Novel Repair Procedure for CFRP Components Instead of EOL

Abstract

:1. Introduction

- (1)

- ‘Matrix-repair’ can be used if the damage of the composite is narrowed to the matrix and the fibers are all intact. The matrix is then removed completely from the affected area, leaving the dry fibers that remain in it. After a surface activation, the repair site can be thermoset-reinfiltrated, and the composite can be restored without cutting any fiber.

- (2)

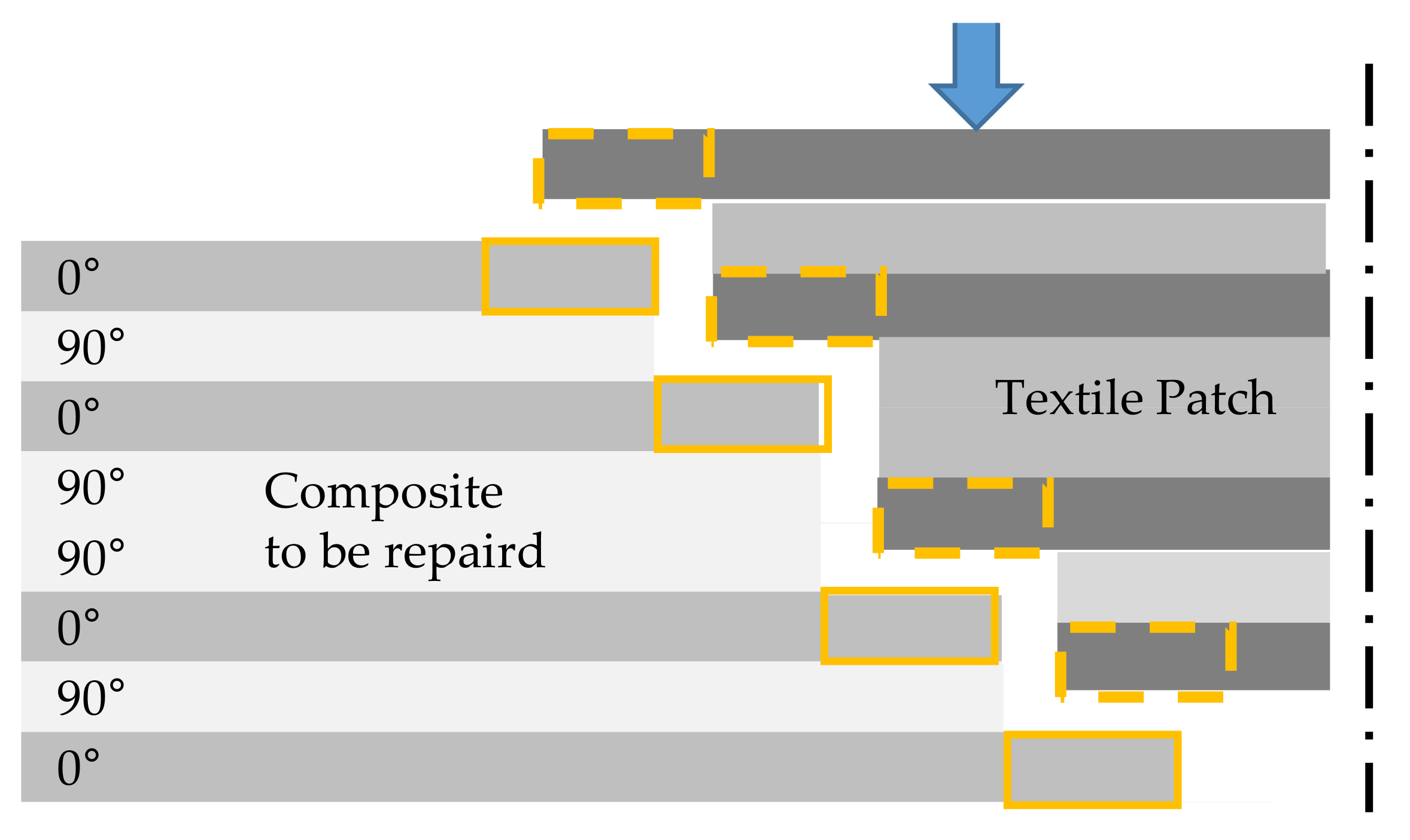

- ‘Patch-repair’ can be used if both components of the composite are damaged, i.e., the fibers and the matrix. The matrix is removed initially in the affected area as in the first scenario. Subsequently, defective CF can be removed. The fibers are cut manually and staggered. A textile patch is fitted in the prepared gradation, and the area is re-infiltrated to restore the composite.

2. Materials and Methods

2.1. Materials

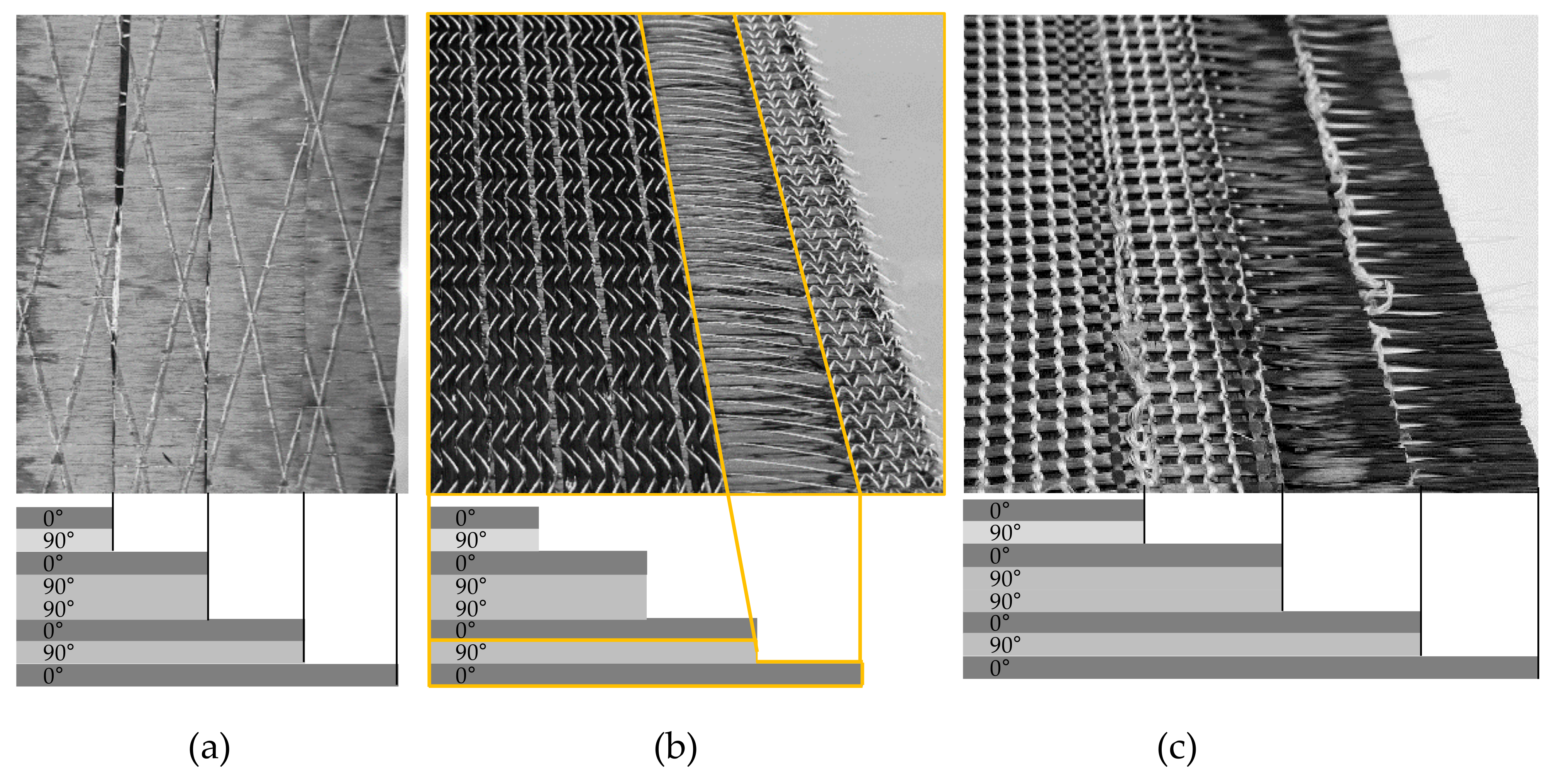

- CNC-cutting and stacking of the UD material (UD): The UD patches were CNC-cut-outs from a roll of UD material with 151 g/m2 areal weight. The CF is fixed by an adhesive thread grid on the back side. After CNC-cutting eight single plies, they were stacked and thermo-bonded with each other (Figure 1a).

- Tailored fiber placement (TFP): The CF was embroidered onto a thermostable film using Grilon KE85, 166 dtex fusible adhesive thread and thus fixed. Four patch-structures with two layers (0/90°) were produced (Figure 1b). In a downstream process, the patch was fixed by heating above 85 °C through the melting of the fusible adhesive yarn so that the embroidery base could be easily removed.

- Multilayer weft knitting (MLG): The four biaxial reinforced repair-patches were knitted in one piece and subsequently divided into four structures. The stacked patch-structure can be seen in Figure 1c. In the edge areas, the stitch thread was thermo-bonded to prevent the mesh thread from unraveling.

2.2. Methods

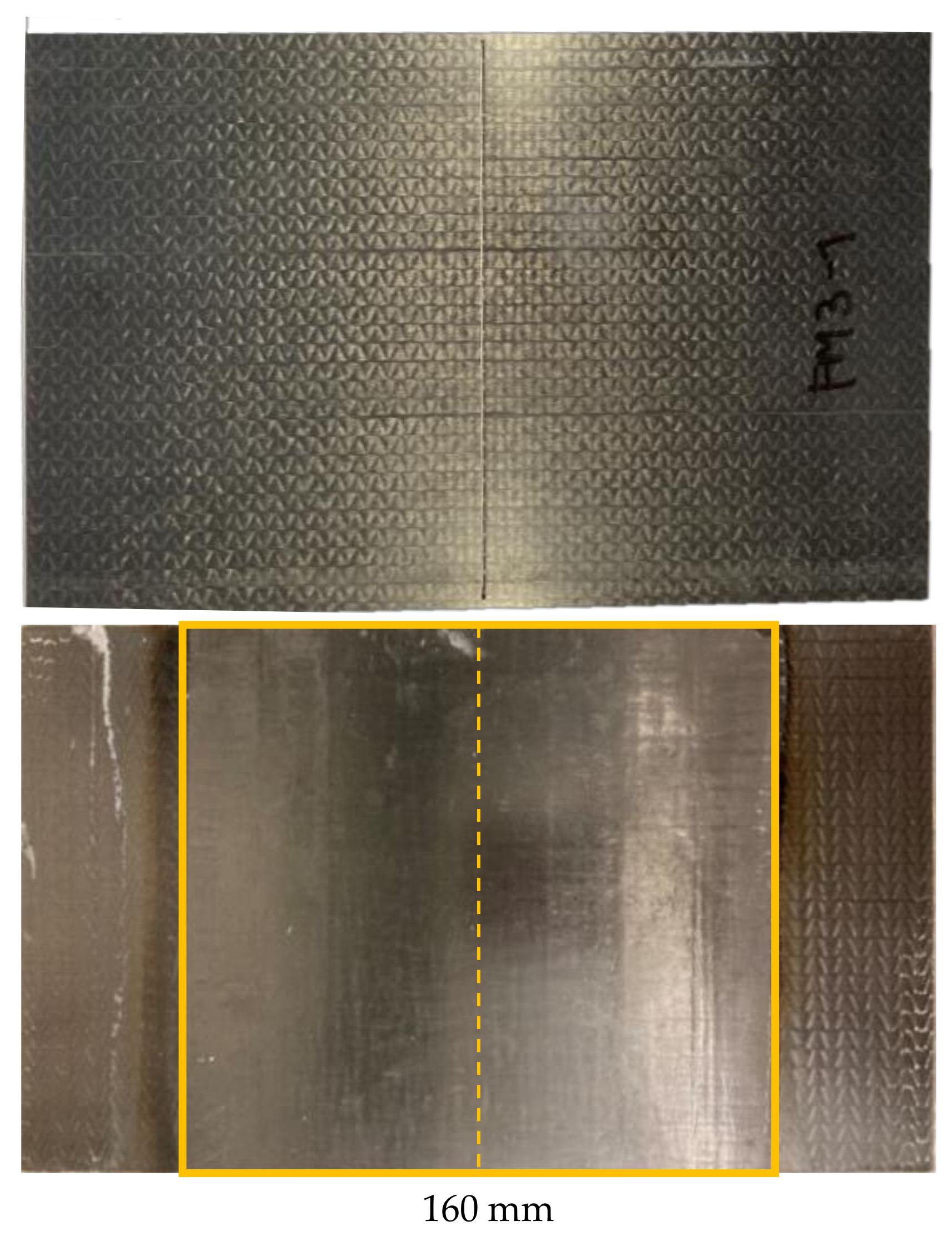

2.2.1. Matrix-Repair

- 0×—cleaned by plasma torch and surface-activated,

- 1×—cleaned, surface-activated and coated in a single cycle by plasma torch,

- 2×—cleaned and surface-activated and coated in a double cycle by plasma torch.

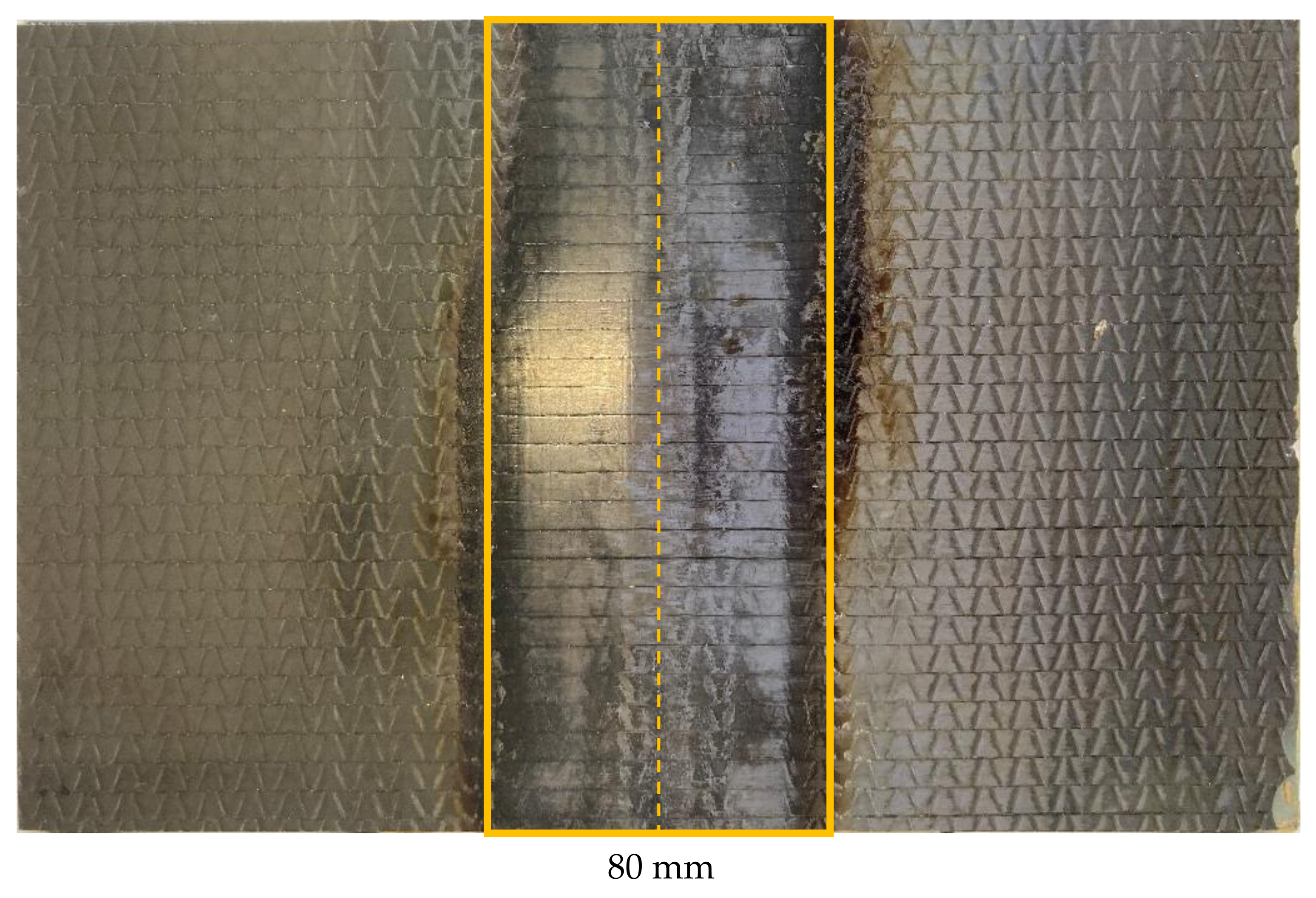

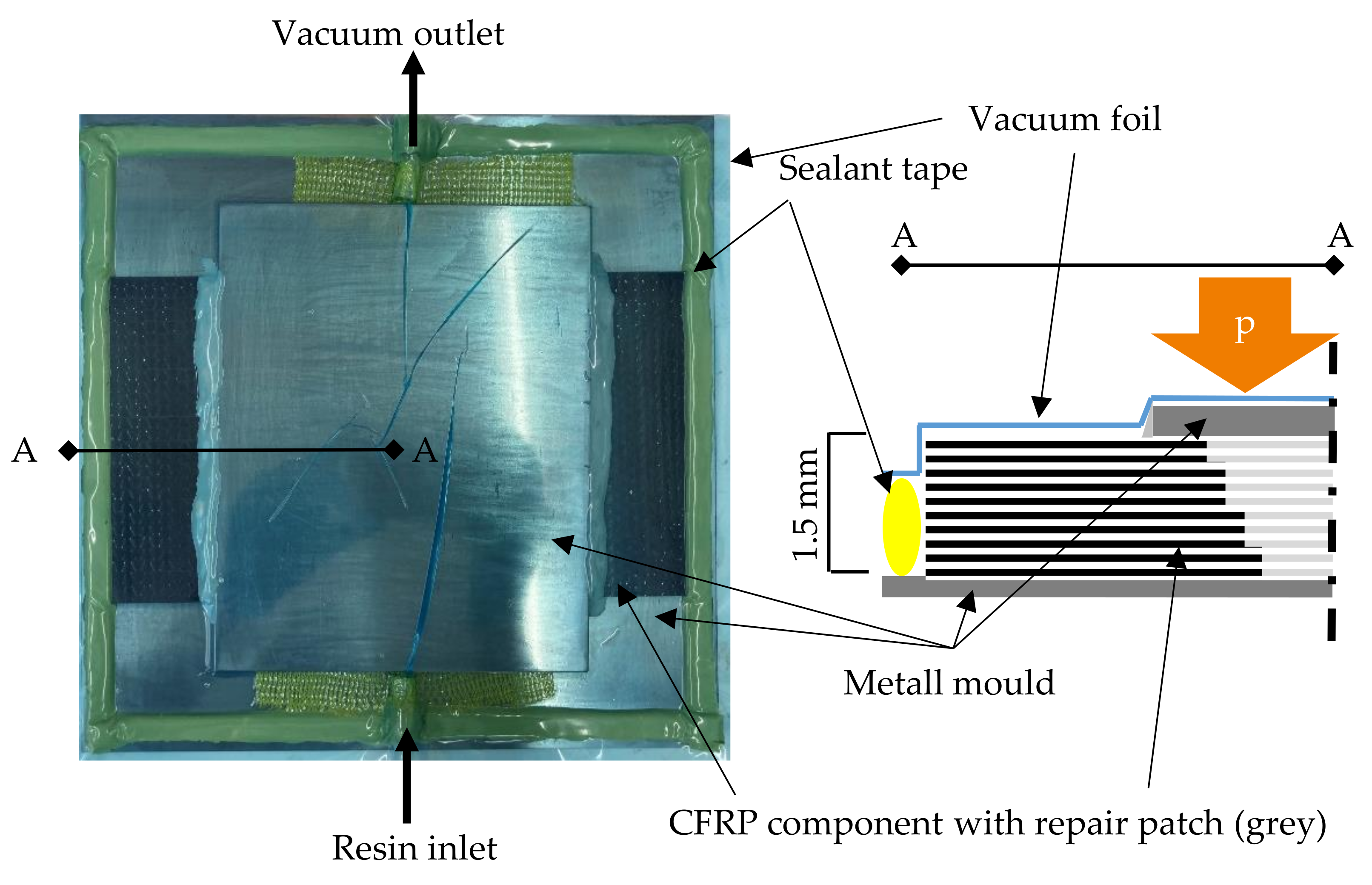

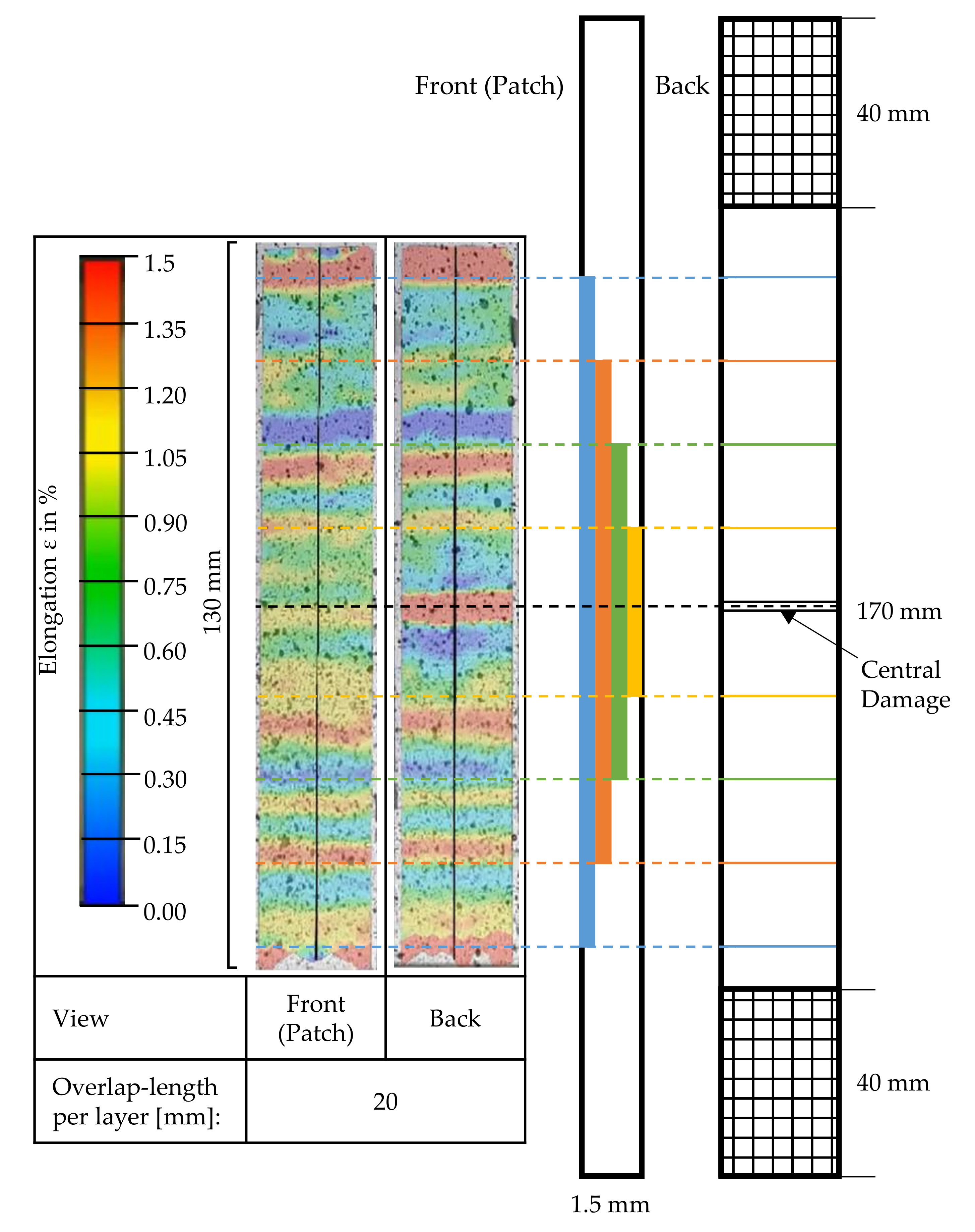

2.2.2. Patch-Repair

2.2.3. Tensile Testing (DIN EN ISO 527-4)

2.2.4. Digital Image Correlation (DIC)

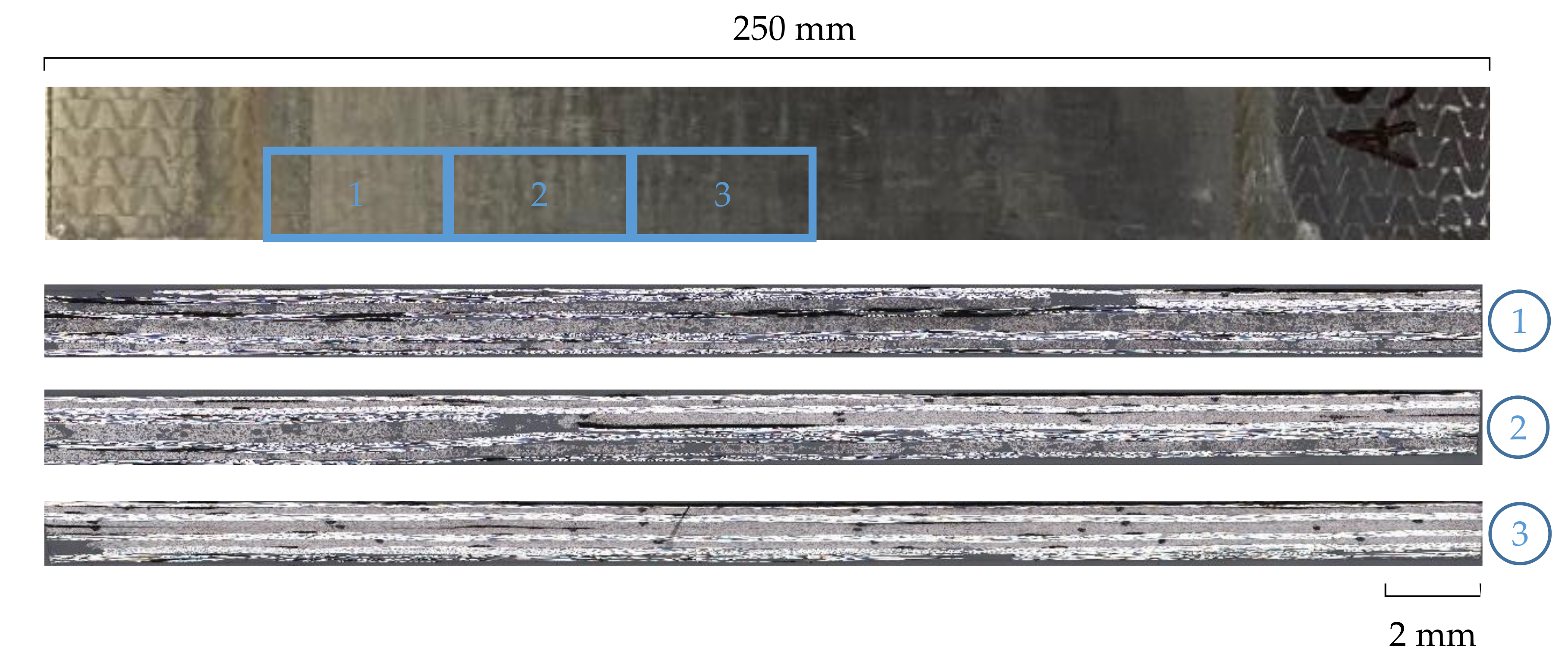

2.2.5. Light Microscopy

3. Results

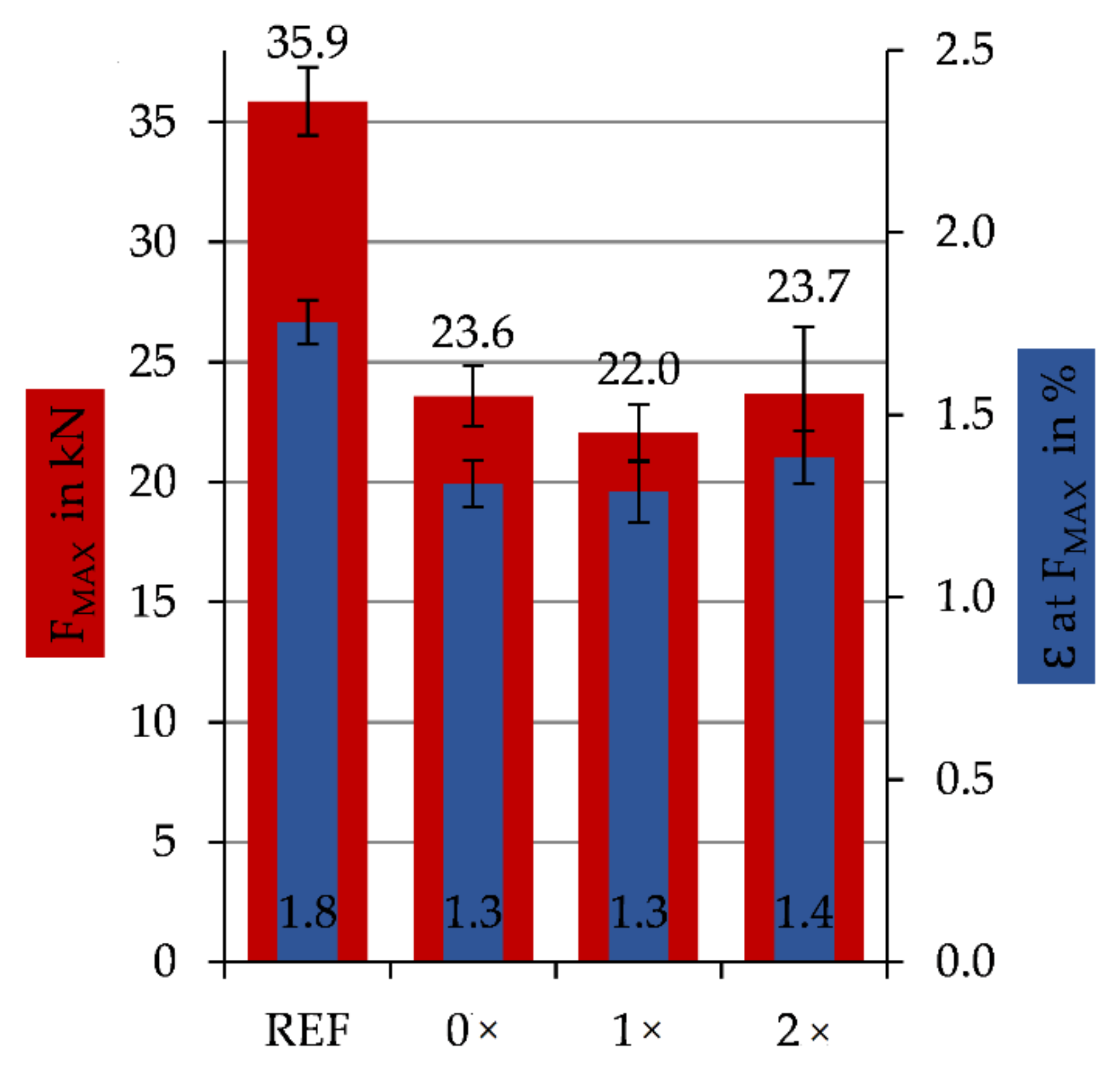

3.1. Investigation of the Influence of the UV-Radiation-Treatment, Resizing and Re-Infiltrating (Matrix-Repair)

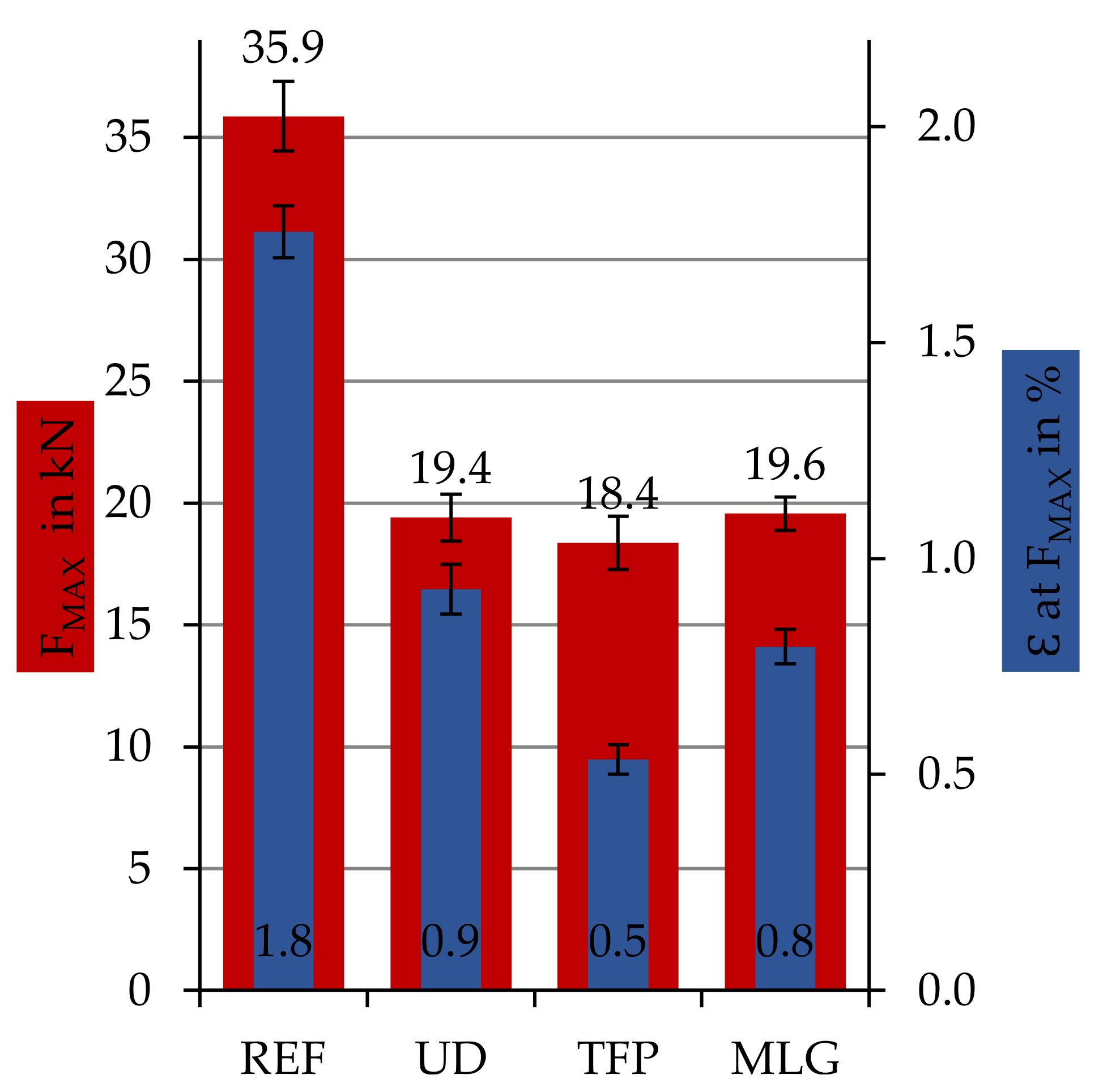

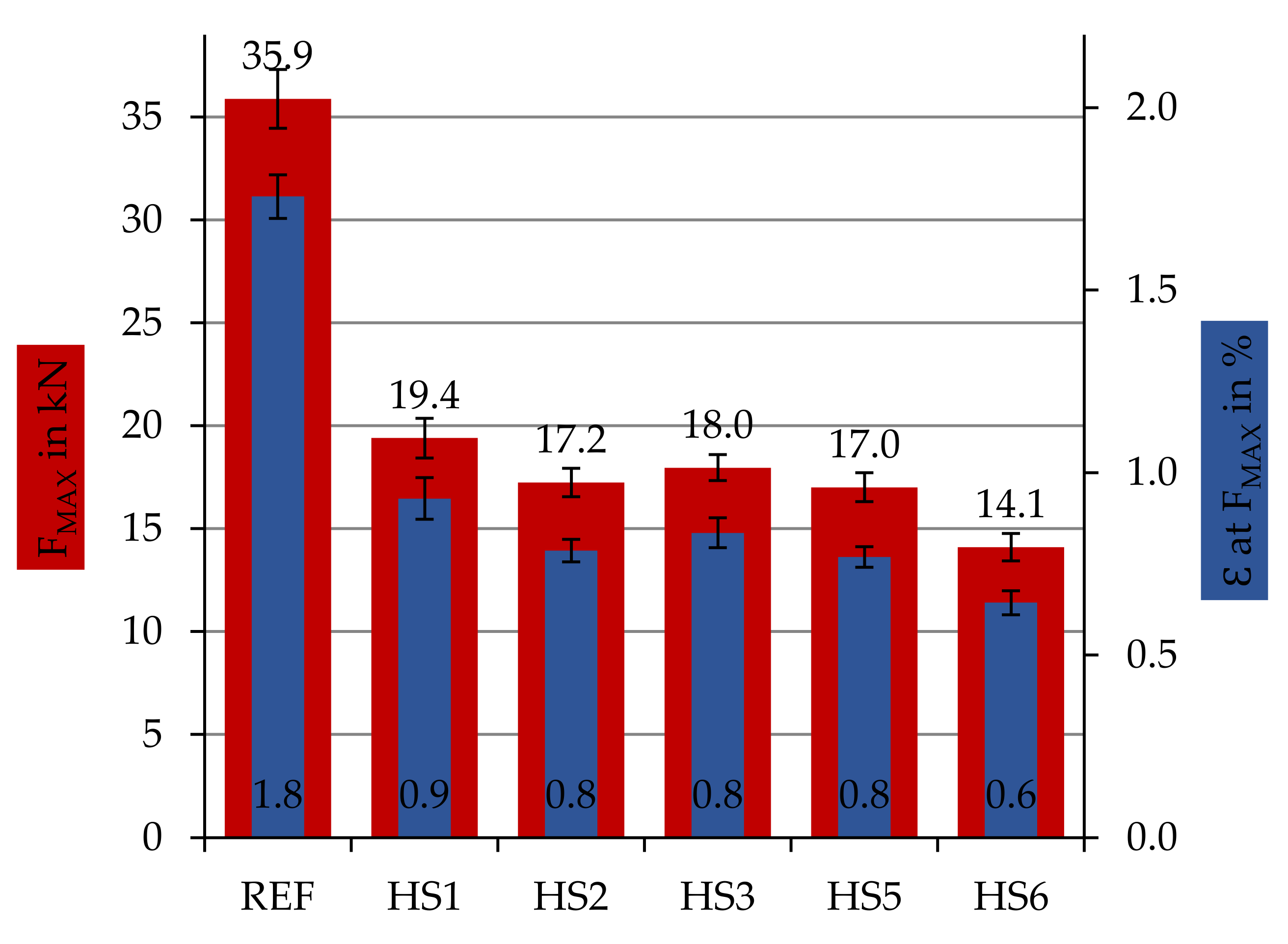

3.2. Investigation of the ‘Patch-Repair’ with Different Patches Made with Different Textile Procedures

3.3. Investigation of the Repair with Different Resin Materials

4. Discussion

4.1. Matrix-Repair

4.2. Patch-Repair

4.2.1. Influence of Repair Patch

4.2.2. Influence of Repair Matrix-System

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lefeuvre, A.; Garnier, S.; Jacquemin, L.; Pillain, B.; Sonnemann, G. Anticipating in-use stocks of carbon fiber reinforced polymers and related waste flows generated by the commercial aeronautical sector until 2050. Resour. Conserv. Recycl. 2017, 125, 264–272. [Google Scholar] [CrossRef]

- Lefeuvre, A.; Garnier, S.; Jacquemin, L.; Pillain, B.; Sonnemann, G. Anticipating in-use stocks of carbon fibre reinforced polymers and related waste generated by the wind power sector until 2050. Resour. Conserv. Recycl. 2019, 141, 30–39. [Google Scholar] [CrossRef]

- Jacob, A. Carbon fibre and cars—2013 in review. Reinf. Plast. 2014, 58, 18–19. [Google Scholar] [CrossRef]

- Kim, Y.J. (Ed.) Advanced Composites in Bridge Construction and Repair; Elsevier Science: Burlington, VT, USA, 2014; ISBN 978-0-85709-694-4. [Google Scholar]

- Xiong, W.; Cai, C.S.; Xiao, R.C. 8—The use of carbon fiber-reinforced polymer (CFRP) composites for cable-stayed bridges. In Advanced Composites in Bridge Construction and Repair; Kim, Y.J., Ed.; Elsevier Science: Burlington, VT, USA, 2014; pp. 210–264. ISBN 978-0-85709-694-4. [Google Scholar]

- McConnell, V.P. Past is prologue for composite repair. Reinf. Plast. 2011, 55, 17–21. [Google Scholar] [CrossRef]

- Campilho, R.; de Moura, M.; Pinto, A.; Morais, J.; Domingues, J. Modelling the tensile fracture behaviour of CFRP scarf repairs. Compos. Eng. 2009, 40, 149–157. [Google Scholar] [CrossRef]

- Gründer, M. Neues Reparaturverfahren. 6 February 2019. Available online: https://www.flugrevue.de/flugzeugbau/neues-reparaturverfahren-reparatur-von-cfk-bauteilen-bei-lufthansa-technik/ (accessed on 16 March 2021).

- Schmutzler, H. Repair Robot—Aircraft Composites | Lufthansa Technik. Available online: https://www.lufthansa-technik.com/caire-repair-robot (accessed on 16 March 2021).

- Pantelakis, S.; Tserpes, K. Revolutionizing Aircraft Materials and Processes, 1st ed.; Springer International Publishing Imprint: Cham, Switzerland, 2020; ISBN 9783030353469. [Google Scholar]

- Harder, S.; Röper, F.; Gibhardt, D.; Koert, B.; Fiedler, B. Strength of scarf-bonded CFRP repairs containing disc-shaped zones of weak bonding considering hot-wet conditioning. Int. J. Adhes. Adhes. 2020, 102, 102643. [Google Scholar] [CrossRef]

- Kim, H.-J.; Kim, H.-S.; Lee, G.-Y.; Kim, M.-S.; Min, S.-H.; Keller, R.; Ihn, J.-B.; Ahn, S.-H. Three-dimensional carbon fiber composite printer for CFRP repair. Compos. Eng. 2019, 174, 106945. [Google Scholar] [CrossRef]

- Heslehurst, R.B. Engineered Repairs of Composite Structures, 1st ed.; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2019; ISBN 9780429198656. [Google Scholar]

- Hoshi, H.; Nakano, K.; Iwahori, Y. Study on Repair of CFRP Laminates for Aircraft Structures. In Proceedings of the 16th International Conference on Composite Materials, Kyoto, Japan, 3–8 July 2007. [Google Scholar]

- Day, R. (Ed.) Proceedings of the Second International Workshop on Advanced Composite Materials and Technologies for Aerospace Applications, Wrexham, UK, 11–13 June 2012; North East Wales Institute: Wrexham, UK, 2012; ISBN 978-0-946881-76-5. [Google Scholar]

- Böhnke, P.R.C.; Kruppke, I.; Hoffmann, D.; Richter, M.; Häntzsche, E.; Gereke, T.; Kruppke, B.; Cherif, C. Matrix Decomposition of Carbon-Fiber-Reinforced Plastics via the Activation of Semiconductors. Materials 2020, 13, 3267. [Google Scholar] [CrossRef] [PubMed]

- Deutsches Institut für Normung. DIN EN ISO 527-4 Bestimmung der Zugeigenschaften, Entwurf; Beuth Verlag GmbH: Berlin, Germany, 2020. [Google Scholar]

| Name | Resin System | Components | Gravimetric Ratio |

|---|---|---|---|

| HS1 | Reference | RIMR135 | 100 |

| RIMH134 | 30 | ||

| HS2 | Reference + Additives 1 | RIMR135 | 100 |

| RIMH134 | 30 | ||

| BYK-C 8013 | 5% of mass of matrix | ||

| BYK-P 9920 | 1.5% of mass of matrix | ||

| HS3 | Leuna-Resin 1 | ER0051 | 100 |

| EC0052 | 25 | ||

| HS5 | Reference + Additives 2 | RIMR135 | 100 |

| RIMH134 | 30 | ||

| BYK-C 8013 | 10% of mass of matrix | ||

| BYK-P 9920 | 3% of mass of matrix | ||

| HS6 | Leuna-Resin 1 + Additives | ER0051 | 100 |

| EC0052 | 30 | ||

| BYK-C 8013 | 5% of mass of matrix | ||

| BYK-P 9920 | 1.5% of mass of matrix |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rabe, D.; Böhnke, P.R.C.; Kruppke, I.; Häntzsche, E.; Cherif, C. Novel Repair Procedure for CFRP Components Instead of EOL. Materials 2021, 14, 2711. https://doi.org/10.3390/ma14112711

Rabe D, Böhnke PRC, Kruppke I, Häntzsche E, Cherif C. Novel Repair Procedure for CFRP Components Instead of EOL. Materials. 2021; 14(11):2711. https://doi.org/10.3390/ma14112711

Chicago/Turabian StyleRabe, David, Philippa Ruth Christine Böhnke, Iris Kruppke, Eric Häntzsche, and Chokri Cherif. 2021. "Novel Repair Procedure for CFRP Components Instead of EOL" Materials 14, no. 11: 2711. https://doi.org/10.3390/ma14112711