The Effects of Temperature Curing on the Strength Development, Transport Properties, and Freeze-Thaw Resistance of Blast Furnace Slag Cement Mortars Modified with Nanosilica

Abstract

:1. Introduction

2. Materials and Methods

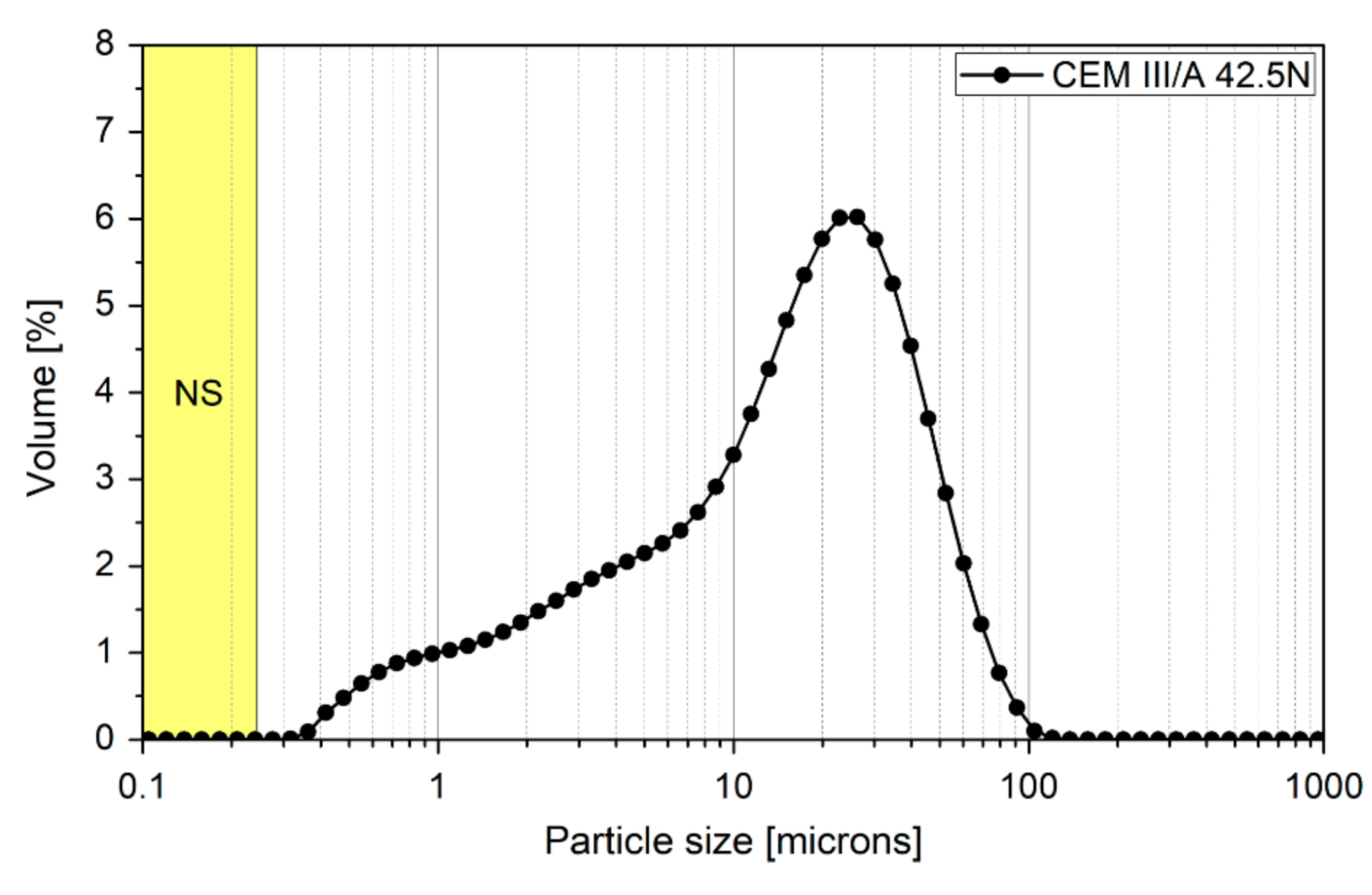

2.1. Materials

2.2. Mixture Design and Mixing Process

2.3. Experimental Protocol

2.4. Method

2.4.1. Compressive Strength

2.4.2. Capillary Water Porosity

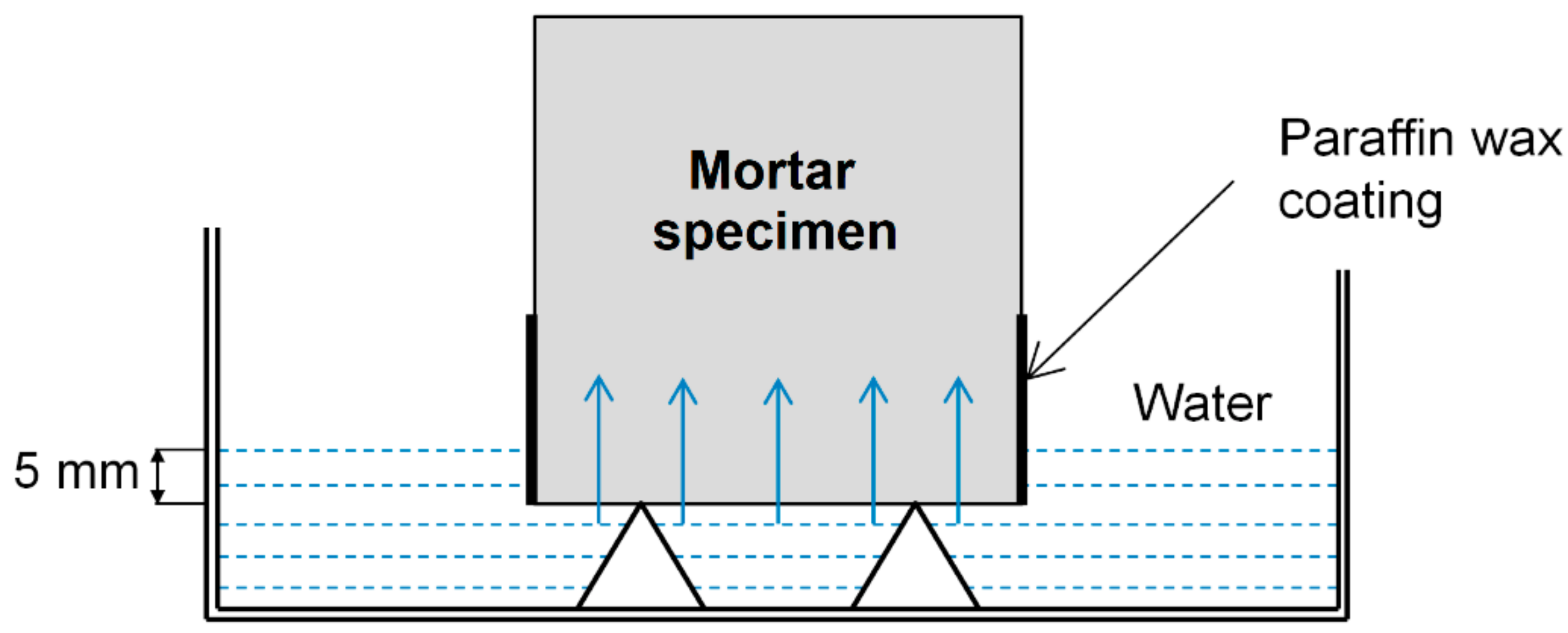

2.4.3. Water Sorptivity

2.4.4. Freezing and Thawing Resistance

2.4.5. Mercury Intrusion Porosimetry

3. Results

3.1. Compressive Strength Development

3.2. Transport Properties

3.3. Freezing and Thawing Resistance

3.4. Mercury Intrusion Porosimetry (MIP)

4. Conclusions

- The proposed curing methods have a considerable effect on the early strength development of low heat blast-furnace slag cement mortars. A strength development trend, comparable to 28-day curing, was noticed when both curing techniques were applied, with curing temperature having a major influence. A temperature of 60 °C had the highest impact on the early strength values, followed by a temperature of 40 °C.

- Based on the compressive strength results, it can be concluded that the hot water curing method facilitates more uniform strength development than oven-air curing. In addition, both temperatures (40 °C and 60 °C) were found to be suitable for enhancing the early strength development of low heat cement mortars. Moreover, irrespective on the curing method, mortars exhibited minimal strength decrement. Thus, it was confirmed that, when thermal curing is applied after 24 h of hydration and not directly after casting, the crossover effect is limited.

- The incorporation of nanosilica in mixtures was found to have a beneficial effect in accelerating specimens’ strength gain in ambient conditions, as well as during exposure to a temperature of 40 °C. However, at a temperature of 60 °C, the beneficial effects were limited, with the major contribution being temperature. NS-modified specimens exhibited higher strength gains, after thermal curing, than corresponding control (pristine) specimens.

- Due to a substantially accelerated cement hydration process and thus early strength gain associated with the synergistic effects of nanosilica and temperature, the effect of nanosilica on compressive strength at 28 days and 180 days was found to be negligible.

- Thermal curing had beneficial effects on improving the transport properties of mortars. The hot air cured specimens exhibited slightly worse transport properties than hot water cured specimens. In addition, significant improvements were reported in specimens containing nanosilica. MIP studies confirmed that NS has substantial effects on refinement of the pore structure in a cement matrix.

- A slight decrement in the freezing and thawing resistance of thermally cured specimens was found, but these changes did not exceed 10%. The incorporation of NS improved the resistance of mortars subjected to water curing, to freezing, and thawing.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Monahan, J.; Powell, J. An embodied carbon and energy analysis of modern methods of construction in housing: A case study using a lifecycle assessment framework. Energy Build. 2011, 43, 179–188. [Google Scholar] [CrossRef]

- Erdem, T.K.; Kırca, Ö. Use of binary and ternary blends in high strength concrete. Constr. Build. Mater. 2008, 22, 1477–1483. [Google Scholar] [CrossRef]

- Tazawa, E.-I.; Miyazawa, S.; Kasai, T. Chemical shrinkage and autogenous shrinkage of hydrating cement paste. Cem. Concr. Res. 1995, 25, 288–292. [Google Scholar] [CrossRef]

- Darquennes, A.; Staquet, S.; Espion, B. Behaviour of slag cement concrete under restraint conditions. Eur. J. Environ. Civ. Eng. 2011, 15, 787–798. [Google Scholar] [CrossRef]

- Monkman, S.; Shao, Y. Carbonation Curing of Slag-Cement Concrete for Binding CO2 and Improving Performance. J. Mater. Civ. Eng. 2010, 22, 296–304. [Google Scholar] [CrossRef]

- Divsholi, B.S.; Lim, T.Y.D.; Teng, S. Durability Properties and Microstructure of Ground Granulated Blast Furnace Slag Cement Concrete. Int. J. Concr. Struct. Mater. 2014, 8, 157–164. [Google Scholar] [CrossRef] [Green Version]

- Darquennes, A.; Staquet, S.; Delplancke-Ogletree, M.-P.; Espion, B. Effect of autogenous deformation on the cracking risk of slag cement concretes. Cem. Concr. Compos. 2011, 33, 368–379. [Google Scholar] [CrossRef]

- Schuldyakov, K.; Kramar, L.; Trofimov, B. The Properties of Slag Cement and its Influence on the Structure of the Hardened Cement Paste. Procedia Eng. 2016, 150, 1433–1439. [Google Scholar] [CrossRef] [Green Version]

- Su, Y.; Wei, X.; Huang, J.; Wang, Y.; He, X.; Wang, X.; Ma, B. Use of different barium salts to inhibit the thaumasite form of sulfate attack in cement-based materials. J. Wuhan Univ. Technol. Sci. Ed. 2016, 31, 361–366. [Google Scholar] [CrossRef]

- Jiang, W.; Li, X.; Lv, Y.; Zhou, M.; Liu, Z.; Ren, Z.; Yu, Z. Cement-Based Materials Containing Graphene Oxide and Polyvinyl Alcohol Fiber: Mechanical Properties, Durability, and Microstructure. Nanomaterials 2018, 8, 638. [Google Scholar] [CrossRef] [Green Version]

- Zhang, P.; Wittmann, F.H.; Lura, P.; Müller, H.S.; Han, S.; Zhao, T. Application of neutron imaging to investigate fundamental aspects of durability of cement-based materials: A review. Cem. Concr. Res. 2018, 108, 152–166. [Google Scholar] [CrossRef]

- Zuquan, J.; Wei, S.; Yunsheng, Z.; Jinyang, J.; Jianzhong, L. Interaction between sulfate and chloride solution attack of concretes with and without fly ash. Cem. Concr. Res. 2007, 37, 1223–1232. [Google Scholar] [CrossRef]

- Uthaman, S.; Vishwakarma, V.; George, R.; Ramachandran, D.; Kumari, K.; Preetha, R.; Premila, M.; Rajaraman, R.; Mudali, U.K.; Amarendra, G. Enhancement of strength and durability of fly ash concrete in seawater environments: Synergistic effect of nanoparticles. Constr. Build. Mater. 2018, 187, 448–459. [Google Scholar] [CrossRef]

- Shaikh, F.U.A.; Supit, S.W. Chloride induced corrosion durability of high volume fly ash concretes containing nano particles. Constr. Build. Mater. 2015, 99, 208–225. [Google Scholar] [CrossRef]

- Ragoug, R.; Metalssi, O.O.; Barberon, F.; Torrenti, J.-M.; Roussel, N.; Divet, L.; De Lacaillerie, J.D. Durability of cement pastes exposed to external sulfate attack and leaching: Physical and chemical aspects. Cem. Concr. Res. 2019, 116, 134–145. [Google Scholar] [CrossRef]

- Deng, Y.; Zhang, C.; Wei, X. Influence of lithium sulfate addition on the properties of Portland cement paste. Constr. Build. Mater. 2014, 50, 457–462. [Google Scholar] [CrossRef]

- Sumra, Y.; Shafigh, P.; Ibrahim, Z.; Hashim, H.; Panjehpour, M. Crossover Effect in Cement-Based Materials: A Review. Appl. Sci. 2019, 9, 2776. [Google Scholar] [CrossRef] [Green Version]

- Liu, B.; Shi, J.; Zhou, F.; Shen, S.; Ding, Y.; Qin, J. Effects of steam curing regimes on the capillary water absorption of concrete: Prediction using multivariable regression models. Constr. Build. Mater. 2020, 256, 119426. [Google Scholar] [CrossRef]

- Ezziane, K.; Bougara, A.; Kadri, A.; Khelafi, H.; Kadri, E. Compressive strength of mortar containing natural pozzolan under various curing temperature. Cem. Concr. Compos. 2007, 29, 587–593. [Google Scholar] [CrossRef]

- Lothenbach, B.; Winnefeld, F.; Alder, C.; Wieland, E.; Lunk, P. Effect of temperature on the pore solution, microstructure and hydration products of Portland cement pastes. Cem. Concr. Res. 2007, 37, 483–491. [Google Scholar] [CrossRef]

- Mardani-Aghabaglou, A.; Bursa Uludag University; Özen, S.; Altun, M.G.; Bursa Technical University. Effect of curing conditions during the first 24 hours after casting on the properties of mortar mixtures. Revista de la construcción 2020, 19, 68–79. [Google Scholar] [CrossRef]

- Jiang, C.; Jin, C.; Wang, Y.; Yan, S.; Chen, D. Effect of heat curing treatment on the drying shrinkage behavior and microstructure characteristics of mortar incorporating different content ground granulated blast-furnace slag. Constr. Build. Mater. 2018, 186, 379–387. [Google Scholar] [CrossRef]

- Mardani, A.; Özen, S.; Altun, M.G.; Faqiri, Z.A. Effect of Water Curing Temperature on Compressive Strength Development and Water Absorption Capacity of Mortar Mixtures. Sigma J. Eng. Nat. Sci. 2020, 38, 135–148. [Google Scholar]

- Wang, M.; Hu, Y.; Wang, Q.; Tian, H.; Liu, D. A study on strength characteristics of concrete under variable temperature curing conditions in ultra-high geothermal tunnels. Constr. Build. Mater. 2019, 229, 116989. [Google Scholar] [CrossRef]

- Sajedi, F.; A Razak, H. Thermal activation of ordinary Portland cement–slag mortars. Mater. Des. 2010, 31, 4522–4527. [Google Scholar] [CrossRef] [Green Version]

- Zou, C.; Long, G.; Ma, C.; Xie, Y. Effect of subsequent curing on surface permeability and compressive strength of steam-cured concrete. Constr. Build. Mater. 2018, 188, 424–432. [Google Scholar] [CrossRef]

- Tasdemir, C. Combined effects of mineral admixtures and curing conditions on the sorptivity coefficient of concrete. Cem. Concr. Res. 2003, 33, 1637–1642. [Google Scholar] [CrossRef]

- Liu, B.; Qin, J.; Sun, M. Influence of Silane-based Impregnation Agent on the Permeability of Concretes. KSCE J. Civ. Eng. 2019, 23, 3443–3450. [Google Scholar] [CrossRef]

- Kumar, S.; Kothiyal, A.D.; Bisht, M.S.; Kumar, A. Effect of nanofluid flow and protrusion ribs on performance in square channels: An experimental investigation. J. Enhanc. Heat Transf. 2019, 26, 75–100. [Google Scholar] [CrossRef]

- Shi, J.; Liu, B.; Qin, J.; Jiang, J.; Wu, X.; Tan, J. Experimental study of performance of repair mortar: Evaluation of in-situ tests and correlation analysis. J. Build. Eng. 2020, 31, 101325. [Google Scholar] [CrossRef]

- Liu, B.; Luo, G.; Xie, Y. Effect of curing conditions on the permeability of concrete with high volume mineral admixtures. Constr. Build. Mater. 2018, 167, 359–371. [Google Scholar] [CrossRef]

- Yu, Z.; Ni, C.; Tang, M.; Shen, X. Relationship between water permeability and pore structure of Portland cement paste blended with fly ash. Constr. Build. Mater. 2018, 175, 458–466. [Google Scholar] [CrossRef]

- De Schutter, G. Evaluation of water absorption of concrete as a measure for resistance against carbonation and chloride migration. Mater. Struct. 2004, 37, 591–596. [Google Scholar] [CrossRef]

- Li, H.; Xiao, H.-G.; Yuan, J.; Ou, J. Microstructure of cement mortar with nano-particles. Compos. Part B Eng. 2004, 35, 185–189. [Google Scholar] [CrossRef]

- Said, A.; Zeidan, M.S.; Bassuoni, M.; Tian, Y. Properties of concrete incorporating nano-silica. Constr. Build. Mater. 2012, 36, 838–844. [Google Scholar] [CrossRef]

- Szymanowski, J.; Sadowski, Ł. Functional and adhesive properties of cement-based overlays modified with amorphous silica nanospheres. J. Adhes. 2019, 96, 207–228. [Google Scholar] [CrossRef]

- Armentrout, J.B. The Investigation of Nano Silica in the Cement Hydration Process. Mater. Sci. 2009, 267. [Google Scholar] [CrossRef]

- Krivenko, P.; Sanytsky, M.; Kropyvnytska, T. The Effect of Nanosilica on the Early Strength of Alkali-Activated Portland Composite Cements. Solid State Phenom. 2019, 296, 21–26. [Google Scholar] [CrossRef]

- Marushchak, U.D.; Sanytsky, M.; Korolko, S.; Shabatura, Y.V.; Sydor, N. Development of nanomodifiedrapid hardening fiber-reinforced concretes for special-purpose facilities. Eastern-European J. Enterp. Technol. 2018, 2, 34–41. [Google Scholar] [CrossRef] [Green Version]

- Sikora, P.; Cendrowski, K.; Elrahman, M.A.; Chung, S.-Y.; Wenelska, K.; Stephan, D. The effects of seawater on the hydration, microstructure and strength development of Portland cement pastes incorporating colloidal silica. Appl. Nanosci. 2020, 10, 2627–2638. [Google Scholar] [CrossRef] [Green Version]

- Sikora, P.; Lootens, D.; Liard, M.; Stephan, D. The effects of seawater and nanosilica on the performance of blended cements and composites. Appl. Nanosci. 2020, 10, 5009–5026. [Google Scholar] [CrossRef] [Green Version]

- Shi, J.; Wang, J.; Muzenda, T.R.; Qu, Y.; Hou, P.; Cheng, X.; Liu, M. Effects of nanosilica on the hydration and hardening properties of blended cement-based materials under heat curing. J. Therm. Anal. Calorim. 2020, 141, 1317–1330. [Google Scholar] [CrossRef]

- Ma, C.; He, J.; Qin, T.; Long, G.; Du, Y.; Xie, Y. A comparison of the influence of micro- and nano-silica on hydration kinetics of Portland cement under different temperatures. Constr. Build. Mater. 2020, 248, 118670. [Google Scholar] [CrossRef]

- Li, H.; Ma, B.; Tan, H.; Li, H.; Liu, X.; Jiang, W.; Zhang, T.; Guo, Y. Influence of steam curing and nano silica on hydration and microstructure characteristics of high volume fly ash cement system. Constr. Build. Mater. 2018, 171, 83–95. [Google Scholar] [CrossRef]

- Sikora, P. The microstructural and thermal characteristics of silica nanoparticle-modified cement mortars after exposure to high temperatures. Part I. Nanotechnol. Constr. A Sci. Internet-J. 2020, 12, 108–115. [Google Scholar] [CrossRef]

- Elrahman, M.A.; Chung, S.-Y.; Sikora, P.; Rucinska, T.; Stephan, D. Influence of Nanosilica on Mechanical Properties, Sorptivity, and Microstructure of Lightweight Concrete. Materials 2019, 12, 3078. [Google Scholar] [CrossRef] [Green Version]

- PN-B-04500:1985 Zaprawy Budowlane—Badania Cech Fizycznych i Wytrzymałościowych; Polish Committee for Standardization: Warsaw, Poland, 1985.

- Strzałkowski, J.; Garbalińska, H. The Effect of Aggregate Shape on the Properties of Concretes with Silica Fume. Materials 2020, 13, 2780. [Google Scholar] [CrossRef]

- Yan, D.; Xie, L.; Qian, X.; Ruan, S.; Zeng, Q. Compositional Dependence of Pore Structure, Strengthand Freezing-Thawing Resistance of Metakaolin-Based Geopolymers. Materials 2020, 13, 2973. [Google Scholar] [CrossRef]

- El-Feky, M.S.; Youssef, P.; El-Tair, A.M.; Ibrahim, S.; Serag, M. Effect of nano silica addition on enhancing the performance of cement composites reinforced with nano cellulose fibers. AIMS Mater. Sci. 2019, 6, 864–883. [Google Scholar] [CrossRef]

- Skoczyla, K.N.; Rucinska, T. Strength and Durability of Cement Mortars Containing Nanosilica and Waste Glass Fine Aggregate. Cem. Wapno Bet. 2018, 3, 206–215. [Google Scholar]

- Zhang, Y.; Liu, H.; Tong, R.; Ren, J. Effect of Nano Silica on Freeze-Thaw Resistance of Cement-fl y Ash Mortars, Cured in Corrosive Condition at Different Temperature. Cem. Wapno Bet. 2019, 24, 137–153. [Google Scholar]

- Oltulu, M.; Şahin, R. Pore structure analysis of hardened cement mortars containing silica fume and different nano-powders. Constr. Build. Mater. 2014, 53, 658–664. [Google Scholar] [CrossRef]

- Quercia, G.G.; Spiesz, P.P.; Hüsken, G.G.; Brouwers, H.; Jos, J. SCC modification by use of amorphous nano-silica. Cem. Concr. Compos. 2014, 45, 69–81. [Google Scholar] [CrossRef] [Green Version]

- Zeidan, M.; Bassuoni, M.T.; Said, A. Physical salt attack on concrete incorporating nano-silica. J. Sustain. Cem. Mater. 2016, 6, 195–216. [Google Scholar] [CrossRef]

| Particle Size | Solid Content | Density | Viscosity | pH |

|---|---|---|---|---|

| 10–140 nm * | 50 wt.-% | 1.4 g/cm3 | 8 cP | 9.5 |

| Mix | C20A | N20A | C40A | N40A | C60A | N60A | C20W | N20W | C40W | N40W | C60W | N60W |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Total intruded vol. [mm3/g] | 61.60 | 70.83 | 48.77 | 43.94 | 50.21 | 59.56 | 61.75 | 55.06 | 52.47 | 62.25 | 71.09 | 48.69 |

| Porosity by Hg intrusion [%] | 13.05 | 13.78 | 10.35 | 9.38 | 10.03 | 12.22 | 12.24 | 11.12 | 10.67 | 12.75 | 13.46 | 9.86 |

| Average pore diameter [nm] | 51.61 | 62.52 | 26.28 | 25.46 | 25.94 | 25.82 | 28.61 | 22.58 | 29.96 | 27.8 | 25.45 | 26.41 |

| Median pore diameter [nm] | 256.12 | 216.3 | 40.46 | 34.66 | 36.47 | 25.1 | 49.84 | 28.46 | 49.01 | 52.96 | 32.8 | 38.53 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Federowicz, K.; Figueiredo, V.A.; Al-kroom, H.; Abdel-Gawwad, H.A.; Abd Elrahman, M.; Sikora, P. The Effects of Temperature Curing on the Strength Development, Transport Properties, and Freeze-Thaw Resistance of Blast Furnace Slag Cement Mortars Modified with Nanosilica. Materials 2020, 13, 5800. https://doi.org/10.3390/ma13245800

Federowicz K, Figueiredo VA, Al-kroom H, Abdel-Gawwad HA, Abd Elrahman M, Sikora P. The Effects of Temperature Curing on the Strength Development, Transport Properties, and Freeze-Thaw Resistance of Blast Furnace Slag Cement Mortars Modified with Nanosilica. Materials. 2020; 13(24):5800. https://doi.org/10.3390/ma13245800

Chicago/Turabian StyleFederowicz, Karol, Vitoria Alves Figueiredo, Hussein Al-kroom, Hamdy A. Abdel-Gawwad, Mohamed Abd Elrahman, and Pawel Sikora. 2020. "The Effects of Temperature Curing on the Strength Development, Transport Properties, and Freeze-Thaw Resistance of Blast Furnace Slag Cement Mortars Modified with Nanosilica" Materials 13, no. 24: 5800. https://doi.org/10.3390/ma13245800

APA StyleFederowicz, K., Figueiredo, V. A., Al-kroom, H., Abdel-Gawwad, H. A., Abd Elrahman, M., & Sikora, P. (2020). The Effects of Temperature Curing on the Strength Development, Transport Properties, and Freeze-Thaw Resistance of Blast Furnace Slag Cement Mortars Modified with Nanosilica. Materials, 13(24), 5800. https://doi.org/10.3390/ma13245800