Mechanical Properties of Mortars Reinforced with Amazon Rainforest Natural Fibers

Abstract

:1. Introduction

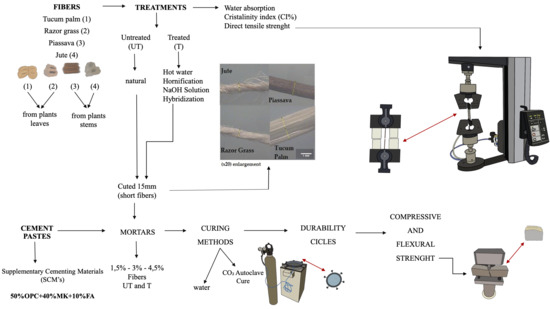

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Treatments of the Fibers

2.2.2. Water Absorption of the Fibers

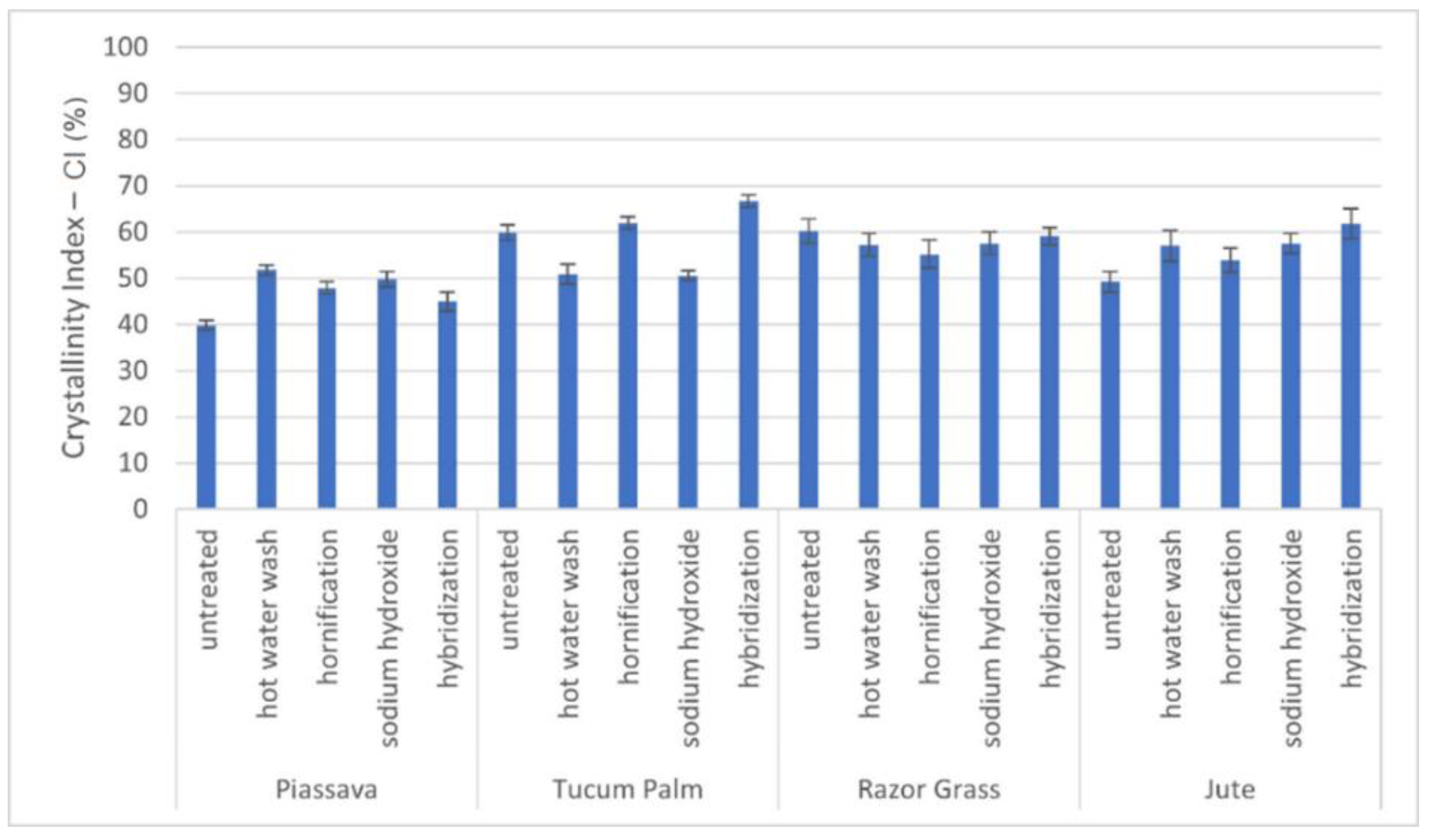

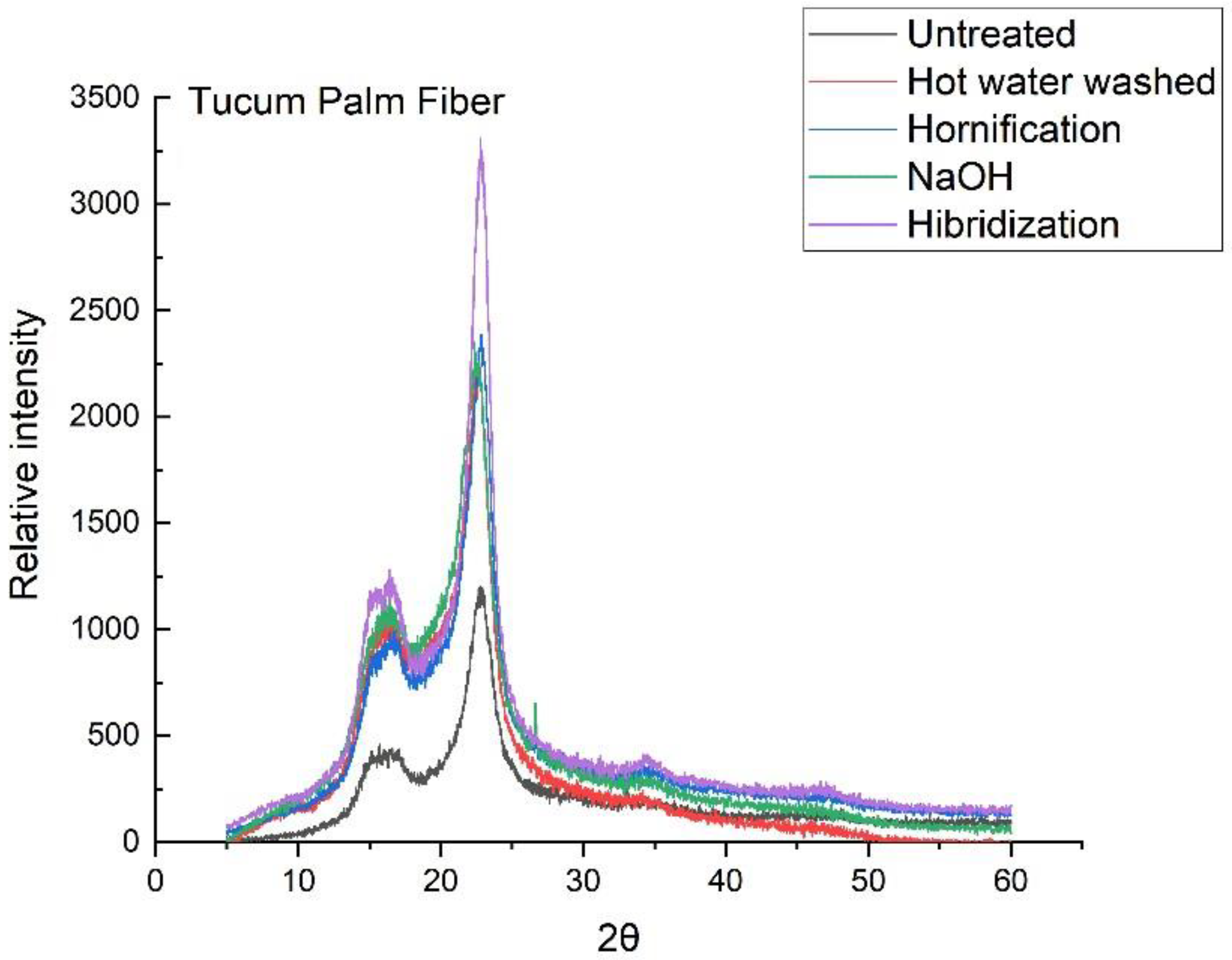

2.2.3. Crystallinity Index (CI %)

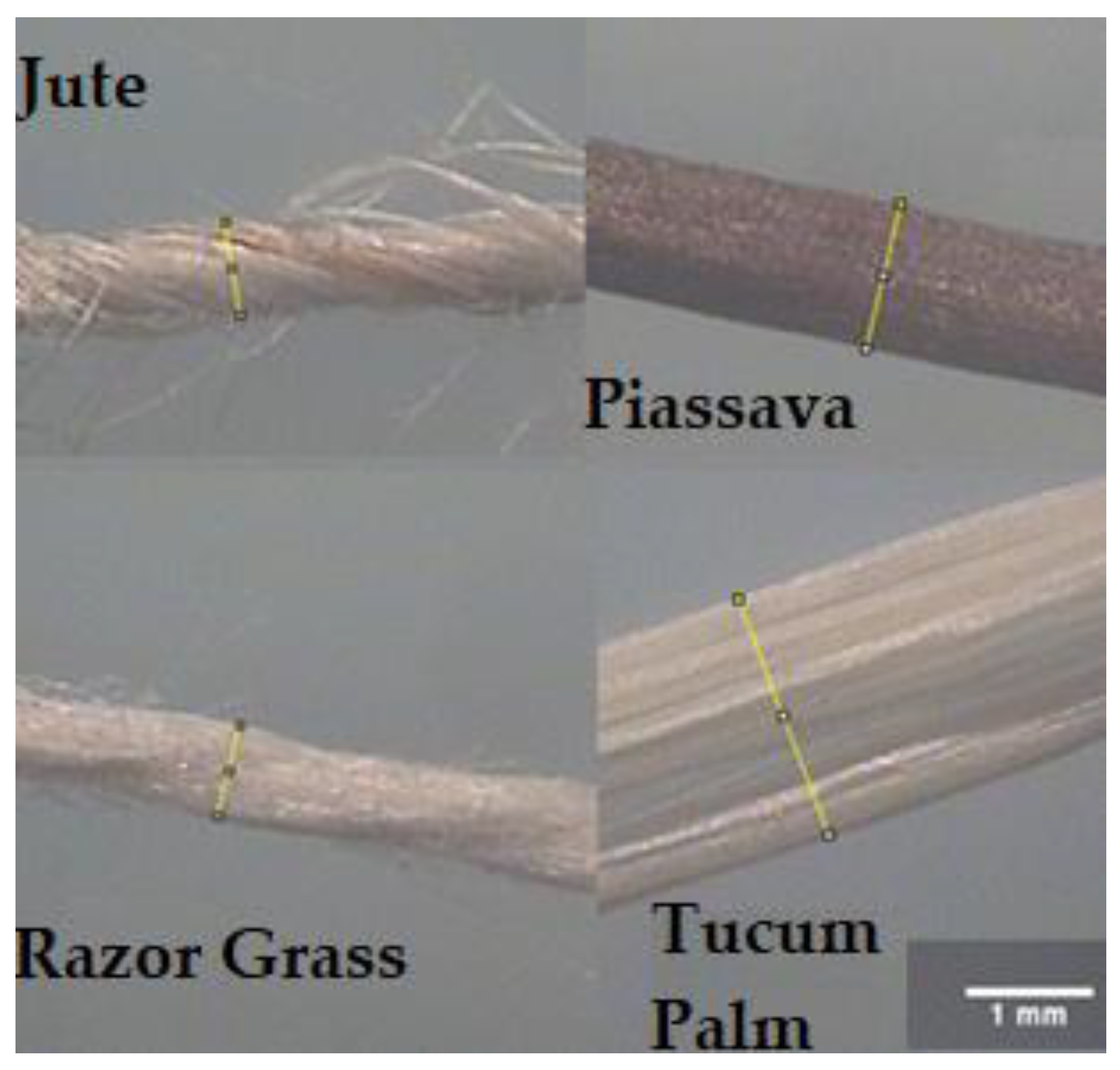

2.2.4. Direct Tensile Strength of the Fibers

2.2.5. Thermogravimetry of Pastes

- W400 = sample mass at 400 °C.

- W500 = sample mass at 500 °C.

- = ratio between CH molar mass and H2O molar mass = 4.11

2.2.6. Curing Methods

2.2.7. Compressive and Flexural Strength

3. Results and Discussion

3.1. Water Absorption of Fibers

3.2. Crystallinity Index

3.3. Direct Tensile Strength of Fibers

3.4. Metakaolin (MK) and Fly Ash (FA) Content Determination

3.5. Chosen Fiber Treatment for Reinforced Mortars

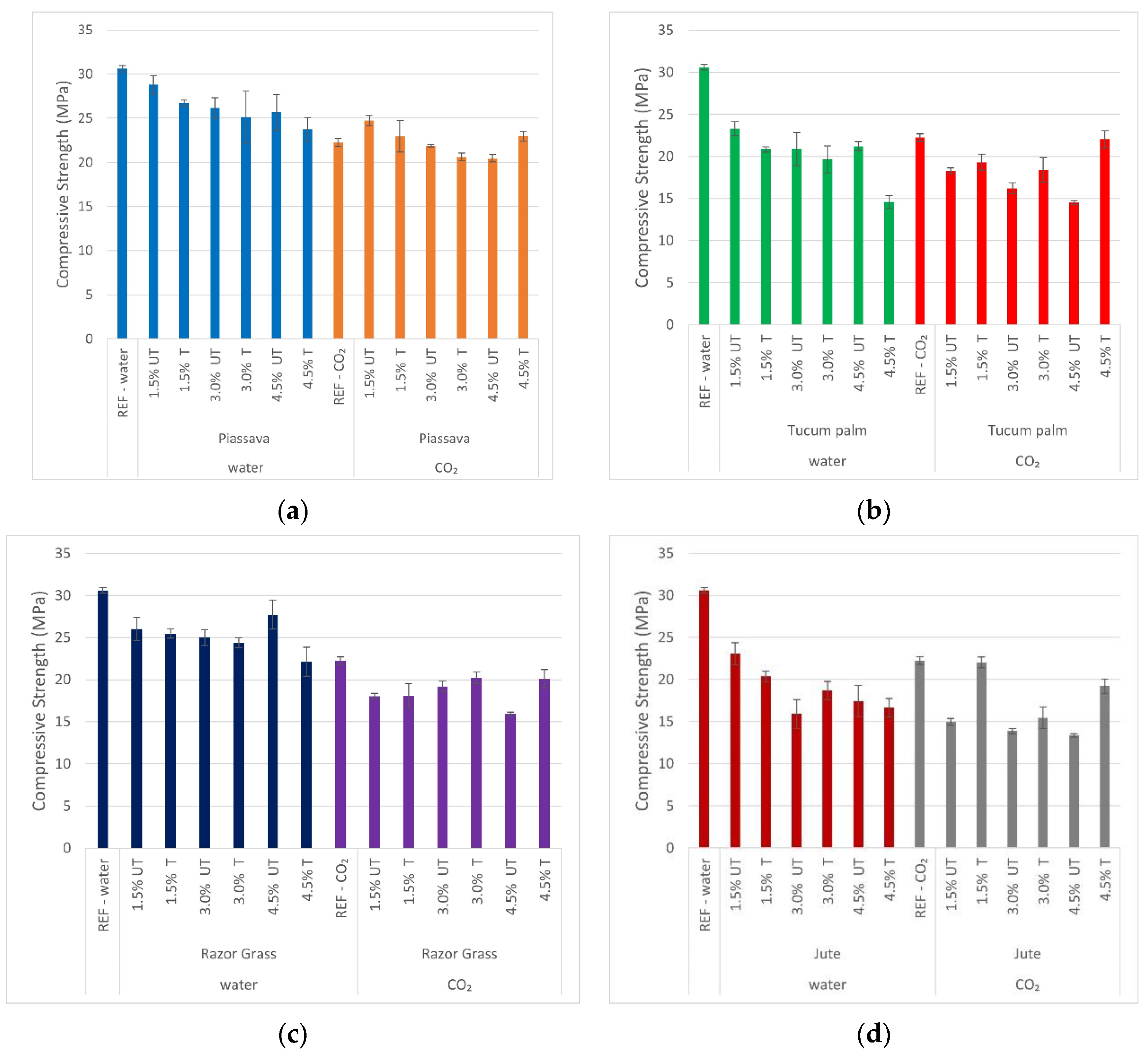

3.6. Compressive Strength

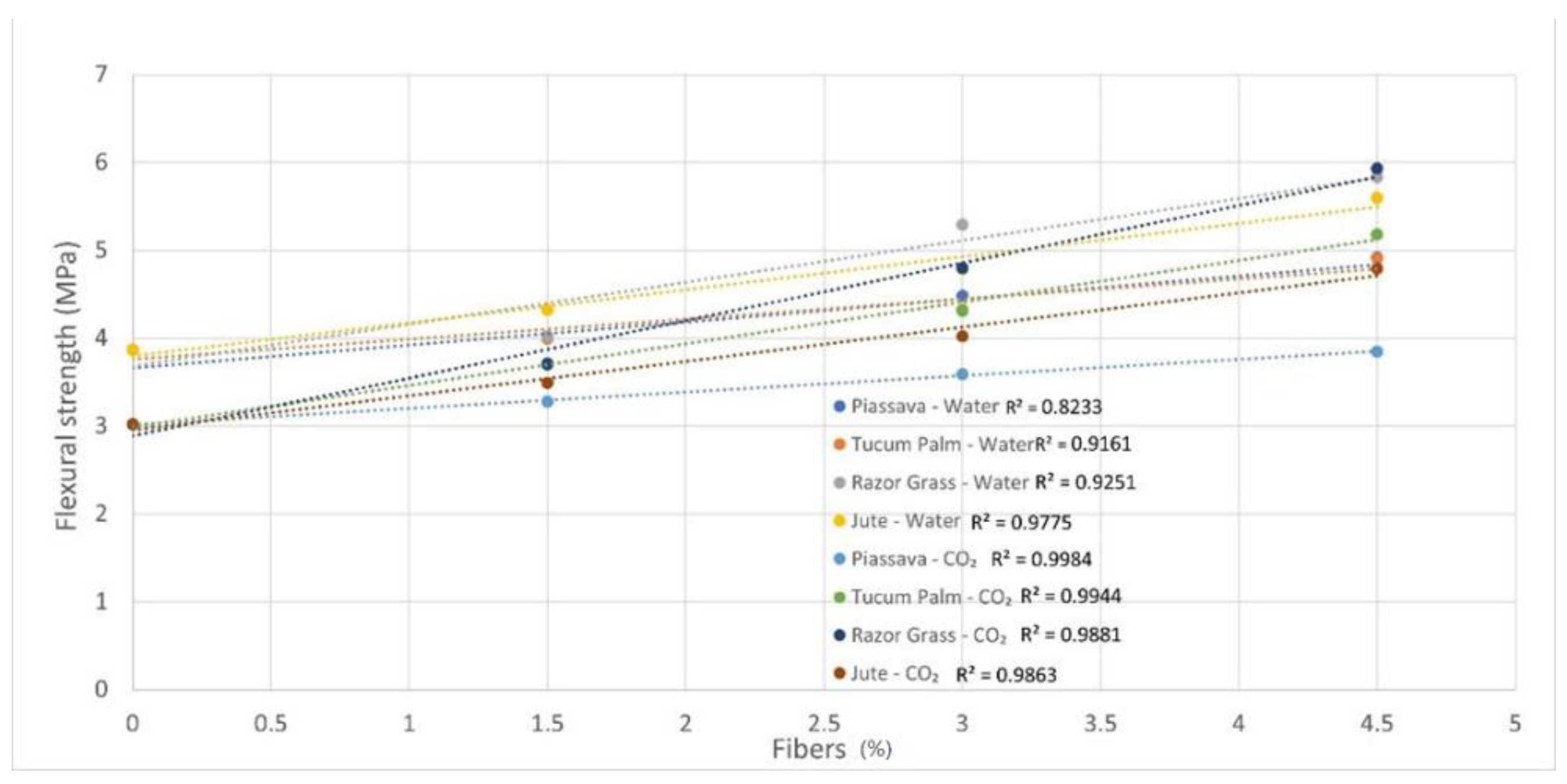

3.7. Flexural Strenght

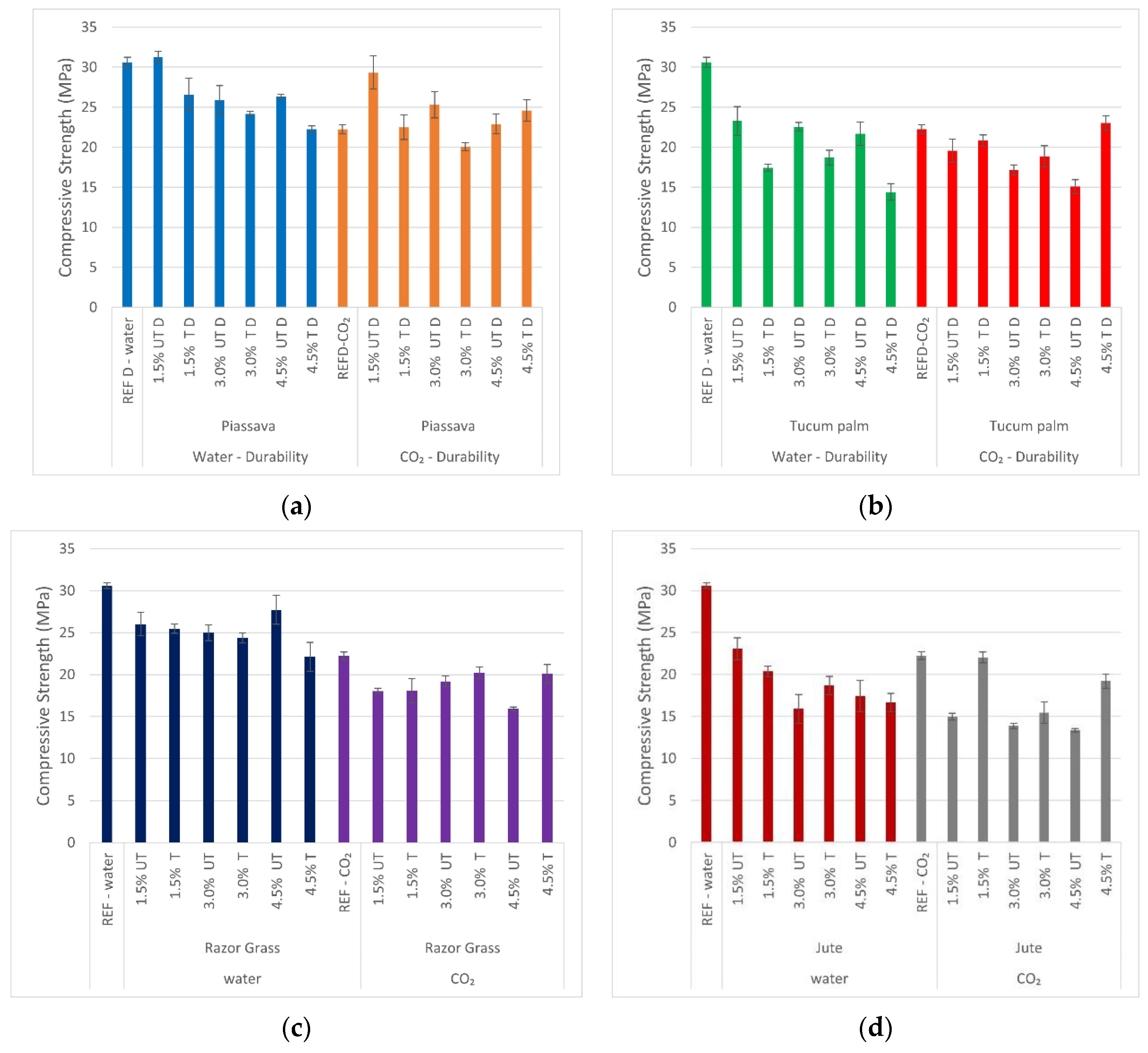

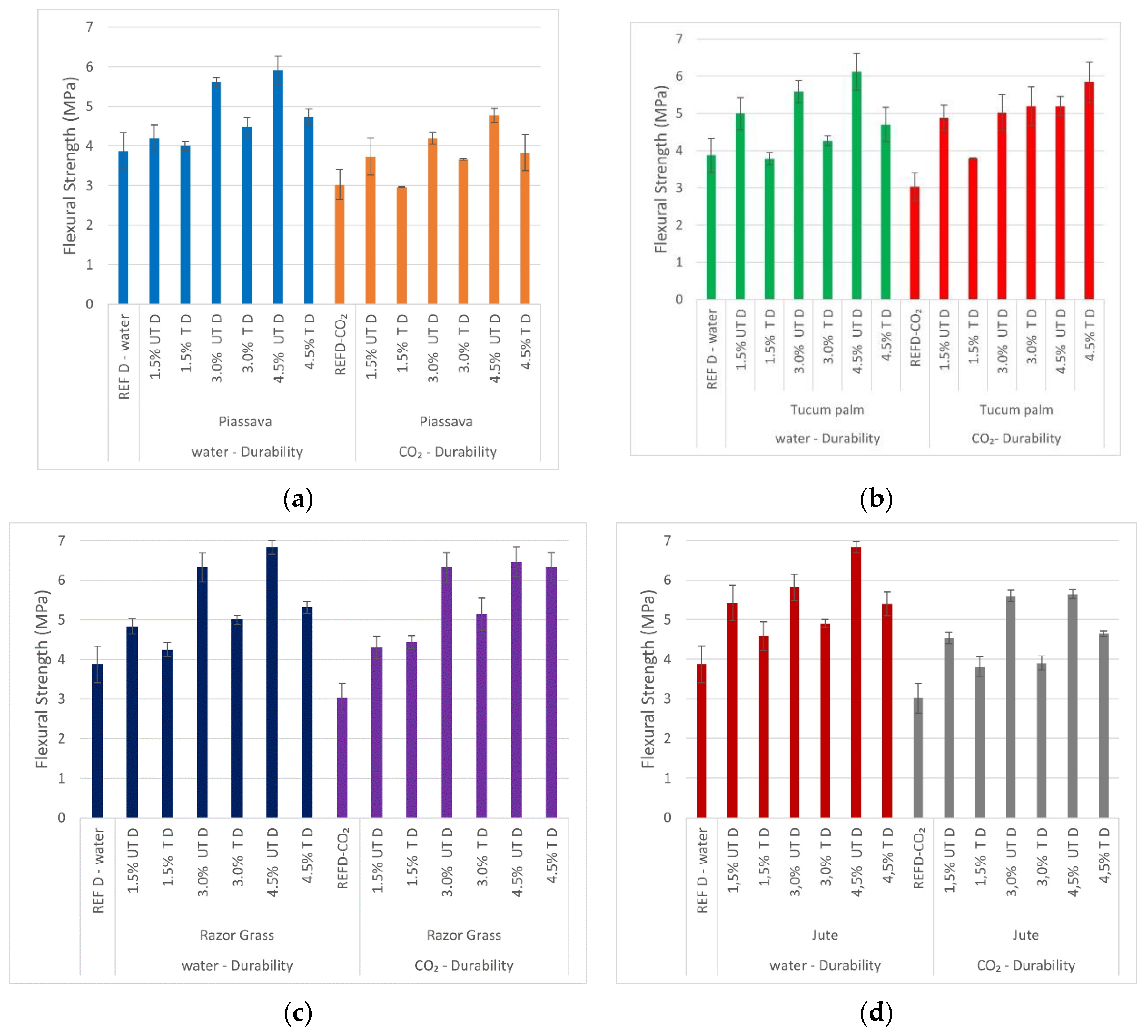

3.8. Durability Cycles

3.8.1. Durability Cycles—Compressive Strength

3.8.2. Durability Cycles—Flexural Strength

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jorillo, P.; Shimizu, G.; Suzuki, T. New technology approach to age-old waste material (natural fibers) for composites. In Waste Management Series; Woolley, G.R., Goumans, J.J.J.M., Wainwright, P.J., Eds.; Elsevier: Amsterdam, The Netherlands, 2000; Volume 1, pp. 45–56. [Google Scholar] [CrossRef]

- Juarez, C.; Durán, A.; Valdez-Tamez, P.; Fajardo, G. Performance of “Agave lecheguilla” natural fiber in portland cement composites exposed to severe environment conditions. Build. Environ. 2007, 42, 1151–1157. [Google Scholar] [CrossRef]

- Murray, R. Asbestos: A chronology of its origins and health effects. Occup. Environ. Med. 1990, 47, 361–365. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lertwattanaruk, P.; Suntijitto, A. Properties of natural fiber cement materials containing coconut coir and oil palm fibers for residential building applications. Constr. Build. Mater. 2015, 94, 664–669. [Google Scholar] [CrossRef]

- Li, L.; Xiao, B.; Fang, Z.; Xiong, Z.; Chu, S.; Kwan, A. Feasibility of glass/basalt fiber reinforced seawater coral sand mortar for 3D printing. Addit. Manuf. 2020, 101684. [Google Scholar] [CrossRef]

- Tonoli, G.H.D. Aspectos produtivos e análise do desempenho do fibrocimento sem amianto no desenvolvimento de tecnologia para telhas onduladas. Master’s Thesis, Universidade de São Paulo, São Paulo, Brazil, 2006. [Google Scholar]

- Hwang, C.-L.; Tran, V.-A.; Hong, J.-W.; Hsieh, Y.-C. Effects of short coconut fiber on the mechanical properties, plastic cracking behavior, and impact resistance of cementitious composites. Constr. Build. Mater. 2016, 127, 984–992. [Google Scholar] [CrossRef]

- Al-Rubaye, M.; Manalo, A.; Alajarmeh, O.; Ferdous, W.; Lokuge, W.; Benmokrane, B.; Edoo, A. Flexural behaviour of concrete slabs reinforced with GFRP bars and hollow composite reinforcing systems. Compos. Struct. 2020, 236, 111836. [Google Scholar] [CrossRef] [Green Version]

- Mohammed, A.A.; Manalo, A.C.; Ferdous, W.; Zhuge, Y.; Vijay, P.; Pettigrew, J. Experimental and numerical evaluations on the behaviour of structures repaired using prefabricated FRP composites jacket. Eng. Struct. 2020, 210, 110358. [Google Scholar] [CrossRef]

- Jo, B.-W.; Chakraborty, S.; Yoon, K.W. A hypothetical model based on effectiveness of combined alkali and polymer latex modified jute fibre in controlling the setting and hydration behaviour of cement. Constr. Build. Mater. 2014, 68, 1–9. [Google Scholar] [CrossRef]

- Codispoti, R.; Oliveira, D.V.; Olivito, R.S.; Lourenço, P.B.; Fangueiro, R. Mechanical performance of natural fiber-reinforced composites for the strengthening of masonry. Compos. Part B Eng. 2015, 77, 74–83. [Google Scholar] [CrossRef]

- Satyanarayana, K.G.; Guimarães, J.L.; Wypych, F. Studies on lignocellulosic fibers of Brazil. Part I: Source, production, morphology, properties and applications. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1694–1709. [Google Scholar] [CrossRef]

- JICA (Agência de Cooperação Internacional do Japão). Estudo para o Desenvolvimento de uma Solução Integrada Relativa à Gestão de Resíduos Industriais no Pólo Industrial de Manaus; SUFRAMA: Manaus, Brazil, 2010. [Google Scholar]

- Khorami, M.; Ganjian, E. Comparing flexural behaviour of fibre–cement composites reinforced bagasse: Wheat and eucalyptus. Constr. Build. Mater. 2011, 25, 3661–3667. [Google Scholar] [CrossRef]

- Savastano, H.; Agopyan, V.; Nolasco, A.M.; Pimentel, L. Plant fibre reinforced cement components for roofing. Constr. Build. Mater. 1999, 13, 433–438. [Google Scholar] [CrossRef]

- Savastano, H.; Warden, P.; Coutts, R. Microstructure and mechanical properties of waste fibre–cement composites. Cem. Concr. Compos. 2005, 27, 583–592. [Google Scholar] [CrossRef]

- Claramunt, J.; Ardanuy, M.; García-Hortal, J.A.; Filho, R.D.T. The hornification of vegetable fibers to improve the durability of cement mortar composites. Cem. Concr. Compos. 2011, 33, 586–595. [Google Scholar] [CrossRef]

- Tian, H.; Zhang, Y.; Yang, C.; Ding, Y. Recent advances in experimental studies of the mechanical behaviour of natural fibre-reinforced cementitious composites. Struct. Concr. 2016, 17, 564–575. [Google Scholar] [CrossRef]

- ABNT. NBR 16697: Cimento Portland—Requisitos; ABNT: Rio de Janeiro, Brazil, 2018. [Google Scholar]

- ASTM. ASTM C150: Standard Specification for Portland Cement; ASTM: West Conshohocken, PA, USA, 2020. [Google Scholar]

- TAPPI. T 201 om-93: Alpha-, Beta- and Gamma-Cellulose in Pulp; TAPPI: Peachtree Corners, GA, USA, 2009. [Google Scholar]

- TAPPI. T 204 cm-07: Solvent Extractives of Wood and Pulp; TAPPI: Peachtree Corners, GA, USA, 1998. [Google Scholar]

- TAPPI. T 222 cm-00: Acid in-Soluble Lignin in Wood and Pulp; TAPPI: Peachtree Corners, GA, USA, 1988. [Google Scholar]

- TAPPI. T 211 om-07: Ash in Wood, pulp, Paper and Paperboard: Combustion at 525 C; TAPPI: Peachtree Corners, GA, USA, 2007. [Google Scholar]

- Yan, L.; Kasal, B.; Huang, L. A review of recent research on the use of cellulosic fibres, their fibre fabric reinforced cementitious, geo-polymer and polymer composites in civil engineering. Compos. Part B Eng. 2016, 92, 94–132. [Google Scholar] [CrossRef]

- Asasutjarit, C.; Charoenvai, S.; Hirunlabh, J.; Khedari, J. Materials and mechanical properties of pretreated coir-based green composites. Compos. Part B Eng. 2009, 40, 633–637. [Google Scholar] [CrossRef]

- Ferreira, S.R.; Silva, F.D.A.; Lima, P.R.L.; Filho, R.D.T. Effect of hornification on the structure, tensile behavior and fiber matrix bond of sisal, jute and curauá fiber cement based composite systems. Constr. Build. Mater. 2017, 139, 551–561. [Google Scholar] [CrossRef]

- Ballesteros, J.E.M.; Santos, S.F.; Mármol, G.; Savastano, H.; Fiorelli, J. Evaluation of cellulosic pulps treated by hornification as reinforcement of cementitious composites. Constr. Build. Mater. 2015, 100, 83–90. [Google Scholar] [CrossRef] [Green Version]

- Segal, L.; Creely, J.; Martin, A.; Conrad, C. An Empirical Method for Estimating the Degree of Crystallinity of Native Cellulose Using the X-ray Diffractometer. Text. Res. J. 2008, 29, 786–794. [Google Scholar] [CrossRef]

- ASTM. ASTM C1557: Standard Test Method for Tensile Strength and Young’s Modulus of Fibers; ASTM: West Conshohocken, PA, USA, 2020. [Google Scholar]

- Filho, R.D.T.; Silva, F.D.A.; Fairbairn, E.; Filho, J.D.A.M. Durability of compression molded sisal fiber reinforced mortar laminates. Constr. Build. Mater. 2009, 23, 2409–2420. [Google Scholar] [CrossRef]

- Filho, J.D.A.M.; Silva, F.D.A.; Filho, R.D.T. Degradation kinetics and aging mechanisms on sisal fiber cement composite systems. Cem. Concr. Compos. 2013, 40, 30–39. [Google Scholar] [CrossRef]

- Fidelis, M.E.A.; Filho, R.D.T.; Silva, F.D.A.; Mobasher, B.; Müller, S.; Mechtcherine, V. Interface characteristics of jute fiber systems in a cementitious matrix. Cem. Concr. Res. 2019, 116, 252–265. [Google Scholar] [CrossRef]

- ABNT. NBR 7215: Cimento Portland: Determinação da Resistência à Compressão; ABNT: Rio de Janeiro, Brazil, 2019. [Google Scholar]

- ABNT. NBR 13279: Argamassa para Assentamento e Revestimento de Paredes e tetos-Determinação da Resistência à Tração na Flexão e à Compressão; ABNT: Rio de Janeiro, Brazil, 2005. [Google Scholar]

- Benmansour, N.; Agoudjil, B.; Gherabli, A.; Kareche, A.; Boudenne, A. Thermal and mechanical performance of natural mortar reinforced with date palm fibers for use as insulating materials in building. Energy Build. 2014, 81, 98–104. [Google Scholar] [CrossRef]

- Bennehalli, B.; Sampathkumar, D.; Punyamurth, R.; Venkateshappa, S.C. Effect of esterification on moisture absorption of single areca fiber. Int. J. Agric. Sci. 2012, 4, 227–229. [Google Scholar] [CrossRef] [Green Version]

- Yilmaz, N.D.; Yılmaz, N.D. Agro-Residual Fibers as Potential Reinforcement Elements for Biocomposites. In Lignocellulosic Polymer Composites; Thakur, V.K., Ed.; Scrivener Publishing: Denizli, Turkey, 2014; pp. 231–270. [Google Scholar]

- Quiroga, A.; Marzocchi, V.; Rintoul, I. Influence of wood treatments on mechanical properties of wood–cement composites and of Populus Euroamericana wood fibers. Compos. Part B Eng. 2016, 84, 25–32. [Google Scholar] [CrossRef]

- El Oudiani, A.; Chaabouni, Y.; Msahli, S.; Sakli, F. Crystal transition from cellulose I to cellulose II in NaOH treated Agave americana L. fibre. Carbohydr. Polym. 2011, 86, 1221–1229. [Google Scholar] [CrossRef]

- Reddy, N.; Yang, Y. Structure and properties of high quality natural cellulose fibers from cornstalks. Polymer 2005, 46, 5494–5500. [Google Scholar] [CrossRef]

- Roy, A.; Chakraborty, S.; Kundu, S.P.; Basak, R.K.; Majumder, S.B.; Adhikari, B. Improvement in mechanical properties of jute fibres through mild alkali treatment as demonstrated by utilisation of the Weibull distribution model. Bioresour. Technol. 2012, 107, 222–228. [Google Scholar] [CrossRef]

- Yazici, H.; Yardımcı, M.Y.; Aydın, S.; Karabulut, A.Ş. Mechanical properties of reactive powder concrete containing mineral admixtures under different curing regimes. Constr. Build. Mater. 2009, 23, 1223–1231. [Google Scholar] [CrossRef]

- Wongkeo, W.; Thongsanitgarn, P.; Chaipanich, A. Compressive Strength of Binary and Ternary Blended Cement Mortars Containing Fly Ash and Silica Fume under Autoclaved Curing. Adv. Mater. Res. 2011, 343, 316–321. [Google Scholar] [CrossRef]

- Jo, B.-W.; Chakraborty, S. A mild alkali treated jute fibre controlling the hydration behaviour of greener cement paste. Sci. Rep. 2015, 5, 7837. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- ABNT. NBR 6136: Blocos Vazados de Concreto Simples para Alvenaria-Requisitos; ABNT: Rio de Janeiro, Brazil, 2016. [Google Scholar]

- EN. EN 12467: Fiber-Cement Flat Sheets. Product Specification and Test Methods; Chiswick High Road: Greater London, UK, 2013. [Google Scholar]

| Materials | L.O.I (%) | CaO (%) | SiO2 (%) | MgO (%) | Al2O3 (%) | SO3 (%) | Fe2O3 (%) | K2O (%) | TiO2 (%) | Specific Gravity (g/cm3) | Fineness (cm2/g) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cement (OPC) | 5.38 | 54.5 | 19.96 | 8.34 | 4.25 | 3.81 | 2.29 | 0.92 | 0.26 | 3.17 | 3605 |

| Fly ash (FA) | 0.8 | 2.31 | 61.18 | 0.70 | 30.64 | 0.36 | 1.67 | 1.27 | 0.81 | 2.17 | 3337 |

| Metakaolin (MK) | 2.38 | 0.12 | 43.90 | - | 46.56 | 0.08 | 3.05 | 0.46 | 0.76 | 2.81 | 12,531 |

| Fiber | Holocellulose (%) | Alpha-Cellulose (%) | Hemicellulose (%) | Lignin (%) | Extractives (%) |

|---|---|---|---|---|---|

| Piassava | 53.16 | 51.45 | 1.71 | 45.68 | 1.17 |

| Tucum palm | 78.90 | 77.52 | 1.38 | 17.36 | 3.74 |

| Razor grass | 95.3 | 86.85 | 8.45 | 0.81 | 3.89 |

| Jute | 83.18 | 64.07 | 19.11 | 12.46 | 4.36 |

| Pastes | Cement (OPC) (g) | Metakaolin (MK) (g) | Fly Ash (FA) (g) | Water (g) | S.P (%) |

|---|---|---|---|---|---|

| REF (control) | 500 | 0 | 0 | 200 | - |

| 10MK + 40FA | 250 | 50 | 200 | 200 | - |

| 20MK + 30FA | 250 | 100 | 150 | 200 | 0.30 |

| 30MK + 20FA | 250 | 150 | 100 | 200 | 0.30 |

| 40MK + 10FA | 250 | 200 | 50 | 200 | 0.50 |

| Cement Pastes | REF (100% OPC) | 10 MK + 40 FA | 20 MK + 30 FA | 30 MK + 20 FA | 40 MK + 10 FA |

|---|---|---|---|---|---|

| CH% | 16.86 | 6.66 | 5.03 | 4.13 | 3.84 |

| Compressive Strength (MPa) | 36.92 | 27.82 | 37.89 | 39.40 | 42.12 |

| Fiber/Cure | % Fiber | Treatment | CI (%) | CS (MPa) |

|---|---|---|---|---|

| Piassava/water | 1.50 | UT | 39.83 | 28.78 |

| T | 51.8 | 26.71 | ||

| Piassava/water | 3.00 | UT | 39.83 | 26.14 |

| T | 51.8 | 25.12 | ||

| Piassava/water | 4.50 | UT | 39.83 | 25.65 |

| T | 51.8 | 23.71 | ||

| Piassava/CO2 | 1.50 | UT | 39.83 | 24.73 |

| T | 51.8 | 22.94 | ||

| Piassava/CO2 | 3.00 | UT | 39.83 | 21.86 |

| T | 51.8 | 20.61 | ||

| Piassava/CO2 | 4.50 | UT | 39.83 | 20.45 |

| T | 51.8 | 22.97 | ||

| Tucum palm/water | 1.50 | UT | 59.84 | 23.29 |

| T | 66.73 | 20.84 | ||

| Tucum palm/Water | 3.00 | UT | 59.84 | 20.87 |

| T | 66.73 | 19.65 | ||

| Tucum palm/water | 4.50 | UT | 59.84 | 21.21 |

| T | 66.73 | 14.59 | ||

| Tucum palm/CO2 | 1.50 | UT | 59.84 | 18.27 |

| T | 66.73 | 19.32 | ||

| Tucum palm/CO2 | 3.00 | UT | 59.84 | 16.19 |

| T | 66.73 | 18.41 | ||

| Tucum palm/CO2 | 4.50 | UT | 59.84 | 14.51 |

| T | 66.73 | 22.03 | ||

| Razor grass/water | 1.50 | UT | 60.23 | 26.02 |

| T | 55.21 | 25.48 | ||

| Razor grass/water | 3.00 | UT | 60.23 | 24.98 |

| T | 55.21 | 24.36 | ||

| Razor grass/water | 4.50 | UT | 60.23 | 27.72 |

| T | 55.21 | 22.12 | ||

| Razor grass/CO2 | 1.50 | UT | 60.23 | 18.00 |

| T | 55.21 | 18.06 | ||

| Razor grass/CO2 | 3.00 | UT | 60.23 | 19.17 |

| T | 55.21 | 20.19 | ||

| Razor grass/CO2 | 4.50 | UT | 60.23 | 15.91 |

| T | 55.21 | 20.09 | ||

| Jute/water | 1.50 | UT | 49.28 | 23.04 |

| T | 57.53 | 20.34 | ||

| Jute/water | 3.00 | UT | 49.28 | 15.88 |

| T | 57.53 | 18.66 | ||

| Jute/water | 4.50 | UT | 49.28 | 17.43 |

| T | 57.53 | 16.64 | ||

| Jute/CO2 | 1.50 | UT | 49.28 | 14.97 |

| T | 57.53 | 22.01 | ||

| Jute/CO2 | 3.00 | UT | 49.28 | 13.84 |

| T | 57.53 | 15.43 | ||

| Jute/CO2 | 4.50 | UT | 49.28 | 13.33 |

| T | 57.53 | 19.19 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

da Fonseca, R.P.; Rocha, J.C.; Cheriaf, M. Mechanical Properties of Mortars Reinforced with Amazon Rainforest Natural Fibers. Materials 2021, 14, 155. https://doi.org/10.3390/ma14010155

da Fonseca RP, Rocha JC, Cheriaf M. Mechanical Properties of Mortars Reinforced with Amazon Rainforest Natural Fibers. Materials. 2021; 14(1):155. https://doi.org/10.3390/ma14010155

Chicago/Turabian Styleda Fonseca, Régis Pamponet, Janaíde Cavalcante Rocha, and Malik Cheriaf. 2021. "Mechanical Properties of Mortars Reinforced with Amazon Rainforest Natural Fibers" Materials 14, no. 1: 155. https://doi.org/10.3390/ma14010155

APA Styleda Fonseca, R. P., Rocha, J. C., & Cheriaf, M. (2021). Mechanical Properties of Mortars Reinforced with Amazon Rainforest Natural Fibers. Materials, 14(1), 155. https://doi.org/10.3390/ma14010155