Effect of Ultrasonic Bending Vibration Introduced by the L-shaped Ultrasonic Rod on Solidification Structure and Segregation of Large 2A14 Ingots

Abstract

1. Introduction

2. Material and Methods

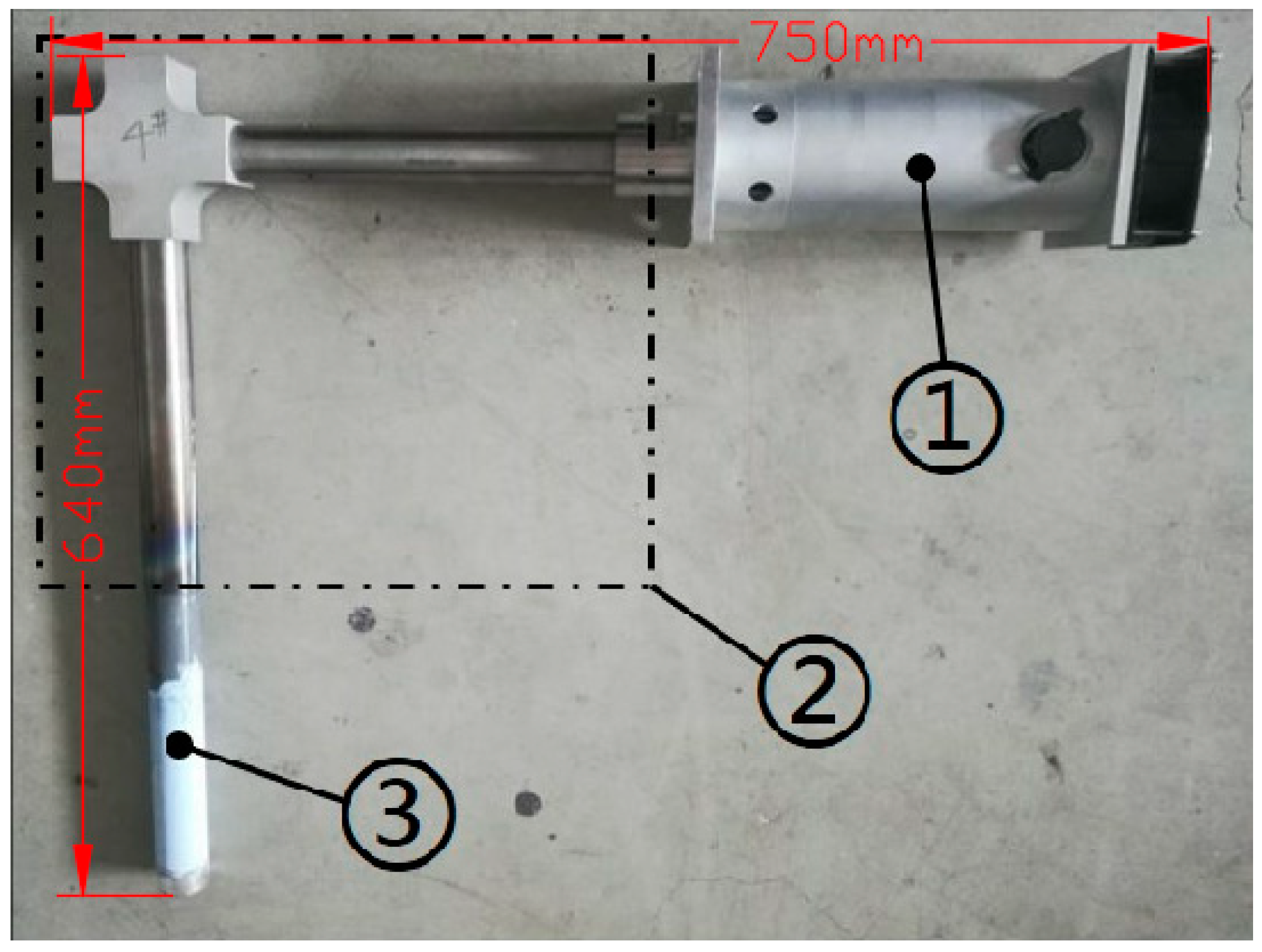

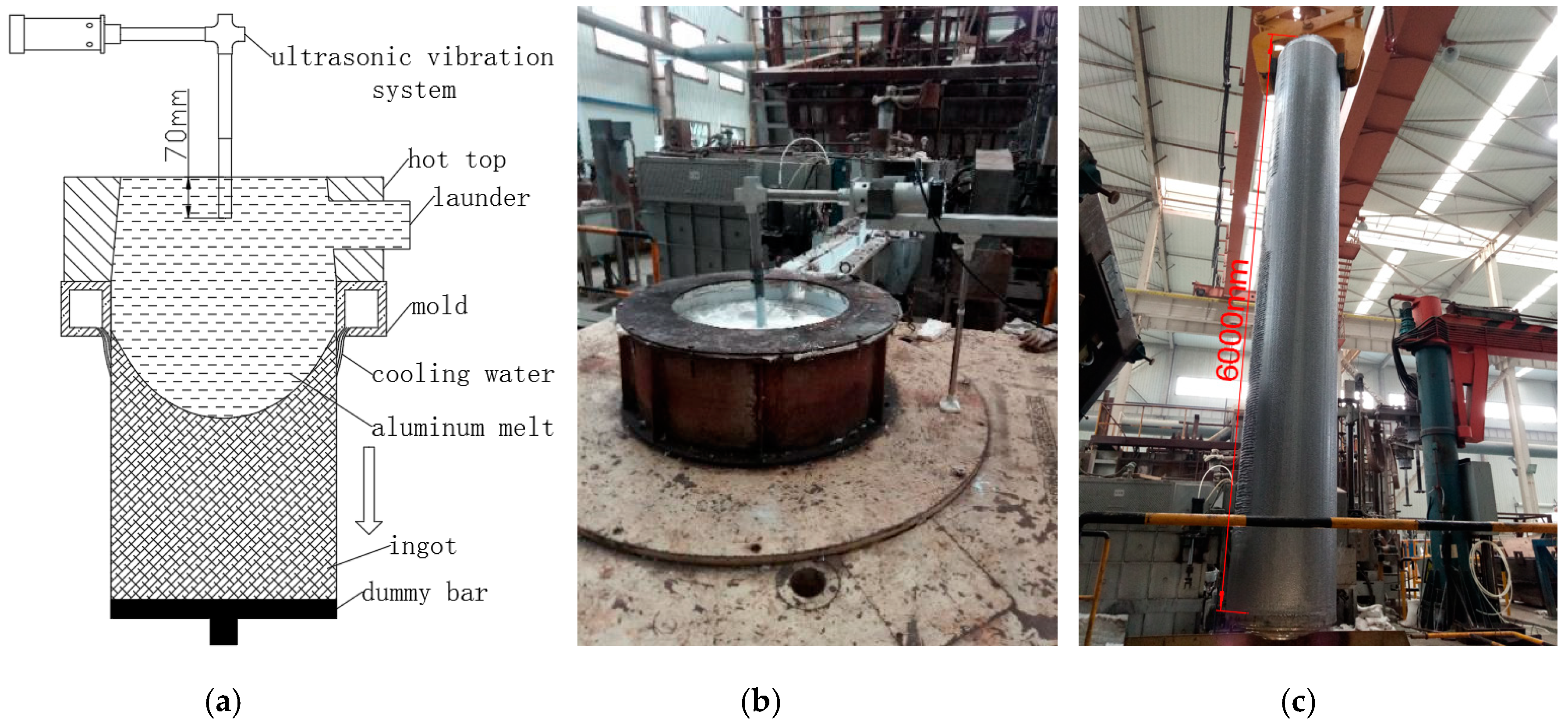

2.1. Experimental Equipment

2.2. Materials

2.3. Experimental Process

3. Results and Discussions

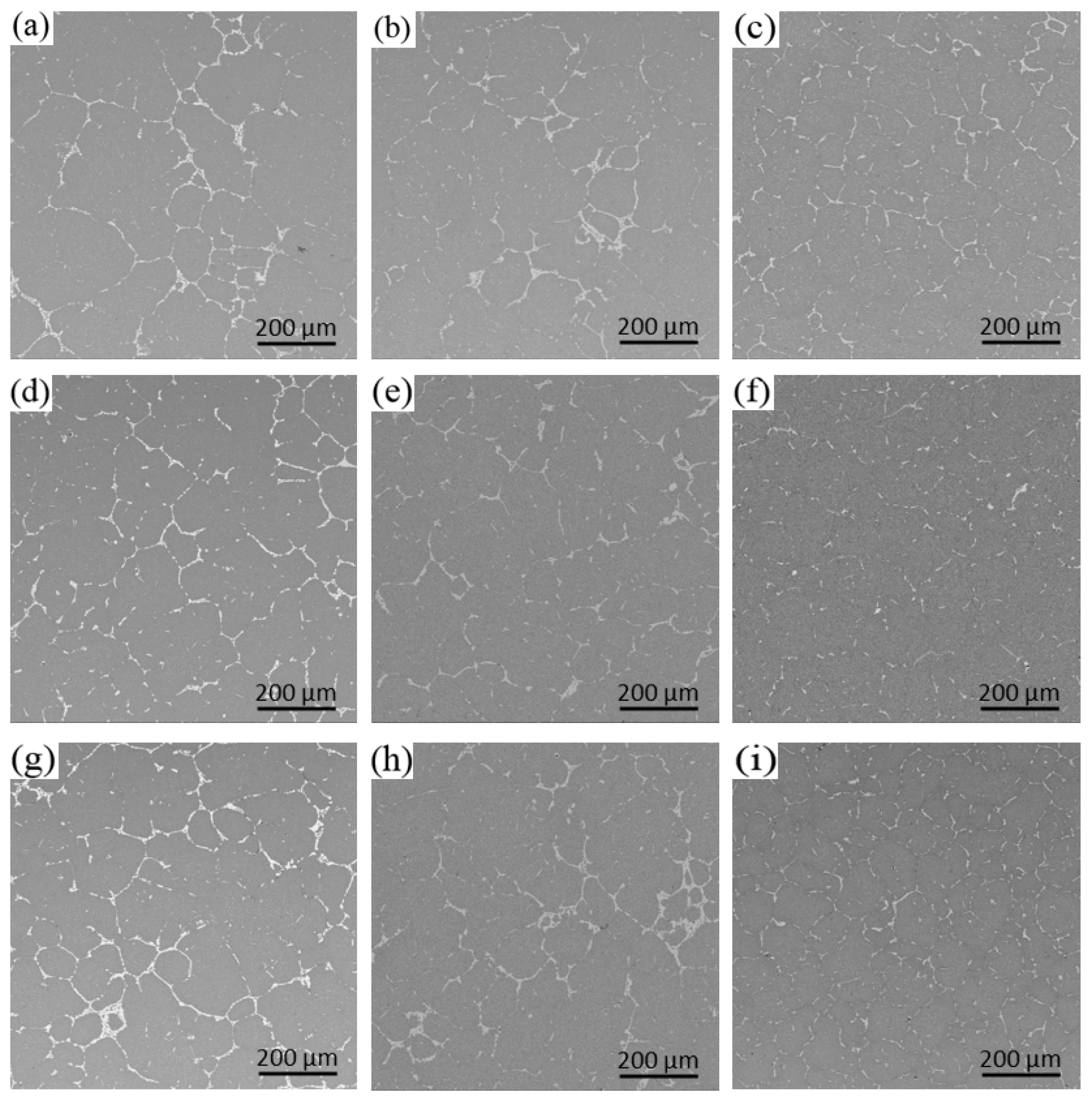

3.1. Effect on Macrostructure

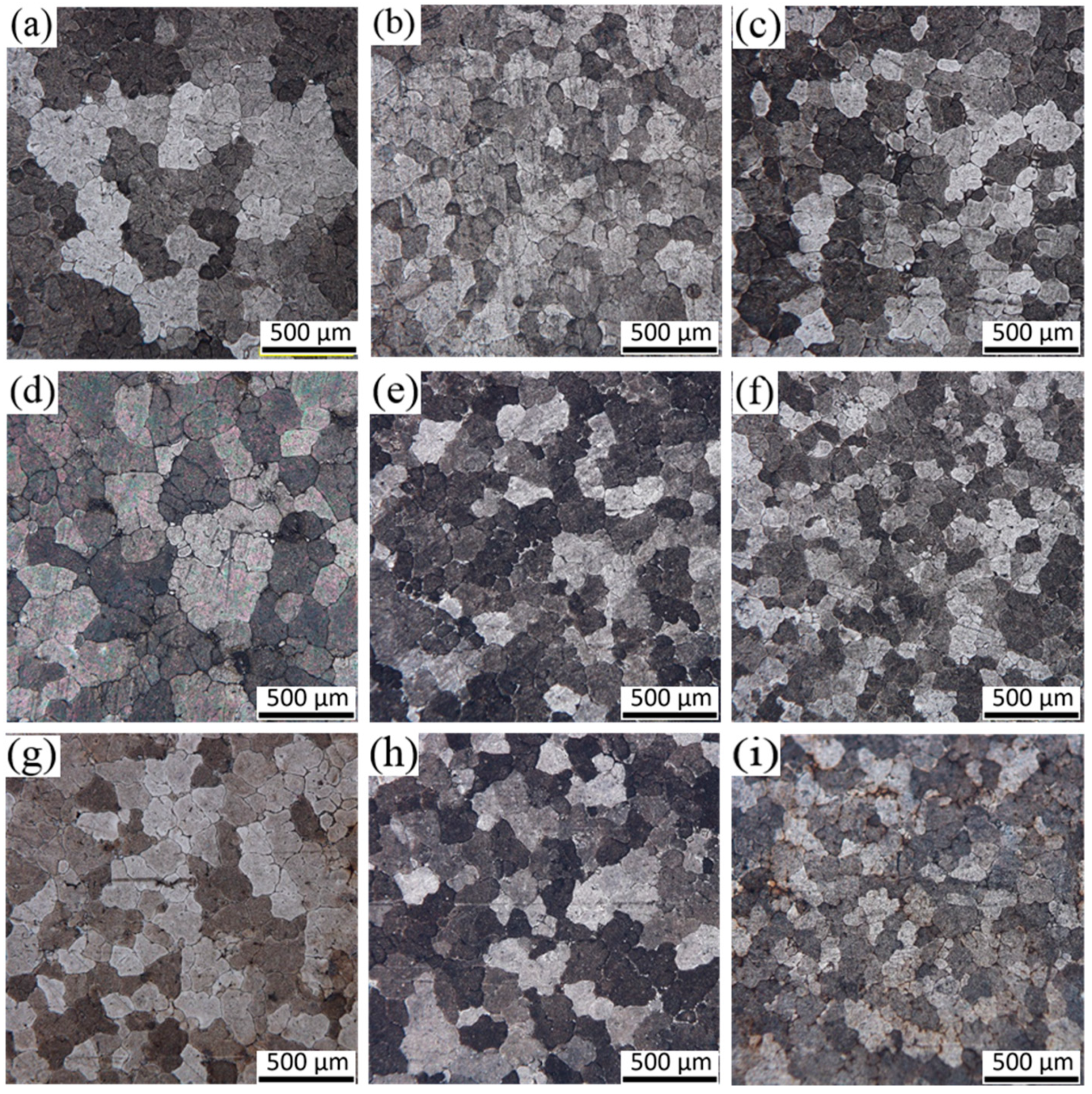

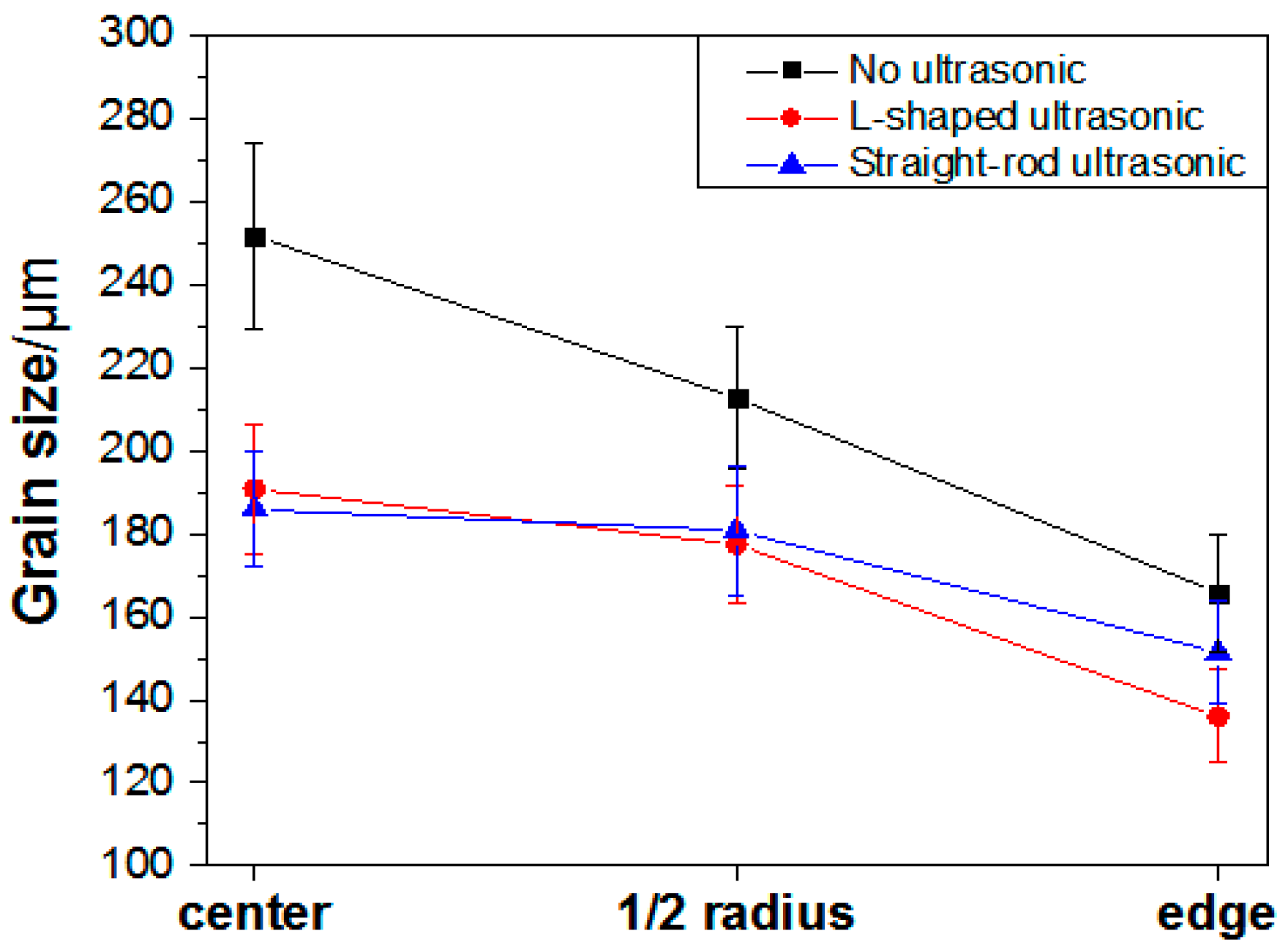

3.2. Effect on Microstructure

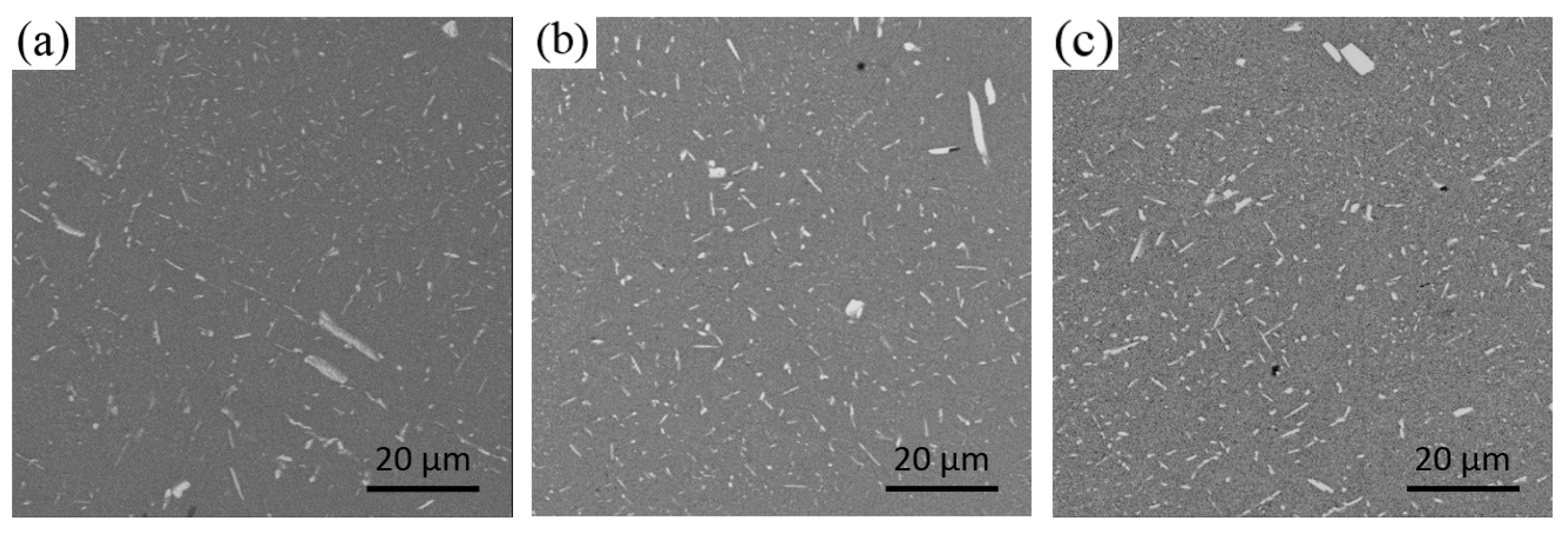

3.3. Effect on the Secondary Phase

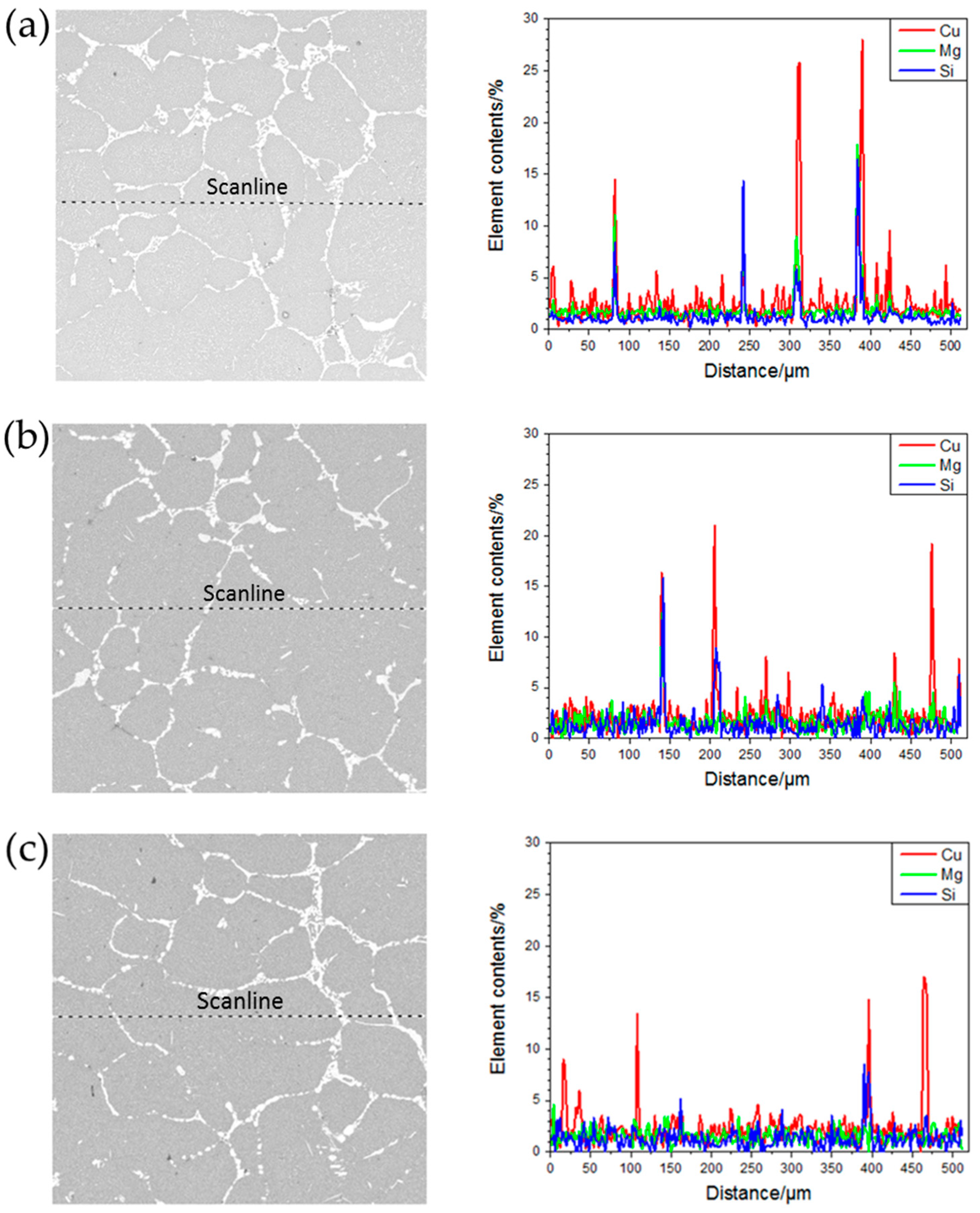

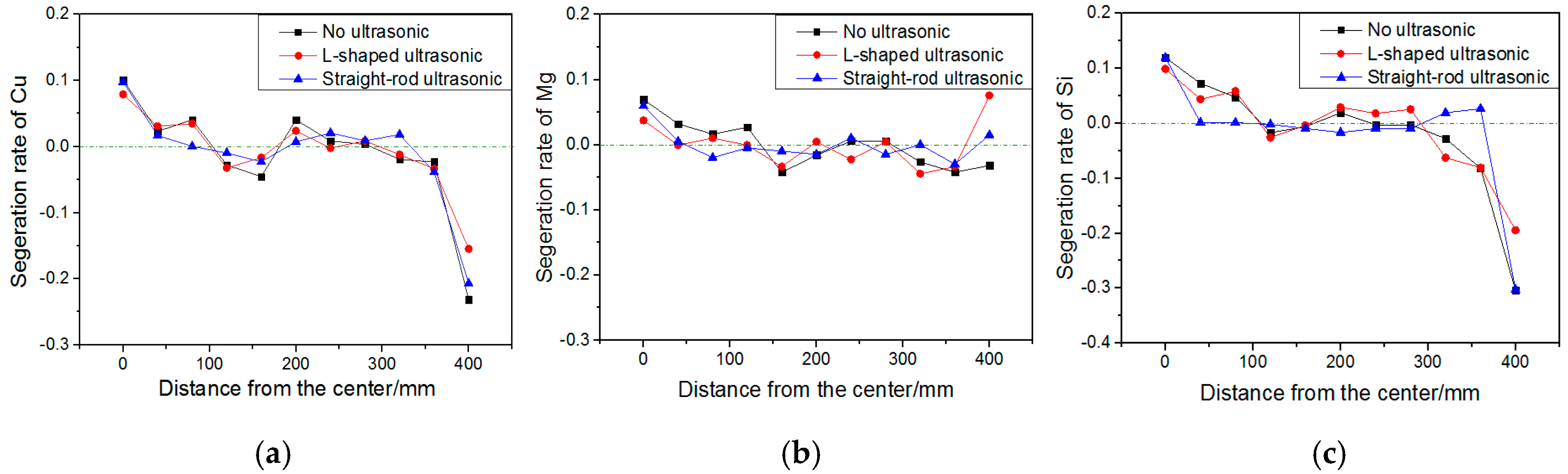

3.4. Effect on MacroSegregation

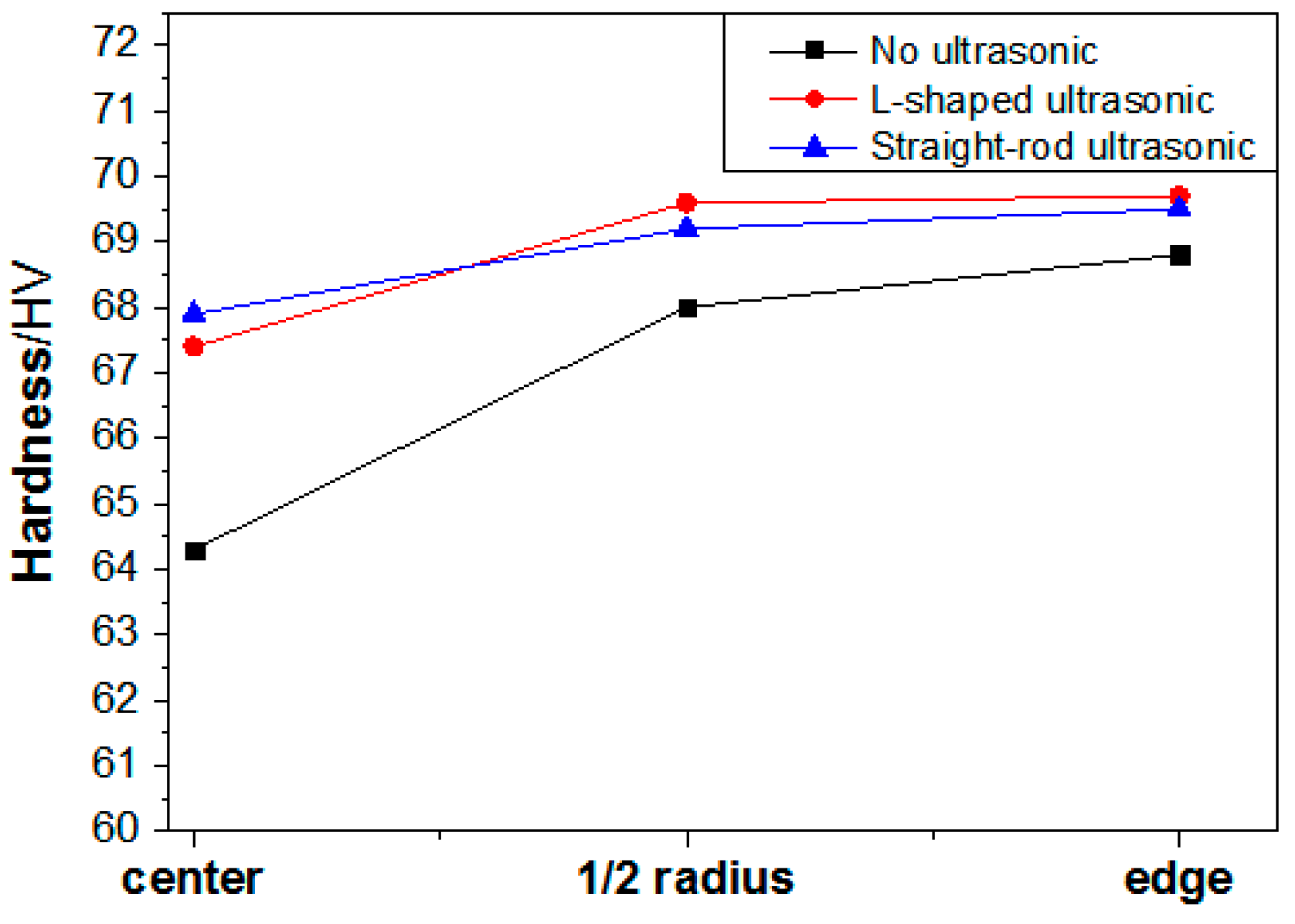

3.5. Effect on Mechanical Property

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gavgali, M.; Aksakal, B. Effects of various homogenisation treatments on the hot workability of ingot aluminium alloy AA2014. Mater. Sci. Eng. 1998, 254, 189–199. [Google Scholar] [CrossRef]

- Yuan, H.R.; Lin, S.B.; Yang, C.L.; Fan, C.L.; Wang, S. Microstructure and porosity analysis in ultrasonic assisted TIG welding of 2014 aluminum alloy. Int. J. Lightweight Mater. Manuf. 2011, 20, 39–43. [Google Scholar]

- Sinan, A.; Bülent, B. Effects of Ageing and Cryo-ageing Treatments on Microstructure and Hardness Properties of AA2014–SiC MMCs. Trans. Indian Inst. Met. 2018, 71, 2035–2042. [Google Scholar]

- Zhao, Y.H.; Lin, S.B.; He, Z.Q.; Wu, L. Microhardness prediction in friction stir welding of 2014 aluminium alloy. Sci. Technol. Weld. Join. 2006, 11, 178–182. [Google Scholar] [CrossRef]

- Ghosh, K.S.; Tripati, K. Microstructural Characterization and Electrochemical Behavior of AA2014 Al-Cu-Mg-Si Alloy of Various Tempers. J. Mater. Eng. Perform. 2018, 27, 5926–5937. [Google Scholar] [CrossRef]

- Ersin, A.G. An Investigation on the Effects of Pre-deformation and Temperature on Thixotropic Microstructure of AA2014 Aluminum Alloy. Trans. Indian Inst. Met. 2016, 69, 935–940. [Google Scholar]

- Fu, J.; Jin, H.J.; Wu, S.J.; Zhang, J.Z. Effect of heat treatment on microstructure and properties of 2A14 aluminum alloy. J. Trans. Mater. Heat. Treat. 2016, 37, 189–194. [Google Scholar]

- Goncalves, M.C.; Martins, M.G.; Misiolek, W.Z.; Van Geertruyden, W.H. Homogenization and Hot Workability of Alloy AA2014. Mater. Sci. Forum 2002, 396–402, 393–398. [Google Scholar] [CrossRef]

- Luo, H.J.; Jie, W.Q.; Gao, Z.M.; Zheng, Y.J. Numerical simulation for macrosegregation in direct-chill casting of 2024 aluminum alloy with an extended continuum mixture model. Trans. Nonferrous Met. Soc. China 2018, 28, 1007–1015. [Google Scholar] [CrossRef]

- Fezi, K.; Plotkowski, A.; Krane, M.J.M. Macrosegregation modeling during direct-chill casting of aluminum alloy 7050. Numer. Heat Transf. Part A Appl. 2016, 70, 1–25. [Google Scholar] [CrossRef]

- Jamaly, N.; Haghdadi, N.; Phillion, A.B. Microstructure, macrosegregation, and thermal analysis of direct chill cast AA5182 aluminum alloy. J. Mater. Eng. Perform. 2015, 24, 2067–2073. [Google Scholar] [CrossRef]

- Li, R.Q.; Liu, Z.L.; Chen, P.H.; Zhong, Z.T.; Li, X.Q. Investigation on the manufacture of a large-scale aluminum alloy ingot: Microstructure and macrosegregation. Adv. Eng. Mater. 2016, 19, 1600375. [Google Scholar] [CrossRef]

- Peng, H.; Li, R.Q.; Li, X.Q.; Ding, S.; Chang, M.J.; Liao, L.Q.; Zhang, Y.; Chen, P.H. Effect of multi-source ultrasonic on segregation of Cu elements in large Al-Cu alloy cast ingot. Materials 2019, 12, 2828. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Dargusch, M.S.; Qian, M.; Eskin, D.G.; StJohn, D.H. The role of ultrasonic treatment in refining the as-cast grain structure during the solidification of an Al–2Cu alloy. J. Cryst. Growth 2014, 408, 119–124. [Google Scholar] [CrossRef]

- Zhao, Z.F.; Qi, J.G.; Zhang, C.J.; Dai, S.; Wang, J.Z. Review on the Application of Liquid Metal Modification on the Study of Solidification Control. J. Foundry Technol. 2011, 32, 722–725. [Google Scholar]

- Liang, G.; Shi, C.; Mao, D.H. Research Progress on External Energy Filed Removing Solidification Forming Defects of Steels. J. Mater. Mech. Eng. 2016, 40, 20–23. [Google Scholar]

- Tzanakis, I.; Lebon, G.S.B.; Eskin, D.G.; Pericleous, K. Investigation of the factors influencing cavitation intensity during the ultrasonic treatment of molten aluminium. J. Mater. Des. 2016, 90, 979–983. [Google Scholar] [CrossRef]

- Abramov, V.; Abramov, O.; Bulgakov, V.; Sommer, F. Solidification of aluminium alloys under ultrasonic irradiation using water-cooled resonator. J. Mater. Lett. 1998, 37, 27–34. [Google Scholar] [CrossRef]

- Eskin, G.I.; Eskin, D.G. Ultrasonic Treatment of Light Alloy Melts, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Liu, Z.L.; Li, R.Q.; Jiang, R.P.; Zhang, L.H.; Li, X.Q. Scalable ultrasound-assisted casting of ultra-large 2219 Al alloy ingots. J. Metall. Mater. Trans. A 2019, 50, 1146–1152. [Google Scholar] [CrossRef]

- Jiang, R.P.; Li, X.Q.; Chen, P.H.; Li, R.Q.; Zhang, X. Effect and kinetic mechanism of ultrasonic vibration on solidification of 7050 aluminum alloy. Aip Adv. 2014, 4, 077125. [Google Scholar] [CrossRef]

- Li, X.Q.; Li, R.Q.; Dong, F.; Chen, P.H.; Jiang, R.P. Simulation and experimental study of cavitation region caused by longitudinal and transverse vibration of casting ultrasonic radiator. IOP Conf. Ser. Mater. Sci. Eng. 2015, 72, 052052. [Google Scholar] [CrossRef]

- Li, R.Q.; Li, X.Q.; Chen, P.H.; Guo, X.; Zhang, M. Effect rules and function mechanism of ultrasonic cavitation on solidification microstructure of large size high-strength aluminum alloy with hot top casting. J. Cent. South Univ. (Sci. Technol.) 2016, 47, 3360. [Google Scholar]

- Tian, Y.; Liu, Z.L.; Li, X.Q.; Zhang, L.H.; Li, R.Q.; Jiang, R.P. The cavitation erosion of ultrasonic sonotrode during large-scale metallic casting: Experiment and simulation. Ultrason. Sonochem. 2018, 43, 29–37. [Google Scholar] [CrossRef] [PubMed]

- Dong, F.; Li, X.Q.; Zhang, M. Experiment and mechanism study on cavitation erosion of ultrasound radiator in aluminum melt. J. Huazhong Univ. Sci. Technol. (Nat. Sci. Ed.) 2015, 43, 85–88. [Google Scholar]

- Dong, F.; Li, X.Q.; Zhang, L.H.; Ma, L.Y.; Li, R.Q. Experiment and mechanism study on cavitation erosion of ultrasound radiator in aluminum melt. Ultrason. Sonochem. 2016, 31, 150–156. [Google Scholar] [CrossRef] [PubMed]

- Liang, G.; Shi, C.; Zhou, Y.J.; Mao, D.H. Effect of ultrasonic treatment on the solidification microstructure of die-cast 35crmo steel. Metals 2016, 6, 260. [Google Scholar] [CrossRef]

- Guo, C.X.; Li, X.Q.; Zhang, M.; Jiang, R.P. Dynamic characteristics study of ultrasonic transducer system for casting. J. Mach. Des. 2015, 32, 47–50. [Google Scholar]

- Haghayeghi, R.; Ezzatneshan, E.; Bahai, H. Grain refinement of AA5754 aluminum alloy by ultrasonic cavitation: Experimental study and numerical simulation. Met. Mater. Int. 2014, 21, 109–117. [Google Scholar] [CrossRef]

- Zheng, D.S.; Chen, R.R.; Wang, J.; Ma, T.F. Novel casting TiAl alloy with fine microstructure and excellent performance assisted by ultrasonic melt treatment. Mater. Lett. 2017, 200, 67–70. [Google Scholar]

- Chen, D.D.; Zhang, H.T.; Wang, X.J.; Cui, J.Z. Investigation on microsegregation of Al-4.5%Cu alloy produced by low frequency electromagnetic casting. Acta Metall. Sin. 2011, 47, 185–190. [Google Scholar]

| Element | Si | Cu | Mg | Zn | Mn | Ti | Ni | Fe | Al |

|---|---|---|---|---|---|---|---|---|---|

| Content | 0.6–1.2 | 3.9–4.8 | 0.4–0.8 | ≤0.30 | 0.4–1.0 | ≤0.15 | ≤0.10 | 0.0–0.7 | Bal. |

| Size/mm | Pouring Temperature/°C | Cooling Temperature/°C | Speed of Water Flow/(L/min) | Speed of Introducing Ingot/(mm/min) |

|---|---|---|---|---|

| φ 830 × 6000 | 706 | 24 | 540 | 22 |

| Solute Elements | No Ultrasonic | L-Shaped Ultrasonic | Straight-Rod Ultrasonic |

|---|---|---|---|

| Cu | 3.40 | 3.65 | 3.68 |

| Si | 0.89 | 1.21 | 1.17 |

| Mg | 0.94 | 1.07 | 1.09 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, C.; Wu, Y.; Mao, D.; Fan, G. Effect of Ultrasonic Bending Vibration Introduced by the L-shaped Ultrasonic Rod on Solidification Structure and Segregation of Large 2A14 Ingots. Materials 2020, 13, 807. https://doi.org/10.3390/ma13030807

Shi C, Wu Y, Mao D, Fan G. Effect of Ultrasonic Bending Vibration Introduced by the L-shaped Ultrasonic Rod on Solidification Structure and Segregation of Large 2A14 Ingots. Materials. 2020; 13(3):807. https://doi.org/10.3390/ma13030807

Chicago/Turabian StyleShi, Chen, Yongjun Wu, Daheng Mao, and Gaofeng Fan. 2020. "Effect of Ultrasonic Bending Vibration Introduced by the L-shaped Ultrasonic Rod on Solidification Structure and Segregation of Large 2A14 Ingots" Materials 13, no. 3: 807. https://doi.org/10.3390/ma13030807

APA StyleShi, C., Wu, Y., Mao, D., & Fan, G. (2020). Effect of Ultrasonic Bending Vibration Introduced by the L-shaped Ultrasonic Rod on Solidification Structure and Segregation of Large 2A14 Ingots. Materials, 13(3), 807. https://doi.org/10.3390/ma13030807