Mechanical Properties of Ultra-High Performance Concrete before and after Exposure to High Temperatures

Abstract

1. Introduction

2. Experimental Details

2.1. Materials

2.2. Mix Proportions and Casting of Specimens

- (1)

- Before mixing, the fine aggregates were treated in a dry state because their water absorption rate approached zero.

- (2)

- We placed the cementitious materials, aggregates, and fibers (steel fiber and polypropylene fiber) into a mixing tank, and then dry blended uniformly for 5 min.

- (3)

- We poured the water into the mixer. After mixing for about 1 min, we poured all the superplasticizer and viscous agent into the mixture and mixed for another 4 min to produce fresh concrete.

2.3. Test Methods and Instrumentation

3. Results and Discussion

3.1. Fresh Concrete Properties

3.2. Hardened Concrete Properties at Room Temperature

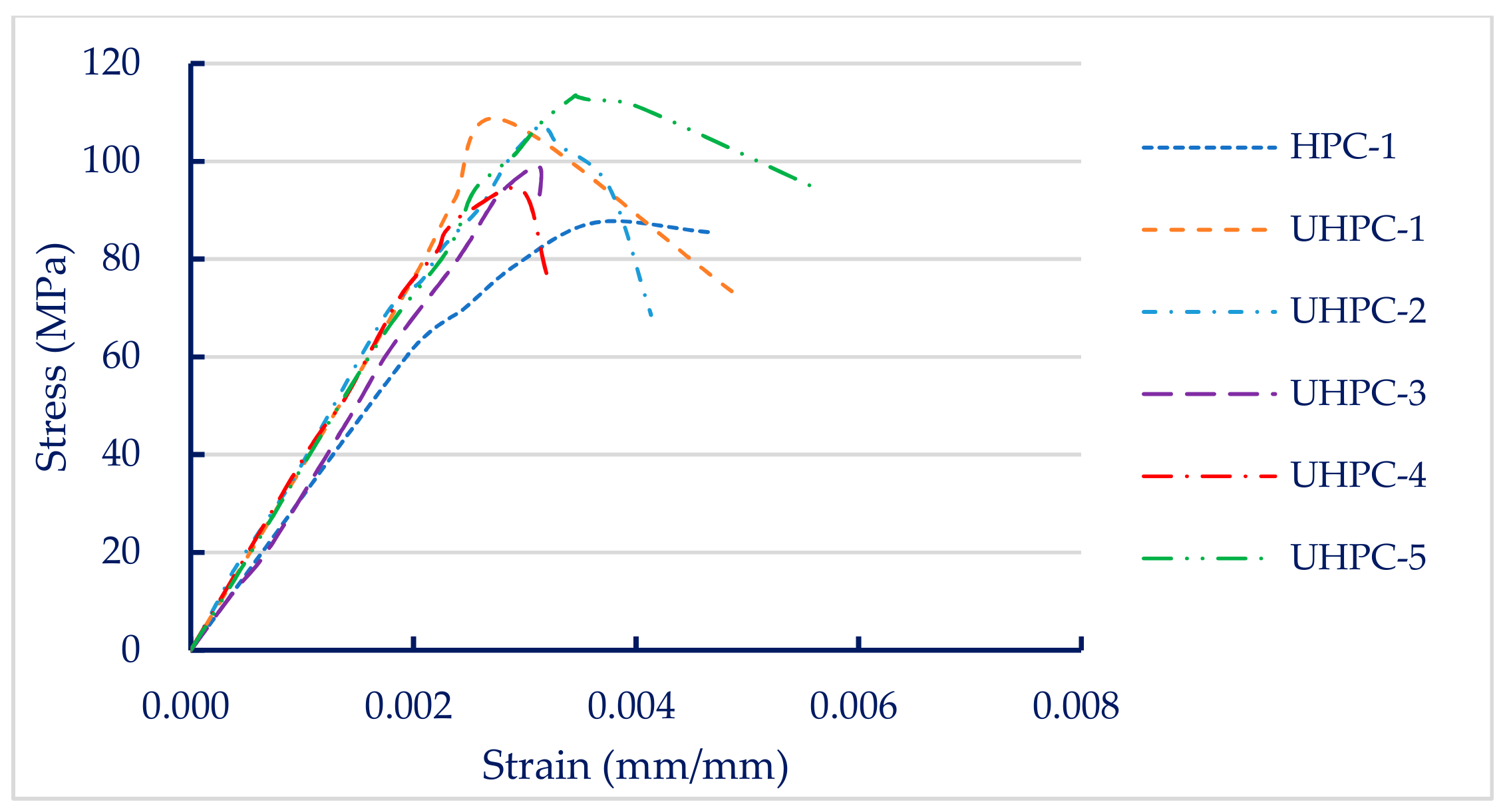

3.2.1. Compressive Strength of Concrete at Room Temperature

3.2.2. Elastic Modulus of Concrete at Room Temperature

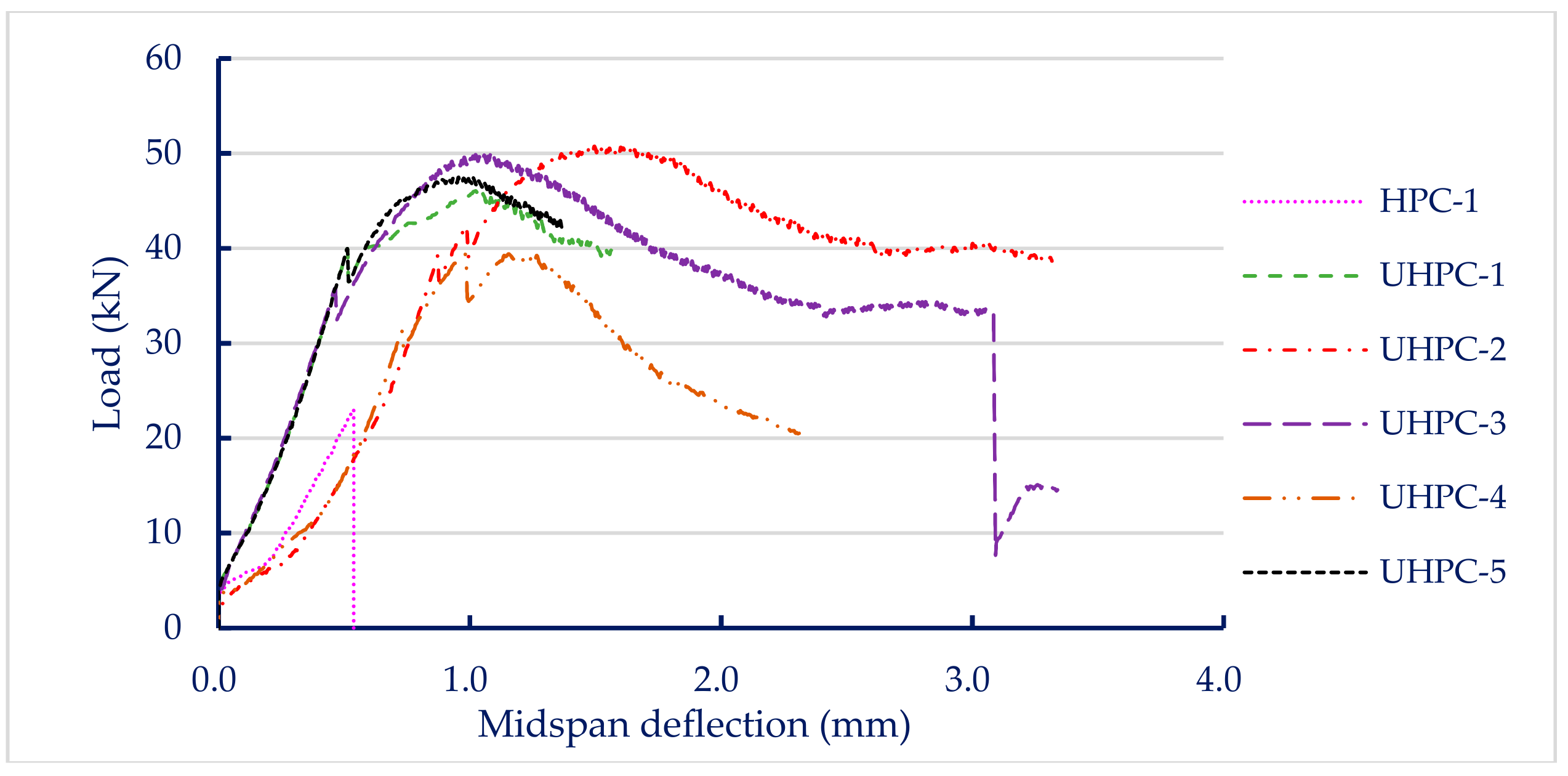

3.2.3. Flexural Strength of Concrete at Room Temperature

3.2.4. Splitting Strength of Concrete at Room Temperature

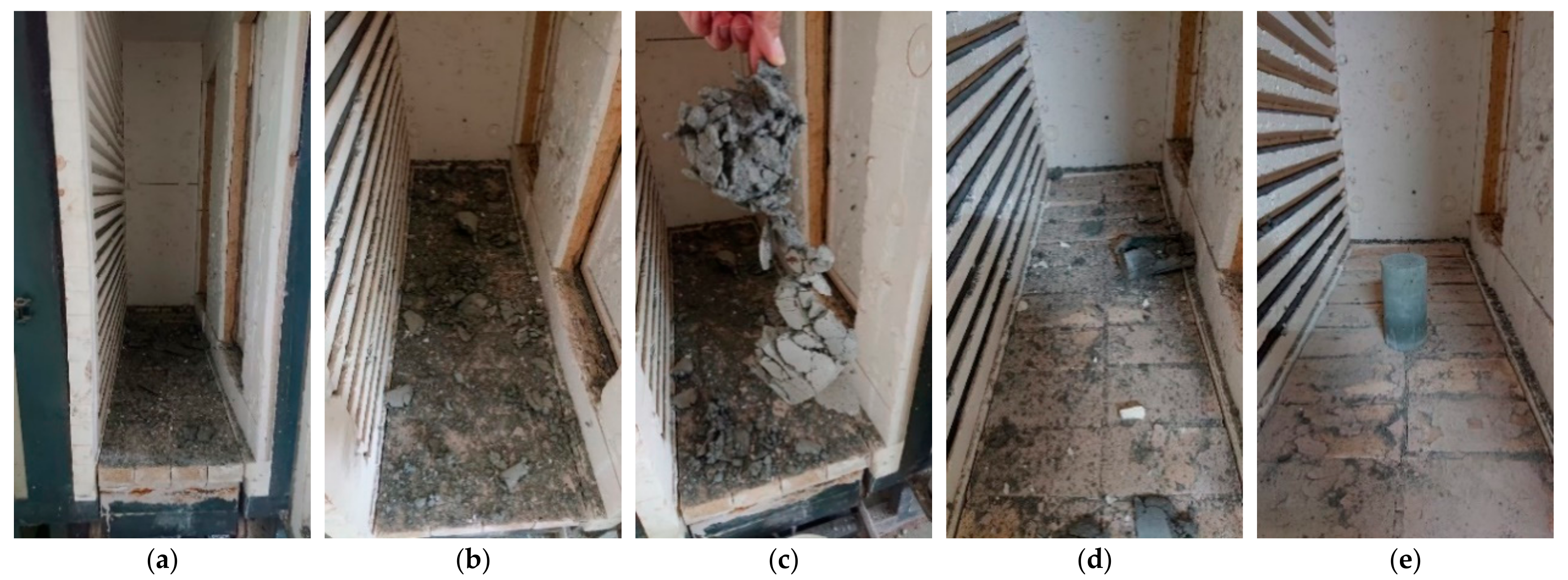

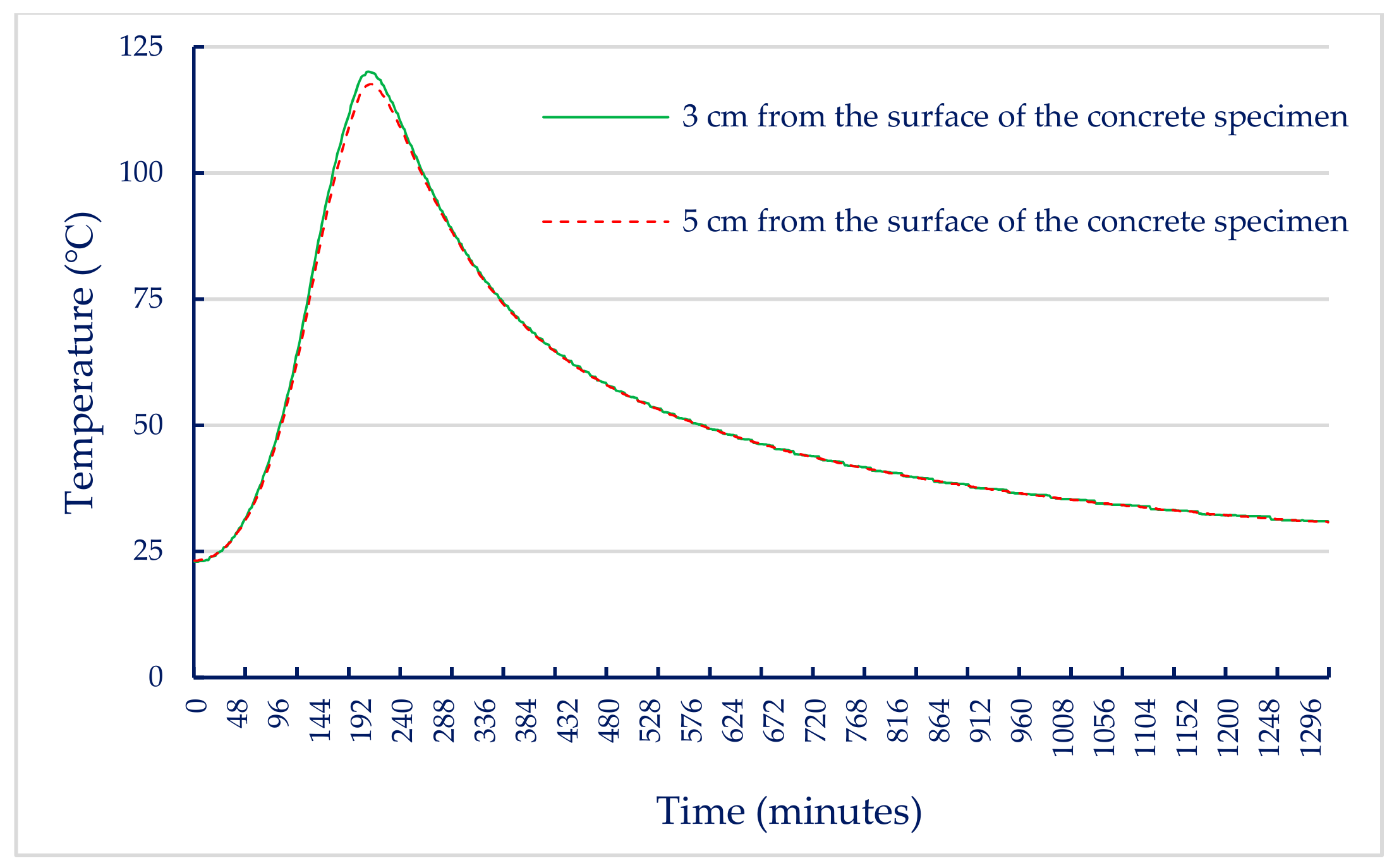

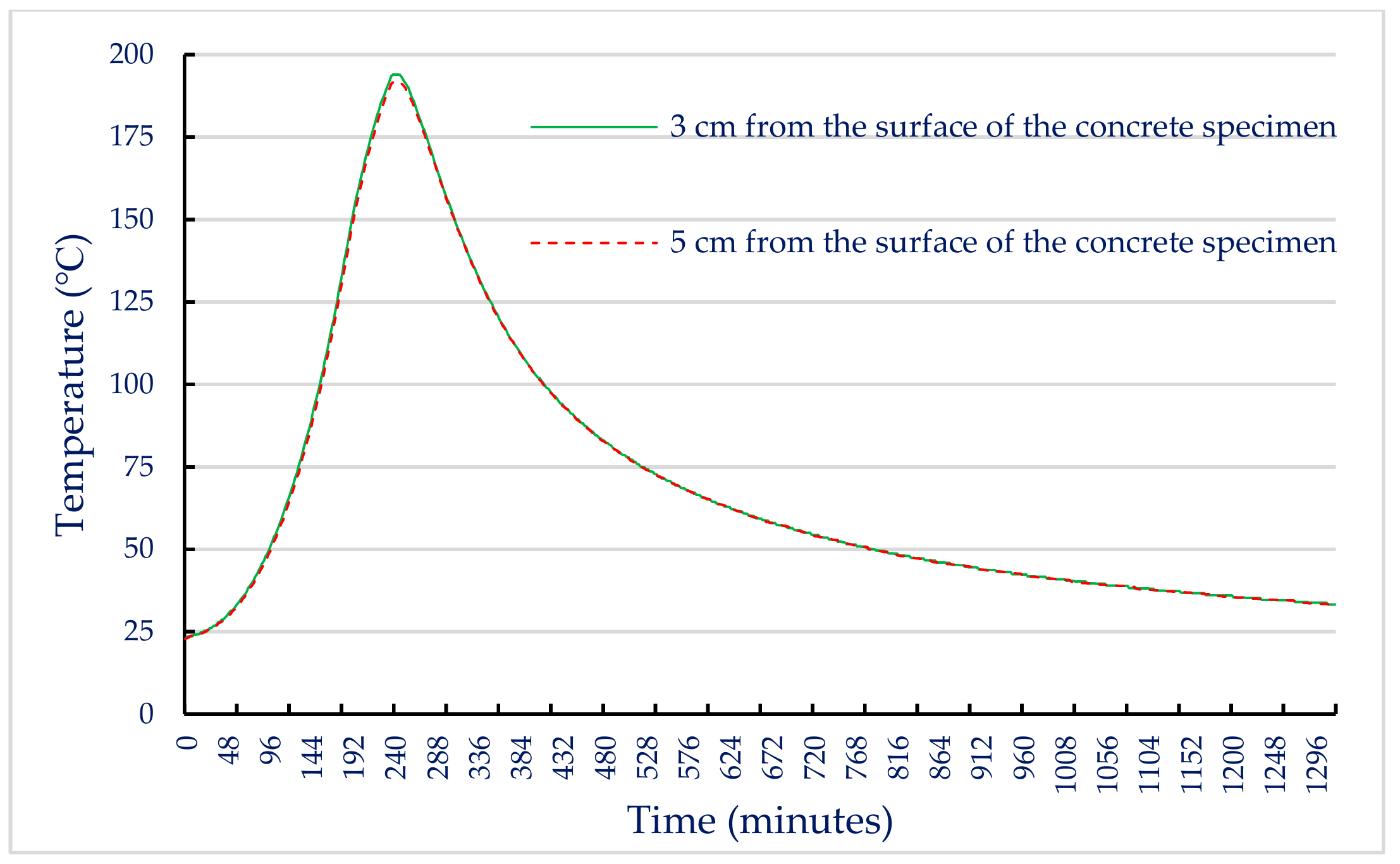

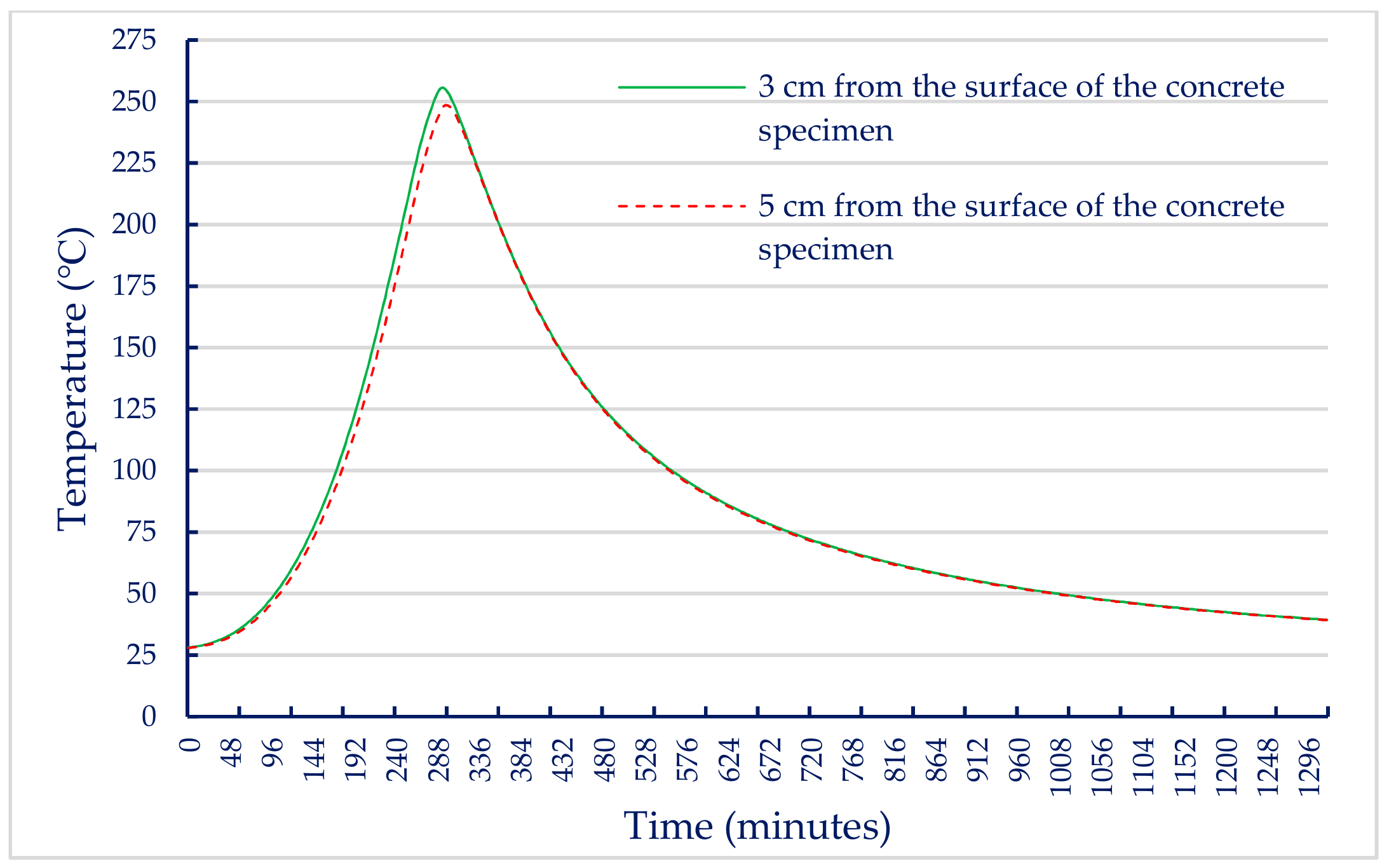

3.3. Test Results of Hardened Concrete Properties after Exposure to High Temperatures

3.3.1. Compressive Strength of Concrete after Exposure to High Temperatures

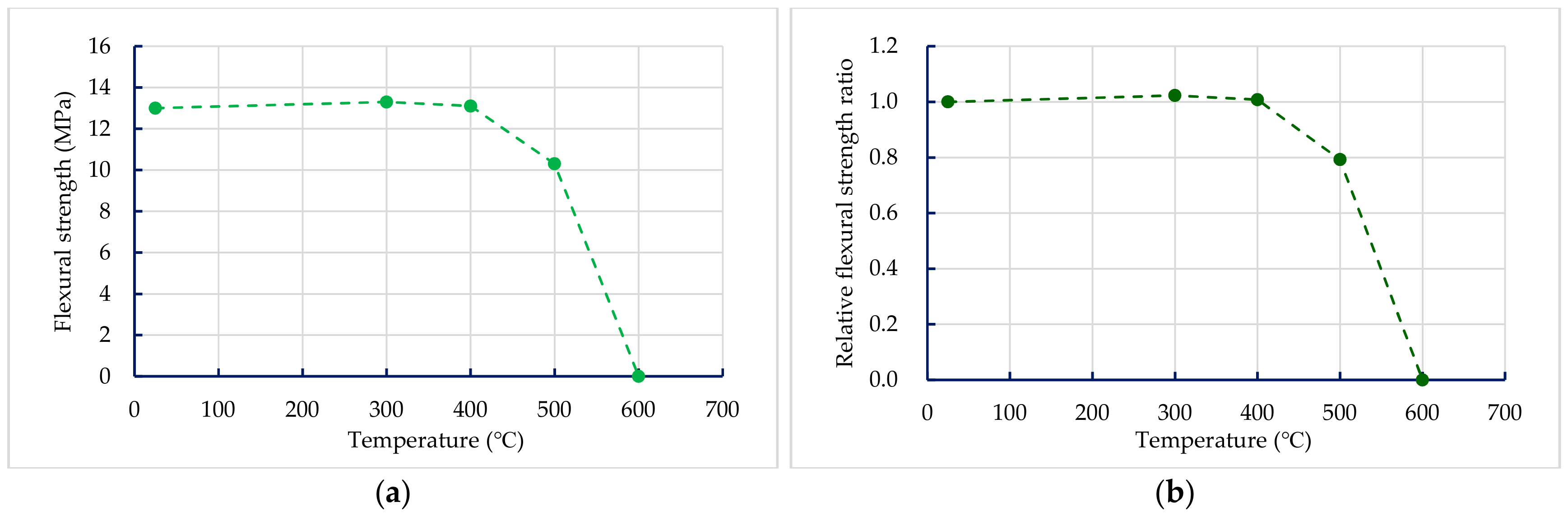

3.3.2. Flexural Strength of Concrete after Exposure to High Temperatures

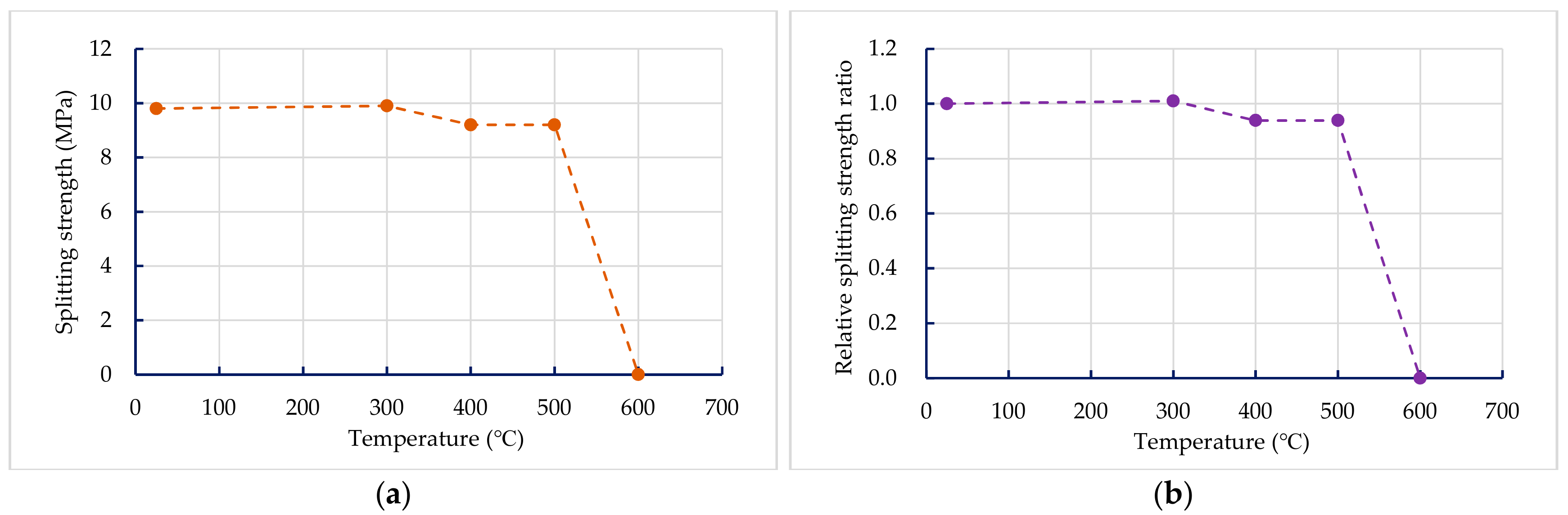

3.3.3. Splitting Strength of Concrete after Exposure to High Temperatures

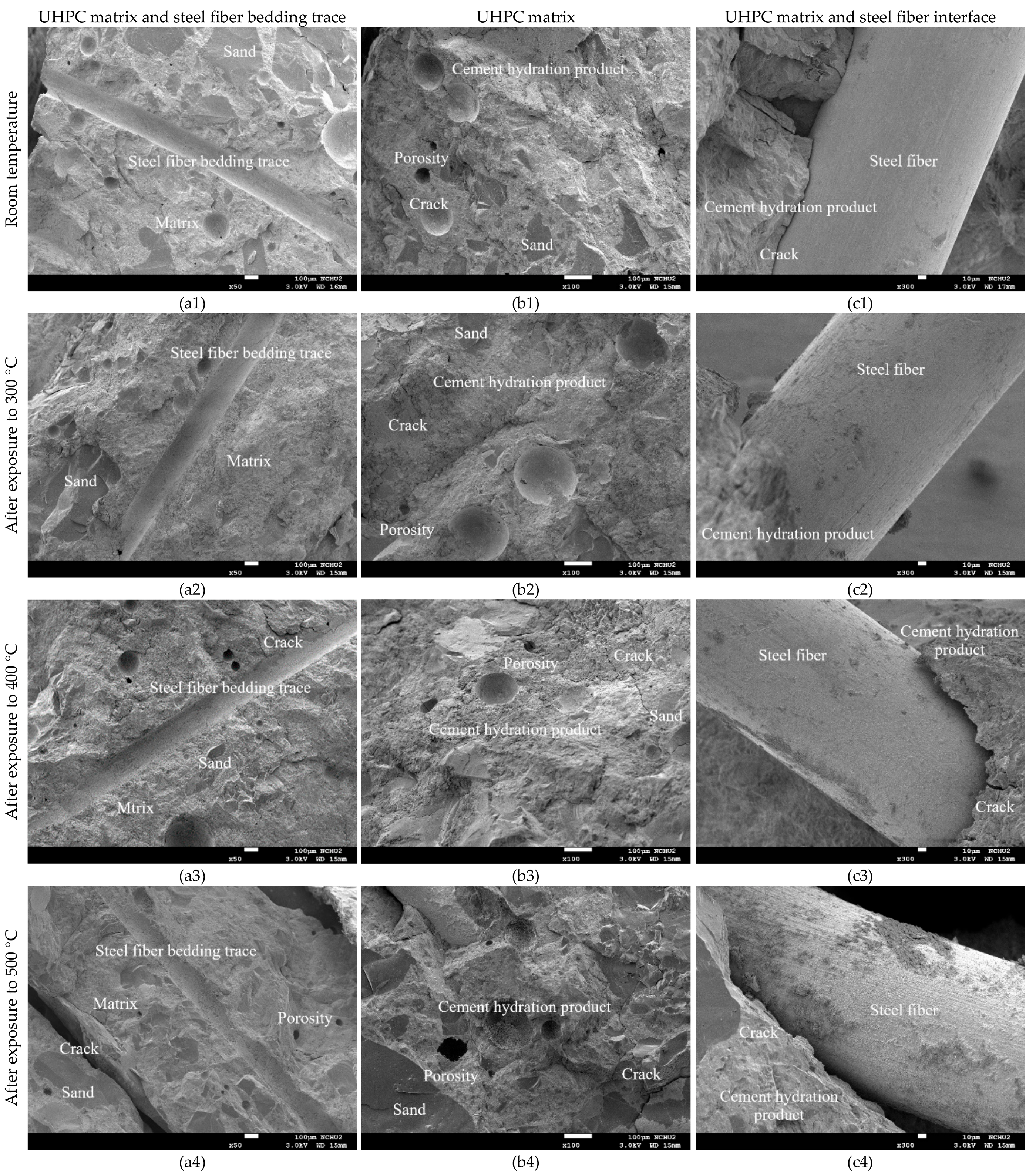

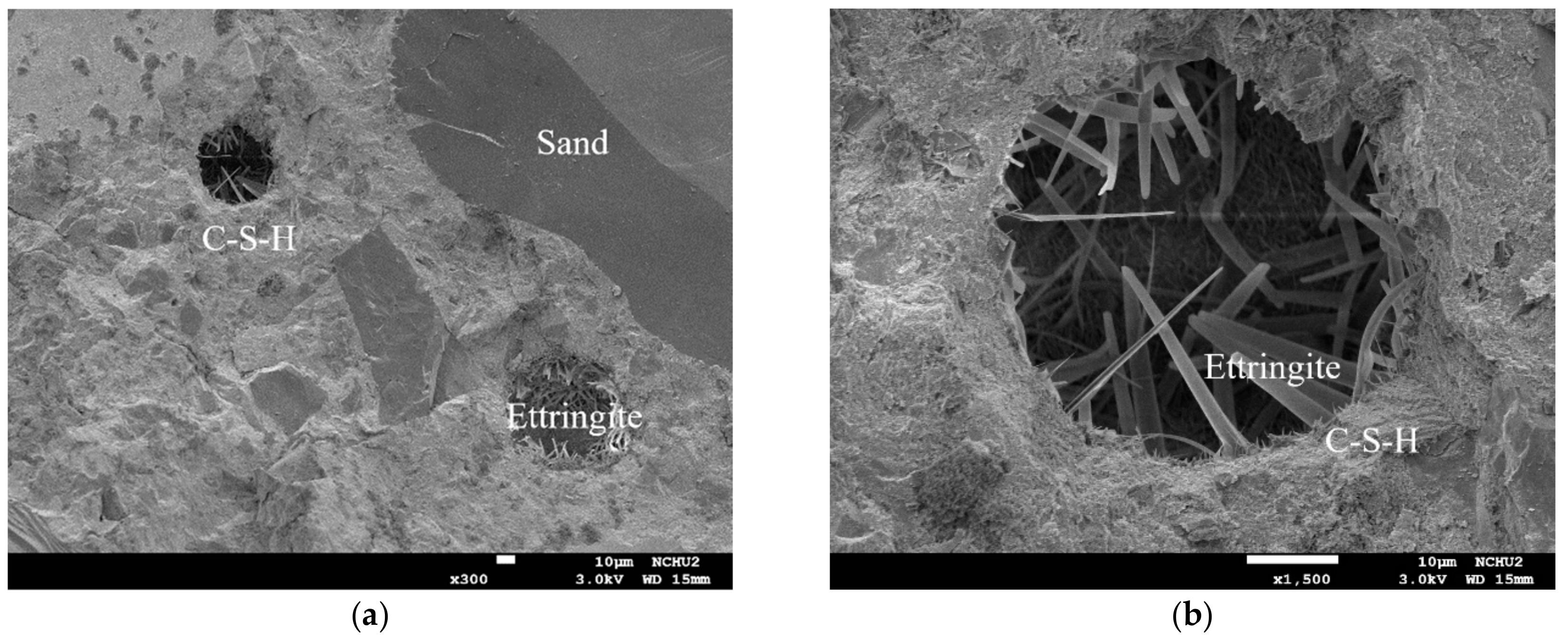

3.3.4. SEM Observation before and after Exposure to High Temperatures

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, J.; Jin, H.; Zhao, X.; Wang, C. Effect of Multi-Walled Carbon Nanotubes on Improving the Toughness of Reactive Powder Concrete. Materials 2019, 12, 2625. [Google Scholar] [CrossRef] [PubMed]

- Yu, K.Q.; Lu, Z.D.; Dai, J.G.; Shah, S.P. Direct Tensile Properties and Stress–Strain Model of UHP-ECC. J. Mater. Civ. Eng. 2019, 32, 04019334. [Google Scholar] [CrossRef]

- Sharma, R.; Bansal, P.P. Efficacy of supplementary cementitious material and hybrid fiber to develop the ultra high performance hybrid fiber reinforced concrete. Adv. Concr. Constr. 2019, 8, 21–31. [Google Scholar] [CrossRef]

- Erdogdu, S.; Kandil, U.; Nayir, S. Effects of cement dosage and steel fiber ratio on the mechanical properties of reactive powder concrete. Adv. Concr. Constr. 2019, 8, 139–144. [Google Scholar] [CrossRef]

- Wan, L.; Wendner, R.; Liang, B.; Cusatis, G. Analysis of the behavior of ultra high performance concrete at early age. Cem. Concr. Compos. 2016, 74, 120–135. [Google Scholar] [CrossRef]

- Du, R.Y.; Huang, Q.W.; Chen, B.C. Application and study of reactive powder concrete to bridge engineering. World Bridges 2013, 41, 69–74. [Google Scholar]

- Hajek, P.; Fiala, C. Environmentally optimized floor slabs using UHPC-contribution to sustainable building. In Proceedings of the 2nd International Symposium on Ultra-High Performance Concrete, Kassel, Germany, 5–7 March 2008; pp. 879–886. [Google Scholar]

- Zollo, R.F. Fiber-reinforced concrete: An overview after 30 years of development. Cem. Concr. Compos. 1997, 19, 107–122. [Google Scholar] [CrossRef]

- Magureanu, C.; Sosa, I.; Negrutiu, C.; Heghes, B. Mechanical properties and durability of ultra-high performance concrete. ACI Mater. J. 2012, 109, 177–183. [Google Scholar]

- Walraven, J. On the way to design recommendations for UHPFRC. In Proceedings of the 2nd International Symposium on Ultra-High Performance Concrete, Kassel, Germany, 5–7 March 2008. [Google Scholar]

- Racky, P. Cost-effectiveness and sustainability of UHPC. In Proceedings of the International Symposium on Ultra High Performance Concrete, Kassel, Germany, 13–15 September 2004; pp. 797–805. [Google Scholar]

- Aitcin, P. Cements of yesterday and today—Concrete of tomorrow. Cem. Concr. Res. 2000, 30, 1349–1359. [Google Scholar] [CrossRef]

- Azmee, N.M.; Shafiq, N. Ultra-high performance concrete: From fundamental to applications. Case Stud. Constr. Mater. 2018, 9, e00197. [Google Scholar] [CrossRef]

- Gosavi, J.S.; Awari, U.R. A Review on High-Performance Concrete. Int. Res. J. Eng. Technol. 2018, 5, 1965–1968. [Google Scholar]

- He, Z.H.; Du, S.G.; Chen, D. Microstructure of ultra high performance concrete containing lithium slag. J. Hazard Mater. 2018, 5, 35–43. [Google Scholar] [CrossRef] [PubMed]

- Abbas, S.; Nehdi, M.L.; Saleem, M.A. Ultra-high performance concrete: Mechanical performance, durability, sustainability and implementation challenges. Int. J. Concr. Struct. Mater. 2016, 10, 271–295. [Google Scholar] [CrossRef]

- Soliman, N.A.; Tagnit-Hamou, A. Development of ultra-high-performance concrete using glass powder—Towards ecofriendly concrete. Constr. Build. Mater. 2016, 125, 600–612. [Google Scholar] [CrossRef]

- Pyo, S.; Kim, H.K. Fresh and hardened properties of ultra-high performance concrete incorporating coal bottom ash and slag powder. Constr. Build. Mater. 2017, 131, 459–466. [Google Scholar] [CrossRef]

- Mindess, S.; Young, J.F.; Darwin, D. Concrete, 2nd ed.; Prentice-Hall: Upper Saddle River, NJ, USA, 2003. [Google Scholar]

- Metha, P.K.; Monteiro, P.J.M. Concrete, Microstructure, Properties and Materials, 3rd ed.; McGraw-Hill: New York, NY, USA, 2006. [Google Scholar]

- Way, R.; Wille, K. Material characterization of an ultra-high performance fibre-reinforced concrete under elevated temperature. In Proceedings of the 3rd International Symposium on UHPC and Nanotechnology for High Performance Construction Materials, Kassel, Germany, 7–9 March 2012; pp. 565–572. [Google Scholar]

- Abid, M.; Hou, X.; Zheng, W.; Hussain, R.R. Effect of Fibers on High-Temperature Mechanical Behavior and Microstructure of Reactive Powder Concrete. Materials 2019, 12, 329. [Google Scholar] [CrossRef]

- Dong, X.; Ding, Y.; Wang, T.J. Spalling and Mechanical Properties of Fiber Reinforced High-performance Concrete Subjected to Fire. Wuhan Univ. Technol.-Mater. Sci. Ed. 2008, 23, 743. [Google Scholar] [CrossRef]

- Hager, I.; Mróz, K.; Tracz, T. Contribution of polypropylene fibres melting to permeability change in heated concrete—The fibre amount and length effect. IOP Conf. Ser. Mater. Sci. Eng. 2019, 706, 012009. [Google Scholar] [CrossRef]

- Wu, L.; Lu, Z.; Zhuang, C.; Chen, Y.; Hu, R. Mechanical Properties of Nano SiO2 and Carbon Fiber Reinforced Concrete after Exposure to High Temperatures. Materials 2019, 12, 3773. [Google Scholar] [CrossRef] [PubMed]

- Heinz, D.; Ludwig, H. Heat treatment and the risk of DEF delayed ettringite formation in UHPC. In Proceedings of the International Symposium on UHPC, Kassel, Germany, 13–15 September 2004; pp. 717–730. [Google Scholar]

- Schmidt, D.; Dehn, F.; Urbonas, L. Fire resistance of ultra-high performance concrete (UHPC)—Testing of laboratory samples and columns under load. In Proceedings of the International Symposium on UHPC, Kassel, Germany, 13–15 September 2004; pp. 703–715. [Google Scholar]

- Tai, S.; Pan, H.; Kung, N. Mechanical properties of steel fiber reinforced reactive powder concrete following exposure to high temperature reaching 800 °C. Nucl. Eng. Des. 2011, 241, 2416–2424. [Google Scholar] [CrossRef]

- Li, H.; Liu, G. Tensile properties of hybrid fiber reinforced reactive powder concrete after expose to elevated temperature. Int. J. Concr. Struct. Mater. 2016, 10, 29–37. [Google Scholar] [CrossRef]

- Khoury, G.A. Effect of fire on concrete and concrete structures. Prog. Struct. Eng. Mater. 2000, 2, 429–447. [Google Scholar] [CrossRef]

- ASTM C138/C138M-17a. Standard Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM C143/C143M-15a. Standard Test Method for Slump of Hydraulic-Cement Concrete; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM C1611/C1611M-18. Standard Test Method for Slump Flow of Self-Consolidating Concrete; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- ASTM C39/C39M-18. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- ASTM C469/C469M-14. Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ASTM C496/C496M-11. Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2004. [Google Scholar]

- ASTM C78/C78M-18. Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading); ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Nehdi, M.; Soliman, A.M. Early-age properties of concrete: Overview of fundamental concepts and state-of-the-art research. Proc. Inst. Civ. Eng. Constr. Mater. 2011, 164, 57–77. [Google Scholar] [CrossRef]

- Myers, J.J. How to Achieve a Higher Modulus of Elasticity. Publication-HPC Bridge Views, FHW A Sponsored NCBC Co-Sponsored Newsletter. Available online: https://trid.trb.org/view/869749 (accessed on 1 February 2020).

- Siddique, R.; Kaur, D. Properties of concrete containing ground granulated blast furnace slag (GGBFS) at elevated temperatures. J. Adv. Res. 2012, 3, 45–51. [Google Scholar] [CrossRef]

- Deshpande, A.A.; Kumar, D.; Ranade, R. Influence of high temperatures on the residual mechanical properties of a hybrid fiber-reinforced strain-hardening cementitious composite. Constr. Build. Mater. 2019, 208, 283–295. [Google Scholar] [CrossRef]

| Type of Quartz Sand | Physical Properties | Chemical Composition | |||

|---|---|---|---|---|---|

| Specific Gravity (S.S.D.) | Water Absorption Rate (%) (S.S.D.) | SiO2 (%) | Fe2O3 (%) | Al2O3 (%) | |

| Type I | 2.65 | ≈0 | 99.82 | 0.014 | 0.033 |

| Type II | 2.65 | ≈0 | 99.84 | 0.016 | 0.034 |

| Sieve No. (ASTM E11-70) | Particle Size (μm) | Percentage Retained (%) | |

|---|---|---|---|

| Type I | Type II | ||

| 20 | 850 | 0.04 | - |

| 30 | 600 | 20.15 | - |

| 40 | 425 | 67.83 | - |

| 50 | 300 | 11.81 | - |

| 60 | 250 | - | 0.05 |

| 70 | 212 | 0.17 | 13.69 |

| 100 | 150 | - | 36.55 |

| 140 | 106 | - | 32.39 |

| 200 | 75 | - | 12.73 |

| 270 | 53 | - | 3.61 |

| Type of Fiber | Length (mm) | Diameter (mm) | Density (g/cm3) | Elastic Modulus (GPa) | Tensile Strength (MPa) | Melting Point (°C) |

|---|---|---|---|---|---|---|

| Steel Fibers | 13 | 0.2 | 7.8 | 200 | 2000 | - |

| Polypropylene Fibers | 12 | 0.05 | 0.9 | - | 300 | 165 |

| Mix No. | W/B |

W (kg/m3) |

C (kg/m3) |

SF (kg/m3) |

SFP (kg/m3) |

SP (kg/m3) |

VA (kg/m3) |

PP (kg/m3) |

Steel Fiber (kg/m3) |

FA (kg/m3) |

|---|---|---|---|---|---|---|---|---|---|---|

| HPC-1 | 0.195 | 196 | 1005 | 0 | 0 | 26 | 1 | 0 | 0 | 1286 |

| UHPC-1 | 0.195 | 187 | 774 | 167 | 21 | 25 | 1 | 0.3 | 39 | 1231 |

| UHPC-2 | 0.195 | 186 | 756 | 179 | 21 | 25 | 1 | 0.5 | 78 | 1223 |

| UHPC-3 | 0.195 | 186 | 747 | 179 | 31 | 25 | 1 | 0.3 | 59 | 1225 |

| UHPC-4 | 0.195 | 186 | 744 | 191 | 21 | 25 | 1 | 0.8 | 59 | 1223 |

| UHPC-5 | 0.195 | 186 | 737 | 191 | 26 | 25 | 1 | 0.3 | 78 | 1220 |

| Mix No. | Parameter | |||

|---|---|---|---|---|

| Percentage of Cement Replaced by SF (%) | Percentage of Cement Replaced by SFP (%) | Amount of PP (Volume Percent) (%) | Amount of Steel Fiber (Volume Percentage) (%) | |

| UHPC-1 | 17.4 | 2.2 | 0.03 | 0.5 |

| UHPC-2 | 18.7 | 2.2 | 0.06 | 1.0 |

| UHPC-3 | 18.7 | 3.2 | 0.03 | 0.75 |

| UHPC-4 | 20.0 | 2.2 | 0.09 | 0.75 |

| UHPC-5 | 20.0 | 2.7 | 0.03 | 1.0 |

| Property | Experimental Method |

|---|---|

| Unit weight | ASTM C138 |

| Slump | ASTM C143 |

| Slump flow | ASTM C1611 |

| Compressive strength | ASTM C39 |

| Elastic modulus | ASTM C469 |

| Splitting tensile strength | ASTM C496 |

| Flexural strength | ASTM C78 |

| Mix No. | Slump (mm) | Slump Flow (mm) | Unit Weight (kg/m3) |

|---|---|---|---|

| HPC-1 | 262 | 690 | 2318 |

| UHPC-1 | 255 | 530 | 2263 |

| UHPC-2 | 257 | 540 | 2316 |

| UHPC-3 | 260 | 490 | 2274 |

| UHPC-4 | 255 | 530 | 2288 |

| UHPC-5 | 250 | 510 | 2308 |

| Mix No. | 7-day Experimental Results | |||

|---|---|---|---|---|

| fc′ (MPa) | Ec (GPa) | fr (MPa) | fs (MPa) | |

| HPC-1 | 81.6 (7.8) | 32.3 | 6.6 (0.5) | 4.4 (0.2) |

| UHPC-1 | 95.7 (11.2) | 34.9 | 12.6 (1.4) | 7.3 (0.9) |

| UHPC-2 | 107.0 (2.8) | 37.2 | 15.1 (0.2) | 9.6 (0.8) |

| UHPC-3 | 97.8 (7.9) | 33.9 | 14.7 (0.3) | 10.5 (0.3) |

| UHPC-4 | 95.6 (1.5) | 35.4 | 12.2 (0.6) | 8.9 (0.4) |

| UHPC-5 | 111.5 (3.3) | 36.9 | 12.7 (1.4) | 10.8 (0.1) |

| Mix No. | |||

|---|---|---|---|

| HPC-1 | 81.6 (7.8) | 90.0 (3.4) | 0.91 |

| UHPC-1 | 95.7 (11.2) | 128.1 (5.4) | 0.75 |

| UHPC-2 | 107.0 (2.8) | 127.0 (5.4) | 0.84 |

| UHPC-3 | 97.8 (7.9) | 121.6 (14.9) | 0.80 |

| UHPC-4 | 95.6 (1.5) | 123.6 (4.4) | 0.77 |

| UHPC-5 | 111.5 (3.3) | 125.8 (6.8) | 0.89 |

| Mix No. | Ec-7D (GPa) | Ec-28D (GPa) | Ec-7D/Ec-28D |

|---|---|---|---|

| HPC-1 | 32.3 | 37.2 | 0.87 |

| UHPC-1 | 34.9 | 39.5 | 0.88 |

| UHPC-2 | 37.2 | 38.1 | 0.98 |

| UHPC-3 | 33.9 | 34.0 | 1.00 |

| UHPC-4 | 35.4 | 48.0 | 0.74 |

| UHPC-5 | 36.9 | 44.8 | 0.82 |

| Target Temperature | fc′ (MPa) | fr (MPa) | fs (MPa) |

|---|---|---|---|

| Room | 155.8 (8.8) | 13.0 (0.28) | 9.8 (0.39) |

| 300 °C | 157.0 (7.3) | 13.3 (1.33) | 9.9 (0.98) |

| 400 °C | 156.5 (9.7) | 13.1 (1.07) | 9.2 (0.85) |

| 500 °C | 155.0 (8.9) | 10.3 (1.24) | 9.2 (0.27) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.-J.; Yu, Y.-L.; Tang, C.-W. Mechanical Properties of Ultra-High Performance Concrete before and after Exposure to High Temperatures. Materials 2020, 13, 770. https://doi.org/10.3390/ma13030770

Chen H-J, Yu Y-L, Tang C-W. Mechanical Properties of Ultra-High Performance Concrete before and after Exposure to High Temperatures. Materials. 2020; 13(3):770. https://doi.org/10.3390/ma13030770

Chicago/Turabian StyleChen, How-Ji, Yi-Lin Yu, and Chao-Wei Tang. 2020. "Mechanical Properties of Ultra-High Performance Concrete before and after Exposure to High Temperatures" Materials 13, no. 3: 770. https://doi.org/10.3390/ma13030770

APA StyleChen, H.-J., Yu, Y.-L., & Tang, C.-W. (2020). Mechanical Properties of Ultra-High Performance Concrete before and after Exposure to High Temperatures. Materials, 13(3), 770. https://doi.org/10.3390/ma13030770