The Mechanism of Effect of Flux Bands on The Arc Behavior in Flux Bands Constricting Arc Welding Process

Abstract

1. Introduction

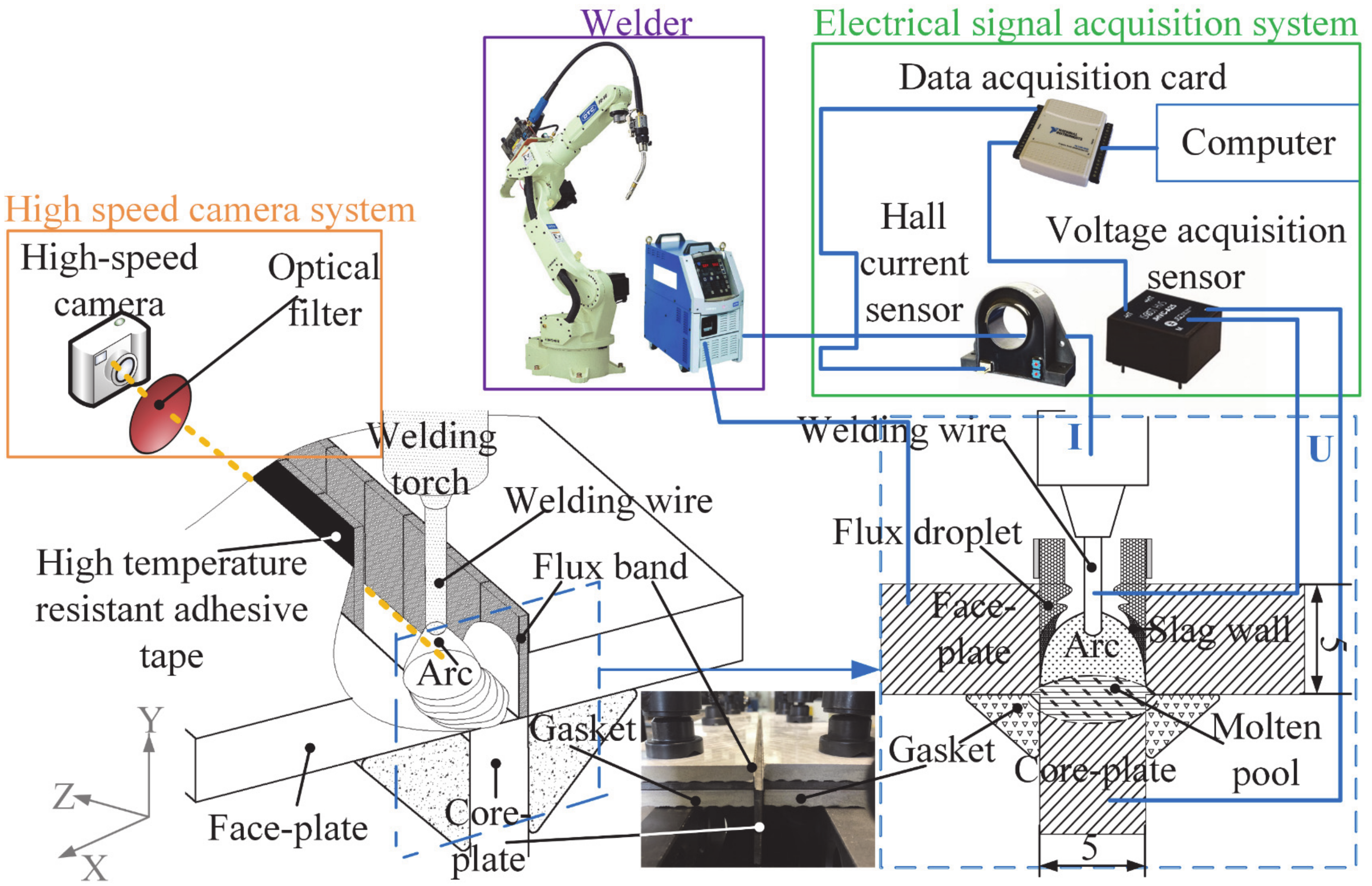

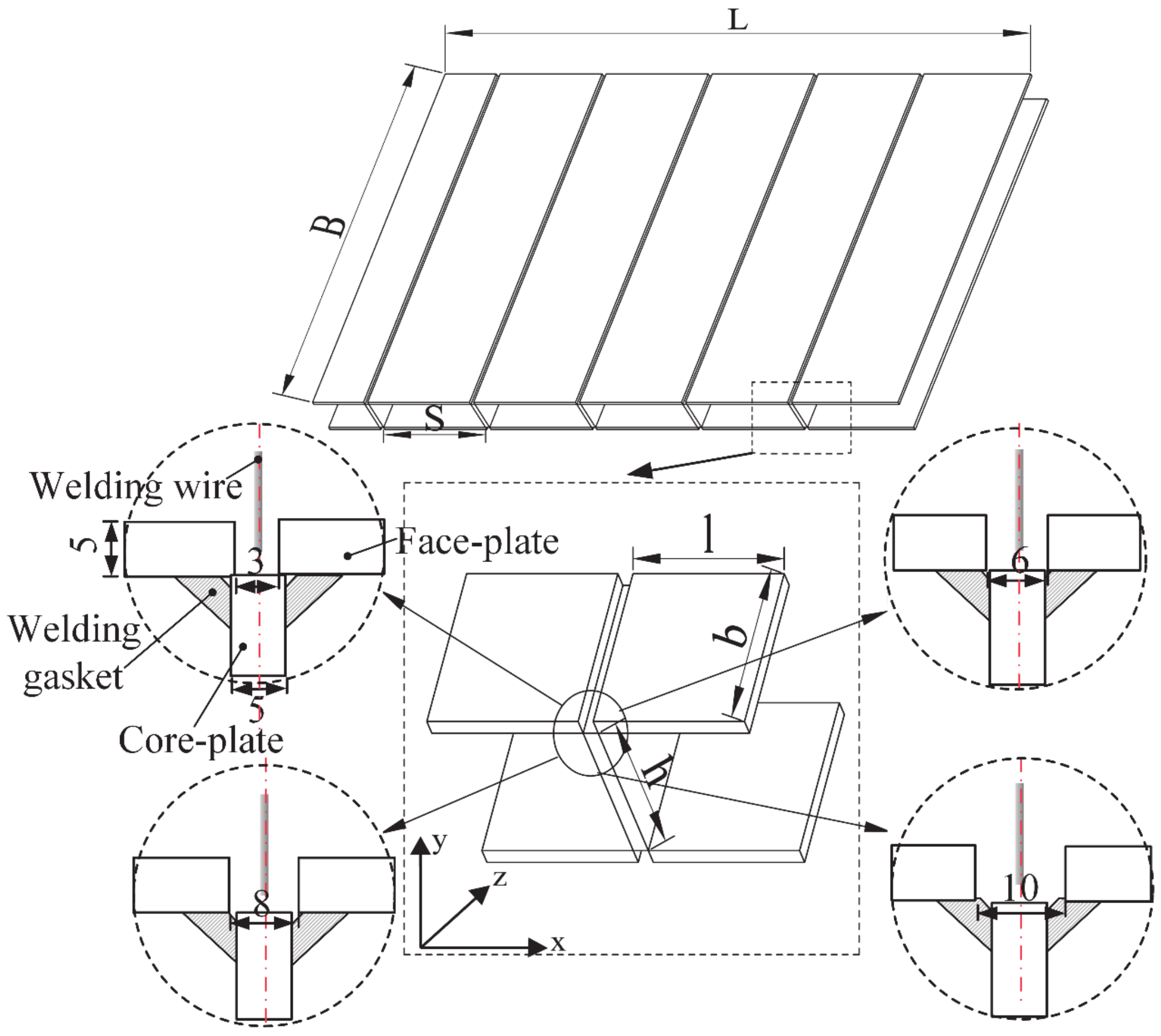

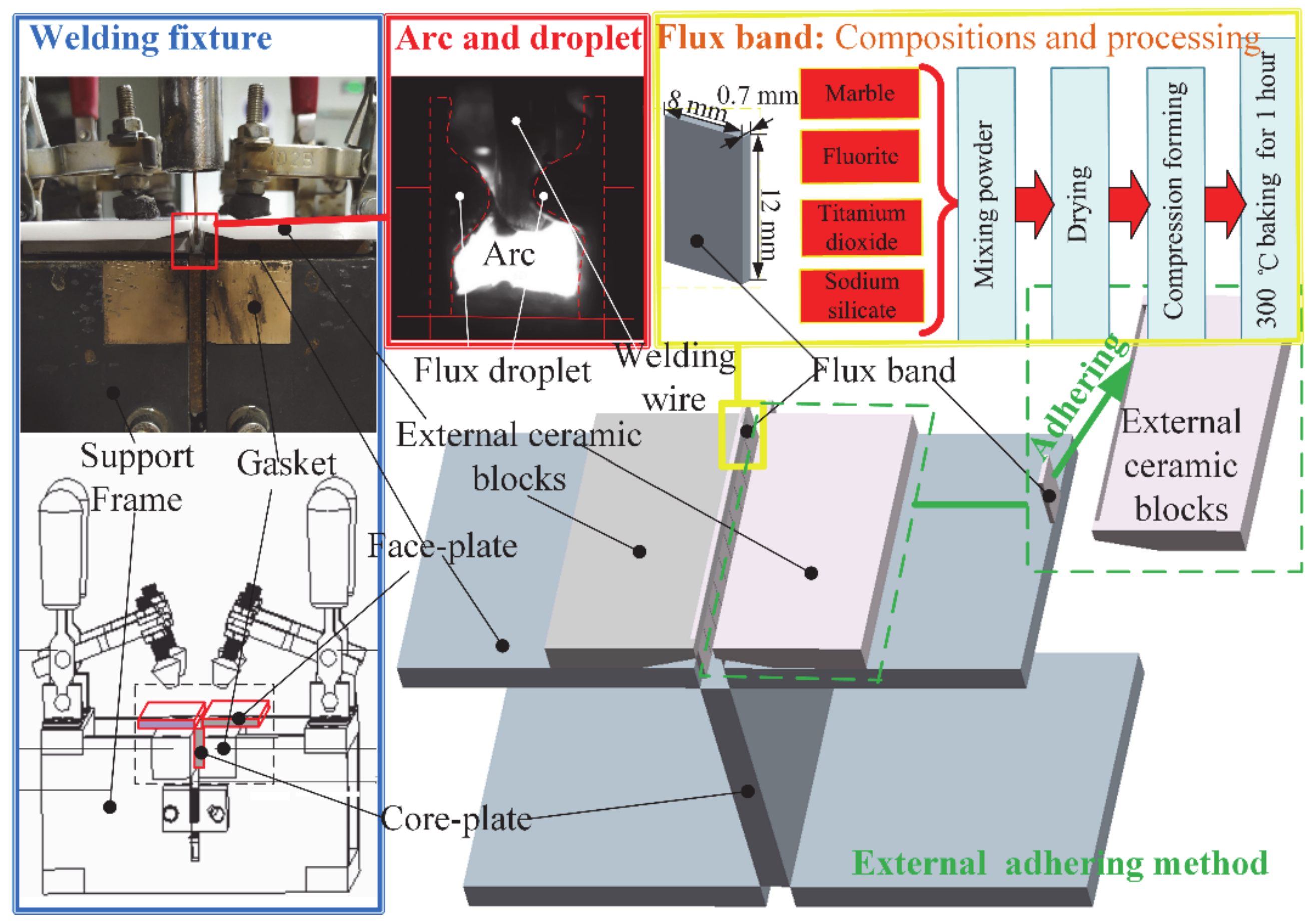

2. Experimental Setup and Procedures

3. Results and Discussion

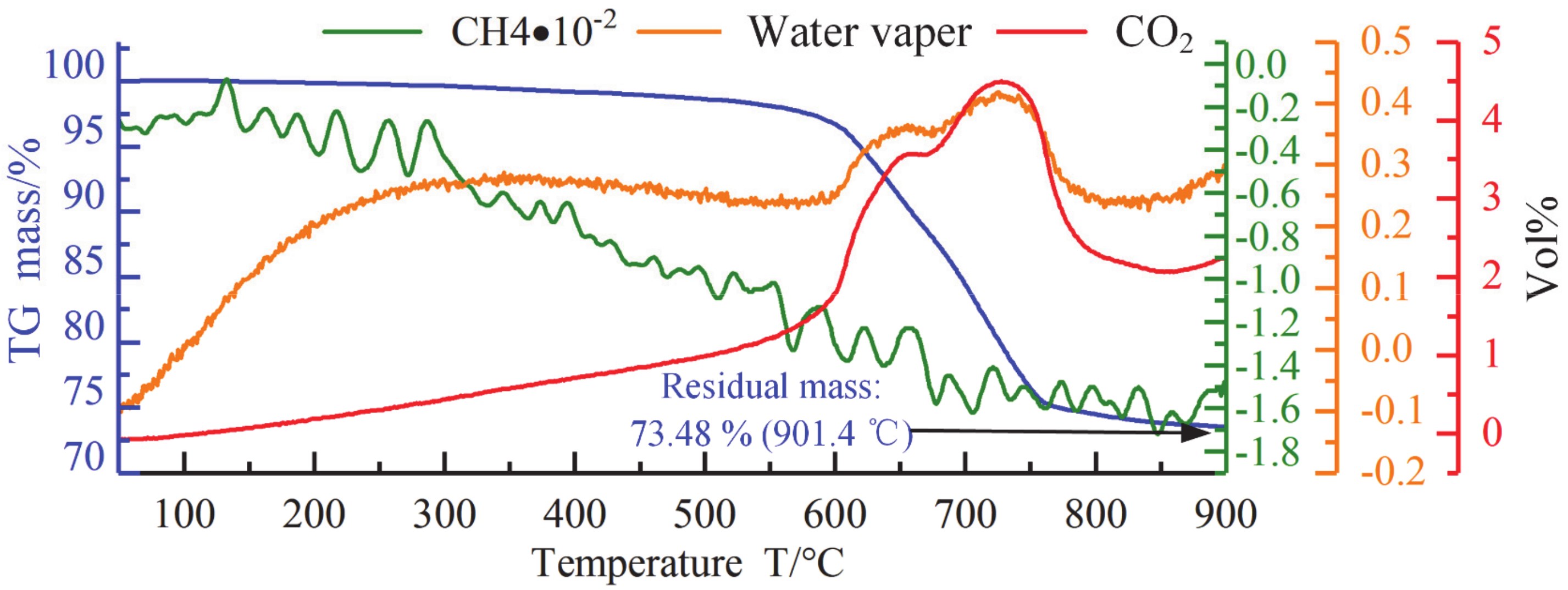

3.1. Flux Bands States in High Temperature

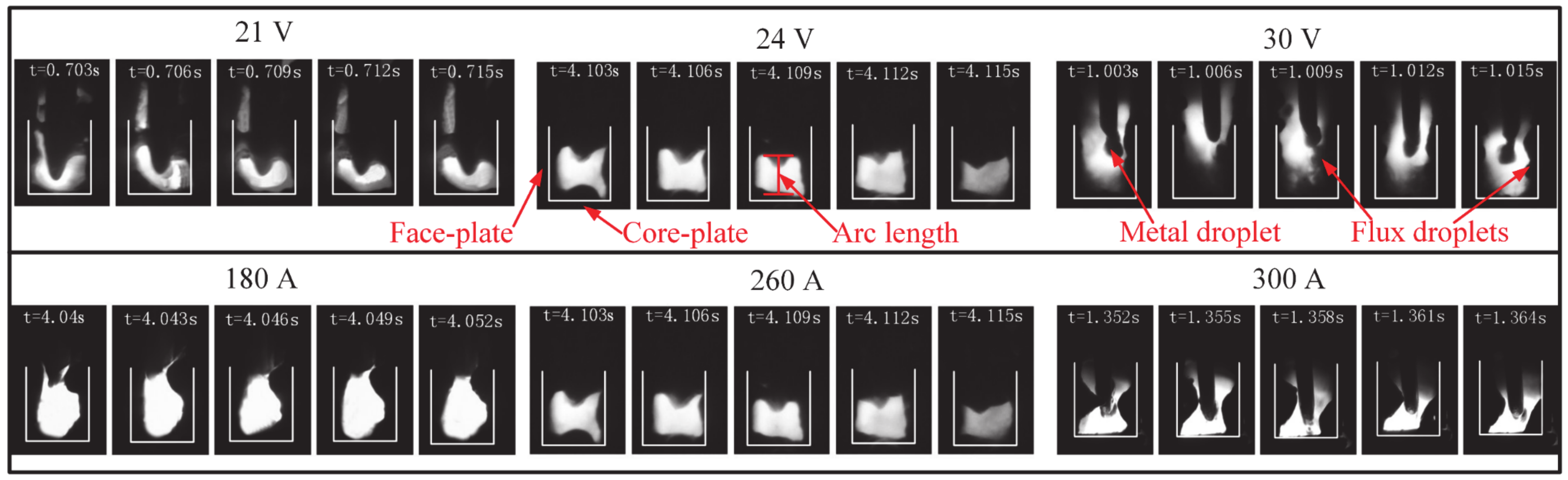

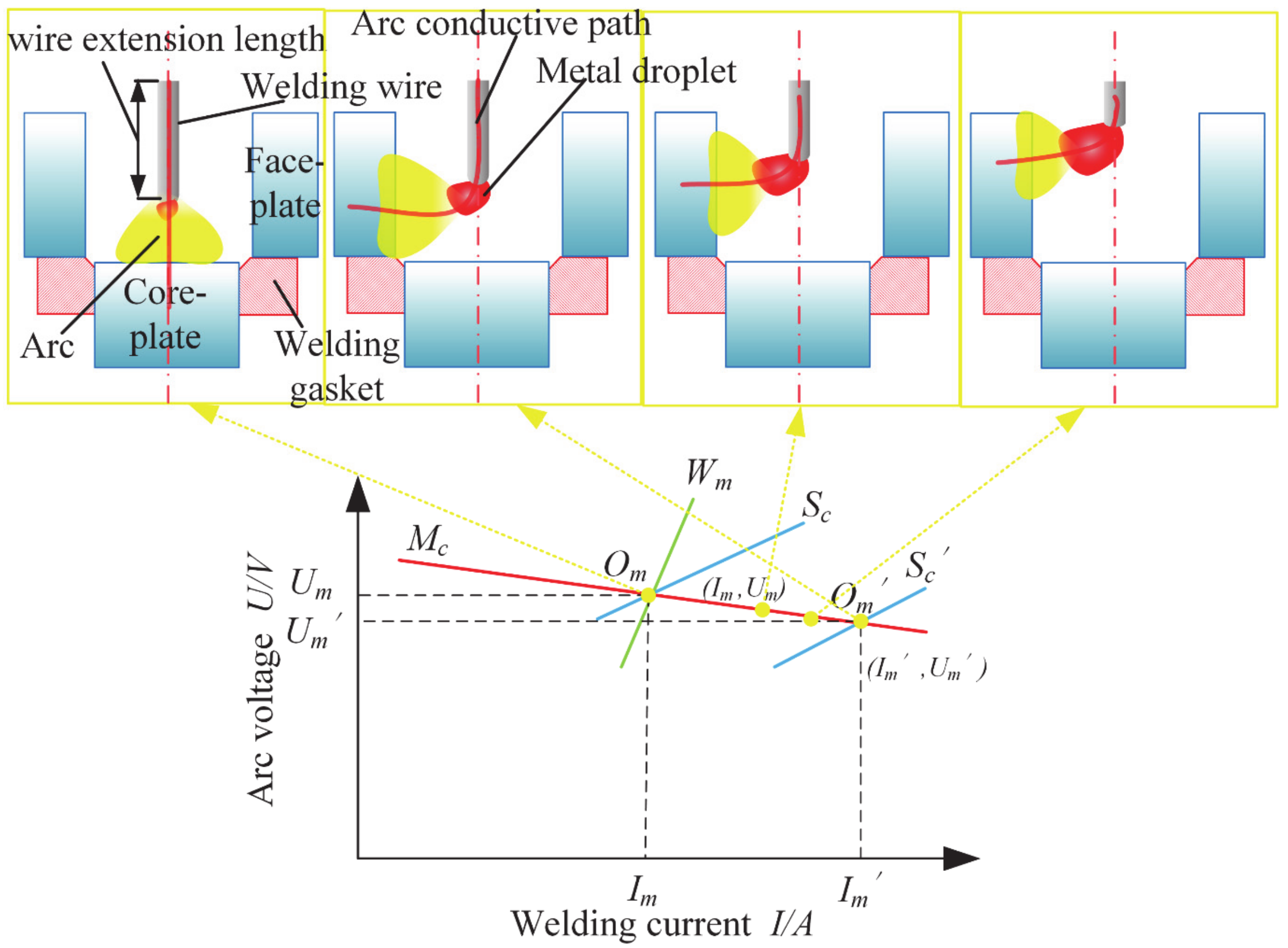

3.2. Determination of the Best Process Parameters (Welding Current and Arc Voltage) in FBCA Welding

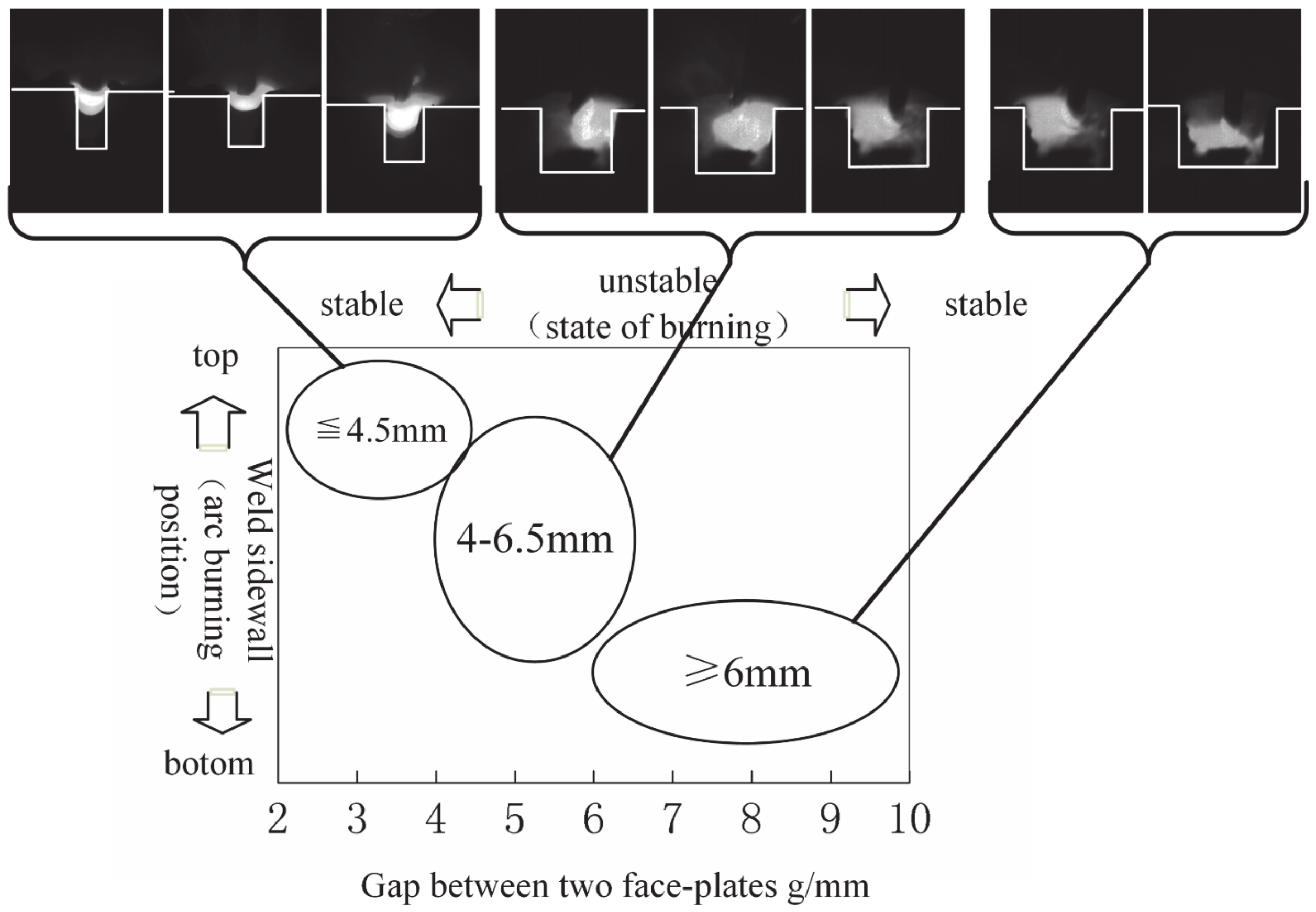

3.3. Effect of Flux Bands on Arc Burning Position

3.3.1. Arc Burning Position Climbing up Phenomenon (APCP)

3.3.2. Arc Burning Position in FBCA Welding

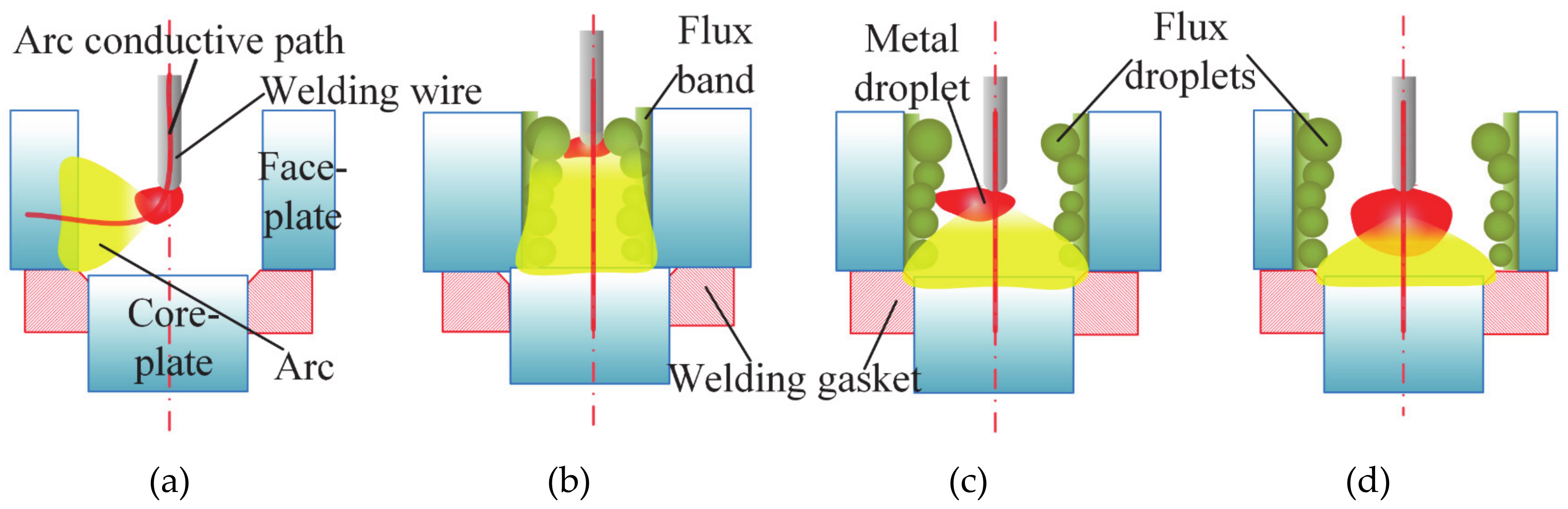

3.4. Effect of Flux Bands on Arc Shape

3.5. Effect of Flux Bands on Arc Heat

3.6. Effect of Flux Bands on Metal Transfer

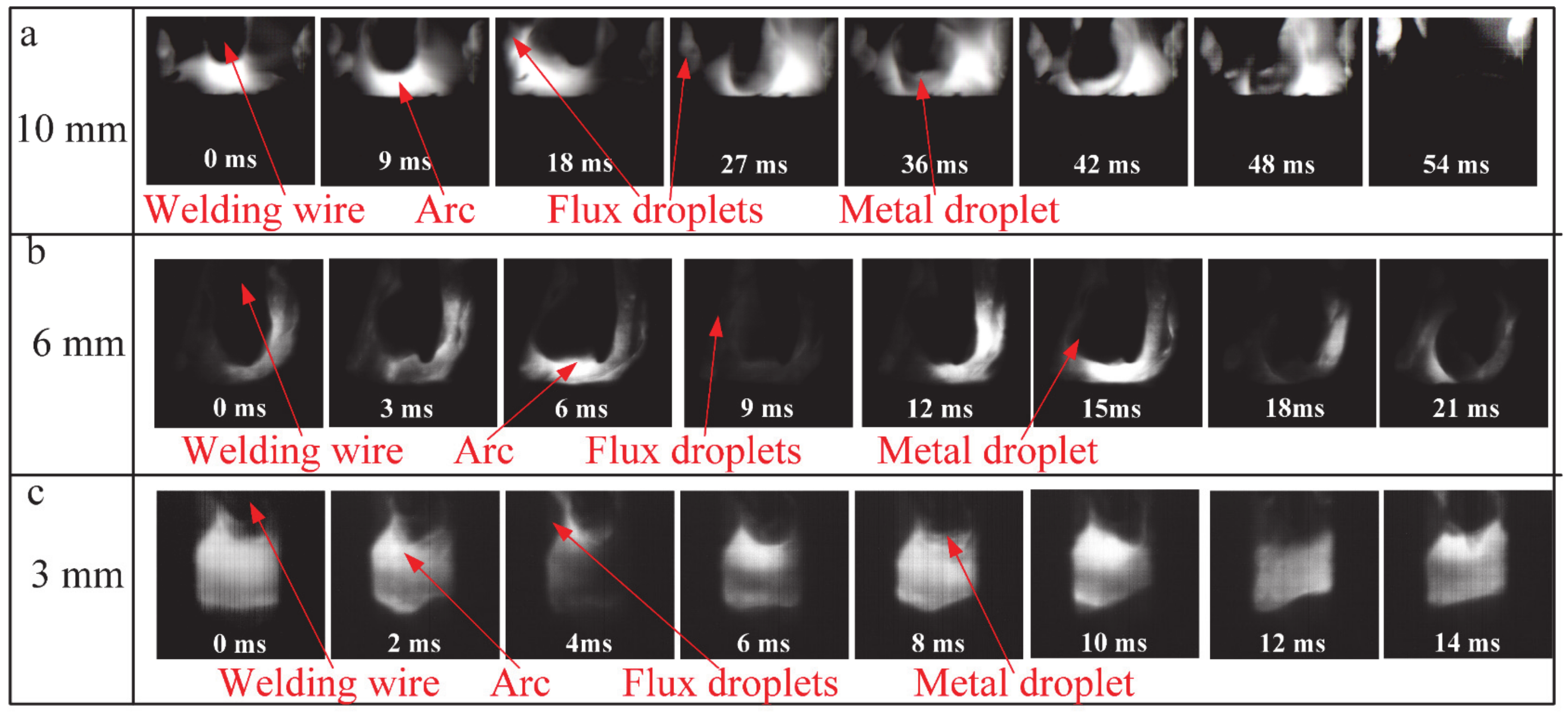

3.7. Effect of Flux Bands on Arc Stability

4. Conclusions

- (1)

- Flux bands localized melting start at 600 °C, then change from solid state to gas-liquid mixture state at 800 °C. Non-conductive flux bands will have a solid-wall constricting effect (SWCE) on the arc. The flux bands decompose in high temperature to product CO2 gas and CaO-CaF2 slag system, which can protect the welding process with the function of self-producing slag and gas. The flux bands also have a thermo-compression effect (TCE) on the arc as the melting of flux bands takes away part of the heat of the arc.

- (2)

- In ultra-narrow groove gap, arc in GMAW welding process undergoes APCP, the SWCE of flux bands on arc suppresses the APCP because of the insulation of flux bands.

- (3)

- Arc shapes of GMAW welding in ultra-narrow gap without flux bands changes irregularly with the different conductive position, and arc burning state is unstable. FBCA welding arc is more stable than GMAW. In the FBCA welding process, the arc is obviously squeezed by flux bands from an inverted bell shape to a rectangle shape, the arc width is equal to the groove gap, and the arc length increases obviously. The effective heating area of the arc is increased by at least 5 mm2 compared with that in GMAW, which indicates that the flux bands are beneficial to the increase of the effective heating area of the arc.

- (4)

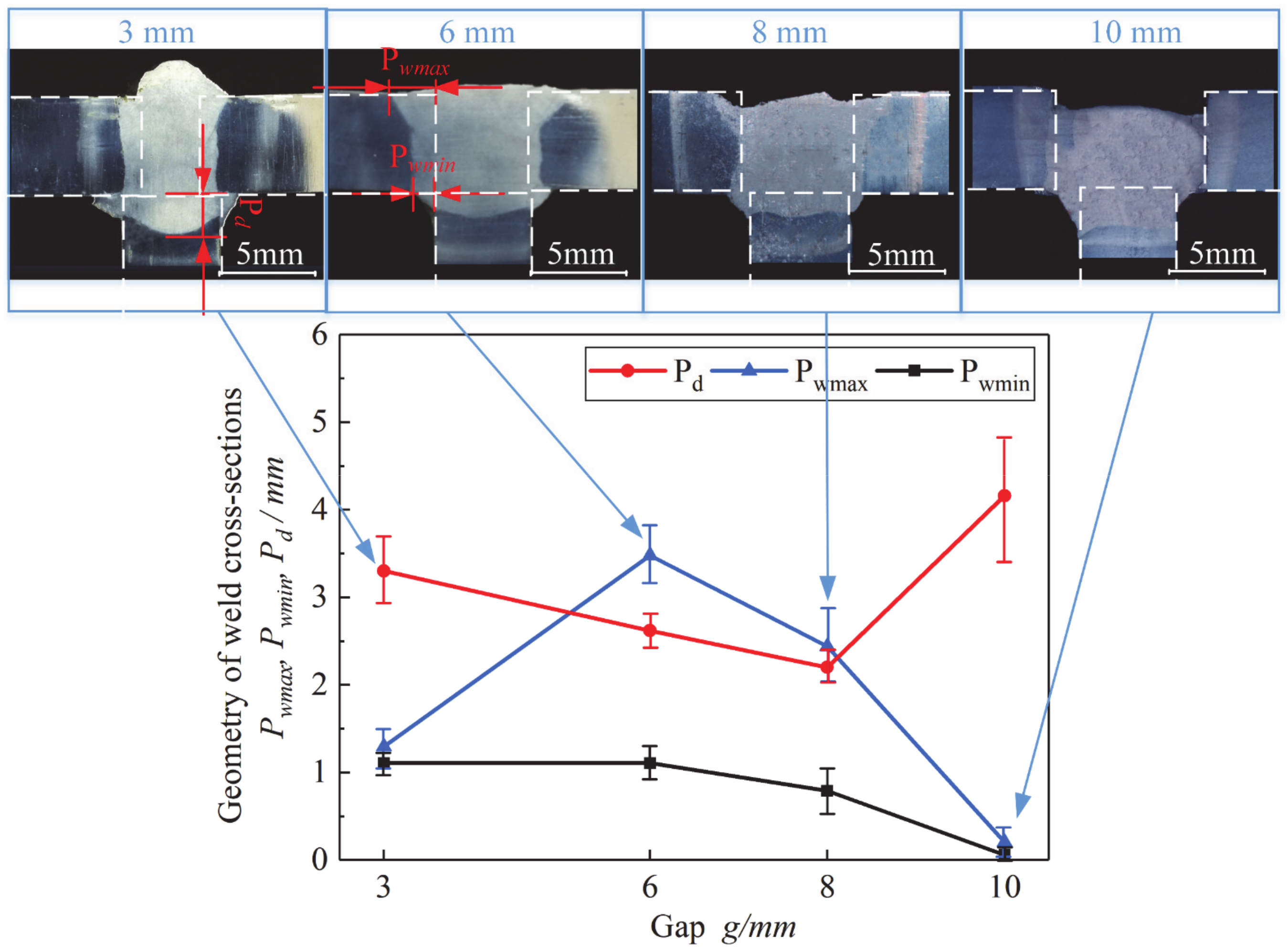

- The temperature distribution of the end-face of T-joint cross-section in FBCA welding process shows the 660 °C isotherm on the core-plate increase from 3 mm to 8 mm with the groove gap increasing from 7 mm to 3 mm. The FBCA welding T-joint cross-sections show that flux bands regulate the heat of arc heating side-wall: Under strong constricting effect (groove gap is 3 mm), the maximum penetration of side-wall is 1.3 mm, while the maximum penetration of side-wall increases to 3.5 mm under medium constricting effect (groove gap is 6 mm). The maximum and minimum penetration of side-wall decrease to 0 mm when groove gap is 10 mm, indicating that weak constricting effect is not conducive to side-wall fusion.

- (5)

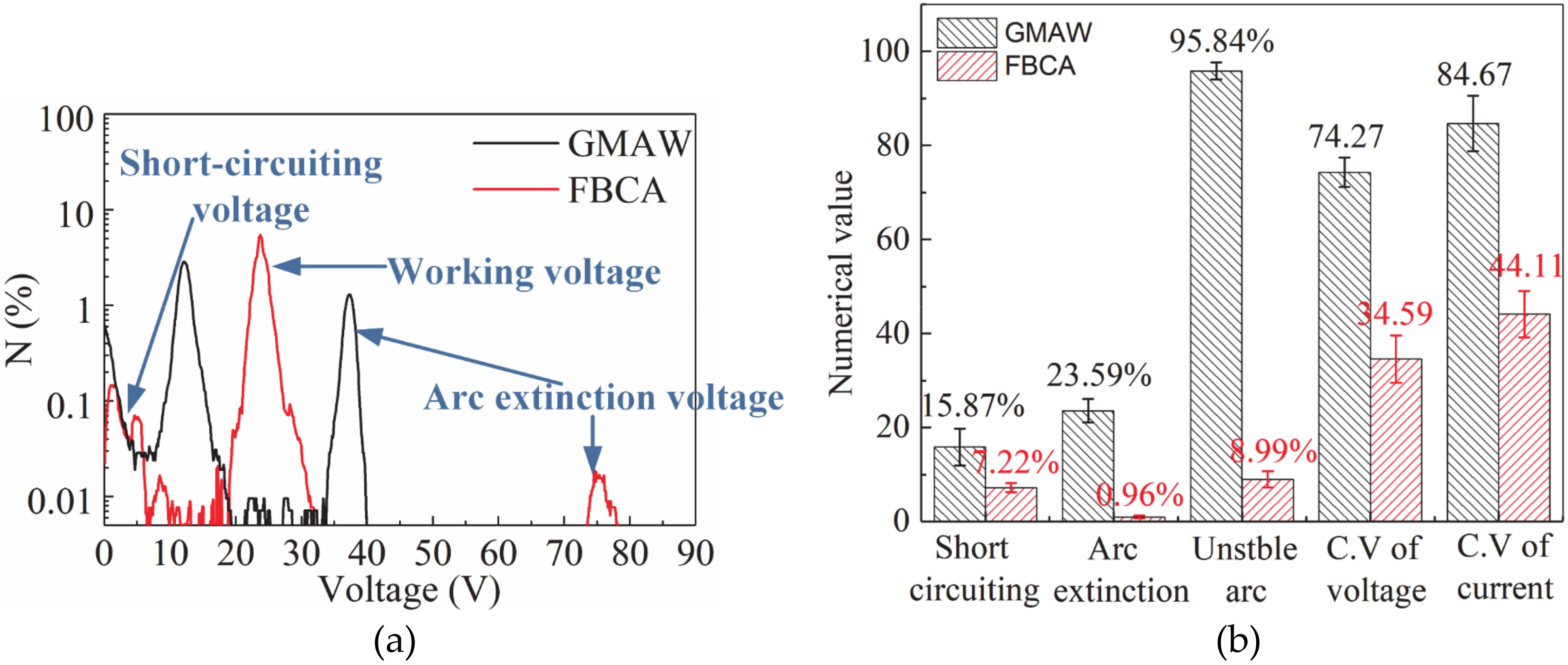

- The proportion of short-circuiting time, arc extinction time, and unstable arc burning time are respectively reduced by 8.65%, 22.63%, and 86.85%, and the fluctuation of voltage and current are significantly reduced by the flux bands. The flux bands effectively increase the arc stability in the ultra-narrow gap through its SWCE on the arc.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jelovica, J.; Romanoff, J.; Ehlers, S.; Aromaa, J. Ultimate strength of corroded web-core sandwich beams. Mar. Struct. 2013, 31, 1–14. [Google Scholar] [CrossRef]

- Jelovica, J.; Romanoff, J.; Klein, R. Eigenfrequency analyses of laser-welded web–core sandwich panels. Thin Walled Struct. 2016, 101, 120–128. [Google Scholar] [CrossRef]

- Crupi, V.; Epasto, G.; Guglielmino, E. Low-velocity impact strength of sandwich materials. J. Sandw. Struct. Mater. 2011, 13, 409–426. [Google Scholar] [CrossRef]

- Wadley, H.N.; Fleck, N.A.; Evans, A.G. Fabrication and structural performance of periodic cellular metal sandwich structures. Compos. Sci. Technol. 2003, 63, 2331–2343. [Google Scholar] [CrossRef]

- Jiang, X.; Li, J.; Cao, R.; Zhu, L.; Chen, J.; Wu, Y.; Li, Z. Microstructures and properties of sandwich plane laser-welded joint of hull steel. Mater. Sci. Eng. A Struct. 2014, 595, 43–53. [Google Scholar] [CrossRef]

- Niklas, K.; Kozak, J. The effect of numerical 2D and 3D FEM element modelling on strain and stress distributions at laser weld notches in steel sandwich type panels. Pol. Marit. Res. 2018, 25, 121–127. [Google Scholar] [CrossRef]

- Frank, D.; Romanoff, J.; Remes, H. Fatigue strength assessment of laser stake-welded web-core steel sandwich panels. Fatigue Fract. Eng. Mater. Struct. 2013, 36, 724–737. [Google Scholar] [CrossRef]

- Jiang, X.X.; Fei, S.C.; Zhang, S.; Ji, H.; Zhu, L. Failure Analysis of the Laser-Welded Web-Core Steel Sandwich Panel with Narrow Weld Width T-Joints. Appl. Mech. Mater. 2017, 551, 311–316. [Google Scholar] [CrossRef]

- Romanoff, J.; Remes, H.; Socha, G.; Jutila, M.; Varsta, P. The stiffness of laser stake welded T-joints in web-core sandwich structures. Thin Walled Struct. 2007, 45, 453–462. [Google Scholar] [CrossRef]

- Jelovica, J.; Romanoff, J.; Ehlers, S.; Varsta, P. Influence of weld stiffness on buckling strength of laser-welded web-core sandwich plates. J. Constr. Steel Res. 2012, 77, 12–18. [Google Scholar] [CrossRef]

- Wang, L.; Qiao, J.; Chen, Z.; Zhu, L.; Chen, J. Method exploration of flux bands constricting arc welding for high-strength steel T-joints. Int. J. Adv. Manuf. Technol. 2019, 105, 2447–2460. [Google Scholar] [CrossRef]

- Gong, L.; Zhu, L.; Zhou, H.X. Effect on Hardness and Microstructures of Rail Joint with Ultra-Narrow Gap Arc Welding by Post Weld Heat Treatment. Key Eng. Mater. 2017, 737, 90–94. [Google Scholar] [CrossRef]

- Nakamura, T.; Hiraoka, K. Ultranarrow GMAW process with newly developed wire melting control system. Sci. Technol. Weld. Join. 2001, 6, 355–362. [Google Scholar] [CrossRef]

- Elmesalamy, A.; Li, L.; Francis, J.; Sezer, H. Understanding the process parameter interactions in multiple-pass ultra-narrow-gap laser welding of thick-section stainless steels. Int. J. Adv. Manuf. Technol. 2013, 68, 1–17. [Google Scholar] [CrossRef]

- Zhang, G.; Shi, Y.; Zhu, M.; Fan, D. Arc characteristics and metal transfer behavior in narrow gap gas metal arc welding process. J. Mater. Process. Technol. 2017, 245, 15–23. [Google Scholar] [CrossRef]

- Meng, Y.; Li, G.; Gao, M.; Zeng, X. Effects of groove parameters on space constraint of narrow gap laser-arc hybrid welding. J. Manuf. Process. 2018, 33, 144–149. [Google Scholar] [CrossRef]

- Wang, J.; Sun, Q.; Feng, J.; Wang, S.; Zhao, H. Characteristics of welding and arc pressure in TIG narrow gap welding using novel magnetic arc oscillation. Int. J. Adv. Manuf. Technol. 2017, 90, 413–420. [Google Scholar] [CrossRef]

- Huang, J.; Chen, H.; He, J.; Yu, S.; Pan, W.; Fan, D. Narrow gap applications of swing TIG-MIG hybrid weldings. J. Mater. Process. Technol. 2019, 271, 609–614. [Google Scholar] [CrossRef]

- Nivas, R.; Singh, P.; Das, G.; Das, S.; Kumar, S.; Mahato, B.; Sivaprasad, K.; Ghosh, M. A comparative study on microstructure and mechanical properties near interface for dissimilar materials during conventional V-groove and narrow gap welding. J. Manuf. Process. 2017, 25, 274–283. [Google Scholar] [CrossRef]

- Kang, Y.; Na, S. Characteristics of welding and arc signal in narrow groove gas metal arc welding using electromagnetic arc oscillation. Weld. J. 2003, 82, 93–99. [Google Scholar]

- Xu, W.; Lin, S.; Fan, C.; Yang, C. Prediction and optimization of weld bead geometry in oscillating arc narrow gap all-position GMA welding. Int. J. Adv. Manuf. Technol. 2015, 79, 183–196. [Google Scholar] [CrossRef]

- Sun, Q.; Wang, J.; Cai, C.; Li, Q.; Feng, J. Optimization of magnetic arc oscillation system by using double magnetic pole to TIG narrow gap welding. Int. J. Adv. Manuf. Technol. 2016, 86, 761–767. [Google Scholar] [CrossRef]

- Cai, X.; Dong, B.; Lin, S.; Murphy, A.B.; Fan, C.; Yang, C. Heat Source Characteristics of Ternary-Gas-Shielded Tandem Narrow-Gap GMAW. Materials 2019, 12, 1397. [Google Scholar] [CrossRef] [PubMed]

- Guo, N.; Lin, S.; Zhang, L.; Yang, C. Metal transfer characteristics of rotating arc narrow gap horizontal GMAW. Sci. Technol. Weld. Join. 2009, 14, 760–764. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, J.; Fu, P.; Su, R.; Han, W.; Yang, F. A swing arc system for narrow gap GMA welding. ISIJ Int. 2012, 2, 110–114. [Google Scholar] [CrossRef]

- Zhang, C.; Li, G.; Gao, M.; Zeng, X. Microstructure and Mechanical Properties of Narrow Gap Laser-Arc Hybrid Welded 40 mm Thick Mild Steel. Materials 2017, 10, 106. [Google Scholar] [CrossRef]

- Ribeiro, R.A.; Assunção, P.D.C.; Dos Santos, E.B.F.; Filho, A.A.C.; Braga, E.M.; Gerlich, A.P. Application of Cold Wire Gas Metal Arc Welding for Narrow Gap Welding (NGW) of High Strength Low Alloy Steel. Materials 2019, 12, 335. [Google Scholar] [CrossRef]

- Wang, L.; Qiao, J.; Zhu, L.; Chen, J. Effects of flux bands on arc stability in flux bands constricting arc welding. J. Manuf. Process. 2020, 54, 190–200. [Google Scholar] [CrossRef]

| Case No. | Arc Voltage (U/V) | Welding Current (I/A) | Welding Velocity (v/mm·s−1) | Groove Gap (g/mm) |

|---|---|---|---|---|

| Case 1 | 21, 24, 30 | 260 | 7.5 | 6 |

| Case 2 | 24 | 180, 260, 300 | 7.5 | 6 |

| Case 3 | 24 | 260 | 7.5 | 3, 6, 8, 10 |

| Marble | Fluorite | Titanium Dioxide | Mica | Ferrotitanium | Sodium Silicate | Others |

|---|---|---|---|---|---|---|

| 40 | 27 | 7 | 2 | 15 | 1 | 8 |

| Experiments No. | Proportion of Short-Circuiting Time (%) | Proportion of Arc Extinction Time (%) | Proportion of Unstable Arc Burning Time (%) | C·V of Voltage | C·V of Current |

|---|---|---|---|---|---|

| 1 | 19.99 | 26.40 | 96.34 | 77.65 | 90.17 |

| 2 | 12.17 | 21.68 | 93.82 | 71.45 | 78.46 |

| 3 | 15.46 | 22.72 | 97.35 | 73.71 | 85.40 |

| GMAW average | 15.87 ± 3.93 | 23.59 ± 2.48 | 95.84 ± 1.82 | 74.27 ± 3.14 | 84.67 ± 5.89 |

| 1 | 8.19 | 1.28 | 9.78 | 40.37 | 48.62 |

| 2 | 6.21 | 0.77 | 6.99 | 31.25 | 38.88 |

| 3 | 7.27 | 0.82 | 10.20 | 32.16 | 44.83 |

| FBCA average | 7.22 ± 0.99 | 0.96 ± 0.28 | 8.99 ± 1.75 | 34.59 ± 5.02 | 44.11 ± 4.91 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Qiao, J.; Chen, J. The Mechanism of Effect of Flux Bands on The Arc Behavior in Flux Bands Constricting Arc Welding Process. Materials 2020, 13, 1652. https://doi.org/10.3390/ma13071652

Wang L, Qiao J, Chen J. The Mechanism of Effect of Flux Bands on The Arc Behavior in Flux Bands Constricting Arc Welding Process. Materials. 2020; 13(7):1652. https://doi.org/10.3390/ma13071652

Chicago/Turabian StyleWang, Lei, Jisen Qiao, and Jianhong Chen. 2020. "The Mechanism of Effect of Flux Bands on The Arc Behavior in Flux Bands Constricting Arc Welding Process" Materials 13, no. 7: 1652. https://doi.org/10.3390/ma13071652

APA StyleWang, L., Qiao, J., & Chen, J. (2020). The Mechanism of Effect of Flux Bands on The Arc Behavior in Flux Bands Constricting Arc Welding Process. Materials, 13(7), 1652. https://doi.org/10.3390/ma13071652