Experimental Wear Behavior Analysis of Coated Spindle Hook Teeth under Real Harvesting Work Conditions

Abstract

:1. Introduction

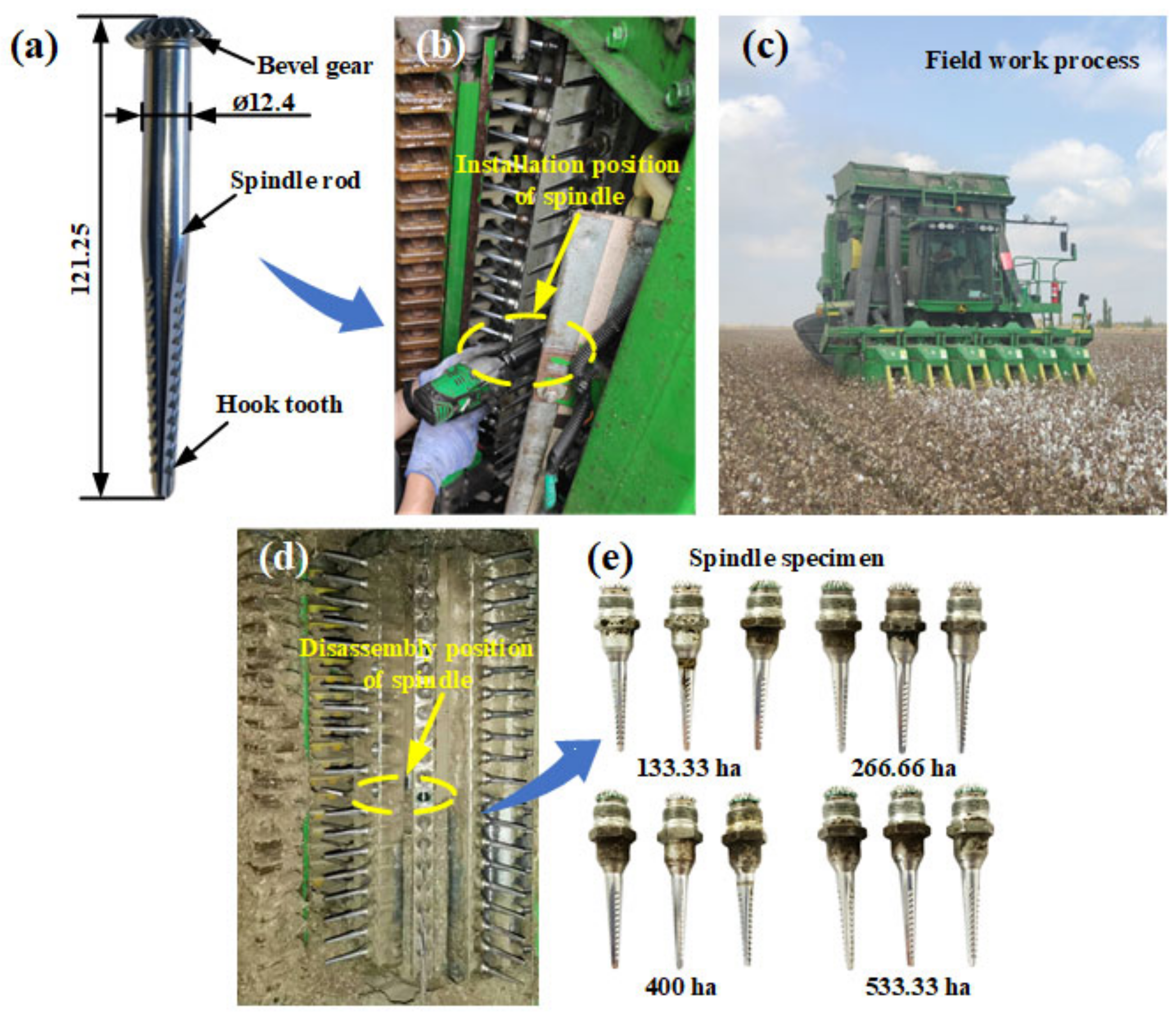

2. Work Process of the Spindle in the Field

3. Materials and Methods

3.1. Equipment

3.2. Cutting Process of Spindles

4. Results and Discussion

4.1. Surface Morphology of the Hook Tooth

4.2. Cross Section Morphology of the Hook Tooth

5. Conclusions

- The analysis of the surface of the spindle hook tooth showed that during field work, the wear on the surface of the spindle hook tooth initially occurs at the tooth tip and tooth edge, and then gradually spreads to the entire hook tooth surface. The wear area of the hook teeth increases exponentially with an increase in field work area, and the wear width changes linearly. In this study, when the working area of the field work section reached 533.33 ha, the maximum wear area and wear width change rates were 2.33 × 103 µm2/ha and 1.84 µm/ha, respectively.

- Through the analysis of the wear failure of the spindle hook teeth, we determined that the wear of the spindle hook teeth was caused by the combined actions of abrasive wear, oxidative wear, and the fatigue peeling of the coating.

- In the analysis of the cross section of the spindle hook teeth, we found microcracks and holes in the spindle coating used in this study. The thickness of the coating on the tooth edge was small, and the thickness of the surface coating of the hook tooth was between 66.1 µm and 74.4 µm.

- During field work, the thickness of the coating on the surface of the same spindle hook tooth gradually decreased from the cutting surface to the tooth edge at different positions. However, the surface coating of the hook tooth at the same position exhibited a slower wear rate near the cutting surface under the conditions of different work areas, whereas the wear rate of the coating near the tooth edge was faster. In this study, the wear rate at Position 1 was the slowest, at 0.01 µm/ha, and the wear rate at Position 5 was the fastest, at 0.25 µm/ha. The wear failure change of the hook teeth and the reasons for the wear failure of the hook teeth were explored during field work, and a reference for further exploration of the wear failure mechanism of spindle hook teeth is provided. However, this study only analyzed the wear of the first hook tooth of the spindle. The wear of the remaining hook teeth of the spindle will be studied in follow-up research.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fue, K.G.; Barnes, E.M.; Porter, W.M.; Rains, G.C. Visual Control of Cotton-picking Rover and Manipulator using a ROS-independent Finite State Machine. In Proceedings of the 2019 Beltwide Cotton Conferences, New Orleans, LA, USA, 8–10 January 2019. [Google Scholar]

- Arshad, A.; Raza, M.; Zhang, Y.; Zhang, L.; Wang, X.; Ahmed, M.; Habib-Ur-Rehman, M. Impact of Climate Warming on Cotton Growth and Yields in China and Pakistan: A Regional Perspective. Agriculture 2021, 11, 97. [Google Scholar] [CrossRef]

- Hosseinali, F.; Thomasson, J.A. Variability of fiber friction among cotton varieties: Influence of salient fiber physical metrics. Tribol. Int. 2018, 127, 433–445. [Google Scholar] [CrossRef]

- Chen, H.; Zhao, X.; Han, Y.; Xing, F.; Feng, L.; Wang, Z.; Wang, G.; Yang, B.; Lei, Y.; Xiong, S.; et al. Competition for Light Interception in Cotton Populations of Different Densities. Agronomy 2021, 11, 176. [Google Scholar] [CrossRef]

- Chen, X.G.; Zhang, H.W.; Wang, L.; Zhang, L.; Wang, J.; Li, J.; Gu, Y. Optimization and experiment of picking head transmission system of horizontal spindle type cotton picker. Trans. Chin. Soc. Agric. Eng. 2020, 36, 18–26. [Google Scholar]

- Wang, X.J.; Li, Y.C.; Fu, W.D.; Li, X.J.; Hu, Q.R. Analysis of meteorological conditions for cotton growth in Xinjiang in 2020. China Cotton. 2021, 48, 42–44. [Google Scholar]

- Du, W.D.; Zhu, X.Z. Analysis on the Related Factors Affecting Xinjiang Cotton Quality in 2020; China Fiber Inspection: Beijing, China, 2021; pp. 42–44. [Google Scholar]

- Wu, J.S.; Chen, X.G. Present situation, problems and countermeasures of cotton production mechanization development in Xinjiang Production and Construction Corps. Trans. Chin. Soc. Agric. Eng. 2015, 31, 5–10. [Google Scholar]

- Baker, K.D.; Delhom, C.D.; Hughs, E. Spindle diameter effects for cotton pickers. Trans. ASABE. 2017, 33, 321–327. [Google Scholar] [CrossRef]

- Baker, K.D.; Hughs, E.; Foulk, J. Cotton quality as affected by changes in spindle speed. Trans. ASABE 2010, 26, 363–369. [Google Scholar]

- Baker, K.D.; Hughs, E.; Foulk, J. Spindle speed optimization for cotton pickers. Trans. ASABE. 2015, 31, 217–225. [Google Scholar]

- Zhang, Y.Q.; Wang, W.; Liao, J.A. Wear failure analysis on spindle of cotton picker. Trans. Chin. Soc. Agric. Eng. 2017, 33, 45–50. [Google Scholar]

- Li, W.C.; Qiao, Y.Y.; Deng, Y.M.; Liu, X.M.; Zhang, H.W. Valuation and analysis of hook tooth wear for cotton picker spindle. J. Chin. Agric. Mech. 2018, 39, 11–14. [Google Scholar]

- Zhang, Y.Q.; Cai, Z.P.; Tian, Y.; Meng, Y. Improvement of mechanical properties and wear resistance of cotton pickers spindle by electromagnetic treatment. Trans. Chin. Soc. Agric. Eng. 2018, 34, 31–37. [Google Scholar]

- Lackner, J.M.; Waldhauser, W.; Major, L.; Kot, M. Tribology and Micromechanics of Chromium Nitride Based Multilayer Coatings on Soft and Hard Substrates. Coatings 2014, 4, 121–138. [Google Scholar] [CrossRef]

- Meng, F.M.; Chen, N.W.; Chen, Z.W. Hard chromium coating effects on tribological performances for nonlubricated and lubricated spindle of cotton picker. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2016, 230, 446–453. [Google Scholar] [CrossRef]

- Meng, F.; Chen, Y.; Yang, Y.; Chen, Z. Friction and wear behavior of electroless nick coating used for spindle of cotton picker. Ind. Lubr. Tribol. 2016, 68, 220–226. [Google Scholar] [CrossRef]

- Pinate, S.; Zanella, C. Wear Behavior of Ni-Based Composite Coatings with Dual Nano-SiC: Graphite Powder Mix. Coatings 2020, 10, 1060. [Google Scholar] [CrossRef]

- Luo, S.L.; Zhang, Y.Q.; Ma, S.H. Wear Mechanism Analysis on Spindle of Cotton Picker. J. Tarim Univ. 2018, 30, 132–137. [Google Scholar]

- Amanov, A.; Sembiring, J.P.B.; Amanov, T. Experimental Investigation on Friction and Wear Behavior of the Vertical Spindle and V-belt of a Cotton Picker. Materials 2019, 12, 773. [Google Scholar] [CrossRef] [Green Version]

- Deng, Y.M.; Li, W.C.; Yu, T.Z.; Wang, C.H.; Xu, J.T.; Qiao, Y.Y. Analysis and study on spindle component wear factors of horizontal cotton picker. J. Chin. Agric. Mech. 2017, 38, 11–13. [Google Scholar]

- Wu, B.; Zhang, L.X.; Zuo, Y.T.; Min, W. Research of Material Elements Distribution in Cotton Picker’s Level Spindle Based on SEM and EDS. J. Agric. Mech. Res. 2013, 35, 174–178. [Google Scholar]

- Zhang, Y.Q.; Li, Y.; Meng, Y.Q. Wear Behavior of Spindles of Cotton Picker in Field Work. J. Tribol. 2021, 143. [Google Scholar] [CrossRef]

- Zhang, H.W. The Working Mechanism and Experimental Study of the Key Components of the Cotton Picker Head of the Glue Stick Roller; Nanjing Agricultural University: Nanjing, China, 2013. [Google Scholar]

- Pina, J.; Dias, A.; Francois, M.; Lebrun, J. Residual stresses and crystallographic texture in hard-chromium electroplated coatings. Surf. Coat. Technol. 1997, 96, 148–162. [Google Scholar] [CrossRef]

- Lee, S.L.; Capsimalis, G.P. Elastic anisotrophy and residual stress in textured production electrolytic chromium coatings on steel. Adv. X-ray Anal. 1997, 39, 257–266. [Google Scholar]

- Wang, L.; Nam, K.S.; Kwon, S.C. Effect of plasma nitriding of electroplated chromium coatings on the corrosion protection C45 mild steel. Surf. Coat. Technol. 2007, 202, 203–207. [Google Scholar] [CrossRef]

- Gouveia, R.M.; Silva, F.J.G.; Reis, P.; Baptista, A.P.M. Machining Duplex Stainless Steel: Comparative Study Regarding End Mill Coated Tools. Coatings 2016, 6, 51. [Google Scholar] [CrossRef] [Green Version]

- Weiss, B.; Lefebvre, A.; Sinot, O.; Marquer, M.; Tidu, A. Effect of grinding on the sub-surface and surface of electrodeposited chromium and steel substrate. Surf. Coat. Technol. 2015, 272, 165–175. [Google Scholar] [CrossRef]

- Lunarska, E.; Nikiforow, K.; Wierzchoń, T.; Ulbin-Pokorska, I. Effect of plasma nitriding on hydrogen behavior in electroplated chromium coating. Surf. Coat. Technol. 2001, 145, 139–145. [Google Scholar] [CrossRef]

- Yu, W.P.; Zhang, M.J.; He, Y.D. The effect of hydrogen on the structural transformation of electroplationg chromium coatings. J. Beijing Univ. Aeronaut. Astronaut. 1990, 2, 129–132. [Google Scholar]

- Korzynski, M.; Dzierwa, A.; Pacana, A.; Cwanek, J. Fatigue strength of chromium coated elements and possibility of its improvement with ball peening. Surf. Coat. Technol. 2009, 204, 615–620. [Google Scholar] [CrossRef]

- Imaz, N.; Ostra, M.; Vidal, M.; Díez, J.; Sarret, M.; García-Lecina, E. Corrosion behaviour of chromium coatings obtained by direct and reverse pulse plating electrodeposition in NaCl aqueous solution. Corros. Sci. 2014, 78, 251–259. [Google Scholar] [CrossRef]

- Dzierwa, A.; Pawlus, P.; Reizer, R. Surface Topography of Chromium Coatings after Pneumatic Ball Peening. Key Eng. Mater. 2008, 381–382, 113–116. [Google Scholar] [CrossRef]

- Korzynski, M.; Pacana, A.; Cwanek, J. Fatigue strength of chromium coated elements and possibility of its improvement with slide diamond burnishing. Surf. Coat. Technol. 2009, 203, 1670–1676. [Google Scholar] [CrossRef]

- Silva, F.; Martinho, R.; Andrade, M.; Baptista, A.; Alexandre, R. Improving the Wear Resistance of Moulds for the Injection of Glass Fibre–Reinforced Plastics Using PVD Coatings: A Comparative Study. Coatings 2017, 7, 28. [Google Scholar] [CrossRef] [Green Version]

- Brezinová, J.; Landová, M.; Guzanová, A.; Dulebová, L.; Draganovská, D. Microstructure, Wear Behavior and Corrosion Resistance of WC–FeCrAl and WC–WB–Co Coatings. Metals 2018, 8, 399. [Google Scholar] [CrossRef] [Green Version]

- Purkayastha, S.; Dwivedi, D.K. Abrasive and erosive wear performance of rare earth oxide doped Ni/WC coatings. J. Tribol. 2014, 136. [Google Scholar] [CrossRef]

- Szparaga, Ł.; Bartosik, P.; Gilewicz, A.; Mydłowska, K.; Ratajski, J. Optimisation of Mechanical Properties of Gradient Zr–C Coatings. Materials 2021, 14, 296. [Google Scholar] [CrossRef] [PubMed]

- Vladoiu, R.; Tichý, M.; Mandes, A.; Dinca, V.; Kudrna, P. Thermionic Vacuum Arc–A Versatile Technology for Thin Film Deposition and Its Applications. Coatings 2020, 10, 211. [Google Scholar] [CrossRef] [Green Version]

- De Oliveira Junior, M.M.; Costa, H.L.; Silva Junior, W.M.; De Mello, J.D. Effect of iron oxide debris on the reciprocating sliding wear of tool steels. Wear 2019, 426, 1065–1075. [Google Scholar] [CrossRef]

- Cellard, A.; Garnier, V.; Fantozzi, G. Wear resistance of chromium oxide nanostructured coatings. Ceram. Int. 2009, 35, 913–916. [Google Scholar] [CrossRef]

- Wery, M.; Feki, M.; Elleuch, K.; Wery, M.; Ayedi, H.F. Mechanical and Abrasive Wear Properties of Anodic Oxide Layers Formed on Aluminium. J. Mater. Sci. Technol. 2009, 25, 508–512. [Google Scholar]

| Parameter | Field Speed (km/h) | Front Drum Speed (rpm) | Spindle Speed (rpm) | Doffer Pads Speed (rpm) |

|---|---|---|---|---|

| Value | 0–7.1 | 0–152 | 0–4652 | 0–1960 |

| Picking Location | Picking Date | Picking Time | Temperature (°C) | Humidity (%) |

|---|---|---|---|---|

| Machine-picked cotton in Kuitun, Xinjiang, China | 2020.9.25–2020.10.18 | 8:00 a.m.–12:00 p.m. | −2.00–18.50 | 22.62–67.92 |

| Element | Fe Content (wt%) | Cr Content (wt%) | Mn Content (wt%) | Ni Content (wt%) |

|---|---|---|---|---|

| Coating | ― | 95.60 | ― | 4.40 |

| Substrate | 91.48 | ― | 6.08 | 2.44 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, Y.; Zhang, H.; Fu, X.; Wang, L.; Shen, Z.; Wang, J.; Song, Z.; Zhang, L. Experimental Wear Behavior Analysis of Coated Spindle Hook Teeth under Real Harvesting Work Conditions. Materials 2021, 14, 2487. https://doi.org/10.3390/ma14102487

Gu Y, Zhang H, Fu X, Wang L, Shen Z, Wang J, Song Z, Zhang L. Experimental Wear Behavior Analysis of Coated Spindle Hook Teeth under Real Harvesting Work Conditions. Materials. 2021; 14(10):2487. https://doi.org/10.3390/ma14102487

Chicago/Turabian StyleGu, Yanqing, Hongwen Zhang, Xiuqing Fu, Lei Wang, Zhenyu Shen, Jun Wang, Zhaoyang Song, and Longchang Zhang. 2021. "Experimental Wear Behavior Analysis of Coated Spindle Hook Teeth under Real Harvesting Work Conditions" Materials 14, no. 10: 2487. https://doi.org/10.3390/ma14102487