Effect of Mineral Aggregates and Chemical Admixtures as Internal Curing Agents on the Mechanical Properties and Durability of High-Performance Concrete

Abstract

:1. Introduction

2. Experimental Procedure

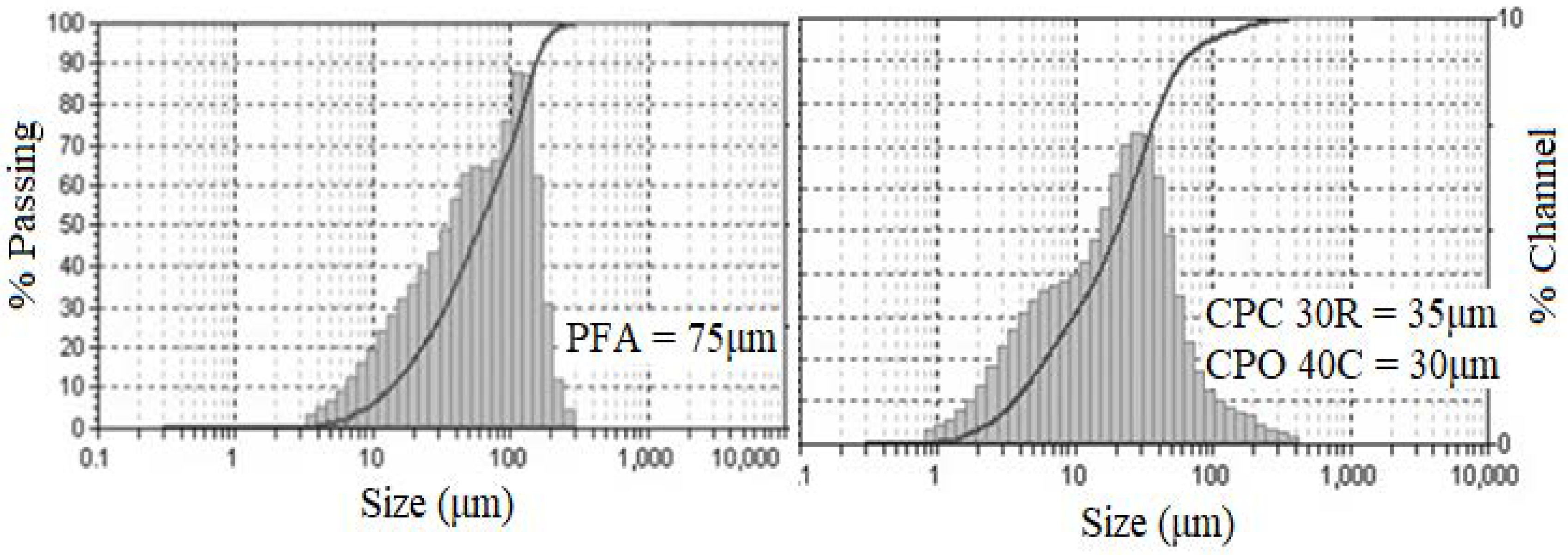

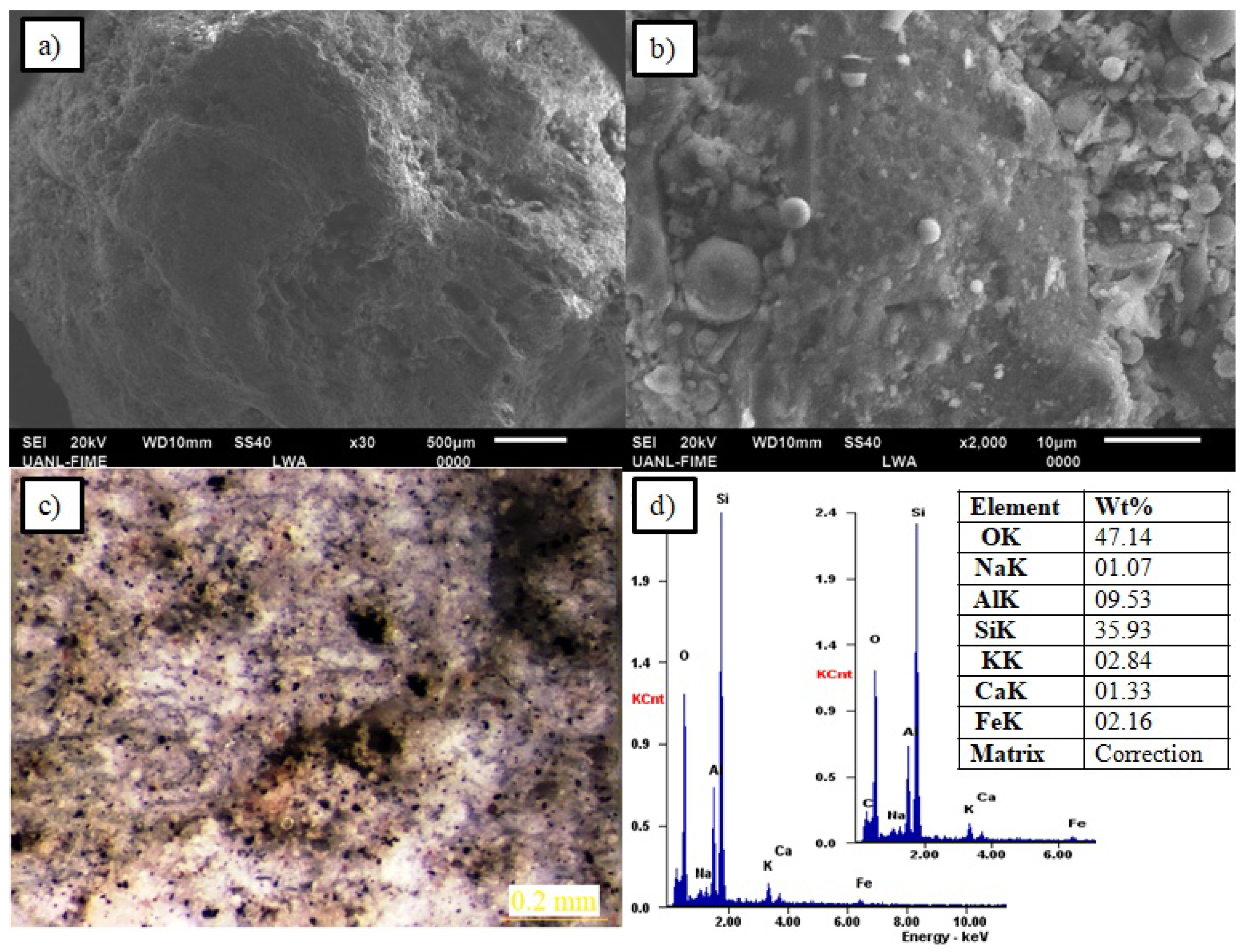

2.1. Materials

2.2. Concrete Mixtures

2.3. Specimen Preparation

2.3.1. Curing conditions in stage 1

2.3.2. Curing conditions in stage 2

2.4. Testing Methods

2.4.1. Volumetric Weight

2.4.2. Air Content

2.4.3. Slump

2.4.4. Compressive Strength

2.4.5. Microstructural Evaluation

2.4.6. Open Porosity

2.4.7. Depth of Chloride Ion Penetration

3. Results and Discussion

3.1. Properties of Concrete in the Fresh State

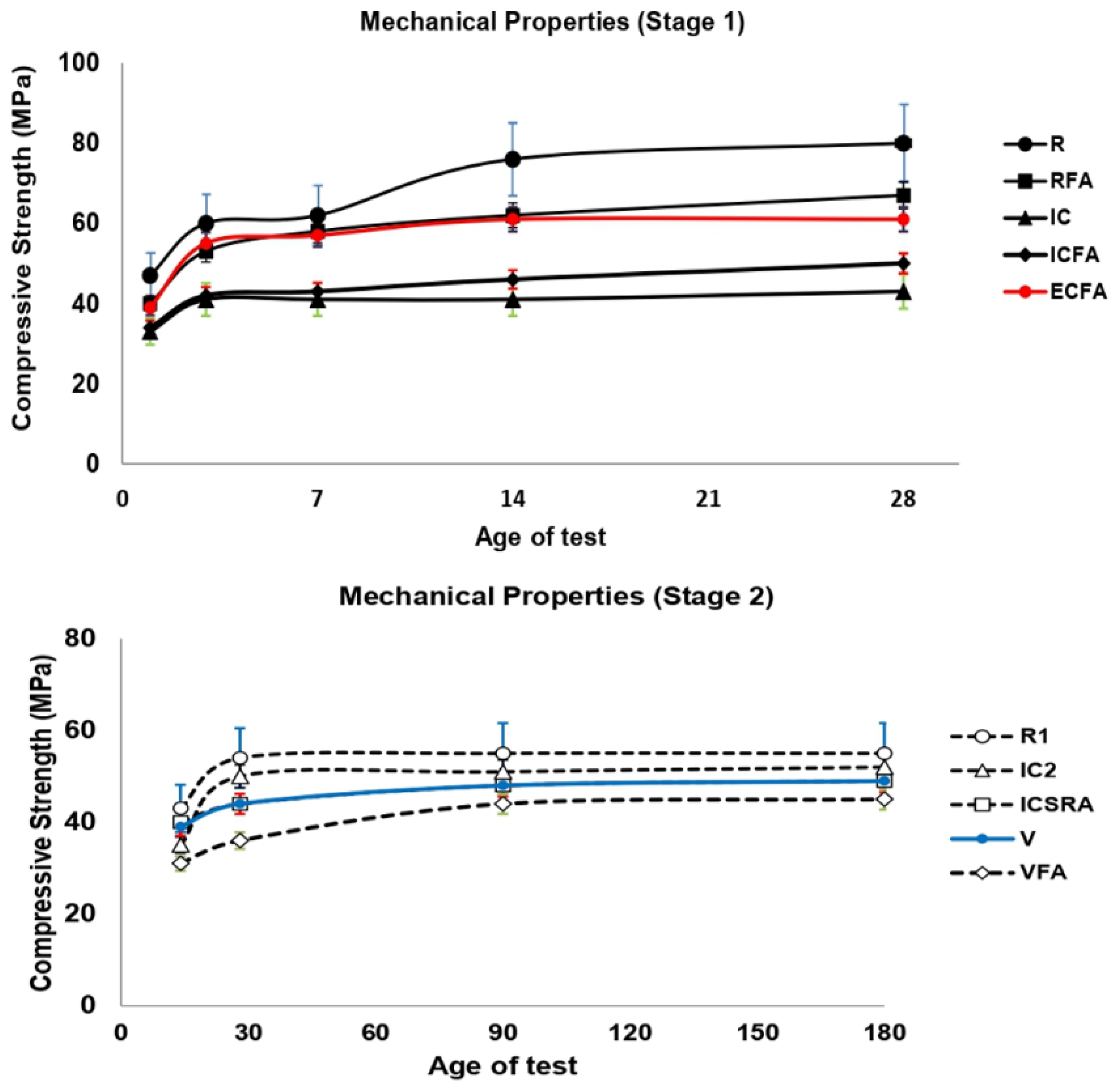

3.2. Properties of Concrete in the Hardened State (Compressive Strength)

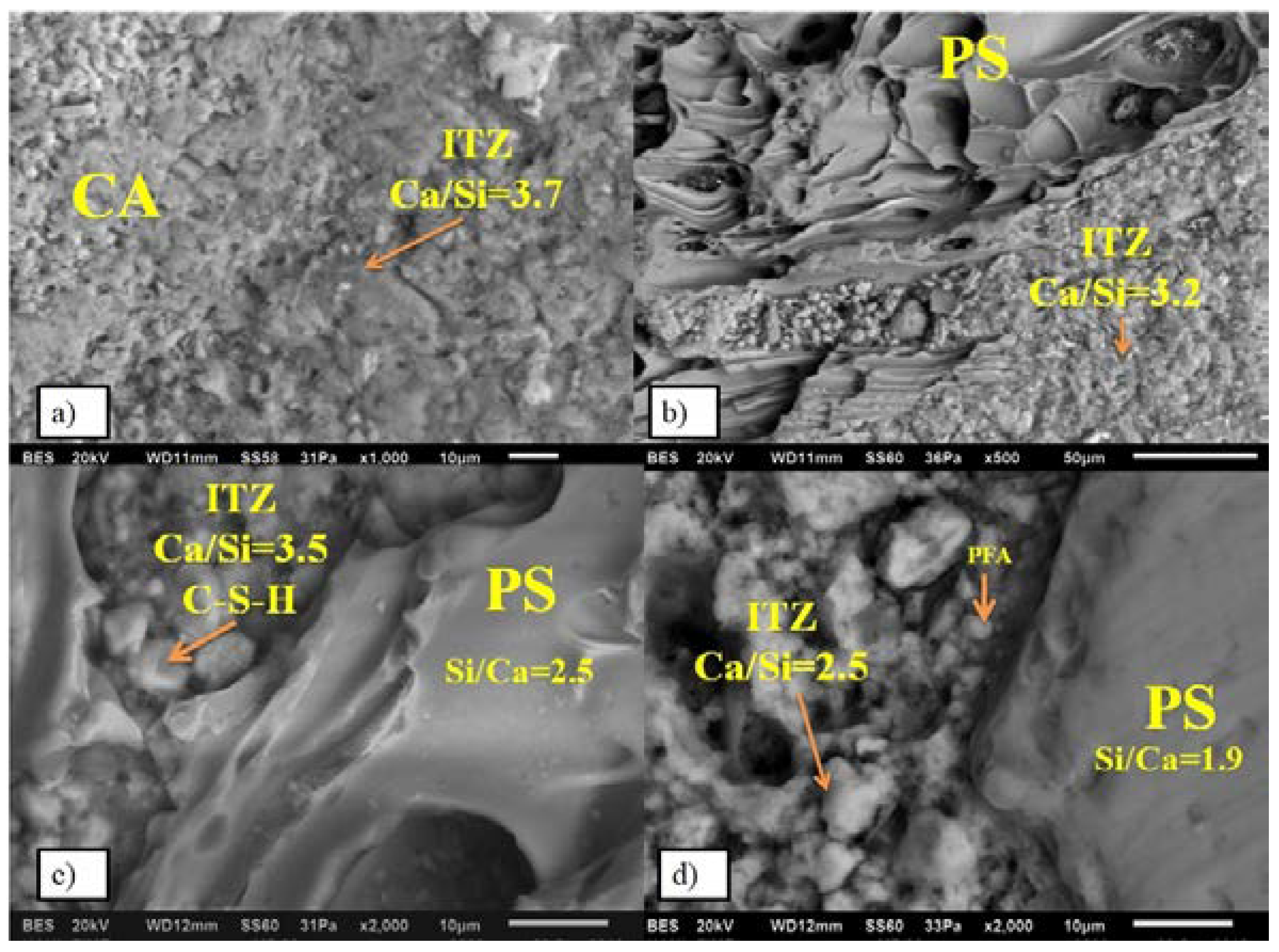

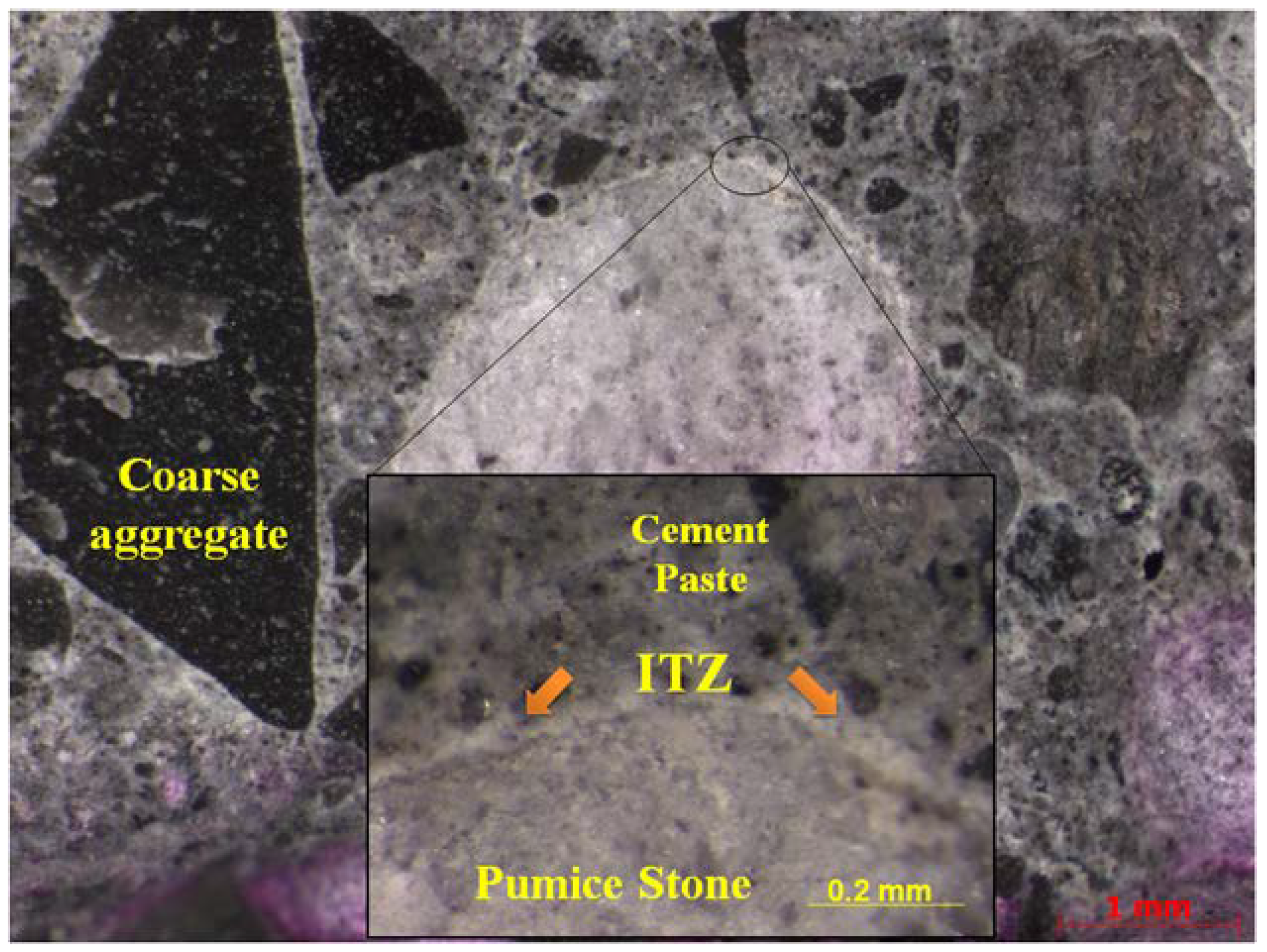

3.3. Microstructural Evaluation

3.4. Open Porosity

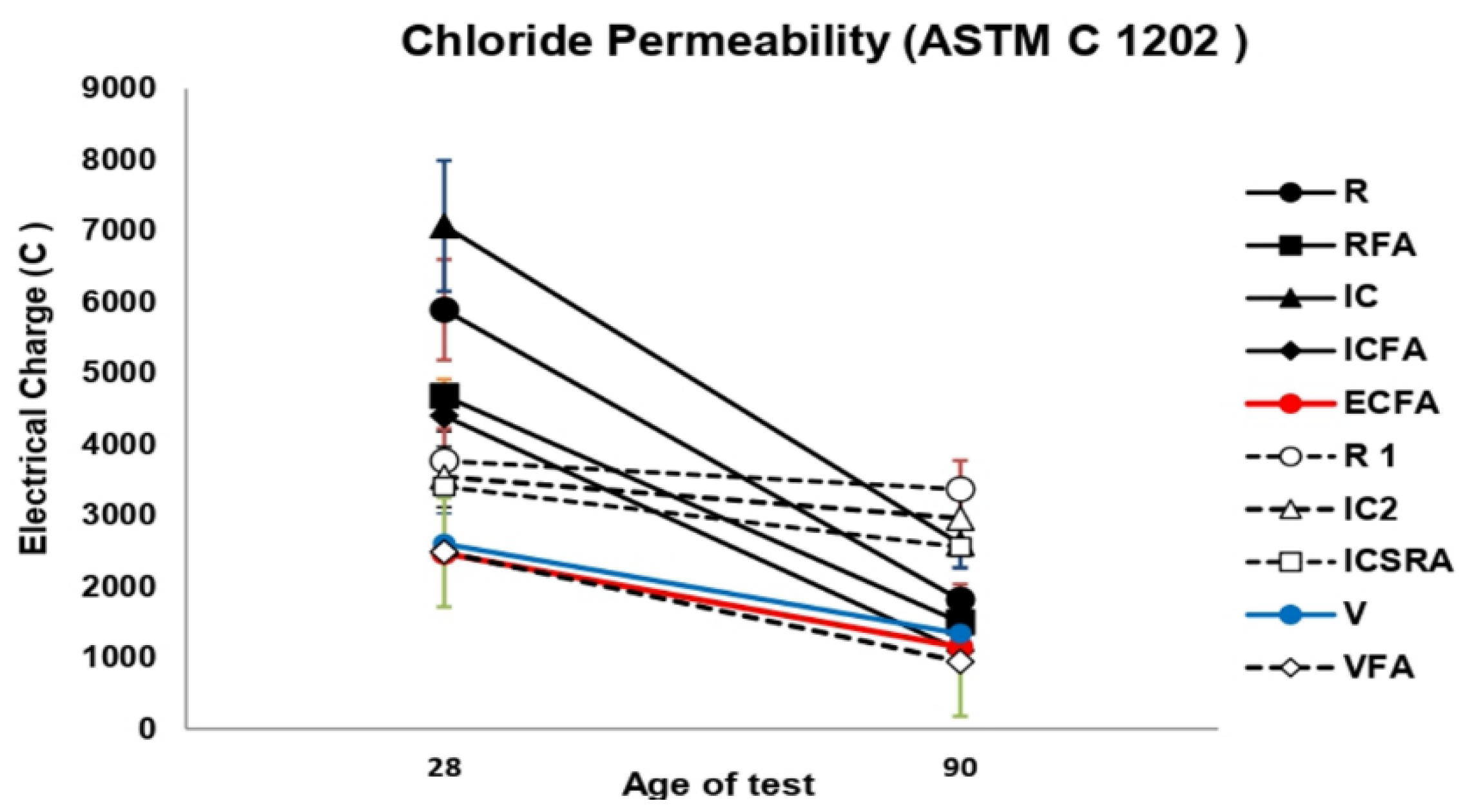

3.5. Penetration Depth of Chloride Ions

4. Conclusions

- (1)

- Structural high-performance concretes with compressive strengths of 45 to 67 MPa and densities of 2130 to 2310 kg/m3 were obtained. All these ranges are favorable for the development of structural concretes. The structural efficiencies of these concretes are much higher than the conventional normal density concretes.

- (2)

- The adverse effect of internal curing on the mechanical strength of the concrete at early-age was improving at later ages, where acceptable compressive strengths were achieved.

- (3)

- A less porous curing agent such as expanded clay (EC) compared to pumice stone (PS) allowed to exhibit the highest mechanical strength at 28 days (61 MPa), due to the development of a denser cementitious matrix (ECFA at stage 1).

- (4)

- In IC2 concrete, where 20% fine aggregate (FA) was replaced by pumice stone (PS), the effect of high water release by the internal curing agent allowed to increase the compressive strength from 35 MPa at 14 days to 50 MPa at 28 days, and subsequently achieve the highest compressive strength among the concretes with an internal curing agent at 180 days.

- (5)

- The VFA concrete exhibited the lowest permeability value at 90 days (945 C). This concrete included substitutions of fine aggregate by 20% of the PS saturated with shrinkage reducing admixture into pores and substitutions of OPC40C by 15% of PFA. Interestingly, the VFA concrete exhibited the highest porosity at 90 days and 180 days (~ 19% and ~ 16% respectively). The relationship between the porosity in the concrete and the connectivity may affect the chloride penetration. Even if the porosity of concrete is high, chloride penetration may be low when the connectivity of pores is low. Therefore, it was presumed that the VFA concrete developed low connectivity between pores into the matrix.

- (6)

- Similar behavior in permeability at 90 days was exhibited by ICFA (1100 C) and ECFA (1150 C), V (1338 C), and RFA (1500 C) concrete. This concrete showed outstanding performance since their permeability values at 90 days are below 1500 C with almost no penetration.

- (7)

- The total of chloride ions permeability in internal curing concrete with pulverized fly ash (PFA) were lower than those in the control concrete (R and R1 concrete). It might be due to impeded diffusion of chloride ions into cement paste in the vicinity of PFA, where the pozzolanic reaction has occurred.

- (8)

- As known, it is generally believed that SRA improves the water absorption and chloride permeability of concrete due to the reduced surface tension of pore solution, increased viscosity, and refinement of pore structure. However, in the present study, the effect of SRA merely affected the durability property.

- (9)

- The effect of superplasticizer on the concrete properties was not clearly understood.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Aïtcin, P.-C. High Performance Concrete; CRC press: Boca Raton, FL, USA, 1998. [Google Scholar]

- Zhutovsky, S.; Kovler, K. Influence of water to cement ratio on the efficiency of internal curing of high-performance concrete. Constr. Build. Mater. 2017, 144, 311–316. [Google Scholar] [CrossRef]

- Kovler, K.; Jensen, O.M. Internal Curing of Concrete, State-of-the-Art Report of RILEM Technical Committee 196-ICC.; RILEM Report 41: Paris, France, 2007. [Google Scholar]

- Kovler, K.; Jensen, O.M. Novel technologies of concrete curing. Concr. Int. 2005, 27, 4. [Google Scholar]

- Suzuki, M.; Meddah, M.S.; Sato, R. Use of porous ceramic waste aggregates for internal curing of high-performance concrete. Cem. Concr. Res. 2009, 39, 373–381. [Google Scholar] [CrossRef]

- Kovler, K.; Zhutovsky, S. Overview and future trends of shrinkage research. Mater. Struct. 2006, 39, 827. [Google Scholar] [CrossRef]

- Hoff, C.; Eng, D. The Use of Lightweight Fines for the Internal Curing of Concrete; Pennsylvania State University: State College, PA, USA, 2002. [Google Scholar]

- Babcock, A.E.; Taylor, P. Impacts of Internal Curing on Concrete Properties; Iowa State University: Ames, IA, USA, 2015. [Google Scholar]

- Carino, N.J.; Meeks, K.W. Curing of High-Performance Concrete: Phase I Study; US Department of Commerce, Technology Administration; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2001.

- Report on Internally Cured Concrete Using Prewetted Absorptive, Lightweight Aggregate. In American, C.I.C. 308 (Eds.) ACI (308-213)R-13; American Concrete Institute: Farmington Hills, MI, USA, 2013.

- Byard, B.E.; Schindler, A.K. Cracking Tendency of Lightweight Concrete; Highway Research Center, Auburn University: Auburn, AL, USA, 2010. [Google Scholar]

- Bentur, A.; Igarashi, S.-I.; Kovler, K. Prevention of autogenous shrinkage in high-strength concrete by internal curing using wet lightweight aggregates. Cem. Concr. Res. 2001, 31, 1587–1591. [Google Scholar] [CrossRef]

- Cleary, J.; Delatte, N. Implementation of internal curing in transportation concrete. Transp. Res. Rec. 2008, 2070, 1–7. [Google Scholar] [CrossRef]

- Zia, P.; Ahmad, S.; Leming, M. High-Performance Concretes: A State-of-Art Report (1989–1994); US Department of Transportation: Washington, DC, USA, 1997.

- Campbell, R.H.; Tobin, R.E. Core and cylinder strengths of natural and lightweight concrete. J. Proc. 1967, 64, 190–195. [Google Scholar]

- Jones, T.R.; Stephenson, H.K. Properties of Lightweight Concrete Related to Prestressing. In Proceedings of the World Conference on Prestressed Concret, San Francisc, CA, USA, 16 July 1957; p. 12. [Google Scholar]

- Klieger, P. Early High-Strength Concrete for Prestressing; Media Info: Brooklyn, NY, USA, 1969. [Google Scholar]

- Philleo, R.E. Concrete science and reality. In Materials Science of Concrete II; ASTM, International: West Conshohocken, PA, USA, 1991; p. 8. [Google Scholar]

- Liu, J.; Shi, C.; Ma, X.; Khayat, K.H.; Zhang, J.; Wang, D. An overview on the effect of internal curing on shrinkage of high performance cement-based materials. Constr. Build. Mater. 2017, 146, 702–712. [Google Scholar] [CrossRef] [Green Version]

- Lura, P. Autogenous Deformation and Internal Curing of Concrete; Delft University Press: Delft, The Netherlands, 2003. [Google Scholar]

- Jensen, O.M.; Hansen, P.F. Water-entrained cement-based materials: I. Principles and theoretical background. Cem. Concr. Res. 2001, 31, 647–654. [Google Scholar] [CrossRef]

- Ranjbar, S. Effect of Pre-Wetted Perlite and Fibers on Autogenous and Plastic Shrinkage of High Strength Concrete. Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, 2013. [Google Scholar]

- Afzal, S.; Shahzada, K.; Fahad, M.; Saeed, S.; Ashraf, M. Assessment of early-age autogenous shrinkage strains in concrete using bentonite clay as internal curing technique. Constr. Build. Mater. 2014, 66, 403–409. [Google Scholar] [CrossRef]

- Van Tuan, N.; Ye, G.; van Breugel, K. Internal Curing of Ultra High Performance Concrete by Using Rice Husk Ash. In International RILEM Conference on Material Science; RILEM Publications SARL: Paris, France, 2010; pp. 265–274. [Google Scholar]

- Wyrzykowski, M.; Ghourchian, S.; Sinthupinyo, S.; Chitvoranund, N.; Chintana, T.; Lura, P. Internal curing of high performance mortars with bottom ash. Cem. Concr. Compos. 2016, 71, 1–9. [Google Scholar] [CrossRef]

- Liu, F.; Wang, J.; Qian, X.; Hollingsworth, J. Internal curing of high performance concrete using cenospheres. Cem. Concr. Res. 2017, 95, 39–46. [Google Scholar] [CrossRef] [Green Version]

- Ghourchian, S.; Wyrzykowski, M.; Lura, P.; Shekarchi, M.; Ahmadi, B. An investigation on the use of zeolite aggregates for internal curing of concrete. Constr. Build. Mater. 2013, 40, 135–144. [Google Scholar] [CrossRef]

- Weber, S.; Reinhardt, H.W. A new generation of high performance concrete: Concrete with autogenous curing. Adv. Cem. Based Mater. 1997, 6, 59–68. [Google Scholar] [CrossRef]

- Castro, J.; Keiser, L.; Golias, M.; Weiss, J. Absorption and desorption properties of fine lightweight aggregate for application to internally cured concrete mixtures. Cem. Concr. Compos. 2011, 33, 1001–1008. [Google Scholar] [CrossRef]

- Zou, D.; Zhang, H.; Wang, Y.; Zhu, J.; Guan, X. Internal curing of mortar with low water to cementitious materials ratio using a normal weight porous aggregate. Constr. Build. Mater. 2015, 96, 209–216. [Google Scholar] [CrossRef]

- Dilli, M.E.; Atahan, H.N.; Şengül, C. A comparison of strength and elastic properties between conventional and lightweight structural concretes designed with expanded clay aggregates. Constr. Build. Mater. 2015, 101, 260–267. [Google Scholar] [CrossRef]

- Zou, D.; Li, K.; Li, W.; Li, H.; Cao, T. Effects of pore structure and water absorption on internal curing efficiency of porous aggregates. Constr. Build. Mater. 2018, 163, 949–959. [Google Scholar] [CrossRef]

- Vijayalakshmi, R.; Ramanagopal, S. Structural Concrete Using Expanded Clay Aggregate: A Review. Indian. J. Sci. Technol. 2018, 8, 1–12. [Google Scholar] [CrossRef]

- Gopi, R.; Revathi, V. Influence of presaturated light expanded clay and fly ash aggregate in self compacting concrete. Rev. Romana de Mater. 2019, 49, 370–378. [Google Scholar]

- Zhutovsky, S.; Kovler, K.; Bentur, A. Efficiency of lightweight aggregates for internal curing of high strength concrete to eliminate autogenous shrinkage. Mater. Struct. 2002, 35, 97–101. [Google Scholar] [CrossRef]

- Liu, K.; Yu, R.; Shui, Z.; Li, X.; Ling, X.; He, W.; Yi, S.; Wu, S. Effects of pumice-based porous material on hydration characteristics and persistent shrinkage of ultra-high performance concrete (UHPC). Materials 2019, 12, 11. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lyu, Y.; Huang, H.; Ye, G.; De Schutter, G. Autogenous shrinkage of zeolite cement pastes with low water-binder ratio. In Proceedings of the 14th International Congress on the Chemistry of Cement (ICCC 2015), Beijing, China, 13 October 2015; pp. 1–8. [Google Scholar]

- Lura, P.; Wyrzykowski, M.; Tang, C.; Lehmann, E. Internal curing with lightweight aggregate produced from biomass-derived waste. Cem. Concr. Res. 2014, 59, 24–33. [Google Scholar] [CrossRef]

- Van, V.-T.-A.; Rößler, C.; Bui, D.-D.; Ludwig, H.-M. Rice husk ash as both pozzolanic admixture and internal curing agent in ultra-high performance concrete. Cem. Concr. Compos. 2014, 53, 270–278. [Google Scholar] [CrossRef]

- De Sensale, G.R.; Ribeiro, A.B.; Gonçalves, A. Effects of RHA on autogenous shrinkage of Portland cement pastes. Cem. Concr. Compos. 2008, 30, 892–897. [Google Scholar] [CrossRef]

- Huang, Z.Y.; Zhang, C.B. Effect of porous superfine powder on the performance of ultra-high performance concrete. Bull. Chin. Ceram. Soc. 2015, 7, 22–27. [Google Scholar]

- Askar, L.K.; Tayeh, B.A.; Abu Bakar, B.H. Effect of Different Curing Conditions on the Mechanical Properties of UHPFC. Iran. J. Energy Environ. 2013, 4, 299–303. [Google Scholar] [CrossRef]

- Askar, L.K.; Tayeh, B.A.; Bakar, B.H.A.; Zeyad, A.M. Properties of ultra-high performance fiber concrete (UHPFC) under different curing regimes. In Properties of Ultra-High Performance Fiber Concrete (UHPFC) under Different Curing Regimes; IAEME Publication: Tamil Nadu, India, 2017; Volume 8. [Google Scholar]

- Akcay, B.; Tasdemir, M.A. Effects of distribution of lightweight aggregates on internal curing of concrete. Cem. Concr. Compos. 2010, 32, 611–616. [Google Scholar] [CrossRef]

- Tazawa, E.-I.; Miyazawa, S.; Kasai, T. Chemical shrinkage and autogenous shrinkage of hydrating cement paste. Cem. Concr. Res. 1995, 25, 288–292. [Google Scholar] [CrossRef]

- Van Breugel, K.; Ouwerkerk, H.; De Vries, J. Effect of mixture composition and size effect on shrinkage of high strength concrete. In Proc. Int. RILEM Workshop Shrinkage of Concrete; Rilem: Paris, France, 2000; pp. 161–177. [Google Scholar]

- Lura, P.; Van Breugel, K.; Maruyama, I. Autogenous and drying shrinkage of high-strength lightweight aggregate concrete at early ages–The effect of specimen size. PRO 2002, 23, 335–342. [Google Scholar]

- Maruyama, I.; Sato, R. A trial of reducing autogenous shrinkage by recycled aggregate. In Proceedings of the Self-Desiccation and Its Importance in Concrete Technology, Gaithersburg, MD, USA, 15 June 2005; Volume 20, pp. 264–270. [Google Scholar]

- Schwesinger, P.; Sickert, G. Reducing shrinkage in HPC by internal curing by using pre-soaked LWA. In Proceedings of the International Workshop on Control of Cracking in Early-Age Concrete, Tohoku University, Sendai, Japan, 26 August 2000. [Google Scholar]

- Goto, T.; Sato, T.; Sakai, K.; Ii, M. Cement-Shrinkage-Reducing Agent and Cement Composition. U.S. Patent No. 4,547,223, 15 October 1985. [Google Scholar]

- Zuo, W.; Feng, P.; Zhong, P.; Tian, Q.; Gao, N.; Wang, Y.; Yu, C.; Miao, C. Effects of novel polymer-type shrinkage-reducing admixture on early age autogenous deformation of cement pastes. Cem. Concr. 2017, 100, 413–422. [Google Scholar] [CrossRef]

- Nair, H.; Ozyildirim, H.C. Lightweight Aggregates and Shrinkage-Reducing Admixtures for Low-Cracking Concrete. ACI Mater. J. 2019, 116, 91–98. [Google Scholar] [CrossRef]

- Rodriguez, F.J.V.; De los Santos, U.; Rangel, J.M.M.; Rodríguez, C.G.; Tovar, A.M.A.; Rodríguez, A. High performance reinforced concrete, corrosion–resistant into aggressive industrial environments. Rev. Română de Mater. Rom. J. Mater. 2017, 47, 505–513. [Google Scholar]

- Chen, S.; Zhao, H.; Chen, Y.; Huang, D.; Chen, Y.; Chen, X. Experimental study on interior relative humidity development in early-age concrete mixed with shrinkage-reducing and expansive admixtures. Constr. Build. Mater. 2020, 232, 117204. [Google Scholar] [CrossRef]

- Zhan, P.-M.; He, Z.-H. Application of shrinkage reducing admixture in concrete: A review. Constr. Build. Mater. 2019, 201, 676–690. [Google Scholar] [CrossRef]

- Liu, C.; Chen, D. Internal structure characterizations of hardened cement paste containing shrinkage reducing admixture using nanoindentation and sem techniques. Rev. Romana de Mater. 2020, 50, 113–118. [Google Scholar]

- Al Saffar, D.M.; al Saad, A.J.K.; Tayeh, B.A. Effect of internal curing on behavior of high performance concrete: An overview. Case Stud. Constr. Mater. 2019, 10, e00229. [Google Scholar] [CrossRef]

- Vázquez-Rodríguez, F.J.; Arato, A.; Martínez-Delgado, D.I.; Guzmán, A.; Elizondo-Villarreal, N.; Puente-Ornelas, R.; Rodríguez, E. Evaluation of Chloride Diffusion and Corrosion Resistance in Reinforced Concrete Using Internal Curing and Shrinkage Reducing Admixtures. Int. J. Electrochem. Sci. 2018, 13, 6027–6047. [Google Scholar] [CrossRef]

- Khitab, A.; Anwar, W.; Mansouri, I.; Tariq, M.K.; Mehmood, I. Future of civil engineering materials: A review from recent developments. Rev. Adv. Mater. Sci. 2015, 42, 20–27. [Google Scholar]

- Trujillo Rodríguez, R. Uso de Agregado Ligero Como Medio de Curado Interno en Concretos de Alto Comportamiento Fabricado con Puzolanas. Ph.D. Thesis, Universidad Autónoma de Nuevo León, San Nicolás de los Garza, Mexico, 2011. [Google Scholar]

- Zhutovsky, S.; Kovler, K. Effect of internal curing on durability-related properties of high performance concrete. Cem. Concr. Res. 2012, 42, 20–26. [Google Scholar] [CrossRef]

- Haug, A.K.; Fjeld, S. A floating concrete platform hull made of lightweight aggregate concrete. Eng. Struct. 1996, 18, 831–836. [Google Scholar] [CrossRef]

- Woodhead, H.R. Hibernia offshore oil platform. Concr. Int. 1993, 15, 23–30. [Google Scholar]

- Valenchon, C.; Nagel, R.; Viallon, J.P.; Belbeoc’h, H.; Rouillon, J. A concrete oil production barge, Congo. Struct. Eng. Int. 1996, 6, 19–21. [Google Scholar] [CrossRef]

- Aıtcin, P.C. The durability characteristics of high performance concrete: A review. Cem. Concr. Compos. 2003, 25, 409–420. [Google Scholar] [CrossRef]

- Ingebrigtsen, T. Stolma Bridge, norway. Struct. Eng. Int. 1999, 9, 100–102. [Google Scholar] [CrossRef]

- Chia, K.S.; Zhang, M.-H. Water permeability and chloride penetrability of high-strength lightweight aggregate concrete. Cem. Concr. Res. 2002, 32, 639–645. [Google Scholar] [CrossRef]

- Elsharief, A.; Cohen, M.D.; Olek, J. Influence of lightweight aggregate on the microstructure and durability of mortar. Cem. Concr. Res. 2005, 35, 1368–1376. [Google Scholar] [CrossRef]

- Zhutovsky, S.; Kovler, K.; Bentur, A. Effect of hybrid curing on cracking potential of high-performance concrete. Cem. Concr. Res. 2013, 54, 36–42. [Google Scholar] [CrossRef]

- Witjaksana, B. Additional steel fibers in concrete mixture: Studies of compressive and tensile strength of concrete. Mater. Phys. Mech. 2018, 37, 104–108. [Google Scholar]

- ASTM International. Available online: https://www.astm.org/DATABASE.CART/HISTORICAL/C29C29M-17.htm (accessed on 30 April 2020).

- ASTM International. Available online: https://www.astm.org/Standards/C204.htm (accessed on 30 April 2020).

- ASTM International. Available online: https://www.astm.org/Standards/C128.htm (accessed on 30 April 2020).

- ASTM International. Available online: https://www.astm.org/Standards/C138.htm (accessed on 30 April 2020).

- ASTM International. Available online: https://www.astm.org/DATABASE.CART/HISTORICAL/C150C150M-18.htm (accessed on 30 April 2020).

- ASTM International. Available online: https://www.astm.org/DATABASE.CART/HISTORICAL/C531-00R12.htm (accessed on 30 April 2020).

- ASTM International. Available online: https://www.astm.org/Standards/C31.htm (accessed on 30 April 2020).

- ASTM International. Available online: https://www.astm.org/Standards/C94.htm (accessed on 30 April 2020).

- ASTM International. Available online: https://www.astm.org/Standards/C173.htm (accessed on 30 April 2020).

- ASTM International. Available online: https://www.astm.org/Standards/C143.htm (accessed on 30 April 2020).

- ASTM International. Available online: https://www.astm.org/DATABASE.CART/HISTORICAL/C39C39M-18.htm (accessed on 30 April 2020).

- ASTM International. Available online: https://www.astm.org/Standards/C642.htm (accessed on 30 April 2020).

- ASTM International. Available online: https://www.astm.org/DATABASE.CART/HISTORICAL/C1202-12.htm (accessed on 30 April 2020).

- ASTM International. Available online: https://www.astm.org/Standards/C185.htm (accessed on 30 April 2020).

- Péra, J.; Husson, S.; Guilhot, B. Influence of finely ground limestone on cement hydration. Cem. Concr. Compos. 1999, 21, 99–105. [Google Scholar] [CrossRef] [Green Version]

- Bonavetti, V.L.; Rahhal, V.F.; Irassar, E.F. Studies on the carboaluminate formation in limestone filler-blended cements. Cem. Concr. Res. 2001, 31, 853–859. [Google Scholar] [CrossRef]

| Raw Material | CaO | SiO2 | Al2O3 | Fe2O3 | Na2O | K2O |

|---|---|---|---|---|---|---|

| PS | 2.7 | 72 | 143 | 3.7 | 1.7 | 0.1 |

| EC [70] | 0.2 | 58 | 27 | 1.0 | 0.3 | 2.3 |

| PFA | 2.2 | 63.7 | 25 | 4.9 | 0.6 | − |

| OPC40C | 65.8 | 20.7 | 5.8 | 2.3 | 0.3 | − |

| CPC30R [70] | 62.2 | 17 | 3.9 | 2.4 | 0.6 | 0.1 |

| Material | Density ASTM C29-17 (kg/m3) | Blaine ASTM C204-17 (%) | Absorption ASTM C128-15 (%) | Volumetric Weight Dry ASTM C138-17 (kg/m3) |

|---|---|---|---|---|

| Clay aggregate (EC) [60] | 1840 | 4.1 | 27 | 990 |

| Pumice stone (PS) | 1470 | 4.9 | 30 | 460 |

| Stage 1 [60] Sample Code | Description of Concrete Mixture |

| R | Reference concrete elaborated with CPC30R (maximum consumption of cement 400 kg/m3). |

| RFA | Substitutions of CPC30R by the PFA in 15% of the mass. |

| IC | Internal curing with substitutions of fine aggregate by the PS (20% mass). |

| ICFA | Internal curing with substitutions of fine aggregate by the PS (20% in mass) and substitutions of CPC30R by the PFA in 15% of the mass. |

| ECFA | Substitution of coarse aggregates for clay aggregates and substitutions of CPC30R by the PFA in 15% of the mass. |

| Stage 2 Sample Code | Description of Concrete Mixture |

| R1 | Reference 1 is elaborated with OPC40C (maximum consumption of the cement 400 kg/m3). |

| IC2 | Substitutions of fine aggregate by the PS (20% in mass). |

| ICSRA | Substitutions of fine aggregate by the PS (20% in mass) with shrinkage reducing admixture. |

| V | Substitutions of fine aggregate by the PS (20% in mass) saturated with shrinkage reducing admixture into pores. |

| VFA | Substitutions of fine aggregate by the PS 20% (in mass) saturated with shrinkage reducing admixture into pores with substitutions of OPC40C by the PFA in 15% of the mass. |

| Mixture | CPC30R | PFA | SRA | PS | EC | Water (w/c = 0.35) |

|---|---|---|---|---|---|---|

| R | 619 | − | 4 | 1440 | − | 214.6 |

| RFA | 510 | 90 | 4 | 1440 | − | 209.2 |

| IC | 620 | − | 4 | 1155 | − | 214.6 |

| ICFA | 510 | 90 | 4 | 1155 | − | 209.2 |

| ECFA | 510 | 90 | 4 | 1155 | 200 | 209.2 |

| Mixture | OPC 40C | PFA | FAg | CA | SRA | PS | Water (w/c = 0.40) |

|---|---|---|---|---|---|---|---|

| R1 | 382.5 | − | 889.9 | 712.9 | 2 | − | 153.7 |

| IC2 | 382.5 | − | 703.5 | 711.7 | − | 130.8 | 138.4 |

| ICSRA | 382.5 | − | 699.3 | 707.5 | 2 | 130.1 | 136.3 |

| V | 403.7 | − | 933.3 | 752.7 | 2 | 112.0 | 162.2 |

| VFA | 323 | 59.5 | 742.9 | 747.1 | 2 | 112.0 | 165.5 |

| Mixtures (Stage 1) [60] | Volumetric Weight (kg/m3) | Mixtures (Stage 2) | Volumetric Weight (kg/m3) |

|---|---|---|---|

| R | 2350 | R1 | 2400 |

| RFA | 2310 | IC2 | 2310 |

| IC | 2130 | ICSRA | 2310 |

| ICFA | 2160 | V | 2290 |

| ECFA | 2210 | VFA | 2260 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vázquez-Rodríguez, F.J.; Elizondo-Villareal, N.; Verástegui, L.H.; Arato Tovar, A.M.; López-Perales, J.F.; Contreras de León, J.E.; Gómez-Rodríguez, C.; Fernández-González, D.; Verdeja, L.F.; García-Quiñonez, L.V.; et al. Effect of Mineral Aggregates and Chemical Admixtures as Internal Curing Agents on the Mechanical Properties and Durability of High-Performance Concrete. Materials 2020, 13, 2090. https://doi.org/10.3390/ma13092090

Vázquez-Rodríguez FJ, Elizondo-Villareal N, Verástegui LH, Arato Tovar AM, López-Perales JF, Contreras de León JE, Gómez-Rodríguez C, Fernández-González D, Verdeja LF, García-Quiñonez LV, et al. Effect of Mineral Aggregates and Chemical Admixtures as Internal Curing Agents on the Mechanical Properties and Durability of High-Performance Concrete. Materials. 2020; 13(9):2090. https://doi.org/10.3390/ma13092090

Chicago/Turabian StyleVázquez-Rodríguez, Francisco Javier, Nora Elizondo-Villareal, Luz Hypatia Verástegui, Ana Maria Arato Tovar, Jesus Fernando López-Perales, José Eulalio Contreras de León, Cristian Gómez-Rodríguez, Daniel Fernández-González, Luis Felipe Verdeja, Linda Viviana García-Quiñonez, and et al. 2020. "Effect of Mineral Aggregates and Chemical Admixtures as Internal Curing Agents on the Mechanical Properties and Durability of High-Performance Concrete" Materials 13, no. 9: 2090. https://doi.org/10.3390/ma13092090

APA StyleVázquez-Rodríguez, F. J., Elizondo-Villareal, N., Verástegui, L. H., Arato Tovar, A. M., López-Perales, J. F., Contreras de León, J. E., Gómez-Rodríguez, C., Fernández-González, D., Verdeja, L. F., García-Quiñonez, L. V., & Rodríguez Castellanos, E. A. (2020). Effect of Mineral Aggregates and Chemical Admixtures as Internal Curing Agents on the Mechanical Properties and Durability of High-Performance Concrete. Materials, 13(9), 2090. https://doi.org/10.3390/ma13092090