The Influence of the Welding Process on the Ultrasonic Inspection of 9%Ni Steel Pipe Circumferential Welded Joints

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

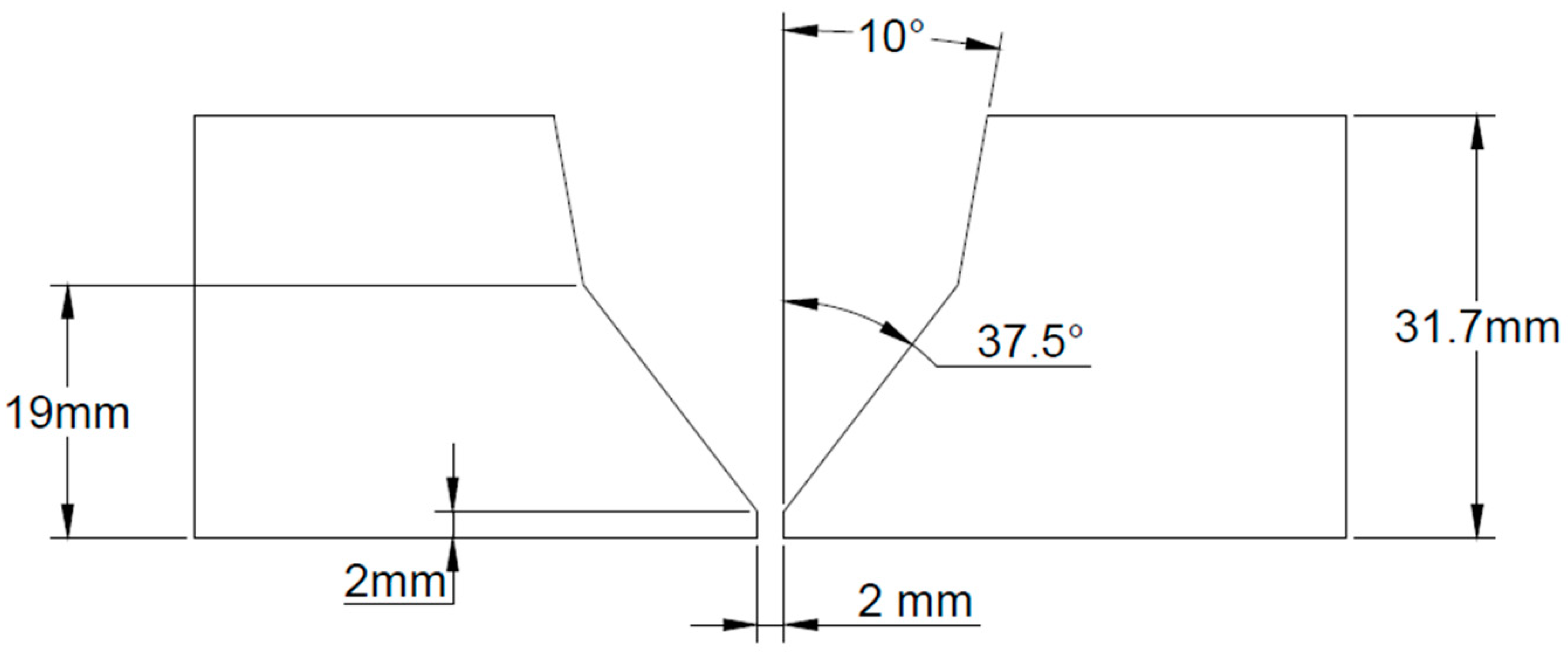

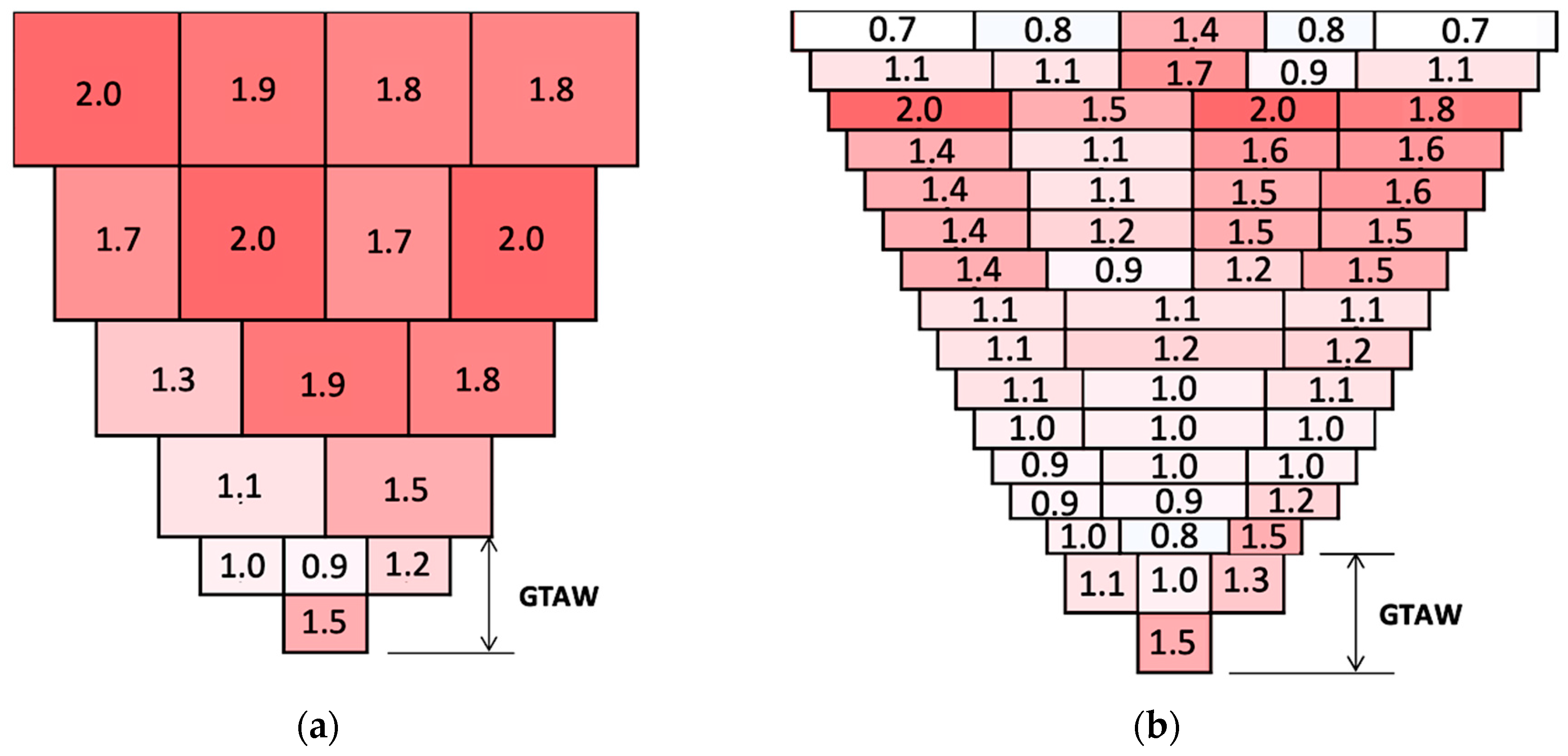

2.2.1. Welding

2.2.2. Ultrasonic Tests

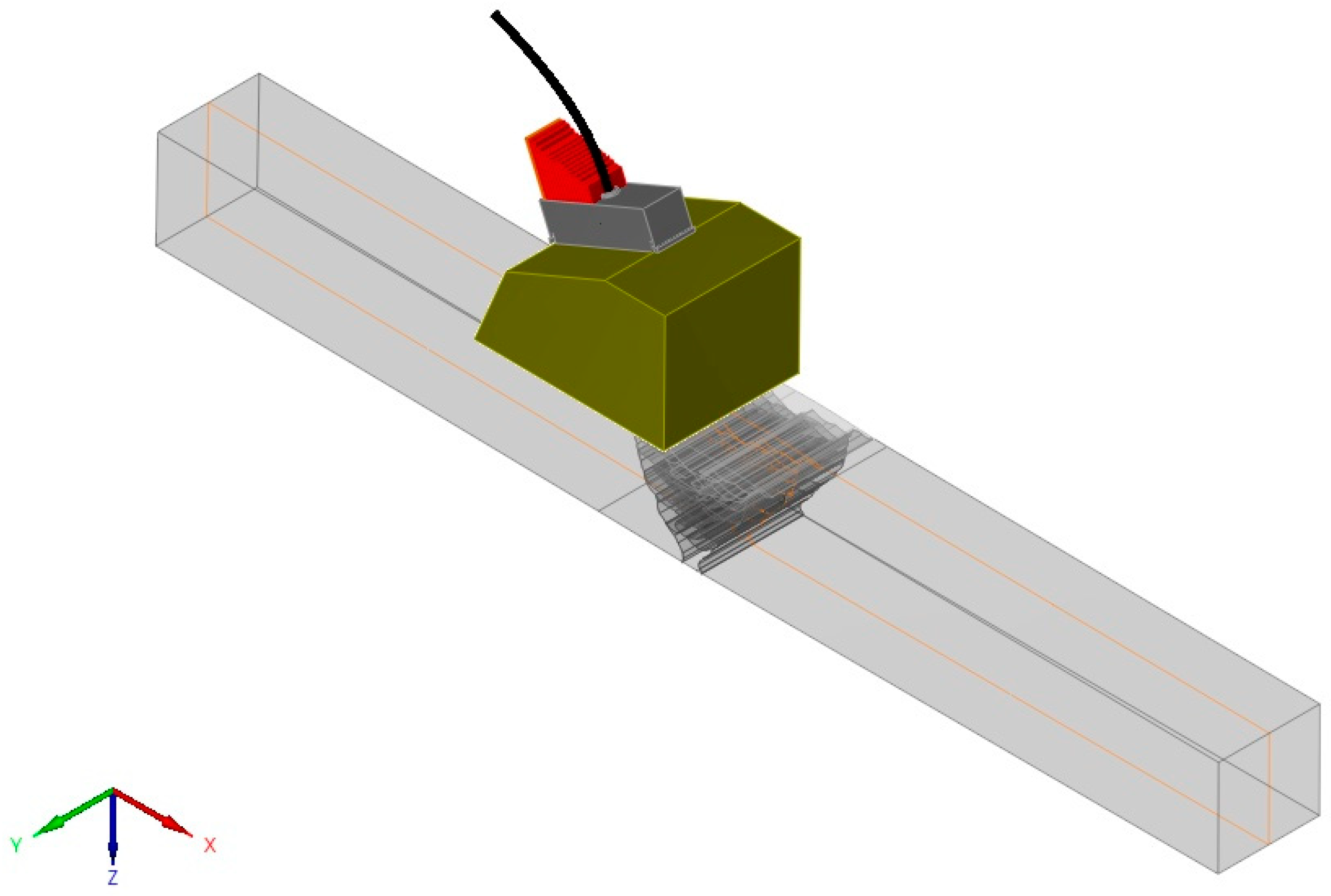

2.2.3. Computational Simulation Procedure

2.2.4. Metallographic Characterization

3. Results

3.1. Preliminary Tests

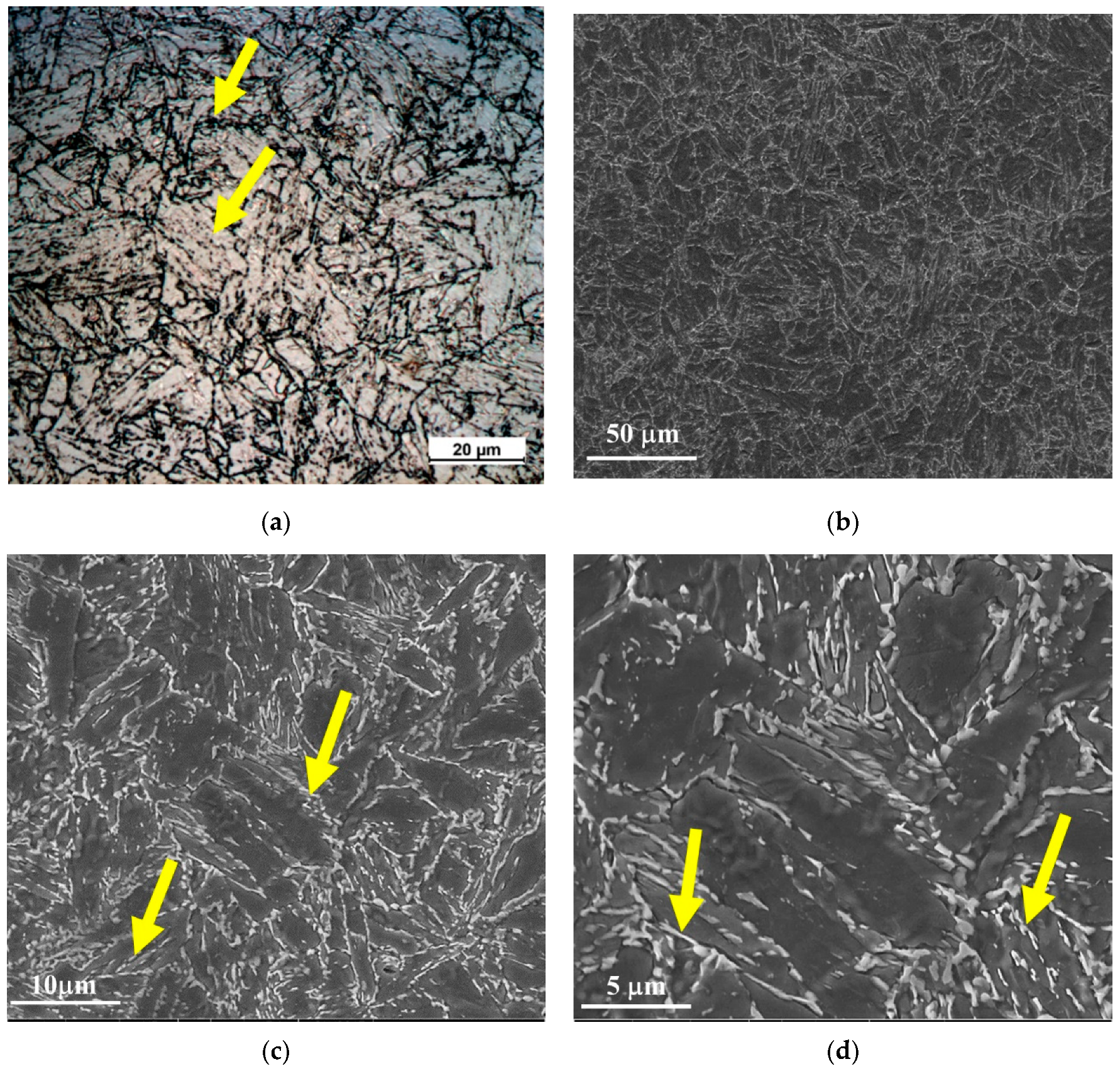

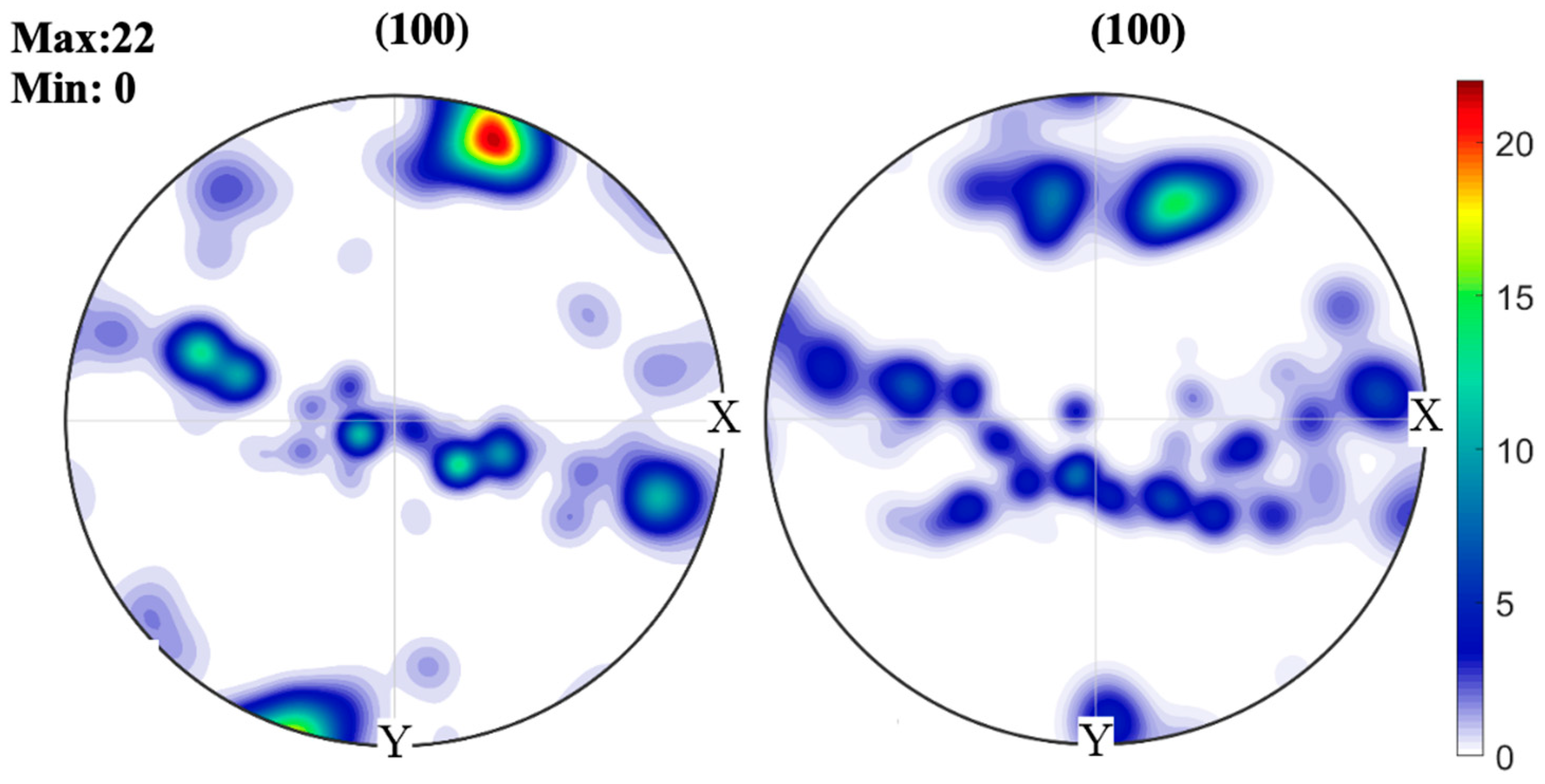

3.2. Microstructural Characterization

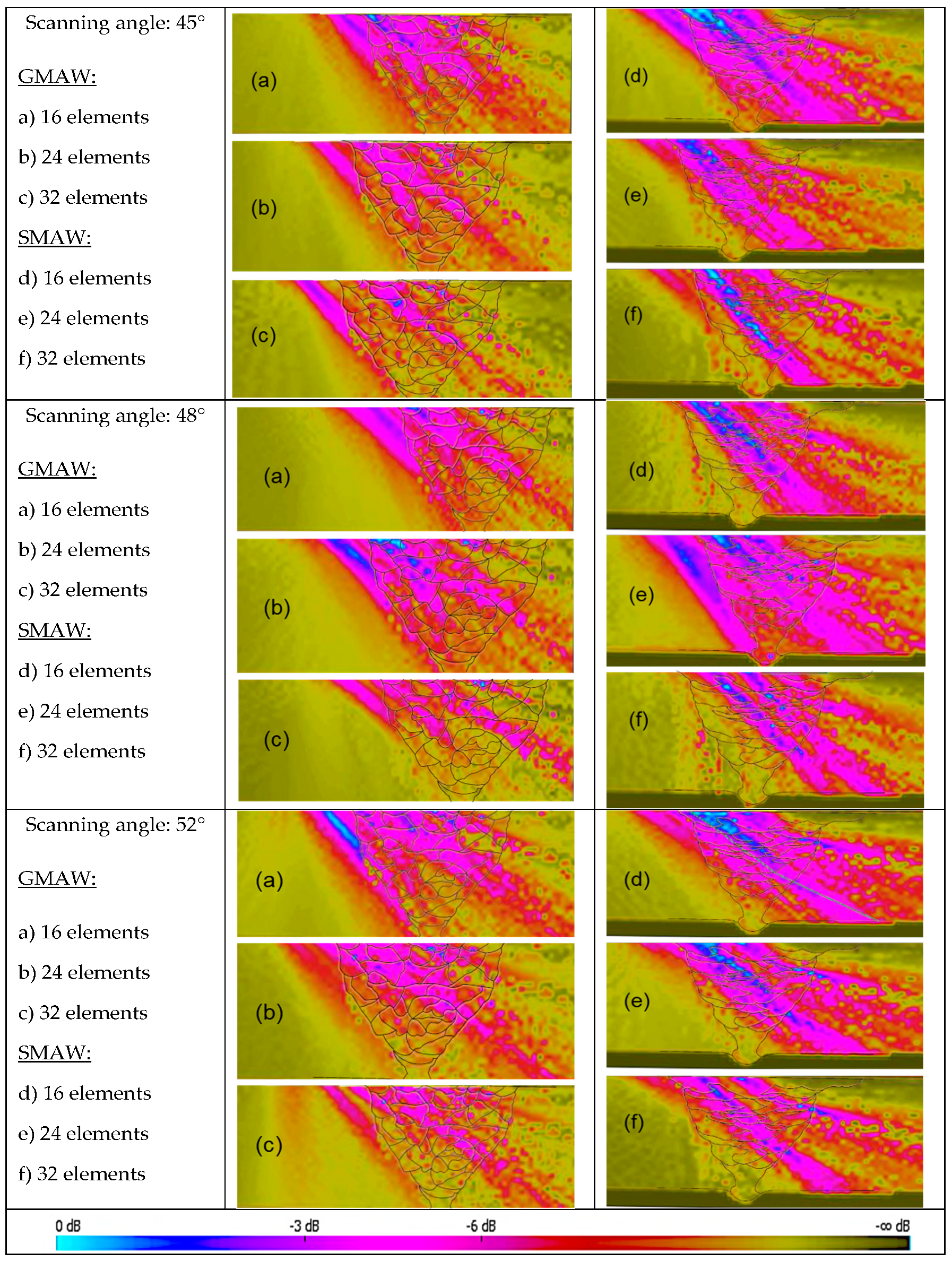

3.3. Computational Simulation

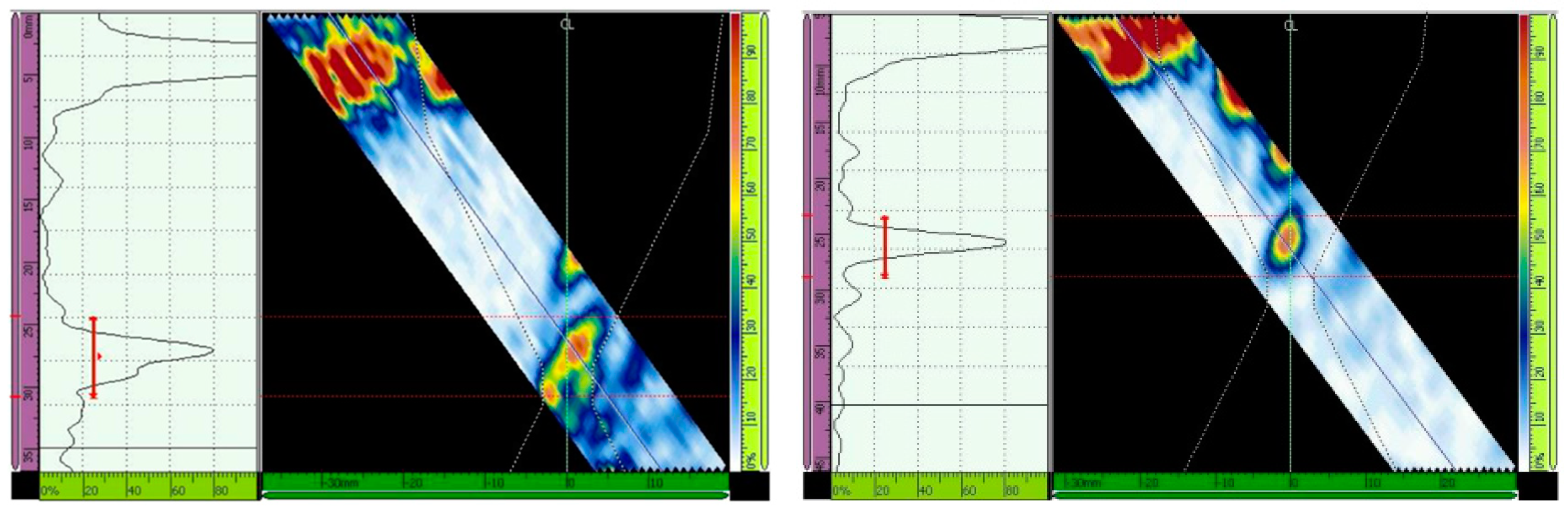

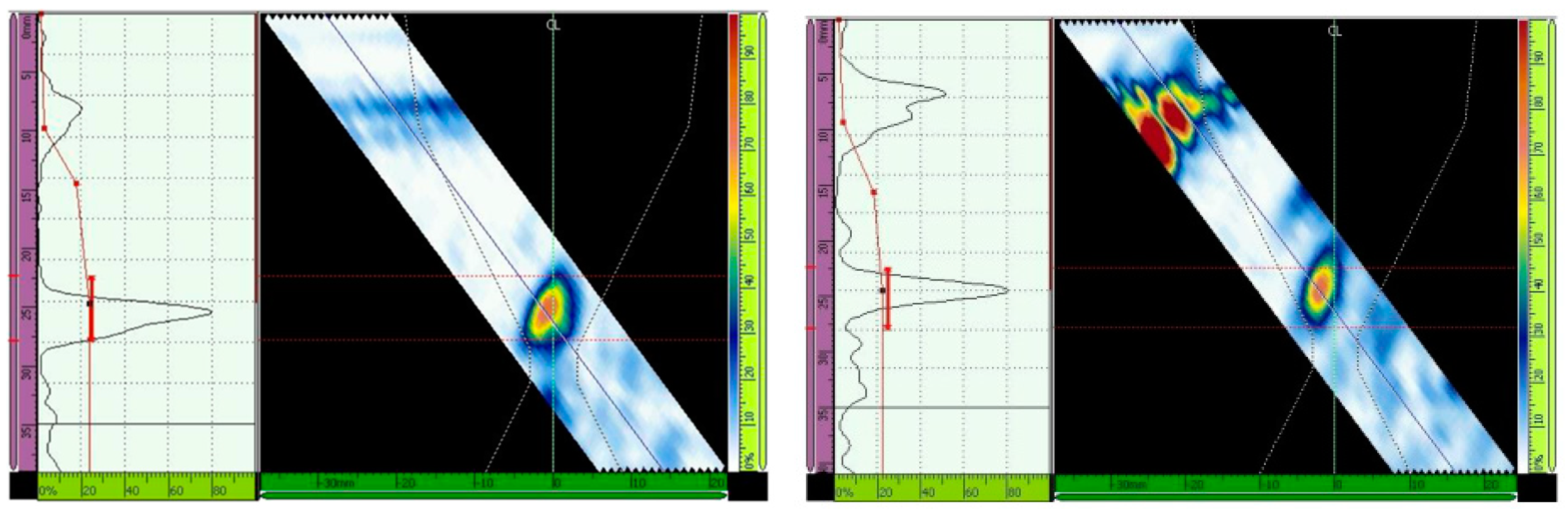

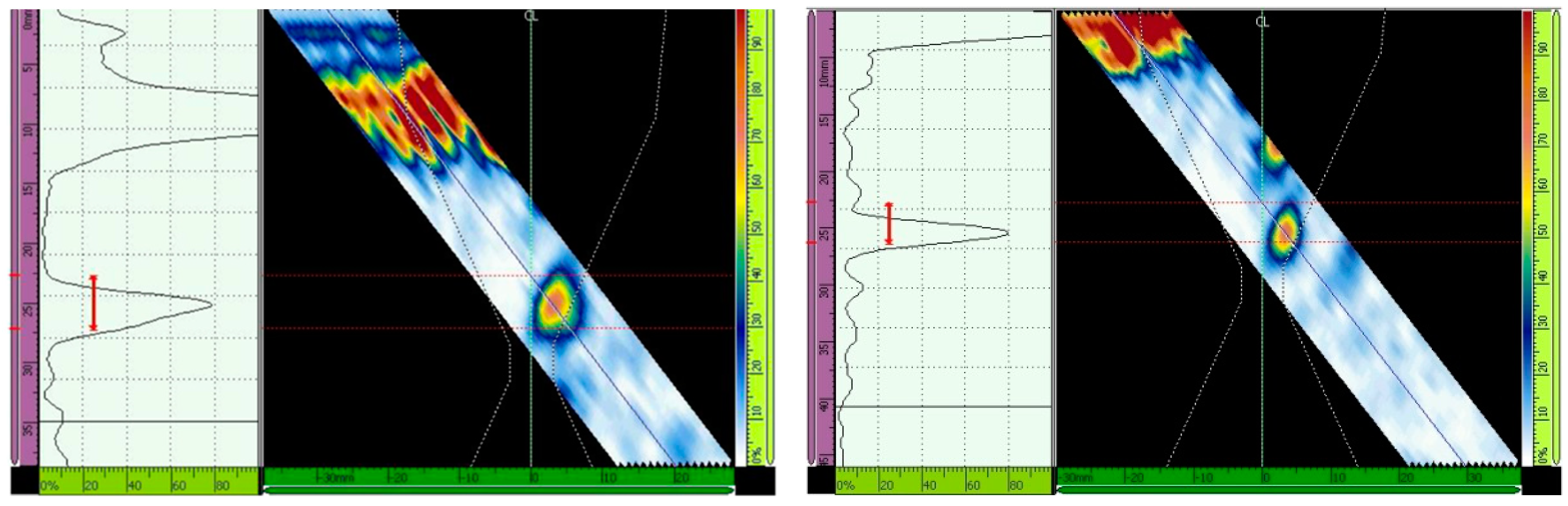

3.4. Ultrasonic Testing

4. Discussion

4.1. Preliminary Tests and Characterization

- α = attenuation factor (dB/mm);

- ΔVg = difference in amplitude of the first two echoes (dB);

- d = thickness of the material (mm).

4.2. Computational Simulation

4.3. Ultrasonic Tests

5. Conclusions

- Preliminary tests revealed that the attenuation is significantly greater in GMAW joints than in SMAW joints.

- The CIVA simulation showed that the results for the SMAW joint were significantly better than those for the GMAW joint in terms of sound pressure and attenuation. The sonic beam covered almost all the weld metal, although the GMAW process needed greater sonic pressure to ensure the same behavior, which compromised the signal-to-noise ratio.

- The configuration with 16 active elements proved to be the most effective scanning technique for SMAW and GMAW joints inspection, covering a large volume of the weld using the same combination of low frequency (2.25 MHz) and angles of 45° and 48°.

- Ultrasonic tests revealed that the inspection configuration with longitudinal waves and angles of 45°, 48°, and 52° allowed the detection of the three holes aligned along the fusion line of the calibration block. However, the scanning incidence angle of 48° showed the best results.

- The results of the longitudinal wave inspection showed an optimized parameter range; as the scanning angle moved away from this range, the signal-to-noise increased, which could jeopardize defect detection and size estimation.

- The experimental tests validated the simulation results, and the hypothetical assumptions were confirmed.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tenge, P.; Solli, O.; Forli, O. Significance of defects in liquefied natural gas tanks in ships. In Properties of Materials for Liquefied Natural Gas Tankage; Kaufman, J., Ed.; ASTM International: West Conshohocken, PA, USA, 1975; pp. 10–43. [Google Scholar]

- Rentala, V.; Mylavarapu, P.; Gopinath, K.; Gautam, J.; Kumar, V. Effect of Elliptical Crack Aspect Ratio on Its Probability of Detection. NDT Net. Non-Destructive Evaluation 2016. Available online: https://pdfs.semanticscholar.org/7579/f282e33c4d48df1cfdd16783929df42b4ac9.pdf (accessed on 1 September 2018).

- Neumann, A.W.E. On the state of the art of the inspection of austenitic welds with ultrasound. Int. J. Press. Vessel. Pip. 1989, 39, 227–246. [Google Scholar] [CrossRef]

- Gueudré, C.; Le Marrec, L.; Chekroun, M.; Moysan, J.; Chassignole, B.; Corneloup, G. Determination of the order of passes of an austenitic weld by optimization of an inversion process of ultrasound data. AIP Conf. Proc. 2011, 1335, 639. [Google Scholar] [CrossRef]

- Fan, Z.; Mark, A.F.; Lowe, M.J.; Withers, P.J. Nonintrusive estimation of anisotropic stiffness maps of heterogeneous steel welds for the improvement of ultrasonic array inspection. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2015, 62, 1530–1543. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chassignole, B.; El Guerjouma, R.; Ploix, M.-A.; Fouquet, T. Ultrasonic and structural characterization of anisotropic austenitic stainless steel welds: Towards a higher reliability in ultrasonic non-destructive testing. NDT E Int. 2010, 43, 273–282. [Google Scholar] [CrossRef]

- Moysan, J.; Corneloup, G. Modelling welded material for ultrasonic testing using MINA: Theory and applications. AIP Conf. Proc. 2012, 1430, 1219. [Google Scholar] [CrossRef]

- Tomlinson, J.R.; Wagg, A.R.; Whittle, M.J. Ultrasonic Inspection of Austenitic Welds (IWGFR--35); International Atomic Energy Agency (IAEA): Manchester, UK, 1980. [Google Scholar]

- Hirsekorn, S. Directional dependence of ultrasonic propagation in textured polycrystals. J. Acoust. Soc. Am. 1986, 79, 1269. [Google Scholar] [CrossRef]

- Payão Filho, J.d.C.; Passos, E.K.D.; Gonzaga, R.S.; Ferreira, R.F.; Santos, D.D.; Juliano, D.R. Ultrasonic inspection of a 9%Ni steel joint welded with Ni-based superalloy 625: Simulation and Experimentation. Metals 2018, 8, 787. [Google Scholar] [CrossRef] [Green Version]

- Standard Specification for Seamless and Welded Steel Pipe for Low-Temperature Service and other Applications with Required Notch Toughness; ASTM A333/A333M-16 2016:4; ASTM International: West Conshohocken, PA, USA, 2016. [CrossRef]

- American Welding Society. Technical Activities Committee. A5.14/A5.14M:2018 Specification for Nickel and Nickel-Alloy Bare Welding Electrodes and Rods. 2018. Available online: https://pubs.aws.org/p/1788/a514a514m2018-specification-for-nickel-and-nickel-alloy-bare-welding-electrodes-and-rods (accessed on 12 August 2018).

- American Welding Society. Technical Activities Committee. A5.11/A5.11M:2018 Specification for Nickel and Nickel-Alloy Welding Electrodes for Shielded Metal Arc Welding. 2018. Available online: https://pubs.aws.org/Download_PDFS/A511_A511M_2018_Web_PV.pdf (accessed on 12 August 2018).

- Olympus NDT. Ultrasonic Transducers Technical Notes; Tech Broch Olympus NDT: Waltham, MA, USA, 2006. [Google Scholar]

- United Kingdom Atomic Energy Authority Northern Division. The Ultrasonic Inspection of Austenitic Materials—State of the Art Report; OECD Nuclear Energy Agency: Oxfordshire, UK, 1985. Available online: https://www.oecd-nea.org/nsd/docs/1985/csni85-94.pdf (accessed on 3 February 2019).

- Papadakis, E.P. Ultrasonic attenuation caused by scattering in polycrystalline metals. J. Acoust. Soc. Am. 1965, 37, 711. [Google Scholar] [CrossRef]

- Jahrsengene, G.; Wenn, M.; Karlsen, M.; Westermann, I.; Akselsen, O.M.; Hjelen, J. EBSD Quantification of Retained Austenite in 9% Ni Steel Related to Thermal Treatments; International Society of Offshore and Polar Engineers: Trondheim, Norway, 2015. [Google Scholar]

- Bhadeshia, H.K.D.H.; Keehan, E.; Karlsson, L.; Andrén, H.O. Coalesced Bainite. Trans. Indian Inst. Metals 2006, 59, 689–694. [Google Scholar]

- Keehan, E.; Karlsson, L.; Andrén, H.O.; Bhadeshia, H.K.D.H. Understanding Mechanical Properties of Novel High Strength Steel Weld Metals through High-Resolution Microstructural Investigations. In Proceedings of the International Conference: Trends in Welding Research, Alanta, GA, USA, 16–20 May 2005; Available online: https://www.phase-trans.msm.cam.ac.uk/2005/coalesce.pdf (accessed on 15 July 2019).

- Kou, S.; Yang, Y.K. Fusion-boundary macrosegregation in dissimilar-filler welds. Weld. J. 2007, 86, 303s–312s. [Google Scholar]

- Reinhart, G.; Buffet, A.; Billia, B.; Jung, H. In-situ and real-time analysis of the formation of strains and microstructure defects during solidification of Al-3.5 wt. pct. Ni alloys. Metall. Mater. Trans. A 2008, 39, 865–874. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.L.; Wei, H.L.; Xue, J.X.; DebRoy, T. A pathway to microstructural refinement through double pulsed gas metal arc welding. Scr. Mater. 2017, 134, 61–65. [Google Scholar] [CrossRef]

- Suwas, S.; Ray, R.K. Crystallographic Texture of Materials, 1st ed.; Springer: London, UK, 2014. [Google Scholar]

- Martin, C.C. Material Didático, Ultrassom, 2nd ed.; ABENDI: São Paulo, Brazil, 2012; p. 342. ISBN 978-85-99153-06-2. [Google Scholar]

- Kurtulmuş, M.; Yükler, I. Effects of probe properties on ultrasonic inspection of austenitic stainless steel weldments. Sci. Res. Essays 2011, 6, 305–312. [Google Scholar]

- Hirasawa, T.; Fukutomi, H.; Ishii, A. Basic Study on the Phased Array UT Technique for Crack Depth Sizing in Ni-Based Alloy Weld. E-J. Adv. Maint. 2013, 5, 146–154. [Google Scholar]

- Wagner, S.; Dugan, S.; Stubenrauch, S.; Jacobs, O. Modification of the grain structure of austenitic welds for improved ultrasonic inspectability. In Proceedings of the 38th MPA-Seminar 2012 Power generation and energy efficiency Materials and component behaviour, Stuttgart, Germany, 1 October 2012; p. 607. [Google Scholar]

- Freitas, M.I. Development of an Ultrasonic Phased Array System to Inspect Welded Joints of Low Thickness Austenitic Steel. Master’s Thesis, Universidade de Lisboa, Lisbon, Portugal, May 2016. [Google Scholar]

- Wooh, S.C.; Shi, Y. Influence of phased array element size on beam steering behavior. Ultrasonics 1998, 36, 737–749. [Google Scholar] [CrossRef]

| Mechanical Property | Base Metal ASTM A333 Gr. 8 (9%Ni Steel) | Filler Metal Ni-Based Superalloy 625 Typical Value | |||

|---|---|---|---|---|---|

| Specified (min) | Analyzed | GTAW | GMAW | SMAW | |

| YS (MPa) | 515 | 693 | 510 | 510 | 530 |

| UTS (MPa) | 690 | 740 | 770 | 770 | 770 |

| El. (%) | 22 | 25 | 42 | 42 | 30 |

| CVEn (−196 °C) (J) | N.A. | 146 | 70 | 70 | 45 |

| CVEx (mm) | 0.38 | 1.78 | N.A. | N.A. | N.A. |

| Element | Chemical Composition (% in Weight) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Base Metal | Filler Metal | Weld Metal (Analyzed) | |||||||

| Specified | GTAW/GMAW | GTAW | GMAW | SMAW | GTAW | GMAW | SMAW | ||

| Specified | Informed by the Supplier | Specified | Informed by the Supplier | ||||||

| C | 0.13 | <0.1 | 0.008 | 0.010 | <0.1 | 0.0326 | 0.08 | 0.0164 | 0.0326 |

| Mn | 0.9 | <0.5 | 0.02 | 0.02 | <1.0 | 0.887 | 0.0757 | 0.103 | 0.887 |

| Si | 0.13/0.32 | <0.5 | 0.05 | 0.05 | <0.75 | 0.494 | 0.0784 | 0.102 | 0.494 |

| P | 0.025 | <0.02 | 0.006 | 0.006 | <0.03 | 0.0035 | <0.0003 | <0.0003 | 0.0035 |

| S | 0.025 | <0.015 | 0.000 | 0.000 | <0.02 | 0.0088 | 0.0009 | 0.0025 | 0.0088 |

| Ni | 8.4/9.6 | >58 | 65.10 | 65.00 | >55 | 63.1 | 62.9 | 65.0 | 63.1 |

| Cu | N.A. | <0.5 | 0.03 | 0.02 | <0.5 | 0.0061 | 0.0354 | 0.0261 | 0.0061 |

| Ti | N.A. | <0.4 | 0.183 | 0.206 | N.A. | 0.0694 | 0.201 | 0.199 | 0.0694 |

| Cr | N.A. | 20/23 | 21.66 | 21.50 | 20/23 | 20 | 20.2 | 20.1 | 20 |

| Mo | N.A. | 8/10 | 8.73 | 8.89 | 8/10 | 8.95 | 8.93 | 9.63 | 8.95 |

| Fe | Balance | <5.0 | 0.430 | 0.380 | <7.0 | 2.49 | 3.49 | 0.840 | 2.49 |

| Pb | N.A. | N.A. | 0.000 | 0.000 | N.A. | 0.0504 | 0.0408 | 0.0386 | 0.0504 |

| Al | N.A. | <0.4 | 0.140 | 0.180 | N.A. | <0.0005 | 0.127 | 0.148 | <0.0005 |

| Nb + Ta | N.A. | 3.15/4.15 | 3.660 | 3.6900 | 3.15/4.15 | 3.478 | 3.435 | 3.3170 | 3.478 |

| Co | N.A. | N.A. | N.A. | N.A. | 0.12 | N.A. | 0.0522 | 0.0682 | N.A. |

| V | N.A. | N.A. | N.A. | N.A. | N.A. | N.A. | 0.0345 | 0.0445 | N.A. |

| W | N.A. | N.A. | N.A. | N.A. | N.A. | N.A. | 0.0248 | 0.0343 | N.A. |

| Welding Parameter | Welding Process/Pass | ||||||

|---|---|---|---|---|---|---|---|

| GTAW | GMAW | SMAW | |||||

| Root | Hot | Fill | Cap | Fill | Cap | ||

| Current (A) | 123 | 120 | 111 | 114 | 90 | 89 | |

| Voltage (V) | 11 | 10 | 26 | 26 | 26 | 26 | |

| Welding speed (cm/min) | 5.1 | 7.5 | 10.8 | 9.5 | 12.6 | 18 | |

| Average heat input (kJ/mm) | 1.5 | 1.0 | 1.7 | 1.9 | 1.2 | 0.9 | |

| Gas type and flow rate (L/min) | Shielding | Ar */12 | 75%Ar + 25%He/16 | N.A. | N.A. | ||

| Purge | Ar */25 | N.A. | N.A. | N.A. | N.A. | ||

| Electrode/Wire type | ERNiCrMo-3 | ERNiCrMo-3 | ENiCrMo-3 | ||||

| Electrode/Wire diameter | 2.4 mm | 1.2 mm | 3.25 mm | ||||

| Polarity | - | DC- | DC+ | DC+ | |||

| Tip angle | - | 60° | N.A. | N.A. | |||

| Stick out | - | N.A. | 15 mm | N.A. | |||

| C11 | C12 | C13 | C23 | C22 | C33 | C44 | C55 | C66 |

|---|---|---|---|---|---|---|---|---|

| 250 | 112 | 180 | 138 | 250 | 250 | 117 | 91 | 70 |

| Scanning Angle (°) | No. of Active Elements |

|---|---|

| 45 | 16, 24, 32 |

| 48 | 16, 24, 32 |

| 52 | 16, 24, 32 |

| Region | Attenuation (dB/mm) |

|---|---|

| 9%Ni steel base metal | 0.098 |

| Weld metal of the GMAW joint | 0.225 |

| Weld metal of the SMAW joint | 0.146 |

| Scanning Angle (o) | Primary Gain (dB) | |||||

|---|---|---|---|---|---|---|

| GMAW Joint | SMAW Joint | |||||

| From the 3rd Hole | After Tracing the TCG | ΔdB | From the 3rd Hole | After Tracing the TCG | ΔdB | |

| 45 | 44.2 | 33.5 | 10.7 | 50 | 22.8 | 27.2 |

| 48 | 37.3 | 21.4 | 15.9 | 40.1 | 22.6 | 17.5 |

| 52 | 40.7 | 23.7 | 17 | 40.8 | 27.2 | 13.6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

da Cruz Payão Filho, J.; Kimus Dias Passos, E.; Stohler Gonzaga, R.; Drumond Santos, D.; Pereira Maia, V.; Russo Juliano, D. The Influence of the Welding Process on the Ultrasonic Inspection of 9%Ni Steel Pipe Circumferential Welded Joints. Materials 2020, 13, 961. https://doi.org/10.3390/ma13040961

da Cruz Payão Filho J, Kimus Dias Passos E, Stohler Gonzaga R, Drumond Santos D, Pereira Maia V, Russo Juliano D. The Influence of the Welding Process on the Ultrasonic Inspection of 9%Ni Steel Pipe Circumferential Welded Joints. Materials. 2020; 13(4):961. https://doi.org/10.3390/ma13040961

Chicago/Turabian Styleda Cruz Payão Filho, João, Elisa Kimus Dias Passos, Rodrigo Stohler Gonzaga, Daniel Drumond Santos, Vinicius Pereira Maia, and Diego Russo Juliano. 2020. "The Influence of the Welding Process on the Ultrasonic Inspection of 9%Ni Steel Pipe Circumferential Welded Joints" Materials 13, no. 4: 961. https://doi.org/10.3390/ma13040961

APA Styleda Cruz Payão Filho, J., Kimus Dias Passos, E., Stohler Gonzaga, R., Drumond Santos, D., Pereira Maia, V., & Russo Juliano, D. (2020). The Influence of the Welding Process on the Ultrasonic Inspection of 9%Ni Steel Pipe Circumferential Welded Joints. Materials, 13(4), 961. https://doi.org/10.3390/ma13040961