Recycling of Waste Materials for Asphalt Concrete and Bitumen: A Review

Abstract

:1. Introduction

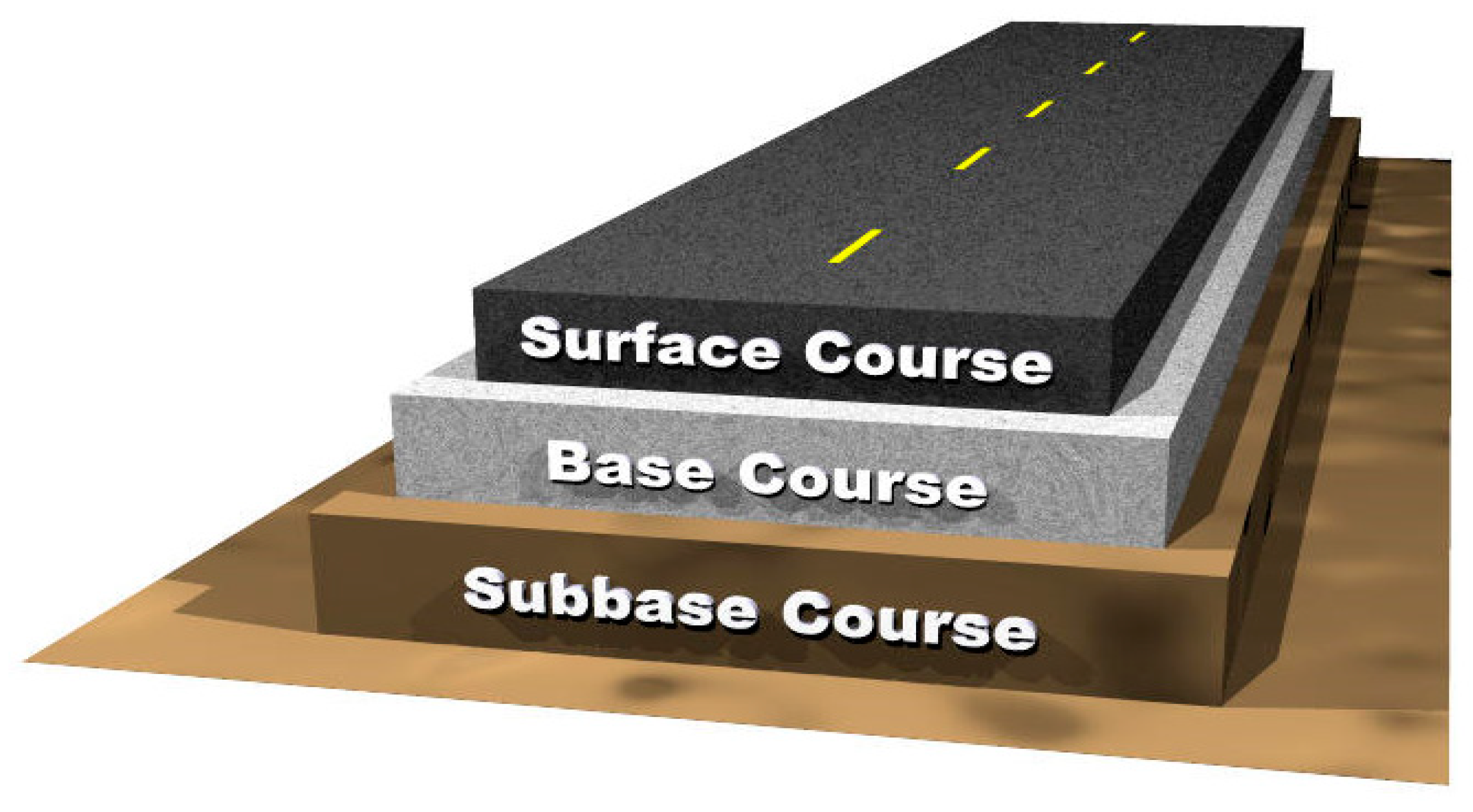

2. Asphalt Concrete

2.1. Hot Mix Asphalt (HMA)

2.2. Stone Mastic Asphalt (SMA)

2.3. Advantages and Disadvantages of Different Type of Asphalt

3. Bitumen

4. Use of Waste Materials in Asphalt Mix and Bitumen

- (1)

- Selection of waste material.

- (2)

- Source, characteristics, and common use.

- (3)

- Method of recycling in asphalt concrete and bitumen.

- (4)

- Discussion on the performance of modified asphalt concrete and bitumen prepared with waste materials.

4.1. Plastic Waste

4.2. Quarry Waste

4.3. Building Demolition Waste

4.4. Ground Tire Rubber

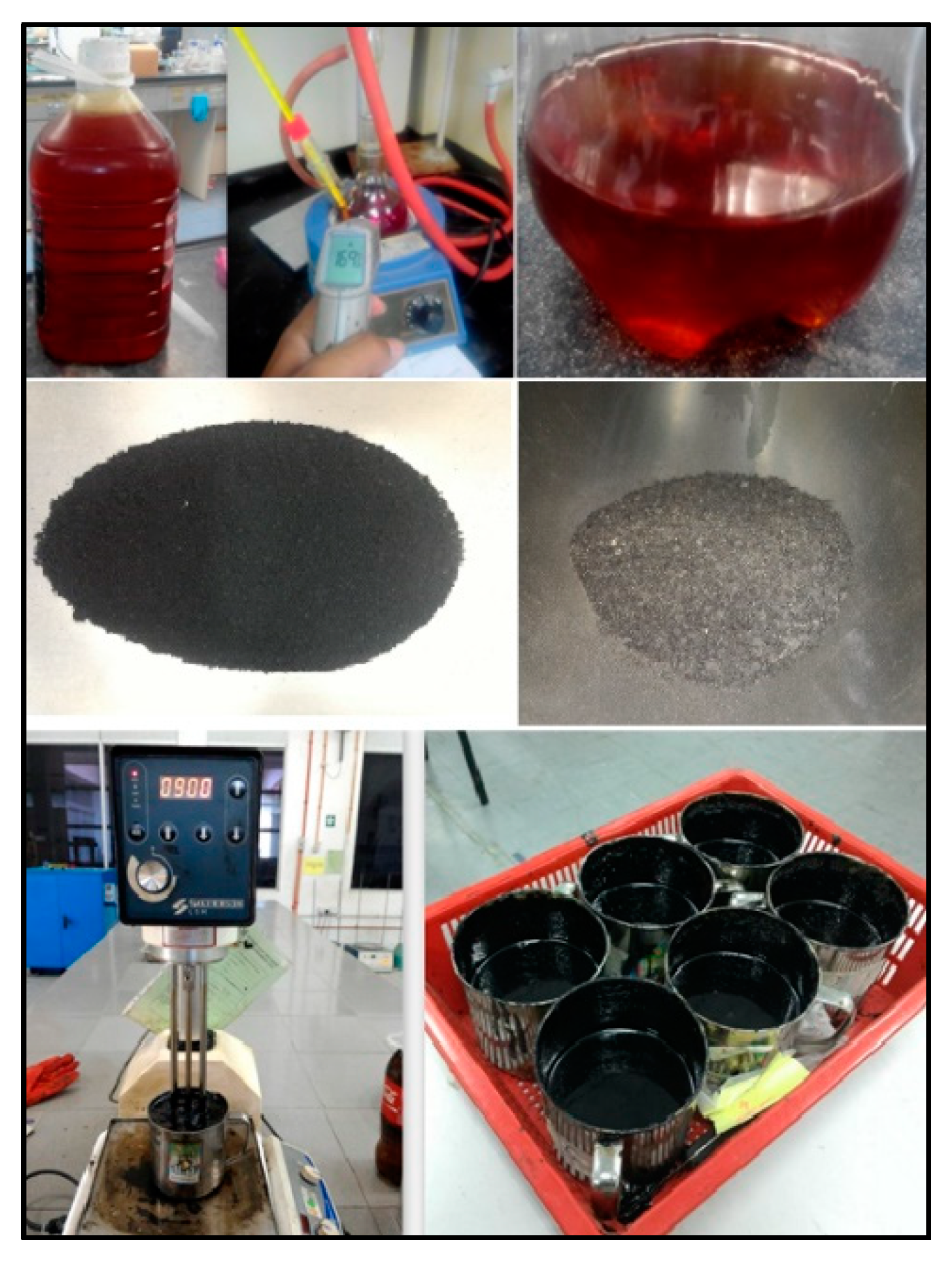

4.5. Waste Cooking Oil and Palm Oil Fuel Ash

4.6. Coconut, Sisal, Cellulose, and Polyester Fibers

4.7. Starch

4.8. Waste Glass

4.9. Waste Brick

4.10. Waste Ceramics

4.11. Waste Fly-ash

4.12. Cigarette Butts (CBs)

5. Significance of Recycling Waste Materials in Asphalt Concrete and Bitumen

5.1. Application

5.2. Economic and Environmental Aspect

6. Conclusions

Recommendations and Scope for Further Research

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pickin, J.; Randell, P. Australian National Waste Report 2016. 2016. Available online: https://www.environment.gov.au/system/files/resources/d075c9bc-45b3-4ac0-a8f2-6494c7d1fa0d/files/national-waste-report-2016.pdf (accessed on 25 March 2020).

- Australian Bureau of Statistics. Waste. 2007. Available online: https://www.abs.gov.au/ausstats/[email protected]/Lookup/by%20Subject/1370.0~2010~Chapter~Landfill%20(6.6.4) (accessed on 25 March 2020).

- Batayneh, M.; Marie, I.; Asi, I. Use of selected waste materials in concrete mixes. Waste Manag. 2007, 27, 1870–1876. [Google Scholar] [CrossRef] [PubMed]

- Bolden, J.; Abu-Lebdeh, T.; Fini, E. Utilization of recycled and waste materials in various construction applications. Am. J. Environ. Sci. 2013, 9, 14–24. [Google Scholar] [CrossRef]

- Cremiato, R.; Mastellone, M.L.; Tagliaferri, C.; Zaccariello, L.; Lettieri, P. Environmental impact of municipal solid waste management using Life Cycle Assessment: The effect of anaerobic digestion, materials recovery and secondary fuels production. Renew. Energy 2018, 124, 180–188. [Google Scholar] [CrossRef] [Green Version]

- Kuhlman, T.; Farrington, J. What is sustainability? Sustainability 2010, 2, 3436–3448. [Google Scholar] [CrossRef] [Green Version]

- Aziz, M.M.A.; Rahman, M.T.; Hainin, M.R.; Bakar WA, W.A. An overview on alternative binders for flexible pavement. Constr. Build. Mater. 2015, 84, 315–319. [Google Scholar] [CrossRef]

- Abu-Lebdeh, T.; Hamoush, S.; Heard, W.; Zornig, B. Effect of matrix strength on pullout behavior of steel fiber reinforced very-high strength concrete composites. Constr. Build. Mater. 2011, 25, 39–46. [Google Scholar] [CrossRef]

- James, M.N.; Choi, W.; Abu-Lebdeh, T. Use of recycled aggregate and fly ash in concrete pavement. Am. J. Eng. Appl. Sci. 2011, 4, 201–208. [Google Scholar] [CrossRef] [Green Version]

- Hamoush, S.; Abu-Lebdeh, T.; Picornell, M.; Amer, S. Development of sustainable engineered stone cladding for toughness, durability, and energy conservation. Constr. Build. Mater. 2011, 25, 4006–4016. [Google Scholar] [CrossRef]

- Anderson, D.; Youtcheff, J.; Zupanick, M. Asphalt Binders. In Transportation in the New Millennium; Transportation Research Board: Washington, DC, USA, 2000; Available online: http://onlinepubs.trb.org/Onlinepubs/millennium/00006.pdf (accessed on 25 March 2020).

- Asphalt Magazine. Asphalt is the pavement of choice in Australia. 2018. Available online: http://asphaltmagazine.com/asphalt-is-the-pavement-of-choice-in-australia/ (accessed on 25 March 2020).

- Trading Economics. Australia—Roads, Paved (% of total roads). 2009. Available online: https://tradingeconomics.com/australia/roads-paved-percent-of-total-roads-wb-data.html (accessed on 25 March 2020).

- Tayabji, S.D.; Brown, J.L.; Mack, J.W.; Hearne, T.M., Jr.; Anderson, J.O.H.N.; Murrell, S.C.O.T.T.; Noureldin, A.S. Pavement Rehabilitation. TRB Committee on Pavement Rehabilitation, TRB Millennium Paper Series. 2000. Available online: http://onlinepubs.trb.org/Onlinepubs/millennium/00086.pdf (accessed on 25 March 2020).

- Mashaan, N.S.; Ali, A.H.; Karim, M.R.; Abdelaziz, M. A review on using crumb rubber in reinforcement of asphalt pavement. Sci. World J. 2014. [Google Scholar] [CrossRef]

- Garcia, J.; Hansen, K. HMA Mix Type Selection Guide. Information Series 128; National Asphalt Pavement Association: Lanham, MD, USA, 2001. [Google Scholar]

- Pavement Interactive. HMA Pavement. [cited 2018 25/06]. 2012. Available online: http://www.pavementinteractive.org/hma-pavement/ (accessed on 25 March 2020).

- Blazejowski, K. Stone Matrix Asphalt: Theory and Practice; CRC Press: Boca Raton, FL, USA, 2016; Available online: http://sirjannano.com/Admin/upload/files/fani-nano/Binder1.pdf (accessed on 25 March 2020).

- Shafabakhsh, G.H.; Sajed, Y. Investigation of dynamic behavior of hot mix asphalt containing waste materials; case study: Glass cullet. Case Stud. Constr. Mater. 2014, 1, 96–103. [Google Scholar] [CrossRef] [Green Version]

- Sehgal, S.K. Stone Matrix Asphalt Indian Experiences. [cited 2019 24th March]. 2017. Available online: https://www.nbmcw.com/tech-articles/roads-and-pavements/36144-stone-matrix-asphalt-indian-experiences.html (accessed on 25 March 2020).

- Rahman, M.T.; Aziz, M.M.A.; Hainin, M.R.; Bakar, W.A. Impact of bitumen binder: Scope of bio-based binder for construction of flexible pavement. J. Technol. 2014, 70, 105–109. [Google Scholar] [CrossRef] [Green Version]

- John Rebbechi, L.P. Guide to Pavement Technology Part 4B: Asphalt; Austroads Ltd.: Sydney, Australia, 2014. [Google Scholar]

- Rahman, M.T.; Hainin, M.R.; Bakar, W.A.W.A. Use of waste cooking oil, tire rubber powder and palm oil fuel ash in partial replacement of bitumen. Constr. Build. Mater. 2017, 150, 95–104. [Google Scholar] [CrossRef]

- Kalantar, Z.N.; Karim, M.R.; Mahrez, A. A review of using waste and virgin polymer in pavement. Constr. Build. Mater. 2012, 33, 55–62. [Google Scholar] [CrossRef] [Green Version]

- Hunter, R.N.; Self, A.; Read, J. The Shell Bitumen Handbook; ICE Publishing: Westminster, UK, 2015. [Google Scholar]

- Azahar, W.N.A.W.; Bujang, M.; Jaya, R.P.; Hainin, M.R.; Mohamed, A.; Ngad, N.; Jayanti, D.S. The potential of waste cooking oil as bio-asphalt for alternative binder—An overview. J. Technol. 2016, 78, 111–116. [Google Scholar]

- Hainin, M.R.; Jaya, R.P.; Ali Akbar, N.A.; Jayanti, D.S.; Yusoff NI, M. Influence of palm oil fuel ash as a modifier on bitumen to improve aging resistance. J. Eng. Res. 2014, 2, 34–46. [Google Scholar]

- Rusbintardjo, G.; Hainin, M.R.; Yusoff, N.I.M. Fundamental and rheological properties of oil palm fruit ash modified bitumen. Constr. Build. Mater. 2013, 49, 702–711. [Google Scholar] [CrossRef]

- Mohajerani, A.; Hui, S.Q.; Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; Abdul Kadir, A.; Rahman, M.T.; Maghool, F. Amazing Types, Properties, and Applications of Fibres in Construction Materials. Materials 2019, 12, 2513. [Google Scholar] [CrossRef] [Green Version]

- Poulikakos, L.D.; Papadaskalopoulou, C.; Hofko, B.; Gschösser, F.; Falchetto, A.C.; Bueno, M.; Loizidou, M. Harvesting the unexplored potential of European waste materials for road construction. Resour. Conserv. Recycl. 2017, 116, 32–44. [Google Scholar] [CrossRef]

- Hu, C.; Lin, W.; Partl, M.; Wang, D.; Yu, H.; Zhang, Z. Waste packaging tape as a novel bitumen modifier for hot-mix asphalt. Constr. Build. Mater. 2018, 193, 23–31. [Google Scholar] [CrossRef]

- Razali, M.N.; Aziz, M.A.A.; Jamin, N.F.M.; Salehan, N.A.M. Modification of bitumen using polyacrylic wig waste. AIP Conf. Proc. 2018. [Google Scholar] [CrossRef]

- Liu, X.; Wu, S. Study on the graphite and carbon fiber modified asphalt concrete. Constr. Build. Mater. 2011, 25, 1807–1811. [Google Scholar] [CrossRef]

- Serin, S.; Morova, N.; Saltan, M.; Terzi, S. Investigation of usability of steel fibers in asphalt concrete mixtures. Constr. Build. Mater. 2012, 36, 238–244. [Google Scholar] [CrossRef]

- VicRoads. SECTION 404—STONE MASTIC ASPHALT. Australia; 2012. Available online: http://webapps.vicroads.vic.gov.au/VRNE/csdspeci.nsf/webscdocs/5916DDA1FE3D3096CA2579E4001945FB/$File/Sec404.doc (accessed on 25 March 2020).

- Toraldo, E.; Mariani, E.; Malvicini, S. Laboratory investigation into the effects of fibers on bituminous mixtures. J. Civ. Eng. Manag. 2015, 21, 45–53. [Google Scholar] [CrossRef]

- Rahman, M.T.; Mohajerani, A.; Giustozzi, F. Possible Recycling of Cigarette Butts as Fiber Modifier in Bitumen for Asphalt Concrete. Materials 2020, 13, 734. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hınıslıoğlu, S.; Ağar, E. Use of waste high density polyethylene as bitumen modifier in asphalt concrete mix. Mater. Lett. 2004, 58, 267–271. [Google Scholar] [CrossRef]

- Dalhat, M.A.; Al-Abdul Wahhab, H.I. Performance of recycled plastic waste modified asphalt binder in Saudi Arabia. Int. J. Pavement Eng. 2017, 18, 349–357. [Google Scholar] [CrossRef]

- Becker, Y.; Mendez, M.P.; Rodriguez, Y. Polymer modified asphalt. Vis. Technol. 2001, 9, 39–50. [Google Scholar]

- Azarhoosh, A.R.; Hamedi, G.H.; Abandansari, H.F. Providing Laboratory Rutting Models for Modified Asphalt Mixes with Different Waste Materials. Period. Polytech. Civ. Eng. 2018, 62, 308–317. [Google Scholar] [CrossRef] [Green Version]

- Al-Salem, S.M.; Lettieri, P.; Baeyens, J. Recycling and recovery routes of plastic solid waste (PSW): A review. Waste Manag. 2009, 29, 2625–2643. [Google Scholar] [CrossRef]

- Ahmadinia, E.; Zargar, M.; Karim, M.R.; Abdelaziz, M.; Shafigh, P. Using waste plastic bottles as additive for stone mastic asphalt. Mater. Des. 2011, 32, 4844–4849. [Google Scholar] [CrossRef]

- Zakaria, N.M.; Hassan, M.K.; Ibrahim AN, H.; Rosyidi SA, P.; Yusoff NI, M.; Mohamed, A.A.; Hassan, N. The use of mixed waste recycled plastic and glass as an aggregate replacement in asphalt mixtures. J. Technol. 2018, 80, 79–88. [Google Scholar] [CrossRef] [Green Version]

- Akbulut, H.; Gürer, C. Use of aggregates produced from marble quarry waste in asphalt pavements. Build. Environ. 2007, 42, 1921–1930. [Google Scholar] [CrossRef]

- Gautam, P.K.; Kalla, P.; Nagar, R.; Agrawal, R.; Jethoo, A.S. Laboratory investigations on hot mix asphalt containing mining waste as aggregates. Constr. Build. Mater. 2018, 168, 143–152. [Google Scholar] [CrossRef]

- Aljassar, A.H.; Al-Fadala, K.B.; Ali, M.A. Recycling building demolition waste in hot-mix asphalt concrete: A case study in Kuwait. J. Mater. Cycles Waste Manag. 2005, 7, 112–115. [Google Scholar] [CrossRef]

- Tavira, J.; Jiménez, J.R.; Ayuso, J.; Sierra, M.J.; Ledesma, E.F. Functional and structural parameters of a paved road section constructed with mixed recycled aggregates from non-selected construction and demolition waste with excavation soil. Constr. Build. Mater. 2018, 164, 57–69. [Google Scholar] [CrossRef]

- Blengini, G.A. Life cycle of buildings, demolition and recycling potential: A case study in Turin, Italy. Build. Environ. 2009, 44, 319–330. [Google Scholar] [CrossRef]

- Chiu, C.T.; Lu, L.C. A laboratory study on stone matrix asphalt using ground tire rubber. Constr. Build. Mater. 2007, 21, 1027–1033. [Google Scholar] [CrossRef]

- Behnood, A.; Olek, J. Rheological properties of asphalt binders modified with styrene-butadiene-styrene (SBS), ground tire rubber (GTR), or polyphosphoric acid (PPA). Constr. Build. Mater. 2017, 151, 464–478. [Google Scholar] [CrossRef]

- Aoudia, K.; Azem, S.; Hocine, N.A.; Gratton, M.; Pettarin, V.; Seghar, S. Recycling of waste tire rubber: Microwave devulcanization and incorporation in a thermoset resin. Waste Manag. 2017, 60, 471–481. [Google Scholar] [CrossRef]

- Pouranian, M.R.; Notani, M.A.; Tabesh, M.T.; Nazeri, B.; Shishehbor, M. Rheological and environmental characteristics of crumb rubber asphalt binders containing non-foaming warm mix asphalt additives. Constr. Build. Mater. 2020, 238, 117707. [Google Scholar] [CrossRef]

- Ding, X.; Chen, L.; Ma, T.; Ma, H.; Gu, L.; Chen, T.; Ma, Y. Laboratory investigation of the recycled asphalt concrete with stable crumb rubber asphalt binder. Constr. Build. Mater. 2019, 203, 552–557. [Google Scholar] [CrossRef]

- Mohajerani, A.; Burnett, L.; Smith, J.V.; Markovski, S.; Rodwell, G.; Rahman, M.T.; Kurmus, H.; Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; et al. Recycling waste rubber tyres in construction materials and associated environmental considerations: A review. Resour. Conserv. Recycl. 2020, 155, 104679. [Google Scholar] [CrossRef]

- Ting, T.L.; Jaya, R.P.; Hassan, N.A.; Yaacob, H. Resilient modulus of double layer porous asphalt: Application of alkali treated coconut shell and fiber as aggregate replacement. Malays. J. Civ. Eng. 2017, 29, 187–194. [Google Scholar]

- Agunsoye, J.O.; Bello, S.A.; Azeez, S.O.; Yekinni, A.A.; Adeyemo, R.G. Recycled polypropylene reinforced coconut shell composite: Surface treatment morphological, mechanical and thermal studies. Int. J. Compos. Mater. 2014, 4, 168–178. [Google Scholar]

- Oda, S.; Fernandes Jr, J.L.; Ildefonso, J.S. Analysis of use of natural fibers and asphalt rubber binder in discontinuous asphalt mixtures. Constr. Build. Mater. 2012, 26, 13–20. [Google Scholar] [CrossRef]

- Al-Hadidy, A.I.; Yi-Qiu, T.; Hameed, A.T. Starch as a modifier for asphalt paving materials. Constr. Build. Mater. 2011, 25, 14–20. [Google Scholar]

- Issa, Y. Effect of adding crushed glass to asphalt mix. Arch. Civil Eng. 2016, 62, 35–44. [Google Scholar] [CrossRef] [Green Version]

- Salem, Z.T.A.; Khedawi, T.S.; Baker, M.B.; Abendeh, R. Effect of waste glass on properties of asphalt concrete mixtures. Jordan J. Civ. Eng. 2017, 11, 117–131. [Google Scholar]

- Mohajerani, A.; Vajna, J.; Cheung TH, H.; Kurmus, H.; Arulrajah, A.; Horpibulsuk, S. Practical recycling applications of crushed waste glass in construction materials: A review. Constr. Build. Mater. 2017, 156, 443–467. [Google Scholar] [CrossRef]

- Chen, M.Z.; Lin, J.T.; Wu, S.P.; Liu, C.H. Utilization of recycled brick powder as alternative filler in asphalt mixture. Constr. Build. Mater. 2011, 25, 1532–1536. [Google Scholar] [CrossRef]

- Arulrajah, A.; Piratheepan, J.; Aatheesan, T.; Bo, M.W. Geotechnical properties of recycled crushed brick in pavement applications. J. Mater. Civ. Eng. 2011, 23, 1444–1452. [Google Scholar] [CrossRef]

- Muniandy, R.; Ismail, D.H.; Hassim, S. Performance of recycled ceramic waste as aggregates in hot mix asphalt (HMA). J. Mater. Cycles Waste Manag. 2018, 20, 844–849. [Google Scholar] [CrossRef]

- Silvestre, R.; Medel, E.; García, A.; Navas, J. Using ceramic wastes from tile industry as a partial substitute of natural aggregates in hot mix asphalt binder courses. Constr. Build. Mater. 2013, 45, 115–122. [Google Scholar] [CrossRef] [Green Version]

- Pasandín, A.R.; Pérez, I.; Ramírez, A.; Cano, M.M. Moisture damage resistance of hot-mix asphalt made with paper industry wastes as filler. J. Clean. Prod. 2016, 112, 853–862. [Google Scholar] [CrossRef] [Green Version]

- Mohammadinia, A.; Arulrajah, A.; Horpibulsuk, S.; Chinkulkijniwat, A. Effect of fly ash on properties of crushed brick and reclaimed asphalt in pavement base/subbase applications. J. Hazard. Mater. 2017, 321, 547–556. [Google Scholar] [CrossRef] [PubMed]

- Mohajerani, A.; Kadir, A.A.; Larobina, L. A practical proposal for solving the world’s cigarette butt problem: Recycling in fired clay bricks. Waste Manag. 2016, 52, 228–244. [Google Scholar] [CrossRef]

- Truth Initiative. 5 Ways Cigarette Litter Impacts the Environment. [cited 2019 10 January]. 2017. Available online: https://truthinitiative.org/news/5-ways-cigarette-litter-impacts-environment (accessed on 25 March 2020).

- Mohajerani, A.; Tanriverdi, Y.; Nguyen, B.T.; Wong, K.K.; Dissanayake, H.N.; Johnson, L.; Whitfield, D.; Thomson, G.; Alqattan, E.; Rezaei, A. Physico-mechanical properties of asphalt concrete incorporated with encapsulated cigarette butts. Constr. Build. Mater. 2017, 153, 69–80. [Google Scholar] [CrossRef]

- Road Traffic Technology The World’s Biggest Road Networks. [cited 2020 10th March]. 2014. Available online: https://www.roadtraffic-technology.com/features/featurethe-worlds-biggest-road-networks-4159235/ (accessed on 25 March 2020).

- De Brimont, M.R.; Hörnig, A.; JENSEN, E.S.; Olsen, J.E. Lightweight filler for waterproofing bitumen membranes. U.S. Patent Application No. 16/331,174, 22 August 2019. [Google Scholar]

- Smith, J.D.; Mellott, I.J.W.; Rus, M.; Sokol, D.; Holland, J. Active polymer modification of bitumen for use in roofing materials. U.S. Patent Application No. 16/245,684, 29 August 2017. [Google Scholar]

- Pouranian, M.R.; Shishehbor, M. Sustainability assessment of green asphalt mixtures: A review. Environments 2019, 6, 73. [Google Scholar] [CrossRef] [Green Version]

- Cuthbertson, D. ‘Have a crack at it’: Glass Plant to Recycle a Billion Bottles a Year, The Age. Australia. Published on 31st March 2019. 2019. Available online: https://www.theage.com.au/national/victoria/have-a-crack-at-it-glass-plant-to-recycle-a-billion-bottles-a-year-20190531-p51t7c.html (accessed on 25 March 2020).

| Type of Asphalt | Advantages | Disadvantages |

|---|---|---|

| Hot mix asphalt (HMA) | Low cost Effective in all traffic conditions | Lower rutting resistance Shorter service life Lesser quality aggregates used |

| Stone mastic asphalt (SMA) | Long service life High resistance to deformation Increased fatigue testing life Noise-reductive properties Decreased water spray when raining | Low skid resistance High cost Increased risk of flat spots occurring due to the SMA design procedure |

| Serial No. | Polymer | Advantages | Disadvantages | Uses |

|---|---|---|---|---|

| 1. | Polyethylene (PE) | High-temperature resistance Aging resistance High modulusLow cost | Hard to disperse in the bitumen Instability problems High polymer contents are required to achieve better properties No elastic recovery | Industrial uses Few road applications |

| 2. | Polypropylene (PP) | No important viscosity increases, even though a high number of polymers are necessary (ease of handling and layout) Low penetration Widens the plasticity range and improves the binder’s load resistance | Separation problems No improvement in elasticity or mechanical properties Low thermal fatigue cracking resistance | Isotactic PP is not commercially applied Atactic PP is used for roofing |

| 3. | Polyvinyl chloride (PVC) | Lower cracking PVC disposal | Acts mostly as filler | Not commercially applied |

| 4. | Styrene-butadiene block copolymer (SBS) | Higher flexibility at low temperatures Better flow and deformation resistance at high temperatures Strength and very good elasticity Increase in rutting resistance | High cost Reduced penetration resistance High viscosity at layout temperatures Resistance to heat and to oxidation is lower than that of polyolefins (due to the presence of double bonds in the main chain) | Paving and roofing |

| 5. | Styrene-isoprene block copolymer (SIS) | Higher aging resistance Better asphalt–aggregate adhesiveness Good blend stability, when used in a low proportion | Bitumen suitable for SBS blends Needs bitumen with a high aromatic and a low bituminous content | - |

| Sample Type | Waste Materials Used | Marshall Stability (kN) | Flow (mm) | |

|---|---|---|---|---|

| Glass | Plastic | |||

| Control | 0% | 0% | 13.42 | 5.64 |

| Glass | 5% | 0% | 6.67 | 5.92 |

| Plastic | 0% | 5% | 14.66 | 5.92 |

| Glass + Plastic Type 1 | 2.5% | 2.5% | 11.56 | 5.61 |

| Glass + Plastic Type 2 | 1% | 4% | 14.81 | 6.26 |

| Glass + Plastic Type 3 | 4% | 1% | 11.24 | 4.08 |

| Type of Material | Possible Recycling in Asphalt Concrete | Performance In Asphalt Concrete | Possible Recycling in Bitumen | Performance in Bitumen |

|---|---|---|---|---|

| Plastic | As aggregate | Improved Marshall stability | As a binder modifier | Improved resistance to permanent deformation |

| Glass | As aggregate | Reduced Marshall stability | - | - |

| Quarry waste | As aggregate | Suitable for low-traffic roads | - | - |

| Building demolition waste | As aggregate | Met standard requirement | - | - |

| Ground tire rubber | As additive | Improved rutting resistance | As a binder modifier | Improved binder drain of resistance and high-temperature properties |

| Waste cooking oil | - | - | As a binder modifier | Improved viscosity |

| Palm oil fuel ash | - | - | As a rejuvenator | Improved penetration property |

| Coconut and sisal fiber | As aggregate | Improved resilient modulus of asphalt concrete | As a fiber modifier | Improved resistance to binder drain-off |

| Starch | - | - | As a binder modifier | Reduced rutting potential and temperature susceptibility |

| Waste brick | As filler | Improved durability and resistance to fatigue | - | - |

| Waste ceramic | As aggregate | Improved mechanical properties | - | - |

| Fly ash | As filler | Reduced resilient modulus in hot mix asphalt | - | - |

| Cigarette butts (CBs) | As aggregate | Encapsulated CBs improved physio-mechanical properties of asphalt concrete | As a fiber modifier | Improved viscosity and resistance to binder drain off |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahman, M.T.; Mohajerani, A.; Giustozzi, F. Recycling of Waste Materials for Asphalt Concrete and Bitumen: A Review. Materials 2020, 13, 1495. https://doi.org/10.3390/ma13071495

Rahman MT, Mohajerani A, Giustozzi F. Recycling of Waste Materials for Asphalt Concrete and Bitumen: A Review. Materials. 2020; 13(7):1495. https://doi.org/10.3390/ma13071495

Chicago/Turabian StyleRahman, Md Tareq, Abbas Mohajerani, and Filippo Giustozzi. 2020. "Recycling of Waste Materials for Asphalt Concrete and Bitumen: A Review" Materials 13, no. 7: 1495. https://doi.org/10.3390/ma13071495