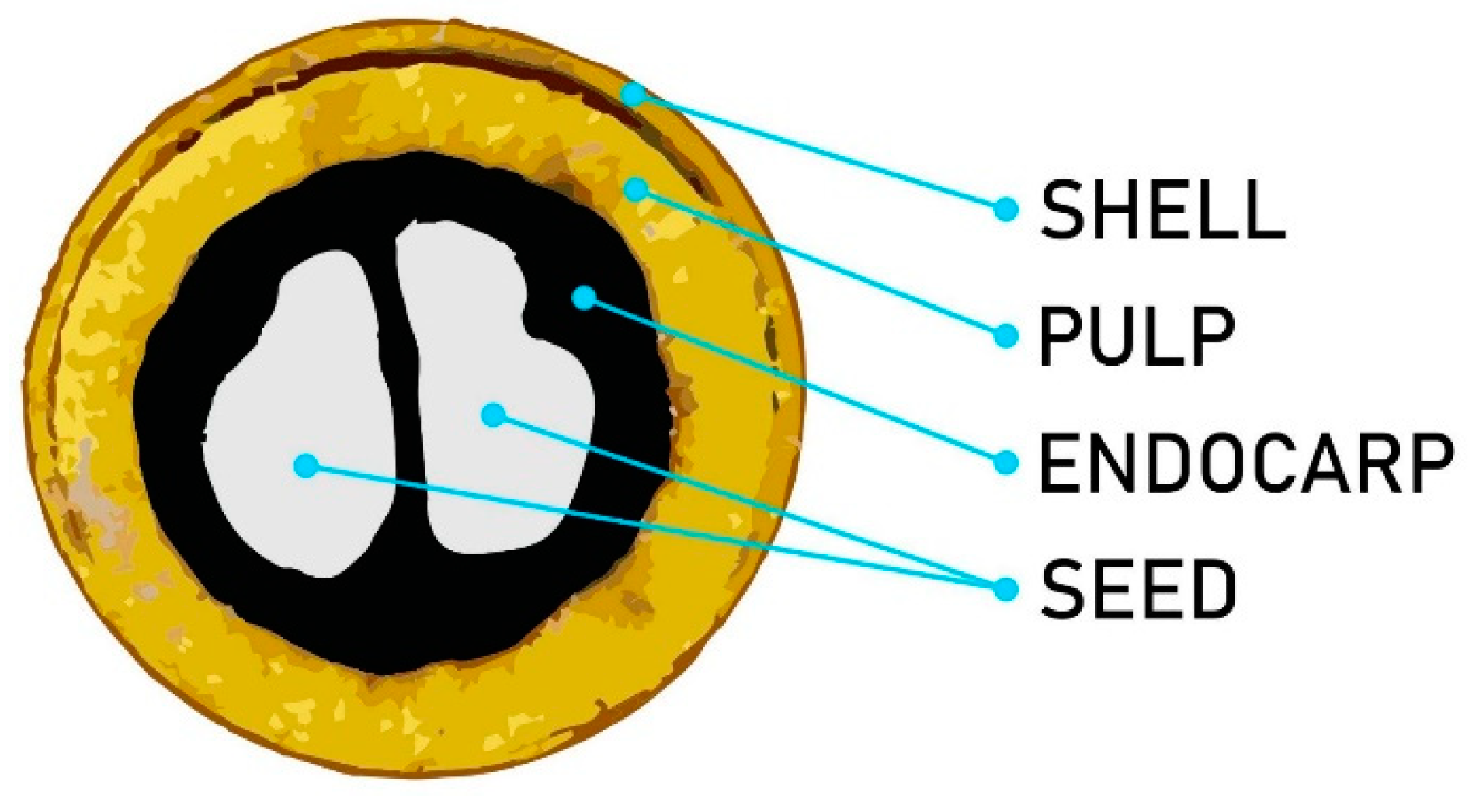

Portland Cement/Acrocomia Aculeata Endocarp Bricks: Thermal Insulation and Mechanical Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials and Sample Preparation

2.2. Sample Characterization

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Moraes, J.C.B.; Akasaki, J.L.; Melges, J.L.P.; Monzo, J.; Borrachero, M.V.; Soriano, L.; Paya, J.; Tashima, M.M. Assessment of sugar cane straw ash (SCSA) as pozzolanic material in blended Portland cement: Microstructural characterization of pastes and mechanical strength of mortars. Constr. Build. Mater. 2015, 94, 670–677. [Google Scholar] [CrossRef] [Green Version]

- Onesippe, C.; Coutrin, N.P.; Toro, F.; Delvasto, S.; Bilba, K.; Arsene, M.A. Sugar Cane bagasse fibers reinforced cement composites: Thermal considerations. Compos. Part A 2010, 41, 549–556. [Google Scholar] [CrossRef]

- Rodrigues, C.S.; Ghavami, K.; Stroeven, P. Rice husk ash as a supplementary raw material for the production of cellulose-cement composite with improved performance. Waste Biomass Valorization 2010, 1, 241–249. [Google Scholar] [CrossRef] [Green Version]

- Sathiparan, N.; Zoysa, T.H.S.M. The effects of using agricultural waste as partial substitute for sand in cement blocks. J. Build. Eng. 2018, 19, 216–226. [Google Scholar] [CrossRef]

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS (ABNT). NBR 8491:2012 Tijolo de Solo-Cimento: Requisitos; ABNT: Rio de Janeiro, Brazil, 2012; p. 9. [Google Scholar]

- Amaral, M.C.; Holanda, J.N.F. Application of sugarcane bagasse ash in the production of low cost soil-cement brick. Adv. Environ. Res. 2017, 6, 255–264. [Google Scholar]

- Blankenhorn, P.R.; Labosky PJr DiCola, M.; Stover, L.R. Compressive strength of hardwood-cement composite. For. Prod. J. 1994, 44, 1–6. [Google Scholar]

- Nardi, I.; Rubeis, T.; Buzzi, E.; Sfarra, S.; Ambrosini, D.; Paoletti, D. Modeling and Optimization of the Thermal Performance of a Wood-Cement Block in a Low-Energy House Construction. Energies 2016, 9, 677. [Google Scholar] [CrossRef] [Green Version]

- Rencoret, J.; Kim, H.; Evaristo, A.B.; Gutierrez, A.; Ralph, J.; Del Rio, J.C. Variability in Lignin Composition and Structure in Cell Walls of Different Parts of Macaúba (Acrocomia aculeata) Palm Fruit. J. Agric. Food Chem. 2018, 66, 138–153. [Google Scholar] [CrossRef] [Green Version]

- Rettore, R.P.; Martins, H. Produção de Combustíveis Líquidos a Partir de Óleos Vegetais; Vol. 1 Estudo das oleaginosas nativas de Minas Gerais; CETEC: Belo Horizonte, Brazil, 1983. [Google Scholar]

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS (ABNT). NBR NM 248:2003 Agregados—Determinação da Composição Granulométrica; ABNT: Rio de Janeiro, Brazil, 2011; p. 6. [Google Scholar]

- Dantas, V.B.; Gomes, U.U.; Vital, A.B.; Marinho, G.S.; Silva, A.S. Characterization and Granulometric Correction Soil for the Production of Soil-Cement Blocks for Two Method, Particle Size and X-ray Florescence to be Inserted in Phase Change Materials (PCMS). Mater. Sci. Forum 2014, 798–799, 355–359. [Google Scholar] [CrossRef]

- Zziwa, A.; Kizito, S.; Banana, A.Y.; Kaboggoza, J.R.S.; Kambugu, R.K.; Ssremba, O.E. Production of composite bricks from sawdust using Portland cement as a binder. Ugnada J. Agric. Sci. 2006, 12, 38–44. [Google Scholar]

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS (ABNT). NBR 12024:2012 Tijolo de Solo-Cimento: Moldagem e Cura de Corpos de Prova Cilíndricos—Procedimento; ABNT: Rio de Janeiro, Brazil, 2012; p. 4. [Google Scholar]

- Zanetti, T.C.; Cabral, J.S. Calculation of an optical setup for a LIBS system. J. Exp. Tech. Instrum. 2018, 1, 1–8. [Google Scholar] [CrossRef]

- Menegatti, C.R.; Nicolodelli, G.; Senesi, G.S.; Silva, O.A.; Filho, H.J.I.; Boas, P.R.V.; Marangoni, B.S.; Milori, D.M.B.P. Semiquantitative analysis of mercury in landfill leachates using double-pulse laser-induced breakdown spectroscopy. Appl. Opt. 2017, 56, 3730–3735. [Google Scholar] [CrossRef] [PubMed]

- Marangoni, B.S.; Silva, K.S.G.; Nicolodelli, G.; Senesi, G.S.; Cabral, J.S.; Villas-Boas, P.R.; Silva, C.S.; Teixeira, P.C.; Nogueira, A.R.A.; Benites, V.M.; et al. Phosphorous quantification in fertilizers using laser induced breakdown spectroscopy (LIBS): A methodology of analysis to correct physical matrix effects. Anal. Methods 2016, 8, 78–82. [Google Scholar] [CrossRef] [Green Version]

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS (ABNT). NBR 8492:2012 Tijolo de Solo-Cimento: Análise Dimensional, Determinação de Resistência à Compressão e de Absorção de Água; ABNT: Rio de Janeiro, Brazil, 2012; p. 4. [Google Scholar]

- Clark, W.T.; Powell, R.W. Measurement of thermal conduction by the thermal comparator. J. Sci. Instruments. 1962, 39, 545551. [Google Scholar] [CrossRef]

- Rousan, A.A.; Roy, D.M. A thermal comparator method for measuring thermal conductivity of cementitious materials. Ind. Eng. Chem. Prod. Res. Dev. 1982, 22, 349–351. [Google Scholar] [CrossRef]

- Pakhomov, V.I.; Goryunov, A.V.; Pakhomov, P.V.; Chibiskova, N.T. On the structure of alpha-SiO2 crystals doped with Fe3+. Zhurnal Neorganicheskoi Khimii. 1993, 38, 1–8. [Google Scholar]

- Brasileiro, G.A.M.; Vieira, J.A.R.; Barreto, L.S. Use of coir pith particles in composites with Portland cement. J. Environ. Manag. 2013, 131, 228–236. [Google Scholar] [CrossRef]

- Saw, K.; Sarkhel, G.; Choudhury, A. Surface modification of coir fibre involving oxidation of lignins followed by reaction with furfuryl alcohol: Characterization and stability. Appl. Surf. Sci. 2010, 257, 3763–3769. [Google Scholar] [CrossRef]

- Hassan, M.; Khatib, J.M.; Mangat, P.S.; Naseef, A.; Gardiner, P.H.E. FTIR and XRD characterized lime stabilized lead contaminated soil. In Proceedings of the 2nd International Conference on Environmental, Chemistry and Biology, Singapore, 24–25 August 2013; Volume 59, pp. 102–106. [Google Scholar]

- Narendar, R.; Dasan, K.P. Chemical treatments of coir pith: Morphology, chemical composition, thermal and water retention behavior. Compos. Part B Eng. 2014, 56, 770–779. [Google Scholar] [CrossRef]

- Luduena, L.N.; Vecchio, A.; Stefani, P.M.; Alvarez, V.A. Extraction of cellulose nanowhiskers from natural fibers and agricultural byproducts. Fiber Polym. 2013, 14, 1118–1127. [Google Scholar] [CrossRef]

- Toledano, A.; Serrano, L.; Garcia, A.; Mondragon, I.; Labidi, J. Comparative study of lignin fractionation by ultrafiltration and selective precipitation. Chem. Eng. J. 2009, 157, 93–99. [Google Scholar] [CrossRef]

| Chemical Compound | Assignments | Wavenumber (cm−1) |

|---|---|---|

| Lignin | C=O axial deformation | 1724 |

| 1708 | ||

| C=C and C=O stretching | 1600 | |

| C–H bending | 893 | |

| 752 | ||

| Hemi-Cellulose and Cellulose | C=C and C=O stretching | 1509 |

| C-H scissoring | 1371 | |

| C–O axial deformation | 1238 | |

| 1212 | ||

| C–O–C asymmetric stretch | 1160 | |

| C–O stretching | 1100 | |

| 1034 | ||

| C–O asymmetric stretch | 1410 | |

| Portland cement composite | C–O stretching | 1100 |

| C–S–H asymmetric stretch | 967 | |

| C–O asymmetric stretch in Calcium Carbonate; Si–O stretching | 915–775 |

| AE in PC/AE Samples (wt%) | Sample Age/Compressive Strength (MPa) | ||

|---|---|---|---|

| 7 Days | 14 Days | 28 Days | |

| 0 | 6.10 | 7.75 | 8.85 |

| 5 | 5.35 | 5.20 | 5.00 |

| 10 | 3.25 | 3.85 | 3.70 |

| 15 | 1.80 | 2.52 | 1.90 |

| 20 | 1.08 | 1.70 | 1.75 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Calvani, C.C.; Goncalves, A.-M.B.; Silva, M.J.; Oliveira, S.L.; Marangoni, B.S.; Reis, D.D.d.; Cena, C. Portland Cement/Acrocomia Aculeata Endocarp Bricks: Thermal Insulation and Mechanical Properties. Materials 2020, 13, 2081. https://doi.org/10.3390/ma13092081

Calvani CC, Goncalves A-MB, Silva MJ, Oliveira SL, Marangoni BS, Reis DDd, Cena C. Portland Cement/Acrocomia Aculeata Endocarp Bricks: Thermal Insulation and Mechanical Properties. Materials. 2020; 13(9):2081. https://doi.org/10.3390/ma13092081

Chicago/Turabian StyleCalvani, Camila C., Além-Mar B. Goncalves, Michael J. Silva, Samuel L. Oliveira, Bruno S. Marangoni, Diogo D. dos Reis, and Cicero Cena. 2020. "Portland Cement/Acrocomia Aculeata Endocarp Bricks: Thermal Insulation and Mechanical Properties" Materials 13, no. 9: 2081. https://doi.org/10.3390/ma13092081