Reactive Compatibilization of Polyamide 6/Olefin Block Copolymer Blends: Phase Morphology, Rheological Behavior, Thermal Behavior, and Mechanical Properties

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation of the Blends

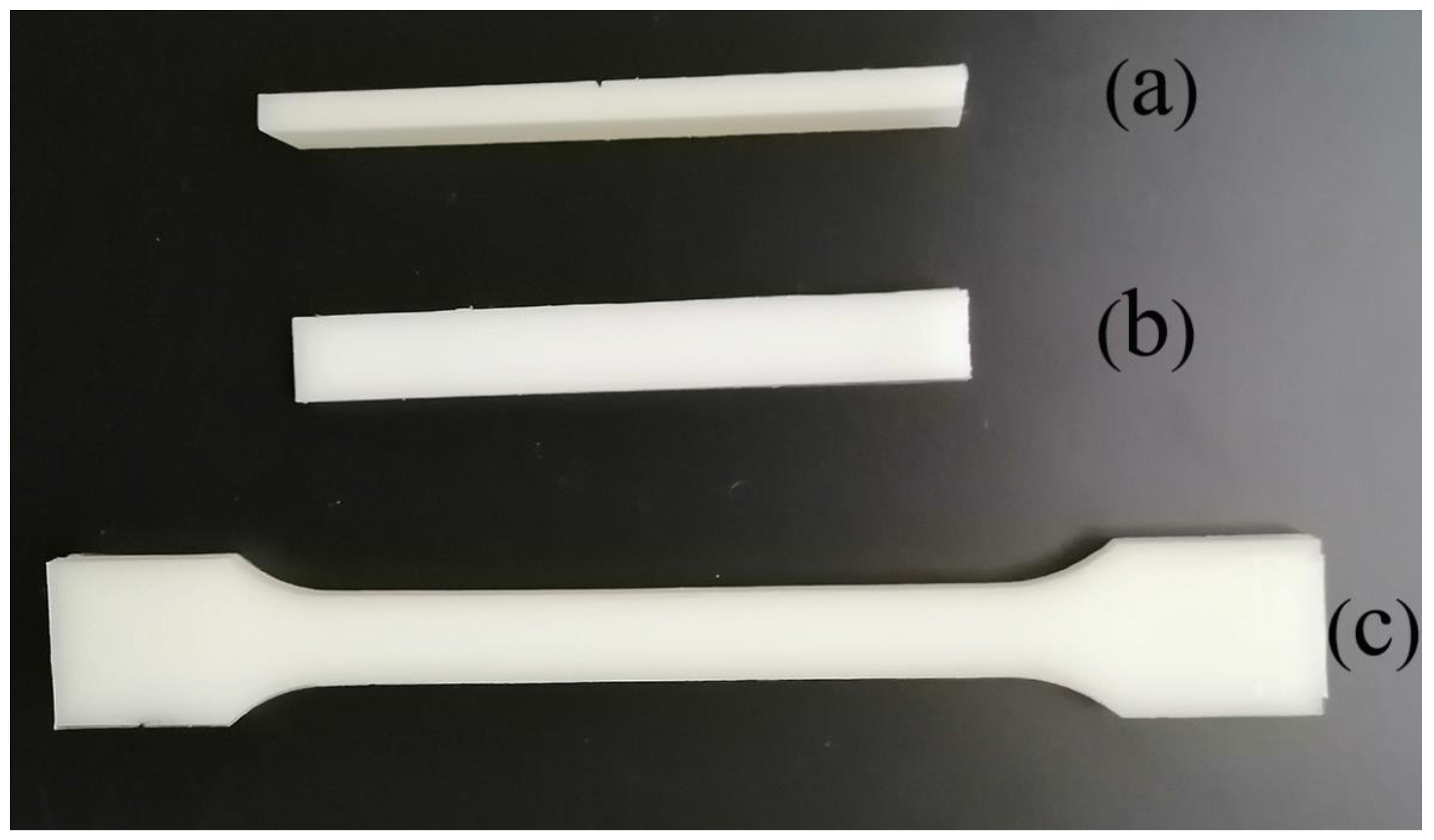

2.3. Characterization

3. Results and Discussion

3.1. Fourier Transform Infrared (FTIR) Spectroscopy Analysis

3.2. Molau Test

3.3. Morphological Analyses

3.4. Rheological Behavior

3.5. Thermal Behavior of The Materials

3.6. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Iqbal, M.Z.; Abdala, A.A.; Mittal, V.; Seifert, S.; Herring, A.M.; Liberatore, M.W. Processable conductive graphene/polyethylene nanocomposites: Effects of graphene dispersion and polyethylene blending with oxidized polyethylene on rheology and microstructure. Polymer 2016, 98, 143–155. [Google Scholar] [CrossRef] [Green Version]

- Kong, Y.; Li, Y.; Hu, G.; Lin, J.; Pan, D.; Dong, D.; Wujick, E.; Shao, Q.; Wu, M.; Zhao, J.; et al. Preparation of polystyrene-b-poly (ethylene/propylene)-b-polystyrene grafted glycidyl methacrylate and its compatibility with recycled polypropylene/recycled high impact polystyrene blends. Polymer 2018, 145, 232–241. [Google Scholar] [CrossRef]

- Ryu, S.C.; Kim, J.Y.; Kim, W.N. Relationship between the interfacial tension and compatibility of polycarbonate and poly (acrylonitrile–butadiene–styrene) blends with reactive compatibilizers. J. Appl. Polym. Sci. 2018, 135, 46418. [Google Scholar] [CrossRef]

- Jafari, S.M.A.; Khajavi, R.; Goodarzi, V.; Kalaee, M.R.; Khonakdar, H.A. Nonisothermal crystallization kinetic studies on melt processed poly(ethylene terephthalate)/polylactic acid blends containing graphene oxide and exfoliated graphite nanoplatelets. J. Appl. Polym. Sci. 2019, 136, 47569. [Google Scholar] [CrossRef]

- Gopanna, A.; Thomas, S.P.; Rajan, K.P.; Rajan, R.; Rainosalo, E.; Zavašnik, J.; Chavali, M. Investigation of mechanical, dynamic mechanical, rheological and morphological properties of blends based on polypropylene (PP) and cyclic olefin copolymer (COC). Eur. Polym. J. 2018, 108, 439–451. [Google Scholar] [CrossRef]

- Ding, Y.; Stoliarov, S.; Kraemer, R. Development of a semiglobal reaction mechanism for the thermal decomposition of a polymer containing reactive flame retardants: Application to glass-fiber-reinforced polybutylene terephthalate blended with aluminum diethyl phosphinate and melamine polyphosphate. Polymers 2018, 10, 1137. [Google Scholar]

- Krause, B.; Kroschwald, L.; Pötschke, P. The influence of the blend ratio in PA6/PA66/MWCNT blend composites on the electrical and thermal properties. Polymers 2019, 11, 122. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.; Yu, X.; Zhou, W.; Peng, S.; Zhao, X. Highly toughened polylactide (PLA) by reactive blending with novel polycaprolactone-based polyurethane (PCLU) blends. Polym. Test. 2018, 70, 275–280. [Google Scholar] [CrossRef]

- Bher, A.; Uysal Unalan, I.; Auras, R.; Rubino, M.; Schvezov, C.E. Toughening of poly (lactic acid) and thermoplastic cassava starch reactive blends using graphene nanoplatelets. Polymers 2018, 10, 95. [Google Scholar] [CrossRef] [Green Version]

- Agrawal, P.; Rodrigues, A.W.; Araújo, E.M.; Mélo, T.J. Influence of reactive compatibilizers on the rheometrical and mechanical properties of PA6/LDPE and PA6/HDPE blends. J. Mater. Sci. 2010, 45, 496–502. [Google Scholar] [CrossRef]

- Vallim, M.R.; Araujo, J.R.; Spinacé, M.A.S.; De Paoli, M.A. Polyamide-6/high-density polyethylene blend using recycled high-density polyethylene as compatibilizer: Morphology, mechanical properties, and thermal stability. Polym. Eng. Sci. 2009, 49, 2005–2014. [Google Scholar] [CrossRef]

- Palabiyik, M.; Bahadur, S. Mechanical and tribological properties of polyamide 6 and high density polyethylene polyblends with and without compatibilizer. Wear 2000, 246, 149–158. [Google Scholar] [CrossRef]

- Mazaheri Kia, M.; Paydayesh, A.; Azar, A.A. Morphology and Mechanical Properties of Polyamide 6/Acrylonitrile-Butadiene-Styrene Blends Containing Carbon Nanotubes. J. Macromol. Sci. B 2019, 58, 355–370. [Google Scholar] [CrossRef]

- Castro, L.D.C.; Oliveira, A.D.; Kersch, M.; Altstädt, V.; Pessan, L.A. Effect of organoclay incorporation and blending protocol on performance of PA6/ABS nanocomposites compatibilized with SANMA. Polym. Eng. Sci. 2017, 57, 1147–1154. [Google Scholar] [CrossRef]

- Xie, T.; Wu, H.; Bao, W.; Guo, S.; Chen, Y.; Huang, H.; Chen, H.; Lai, S.Y.; Jow, J. Enhanced compatibility of PA6/POE blends by POE-g-MAH prepared through ultrasound-assisted extrusion. J. Appl. Polym. Sci. 2010, 118, 1846–1852. [Google Scholar] [CrossRef]

- Wang, B.; Hao, L.; Wang, W.; Hu, G. One-step compatibilization of polyamide 6/poly(ethylene-1-octene) blends with maleic anhydride and peroxide. J. Polym. Res. 2010, 17, 821–826. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, W.; Dou, R.; Li, L.P.; Yin, B.; Yang, M.B. Effect of EPDM-g-MAH on the morphology and properties of PA6/EPDM/HDPE ternary blends. Polym. Eng. Sci. 2013, 53, 1845–1855. [Google Scholar] [CrossRef]

- Bhattacharyya, A.R.; Ghosh, A.K.; Misra, A. Ionomer compatibilised PA6/EVA blends: Mechanical properties and morphological characterisation. Polymer 2003, 44, 1725–1732. [Google Scholar] [CrossRef]

- Tjong, S.C.; Bao, S.P. Impact fracture toughness of polyamide-6/montmorillonite nanocomposites toughened with a maleated styrene/ethylene butylene/styrene elastomer. J. Polym. Sci. Part B Poly. Phys. 2005, 43, 585–595. [Google Scholar] [CrossRef]

- Kim, J.G.; Lee, J.; Son, Y. Toughening of nylon 6 with a ethylene–octene copolymer grafted with maleic anhydride and styrene. Mater. Lett. 2014, 126, 43–47. [Google Scholar] [CrossRef]

- Zhao, Y.; Ma, C.; Cheng, S.; Xu, W.; Du, Y.; Bao, Y.; Xiao, Z. Maleic Anhydride-Grafted Isotactic Polybutene-1 and Modified Polyamide 6. Polymers 2018, 10, 872. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, D.; Song, S.; Li, C.; Cao, C.; Sun, S.; Zhang, H. Compatibilization effect of MMA-co-GMA copolymers on the properties of polyamide 6/Poly (vinylidene fluoride) blends. J. Polym. Res. 2015, 22, 102. [Google Scholar] [CrossRef]

- Filippi, S.; Minkova, L.; Dintcheva, N.; Narducci, P.; Magagnini, P. Comparative study of different maleic anhydride grafted compatibilizer precursors towards LDPE/PA6 blends: Morphology and mechanical properties. Polymer 2005, 46, 8054–8061. [Google Scholar] [CrossRef]

- Shin, B.; Ha, M.; Han, D. Morphological, rheological, and mechanical properties of polyamide 6/polypropylene blends compatibilized by electron-beam irradiation in the presence of a reactive agent. Materials 2016, 9, 342. [Google Scholar] [CrossRef] [Green Version]

- Das, V.; Kumar, V.; Singh, A.; Gautam, S.S.; Pandey, A.K. Compatibilization efficacy of LLDPE-g-MA on mechanical, thermal, morphological and water absorption properties of Nylon-6/LLDPE blends. Polym. Plast. Technol. Eng. 2012, 51, 446–454. [Google Scholar] [CrossRef]

- Huang, B.; Li, D.; Li, Z.; Li, X.; Zhou, W. Reactive compatibilization of PA6/ABS blends by ethylene-acrylate-glycidyl methacrylate copolymer. J. Appl. Polym. Sci. 2011, 122, 586–592. [Google Scholar] [CrossRef]

- Arriola, D.J.; Carnahan, E.M.; Hustad, P.D.; Kuhlman, R.L.; Wenzel, T.T. Catalytic production of olefin block copolymers via chain shuttling polymerization. Science 2006, 312, 714–719. [Google Scholar] [CrossRef]

- Chum, P.S.; Swogger, K.W. Olefin polymer technologies-History and recent progress at The Dow Chemical Company. Prog. Polym. Sci. 2008, 33, 797–819. [Google Scholar] [CrossRef]

- Ren, Q.; Fan, J.; Zhang, Q.; Yi, J.; Feng, J. Toughened polypropylene random copolymer with olefin block copolymer. Mater. Design. 2016, 107, 295–301. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, X.; Li, X.; Chen, H.; Walton, K.; Wang, D. Correlation of miscibility and mechanical properties of polypropylene/olefin block copolymers: Effect of chain composition. J. Appl. Polym. Sci. 2012, 125, 666–675. [Google Scholar] [CrossRef]

- Sui, G.; Wang, K.; Xu, S.; Liu, Z.; Zhang, Q.; Du, R.; Fu, Q. The combined effect of reactive and high-shear extrusion on the phase morphologies and properties of PLA/OBC/EGMA ternary blends. Polymer 2019, 169, 66–73. [Google Scholar] [CrossRef]

- Wang, Y.L.; Hu, X.; Li, H.; Ji, X.; Li, Z.M. Polyamide-6/poly (lactic acid) blends compatibilized by the maleic anhydride grafted polyethylene-octene elastomer. Polym. Plast. Technol. Eng. 2010, 49, 1241–1246. [Google Scholar] [CrossRef]

- Razavi-Nouri, M.; Karami, M. Effect of rubber content on morphology and thermal and rheological behaviors of acrylonitrile-butadiene rubber/poly (ethylene-co-vinyl acetate)/organoclay nanocomposites. Polymer 2014, 55, 6940–6947. [Google Scholar] [CrossRef]

- Wei, Q.; Chionna, D.; Galoppini, E.; Pracella, M. Functionalization of LDPE by Melt Grafting with Glycidyl Methacrylate and Reactive Blending with Polyamide-6. Macromol. Chem. Phys. 2003, 204, 1123–1133. [Google Scholar] [CrossRef]

- Lai, S.M.; Li, C.H.; Kao, H.C.; Liu, L.C. Shape Memory Properties of Melt-Blended Olefin Block Copolymer (OBC)/Ethylene-Vinyl Acetate Blends. J. Macromol. Sci. B 2019, 58, 174–191. [Google Scholar] [CrossRef]

- Marco, C.; Ellis, G.; Gómez, M.A.; Fatou, J.G.; Arribas, J.M.; Campoy, I.; Fontecha, A. Rheological properties, crystallization, and morphology of compatibilized blends of isotactic polypropylene and polyamide. J. Appl. Polym. Sci. 1997, 65, 2665–2677. [Google Scholar] [CrossRef]

- Rossato, J.H.H.; Lemos, H.G.; Mantovani, G.L. The influence of viscosity and composition of ABS on the ABS/SBS blend morphology and properties. J. Appl. Polym. Sci. 2019, 136, 47075. [Google Scholar] [CrossRef]

- Gadgeel, A.A.; Mhaske, S.T. Novel approach for the preparation of a compatibilized blend of nylon 11 and polypropylene with polyhydroxybutyrate: Mechanical, thermal, and barrier properties. J. Appl. Polym. Sci. 2019, 136, 48152. [Google Scholar] [CrossRef]

- Sundararaj, U.; Macosko, C.W. Drop breakup and coalescence in polymer blends: The effects of concentration and compatibilization. Macromolecules 1995, 28, 2647–2657. [Google Scholar] [CrossRef]

- Van Hemelrijck, E.; Van Puyvelde, P.; Macosko, C.W.; Moldenaers, P. The effect of block copolymer architecture on the coalescence and interfacial elasticity in compatibilized polymer blends. J. Rheol. 2005, 49, 783–798. [Google Scholar] [CrossRef] [Green Version]

- Van Hemelrijck, E.; Van Puyvelde, P.; Velankar, S.; Macosko, C.W.; Moldenaers, P. Interfacial elasticity and coalescence suppression in compatibilized polymer blends. J. Rheol. 2004, 48, 143–158. [Google Scholar] [CrossRef] [Green Version]

- Nandan, B.; Kandpal, L.D.; Mathur, G.N. Poly(ether ether ketone)/poly(aryl ether sulfone) blends: Melt rheological behavior. J. Polym. Sci. Part B Polym. Phys. 2004, 42, 1548–1563. [Google Scholar] [CrossRef]

- Du, Y.G.; Gao, J.G.; Yang, J.B.; Liu, X.Q. Dynamic rheological behavior and mechanical properties and of PVC/ASA blends. J. Polym. Res. 2012, 19, 9993. [Google Scholar] [CrossRef]

- Arsad, A.; Rahmat, A.R.; Hassan, A.; Mokhtar, M.; Dali, S.N.M. Flow characteristics and dynamic behavior of polyamide 6/acrylonitile butadiene styrene (PA6/ABS) Blends. Int. J. Polym. Mater. Polym. Biomater. 2013, 62, 209–214. [Google Scholar] [CrossRef]

- Zhang, Z.; Yu, F.; Zhou, N.; Zhang, H. Compatibilization by olefin block copolymer (OBC) in Polypropylene/Ethylene-Propylene-Diene Terpolymer (PP/EPDM) blends. J. Macromol. Sci. B 2015, 54, 159–176. [Google Scholar] [CrossRef]

- Bhattacharyya, A.R.; Ghosh, A.K.; Misra, A. Reactively compatibilised polymer blends: A case study on pa6/eva blend system. Polymer 2001, 42, 9143–9154. [Google Scholar] [CrossRef]

- Wang, X.; Peng, S.; Chen, H.; Yu, X.; Zhao, X. Mechanical properties, rheological behaviors, and phase morphologies of high-toughness PLA/PBAT blends by in-situ reactive compatibilization. Compos Part B Eng. 2019, 173, 107028. [Google Scholar] [CrossRef]

- Wang, K.; Chen, Y. Toughened poly (trimethylene terephthalate) by blending with a functionalized ethylene–propylene–diene copolymer. Polym. Eng. Sci. 2010, 50, 624–628. [Google Scholar] [CrossRef]

- Xu, M.; Qiu, W.; Qiu, G. Ethylene-propylene elastomer grafted maleic anhydride toughened Polyamide-6 morphology and properties. J. Macromol. Sci. B 2013, 52, 155–166. [Google Scholar] [CrossRef]

| Sample Code | Polyamide 6 (PA6) (wt%) | Olefin Block Copolymer (OBC) (wt%) | Maleic Anhydride-Grafted Polyethylene-Octene Copolymer (POE-g-MAH) (wt%) |

|---|---|---|---|

| Pure PA6 | 100 | 0 | 0 |

| PA6/OBC | 90 | 10 | 0 |

| PA6/OBC/1 | 90 | 10 | 1 |

| PA6/OBC/3 | 90 | 10 | 3 |

| PA6/OBC/5 | 90 | 10 | 5 |

| PA6/OBC/7 | 90 | 10 | 7 |

| Sample | Complex Viscosity (*) (Pa·s) | Storage Modulus (G’) (Pa) | Loss Modulus (G”) (Pa) |

|---|---|---|---|

| Pure PA6 | 330.0 | 0.6 | 31.1 |

| Pure OBC | 10472.9 | 110.6 | 1018.3 |

| PA6/OBC | 461.0 | 1.9 | 43.3 |

| PA6/OBC/1 | 485.5 | 2.2 | 46.6 |

| PA6/OBC/3 | 602.6 | 4.7 | 60.0 |

| PA6/OBC/5 | 758.4 | 6.9 | 75.6 |

| PA6/OBC/7 | 806.6 | 10.5 | 80.0 |

| Sample | Tm (°C) | Tc (°C) | ∆Hm (J/g) | Xc (%) |

|---|---|---|---|---|

| Pure PA6 | 220.78 | 189.55 | 72.82 | 31.66 |

| Pure OBC | 121.06 | 78.34 | 18.0 | 6.21 |

| PA6/OBC | 220.86 | 189.05 | 65.85 | 31.81 |

| PA6/OBC/1 | 220.87 | 188.77 | 63.15 | 30.81 |

| PA6/OBC/3 | 220.67 | 188.62 | 63.98 | 31.84 |

| PA6/OBC/5 | 221.17 | 187.78 | 61.57 | 31.23 |

| PA6/OBC/7 | 221.46 | 187.67 | 52.08 | 26.92 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, X.; Liu, Y.; Chen, X.; Wu, Y.; Cui, L.; Mao, L.; Zheng, W.; Lin, M. Reactive Compatibilization of Polyamide 6/Olefin Block Copolymer Blends: Phase Morphology, Rheological Behavior, Thermal Behavior, and Mechanical Properties. Materials 2020, 13, 1146. https://doi.org/10.3390/ma13051146

Lin X, Liu Y, Chen X, Wu Y, Cui L, Mao L, Zheng W, Lin M. Reactive Compatibilization of Polyamide 6/Olefin Block Copolymer Blends: Phase Morphology, Rheological Behavior, Thermal Behavior, and Mechanical Properties. Materials. 2020; 13(5):1146. https://doi.org/10.3390/ma13051146

Chicago/Turabian StyleLin, Xintu, Yuejun Liu, Xi Chen, Yincai Wu, Lingna Cui, Long Mao, Wei Zheng, and Minghao Lin. 2020. "Reactive Compatibilization of Polyamide 6/Olefin Block Copolymer Blends: Phase Morphology, Rheological Behavior, Thermal Behavior, and Mechanical Properties" Materials 13, no. 5: 1146. https://doi.org/10.3390/ma13051146

APA StyleLin, X., Liu, Y., Chen, X., Wu, Y., Cui, L., Mao, L., Zheng, W., & Lin, M. (2020). Reactive Compatibilization of Polyamide 6/Olefin Block Copolymer Blends: Phase Morphology, Rheological Behavior, Thermal Behavior, and Mechanical Properties. Materials, 13(5), 1146. https://doi.org/10.3390/ma13051146