Structural Transitions in Ge2Sb2Te5 Phase Change Memory Thin Films Induced by Nanosecond UV Optical Pulses

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

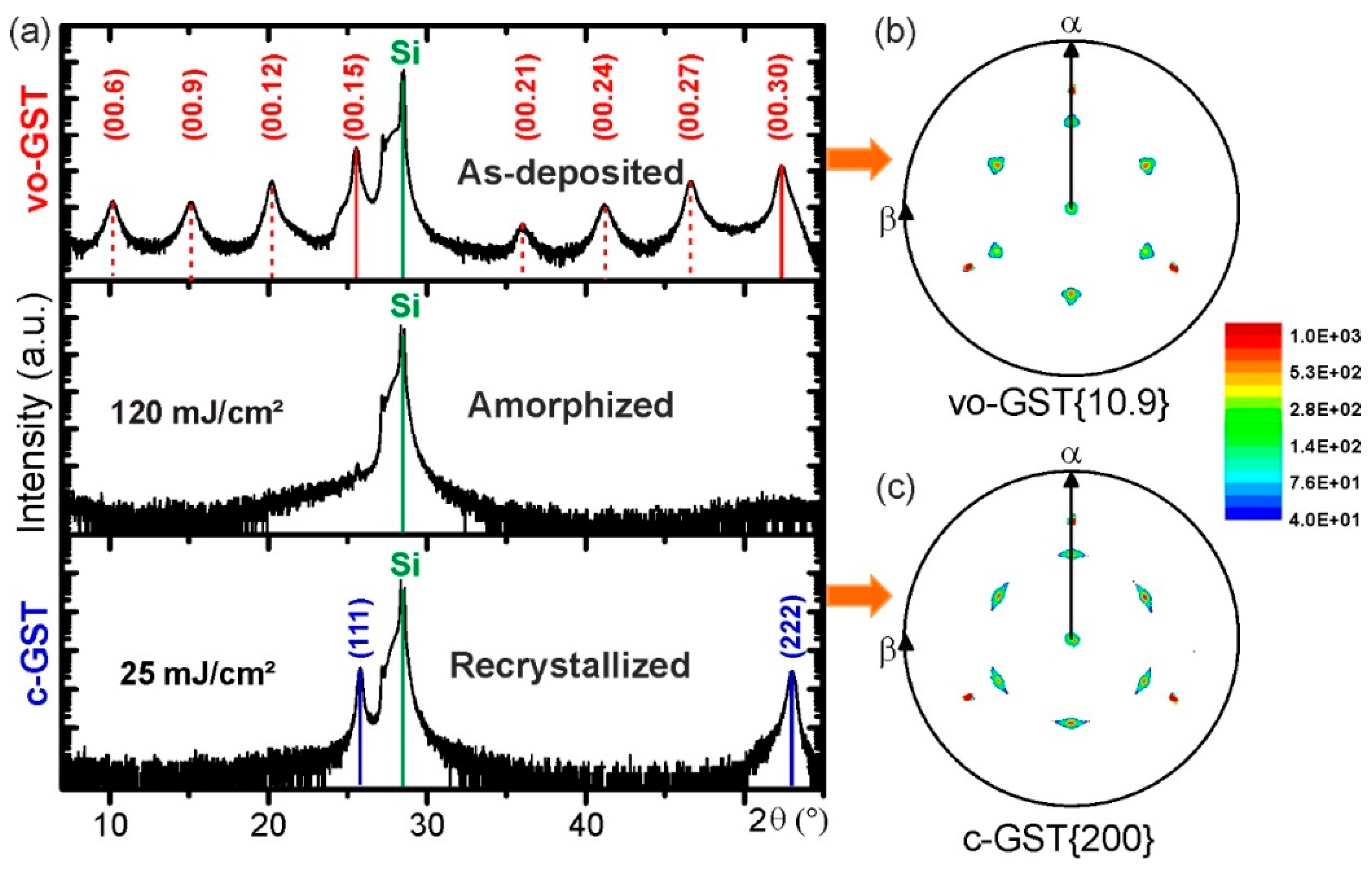

3.1. Crystalline-to-Amorphous Phase Transitions

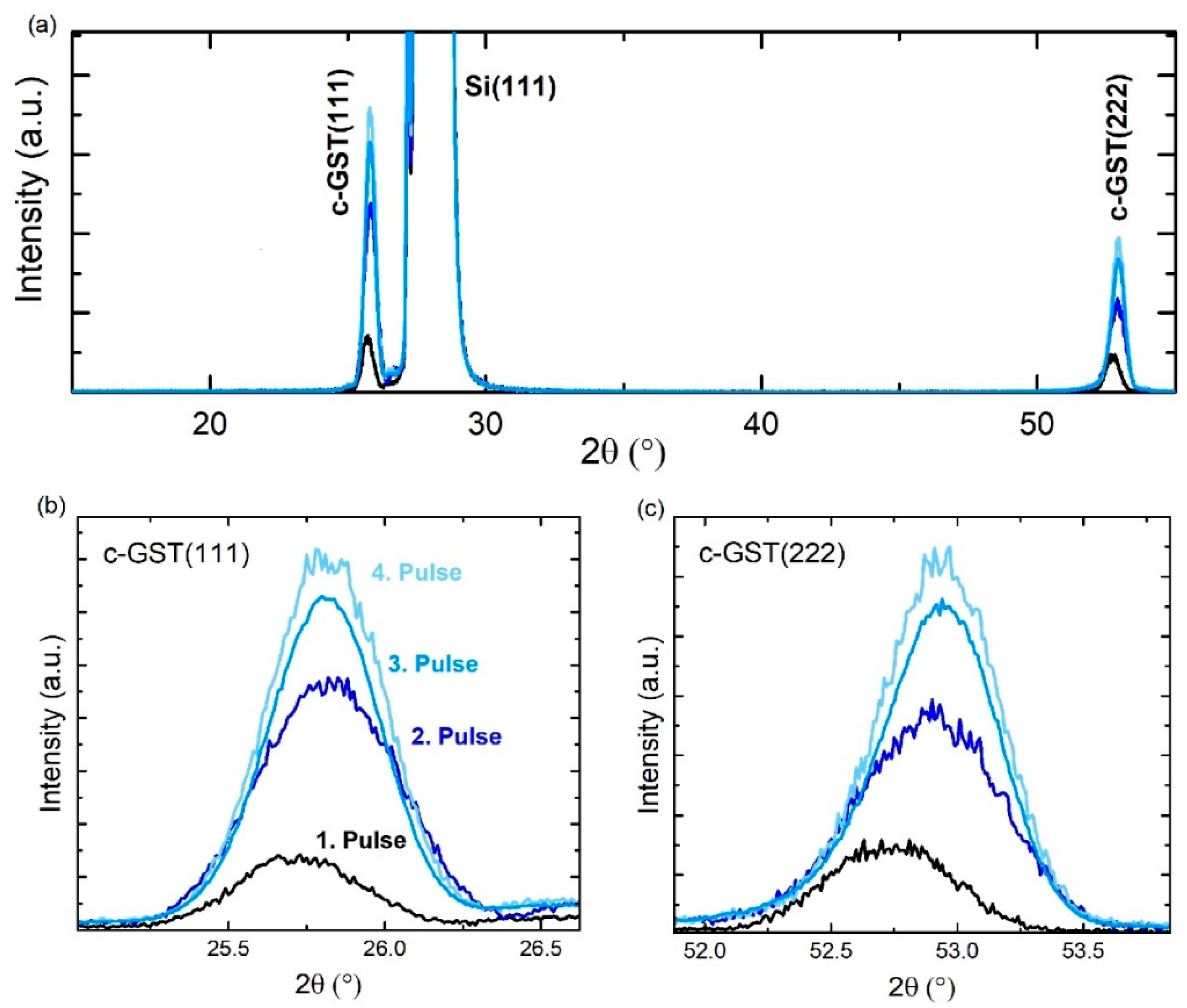

3.2. Influence of Interfaces on Crystallization Process

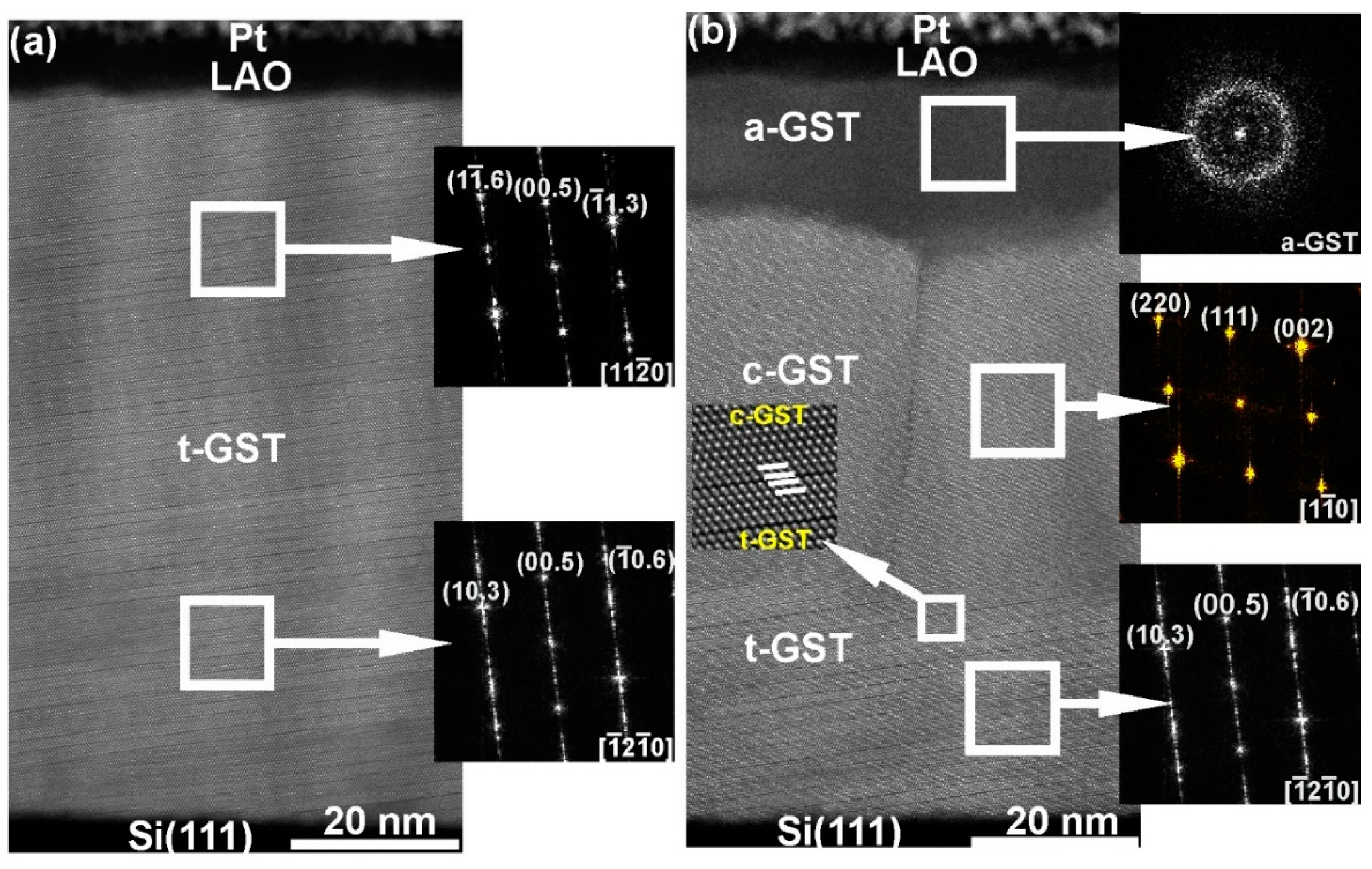

3.3. Interface-Assisted Phase Transitions from Layered Structures to Non-Layered Structure

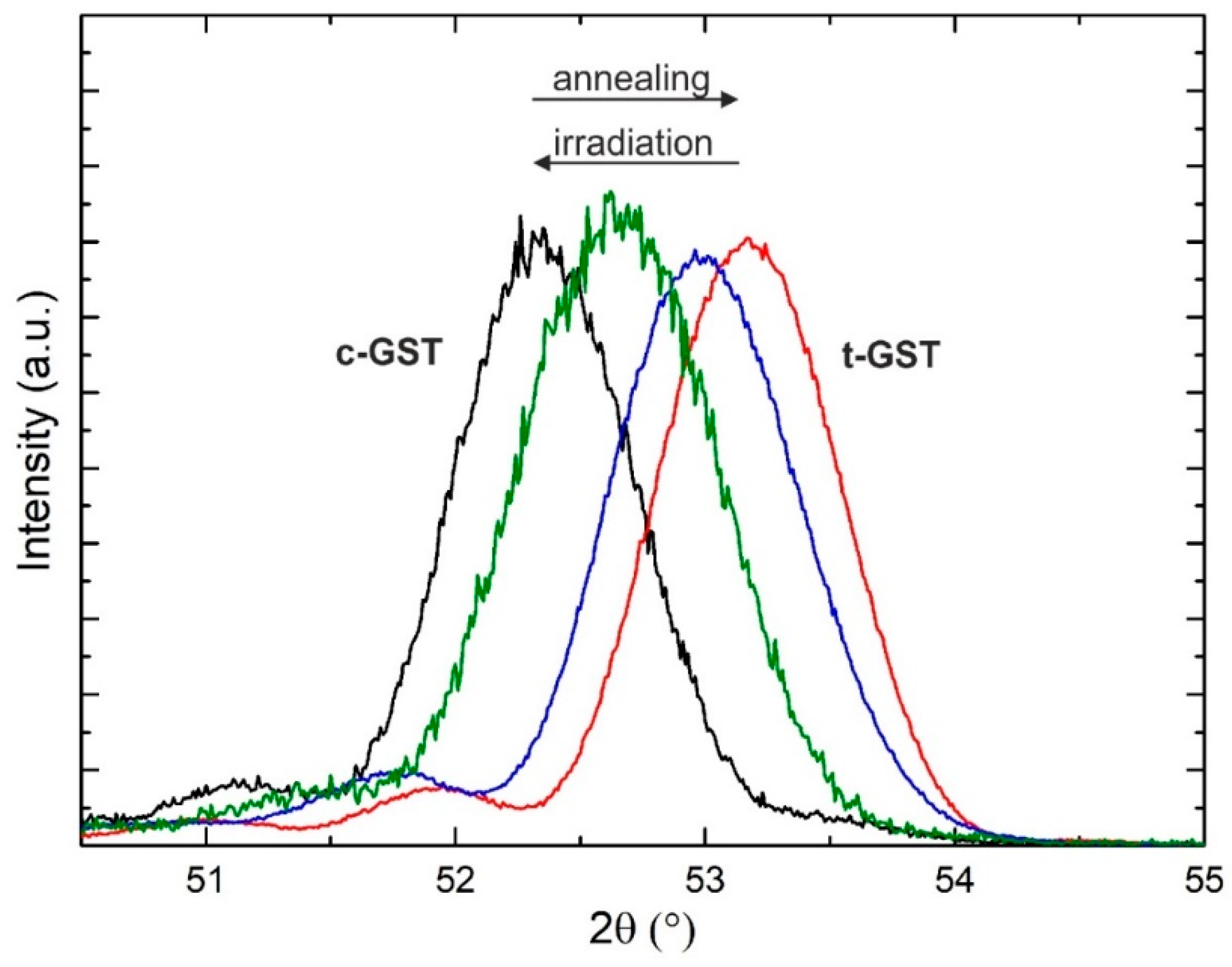

3.4. Crystalline-to-Crystalline Phase Transitions via Structural Rearrangements

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lotnyk, A.; Behrens, M.; Rauschenbach, B. Phase change thin films for non-volatile memory applications. Nanoscale Adv. 2019, 1, 3836–3857. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.; Mazzarello, R.; Wuttig, M.; Ma, E. Designing crystallization in phase-change materials for universal memory and neuro-inspired computing. Nat. Rev. Mater. 2019, 4, 150–168. [Google Scholar] [CrossRef]

- Wuttig, M.; Bhaskaran, H.; Taubner, T. Phase-change materials for non-volatile photonic applications. Nat. Photonics 2017, 11, 465–476. [Google Scholar] [CrossRef]

- Ovshinsky, S.R. Reversible electrical switching phenomena in disordered structures. Phys. Rev. Lett. 1968, 21, 1450. [Google Scholar] [CrossRef]

- Siegel, J.; Schropp, A.; Solis, J.; Afonso, C.N.; Wuttig, M. Rewritable phase-change optical recording in Ge2Sb2Te5 films induced by picosecond laser pulses. Appl. Phys. Lett. 2004, 84, 2250–2252. [Google Scholar] [CrossRef] [Green Version]

- Takeda, J.; Oba, W.; Minami, Y.; Saiki, T.; Katayama, I. Ultrafast crystalline-to-amorphous phase transition in Ge2Sb2Te5 chalcogenide alloy thin film using single-shot imaging spectroscopy. Appl. Phys. Lett. 2014, 104, 261903. [Google Scholar] [CrossRef] [Green Version]

- Zalden, P.; Quirin, F.; Schumacher, M.; Siegel, J.; Wie, S.; Koc, A.; Nicoul, M. Femtosecond x-ray diffraction reveals a liquid-liquid phase transition in phase-change materials. Science 2019, 364, 1062. [Google Scholar] [CrossRef]

- Orava, J.; Greer, A.L.; Gholipour, B.; Hewak, D.W.; Smith, C.E. Characterization of supercooled liquid Ge2Sb2Te5 and its crystallization by ultrafast-heating calorimetry. Nat. Mater. 2012, 11, 279–283. [Google Scholar] [CrossRef]

- Salinga, M.; Carria, E.; Kaldenbach, A.; Bornhofft, M.; Benke, J.; Mayer, J.; Wuttig, M. Measurement of crystal growth velocity in a melt-quenched phase-change material. Nat. Commun. 2013, 4, 2371. [Google Scholar] [CrossRef]

- Suh, D.S.; Kim, K.H.P.; Noh, J.; Shin, W.; Kang, Y.; Kim, C.; Khang, Y.; Yoo, I.K. Critical Quenching Speed Determining Phase of Ge2Sb2Te5 in Phase-Change Memory. In Proceedings of the 2006 IEEE International Electron Devices Meeting, San Francisco, CA, USA, 11–13 Decmber 2006; pp. 1–4. [Google Scholar]

- Wei, S.; Evenson, Z.; Stolpe, M.; Lucas, P.; Angell, C.A. Breakdown of the Stokes-Einstein relation above the melting temperature in a liquid phase-change material. Sci. Adv. 2018, 4, eaat8632. [Google Scholar] [CrossRef] [Green Version]

- Zhu, M.; Xia, M.; Rao, F.; Li, X.; Wu, L.; Ji, X.; Lv, S.; Song, Z.; Feng, S.; Sun, H.; et al. One order of magnitude faster phase change at reduced power in Ti-Sb-Te. Nat. Commun. 2014, 5, 4086. [Google Scholar] [CrossRef] [PubMed]

- Yamada, N.; Ohno, E.; Nishiuchi, K.; Akahira, N. Rapid-phase transitions of GeTe-Sb2Te3 pseudobinary amorphous thin films for an optical disk memory. J. Appl. Phys. 1991, 69, 2849–2856. [Google Scholar] [CrossRef]

- Li, P.; Yang, X.; Maß, T.W.W.; Hanss, J.; Lewin, M.; Michel, A.-K.U.; Wuttig, M.; Taubner, T. Reversible optical switching of highly confined phonon-polaritons with an ultrathin phase-change material. Nat. Mater. 2016, 15, 870–875. [Google Scholar] [CrossRef] [PubMed]

- Rao, F.; Ding, K.; Zhou, Y.; Zheng, Y.; Xia, M.; Lv, S.; Song, Z.; Feng, S.; Ronneberger, I.; Mazzarello, R.; et al. Reducing the stochasticity of crystal nucleation to enable subnanosecond memory writing. Science 2017, 358, 1423–1427. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zewdie, G.M.; Zhou, Y.; Sun, L.; Rao, F.; Deringer, V.L.; Mazzarello, R.; Zhang, W. Chemical Design Principles for Cache-Type Sc-Sb-Te Phase-Change Memory Material. Chem. Mater. 2019, 31, 4008–4015. [Google Scholar] [CrossRef] [Green Version]

- Simpson, R.E.; Fons, P.; Kolobov, A.V.; Fukaya, T.; Krbal, M.; Yagi, T.; Tominaga, J. Interfacial phase-change memory. Nat. Nanotechnol. 2011, 6, 501–505. [Google Scholar] [CrossRef]

- Lotnyk, A.; Hilmi, I.; Ross, U.; Rauschenbach, B. Van der Waals interfacial bonding and intermixing in GeTe-Sb2Te3-based superlattices. Nano Res. 2018, 11, 1676–1686. [Google Scholar] [CrossRef]

- Chong, T.C.; Shi, L.P.; Zhao, R.; Tan, P.K.; Li, J.M.; Lee, H.K.; Miao, X.S.; Du, A.Y.; Tung, C.H. Phase change random access memory cell with superlattice-like structure. App. Phys. Lett. 2006, 88, 122114. [Google Scholar] [CrossRef]

- Sebastian, A.; Le Gallo, M.; Krebs, D. Crystal growth within a phase change memory cell. Nat. Commun. 2014, 5, 4314. [Google Scholar] [CrossRef]

- Behrens, M.; Lotnyk, A.; Gerlach, J.W.; Hilmi, I.; Abel, T.; Lorenz, P.; Rauschenbach, B. Ultrafast interfacial transformation from 2D- to 3D-bonded structures in layered Ge-Sb-Te thin films and heterostructures. Nanoscale 2018, 10, 22946–22953. [Google Scholar] [CrossRef]

- Behrens, M.; Lotnyk, A.; Gerlach, J.W.; Ehrhardt, M.; Lorenz, P.; Rauschenbach, B. Direct measurement of crystal growth velocity in epitaxial phase-change material thin films. ACS Appl. Mater. Interfaces 2019, 11, 41544–41550. [Google Scholar] [CrossRef] [PubMed]

- Rios, C.; Youngblood, N.; Cheng, Z.; Le Gallo, M.; Pernice, W.H.P.; Wright, C.D.; Sebastian, A.; Bhaskaran, H. In-memory computing on a photonic platform. Sci. Adv. 2019, 5, eaau5759. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ríos, C.; Stegmaier, M.; Hosseini, P.; Wang, D.; Scherer, T.; Wright, C.D.; Bhaskaran, H.; Pernice, W.H.P. In-memory computing on a photonic platform. Nat. Photonics 2015, 9, 725–732. [Google Scholar]

- Cao, T.; Cen, M. Phase change materials: Fundamentals and applications of chalcogenide phase-change material photonics. Adv. Theory Simul. 2019, 2, 1900094. [Google Scholar] [CrossRef]

- Behrens, M.; Lotnyk, A.; Roß, U.; Griebel, J.; Schumacher, P.; Gerlach, J.W.; Rauschenbach, B. Impact of disorder on optical reflectivity contrast of epitaxial Ge2Sb2Te5 thin films. Cryst. Eng. Comm. 2018, 20, 3688–3695. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, W.; Shen, Z.; Chen, Y.; Li, J.; Zhang, S.; Zhang, Z.; Wuttig, M.; Mazzarello, R.; Ma, E.; et al. Element-resolved atomic structure imaging of rocksalt Ge2Sb2Te5 phase-change material. Appl. Phys. Lett. 2016, 108, 191902. [Google Scholar] [CrossRef] [Green Version]

- Bragaglia, V.; Arciprete, F.; Zhang, W.; Mio, A.M.; Zallo, E.; Perumal, K.; Giussani, A.; Cecchi, S.; Boschker, J.E.; Riechert, H.; et al. Metal-insulator transition driven by vacancy ordering in GeSbTe phase change materials. Sci. Rep. 2016, 6, 23843. [Google Scholar] [CrossRef]

- Mio, A.M.; Privitera, S.M.S.; Bragaglia, V.; Arciprete, F.; Cecchi, S.; Litrico, G.; Persch, C.; Calarco, R.; Rimini, E. Role of interfaces on the stability and electrical properties of Ge2Sb2Te5 crystalline structures. Sci. Rep. 2017, 7, 2616. [Google Scholar] [CrossRef] [Green Version]

- Zheng, Y.; Wang, Y.; Xin, T.; Cheng, Y.; Huang, R.; Liu, P.; Luo, M.; Zhang, Z.; Lv, S.; Song, Z.; et al. Direct atomic identification of cation migration induced gradual cubic-to-hexagonal phase transition in Ge2Sb2Te5. Commun. Chem. 2019, 2, 13. [Google Scholar] [CrossRef]

- Ross, U.; Lotnyk, A.; Thelander, E.; Rauschenbach, B. Microstructure evolution in pulsed laser deposited epitaxial Ge-Sb-Te chalcogenide thin films. J. Alloys Compd. 2016, 676, 582–590. [Google Scholar] [CrossRef]

- Lotnyk, A.; Ross, U.; Bernutz, S.; Thelander, E.; Rauschenbach, B. Local atomic arrangements and lattice distortions in layered Ge-Sb-Te crystal structures. Sci. Rep. 2016, 6, 26724. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Akola, J.; Jones, R.O. Amorphous structures of Ge/Sb/Te alloys: Density functional simulations. Phys. Status Solidi (b) 2012, 249, 1851–1860. [Google Scholar] [CrossRef]

- Lee, T.H.; Elliott, S.R. The relation between chemical bonding and ultrafast crystal growth. Adv. Mater. 2017, 29, 1700814. [Google Scholar] [CrossRef] [PubMed]

- Bouzid, A.; Ori, G.; Boero, M.; Lampin, E.; Massobrio, C. Atomic-scale structure of the glassy Ge2Sb2Te5 phase change material: A quantitative assessment via first-principles molecular dynamics. Phys. Rev. B 2017, 96, 224204. [Google Scholar] [CrossRef]

- Miao, X.S.; Zheng, Y.X.; Zhang, R.J.; Chen, L.Y.; Wang, C.Z.; Ho, K.M. Evolution of short-and medium-range order in the melt-quenching amorphization of Ge2Sb2Te5. J. Mater. Chem. C 2018, 6, 5001–5011. [Google Scholar]

- Rodenbach, P.; Calarco, R.; Perumal, K.; Katmis, F.; Hanke, M.; Proessdorf, A.; Braun, W.; Giussani, A.; Trampert, A.; Riechert, H.; et al. Epitaxial phase-change materials. Phys. Status Solidi RRL 2012, 6, 415–417. [Google Scholar] [CrossRef]

- Gericke, F.; Flissikowski, T.; Lähnemann, J.; Katmis, F.; Braun, W.; Riechert, H.; Grahn, H.T. Optical switching and related structural properties of epitaxial Ge2Sb2Te5 films. J. Appl. Phys. 2012, 111, 113524. [Google Scholar] [CrossRef]

- Braun, W.; Shayduk, R.; Flissikowski, T.; Grahn, H.T.; Riechert, H.; Fons, P.; Kolobov, A. Epitaxial Phase Change Materials: Growth and Switching of Ge2Sb2Te5 on GaSb (001). MRS Proc. 2009, 1160, H14-05. [Google Scholar] [CrossRef]

- Rodenbach, P.; Giussani, A.; Perumal, K.; Hanke, M.; Dubslaff, M.; Riechert, H.; Calarco, R.; Burghammer, M.; Kolobov, A.V.; Fons, P. Recrystallization of an amorphized epitaxial phase-change alloy: A phoenix arising from the ashes. Appl. Phys. Lett. 2012, 101, 061903. [Google Scholar] [CrossRef] [Green Version]

- Jiang, T.T.; Wang, X.D.; Wang, J.J.; Zhou, Y.X.; Zhang, D.L.; Lu, L.; Jia, C.L.; Wuttig, M.; Mazzarello, R.; Zhang, W. In situ study of vacancy disordering in crystalline phase-change materials under electron beam irradiation. Acta Mater. 2020, 187, 103–111. [Google Scholar] [CrossRef]

- Behrens, M.; Lotnyk, A.; Gerlach, J.W.; Rauschenbach, B. Strain-induced phase selection in Ge2Sb2Te5 epitaxial thin films. Phys. Rev. Mater. 2020, 4, 015001. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Behrens, M.; Lotnyk, A.; Bryja, H.; Gerlach, J.W.; Rauschenbach, B. Structural Transitions in Ge2Sb2Te5 Phase Change Memory Thin Films Induced by Nanosecond UV Optical Pulses. Materials 2020, 13, 2082. https://doi.org/10.3390/ma13092082

Behrens M, Lotnyk A, Bryja H, Gerlach JW, Rauschenbach B. Structural Transitions in Ge2Sb2Te5 Phase Change Memory Thin Films Induced by Nanosecond UV Optical Pulses. Materials. 2020; 13(9):2082. https://doi.org/10.3390/ma13092082

Chicago/Turabian StyleBehrens, Mario, Andriy Lotnyk, Hagen Bryja, Jürgen W. Gerlach, and Bernd Rauschenbach. 2020. "Structural Transitions in Ge2Sb2Te5 Phase Change Memory Thin Films Induced by Nanosecond UV Optical Pulses" Materials 13, no. 9: 2082. https://doi.org/10.3390/ma13092082