Effect of Diisocyanates as Compatibilizer on the Properties of BF/PBAT Composites by In Situ Reactive Compatibilization, Crosslinking and Chain Extension

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Sample Preparation

2.2.1. Purification of Bamboo Flour

2.2.2. Preparation of Composites

2.3. Characterization

3. Results and Discussion

3.1. Mechanical Properties of the Composites

3.2. Structural Characterization

3.3. Rheological Properties of Composites

3.4. Thermogravimetric Analysis of Composite

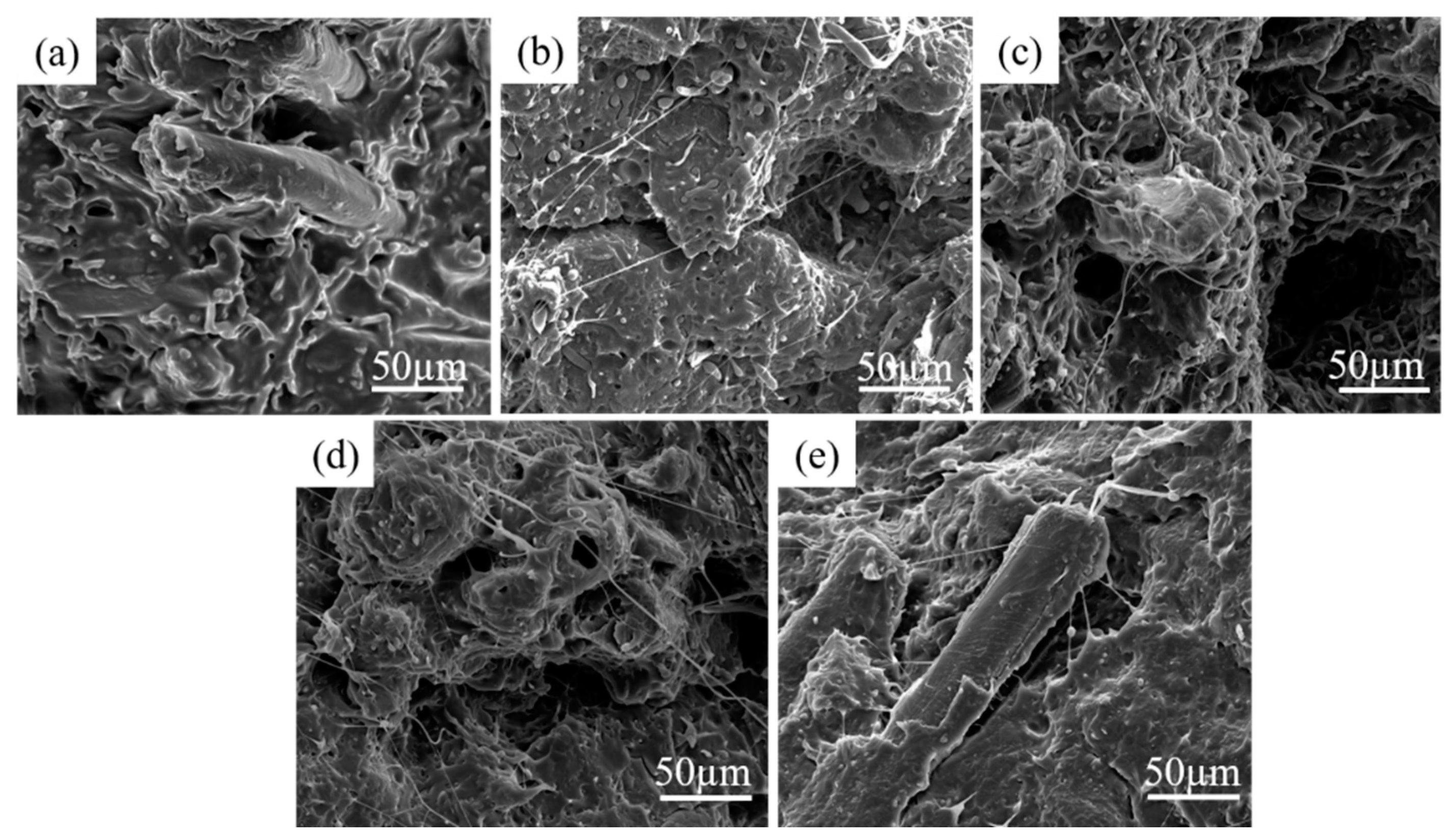

3.5. Morphology of Fracture Surface

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Raja, D.B.P.; Retnam, B.S.J. Effect of short fibre orientation on the mechanical characterization of a composite material-hybrid fibre reinforced polymer matrix. Bull. Mater. Sci. 2019, 42, 111. [Google Scholar] [CrossRef]

- Uppal, N.; Pappu, A.; Patidar, R.; Gowri, V.S. Synthesis and characterization of short sisal fibre polyester composites. Bull. Mater. Sci. 2019, 42, 132. [Google Scholar] [CrossRef]

- Long, H.; Wu, Z.; Dong, Q.; Shen, Y.; Zhou, W.; Luo, Y.; Zhang, C.; Dong, X. Effect of polyethylene glycol on mechanical properties of bamboo fiber-reinforced polylactic acid composites. J. Appl. Polym. Sci. 2019, 136, 47709. [Google Scholar] [CrossRef]

- Kim, H.-S.; Kim, H.-J. Miscibility and performance evaluation of natural-flour-filled PP/PBS and PP/PLA bio-composites. Fibers Polym. 2013, 14, 793–803. [Google Scholar] [CrossRef]

- Oladele, I.O.; Ibrahim, I.O.; Akinwekomi, A.D.; Talabil, S.I. Effect of mercerization on the mechanical and thermal response of hybrid bagasse fiber/CaCO3 reinforced polypropylene composites. Polym. Test. 2019, 76, 192–198. [Google Scholar] [CrossRef]

- Woigk, W.; Fuentes, C.A.; Rion, J.; Hegemann, D.; van Vuure, A.W.; Dransfeld, C.; Masania, K. Interface properties and their effect on the mechanical performance of flax fibre thermoplastic composites. Compos. Part A Appl. Sci. Manuf. 2019, 122, 8–17. [Google Scholar] [CrossRef]

- Yao, L.; Wang, Y.; Li, Y.; Duan, J. Thermal properties and crystallization behaviors of polylactide/redwood flour or bamboo fiber composites. Iran. Polym. J. 2017, 26, 161–168. [Google Scholar] [CrossRef]

- Jandas, P.J.; Mohanty, S.; Nayak, S.K. Thermal properties and cold crystallization kinetics of surface-treated banana fiber (BF)-reinforced poly(lactic acid) (PLA) nanocomposites. J. Therm. Anal. Calorim. 2013, 114, 1265–1278. [Google Scholar] [CrossRef]

- Jandas, P.J.; Mohanty, S.; Nayak, S.K. Mechanical properties of surface-treated banana fiber/polylactic acid biocomposites: A comparative study of theoretical and experimental values. J. Appl. Polym. Sci. 2013, 127, 4027–4038. [Google Scholar] [CrossRef]

- Liu, T.; Yu, F.; Yu, X.; Zhao, X.; Lu, A.; Wang, J. Basalt fiber reinforced and elastomer toughened polylactide composites: Mechanical properties, rheology, crystallization, and morphology. J. Appl. Polym. Sci. 2012, 125, 1292–1301. [Google Scholar] [CrossRef]

- Jandas, P.J.; Mohanty, S.; Nayak, S.K.; Srivastava, H. Effect of Surface Treatments of Banana Fiber on Mechanical, Thermal, and Biodegradability Properties of PLA/Banana Fiber Biocomposites. Polym. Compos. 2011, 32, 1689–1700. [Google Scholar] [CrossRef]

- Fazeli, M.; Florez, J.P.; Simao, R.A. Improvement in adhesion of cellulose fibers to the thermoplastic starch matrix by plasma treatment modification. Compos. Part B Eng. 2019, 163, 207–216. [Google Scholar] [CrossRef]

- Su, S.-K.; Wu, C.-S. The Processing and Characterization of Polyester/Natural Fiber Composites. Polym. Plast. Technol. Eng. 2010, 49, 1022–1029. [Google Scholar] [CrossRef]

- Wang, Y.-N.; Weng, Y.-X.; Wang, L. Characterization of interfacial compatibility of polylactic acid and bamboo flour (PLA/BF) in biocomposites. Polym. Test. 2014, 36, 119–125. [Google Scholar] [CrossRef]

- Song, X.-Y.; Wang, M.; Weng, Y.-X.; Huang, Z.-G. Effect of Bamboo Flour Grafted Lactide on the Interfacial Compatibility of Polylactic Acid/Bamboo Flour Composites. Polymers 2017, 9, 323. [Google Scholar] [CrossRef]

- Sun, J.; Pang, Y.; Yang, Y.; Zhao, J.; Xia, R.; Li, Y.; Liu, Y.; Guo, H. Improvement of Rice Husk/HDPE Bio-Composites Interfacial properties by Silane Coupling Agent and Compatibilizer Complementary Modification. Polymers 2019, 11, 1928. [Google Scholar] [CrossRef] [PubMed]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Compos. Part B Eng. 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Boronat, T.; Montanes, N.; Balart, R.; Torres-Giner, S. Injection-molded parts of fully bio-based polyamide 1010 strengthened with waste derived slate fibers pretreated with glycidyl-and amino-silane coupling agents. Polym. Test. 2019, 77, 105875. [Google Scholar] [CrossRef]

- Safri, S.N.A.; Sultan, M.T.H.; Saba, N.; Jawaid, M. Effect of benzoyl treatment on flexural and compressive properties of sugar palm/glass fibres/epoxy hybrid composites. Polym. Test. 2018, 71, 362–369. [Google Scholar] [CrossRef]

- Wang, D.; Bai, T.; Cheng, W.; Xu, C.; Wang, G.; Cheng, H.; Han, G. Surface Modification of Bamboo Fibers to Enhance the Interfacial Adhesion of Epoxy Resin-Based Composites Prepared by Resin Transfer Molding. Polymers 2019, 11, 2107. [Google Scholar] [CrossRef]

- Fan, W.; Tian, H.; Wang, H.; Zhang, T.; Yang, X.; Yu, Y.; Meng, X.; Yu, X.; Yuan, L.; Xu, B.; et al. Enhanced interfacial adhesion of aramid fiber III reinforced epoxy composites via low temperature plasma treatment. Polym. Test. 2018, 72, 147–156. [Google Scholar] [CrossRef]

- Liew, F.K.; Hamdan, S.; Rahman, M.R.; Mahmood, M.R.; Lai, J.C.H. The effects of nanoclay and tin(IV) oxide nanopowder on morphological, thermo-mechanical properties of hexamethylene diisocyanate treated jute/bamboo/polyethylene hybrid composites. J. Vinyl Addit. Technol. 2018, 24, 358–366. [Google Scholar] [CrossRef]

- Ye, M.; Zhu, N.Q.; Li, X.J.; Ni, Z.B.; Qiu, Z.W.; Chen, M.Q. Monofunctional compatibilizer with long alkyl end for fabrication of superior tensile wood flour-polyolefin composites. J. Appl. Polym. Sci. 2017, 134, 44429. [Google Scholar] [CrossRef]

- Abushammala, H.; Mao, J. A Review of the Surface Modification of Cellulose and Nanocellulose Using Aliphatic and Aromatic Mono-and Di-Isocyanates. Molecules 2019, 24, 2782. [Google Scholar] [CrossRef]

- Guo, C.; Li, L.; Li, H. Evaluation of interfacial compatibility in wood flour/polypropylene composites by grafting isocyanate silane coupling agent on polypropylene. J. Adhes. Sci. Technol. 2019, 33, 468–478. [Google Scholar] [CrossRef]

- Saeng-on, J.; Aht-Ong, D. Compatibility of banana starch nanocrystals/poly(butylene succinate) bio-nanocomposite packaging films. J. Appl. Polym. Sci. 2018, 135, 46836. [Google Scholar] [CrossRef]

- Chan, C.M.; Vandi, L.J.; Pratt, S.; Halley, P.; Richardson, D.; Werker, A.; Laycock, B. Mechanical properties of poly(3-hydroxybutyrate-co-3-hydroxyvalerate)/wood flour composites: Effect of interface modifiers. J. Appl. Polym. Sci. 2018, 135, 46828. [Google Scholar] [CrossRef]

- Rahimizadeh, A.; Kalman, J.; Henri, R.; Fayazbakhsh, K.; Lessard, L. Recycled Glass Fiber Composites from Wind Turbine Waste for 3D Printing Feedstock: Effects of Fiber Content and Interface on Mechanical Performance. Materials 2019, 12, 3929. [Google Scholar] [CrossRef]

- Soundhar, A.; Jayakrishna, K. Investigations on mechanical and morphological characterization of chitosan reinforced polymer nanocomposites. Mater. Res. Express 2019, 6, 075301. [Google Scholar] [CrossRef]

- Huang, G.; Chen, F. Reaction of jute fiber with isocyanate component for the production of plant fiber-reinforced polyurethane composites. Cellulose 2019, 26, 7297–7308. [Google Scholar] [CrossRef]

- Tayfun, U.; Dogan, M.; Bayramli, E. Investigations of the flax fiber/thermoplastic polyurethane eco-composites: Influence of isocyanate modification of flax fiber surface. Polym. Compos. 2017, 38, 2874–2880. [Google Scholar] [CrossRef]

| Material | Length (mm) | Diameter (µm) | Growth Cycle (month) | Cost ($) | Performance Advantages |

|---|---|---|---|---|---|

| Sisal [2] | 1–1.5 | 20–25 | 24–36 | 14 | High elasticity, great strength |

| Bagasse [5] | 0.65–2.17 | 21–28 | 10–15 | 20 | Good durability |

| Basalt fiber [10] | 2.7–3 | 9–17 | / | 2–18 | High strength and high temperature resistance |

| Wood flour [7] | 60–200 | 8–12 | 12 | 20–30 | Good flexibility and moisture resistance |

| Bamboo fiber [3] | 60–200 | 6–10 | 3–6 | 1.3–2 | Antibacterial, bacteriostatic deodorant, UV resistant |

| Banana fiber [11] | 70 | 18–24 | 10–15 | 10–12 | Lightweight, good luster, high water absorption, and strong antibacterial |

| Sample Codes | BF (wt %) | PBAT (wt %) | MDI/phr |

|---|---|---|---|

| BF/PBAT | 50 | 50 | 0 |

| BF/MDI-1/PBAT | 50 | 50 | 1 |

| BF/MDI-2/PBAT | 50 | 50 | 2 |

| BF/MDI-3/PBAT | 50 | 50 | 3 |

| BF/MDI-4/PBAT | 50 | 50 | 4 |

| Sample Codes | Tensile Strength (MPa) | Tensile Modulus (Pa) | Impact Strength (KJ/m2) | Elongation at Break (%) |

|---|---|---|---|---|

| BF/PBAT | 15 ± 1.5 | 693.8 ± 50 | 6.7 ± 0.8 | 5.6 ± 0.5 |

| BF/MDI-1/PBAT | 26.2 ± 0.8 | 1021.5 ± 120 | 36.6 ± 1.5 | 16.3 ± 0.3 |

| BF/MDI-2/PBAT | 28.6 ± 1.6 | 1292.6 ± 80 | 45.6 ± 3.8 | 24.2 ± 0.4 |

| BF/MDI-3/PBAT | 27.6 ± 1.8 | 1208.7 ± 110 | 51.2 ± 7.5 | 22.7 ± 1.8 |

| BF/MDI-4/PBAT | 27.3 ± 2.1 | 1105.4 ± 80 | 48.7 ± 7.8 | 22 ± 1.3 |

| Wavenumber (cm−1) | Assignment |

|---|---|

| 3500–3100 | N–H stretching |

| 2270–2000 | –N=C=O asymmetric stretching |

| 1720–1640 | C=O stretching |

| 1600 | C=C aromatic stretching |

| 1535–1520 | –HNCO– symmetric stretching |

| 1230–1250 | C–N stretching |

| Sample Codes | T5 wt % (°C) | Tp (°C) | |

|---|---|---|---|

| BF | PBAT | ||

| BF/PBAT | 236.9 | 356.7 | 410.1 |

| BF/MDI-1/PBAT | 264.0 | 357.1 | 409.2 |

| BF/MDI-2/PBAT | 266.4 | 357.4 | 408.2 |

| BF/MDI-3/PBAT | 267.6 | 356.8 | 404.0 |

| BF/MDI-4/PBAT | 266.6 | 358.0 | 408.7 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, X.; Zhang, C.; Weng, Y.; Diao, X.; Song, X. Effect of Diisocyanates as Compatibilizer on the Properties of BF/PBAT Composites by In Situ Reactive Compatibilization, Crosslinking and Chain Extension. Materials 2020, 13, 806. https://doi.org/10.3390/ma13030806

Xie X, Zhang C, Weng Y, Diao X, Song X. Effect of Diisocyanates as Compatibilizer on the Properties of BF/PBAT Composites by In Situ Reactive Compatibilization, Crosslinking and Chain Extension. Materials. 2020; 13(3):806. https://doi.org/10.3390/ma13030806

Chicago/Turabian StyleXie, Xiwei, Caili Zhang, Yunxuan Weng, Xiaoqian Diao, and Xinyu Song. 2020. "Effect of Diisocyanates as Compatibilizer on the Properties of BF/PBAT Composites by In Situ Reactive Compatibilization, Crosslinking and Chain Extension" Materials 13, no. 3: 806. https://doi.org/10.3390/ma13030806

APA StyleXie, X., Zhang, C., Weng, Y., Diao, X., & Song, X. (2020). Effect of Diisocyanates as Compatibilizer on the Properties of BF/PBAT Composites by In Situ Reactive Compatibilization, Crosslinking and Chain Extension. Materials, 13(3), 806. https://doi.org/10.3390/ma13030806