Pseudo-random Path Generation Algorithms and Strategies for the Surface Quality Improvement of Optical Aspherical Components

Abstract

:1. Introduction

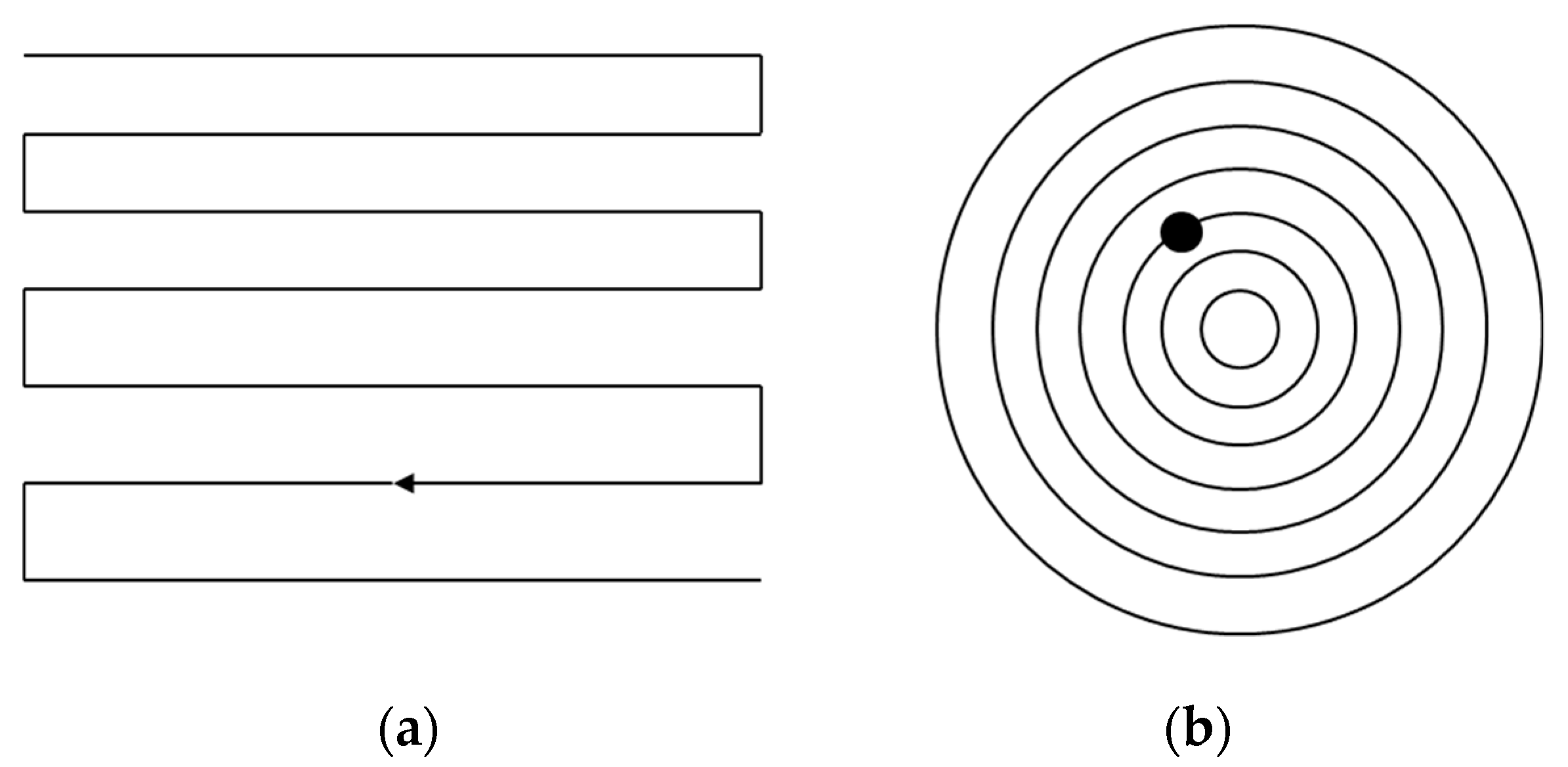

2. Generation Mechanism of Surface Waviness Error

3. Polishing Path Generation Algorithm

- (1)

- Changing the path formation direction to diminish parallel or concentric path lines on the surface of the optical component.

- (2)

- Changing the path interval; a uniform feed of conventional paths is added with uncertainty to suppress the appearance of the surface waviness error.

3.1. Path Direction Changing Algorithm

- (1)

- All dwell points can only be traversed once,

- (2)

- The dwell point (x, y) of the path cannot intersect the existing path,

- (3)

- The path cannot exceed the boundary of the actual polishing area.

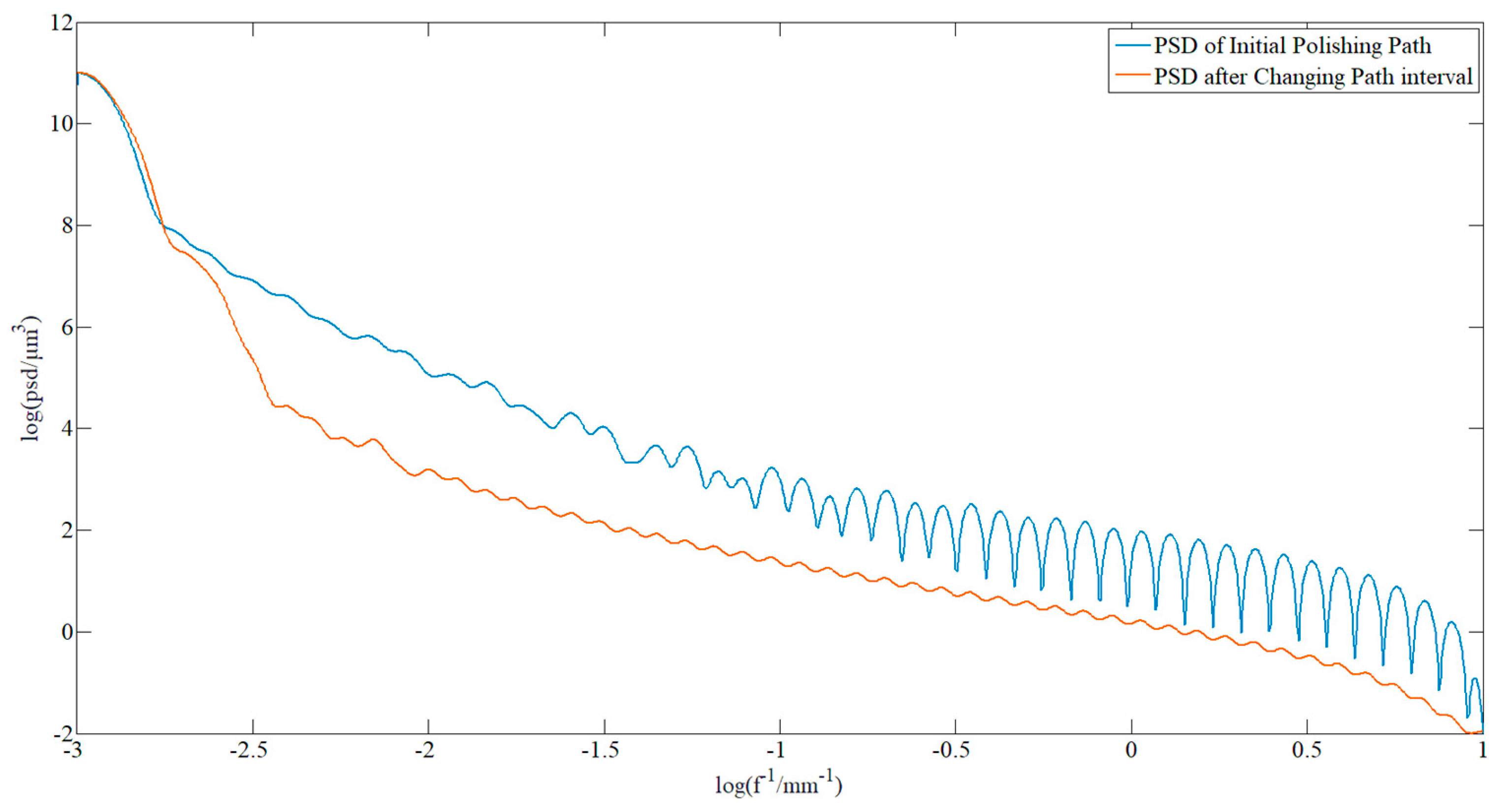

3.2. Path Interval Changing Algorithm

4. Strategies for Surface Waviness Compensation

4.1. Changing Path Direction

4.2. Changing Path Interval

5. Compensation of Surface Roughness

6. Conclusions

- (1)

- The two path generation algorithms proposed in this paper are both feasible for correcting surface waviness. One problem caused by the existence of a large parallel path can be solved by the proposed path direction-changing algorithm, and another problem caused by the convolution effect between path intervals was solved by the path interval changing algorithm.

- (2)

- The path generation algorithm that changes the path direction has better performance, but it has higher requirements on the performance of the machine tool. Therefore, it is suitable for optical components with higher precision requirements.

- (3)

- Different path generation algorithms were applied to polish a workpiece made of K9 optical glass by a polishing agent concentration of 50%. The results show that the PV and RMS converge to 3.58 and 1.06 μm, respectively. Comparisons of the changes in PSD curves before and after polishing suggest that the two paths could correct surface waviness.

Author Contributions

Funding

Conflicts of Interest

References

- Aikens, D.; Roussel, A.; Bray, M. Derivation of preliminary specifications for transmitted wavefront and surface roughness for large optics used in inertial confinement fusion. Proc. SPIE 1995, 2633, 350–360. [Google Scholar]

- Walker, D.D.; Brooks, D.; King, A.; Freeman, R.; Morton, R.; McCavana, G.; Kim, S.W. The ‘Precessions’ tooling for polishing and figuring flat, spherical and aspheric surfaces. Opt. Express 2003, 11, 958–964. [Google Scholar] [CrossRef] [PubMed]

- Wolfe, C.R.; Lawson, J.K. Measurement and analysis of wavefront structure from large-aperture ICF optics. Proc. SPIE 1995, 2633, 361–385. [Google Scholar]

- Nie, X.; Li, S.; Hu, H.; Li, Q. Control of mid-spatial frequency errors considering the pad groove feature in smoothing polishing process. Appl. Opt. 2014, 53, 6332–6339. [Google Scholar] [CrossRef]

- Campbell, J.H.; Hawley-Fedder, R.A.; Stolz, C.J.; Menapace, J.A.; Borden, M.R.; Whitman, P.K.; Yu, J.; Runkel, M.J.; Riley, M.O.; Feit, M.D.; et al. NIF optical materials and fabrication technologies: An overview. Proc. SPIE 2004, 5341, 84–101. [Google Scholar]

- Dong, Z.C.; Cheng, H.B.; Tam, H.Y. Modified dwell time optimization model and its applications in subaperture polishing. Appl. Opt. 2014, 53, 3213–3224. [Google Scholar] [CrossRef]

- Wang, T.; Cheng, H.; Feng, Y.; Tam, H. Strategy of restraining ripple error on surface for optical fabrication. Appl. Opt. 2014, 53, 6058–6065. [Google Scholar] [CrossRef]

- Xiao, H.P.; Chen, Z.; Wang, H.R.; Wang, J.; Zhu, N. Effect of grinding parameters on surface roughness and subsurface damage and their evaluation in fused silica. Opt. Express 2018, 26, 4638–4655. [Google Scholar] [CrossRef]

- Lin, X.H.; Zhang, J.B.; Tang, H.H.; Du, X.Y.; Guo, Y.B. Analysis of surface errors and subsurface damage in flexible grinding of optical fused silica. Int. J. Adv. Manuf. Technol. 2017, 88, 643–649. [Google Scholar] [CrossRef]

- Walker, D.; Yu, G.Y.; Li, H.Y.; Messelink, W.; Evans, R.; Beaucamp, A. Edges in CNC polishing: From mirror-segments towards semiconductors, paper 1: Edges on processing the global surface. Opt. Express 2012, 20, 19787–19798. [Google Scholar] [CrossRef]

- Li, H.Y.; Walker, D.; Yu, G.Y.; Sayle, A.; Messelink, W.; Evans, R.; Beaucamp, A. Edge control in CNC polishing, paper 2: Simulation and validation of tool influence functions on edges. Opt. Express 2013, 21, 370–381. [Google Scholar] [CrossRef] [PubMed]

- Jeffrey, A.L. Optics for the National Ignition Facility. Proc. SPIE 1999, 3749, 250–251. [Google Scholar]

- Jones, R.A. Computer controlled polisher demonstration. Appl. Opt. 1980, 19, 2072–2076. [Google Scholar] [CrossRef] [PubMed]

- Menapace, J.A.; Davis, P.J.; Steele, W.A.; Wong, L.L.; Suratwala, T.I.; Miller, P.E. Utilization of magnetorheological finishing as a diagnostic tool for investigating the three-dimensional structure of fractures in fused silica. Proc. SPIE 2005, 5991, 599102. [Google Scholar]

- Wang, T.; Cheng, H.; Yang, H.; Wu, W.; Tam, H. Controlling mid-spatial frequency errors in magnetorheological jet polishing with a simple vertical model. Appl. Opt. 2015, 54, 6433–6440. [Google Scholar] [CrossRef]

- Wang, H.J.; Zhang, F.H.; Zhao, H.; Luan, D.; Chen, Y.C. Effect of several processing parameters on material removal ratio in ultrasonic-magnetorheological compound finishing. Opt. Precis. Eng. 2007, 15, 1583–1588. [Google Scholar]

- Tam, H.Y.; Cheng, H.; Dong, Z. Peano-like paths for subaperture polishing of optical aspherical surfaces. Appl. Opt. 2013, 52, 3624–3636. [Google Scholar] [CrossRef]

- Tam, H.Y.; Cheng, H. An investigation of the effects of the tool path on the removal of material in polishing. J. Mater. Process. Technol. 2010, 210, 807–818. [Google Scholar] [CrossRef]

- Li, Y.H.; Feng, J.C.; Wang, Y.H. Fractal Tool-Path Planning for Free-Form Surface Polishing System. Key Eng. Mater. 2008, 359, 484–488. [Google Scholar]

- Dong, Z.; Nai, W. Surface ripple suppression in subaperture polishing with fragment-type tool paths. Appl. Opt. 2018, 57, 5523–5532. [Google Scholar] [CrossRef]

- Schinhaerl, M.; Smith, G.; Stamp, R.; Rascher, R.; Smith, L.; Pitschke, E.; Sperber, P.; Geiss, A. Mathematical modelling of influence functions in computer-controlled polishing: Part I. Appl. Math. Model. 2008, 32, 2888–2906. [Google Scholar] [CrossRef]

- Dunn, C.R.; Walker, D.D. Pseudo-random tool paths for CNC sub-aperture polishing and other applications. Opt. Express 2008, 16, 18942–18949. [Google Scholar] [CrossRef] [PubMed]

- Ken, T.; Anthony, B. Comparison of tool feed influence in CNC polishing between a novel circular-random path and other pseudo-random paths. Opt. Express 2017, 25, 22411–22424. [Google Scholar]

- Wang, C.; Wang, Z.; Xu, Q. Unicursal random maze tool path for computer-controlled optical surfacing. Appl. Opt. 2015, 54, 10128–10136. [Google Scholar] [CrossRef]

- Zhao, Q.; Zhang, L.; Fan, C. Six-directional pseudorandom consecutive unicursal polishing path for suppressing mid-spatial frequency error and realizing consecutive uniform coverage. Appl. Opt. 2019, 58, 8529–8541. [Google Scholar] [CrossRef] [PubMed]

- Li, H.Y.; Walker, D.D.; Zheng, X.; Su, X.; Wu, L.; Reynolds, C.; Yu, G.; Li, T.; Zhang, P. Mid-spatial frequency removal on aluminum free-form mirror. Opt. Express 2019, 27, 24885–24899. [Google Scholar] [CrossRef]

- De Lacalle, L.N.L.; Lamikiz, A.; Sanchez, J.A.; Salgado, M.A. Toolpath selection based on the minimum deflection cutting forces in the programming of complex surfaces milling. Int. J. Mach. Tools Manuf. 2007, 47, 388–400. [Google Scholar] [CrossRef]

- Díaz-Tena, E.; Rodríguez-Ezquerro, A.; López de Lacalle, L.N.; Bustinduy, L.G.; Sáenz, A.E. A sustainable process for material removal on pure copper by use of extremophile bacteria. J. Clean. Prod. 2014, 84, 752–760. [Google Scholar] [CrossRef]

- Bo, P.; González, H.; Calleja, A.; de Lacalle, L.N.; Bartoň, M. 5-axis double-flank CNC machining of spiral bevel gears via custom-shaped milling tools—Part I: Modeling and simulation. Precis. Eng. 2020, 62, 204–212. [Google Scholar] [CrossRef] [Green Version]

- Artetxe, E.; Urbikain, G.; Lamikiz, A.; López-de-Lacalle, L.N.; González, R.; Rodal, P. A mechanistic cutting force model for new barrel end mills. Procedia Eng. 2015, 132, 553–560. [Google Scholar] [CrossRef] [Green Version]

- Urbikain, G.; Artetxe, E.; López De Lacalle, L.N. Numerical simulation of milling forces with barrel-shaped tools considering runout and tool inclination angles. Appl. Math. Model. 2017, 47, 619–636. [Google Scholar] [CrossRef]

- Calleja, A.; Bo, P.; González, H.; Bartoň, M.; de Lacalle, L.N. Highly-accurate 5-axis flank CNC machining with conical tools. Int. J. Adv. Manuf. Technol. 2018, 97, 1605–1615. [Google Scholar] [CrossRef] [Green Version]

- López de Lacalle, L.N.; Lamikiz, A.; Muñoa, J.; Salgado, M.A.; Sánchez, J.A. Improving the high-speed finishing of forming tools for advanced high-strength steels (AHSS). Int. J. Adv. Manuf. Technol. 2006, 29, 49–63. [Google Scholar] [CrossRef]

- Spaeth, M.L.; Manes, K.R.; Widmayer, C.C.; Williams, W.H.; Whitman, P.K.; Henesian, M.A.; Stowers, I.F.; Honig, J. The National Ignition Facility wavefront requirements and optical architecture. Opt. Eng. 2004, 43, 25–42. [Google Scholar] [CrossRef]

- Gorana, V.K.; Jain, V.K.; Lal, G.K. Prediction of surface roughness during abrasive flow machining. Int. J. Adv. Manuf. Technol. 2006, 31, 258–267. [Google Scholar] [CrossRef]

| Overlap | Standard Deviation |

|---|---|

| 10% | 0.3057 |

| 20% | 0.3030 |

| 30% | 0.3015 |

| 40% | 0.2933 |

| 50% | 0.3258 |

| 60% | 0.3679 |

| Number | Polishing Agent (%) | Lapping Oil (%) |

|---|---|---|

| 1 | 100 | 0 |

| 2 | 90 | 10 |

| 3 | 80 | 20 |

| 4 | 70 | 30 |

| 5 | 60 | 40 |

| 6 | 50 | 50 |

| 7 | 40 | 60 |

| 8 | 30 | 70 |

| 9 | 20 | 80 |

| 10 | 10 | 90 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zha, J.; Zhang, H.; Li, Y.; Chen, Y. Pseudo-random Path Generation Algorithms and Strategies for the Surface Quality Improvement of Optical Aspherical Components. Materials 2020, 13, 1216. https://doi.org/10.3390/ma13051216

Zha J, Zhang H, Li Y, Chen Y. Pseudo-random Path Generation Algorithms and Strategies for the Surface Quality Improvement of Optical Aspherical Components. Materials. 2020; 13(5):1216. https://doi.org/10.3390/ma13051216

Chicago/Turabian StyleZha, Jun, Hangcheng Zhang, Yipeng Li, and Yaolong Chen. 2020. "Pseudo-random Path Generation Algorithms and Strategies for the Surface Quality Improvement of Optical Aspherical Components" Materials 13, no. 5: 1216. https://doi.org/10.3390/ma13051216

APA StyleZha, J., Zhang, H., Li, Y., & Chen, Y. (2020). Pseudo-random Path Generation Algorithms and Strategies for the Surface Quality Improvement of Optical Aspherical Components. Materials, 13(5), 1216. https://doi.org/10.3390/ma13051216