Effects of Saturation Levels on the Ultrasonic Pulse Velocities and Mechanical Properties of Concrete

Abstract

:1. Introduction

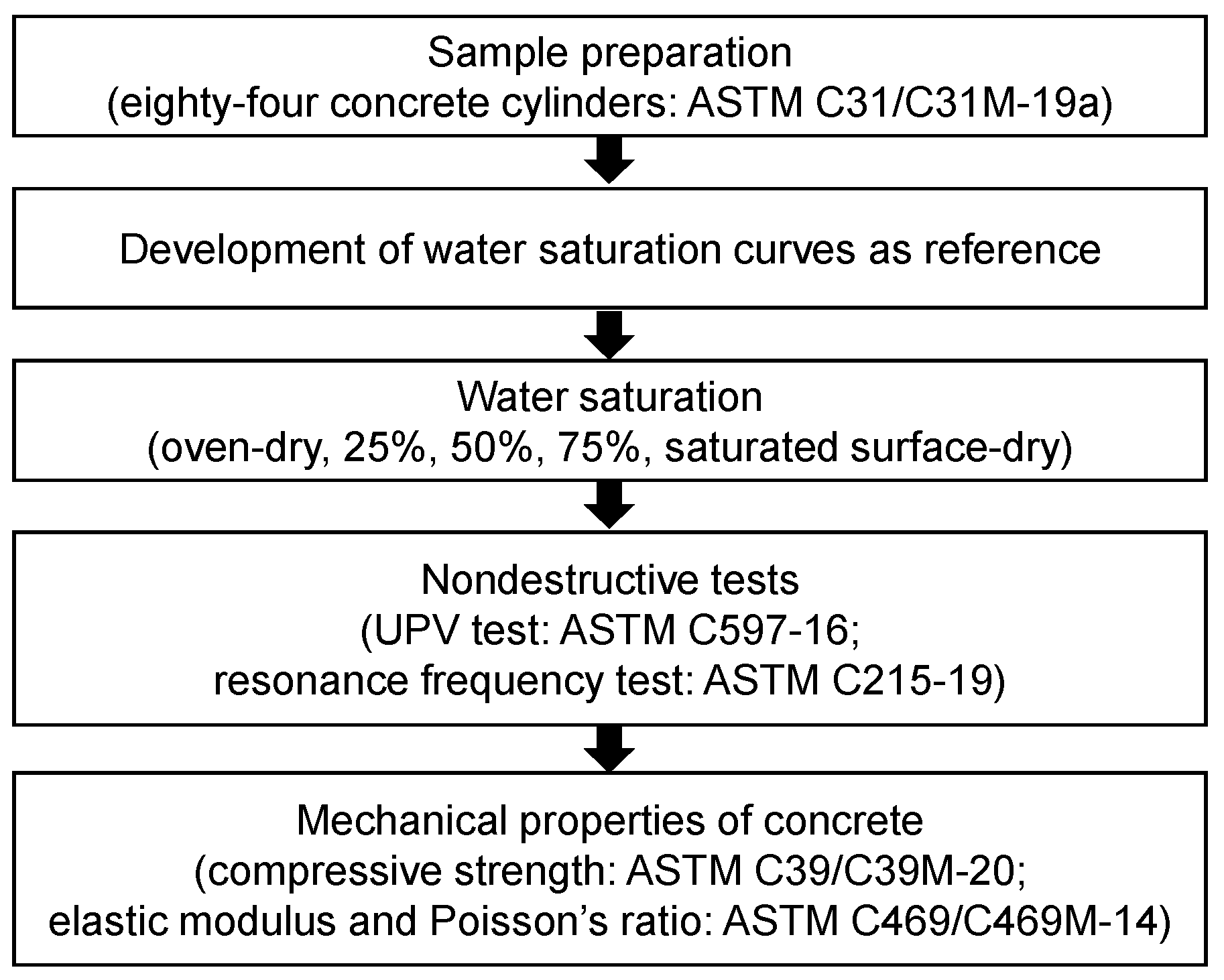

2. Materials and Method

2.1. Sample Preparation

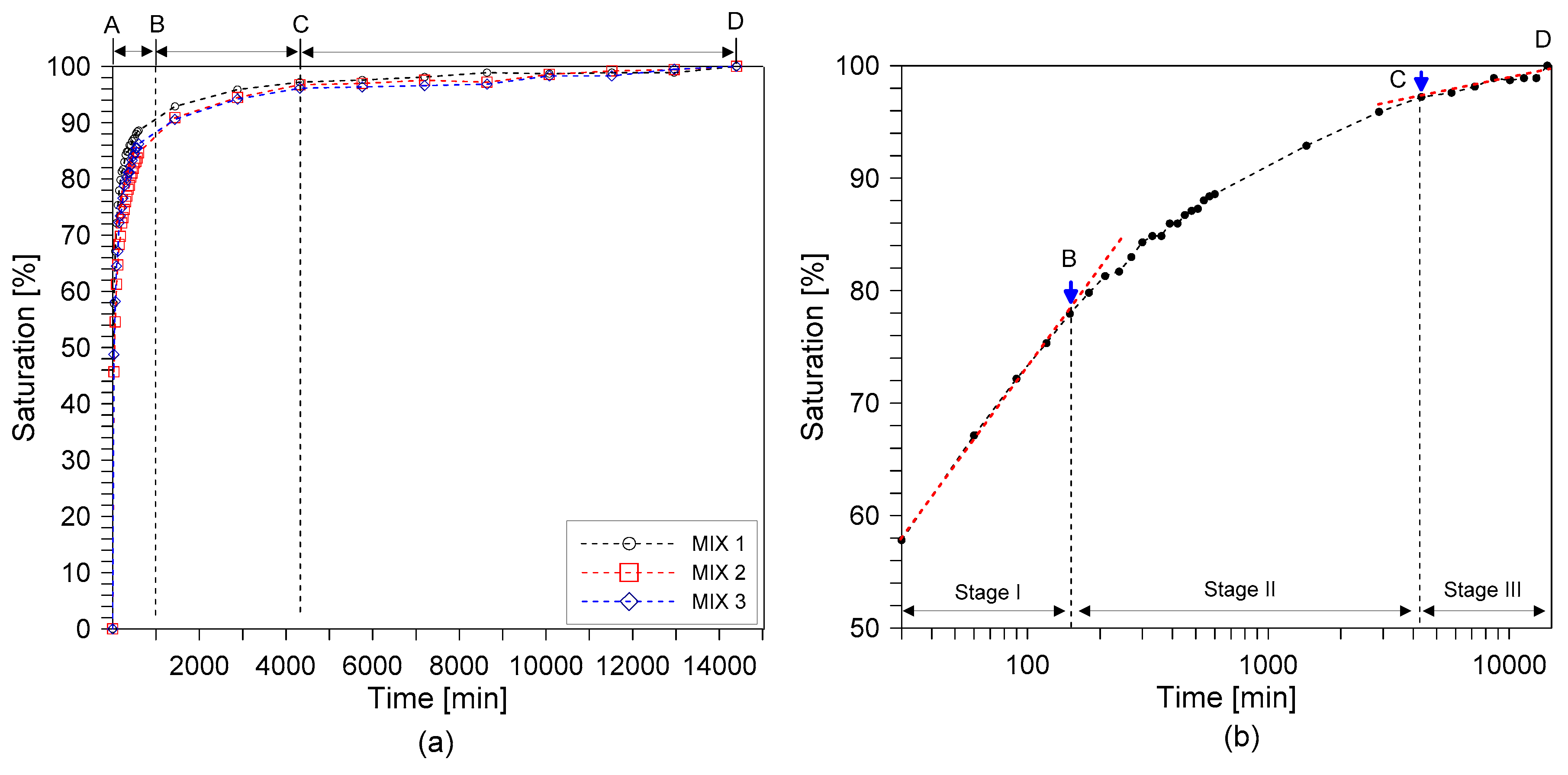

2.2. Water Saturation

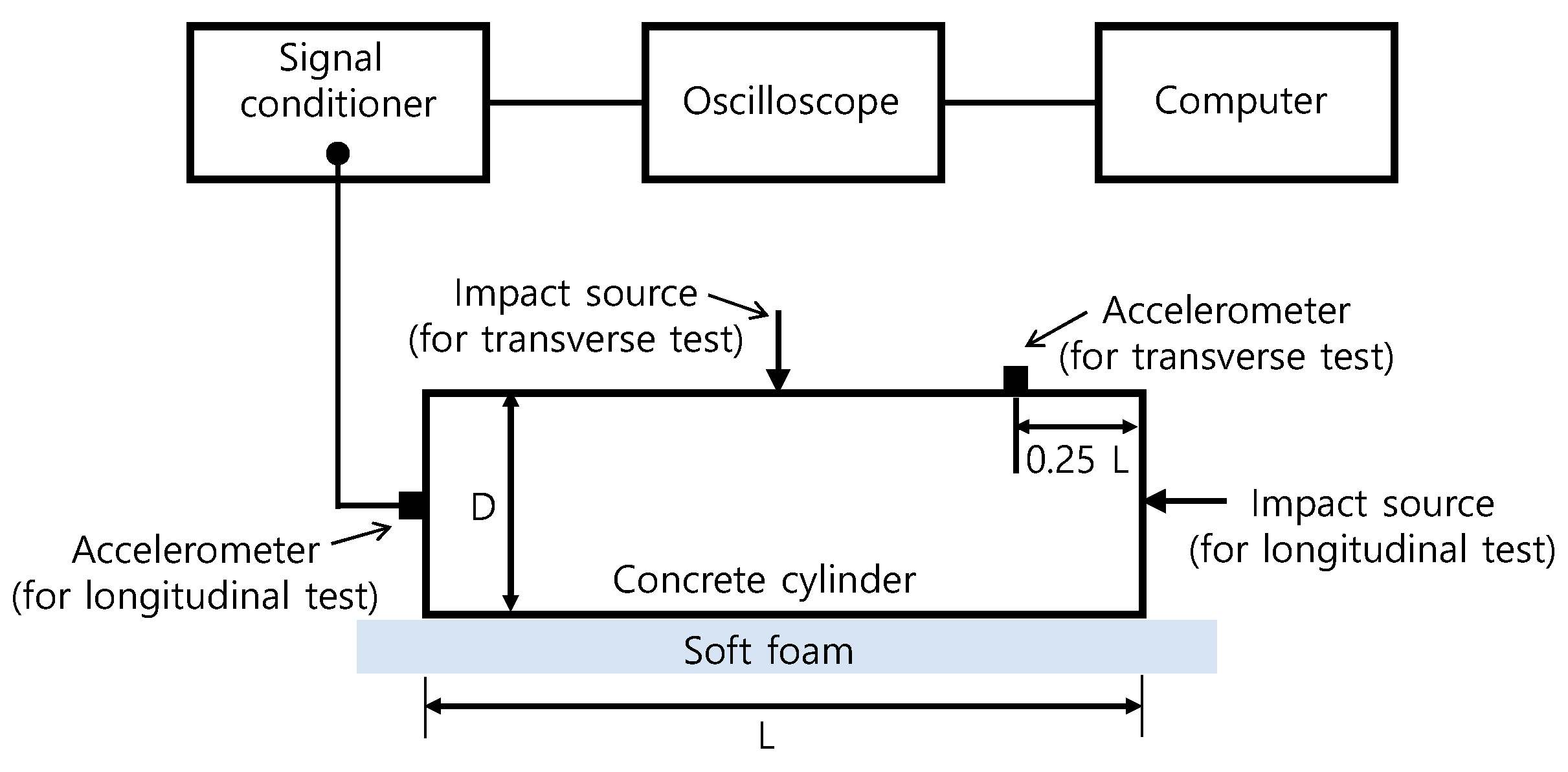

2.3. Stress Wave Velocity Measurement

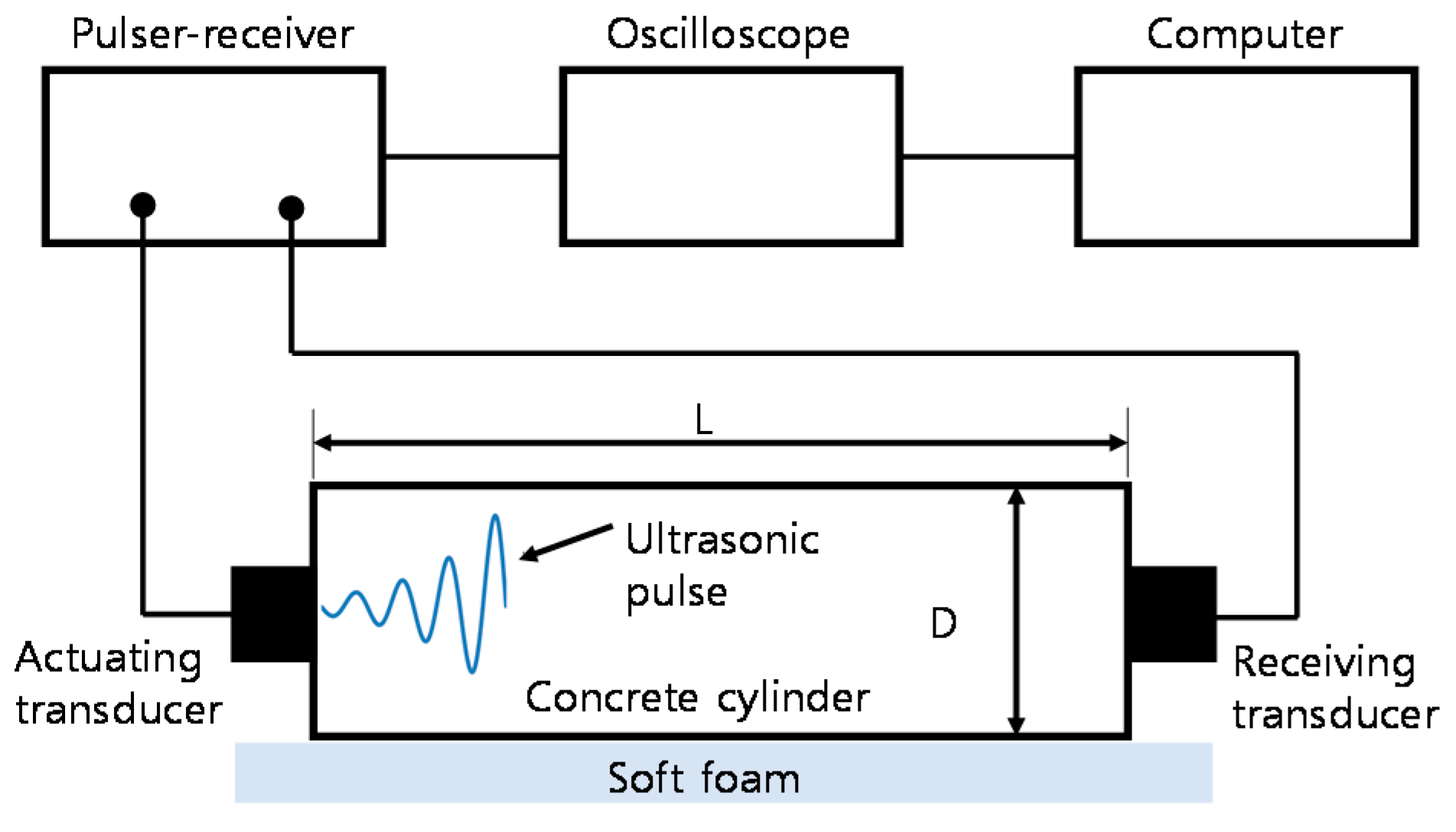

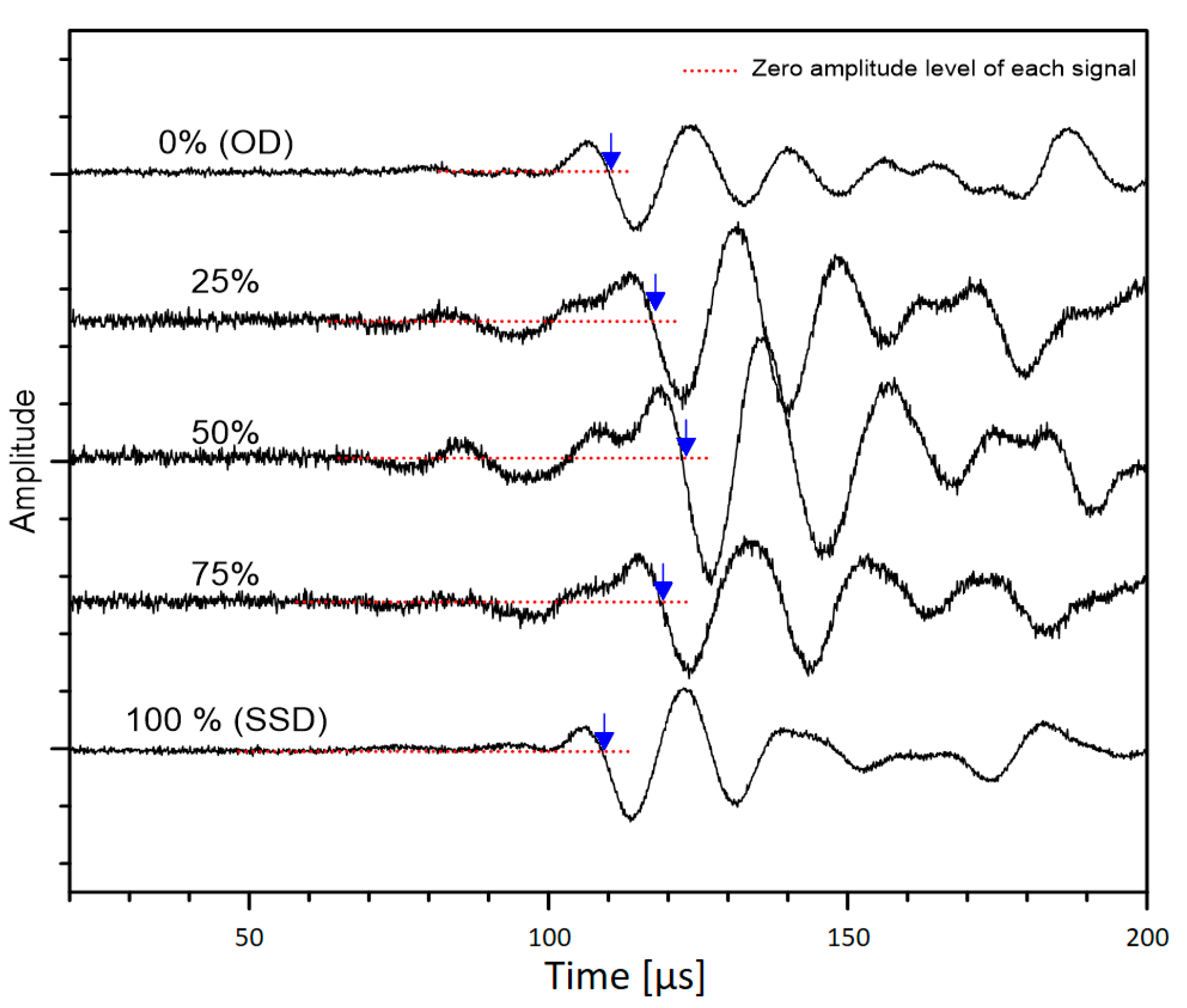

2.3.1. Ultrasonic Pulse Velocity

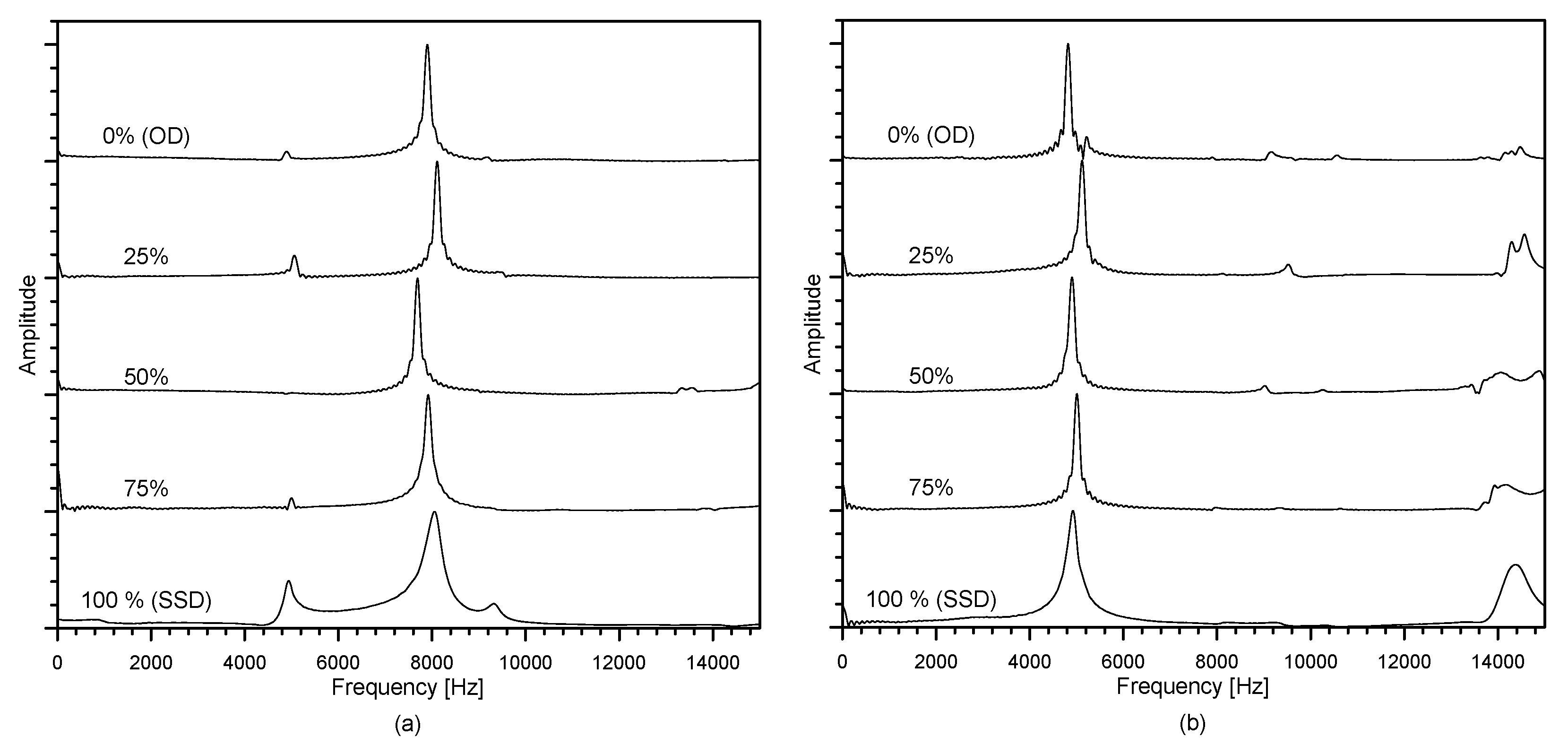

2.3.2. Resonance Frequency

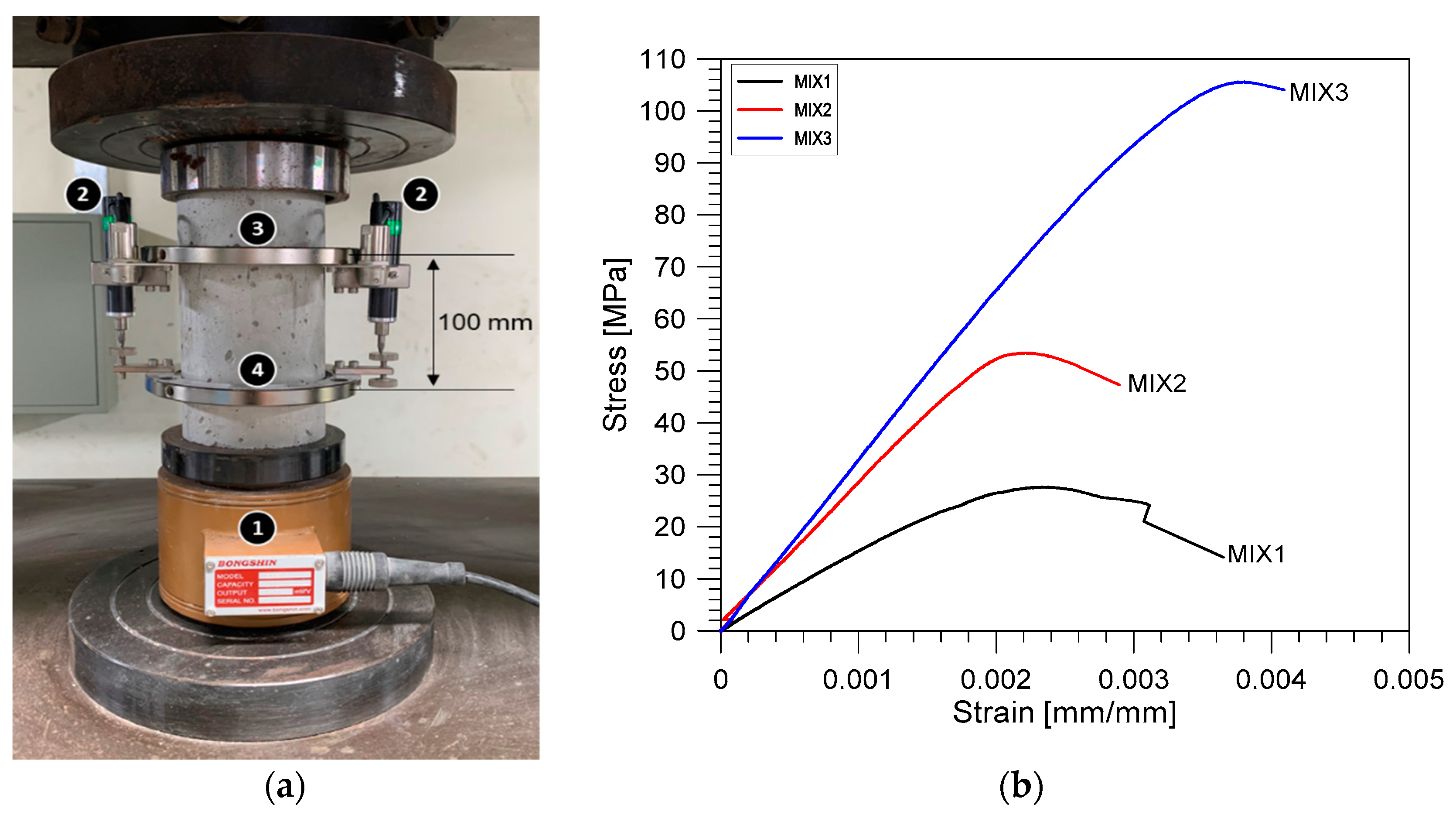

2.3.3. Measurement of Mechanical Properties

3. Results and Discussion

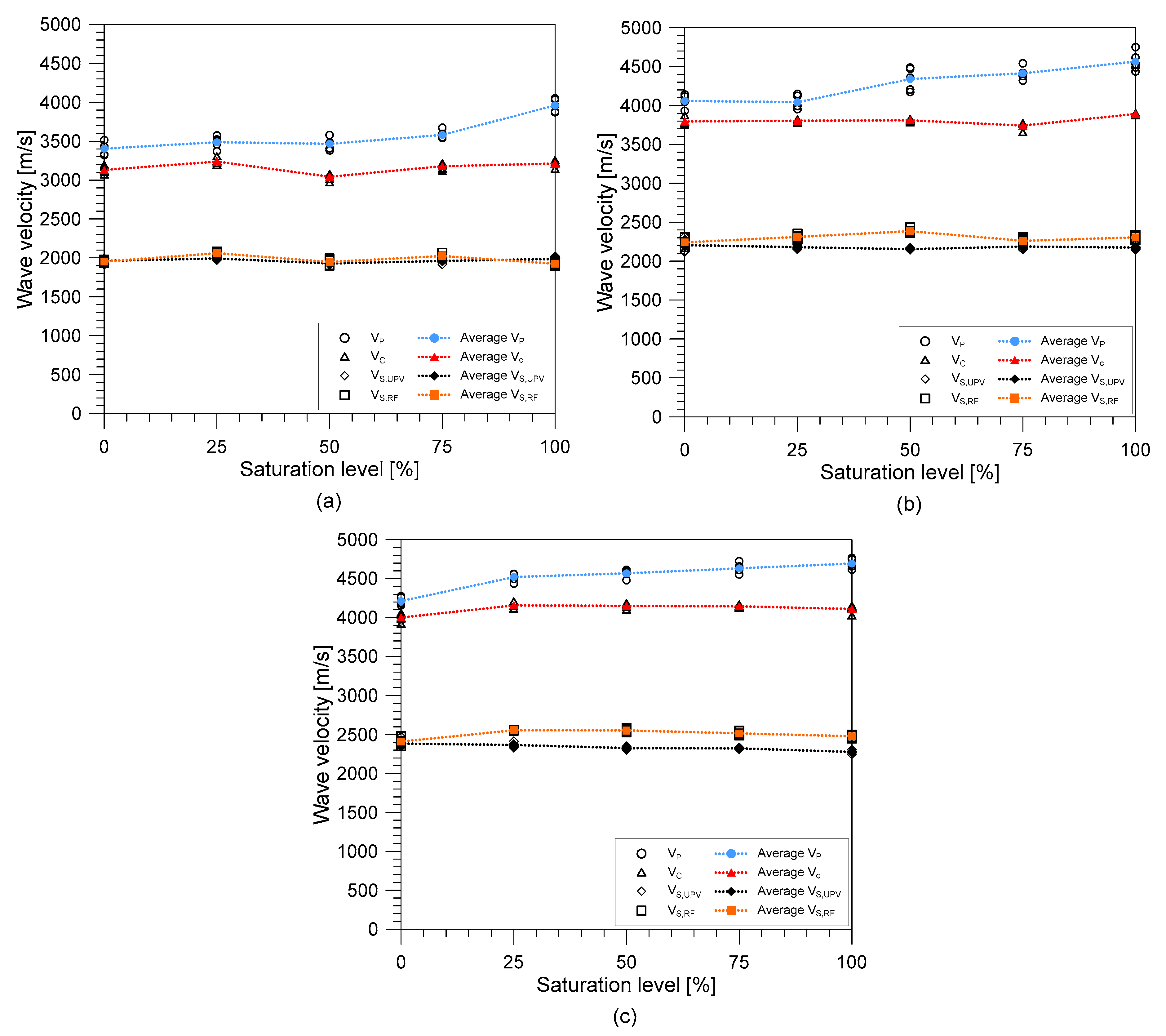

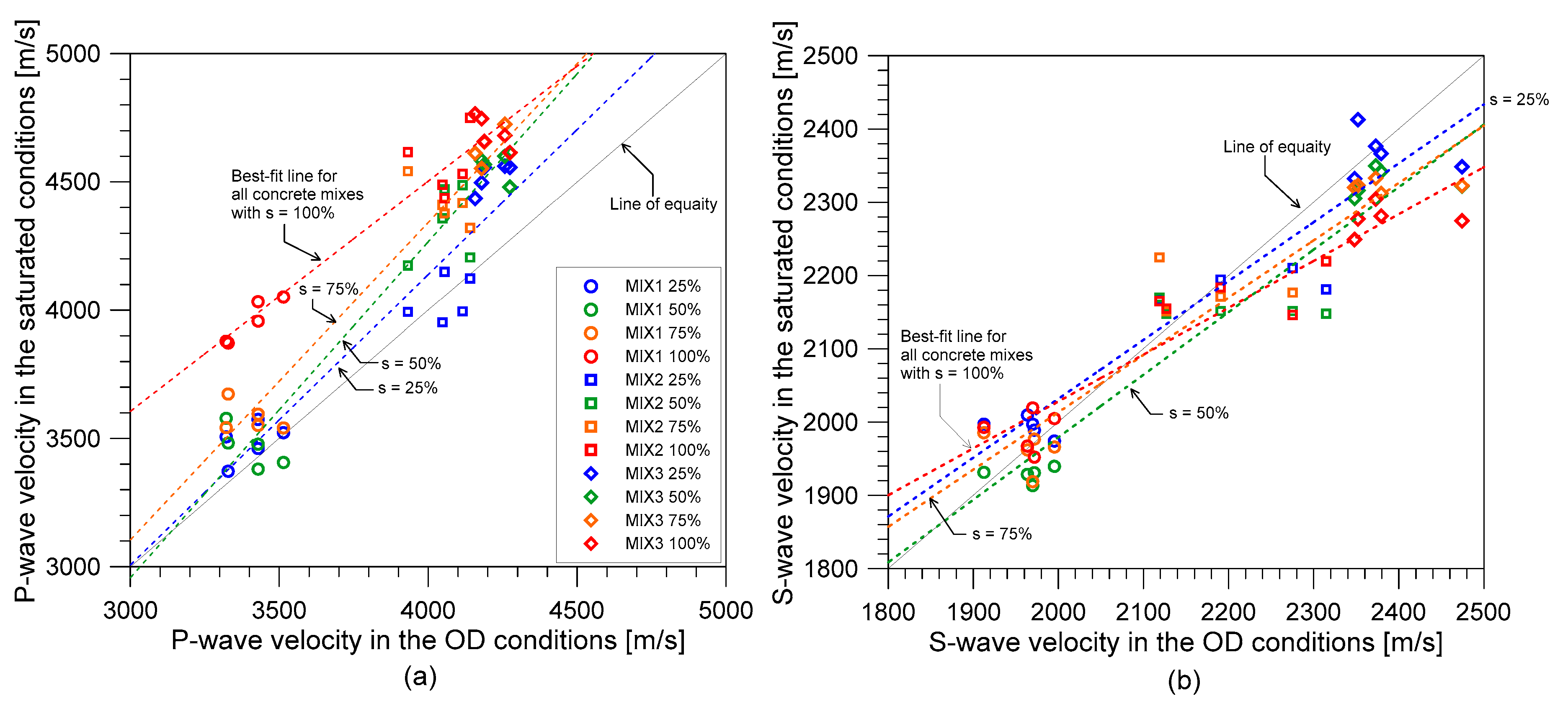

3.1. Variation of Stress Wave Velocities with Water Saturation Level

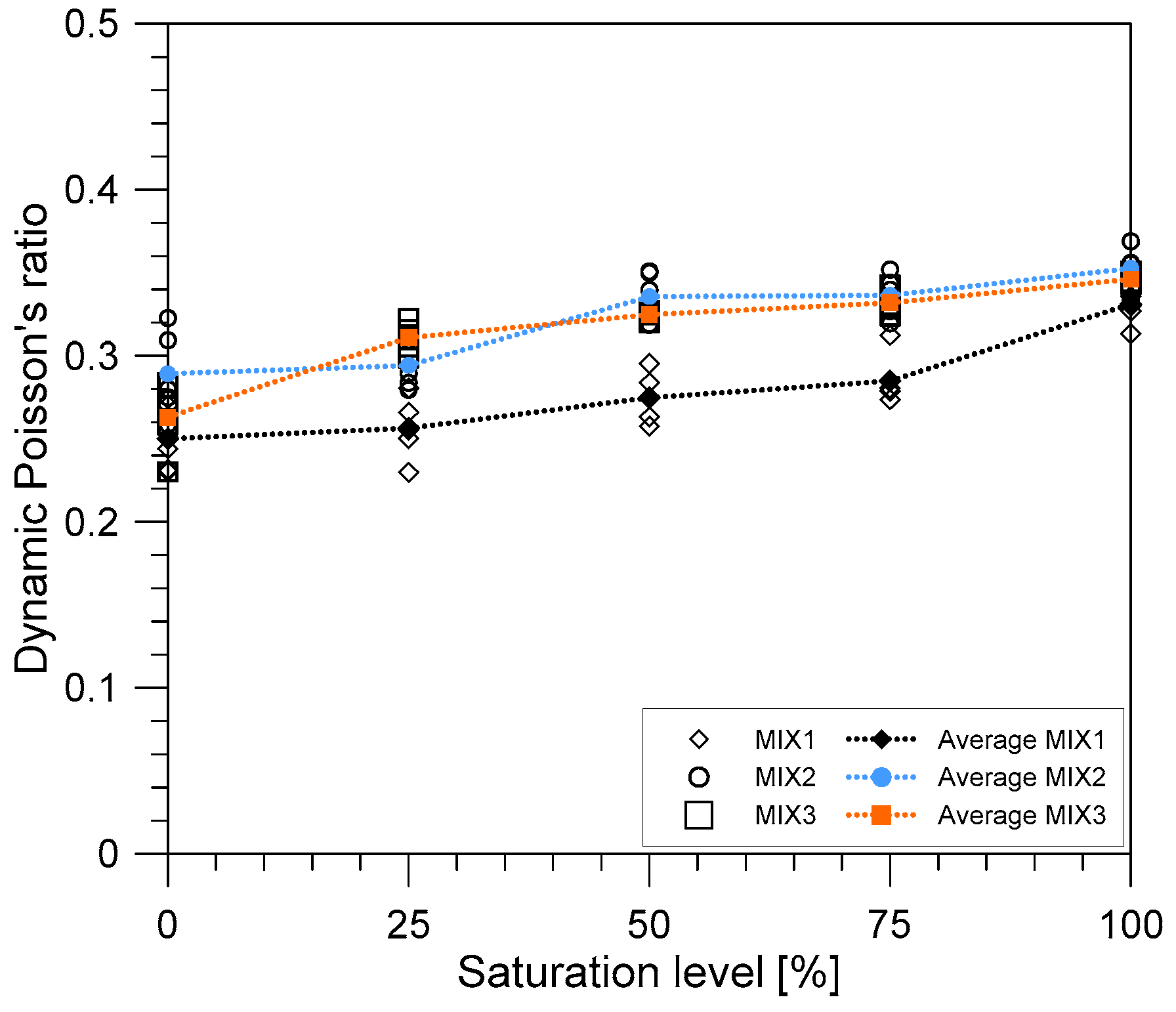

3.2. Poisson’s Ratio of Concrete at Different Saturation Levels

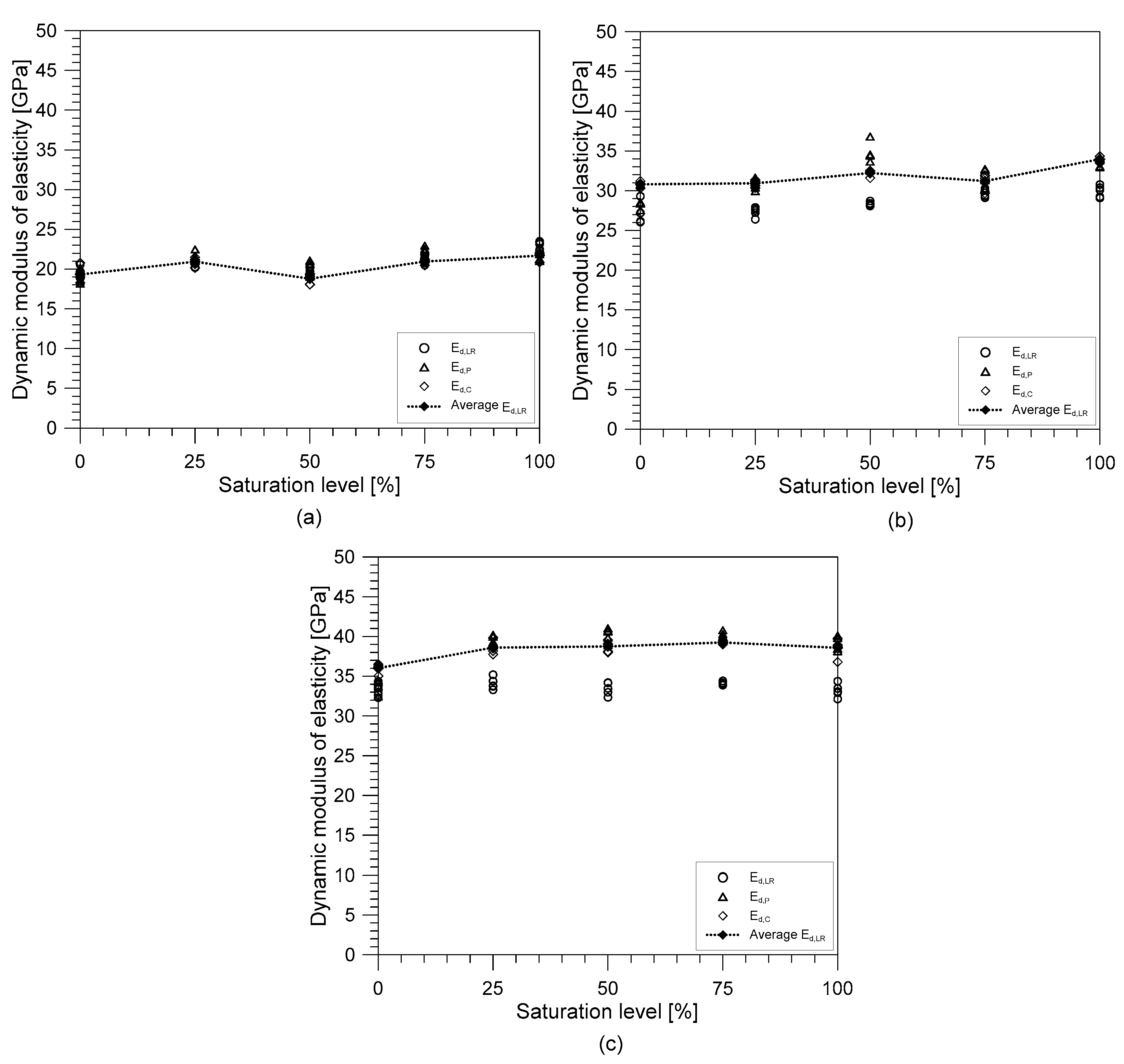

3.3. Static and Dynamic Elastic Modulus of Concrete at Different Saturation Levels

3.4. Relationship between Dynamic and Static Elastic Moduli

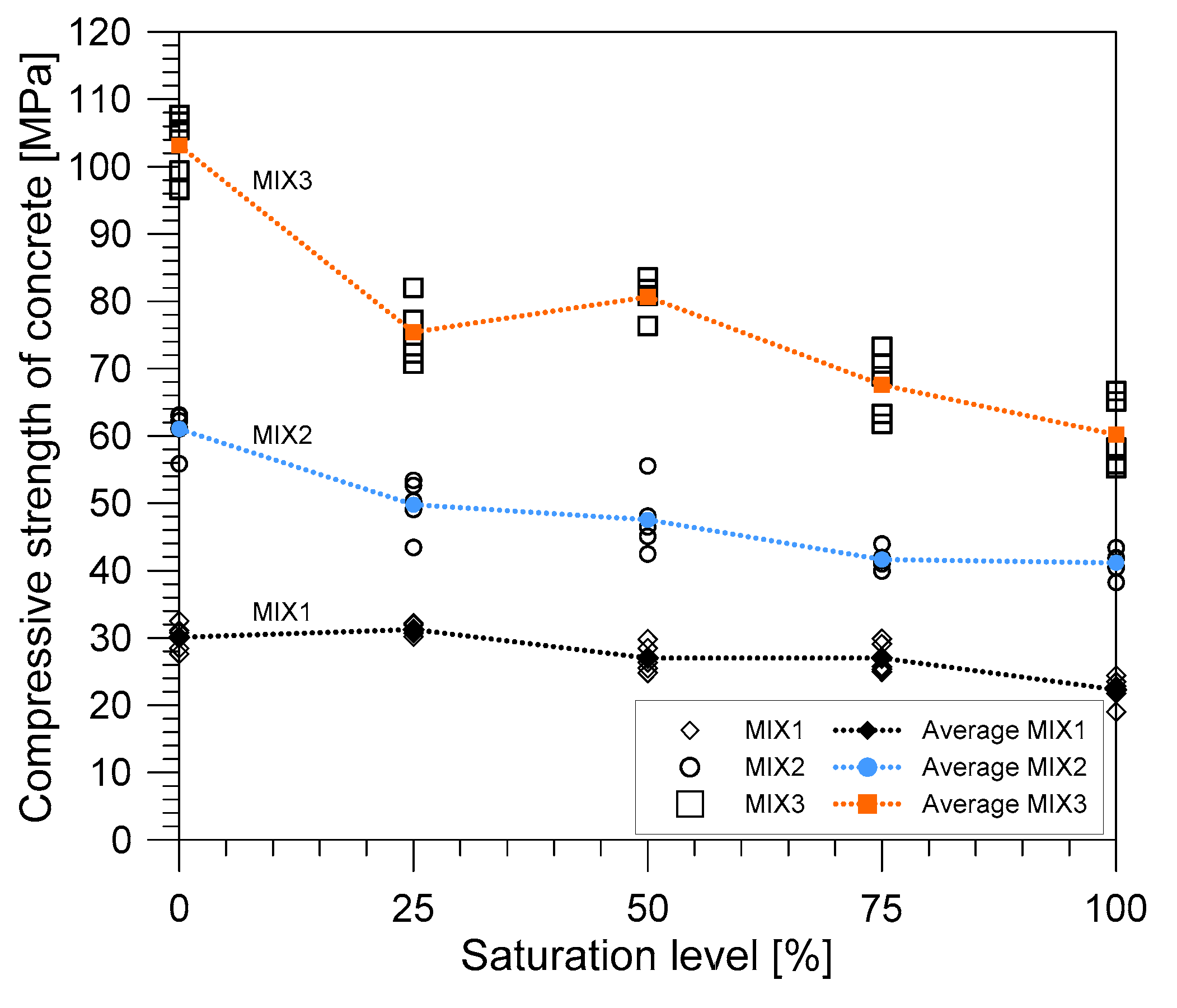

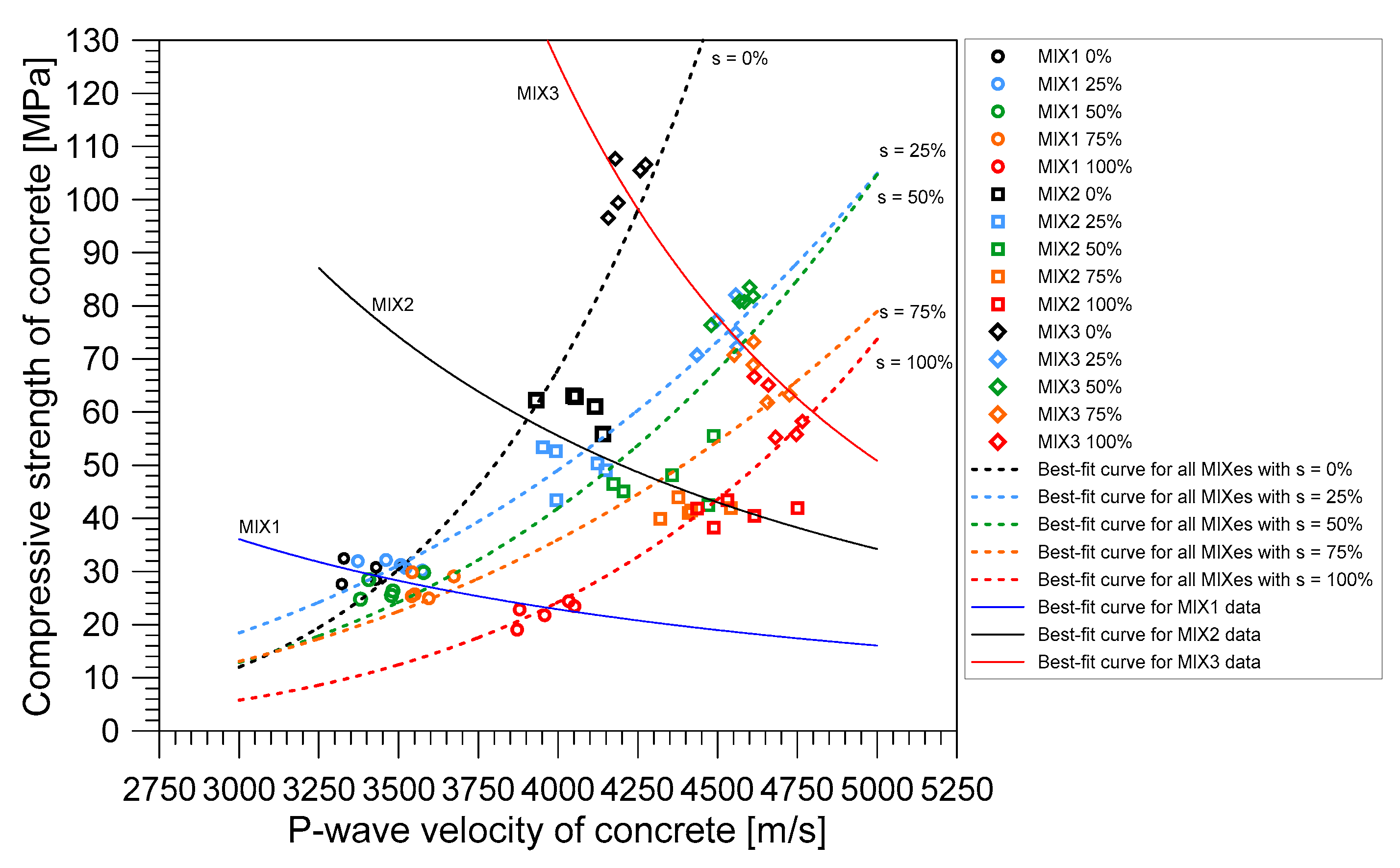

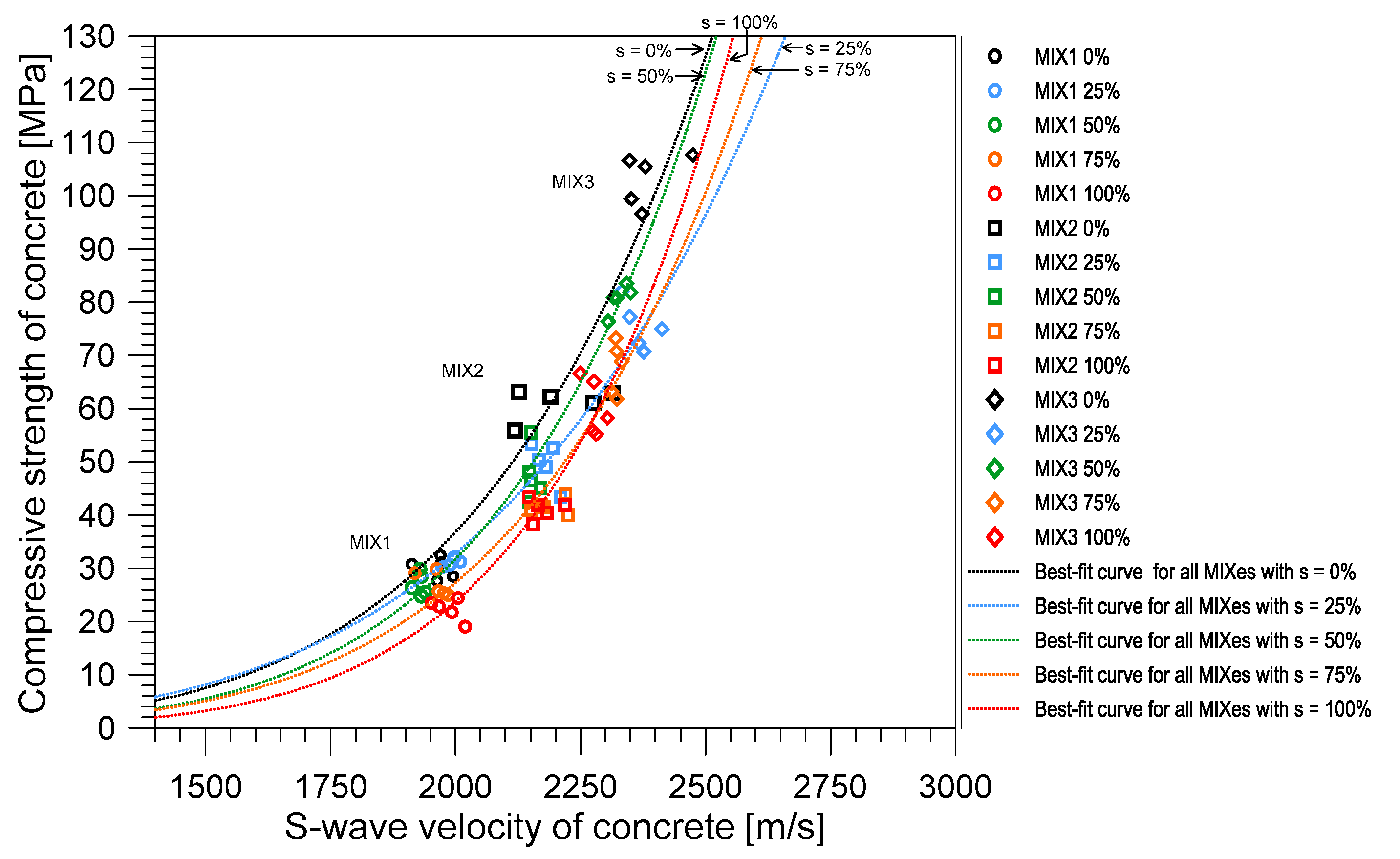

3.5. Compressive Strength

4. Conclusions

- The effect of the saturation condition was more evident on the P-wave velocity than in S-wave velocity. The contained compressive wave velocities, from the UPV test, and the unconstrained wave velocity, from the resonance test, increased as the saturation level also increased. S-wave velocities measured from both the UPV and resonance methods exhibited slight changes as the saturation condition increased. This shows that S-wave velocities were less sensitive to the effect of water saturation than the P-wave velocities. This observation could confirm that the use of S-wave velocity to estimate some properties of in-situ concrete was more reliable than the use of P-wave velocity because P-wave velocity was affected by many environmental factors.

- It is expected that the shear wave velocities will slightly decrease because of the effect of water saturation to the density of the concrete specimens. As such, the saturation condition also affected the dynamic Poisson’s ratio of the concrete cylinders since the values were based on the P-wave and shear wave velocities.

- The elastic moduli of the concrete specimen were affected differently by the saturation condition. The dynamic modulus of elasticity increased as the saturation also increased. Based on the standard Ed,LR, MIX 1 exhibited the highest increase with 12.25% increase from OD to SSD condition, followed by Mix 2 with 10.25%, and then Mix 3 with 7.09%. The static modulus of elasticity also increased but not as much as the dynamic elastic modulus. The increase for Mixes 1 and 2 were about 1-2% while the elastic modulus for Mix 3 decreased by 3.9%. From this observation, it can be said that the effect of water saturation was more evident in the dynamic elastic modulus of concrete than its static elastic modulus.

- The relationship between the static and dynamic elastic moduli was also investigated. It was shown that both the empirical equations (Equations (15) and (16)) from previous studies and the proposed equation from this research ( were effective in representing the relationship between the static and dynamic moduli of elasticity regardless of the saturation condition. The empirical equation proposed by Lydon and Balendran shows better agreement with the data from partial saturation conditions in this research. The proposed equation could be used as a reference in evaluating elastic moduli of concrete, which were under different saturation conditions.

- The compressive strength of concrete from all mix proportions decreased as the saturation level increased. Among the three concrete mix proportions, MIX 3 established the highest reduction in compressive strength, followed by MIX 2 and then MIX 1. In this study, it could be interpreted that the lowest water-to-cement ratio would be more sensitive to the increased water saturation. However, it is suggested that further investigation on the effect of water saturation should be done involving the porosity and different material constituents of concrete materials.

- The relationship between the stress wave velocities and the compressive strength was also investigated. The compressive strength decreased as the P-wave velocities increased. This observation was true for all the mix proportions used in this study. P-wave was greatly affected by the amount of water present in the concrete and other factors as shown in this study. Thus, estimation of compressive strength using P-wave velocity was not considered a proper method. In contrast, shear wave velocity was closely correlated with compressive strength of concrete, which was much less sensitive to water saturation level compared to compressive velocity.

- This study was based on the laboratory investigations and might not fully represent the environmental factors affecting concrete in the field. This study only focused on water saturation. Saturation with different liquid may affect the behavior of concrete when the saturation level increases. Hence, it is also suggested that further investigations using other fluid that may affect concrete be investigated, such as chloride, among others.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, W.; Lu, C.; Yuan, G.; Zhang, Y. Effects of pore water saturation on the mechanical properties of fly ash concrete. Constr. Build. Mater. 2017, 130, 54–63. [Google Scholar] [CrossRef]

- Hover, K.C. The influence of water on the performance of concrete. Constr. Build. Mater. 2011, 25, 3003–3013. [Google Scholar] [CrossRef]

- Vasanelli, E.; Colangiuli, D.; Calia, A.; Luprano, V.A.M. Estimating in situ concrete strength combining direct and indirect measures via cross validation procedure. Constr. Build. Mater. 2017, 151, 916–924. [Google Scholar] [CrossRef]

- Pessiki, S.P.; Olson, L.D.; Concrete, A.C. Innovations in Nondestructive Testing of Concrete; American Concrete Institute: Detroit, MI, USA, 1997. [Google Scholar]

- Malhotra, V.M.; Carino, N.J. Handbook on Nondestructive Testing of Concrete; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Maierhofer, C.; Reinhardt, H.W.; Dobmann, G. Non-Destructive Evaluation of Reinforced Concrete Structures: Deterioration Processes and Standard Test Methods; Elsevier: Amsterdam, The Netherlands, 2010. [Google Scholar]

- Balayssac, J.P.; Garnier, V. Non-Destructive Testing and Evaluation of Civil Engineering Structures; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Wiciak, P.; Cascante, G.; Polak, M.A. Sensor and Dimensions Effects in Ultrasonic Pulse Velocity Measurements in Mortar Specimens. Procedia Eng. 2017, 193, 409–416. [Google Scholar] [CrossRef]

- Sadowski, Ł.; Piechówka-Mielnik, M.; Widziszowski, T.; Gardynik, A.; Mackiewicz, S. Hybrid ultrasonic-neural prediction of the compressive strength of environmentally friendly concrete screeds with high volume of waste quartz mineral dust. J. Clean. Prod. 2019, 212, 727–740. [Google Scholar] [CrossRef]

- Toubal Seghir, N.; Benaimeche, O.; Krzywiński, K.; Sadowski, Ł. Ultrasonic Evaluation of Cement-Based Building Materials Modified Using Marble Powder Sourced from Industrial Wastes. Buildings 2020, 10, 38. [Google Scholar] [CrossRef] [Green Version]

- Hong, S.; Yoon, S.; Kim, J.; Lee, C.; Kim, S.; Lee, Y. Evaluation of Condition of Concrete Structures Using Ultrasonic Pulse Velocity Method. Appl. Sci. 2020, 10, 706. [Google Scholar] [CrossRef] [Green Version]

- Saint-Pierre, F.; Philibert, A.; Giroux, B.; Rivard, P. Concrete Quality Designation based on Ultrasonic Pulse Velocity. Constr. Build. Mater. 2016, 6, 1022–1027. [Google Scholar] [CrossRef]

- Benouis, A.; Grini, A. Estimation of Concrete’s Porosity by Ultrasounds. Phys. Procedia 2011, 21, 53–58. [Google Scholar] [CrossRef] [Green Version]

- Salam, M.; Safiuddin, M.; Jumaat, M. Durability Indicators for Sustainable Self-Consolidating High-Strength Concrete Incorporating Palm Oil Fuel Ash. Sustainability 2018, 10, 2345. [Google Scholar] [CrossRef] [Green Version]

- Godinho, J.P.; De Souza Júnior, T.F.; Medeiros, M.H.F.; Silva, M.S.A. Factors influencing ultrasonic pulse velocity in concrete. Rev. IBRACON Estrut. Mater. 2020, 13, 222–247. [Google Scholar] [CrossRef]

- Ali-Benyahia, K.; Sbartaï, Z.-M.; Breysse, D.; Ghrici, M.; Kenai, S. Improvement of nondestructive assessment of on-site concrete strength: Influence of the selection process of cores location on the assessment quality for single and combined NDT techniques. Constr. Build. Mater. 2019, 195, 613–622. [Google Scholar] [CrossRef]

- Lee, B.J.; Kee, S.-H.; Oh, T.; Kim, Y.-Y. Evaluating the Dynamic Elastic Modulus of Concrete Using Shear-Wave Velocity Measurements. Adv. Mater. Sci. Eng. 2017, 2017, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Lee, B.J.; Kee, S.-H.; Oh, T.; Kim, Y.-Y. Effect of Cylinder Size on the Modulus of Elasticity and Compressive Strength of Concrete from Static and Dynamic Tests. Adv. Mater. Sci. Eng. 2015, 2015, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Zhang, G.; Li, X.; Li, Z. Experimental Study on Static Mechanical Properties and Moisture Contents of Concrete under Water Environment. Sustainability 2019, 11, 2962. [Google Scholar] [CrossRef] [Green Version]

- Yang, K.-H.; Mun, J.-H.; Sim, J.-I.; Song, J.-K. Effect of Water Content on the Properties of Lightweight Alkali-Activated Slag Concrete. J. Mater. Civ. Eng. 2011, 23, 886–894. [Google Scholar] [CrossRef]

- Mustafa, A.; Mahmoud, M.A.; Abdulraheem, A.; Furquan, S.A.; Al-Nakhli, A.; BaTaweel, M. Comparative Analysis of Static and Dynamic Mechanical Behavior for Dry and Saturated Cement Mortar. Materials 2019, 12, 3299. [Google Scholar] [CrossRef] [Green Version]

- Downie, B. Effect of moisture and temperature on the mechanical properties of concrete. Constr. Build. Mater. 2011, 25, 688–696. [Google Scholar]

- Wang, H.; Jin, W.; Li, Q. Saturation Effect on Dynamic Tensile and Compressive Strength of Concrete. Adv. Struct. Eng. 2009, 12, 279–286. [Google Scholar] [CrossRef]

- Wu, S.; Chen, X.; Zhou, J. Influence of strain rate and water content on mechanical behavior of dam concrete. Constr. Build. Mater. 2012, 36, 448–457. [Google Scholar] [CrossRef]

- Zhou, J.; Chen, X.; Wu, L.; Kan, X. Influence of free water content on the compressive mechanical behaviour of cement mortar under high strain rate. Sadhana 2011, 36, 357–369. [Google Scholar] [CrossRef]

- Liu, B.D.; Lv, W.J.; Li, L.; Li, P.F. Effect of moisture content on static compressive elasticity modulus of concrete. Constr. Build. Mater. 2014, 69, 133–142. [Google Scholar] [CrossRef]

- Cadoni, E.; Labibes, K.; Albertini, C. Strain-rate effect on the tensile behaviour of concrete at different relative humidity levels. Mater. Struct. 2001, 34, 21. [Google Scholar] [CrossRef]

- Popovics, S. Effects of uneven moisture distribution on the strength of and wave velocity in concrete. Ultrasonics 2005, 43, 429–434. [Google Scholar] [CrossRef]

- An, J.-H.; Nam, J.-H.; Kwon, S.A.; Joh, S.-H. Estimation of the Compressive Strength of Concrete Using Shear Wave Velocity. Charact. Model. Perform. Geomater. 2009. [Google Scholar] [CrossRef]

- Voigt, T.; Ye, G.; Sun, Z.; Shah, S.P.; van Breugel, K. Early age microstructure of Portland cement mortar investigated by ultrasonic shear waves and numerical simulation. Cem. Concr. Res. 2005, 35, 858–866. [Google Scholar] [CrossRef]

- Ciancio, D.; Helinski, M. The use of shear wave velocity for assessing strength development in fibre reinforced shotcrete. In Shotcrete: Elements of a System; CRC Press: Boca Raton, FL, USA, 2010; pp. 65–70. [Google Scholar]

- Zhu, J.; Kee, S.-H.; Han, D.; Tsai, Y.-T. Effects of air voids on ultrasonic wave propagation in early age cement pastes. Cem. Concr. Res. 2011, 41, 872–881. [Google Scholar] [CrossRef]

- Liu, S.; Zhu, J.; Seraj, S.; Cano, R.; Juenger, M. Monitoring setting and hardening process of mortar and concrete using ultrasonic shear waves. Constr. Build. Mater. 2014, 72, 248–255. [Google Scholar] [CrossRef]

- Lee, Y.H.; Oh, T. The Measurement of P-, S-, and R-Wave Velocities to Evaluate the Condition of Reinforced and Prestressed Concrete Slabs. Adv. Mater. Sci. Eng. 2016, 2016, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Choi, P.; Kim, D.-H.; Lee, B.-H.; Won, M.C. Application of ultrasonic shear-wave tomography to identify horizontal crack or delamination in concrete pavement and bridge. Constr. Build. Mater. 2016, 121, 81–91. [Google Scholar] [CrossRef]

- De La Haza, A.O.; Samokrutov, A.A.; Samokrutov, P.A. Assessment of concrete structures using the Mira and Eyecon ultrasonic shear wave devices and the SAFT-C image reconstruction technique. Constr. Build. Mater. 2013, 38, 1276–1291. [Google Scholar] [CrossRef]

- Practice for Making and Curing Concrete Test Specimens in the Field; C31/C31M-19a; ASTM International: West Conshohochken, PA, USA, 2016.

- Standard Test Method for Pulse Velocity Through Concrete; C597-16; ASTM International: West Conshohochken, PA, USA, 2016.

- Popovics, J.S.; Song, W.; Achenbach, J.D.; Lee, J.H.; Andre, R.F. One-Sided Stress Wave Velocity Measurement in Concrete. J. Eng. Mech. 1998, 124, 1346–1353. [Google Scholar] [CrossRef]

- Lin, J.-M.; Sansalone, M. A procedure for determining P-wave speed in concrete for use in Impact-Echo Testing using a Rayleigh wave speed measurement technique. Spec. Publ. 1997, 168, 137–166. [Google Scholar]

- Test Method for Fundamental Transverse, Longitudinal, and Torsional Resonant Frequencies of Concrete Specimens; C215-19; ASTM International: West Conshohochken, PA, USA, 2019.

- PCB Model 352C33. Available online: https://www.pcb.com/products?m=352C33 (accessed on 3 November 2020).

- Kee, S.-H.; Kang, J.W.; Choi, B.-J.; Kwon, J.; Candelaria, M.D. Evaluation of Static and Dynamic Residual Mechanical Properties of Heat-Damaged Concrete for Nuclear Reactor Auxiliary Buildings in Korea Using Elastic Wave Velocity Measurements. Materials 2019, 12, 2695. [Google Scholar] [CrossRef] [Green Version]

- Verástegui-Flores, R.D.; Di Emidio, G.; Bezuijen, A.; Vanwalleghem, J.; Kersemans, M. Evaluation of the free–free resonant frequency method to determine stiffness moduli of cement-treated soil. Soils Found. 2015, 55, 943–950. [Google Scholar] [CrossRef]

- Test Method for Compressive Strength of Cylindrical Concrete Specimens; C39/C39M-20; ASTM International: West Conshohochken, PA, USA, 2020.

- Test Method for Static Modulus of Elasticity and Poissons Ratio of Concrete in Compression; C469/C469M-14; ASTM International: West Conshohochken, PA, USA, 2014.

- Biot, M.A. Theory of Propagation of Elastic Waves in a Fluid-Saturated Porous Solid. I. Low-Frequency Range. J. Acoust. Soc. Am. 1956, 28, 168. [Google Scholar] [CrossRef]

- Wang, H.; Li, Q. Prediction of elastic modulus and Poisson’s ratio for unsaturated concrete. Int. J. Solids Struct. 2007, 44, 1370–1379. [Google Scholar] [CrossRef] [Green Version]

- Lydon, F.D.; Balendran, R.V. Some observations on elastic properties of plain concrete. Cem. Concr. Res. 1986, 16, 314–324. [Google Scholar] [CrossRef]

- Popovics, S. Verification of relationships between mechanical properties of concrete-like materials. Mat. Constr. 1975, 8, 183–191. [Google Scholar] [CrossRef]

- Ross, C.A.; Jerome, D.M.; Tedesco, J.W.; Hughes, M.L. Moisture and Strain Rate Effects on Concrete Strength. ACI Mater. J. 1996, 93, 6. [Google Scholar]

- Rossi, P.; van Mier, J.G.M.; Boulay, C.; Le Maou, F. The dynamic behaviour of concrete: Influence of free water. Mater. Struct. 1992, 25, 509–514. [Google Scholar] [CrossRef]

- Wittmann, F.H. Interaction of Hardened Cement Paste and Water. J Am. Ceram. Soc. 1973, 56, 409–415. [Google Scholar] [CrossRef]

| W/B (%) | SV/AV | Mixture Proportion (kg/m3) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| W | C | S | G | SCMs | Chemical Admixture | ||||

| FA | SC | AE | |||||||

| MIX 1 | 51.52 | 0.490 | 170 | 99 | 884 | 931 | 33 | 198 | 1.98 |

| MIX 2 | 35.43 | 0.495 | 170 | 110 | 858 | 923 | 37 | 220 | 2.57 |

| MIX 3 | 25.60 | 0.456 | 160 | 312 | 725 | 876 | 63 | 250 | 6.88 |

| Type | Cement | Blast Furnace Slag Cement | Fly Ash | |

|---|---|---|---|---|

| Fineness (cm2/g) | 3.266 | 4.090 | 3.900 | |

| Density (g/cm3) | 3.15 | 3.05 | 2.21 | |

| Chemical composition (%) | SiO2 | 20.68 | 26.32 | 50.72 |

| Al2O3 | 5.51 | 10.51 | 20.76 | |

| Fe2O3 | 3.10 | 1.67 | 6.37 | |

| CaO | 62.28 | 55.39 | 1.82 | |

| MgO | 3.38 | 2.40 | 1.08 | |

| SO3 | 2.56 | 2.80 | 0.62 | |

| IOL (ignition loss) | 1.42 | 0.91 | 1.34 | |

| Type | Class | Color | Main Ingredient | Density [g/cm3] |

|---|---|---|---|---|

| Super plasticizer | Liquid | Lemon yellow | Polycarboxylate | 1.04 ± 0.05 |

| Saturation Degree | 25% | 50% | 75% | 100% | |

|---|---|---|---|---|---|

| Mix 1 | 1 | 25.16 | 49.12 | 77.06 | 100.00 |

| 2 | 24.97 | 51.36 | 73.03 | 97.47 | |

| 3 | 25.73 | 51.41 | 74.05 | 100.00 | |

| 4 | 24.70 | 49.93 | 75.90 | 97.37 | |

| 5 | 25.74 | 50.58 | 75.00 | 97.74 | |

| Ave | 25.26 | 50.48 | 75.01 | 98.52 | |

| Mix 2 | 1 | 26.35 | 50.97 | 76.12 | 99.69 |

| 2 | 23.84 | 49.10 | 73.73 | 97.84 | |

| 3 | 26.14 | 48.80 | 73.17 | 100.00 | |

| 4 | 25.74 | 49.16 | 75.47 | 97.69 | |

| 5 | 26.39 | 50.09 | 74.09 | 100.00 | |

| Ave | 25.69 | 49.62 | 74.51 | 99.04 | |

| Mix 3 | 1 | 26.45 | 48.62 | 76.01 | 97.83 |

| 2 | 24.43 | 50.38 | 75.92 | 100.00 | |

| 3 | 23.65 | 49.22 | 74.79 | 100.00 | |

| 4 | 26.25 | 51.98 | 74.16 | 98.60 | |

| 5 | 26.00 | 48.75 | 76.94 | 99.59 | |

| Ave | 25.36 | 49.79 | 75.57 | 99.20 | |

| Saturation Condition | a | b | R2 |

|---|---|---|---|

| OD | 0.4688 | 1.1885 | 0.93 |

| 25% | 0.5111 | 1.1617 | 0.98 |

| 50% | 0.379 | 1.2413 | 0.99 |

| 75% | 0.4451 | 1.1957 | 0.98 |

| SSD | 0.4325 | 1.1798 | 0.98 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Candelaria, M.D.E.; Kee, S.-H.; Yee, J.-J.; Lee, J.-W. Effects of Saturation Levels on the Ultrasonic Pulse Velocities and Mechanical Properties of Concrete. Materials 2021, 14, 152. https://doi.org/10.3390/ma14010152

Candelaria MDE, Kee S-H, Yee J-J, Lee J-W. Effects of Saturation Levels on the Ultrasonic Pulse Velocities and Mechanical Properties of Concrete. Materials. 2021; 14(1):152. https://doi.org/10.3390/ma14010152

Chicago/Turabian StyleCandelaria, Ma. Doreen Esplana, Seong-Hoon Kee, Jurng-Jae Yee, and Jin-Wook Lee. 2021. "Effects of Saturation Levels on the Ultrasonic Pulse Velocities and Mechanical Properties of Concrete" Materials 14, no. 1: 152. https://doi.org/10.3390/ma14010152