Machinability Analysis and Optimization in Wire EDM of Medical Grade NiTiNOL Memory Alloy

Abstract

1. Introduction

2. Materials and Methods

2.1. Work Material

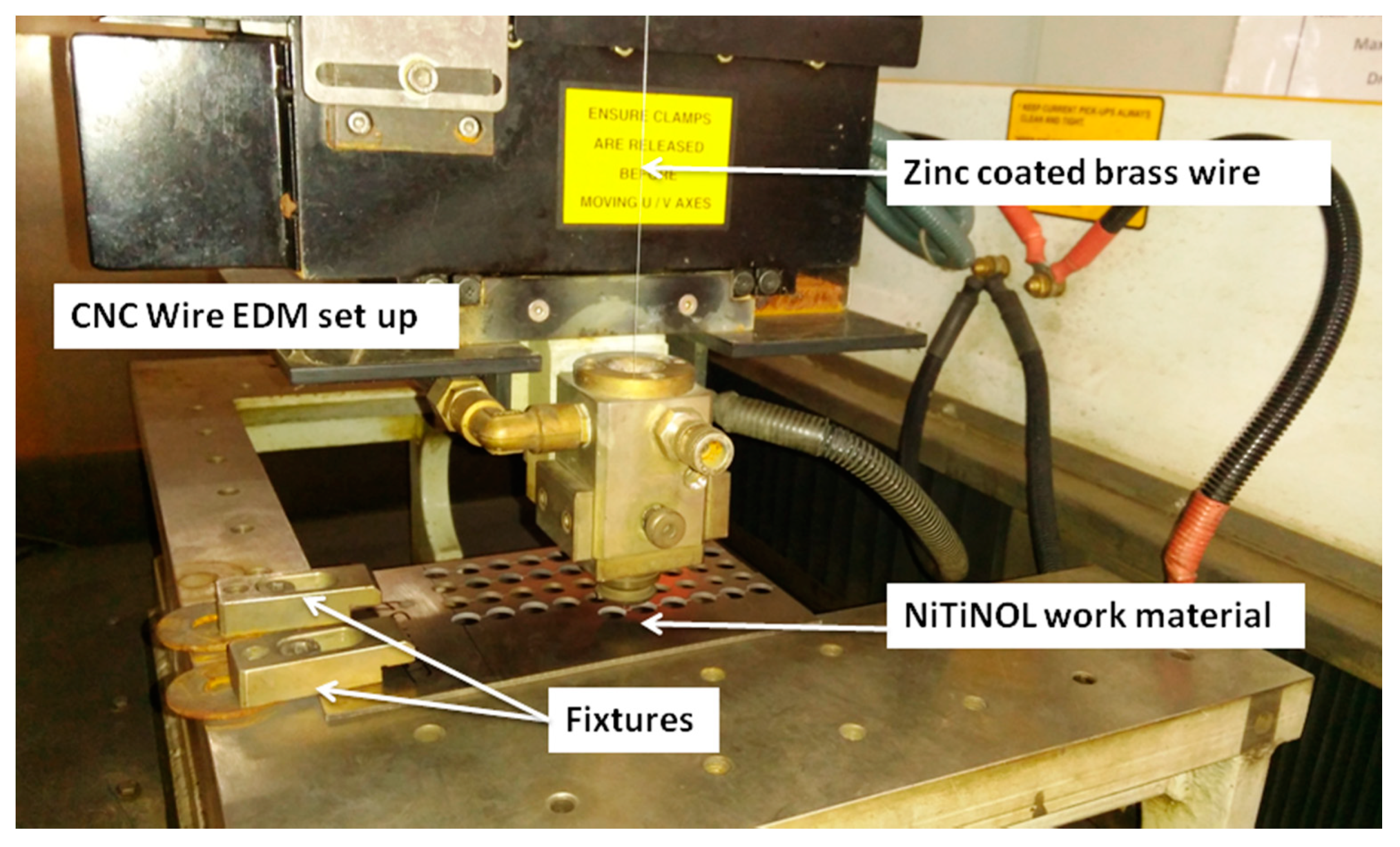

2.2. Experimental Set Up

2.3. Measurement of Performance Characteristics

2.4. Methodology

3. Results and Discussions

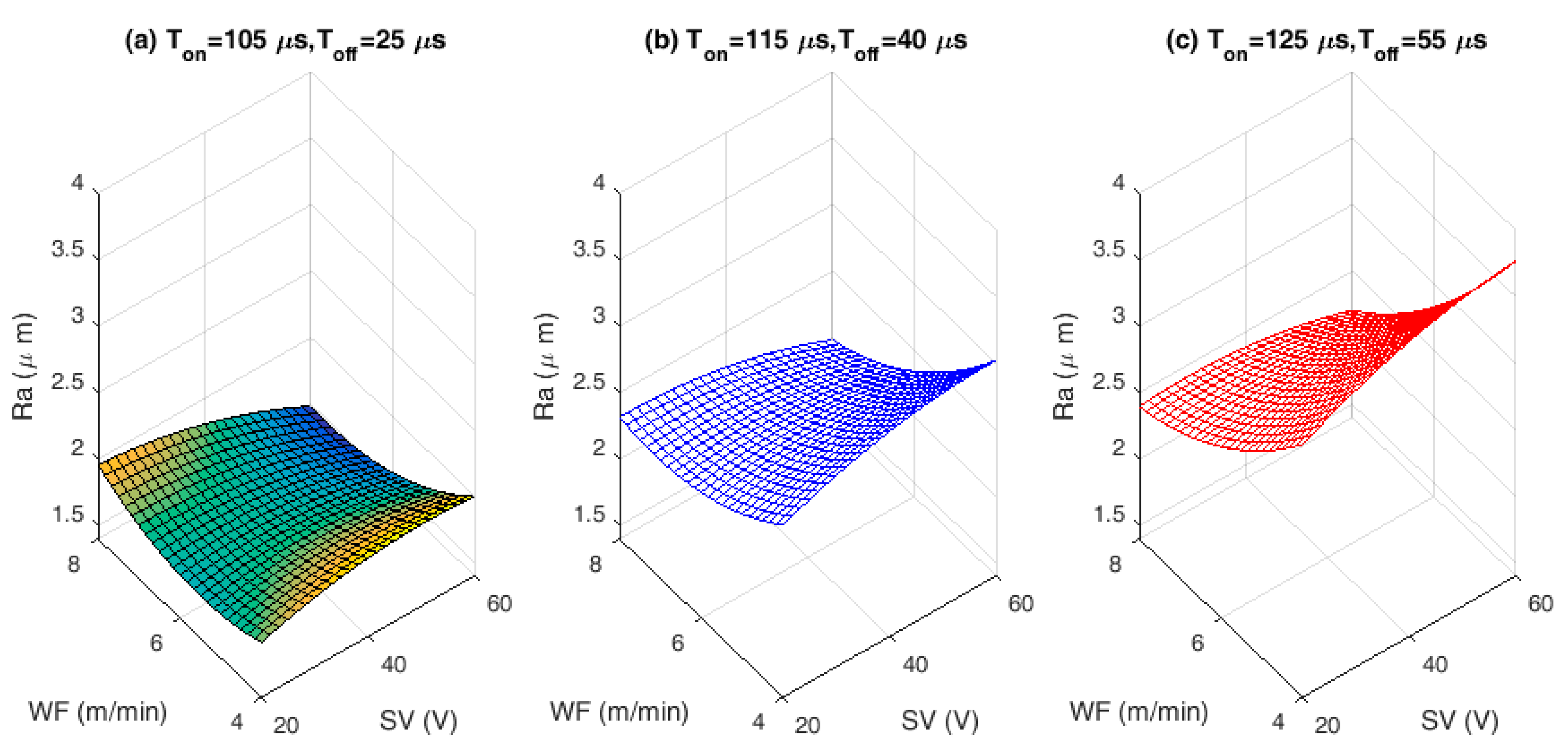

3.1. Analysis of Surface Roughness (SR)

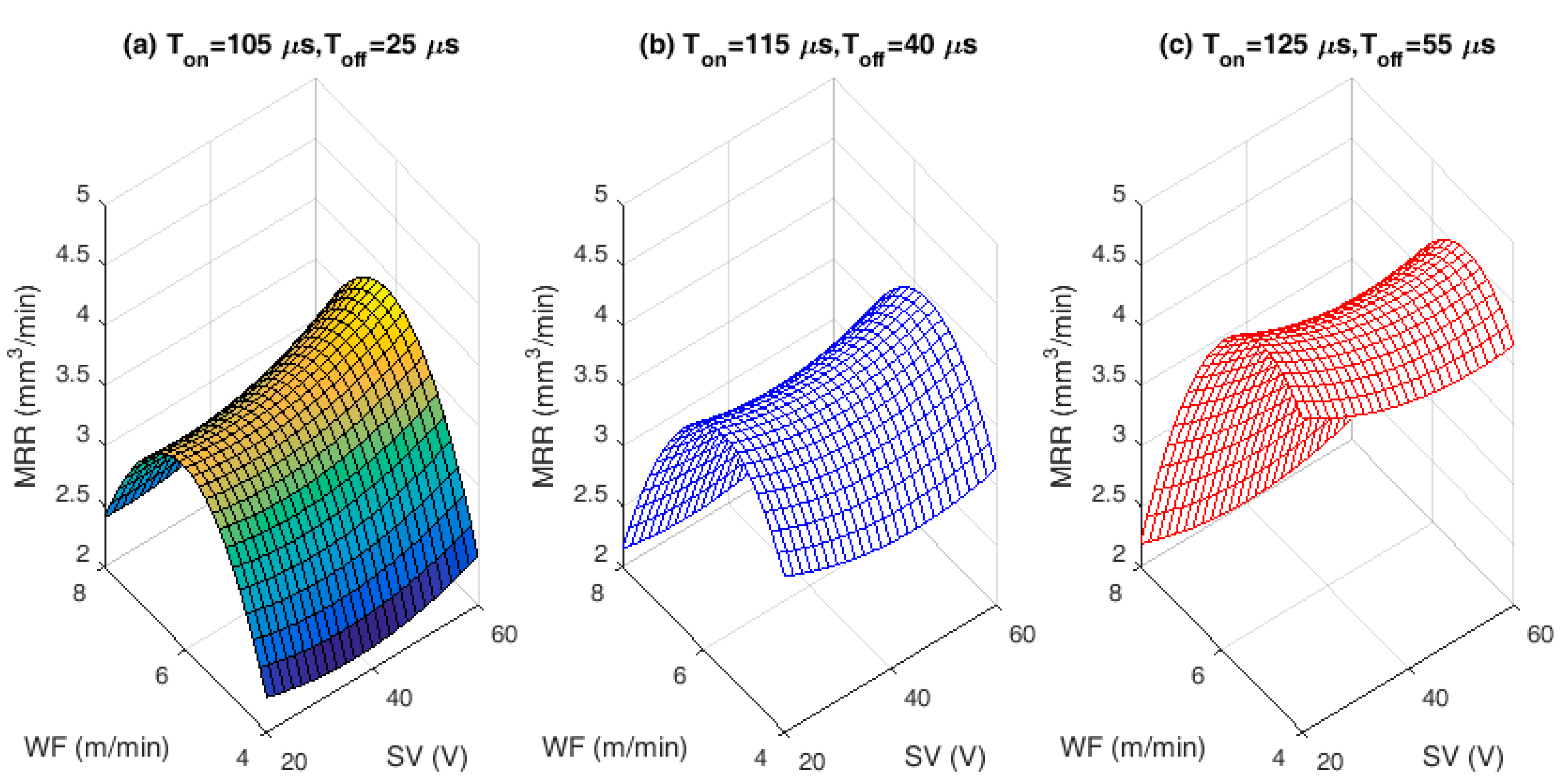

3.2. Analysis of Material Removal Rate (MRR)

3.3. Analysis of Tool Wear Rate (TWR)

4. Modified Differential Evolution (MDE) Optimization Technique and Its Development for WEDM Characteristics

4.1. Differential Evolution(DE)

4.2. Modified Differential Evolution (MDE)

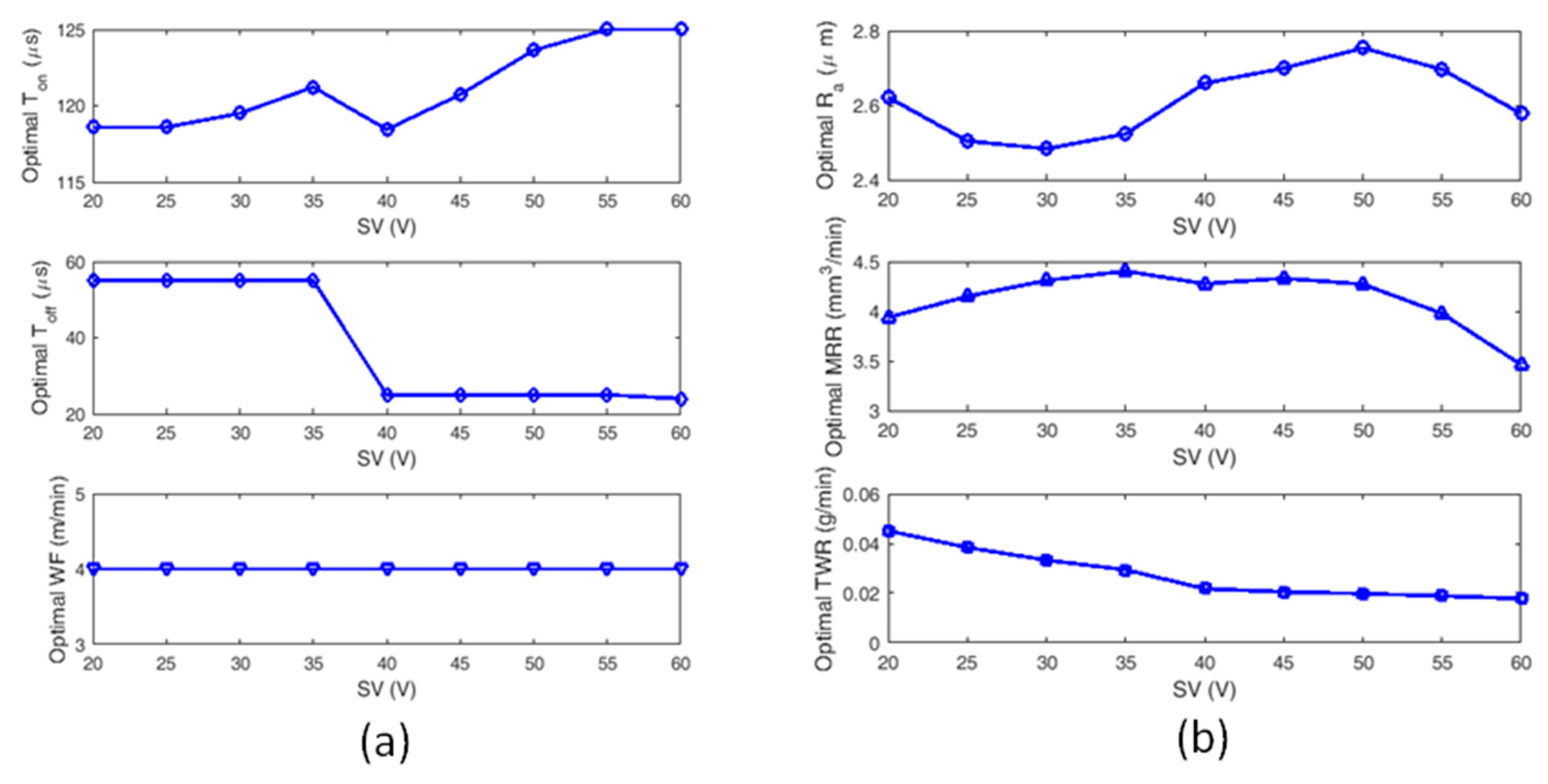

4.3. MDE Optimization Results

5. Conclusions

- The lower SR values are observed with varying SV, at lower hold values of pulse and pause time when compared to middle and higher hold values of pulse and pause time for all WF conditions. This variation can be clearly observed in Figure 2. Lower SR value is observed for a combination of lower pulse and pause time with higher WF rate as well as SV. The lower SR is found to be below 2 µm that is more desirable for biomedical applications. The SV is found to be the most significant factor for achieving better surface quality followed by Ton and Toff. Higher the SV better is the surface quality.

- For any combinational value of Ton, Toff, and WF against SV, the behavior of MRR is found to be same. High MRR is achieved at lower SV with higher pulse and pause time. WF is found to be insignificant for maximizing the MRR. Lower spark gap releases high spark and higher pulse time allows the alloy to melt more and hence high MRR is achieved.

- Nature of TWR for change in SV against three different WF rates and for all three different modes of Ton and Toff combinations (lower, middle, and higher) are found to be same. WF and SV are most influencing factors for TWR.

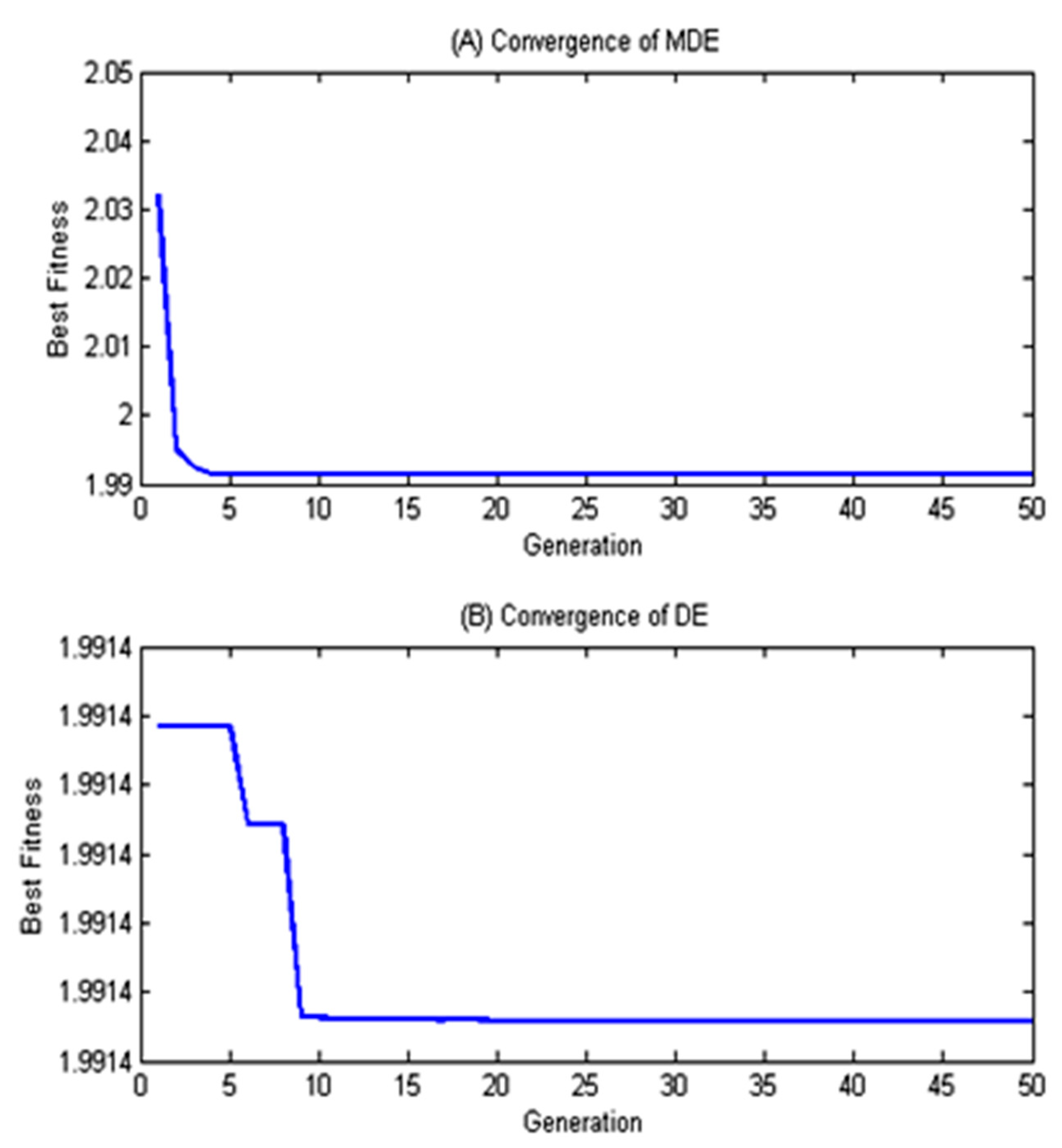

- The convergence curve for modified DE is found to be much better and quicker than normal DE approach, which in turn saves the computational time.

- The zinc coated brass wire (ZnCBW) electrode material shows better results for reduced SR as well as TWR and higher MRR when compared to uncoated brass wire electrode for machining of medical grade NiTiNOL SMA.

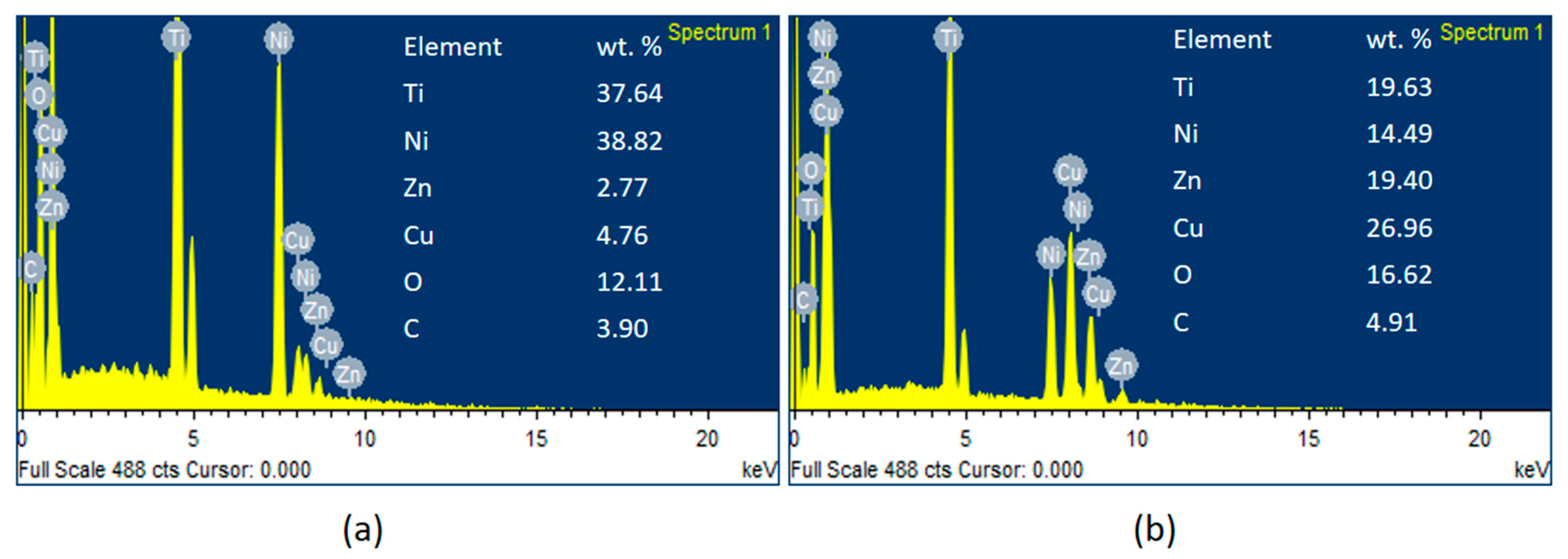

- At higher TWR, the built in compositions of electrode material gets adhered to the machined surface of the alloy. Zinc and copper contents from ZnCBW electrode material are found to be deposited at machined alloy surface with 19.40 and 26.96 wt %, respectively as depicted by EDS analysis.

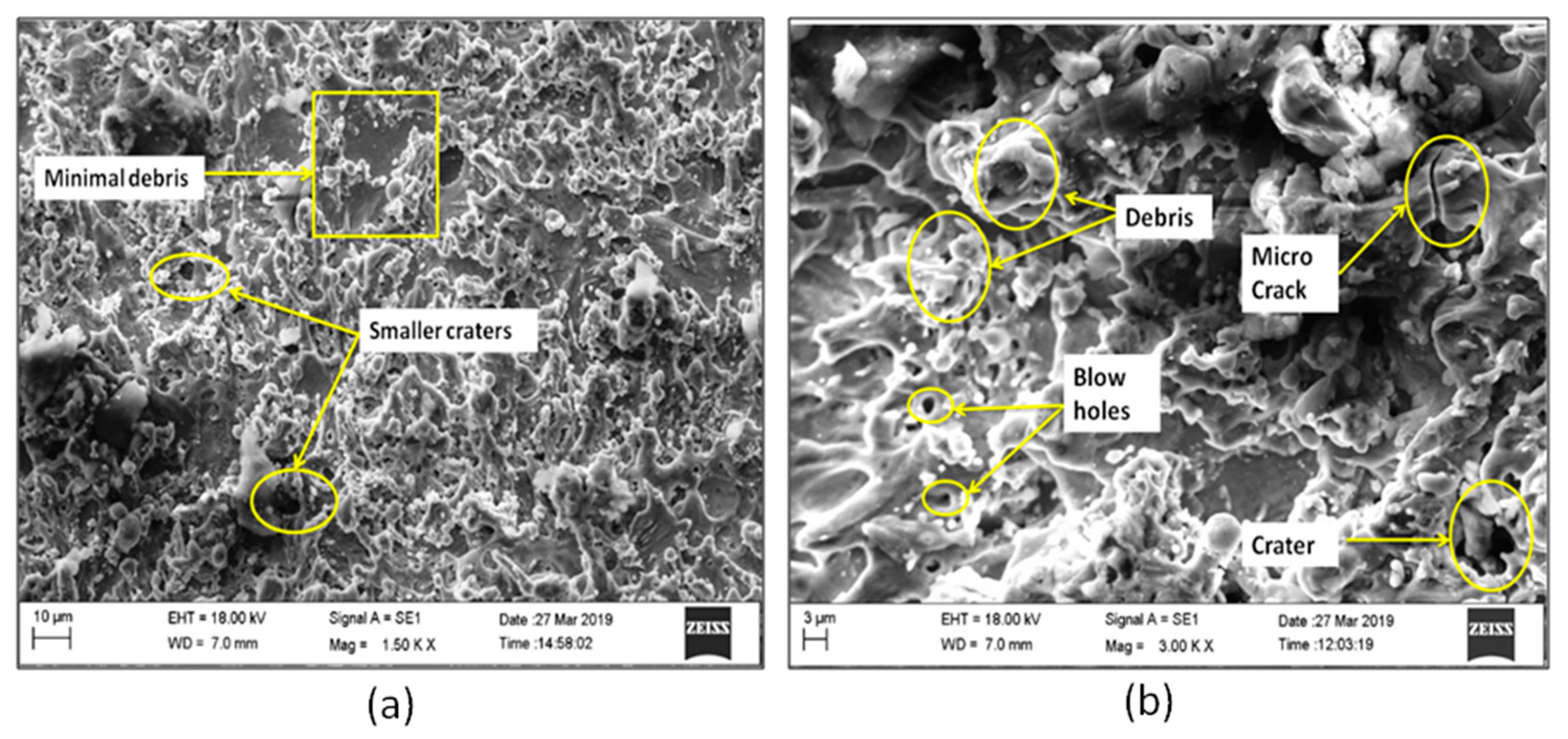

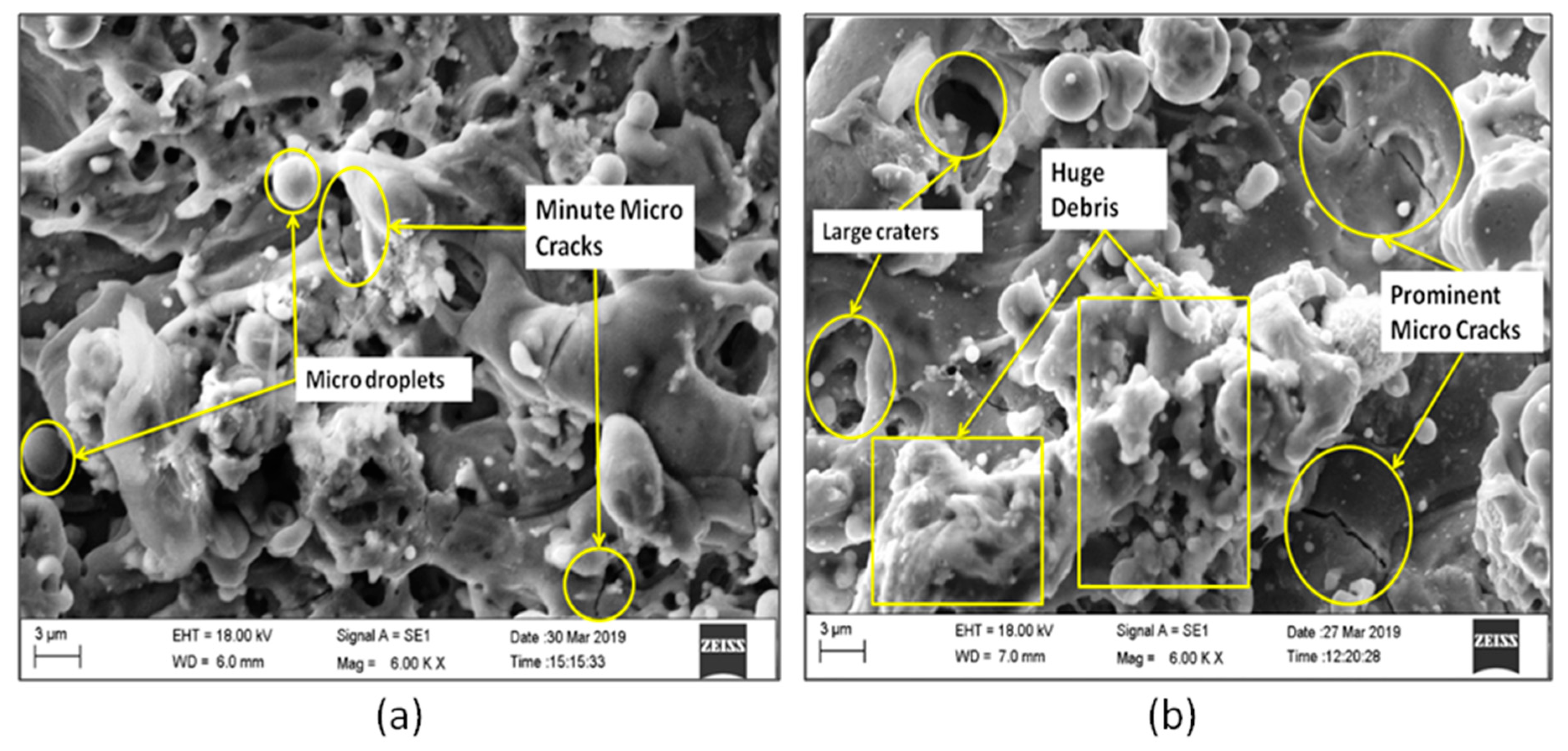

- The SEM images and morphological study on surface analysis visibly confirmed the presence of lots of uncleared debris and blow holes on the surface of machined alloy at higher surface roughness values. On the other hand, prominent micro cracks along with huge debris can be observed for higher MRR.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jani, J.M.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Markopoulos, A.P.; Pressas, I.S.; Manolakos, D.E. A Review on the machining of Nickel-Titanium shape memory alloys. Rev. Adv. Mater. Sci. 2015, 42, 28–35. [Google Scholar]

- Stoeckel, D. Shape memory actuators for automotive applications. Mater. Des. 1990, 11, 302–307. [Google Scholar] [CrossRef]

- Duerig, T.; Pelton, A.; Stöckel, D. An overview of nitinol medical applications. Mater. Sci. Eng. A 1999, 273, 149–160. [Google Scholar] [CrossRef]

- Machado, L.G.; Savi, M.A. Medical applications of shape memory alloys. Braz. J. Med. Biol. Res. 2003, 36, 683–691. [Google Scholar] [CrossRef] [PubMed]

- Hassan, M.R.; Mehrpouya, M.; Dawood, S. Review of the machining difficulties of Nickel-Titanium based shape memory alloys. Appl. Mech. Mater. 2014, 564, 533–537. [Google Scholar] [CrossRef]

- Hsieh, S.F.; Chen, S.L.; Lin, H.C.; Lin, M.H.; Chiou, S.Y. The machining characteristics and shape recovery ability of Ti—Ni—X (X = Zr, Cr) ternary shape memory alloys using the wire electro-discharge machining. Int. J. Mach. Tool Manufact. 2009, 49, 509–514. [Google Scholar] [CrossRef]

- Liu, J.F.; Guo, Y.B.; Butler, T.M.; Weaver, M.L. Crystallography, compositions, and properties of white layer by wire electrical discharge machining of nitinol shape memory alloy. Mater. Des. 2016, 109, 1–9. [Google Scholar] [CrossRef]

- Manjaiah, M.; Narendranath, S.; Basavarajappa, S.; Gaitonde, V.N. Wire electric discharge machining characteristics of titanium nickel shape memory alloy. Trans. Nonferrous Met. Soc. China 2014, 24, 3201–3209. [Google Scholar] [CrossRef]

- Daneshmand, S.; Hessami, R.; Esfandiar, H. Investigation of wire electro discharge machining of Nickel-Titanium shape memory alloys on surface roughness and MRR. Life Sci. 2012, 9, 2904–2909. [Google Scholar]

- LotfiNeyestanak, A.A.; Daneshmand, S. The effect of operational cutting parameters on Nitinol-60 in wire electrodischarge machining. Adv. Master Sci. Eng. 2013, 1–6. [Google Scholar] [CrossRef]

- Sharma, N.; Raj, T.; Jangra, K.K. Parameter optimization and experimental study on wire electrical discharge machining of porous Ni40Ti60 alloy. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2017, 231, 956–970. [Google Scholar] [CrossRef]

- Manjaiah, M.; Narendranath, S.; Basavarajappa, S.; Gaitonde, V.N. Effect of electrode material in wire electro discharge machining characteristics of Ti50Ni50—xCux shape memory alloy. Precis. Eng. 2015, 41, 68–77. [Google Scholar] [CrossRef]

- Majumder, H.; Maity, K. Application of GRNN and multivariate hybrid approach to predict and optimize WEDM responses for Ni—Ti shape memory alloy. Appl. Soft Comput. 2018, 70, 665–679. [Google Scholar] [CrossRef]

- Daneshmand, S.; Kahrizi, E.F.; LotfiNeyestanak, A.A.; Monfared, V. Optimization of electrical discharge machining parameters for Niti shape memory alloy by using the Taguchi method. J. Mar. Sci. Technol. 2014, 22, 506–512. [Google Scholar]

- Kulkarni, V.N.; Gaitonde, V.N.; Karnik, S.R.; Manjaiah, M.; Davim, J.P. Performance studies on wire electric discharge machining of medical grade nickel titanium (niti) shape memory alloy. J. Manuf. Technol. Res. 2019, 11, 101–120. [Google Scholar]

- Alla, R.K.; Ginjupalli, K.; Upadhya, N.; Shammas, M.; Ravi, R.K.; Sekhar, R. Surface roughness of implants: A review. Trends Biomater. Artif. Organs. 2011, 25, 112–118. [Google Scholar]

- Baş, D.; Boyacı, I.H. Modeling and optimization I: Usability of response surface methodology. J. Food Eng. 2007, 78, 836–845. [Google Scholar] [CrossRef]

- Jensen, W.A. Response surface methodology: Process and product optimization using designed experiments. J. Qual. Technol. 2017, 49, 186. [Google Scholar] [CrossRef]

- Manjaiah, M.; Narendranath, S.; Basavarajappa, S.; Gaitonde, V.N. Investigation on material removal rate, surface and subsurface characteristics in wire electro discharge machining of Ti50Ni50−xCux shape memory alloy. Proc. Inst. Mech. Eng. Part L: J. Mater. 2018, 232, 164–177. [Google Scholar] [CrossRef]

- Wang, Z.; Chung, C.Y.; Wong, K.P.; Tse, C.T. Robust power system stabiliser design under multi-operating conditions using differential evolution. IET Gener. Transm. Distrib. 2008, 2, 690–700. [Google Scholar] [CrossRef]

| Parameter (Level) | Pulse Time (µs) | Pause Time (µs) | Wire Feed (m/min) | Servo Voltage (V) |

|---|---|---|---|---|

| 1 | 105 | 25 | 4 | 20 |

| 2 | 115 | 40 | 6 | 40 |

| 3 | 125 | 55 | 8 | 60 |

| Factor | P | Q | R | S |

| Expt No | Ton (µs) | Toff (µs) | WF (m/min) | SV (V) | SR (µm) | MRR (mm3/min) | TWR (g/min) |

|---|---|---|---|---|---|---|---|

| 1 | 105 | 25 | 4 | 20 | 1.6758 | 2.3259 | 0.0329 |

| 2 | 105 | 25 | 6 | 20 | 1.8822 | 1.9985 | 0.0506 |

| 3 | 105 | 25 | 8 | 20 | 2.0375 | 2.4384 | 0.0673 |

| 4 | 105 | 40 | 4 | 20 | 1.7501 | 2.4011 | 0.0392 |

| 5 | 105 | 40 | 6 | 20 | 1.7124 | 2.1842 | 0.0529 |

| 6 | 105 | 40 | 8 | 20 | 1.7745 | 2.4402 | 0.0728 |

| 7 | 105 | 55 | 4 | 20 | 1.4307 | 2.5601 | 0.0363 |

| 8 | 105 | 55 | 6 | 20 | 1.5759 | 2.2004 | 0.0488 |

| 9 | 105 | 55 | 8 | 20 | 1.5821 | 2.2121 | 0.0674 |

| 10 | 115 | 25 | 4 | 20 | 2.7911 | 3.0813 | 0.0337 |

| 11 | 115 | 25 | 6 | 20 | 3.4631 | 3.0083 | 0.0508 |

| 12 | 115 | 25 | 8 | 20 | 2.9914 | 3.2808 | 0.0719 |

| 13 | 115 | 40 | 4 | 20 | 2.5862 | 3.3267 | 0.0407 |

| 14 | 115 | 40 | 6 | 20 | 3.2262 | 2.9824 | 0.0567 |

| 15 | 115 | 40 | 8 | 20 | 2.7956 | 3.1085 | 0.0776 |

| 16 | 115 | 55 | 4 | 20 | 2.4725 | 3.7822 | 0.0405 |

| 17 | 115 | 55 | 6 | 20 | 2.5181 | 3.4794 | 0.0526 |

| 18 | 115 | 55 | 8 | 20 | 2.4402 | 3.2833 | 0.0722 |

| 19 | 125 | 25 | 4 | 20 | 3.913 | 3.7006 | 0.0409 |

| 20 | 125 | 25 | 6 | 20 | 3.972 | 3.3932 | 0.0552 |

| 21 | 125 | 25 | 8 | 20 | 4.725 | 3.5524 | 0.0746 |

| 22 | 125 | 40 | 4 | 20 | 3.6838 | 3.7769 | 0.0509 |

| 23 | 125 | 40 | 6 | 20 | 4.424 | 3.8035 | 0.0643 |

| 24 | 125 | 40 | 8 | 20 | 4.6862 | 3.6656 | 0.0780 |

| 25 | 125 | 55 | 4 | 20 | 3.2273 | 4.3831 | 0.0561 |

| 26 | 125 | 55 | 6 | 20 | 3.4485 | 3.9539 | 0.0664 |

| 27 | 125 | 55 | 8 | 20 | 3.8662 | 3.8891 | 0.0771 |

| 28 | 105 | 25 | 4 | 40 | 1.7063 | 3.3405 | 0.0303 |

| 29 | 105 | 25 | 6 | 40 | 1.9247 | 3.4022 | 0.0460 |

| 30 | 105 | 25 | 8 | 40 | 1.7664 | 3.5056 | 0.0669 |

| 31 | 105 | 40 | 4 | 40 | 1.8583 | 2.9864 | 0.0279 |

| 32 | 105 | 40 | 6 | 40 | 1.6806 | 3.0503 | 0.0445 |

| 33 | 105 | 40 | 8 | 40 | 1.5846 | 3.3768 | 0.0621 |

| 34 | 105 | 55 | 4 | 40 | 1.6078 | 2.4462 | 0.0223 |

| 35 | 105 | 55 | 6 | 40 | 1.7621 | 2.2258 | 0.0333 |

| 36 | 105 | 55 | 8 | 40 | 1.624 | 2.3074 | 0.0483 |

| 37 | 115 | 25 | 4 | 40 | 2.6219 | 4.4190 | 0.0221 |

| 38 | 115 | 25 | 6 | 40 | 2.259 | 3.8225 | 0.0334 |

| 39 | 115 | 25 | 8 | 40 | 2.2639 | 4.0936 | 0.0501 |

| 40 | 115 | 40 | 4 | 40 | 2.3155 | 3.5967 | 0.0228 |

| 41 | 115 | 40 | 6 | 40 | 2.631 | 3.4365 | 0.0359 |

| 42 | 115 | 40 | 8 | 40 | 2.1837 | 3.6602 | 0.0525 |

| 43 | 115 | 55 | 4 | 40 | 1.8948 | 3.3664 | 0.0202 |

| 44 | 115 | 55 | 6 | 40 | 2.0823 | 3.1001 | 0.0298 |

| 45 | 115 | 55 | 8 | 40 | 2.254 | 3.1262 | 0.0399 |

| 46 | 125 | 25 | 4 | 40 | 3.5209 | 4.4800 | 0.0275 |

| 47 | 125 | 25 | 6 | 40 | 3.1682 | 4.7074 | 0.0381 |

| 48 | 125 | 25 | 8 | 40 | 2.9709 | 5.1896 | 0.0531 |

| 49 | 125 | 40 | 4 | 40 | 3.0993 | 4.9329 | 0.0323 |

| 50 | 125 | 40 | 6 | 40 | 3.3186 | 4.9896 | 0.0467 |

| 51 | 125 | 40 | 8 | 40 | 2.8704 | 5.0633 | 0.0633 |

| 52 | 125 | 55 | 4 | 40 | 2.4819 | 5.0511 | 0.0303 |

| 53 | 125 | 55 | 6 | 40 | 2.6619 | 4.5063 | 0.0412 |

| 54 | 125 | 55 | 8 | 40 | 2.6439 | 4.6965 | 0.0558 |

| 55 | 105 | 25 | 4 | 60 | 2.0209 | 2.5349 | 0.0379 |

| 56 | 105 | 25 | 6 | 60 | 1.7671 | 2.6765 | 0.0499 |

| 57 | 105 | 25 | 8 | 60 | 1.6416 | 2.9419 | 0.0721 |

| 58 | 105 | 40 | 4 | 60 | 1.9376 | 1.5572 | 0.0341 |

| 59 | 105 | 40 | 6 | 60 | 1.8274 | 1.3926 | 0.0451 |

| 60 | 105 | 40 | 8 | 60 | 1.6682 | 1.6962 | 0.0609 |

| 61 | 105 | 55 | 4 | 60 | 1.8989 | 0.3672 | 0.0199 |

| 62 | 105 | 55 | 6 | 60 | 1.8148 | 0.1634 | 0.0293 |

| 63 | 105 | 55 | 8 | 60 | 1.8522 | 0.3168 | 0.0416 |

| 64 | 115 | 25 | 4 | 60 | 2.1545 | 2.7576 | 0.0219 |

| 65 | 115 | 25 | 6 | 60 | 1.9434 | 3.1806 | 0.0343 |

| 66 | 115 | 25 | 8 | 60 | 2.0141 | 3.8491 | 0.0531 |

| 67 | 115 | 40 | 4 | 60 | 2.3917 | 2.3328 | 0.0184 |

| 68 | 115 | 40 | 6 | 60 | 2.3154 | 2.2755 | 0.0282 |

| 69 | 115 | 40 | 8 | 60 | 1.9388 | 2.2705 | 0.0402 |

| 70 | 115 | 55 | 4 | 60 | 2.2537 | 1.2264 | 0.0069 |

| 71 | 115 | 55 | 6 | 60 | 2.1384 | 1.0226 | 0.0156 |

| 72 | 115 | 55 | 8 | 60 | 1.9187 | 1.1296 | 0.0266 |

| 73 | 125 | 25 | 4 | 60 | 2.4702 | 3.3770 | 0.0177 |

| 74 | 125 | 25 | 6 | 60 | 2.548 | 3.3421 | 0.0284 |

| 75 | 125 | 25 | 8 | 60 | 2.1594 | 3.7480 | 0.0491 |

| 76 | 125 | 40 | 4 | 60 | 2.7822 | 2.6994 | 0.0163 |

| 77 | 125 | 40 | 6 | 60 | 2.5375 | 2.6880 | 0.0253 |

| 78 | 125 | 40 | 8 | 60 | 2.1383 | 3.3904 | 0.0397 |

| 79 | 125 | 55 | 4 | 60 | 2.3933 | 2.1013 | 0.0089 |

| 80 | 125 | 55 | 6 | 60 | 2.5726 | 2.0112 | 0.0178 |

| 81 | 125 | 55 | 8 | 60 | 2.4393 | 1.9774 | 0.0257 |

| SV | Best Fitness | Optimal Control Factors | Optimal Responses | ||||

|---|---|---|---|---|---|---|---|

| Ton | Toff | WF | Ra(SR) | MRR | TWR | ||

| 20 | 2.3093 | 118.59 | 55 | 4 | 2.6213 | 3.9362 | 0.0451 |

| 25 | 2.1504 | 118.59 | 55 | 4 | 2.504 | 4.149 | 0.0384 |

| 30 | 2.0479 | 119.5 | 55 | 4 | 2.483 | 4.3098 | 0.0333 |

| 35 | 1.9914 | 121.22 | 55 | 4 | 2.523 | 4.4036 | 0.0294 |

| 40 | 1.9773 | 118.44 | 25 | 4 | 2.659 | 4.276 | 0.0218 |

| 45 | 1.9567 | 120.727 | 25 | 4 | 2.6992 | 4.3313 | 0.0205 |

| 50 | 1.9776 | 123.639 | 25 | 4 | 2.7535 | 4.2715 | 0.0198 |

| 55 | 2.0482 | 125 | 25 | 4 | 2.6962 | 3.9765 | 0.0189 |

| 60 | 2.2107 | 125 | 25 | 4 | 2.5775 | 3.4614 | 0.0178 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kulkarni, V.N.; Gaitonde, V.N.; Karnik, S.R.; Manjaiah, M.; Davim, J.P. Machinability Analysis and Optimization in Wire EDM of Medical Grade NiTiNOL Memory Alloy. Materials 2020, 13, 2184. https://doi.org/10.3390/ma13092184

Kulkarni VN, Gaitonde VN, Karnik SR, Manjaiah M, Davim JP. Machinability Analysis and Optimization in Wire EDM of Medical Grade NiTiNOL Memory Alloy. Materials. 2020; 13(9):2184. https://doi.org/10.3390/ma13092184

Chicago/Turabian StyleKulkarni, Vinayak N., V. N. Gaitonde, S. R. Karnik, M. Manjaiah, and J. Paulo Davim. 2020. "Machinability Analysis and Optimization in Wire EDM of Medical Grade NiTiNOL Memory Alloy" Materials 13, no. 9: 2184. https://doi.org/10.3390/ma13092184

APA StyleKulkarni, V. N., Gaitonde, V. N., Karnik, S. R., Manjaiah, M., & Davim, J. P. (2020). Machinability Analysis and Optimization in Wire EDM of Medical Grade NiTiNOL Memory Alloy. Materials, 13(9), 2184. https://doi.org/10.3390/ma13092184