Durability of Metal-Composite Friction Spot Joints under Environmental Conditions

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. FSpJ Process

2.3. Accelerated Aging

2.4. Weathering Conditions

2.5. Microscopy

2.6. EDS and XPS

2.7. Single Lap Shear (SLS) Testing

3. Results and Discussion

3.1. Accelerated Aging

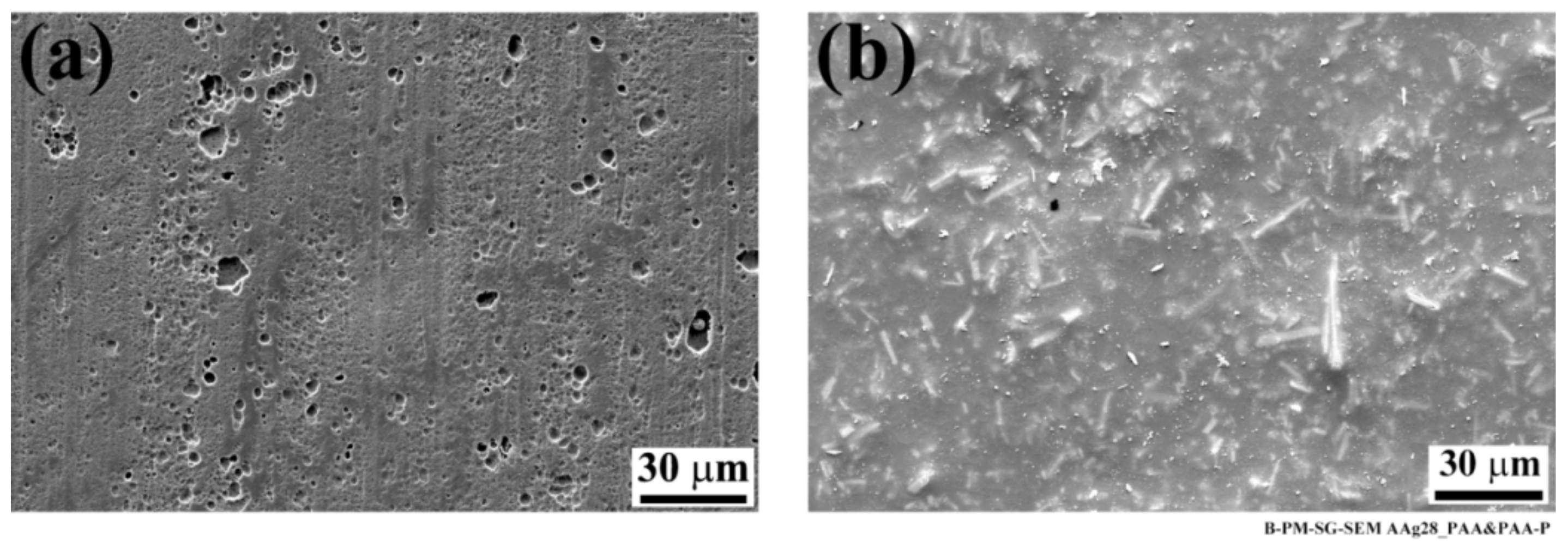

3.1.1. Surface Features and Chemical Composition

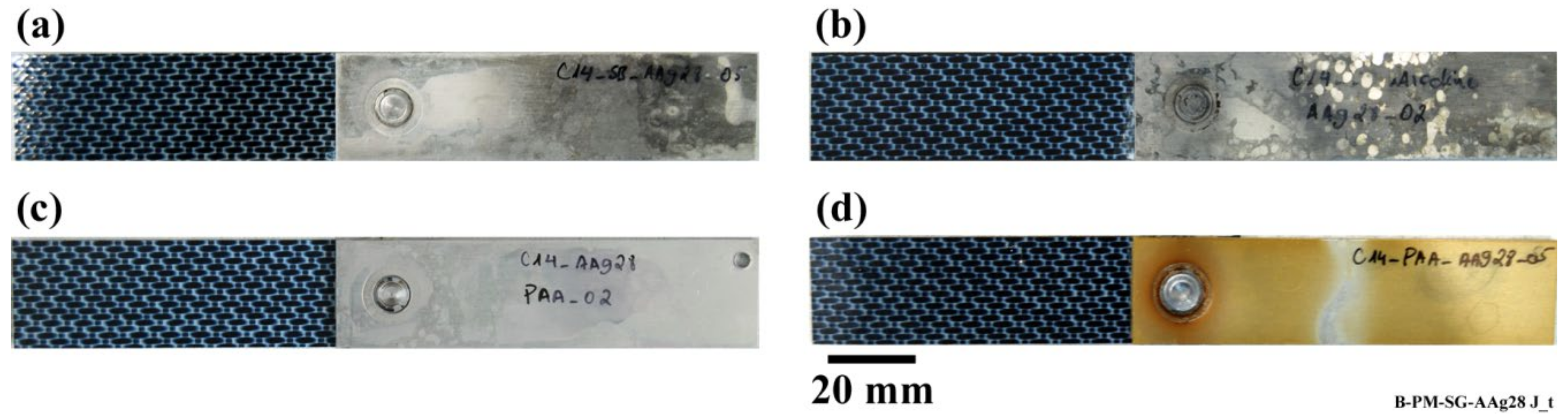

3.1.2. Mechanical Performance of the SLS Joints

- (1)

- Complete wetting and pore filling

- (2)

- Complete wetting, incomplete pore filling

- (3)

- Partial wetting or pore filling

- (4)

- No wetting or pore filling.

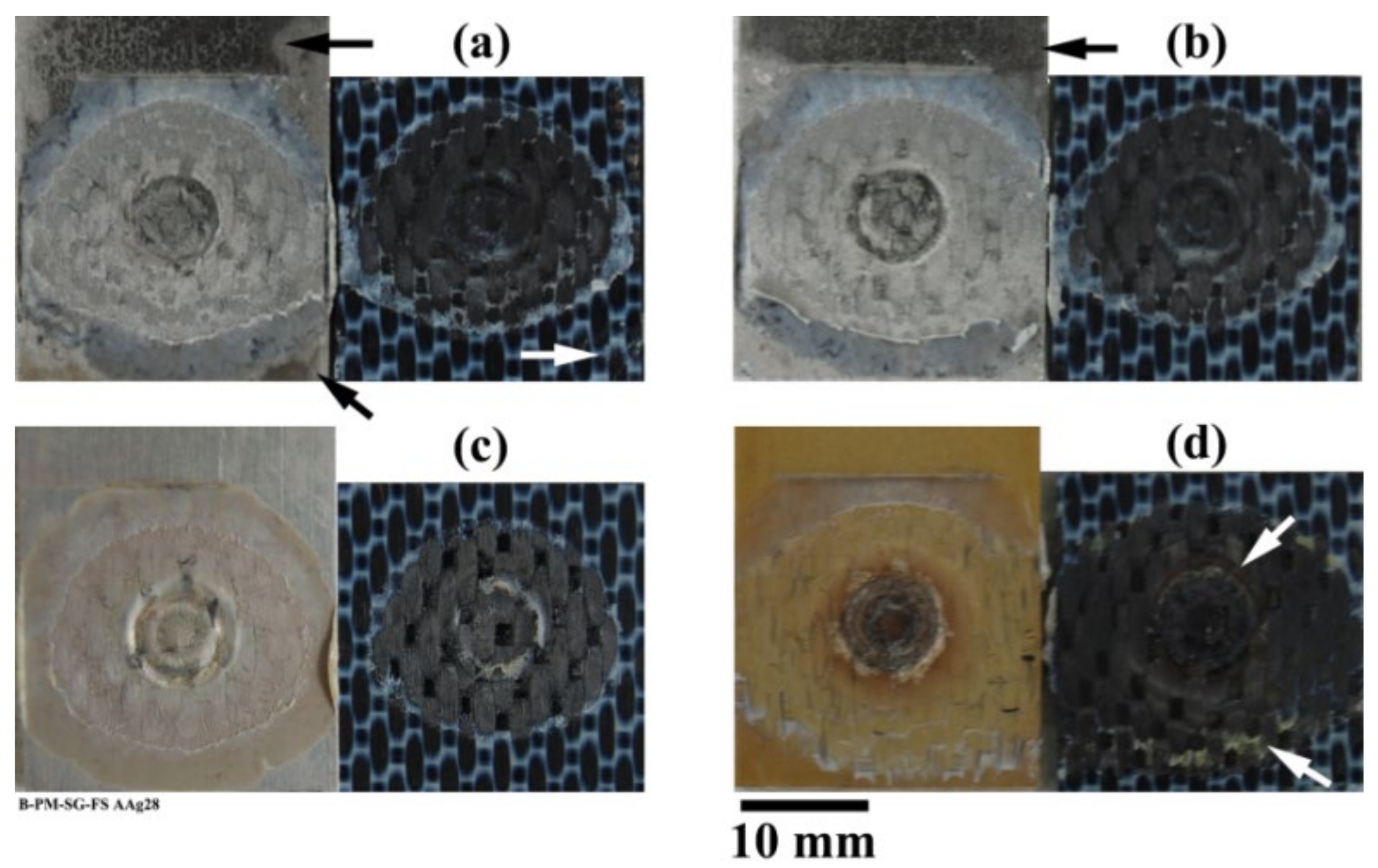

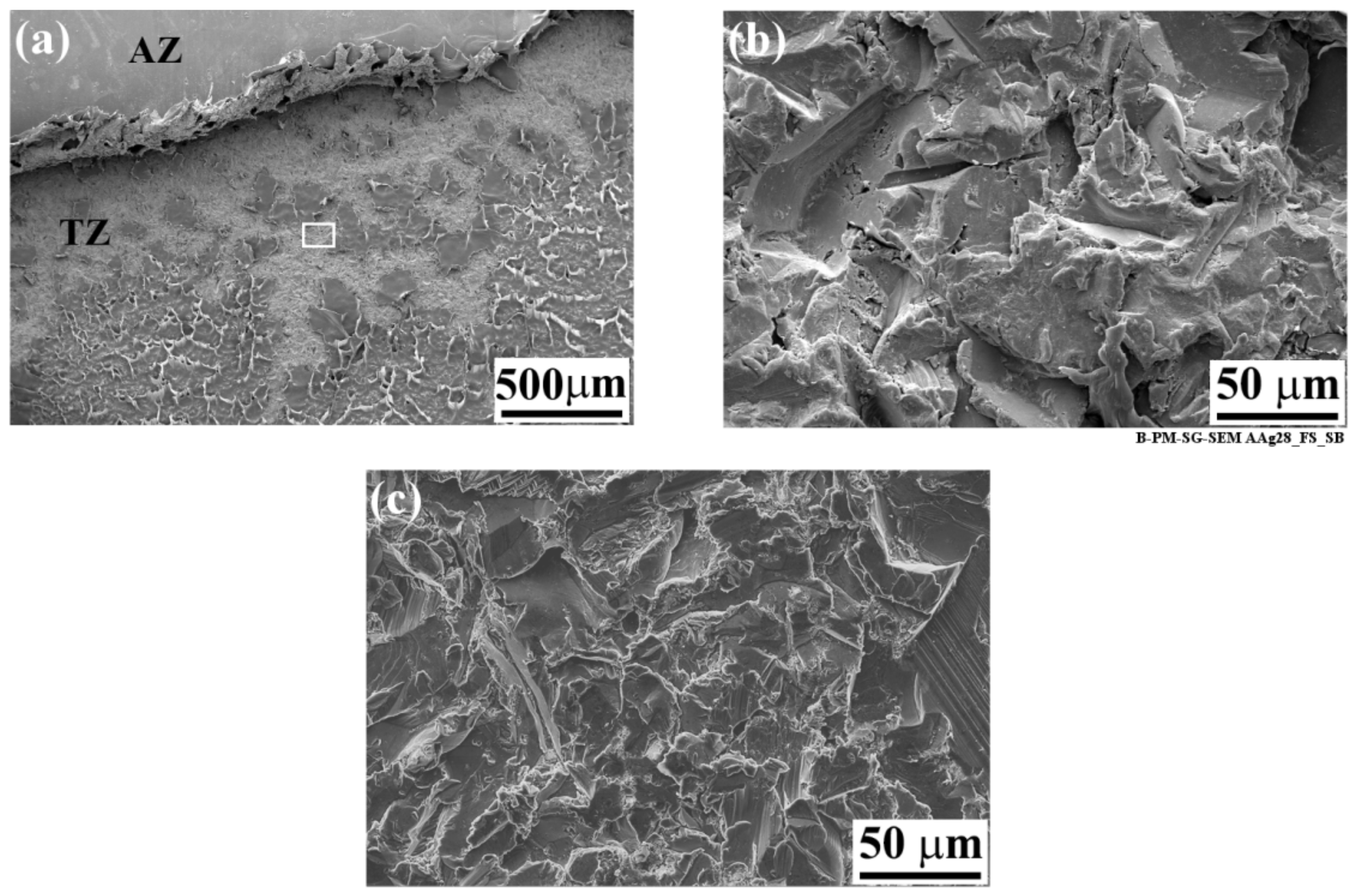

3.1.3. Failure and Fracture Surface Analysis

3.2. Outdoor Natural Weathering

Mechanical Performance of the SLS Joints

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Amancio-Filho, S.T.; Bueno, C.; Dos Santos, J.F.; Huber, N.; Hage, E., Jr. On the feasibility of friction spot joining in magnesium/fiber-reinforced polymer composite hybrid structures. Mater. Sci. Eng. A 2011, 528, 3841–3848. [Google Scholar] [CrossRef] [Green Version]

- Andre, N.M.; Goushegir, S.M.; Dos Santos, J.F.; Canto, L.B.; Amancio-Filho, S.T. Friction Spot Joining of aluminum alloy 2024-T3 and carbon-fiber-reinforced poly (phenylene sulfide) laminate with additional PPS film interlayer: Microstructure, mechanical strength and failure mechanisms. J. Compos. Part B 2016, 94, 197–208. [Google Scholar] [CrossRef]

- Esteves, J.V.; Goushegir, S.M.; Dos Santos, J.F.; Canto, L.B.; Hage, E., Jr.; Amancio-Filho, S.T. Friction spot joining of aluminum AA6181-T4 and carbon fiber-reinforced poly (phenylene sulfide): Effects of process parameters on the microstructure and mechanical strength. Mater. Des. 2014, 66, 437–445. [Google Scholar] [CrossRef] [Green Version]

- Goushegir, S.M.; dos Santos, J.F.; Amancio-Filho, S.T. Friction Spot Joining of aluminum AA2024/carbon-fiber reinforced poly (phenylene sulfide) composite single lap joints: Microstructure and mechanical performance. Mater. Des. 2014, 54, 196–206. [Google Scholar] [CrossRef]

- Goushegir, S.M.; dos Santos, J.F.; Amancio-Filho, S.T. Influence of process parameters on mechanical performance of AA2024/CF-PPS friction spot joints. Mater. Des. 2015, 83, 431–442. [Google Scholar] [CrossRef] [Green Version]

- Goushegir, S.M. Friction spot joining (FSpJ) of aluminum-CFRP hybrid structures. J. Weld World 2016, 60, 1073–1093. [Google Scholar] [CrossRef] [Green Version]

- André, N.M.; dos Santos, J.F.; Amancio-Filho, S.T. Impact resistance of metal-composite hybrid joints produced by frictional Heat. Compos. Struct. 2020, 233, 111754. [Google Scholar] [CrossRef]

- André, N.M.; Bouali, A.; Maawad, E.; Staron, P.; dos Santos, J.F.; Zheludkevich, M.L.; Amancio-Filho, S.T. Corrosion behavior of metal–composite hybrid joints: Influence of precipitation state and bonding zones. Corros. Sci. 2019, 158, 108075. [Google Scholar] [CrossRef]

- Borba, N.Z.; Körbelin, J.; Fiedler, B.; J dos Santos, J.F.; Amancio-Filho, S.T. Low-velocity impact response of friction riveted joints for aircraft application. Mater. Des. 2020, 186, 108369. [Google Scholar] [CrossRef]

- Bolger, C. Acid Base Interactions between Oxide Surfaces and Polar Organic Compounds. In Adhesion Aspects of Polymeric Coatings; Mittal, K.L., Ed.; Plenum Press: New York, NY, USA, 1983; pp. 19–44. [Google Scholar]

- Kerr, C.; Macdonald, N.C.; Orman, S. Effect of certain hostile environments on adhesive joints. J. Appl. Chem. 1967, 17, 62–65. [Google Scholar] [CrossRef]

- Fowkes, F.M. Donor-Acceptor Interactions at Interfaces. J. Adhes. 1972, 4, 155–159. [Google Scholar] [CrossRef]

- Davis, G.D. Durability of Adhesive Joints. In Handbook of Adhesive Technology, Revised and Expanded; Pizzi, A., Mittal, K.L., Eds.; Marcel Dekker: New York, NY, USA, 2003; pp. 273–292. [Google Scholar]

- Davis, G.D.; Shaffer, D.K. Handbook of Adhesive Technology; Pizzi, A., Mittal, K.L., Eds.; Marcel Dekker: New York, NY, USA, 1994; p. 113. [Google Scholar]

- Bjorgum, A.; Lapique, F.; Walmsley, J.; Redford, K. Anodising as pre-treatment for structural bonding. Int. J. Adhes. Adhes. 2003, 23, 401–412. [Google Scholar] [CrossRef]

- Batista, N.L.; de Faria, M.C.M.; Iha, K.; de Oliveira, P.C.; Botelho, E.C. Influence of water immersion and ultraviolet weathering on mechanical and viscoelastic properties of polyphenylene sulfide–carbon fiber composites. J. Thermoplast. Compos. Mater. 2015, 28, 340–356. [Google Scholar] [CrossRef]

- Martínez-Romo, A.; Mota, R.G.; Bernal, J.S.; Reyes, C.F.; Candelas, I.R. Effect of ultraviolet radiation in the photo-oxidation of High Density Polyethylene and Biodegradable Polyethylene films. J. Phys. Conf. Ser. 2015, 582, 012026. [Google Scholar] [CrossRef]

- Kinloch, A.J.; Welch, L.S.; Bishop, H.E. The Locus of Environmental Crack Growth in Bonded Aluminium Alloy Joints. J. Adhes. 1984, 16, 165–177. [Google Scholar] [CrossRef]

- Venables, J.D. Review Adhesion and durability of metal-polymer bonds. J. Mater. Sci. 1984, 19, 2431–2453. [Google Scholar] [CrossRef]

- Davis, G.D.; Sun, T.S.; Ahearn, J.S.; Venables, J.D. Application of surface behaviour diagrams to the study of hydration of phosphoric acid-anodized aluminium. J. Mater. Sci. 1982, 17, 1807–1818. [Google Scholar] [CrossRef]

- Critchlow, G.W.; Yendall, K.A.; Bahrani, D.; Quinn, A.; Andrews, F. Strategies for the replacement of chromic acid anodising for the structural bonding of aluminium alloys. Int. J. Adhes. Adhes. 2006, 26, 419–453. [Google Scholar] [CrossRef] [Green Version]

- Bland, D.J.; Kinloch, A.J.; Watts, J.F. The Role of the Surface Pretreatment in the Durability of Aluminium-Alloy Structural Adhesive Joints: Mechanisms of Failure. J. Adhes. 2013, 89, 369–397. [Google Scholar] [CrossRef] [Green Version]

- Critchlow, G.W.; Brewis, D.M. Review of surface pretreatments for aluminium alloys. Int. J. Adhes. Adhes. 1996, 16, 255–275. [Google Scholar] [CrossRef]

- Didi, M.; Emrich, S.; Mitschang, P.; Kopnarski, M. Characterization of Long-Term Durability of Induction Welded Aluminum/Carbon Fiber Reinforced Polymer-Joints. Adv. Eng. Mat. 2013, 15, 821–829. [Google Scholar] [CrossRef]

- Schricker, K.; Stambke, M.; Bergmann, J.P.; Bräutigam, K. Laser-Based Joining of Thermoplastics to Metals: Influence of Varied Ambient Conditions on Joint Performance and Microstructure. Int. J. Polym. Sci. 2016, 2016. [Google Scholar] [CrossRef] [Green Version]

- Davis, J.R. Handbook of Aluminium & Aluminium Alloys, 3rd ed.; ASM International: Cleveland, OH, USA, 1996. [Google Scholar]

- Favaloro, M.R. Thermoplastic composites for aerospace; The IAPD Magazine: Overland Park, KS, USA, 2010. [Google Scholar]

- Maruszczak, W. Advanced composite polymer for automotive—Long glass fiber linear polyphenylene sulfide. In Proceedings of the SPE ACCE Conference, Troy, MI, USA, 11–13 September 2007. [Google Scholar]

- Spruiell, J.; Janke, C.J. A Review of the Measurement and Development of Crystallinity and Its Relation to Properties in Neat Poly (Phenylene Sulfide) and Its Fiber Reinforced Composites; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2004. [Google Scholar]

- Goushegir, S.M.; dos Santos, J.F.; Amancio-Filho, S.T. Influence of aluminum surface pre-treatments on the bonding mechanisms and mechanical performance of metal-composite single-lap joints. J. Weld World 2017, 61, 1099–1115. [Google Scholar] [CrossRef]

- ASTM. ASTM D3762-03, Standard Test Method for Adhesive-Bonded Surface Durability of Aluminum (Wedge Test); ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- ASTM. ASTM D3163-01, Standard Test Method for Determining Strength of Adhesively Bonded Rigid Plastic Lap-Shear Joints in Shear by Tension Loading; ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- Baer, D.R. State-of-the-art Application of Surface and Interface Analysis Methods to Environmental Material Interactions: In Honor of James, E. Castle’s 65th Year; The Electrochemical Society: Pennington, NJ, USA, 2001. [Google Scholar]

- Juhl, A.D. Anodizing for Aerospace. 2010. Available online: http://www.metalfinishing.com (accessed on 20 December 2014).

- Kinloch, A.J.; Little, M.S.G.; Watts, J.F. The Role of the Interphase in the Environmental Failure of Adhesive Joints. Acta Mater. 2000, 48, 4543–4553. [Google Scholar] [CrossRef]

- Baker, A.A.; Chester, R.J. Minimum surface treatments for adhesively bonded repairs. Int. J. Adhes. Adhes. 1992, 12, 73–78. [Google Scholar] [CrossRef]

- Rider, A.N.; Arnott, D.R. Boiling water and silane pre-treatment of aluminium alloys for durable adhesive bonding. Int. J. Adhes. Adhes. 2000, 20, 209–220. [Google Scholar] [CrossRef]

- Rider, A.; Chalkley, P. The Effect of FM-73 Cure Temperature on the Durability of Bonded Joints Employing BR127 Primer; Aeronautical and Maritime Research Laboratory: Melbourne, Australia, 2000. [Google Scholar]

- NIST. NIST X-ray Photoelectron Spectroscopy Database; Version 4.1; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2012. [Google Scholar] [CrossRef]

- Turner, N.H.; Single, A.M. Determination of peak positions and areas from wide-scan XPS spectra. Surf. Interface Anal. 1990, 15, 215–222. [Google Scholar] [CrossRef]

- Kono, M. Studies of Metal-Polymer Interfaces. Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, 2000. [Google Scholar]

- Hauert, R.; Patscheider, J.; Tobler, M.; Zehringer, R. XPS investigation of the a-C:H/Al interface. Surf. Sci. Lett. 1993, 292, A605–A606. [Google Scholar] [CrossRef]

- Sarapatka, T.J. Palladium-induced charge transports with palladium/alumina/aluminum interface formation. J. Phys. Chem. 1993, 97, 11274–11277. [Google Scholar] [CrossRef]

- Chidambaram, D.; Clayton, C.R.; Halada, G.P. The role of hexafluorozirconate in the formation of chromate conversion coatings on aluminum alloys. Electrochim. Acta 2006, 51, 2862–2871. [Google Scholar] [CrossRef]

- Stralin, A.; Hjertberg, T. Influence of surface composition on initial hydration of aluminium in boiling water. Appl. Surf. Sci. 1994, 74, 263–275. [Google Scholar] [CrossRef]

- Alexander, M.R.; Thompson, G.E.; Beamson, G. Characterization of the oxide/hydroxide surface of aluminium using x-ray photoelectron spectroscopy: A procedure for curve fitting the O 1s core level. Surf. Interface Anal. 2000, 29, 468–477. [Google Scholar] [CrossRef]

- Alwitt, R.S. The Growth of Hydrous Oxide Films on Aluminum. J. Electrochem. Soc. 1974, 121, 1322–1328. [Google Scholar] [CrossRef]

- Kinloch, A.J. Adhesion and Adhesives: Science and Technology, 1st ed.; Springer: Cambridge, UK, 1987. [Google Scholar]

- Butt, R.I.; Cotter, J.L. The Effect of High Humidity on the Dynamic Mechanical Properties and Thermal Transition of an Epoxy-Polyamide Adhesive. J. Adhes. 1976, 8, 11–19. [Google Scholar] [CrossRef]

- Digby, R.P.; Packham, D.E. Pretreatment of aluminium: Topography, surface chemistry and adhesive bond durability. Int. J. Adhes. Adhes. 1995, 15, 61–71. [Google Scholar] [CrossRef]

- Sulka, G.D. Highly Ordered Anodic Porous Alumina Formation by Self-Organized Anodizing. In Nanostructured Materials in Electrochemistry; Eftekhari, A., Ed.; Wiley: Weinheim, Germany, 2008; p. 8. [Google Scholar]

- Goushegir, S.M.; dos Santos, J.F.; Amancio-Filho, S.T. Failure and fracture micro-mechanisms in metal-composite single lap joints produced by welding-based joining techniques. J. Compos. Part A 2016, 81, 121–128. [Google Scholar] [CrossRef] [Green Version]

- Baschek, B.; Schroeder, F.; Brix, H.; Riethmüller, R.; Badewien, T.H.; Breitbach, G.; Brügge, B.; Colijn, F.; Doerffer, R.; Eschenbach, C.; et al. The Coastal Observing System for Northern and Arctic Seas (COSYNA). Ocean Sci. 2017, 13, 379–410. [Google Scholar] [CrossRef] [Green Version]

- Davis, R.J. Corrosion of Aluminum and Aluminum Alloys; ASM International: Cleveland, OH, USA, 1999. [Google Scholar]

- Neal, C.; Kirchner, J.W. Sodium and chloride levels in rainfall, mist, streamwater and groundwater at the Plynlimon catchments, mid-Wales: Interferences on hydrological and chemical controls. Hydrol. Earth Syst. Sci. 2000, 4, 295–310. [Google Scholar] [CrossRef] [Green Version]

| Surface Pre-Treatment | Al | O | C | N |

|---|---|---|---|---|

| SB | 45.7 | 43.2 | 11.1 | - |

| CC | 63.3 | 32.4 | 0.8 | 3.5 |

| Surface Pre-Treatment | Al | O | C | Cu | Mg |

|---|---|---|---|---|---|

| SB | 87.3 | 6.8 | 1.2 | 3.1 | 1.6 |

| CC | 88.1 | 5.1 | 1.5 | 3.9 | 1.4 |

| Surface Pre-Treatment | Al | O | C | Cu | Mg | N | Cr | Sr |

|---|---|---|---|---|---|---|---|---|

| PAA | 69.3 | 14.9 | 11.8 | 2.6 | 1.4 | - | - | - |

| PAA-P | 8.0 | 7.6 | 51.0 | - | - | 10.0 | 9.3 | 14.1 |

| Surface Pre-Treatment | Al | O | C | Cu | Mg | P | S | Cr | Sr |

|---|---|---|---|---|---|---|---|---|---|

| PAA | 76.9 | 14.9 | 2.0 | 3.0 | 1.5 | 1.7 | - | - | - |

| PAA-P | 0.2 | 17.8 | 76.0 | - | - | - | - | 2.5 | 3.5 |

| Features | Al | O | C | Cu | Mg | S |

|---|---|---|---|---|---|---|

| Flake-like | 42.4 | 32.1 | - | 0.5 | 0.5 | 24.5 |

| Agglomerates | 38.5 | 42.1 | 18.3 | 0.8 | 0.3 | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Goushegir, S.M.; Scharnagl, N.; dos Santos, J.F.; Amancio-Filho, S.T. Durability of Metal-Composite Friction Spot Joints under Environmental Conditions. Materials 2020, 13, 1144. https://doi.org/10.3390/ma13051144

Goushegir SM, Scharnagl N, dos Santos JF, Amancio-Filho ST. Durability of Metal-Composite Friction Spot Joints under Environmental Conditions. Materials. 2020; 13(5):1144. https://doi.org/10.3390/ma13051144

Chicago/Turabian StyleGoushegir, Seyed M., Nico Scharnagl, Jorge F. dos Santos, and Sergio T. Amancio-Filho. 2020. "Durability of Metal-Composite Friction Spot Joints under Environmental Conditions" Materials 13, no. 5: 1144. https://doi.org/10.3390/ma13051144

APA StyleGoushegir, S. M., Scharnagl, N., dos Santos, J. F., & Amancio-Filho, S. T. (2020). Durability of Metal-Composite Friction Spot Joints under Environmental Conditions. Materials, 13(5), 1144. https://doi.org/10.3390/ma13051144