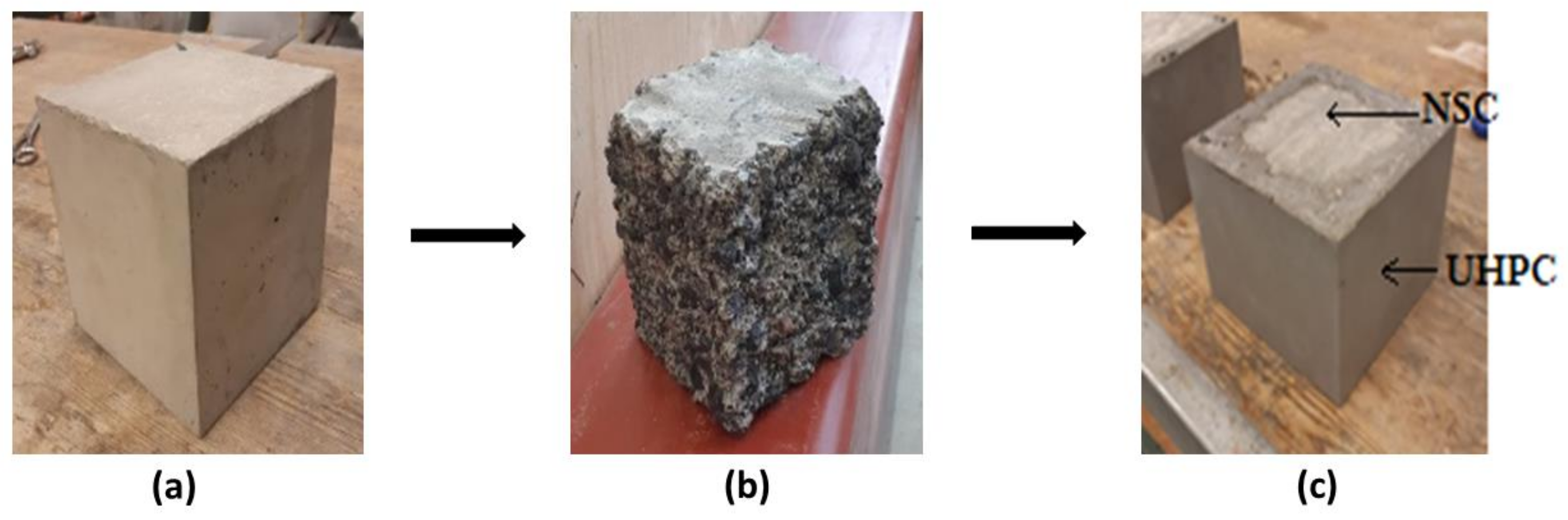

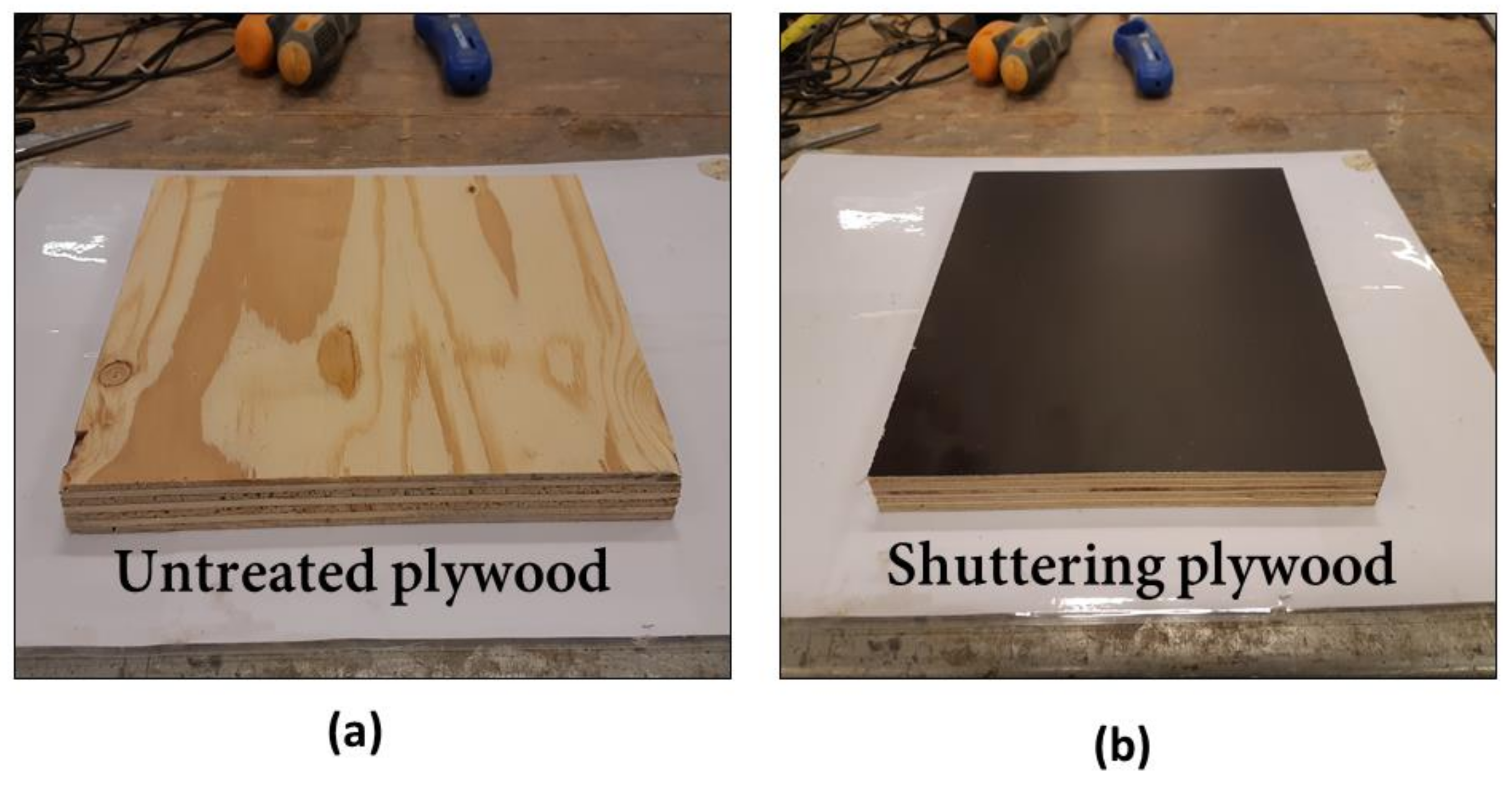

2.1. Materials and Specimen Preparation

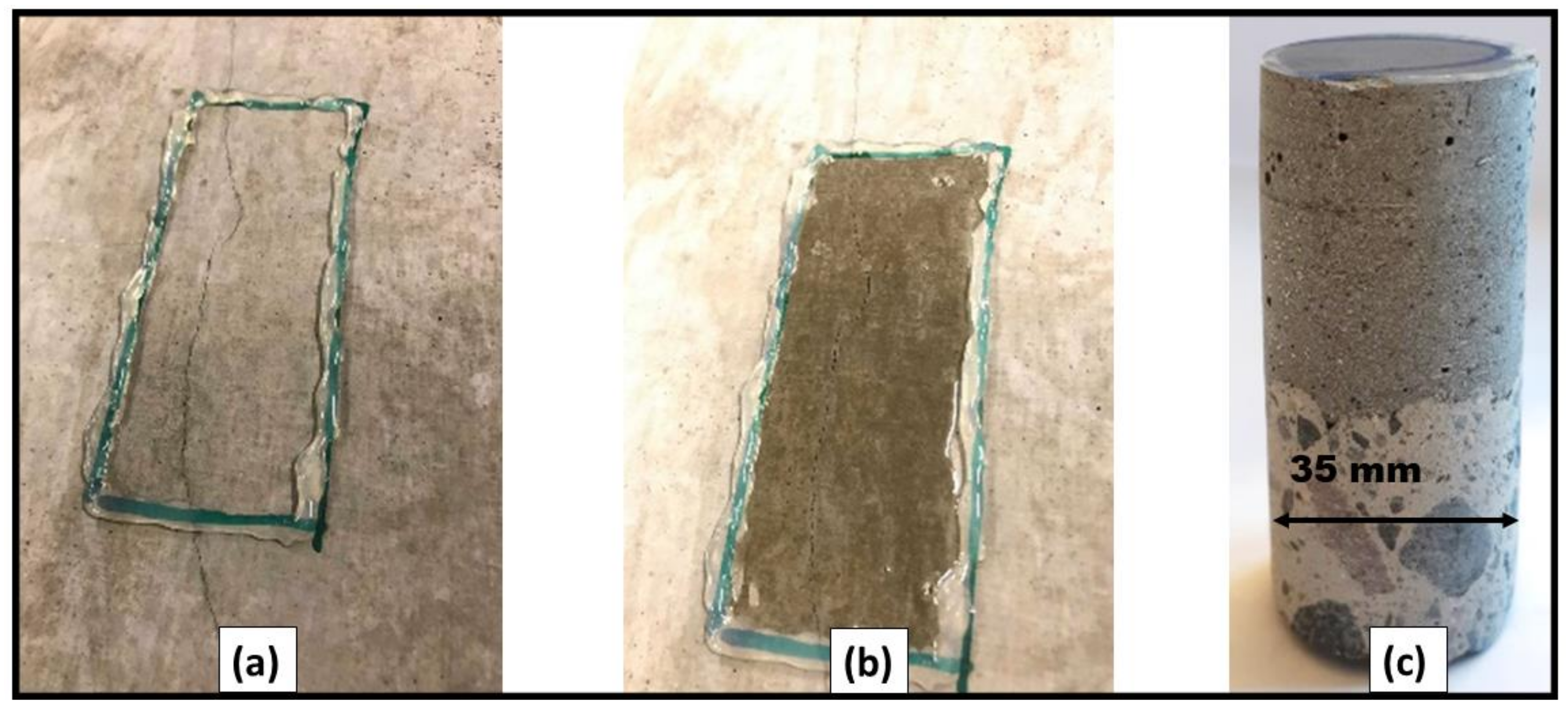

2.2. Testing Methodology

3. Results and Discussion

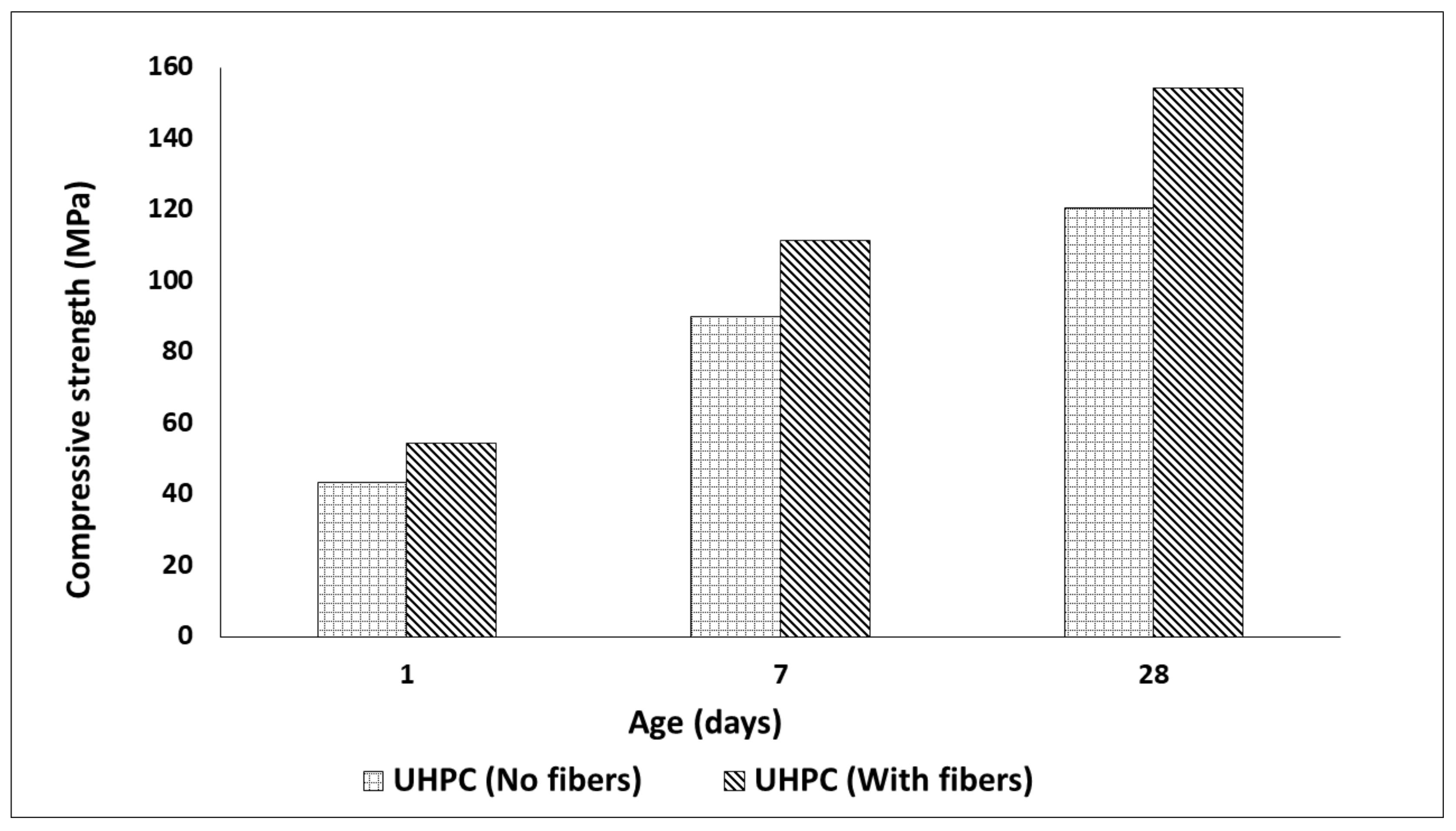

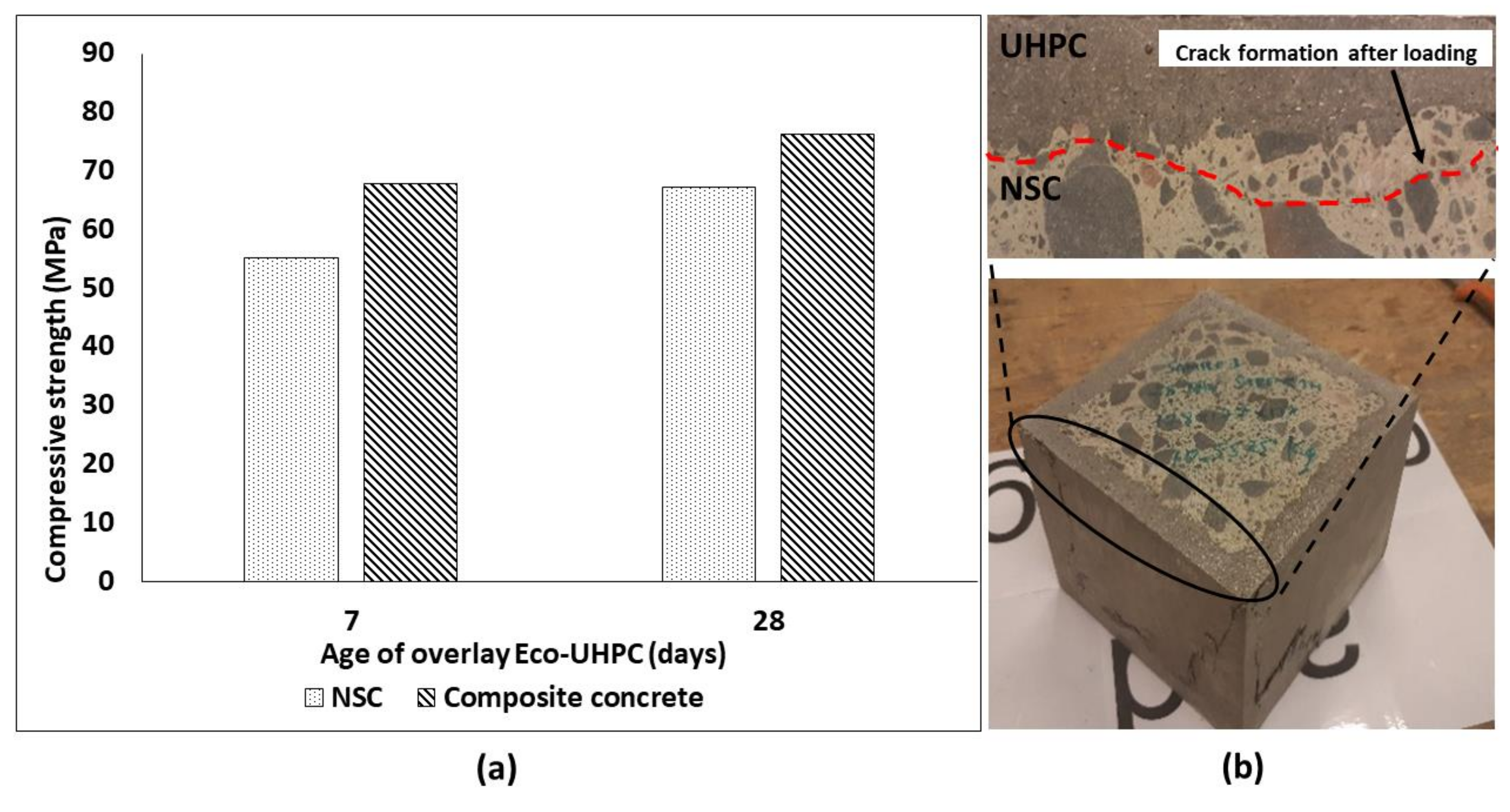

3.1. Fresh and Hardened Properties

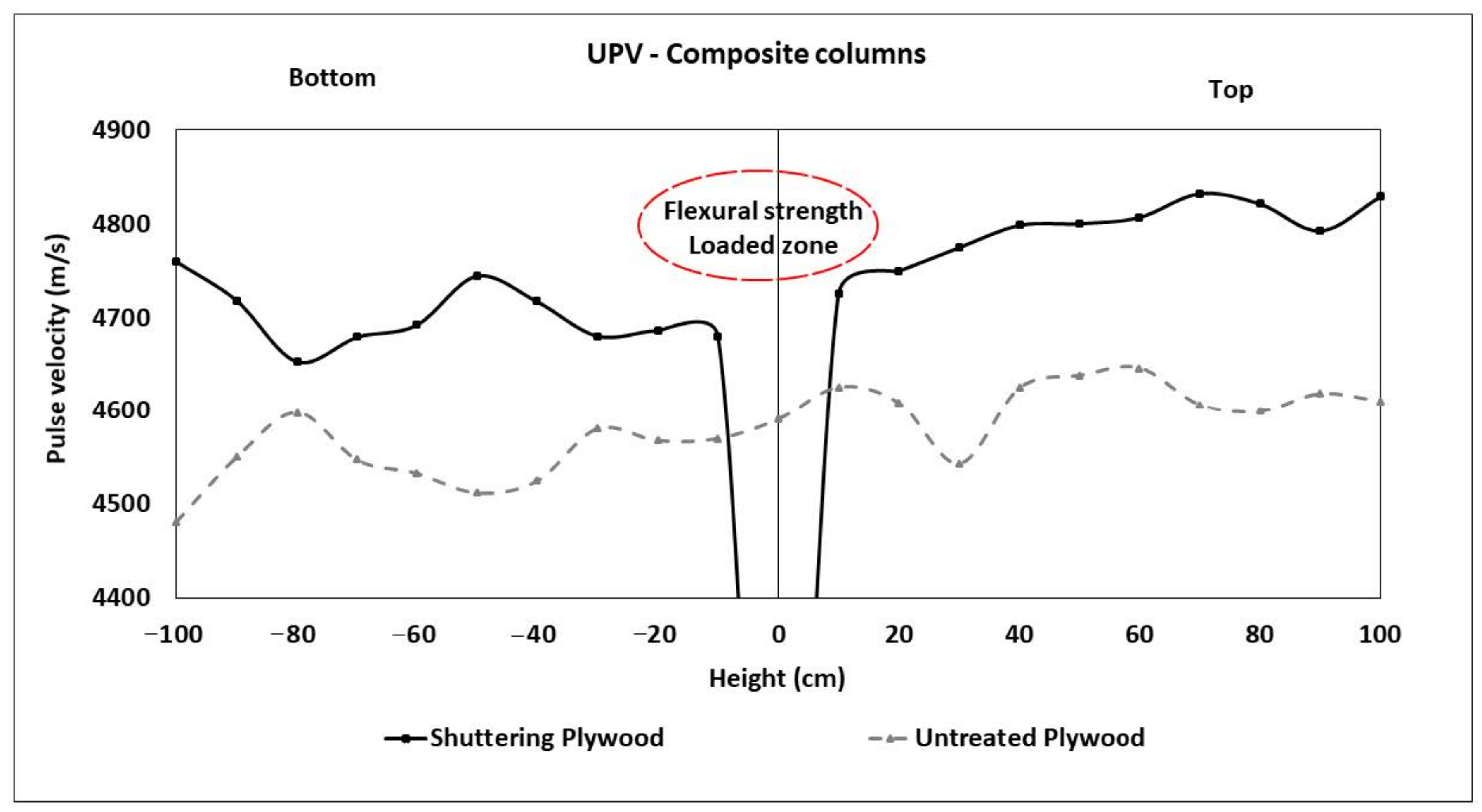

3.2. Ultrasonic Pulse Velocity (UPV)

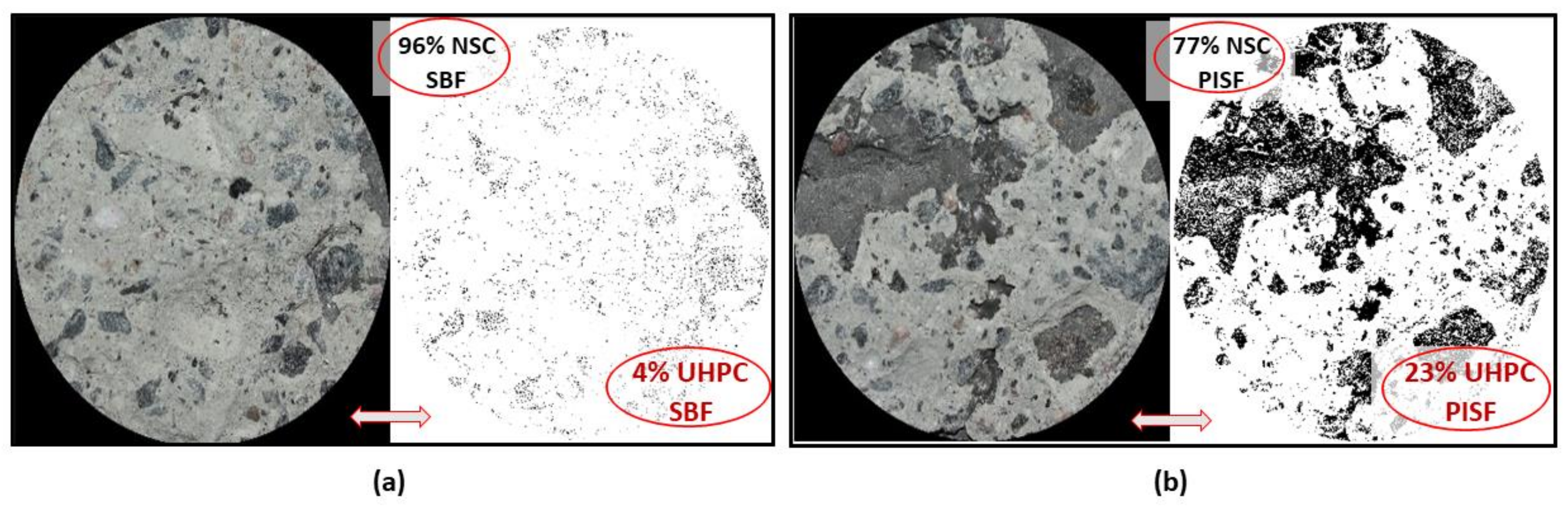

3.3. Bond Strength (Pull-Off Test)

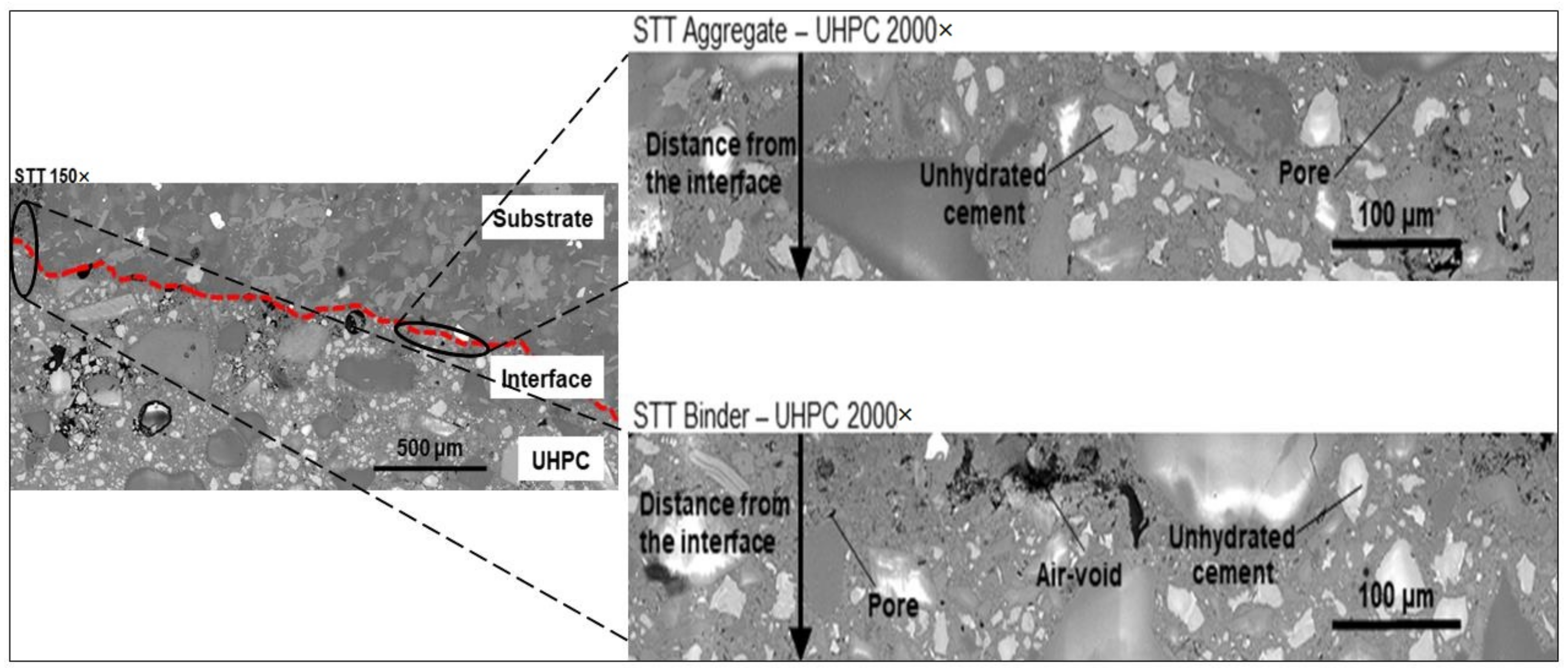

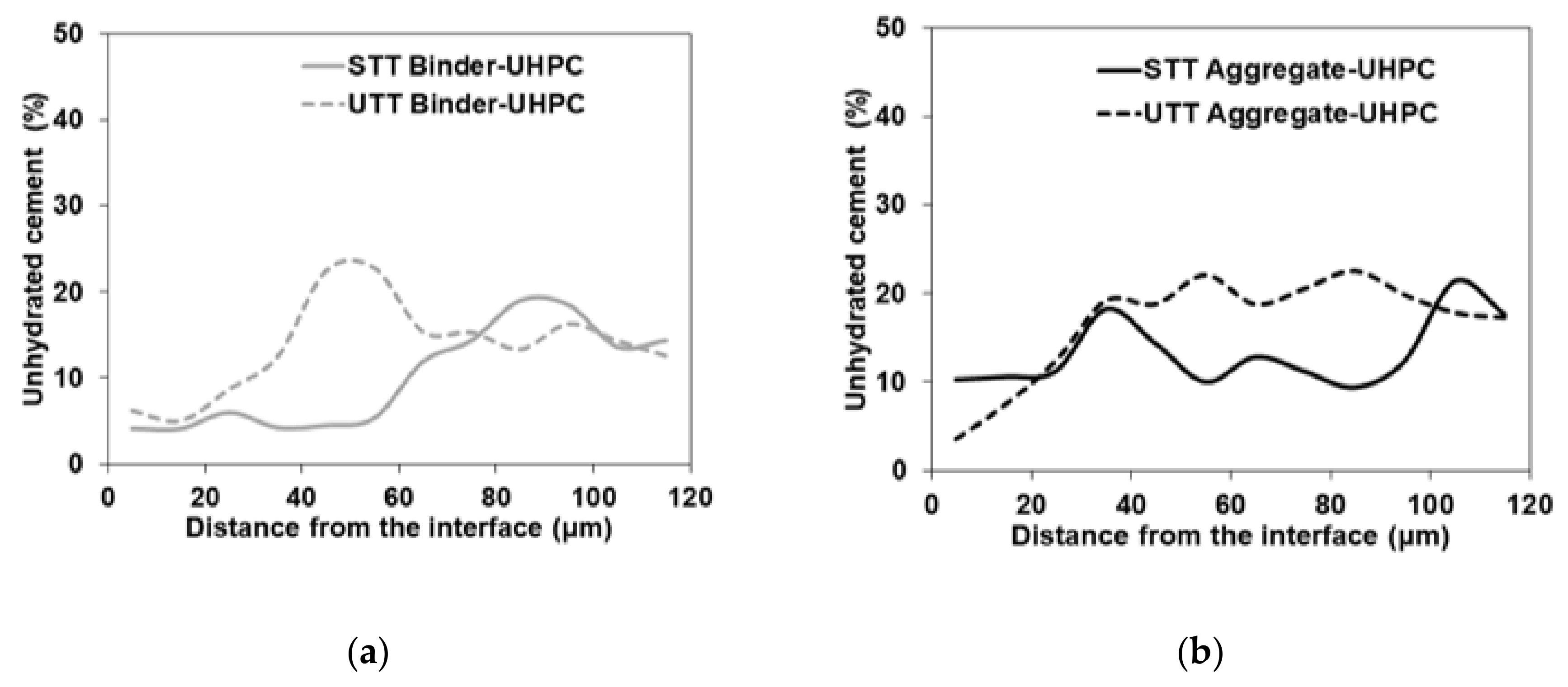

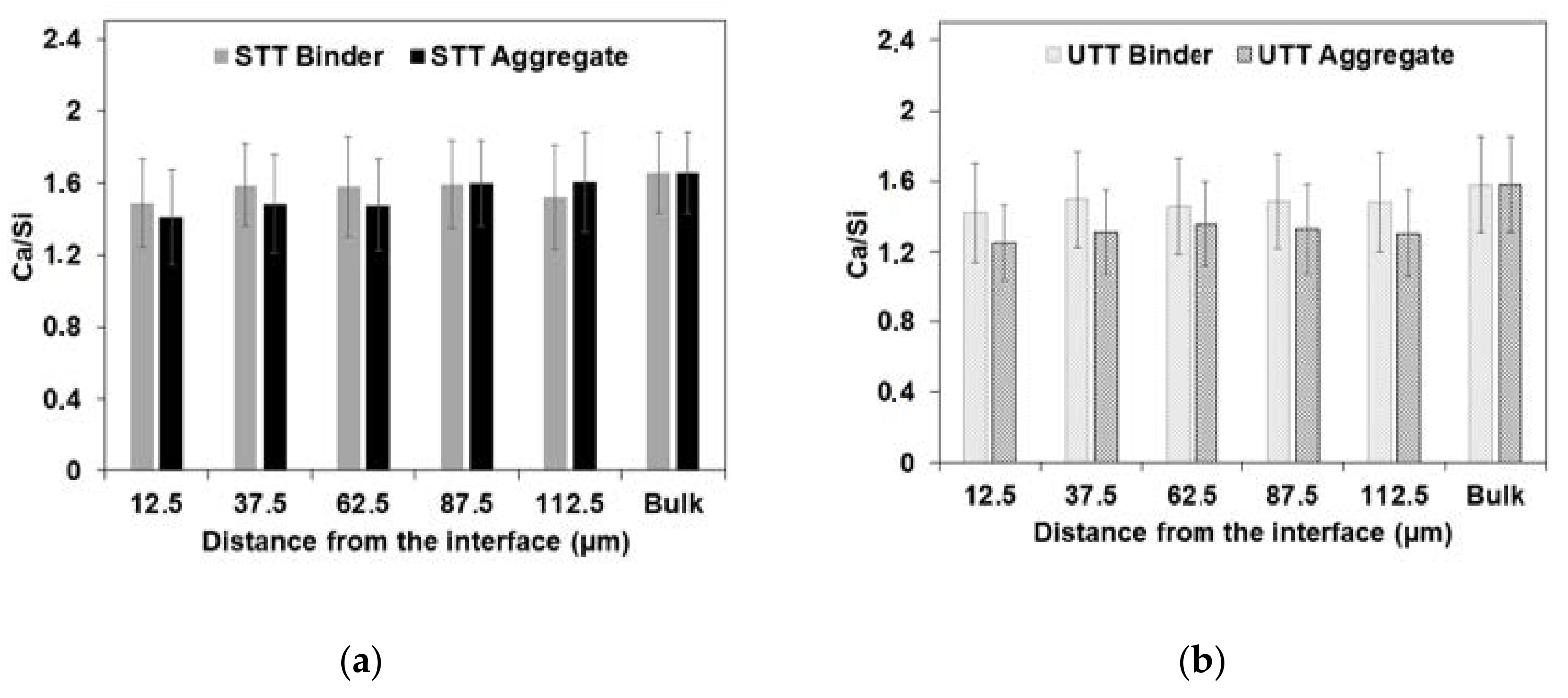

3.4. Scanning Electron Microscope (SEM)

3.5. Self-Healing Efficiency

4. Conclusions

- No delamination between the layers, despite loading parallel to the bond surface being observed indicating the bond strength exceeding the strength of the weaker NSC.

- Bond strength varied between 2 and 2.7 MPa regardless of the used formwork

- The type of the plywood used as formwork affected the microstructure and crack formation of the external layers of the UHPC overlay.

- The rough and water-absorbing untreated plywood reduced the W/C ratio on top of the UHPC surface layer leading locally to a lower hydration degree. At the same time, the surface roughness created a surface friction-based restraint which limited the microcracking due to the autogenous shrinkage.

- Shuttering plywood with smooth surface enabled the development of higher tensile stress on the UHPC surface, which led to more intensive autogenous shrinkage cracking.

- None of the autogenous shrinkage related microcracks developed on the UHPC surface penetrated through the entire thickness of the UHPC overlay.

- Detected ITZ was very narrow, less than 20 μm. The estimated Ca/Si based on the SEM-EDS analysis and corresponding to the C-S-H was uniformly distributed on the interface as well as in the bulk zone with only minor statistically insignificant variations.

- The UHPC overlay showed signs of a limited self-healing when treated with water.

- Repair of degraded NSC using UHPC overlay has a high potential for full-scale application, due to its enhanced bond strength, dense microstructure.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Huang, W.; Kazemi-Kamyab, H.; Sun, W.; Scrivener, K. Effect of cement substitution by limestone on the hydration and microstructural development of ultra-high performance concrete (UHPC). Cem. Concr. Compos. 2017, 77, 86–101. [Google Scholar] [CrossRef]

- Charron, J.P.; Denarié, E.; Brühwiler, E. Permeability of ultra high performance fiber reinforced concretes (UHPFRC) under high stresses. Mater. Struct. Constr. 2007, 40, 269–277. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Abu Bakar, B.H.; Johari, M.A.M.; Voo, Y.L. Mechanical and permeability properties of the interface between normal concrete substrate and ultra high performance fiber concrete overlay. Constr. Build. Mater. 2012, 36, 538–548. [Google Scholar] [CrossRef]

- Prem, P.R.; Murthy, A.R.; Ramesh, G.; Bharatkumar, B.H.; Iyer, N.R. Flexural behaviour of damaged rc beams strengthened with ultra high performance concrete. In Advances in Structural Engineering: Materials; SAGE Publications: Thousand Oaks, CA, USA, 2015; Volume 3, pp. 2057–2069. ISBN 9788132221876. [Google Scholar]

- Safdar, M.; Matsumoto, T.; Kakuma, K. Flexural behavior of reinforced concrete beams repaired with ultra-high performance fiber reinforced concrete (UHPFRC). Compos. Struct. 2016, 157, 448–460. [Google Scholar] [CrossRef]

- Brühwiler, E.; Denarié, E. Rehabilitation and strengthening of concrete structures using ultra-high performance fibre reinforced concrete. Struct. Eng. Int. 2013, 23, 450–457. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, P.; Liao, Z.; Wang, L. Interfacial bond properties between normal strength concrete substrate and ultra-high performance concrete as a repair material. Constr. Build. Mater. 2020, 235. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, X.; Zhu, Y.; Shao, X. Experimental study on flexural behavior of damaged reinforced concrete (RC) beam strengthened by toughness-improved ultra-high performance concrete (UHPC) layer. Compos. Part B Eng. 2020, 186. [Google Scholar] [CrossRef]

- Brühwiler, E.; Denarié, E. Rehabilitation of concrete structures using Ultra-High Performance Fibre Reinforced Concrete. In Proceedings of the The Second International Symposium on Ultra High Performance Concrete, Kassel, Germany, 5–7 March 2008; pp. 1–9. [Google Scholar]

- Gadri, K.; Guettala, A. Evaluation of bond strength between sand concrete as new repair material and ordinary concrete substrate (The surface roughness effect). Constr. Build. Mater. 2017, 157, 1133–1144. [Google Scholar] [CrossRef]

- Hussein, H.H.; Walsh, K.K.; Sargand, S.M.; Steinberg, E.P. Interfacial properties of ultrahigh-performance concrete and high-strength concrete bridge connections. J. Mater. Civ. Eng. 2016, 28. [Google Scholar] [CrossRef]

- Perez, F.; Bissonnette, B.; Gagné, R. Parameters affecting the debonding risk of bonded overlays used on reinforced concrete slab subjected to flexural loading. Mater. Struct. Constr. 2009, 42, 645–662. [Google Scholar] [CrossRef]

- Courard, L.; Piotrowski, T.; Garbacz, A. Near-to-surface properties affecting bond strength in concrete repair. Cem. Concr. Compos. 2014, 46, 73–80. [Google Scholar] [CrossRef]

- Júlio, E.N.B.S.; Branco, F.A.B.; Silva, V.D. Concrete-to-concrete bond strength. Influence of the roughness of the substrate surface. Constr. Build. Mater. 2004, 18, 675–681. [Google Scholar] [CrossRef] [Green Version]

- Jang, H.O.; Lee, H.S.; Cho, K.; Kim, J. Experimental study on shear performance of plain construction joints integrated with ultra-high performance concrete (UHPC). Constr. Build. Mater. 2017, 152, 16–23. [Google Scholar] [CrossRef]

- Hong, S.G.; Kang, S.H. Effect of surface preparation and curing method on bond strength between UHPC and normal strength concrete. IABSE Symp. Rep. Int. Assoc. Bridge Struct. Eng. 2015, 105, 1–7. [Google Scholar] [CrossRef]

- Barros, J.A.O.; Cruz, J.M.S. Strengthening a prestressed concrete slab by epoxy-bonded frp composites and sfrc overlayer Laminates of carbon fibre reinforced polymer (CFRP), layer of steel fibre reinforced concrete (SFRC) and the simultaneous use of CFRP laminates and SFRC overla. In Proceedings of the Seventh International Conference on Inspection Appraisal Repairs & Maintenance of Buildings & Structures, Nottingham, UK, 11–13 September 2001. [Google Scholar]

- Graybeal, B.A. Material Property Characterization of Ultra-High Performance Concrete; US Department of Transportation: McLean, VA, USA, 2006. [Google Scholar]

- Haber, Z.B.; Munoz, J.F.; De la Varga, I.; Graybeal, B.A. Bond characterization of UHPC overlays for concrete bridge decks: Laboratory and field testing. Constr. Build. Mater. 2018, 190, 1056–1068. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Min, K.H.; Lee, J.H.; Yoon, Y.S. Shrinkage and cracking of restrained ultra-high-performance fiber-reinforced concrete slabs at early age. Constr. Build. Mater. 2014, 73, 357–365. [Google Scholar] [CrossRef]

- Courtial, M.; De Noirfontaine, M.N.; Dunstetter, F.; Signes-Frehel, M.; Mounanga, P.; Cherkaoui, K.; Khelidj, A. Effect of polycarboxylate and crushed quartz in UHPC: Microstructural investigation. Constr. Build. Mater. 2013, 44, 699–705. [Google Scholar] [CrossRef]

- Bureau of Indian Standards. IS: 10262—2019 Indian Standard Concrete Mix Proportioning—Guidelines. Bur. Indian Stand. Delhi 2019. Available online: https://law.resource.org/pub/in/bis/S03/is.10262.2009.pdf (accessed on 17 December 2020).

- Soliman, A.M.; Nehdi, M.L. Effect of drying conditions on autogenous shrinkage in ultra-high performance concrete at early-age. Mater. Struct. Constr. 2011, 44, 879–899. [Google Scholar] [CrossRef]

- Oey, T.; Kumar, A.; Bullard, J.W.; Neithalath, N.; Sant, G. The filler effect: The influence of filler content and surface area on cementitious reaction rates. J. Am. Ceram. Soc. 2013, 96, 1978–1990. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Mix design and properties assessment of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC). Cem. Concr. Res. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- Granger, S.; Loukili, A.; Pijaudier-Cabot, G.; Chanvillard, G. Experimental characterization of the self-healing of cracks in an ultra high performance cementitious material: Mechanical tests and acoustic emission analysis. Cem. Concr. Res. 2007, 37, 519–527. [Google Scholar] [CrossRef] [Green Version]

- Richard, P.; Cheyrezy, M. Composition of reactive powder concretes. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- Park, J.J.; Kang, S.T.; Koh, K.T.; Kim, S.W.; Fehling, E. Influence of the Ingredients on the Compressive Strength of UHPC as a Fundamental Study to Optimize the Mixing Proportion. In Proceedings of the The Second International Symposium on Ultra High Performance Concrete, Kassel, Germany, 5–7 March 2008; pp. 105–112. [Google Scholar]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Development of an eco-friendly Ultra-High Performance Concrete (UHPC) with efficient cement and mineral admixtures uses. Cem. Concr. Compos. 2015, 55, 383–394. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Huang, Z.; Cao, F.; Sun, Z.; Shah, S.P. Effects of nano-silica and nano-limestone on flowability and mechanical properties of ultra-high-performance concrete matrix. Constr. Build. Mater. 2015, 95, 366–374. [Google Scholar] [CrossRef]

- Bentz, D.P.; Ardani, A.; Barrett, T.; Jones, S.Z.; Lootens, D.; Peltz, M.A.; Sato, T.; Stutzman, P.E.; Tanesi, J.; Weiss, W.J. Multi-scale investigation of the performance of limestone in concrete. Constr. Build. Mater. 2015, 75, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Camiletti, J.; Soliman, A.M.; Nehdi, M.L. Effects of nano- and micro-limestone addition on early-age properties of ultra-high-performance concrete. Mater. Struct. Constr. 2013, 46, 881–898. [Google Scholar] [CrossRef]

- Lothenbach, B.; Le Saout, G.; Gallucci, E.; Scrivener, K. Influence of limestone on the hydration of Portland cements. Cem. Concr. Res. 2008, 38, 848–860. [Google Scholar] [CrossRef]

- Bédérina, M.; Khenfer, M.M.; Dheilly, R.M.; Quéneudec, M. Reuse of local sand: Effect of limestone filler proportion on the rheological and mechanical properties of different sand concretes. Cem. Concr. Res. 2005, 35, 1172–1179. [Google Scholar] [CrossRef]

- Péra, J.; Husson, S.; Guilhot, B. Influence of finely ground limestone on cement hydration. Cem. Concr. Compos. 1999, 21, 99–105. [Google Scholar] [CrossRef] [Green Version]

- Hewlett, P.C.; Liska, M. Lea’s Chemistry of Cement and Concrete; Elsevier: Amsterdam, The Netherlands, 2019; ISBN 9780081007730. [Google Scholar]

- Camiletti, J.; Soliman, A.M.; Nehdi, M.L. Effect of limestone addition on early-age properties of ultra high-performance concrete. Proc. Inst. Civ. Eng. Constr. Mater. 2014, 167, 65–78. [Google Scholar] [CrossRef]

- British Standards Institution. BS EN 12350-8:2010 Testing Fresh Concrete Part 8: Self-Compacting Concrete—Slump-Flow Test; British Standards Institution: London, UK, 2010. [Google Scholar]

- British Standards Institution. BS EN 12390-3:2009 Testing Hardened Concrete Part 3: Compressive Strength of Test Specimens; British Standards Institution: London, UK, 2009. [Google Scholar]

- British Standards Institution. British Standard Testing Hardened Concrete—Part 5: Flexural Strength of Test Specimens; BS En 12390-52009; British Standards Institution: London, UK, 2009. [Google Scholar]

- British Standards Institution. BS1881-125 Testing Concrete—Part 4: Determination of Ultrasonic Pulse Velocity; Construction Standard, CS1:2010; British Standards Institution: London, UK, 2004. [Google Scholar]

- Robins, P.J.; Austin, S.A. A unified failure envelope from the evaluation of concrete repair bond tests. Mag. Concr. Res. 1995, 47, 57–68. [Google Scholar] [CrossRef]

- ASTM C1583 Standard Test Method for Tensile Strength of Concrete Surfaces and the Bond Strength or Tensile Strength of Concrete Repair and Overlay Materials by Direct Tension (Pull-off Method). ASTM Int. 2013. [CrossRef]

- Schindelin, J.; Arganda-Carreras, I.; Frise, E.; Kaynig, V.; Longair, M.; Pietzsch, T.; Preibisch, S.; Rueden, C.; Saalfeld, S.; Schmid, B.; et al. Fiji: An open-source platform for biological-image analysis. Nat. Methods 2012, 676–682. [Google Scholar] [CrossRef] [Green Version]

- Rossen, J.E.; Scrivener, K.L. Optimization of SEM-EDS to determine the C–A–S–H composition in matured cement paste samples. Mater. Charact. 2017, 123, 294–306. [Google Scholar] [CrossRef] [Green Version]

- Rueden, C.T.; Schindelin, J.; Hiner, M.C.; DeZonia, B.E.; Walter, A.E.; Arena, E.T.; Eliceiri, K.W. ImageJ2: ImageJ for the next generation of scientific image data. BMC Bioinformatics 2017, 18. [Google Scholar] [CrossRef]

- Preibisch, S.; Saalfeld, S.; Tomancak, P. Globally optimal stitching of tiled 3D microscopic image acquisitions. Bioinformatics 2009, 25, 1463–1465. [Google Scholar] [CrossRef]

- Scrivener, K.L. Backscattered electron imaging of cementitious microstructures: Understanding and quantification. Cem. Concr. Compos. 2004, 26, 935–945. [Google Scholar] [CrossRef]

- Beyene, M.A.; Munoz, J.F.; Meininger, R.C.; Di Bella, C. Effect of internal curing as mitigation to minimize alkali-silica reaction damage. ACI Struct. J. 2017, 114, 417–428. [Google Scholar] [CrossRef]

- Rossen, J.E.; Lothenbach, B.; Scrivener, K.L. Composition of C-S-H in pastes with increasing levels of silica fume addition. Cem. Concr. Res. 2015, 75, 14–22. [Google Scholar] [CrossRef] [Green Version]

- Sobuz, H.R.; Visintin, P.; Ali, M.S.M.; Singh, M.; Griffith, M.C.; Sheikh, A.H. Manufacturing ultra-high performance concrete utilising conventional materials and production methods. Constr. Build. Mater. 2016, 111, 251–261. [Google Scholar] [CrossRef]

- Cwirzen, A.; Penttala, V.; Vornanen, C. Reactive powder based concretes: Mechanical properties, durability and hybrid use with OPC. Cem. Concr. Res. 2008, 38, 1217–1226. [Google Scholar] [CrossRef]

- Aaleti, S.; Sritharan, S. Quantifying Bonding Characteristics between UHPC and Normal-Strength Concrete for Bridge Deck Application. J. Bridg. Eng. 2019, 24. [Google Scholar] [CrossRef] [Green Version]

- Bissonnette, B.; Vaysburd, A.M.; Fay, K.F. Best Practices for Preparing Concrete Surfaces Prior to Repairs and Overlays—No MERL 12–17; U.S. Department of the Interior Bureau of Reclamation Technical Service Center: Denver, CO, USA, 2012. [Google Scholar]

- Santos, P.M.D.; Júlio, E.N.B.S.; Silva, V.D. Correlation between concrete-to-concrete bond strength and the roughness of the substrate surface. Constr. Build. Mater. 2007, 21, 1688–1695. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Y.; Zhang, Y.; Hussein, H.H.; Chen, G. Flexural strengthening of reinforced concrete beams or slabs using ultra-high performance concrete (UHPC): A state of the art review. Eng. Struct. 2020, 205. [Google Scholar] [CrossRef]

- Momayez, A.; Ehsani, M.R.; Ramezanianpour, A.A.; Rajaie, H. Comparison of methods for evaluating bond strength between concrete substrate and repair materials. Cem. Concr. Res. 2005, 35, 748–757. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Abu Bakar, B.H.; Johari, M.A.M.; Zeyad, A.M. Microstructural analysis of the adhesion mechanism between old concrete substrate and UHPFC. J. Adhes. Sci. Technol. 2014, 28, 1846–1864. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Abu Bakar, B.H.; Johari, M.A.M.; Zeyad, A.M. The role of silica fume in the adhesion of concrete restoration systems. Adv. Mater. Res. 2013, 626, 265–269. [Google Scholar] [CrossRef]

- Vivekanandam, K.; Patnaikuni, I. Transition zone in high performance concrete during hydration. Cem. Concr. Res. 1997, 27, 817–823. [Google Scholar] [CrossRef]

- Goldman, A.; Bentur, A. The influence of microfillers on enhancement of concrete strength. Cem. Concr. Res. 1993, 23, 962–972. [Google Scholar] [CrossRef]

- Li, P.P.; Brouwers, H.J.H.; Chen, W.; Yu, Q. Optimization and characterization of high-volume limestone powder in sustainable ultra-high performance concrete. Constr. Build. Mater. 2020, 242, 1–11. [Google Scholar] [CrossRef]

- Hakulinen, M.A.; Pajander, J.; Leskinen, J.; Ketolainen, J.; Veen, B.; Niinimäki, K.; Pirskanen, K.; Poso, A.; Lappalainen, R. Ultrasound transmission technique as a potential tool for physical evaluation of monolithic matrix tablets. AAPS PharmSciTech 2008. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sprinkel, M.M.; Ozyildirim, C. Evaluation of high performance concrete overlays placed on route 60 over lynnhaven inlet in Virginia. VTRC-01-R1. Virginia Transp. Res. Counc. 2000. Available online: http://www.virginiadot.org/vtrc/main/online_reports/pdf/Microsoft%20Word%20-%20VTRC%2001-R1%20_Sprinkel%20&%20Ozyildirim_.pdf (accessed on 17 December 2020).

- ACI Committee. 546.3R-14: Guide to Materials Selection for Concrete Repair; American Concrete Institute: Farmington Hills, MI, USA, 2014; ISBN 9780870318955. [Google Scholar]

- Muñoz, M.A.C.; Harris, D.K.; Ahlborn, T.M.; Froster, D.C. Bond performance between ultrahigh-performance concrete and normal-strength concrete. J. Mater. Civ. Eng. 2014, 26. [Google Scholar] [CrossRef]

- Chorinsky, E.G. Repair of Concrete Floors with Polymer Modified Cement Mortars. In Proceedings of the Adhesion between Polymers and Concrete/Adhésion Entre Polymères et Béton; Springer: Boston, MA, USA, 1986; pp. 230–234. [Google Scholar] [CrossRef]

- Valikhani, A.; Jahromi, A.J.; Mantawy, I.M.; Azizinamini, A. Experimental evaluation of concrete-to-UHPC bond strength with correlation to surface roughness for repair application. Constr. Build. Mater. 2020, 238, 117753. [Google Scholar] [CrossRef]

- Scrivener, K.L.; Crumbie, A.K.; Laugesen, P. The interfacial transition zone (ITZ) between cement paste and aggregate in concrete. Interface Sci. 2004, 12, 411–421. [Google Scholar] [CrossRef]

- Cwirzen, A.; Penttala, V. Aggregate-cement paste transition zone properties affecting the salt-frost damage of high-performance concretes. Cem. Concr. Res. 2005, 35, 671–679. [Google Scholar] [CrossRef]

- Rajczakowska, M.; Nilsson, L.; Habermehl-Cwirzen, K.; Hedlund, H.; Cwirzen, A. Does a high amount of unhydrated Portland cement ensure an effective autogenous self-healing of mortar? Materials 2019, 12, 3298. [Google Scholar] [CrossRef] [Green Version]

- Qian, S.Z.; Zhou, J.; Schlangen, E. Influence of curing condition and precracking time on the self-healing behavior of Engineered Cementitious Composites. Cem. Concr. Compos. 2010, 32, 686–693. [Google Scholar] [CrossRef]

- Rajczakowska, M.; Habermehl-Cwirzen, K.; Hedlund, H.; Cwirzen, A. The Effect of Exposure on the Autogenous Self-Healing of Ordinary Portland Cement Mortars. Materials 2019, 12, 3926. [Google Scholar] [CrossRef] [Green Version]

| Mix | Materials | Density (kg/m3) | Proportion (kg/m3) | Percentage Volume |

|---|---|---|---|---|

| Eco-UHPC | Portland Cement (CEM I 42.5N) | 3200 | 651 | 20.3 |

| Silica Fume 920D | 2000 | 130.2 | 6.5 | |

| Limestone | 2600 | 651 | 25 | |

| Quartz | 2650 | 65.1 | 2.5 | |

| Sand—B15 | 2670 | 227.9 | 8.5 | |

| Sand—B35 | 2670 | 227.9 | 8.5 | |

| PCE—Superplasticizer (solid + water) | 1064 (kg/L) | 32.6 | 3.2 | |

| Steel fibers 6 mm | 7500 | 65.1 | 0.9 | |

| Steel fibers 13 mm | 97.7 | 1.3 | ||

| Air | - | - | 4.0 | |

| w/c—0.33 | 1000 | 192 | 19.2 | |

| Test age (days) | Compressive strength (MPa) | |||

| 1 | 54.29 | |||

| 7 | 111.33 | |||

| 28 | 154.25 | |||

| NSC | Materials | Proportion (kg/m3) | ||

| Portland Cement (CEM II/A-V 52.5N) | 340 | |||

| Dolomit filler—KM200 | 160 | |||

| Fine aggregate (0–4) | 1021 | |||

| Coarse aggregate (8–16) | 802 | |||

| MasterGlenium SKY 823 | 3.4 | |||

| w/c—0.55 | 187 | |||

| Test age (days) | Compressive strength (MPa) | |||

| 1 | 19.52 | |||

| 7 | 27.00 | |||

| 28 | 53.17 | |||

| Chemical (%) | Cement I 42.5 N | Silica Fume | Quartz | Sand (B15, B35) |

|---|---|---|---|---|

| CaO | 63.30 | 1 | 99.6 | - |

| SiO2 | 21.20 | ≥85 | - | 90.5 |

| Al2O3 | 3.40 | 1 | 0.25 | 4.9 |

| Fe2O3 | 4.12 | 1 | 0.02 | 0.5 |

| MgO | 2.20 | 1 | - | - |

| Na2O | 0.18 | 0.5 | - | 1.2 |

| K2O | 0.56 | 1.2 | - | 2 |

| SO3 | 2.70 | 2 | - | - |

| Cl | <0.01 | 0.3 | - | - |

| LOI | 2.50 | 4 | 0.15 | - |

| Properties | DM 6/0.175 | DG 13/0.3 − E430 |

|---|---|---|

| Material | Steel − brass coated | Stainless steel |

| Type of fiber | Wire fiber − microfiber | Wire fiber − straight steel |

| Length (L) | 6 mm | 13 mm |

| Diameter (d) | 0.175 mm | 0.3 mm |

| Ratio (L/d) | 34.3 | 43 |

| Tensile strength (MPa) | 2800 | 1100 |

| Modulus of elasticity (GPa) | 210 | 200 |

| Quantity of fibers/kg | 882,000 | 144,174 |

| ID | Bond Failure Mode |

|---|---|

| SBF | Substrate failure |

| OF | Overlay failure |

| IF | Interface failure |

| PISF | Partial interface-substrate failure |

| Shuttering Plywood (STT) | Untreated Plywood (UTT) | ||||||

|---|---|---|---|---|---|---|---|

| Side | Side | ||||||

| Section | Level | A | B | C | A | B | C |

| Top | +90 | SBF | SBF | SBF | PISF | PISF | PISF |

| +60 | SBF | SBF | SBF | SBF | SBF | PISF | |

| +30 | SBF | SBF | SBF | PISF | SBF | PISF | |

| Bottom | −30 | SBF | PISF | SBF | SBF | SBF | SBF |

| −60 | SBF | SBF | SBF | SBF | SBF | SBF | |

| −90 | SBF | SBF | SBF | SBF | SBF | SBF | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kothari, A.; Rajczakowska, M.; Buasiri, T.; Habermehl-Cwirzen, K.; Cwirzen, A. Eco-UHPC as Repair Material—Bond Strength, Interfacial Transition Zone and Effects of Formwork Type. Materials 2020, 13, 5778. https://doi.org/10.3390/ma13245778

Kothari A, Rajczakowska M, Buasiri T, Habermehl-Cwirzen K, Cwirzen A. Eco-UHPC as Repair Material—Bond Strength, Interfacial Transition Zone and Effects of Formwork Type. Materials. 2020; 13(24):5778. https://doi.org/10.3390/ma13245778

Chicago/Turabian StyleKothari, Ankit, Magdalena Rajczakowska, Thanyarat Buasiri, Karin Habermehl-Cwirzen, and Andrzej Cwirzen. 2020. "Eco-UHPC as Repair Material—Bond Strength, Interfacial Transition Zone and Effects of Formwork Type" Materials 13, no. 24: 5778. https://doi.org/10.3390/ma13245778

APA StyleKothari, A., Rajczakowska, M., Buasiri, T., Habermehl-Cwirzen, K., & Cwirzen, A. (2020). Eco-UHPC as Repair Material—Bond Strength, Interfacial Transition Zone and Effects of Formwork Type. Materials, 13(24), 5778. https://doi.org/10.3390/ma13245778