Charpy Impact Behavior of a Novel Stainless Steel Powder Wire Mesh Composite Porous Plate

Abstract

1. Introduction

2. Materials and Methods

2.1. Manufacturing Processes of the PWMCPPs

2.2. Surface Morphology and Charpy Impact Characterization of the PWMCPPs

3. Results and Discussion

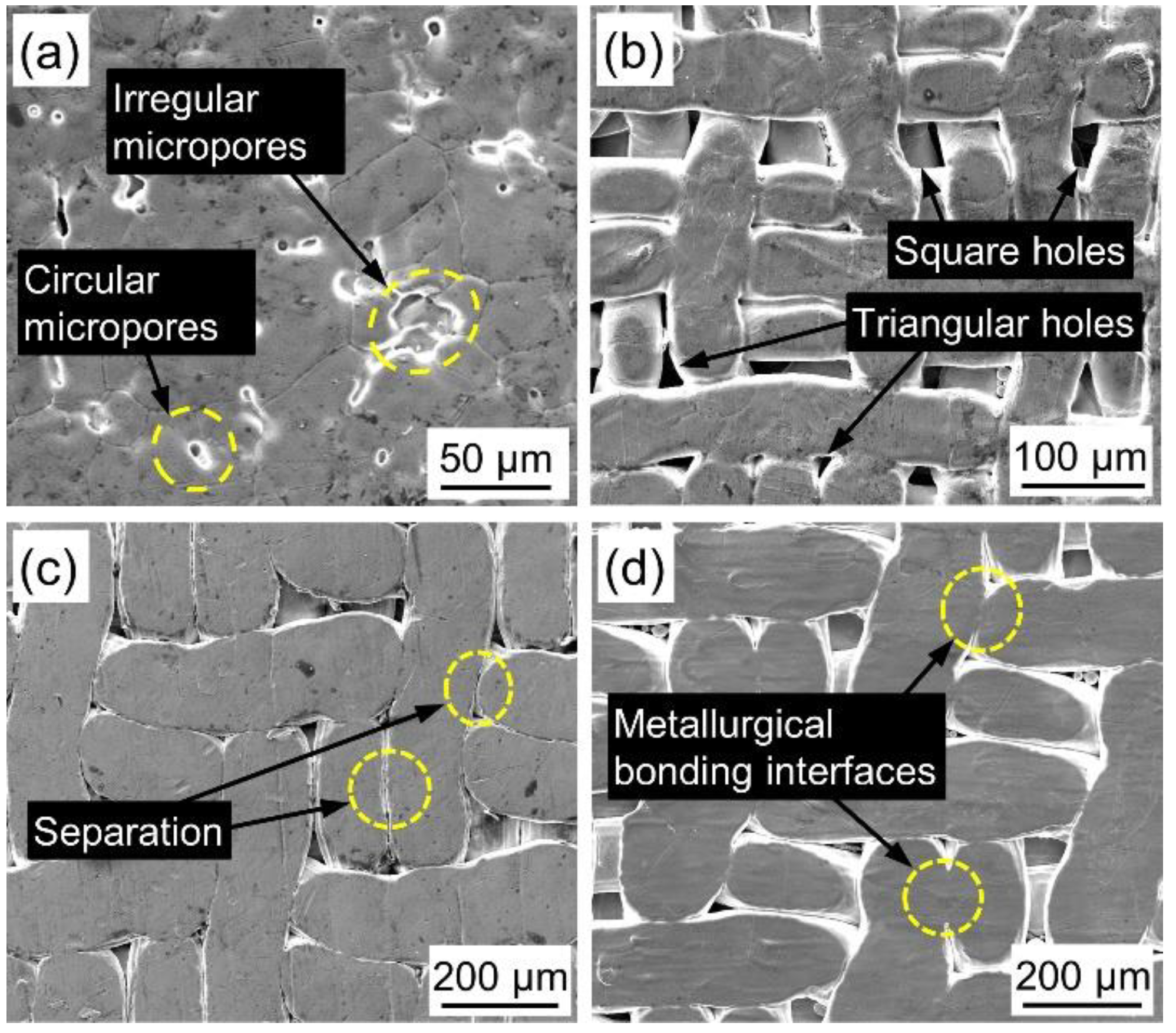

3.1. Surface Morphology of Novel PWMCPPs

3.2. Charpy Impact Properties of Novel PWMCPPs

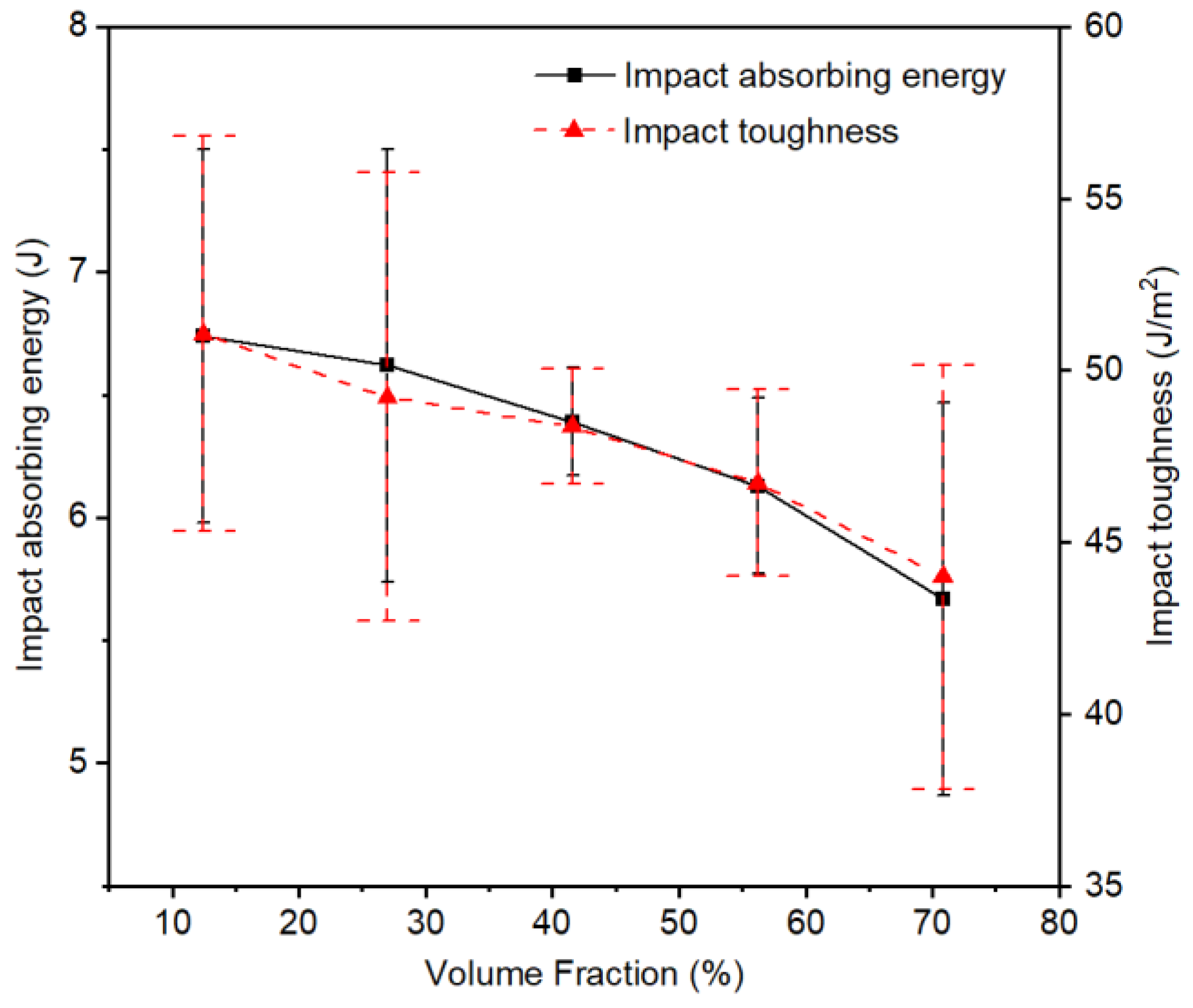

3.2.1. Effect of Wire Mesh Volume Fraction on Charpy Impact Properties

3.2.2. Effect of Wire Mesh Diameter on Charpy Impact Properties

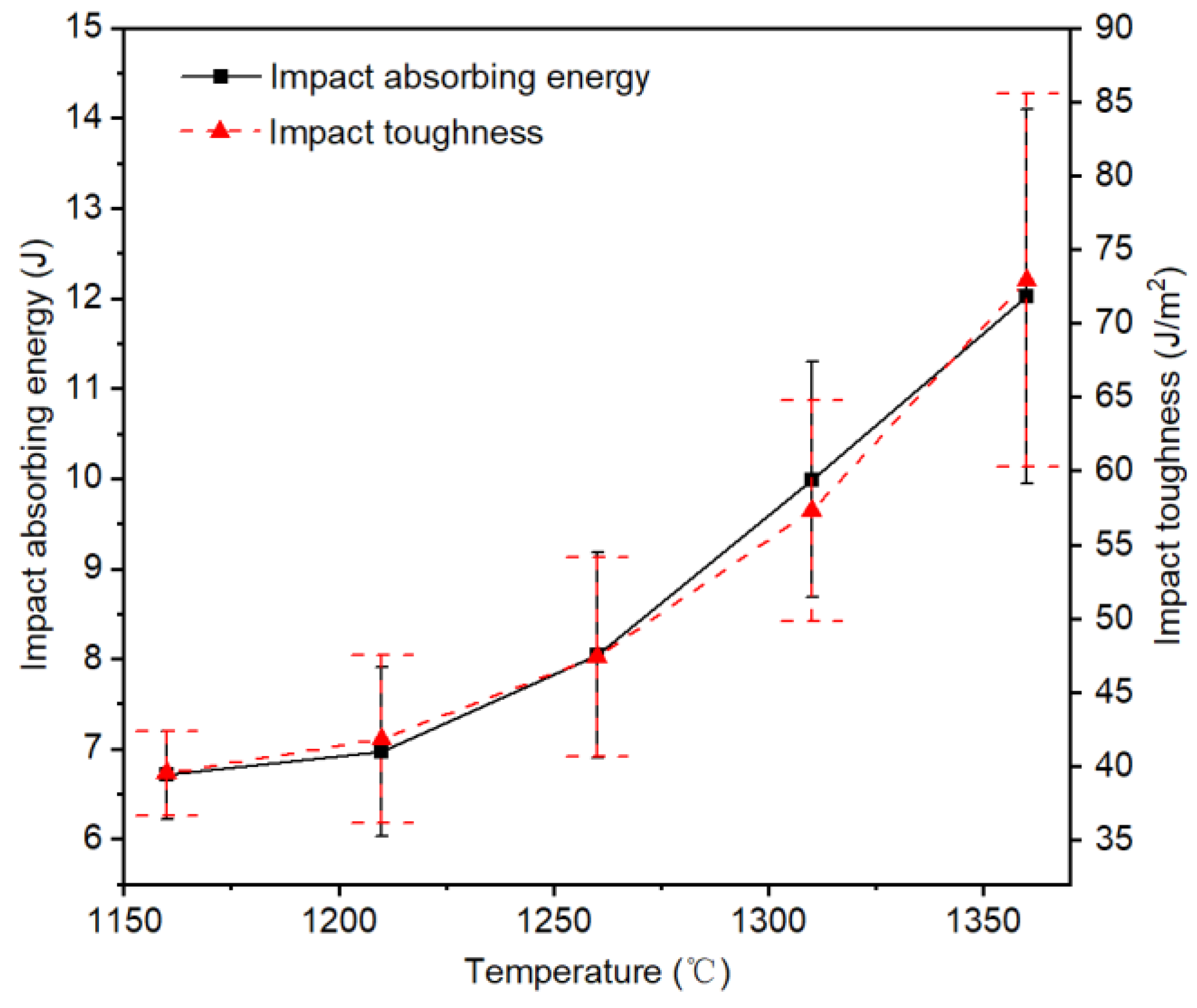

3.2.3. Effect of Sintering Temperature on Charpy Impact Properties

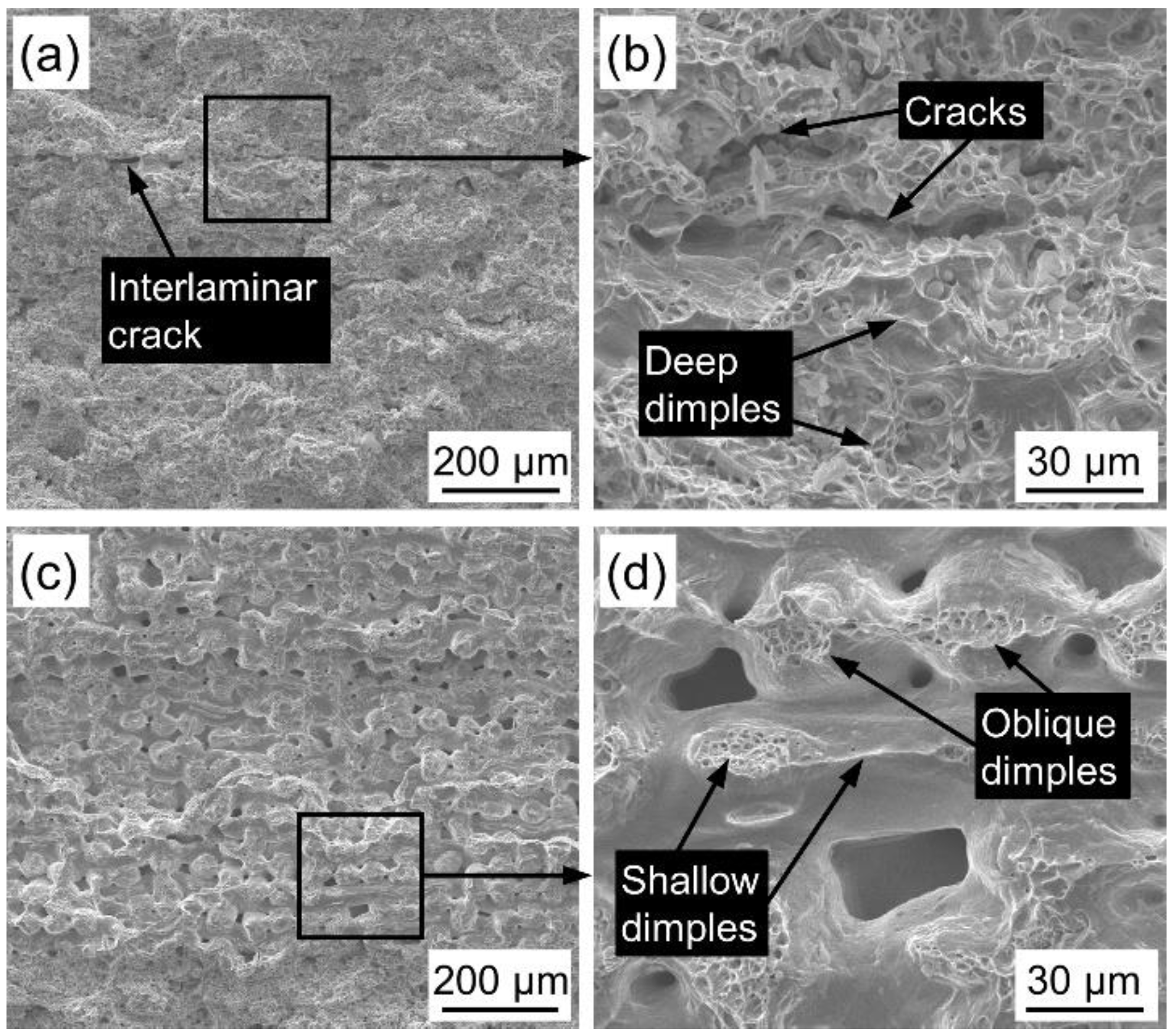

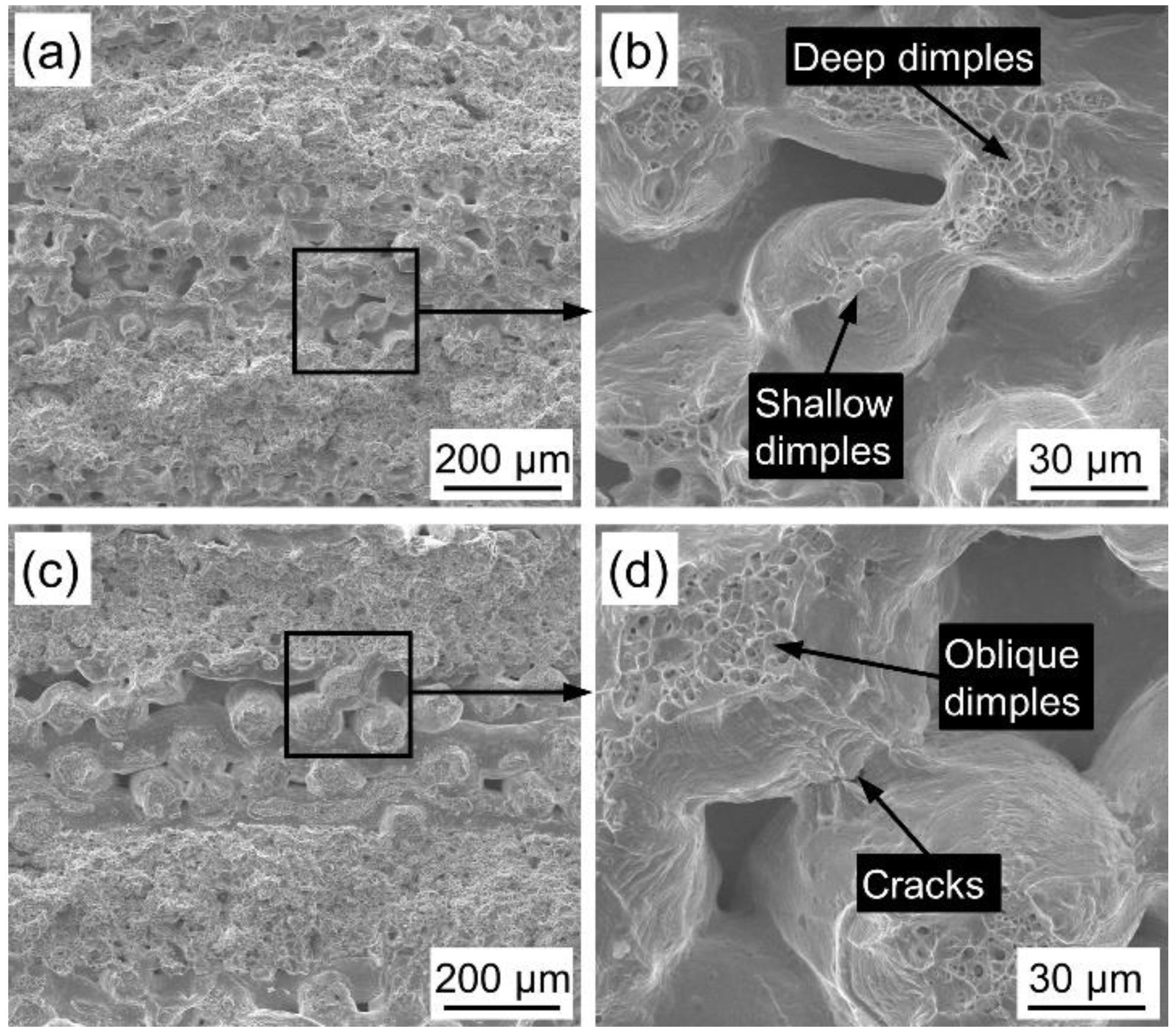

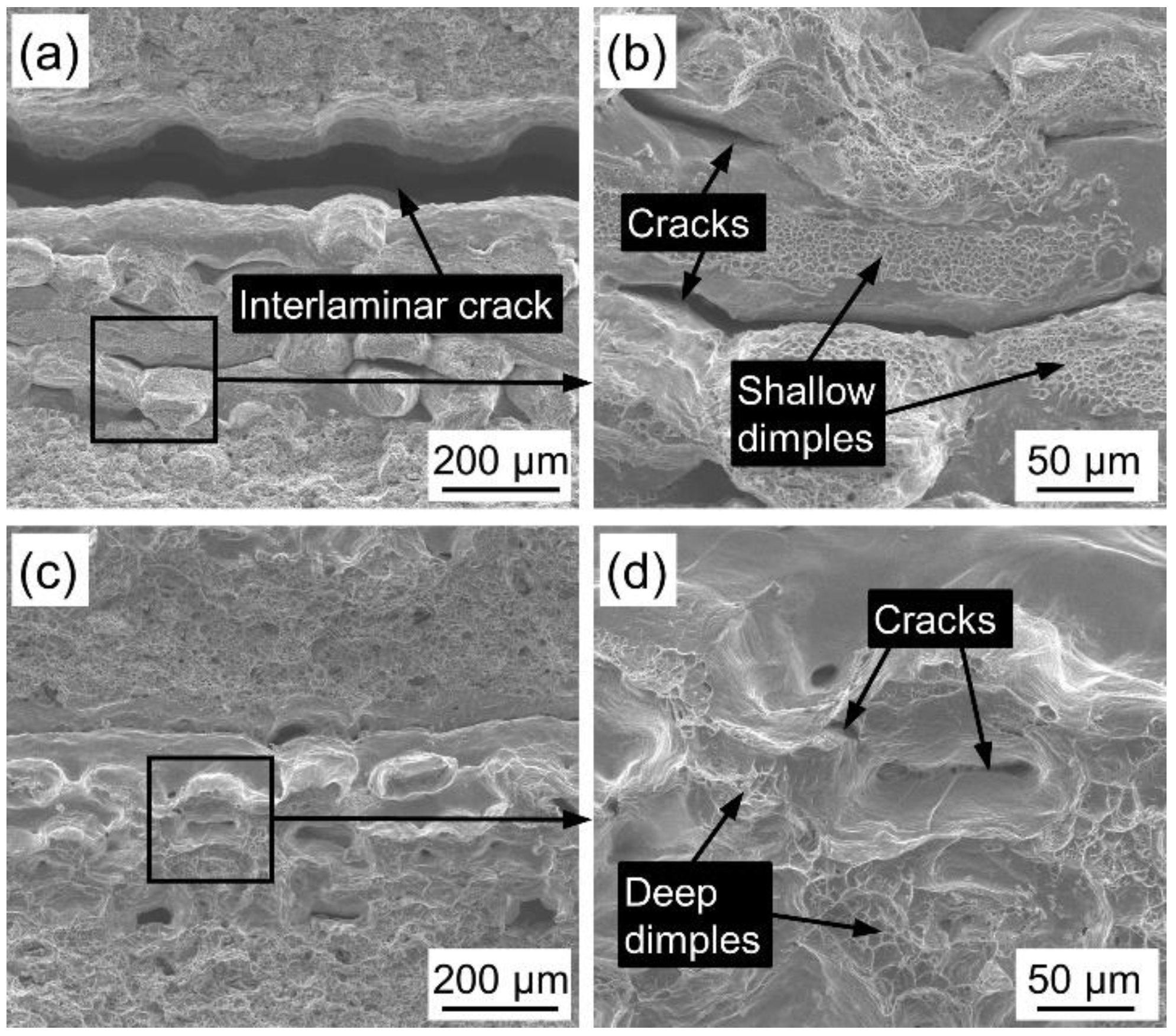

3.3. Charpy Impact Fracture Morphology

4. Conclusions

- (1)

- In this paper, a novel PWMCPP was fabricated by the composite rolling and vacuum solid-state sintering of 304 stainless steel powder and wire mesh as raw materials. SEM images show that PWMCPPs have different shapes and sizes of micropores.

- (2)

- The effects of different wire mesh volume fractions, mesh diameters, and sintering temperatures on the Charpy impact properties of PWMCPPs were studied. The results show that the impact toughness of PWMCPPs decreases with increasing wire mesh volume fraction, and increases first and then decreases with increasing wire mesh diameter, and increases with increasing sintering temperature. Among them, the sintering temperature has the most obvious effect on the impact toughness of PWMCPPs. When the sintering temperature increased from 1160 °C to 1360 °C, the impact toughness increased from 39.54 J/cm2 to 72.95 J/cm2, with an increased ratio of 84.5%.

- (3)

- The macroscopic image of PWMCPPs after impact testing shows a large plastic deformation, which indicates that PWMCPPs have an obvious ductile fracture mechanism.

- (4)

- The mechanism of microscopic impact damage was mainly manifested as the tearing of metallurgical joint between powder and wire mesh layer, between powder and powder, and between wire mesh and wire mesh, and fracture of the wire mesh. Interlaminar cracks, tearing fractures, and oblique dimples were the main characteristics of impact fracture morphology of PWMCPPs.

- (5)

- Low volume fraction and small diameter of wire mesh and sintering temperature over 1310 °C were beneficial for PWMCPPs to obtain higher impact toughness. Based on the porous structure and impact toughness of PWMCPPs, further research is planned on its application in energy absorption, vibration reduction, filtration, and other fields.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Qin, J.; Chen, Q.; Yang, C.; Huang, Y. Research process on property and application of metal porous materials. J. Alloys Compd. 2016, 654, 39–44. [Google Scholar] [CrossRef]

- Lee, J.M.; Sung, N.W.; Cho, G.B.; Oh, K.O. Performance of radial-type metal foam diesel particulate filters. Int. J. Automot. Technol. 2010, 11, 307–316. [Google Scholar] [CrossRef]

- Liu, W.; Canfield, N. Development of thin porous metal sheet as micro-filtration membrane and inorganic membrane support. J. Membr. Sci. 2012, 409, 113–126. [Google Scholar] [CrossRef]

- Zhu, B.; Duke, M.; Dumee, L.F.; Merenda, A.; des Ligneris, E.; Kong, L.; Hodgson, P.D.; Gray, S. Short Review on Porous Metal Membranes-Fabrication, Commercial Products, and Applications. Membranes 2018, 8, 83. [Google Scholar] [CrossRef]

- Du, H.; Lu, D.; Qi, J.; Shen, Y.; Yin, L.; Wang, Y.; Zheng, Z.; Xiong, T. Heat Dissipation Performance of Porous Copper with Elongated Cylindrical Pores. J. Mater. Sci. Technol. 2014, 30, 934–938. [Google Scholar] [CrossRef]

- Jung, S.M.; Preston, D.J.; Jung, H.Y.; Deng, Z.; Wang, E.N.; Kong, J. Porous Cu Nanowire Aerosponges from One-Step Assembly and their Applications in Heat Dissipation. Adv. Mater. 2016, 28, 1413–1419. [Google Scholar] [CrossRef]

- Wang, H.; Wang, F.; Li, Z.; Tang, Y.; Yu, B.; Yuan, W. Experimental investigation on the thermal performance of a heat sink filled with porous metal fiber sintered felt/paraffin composite phase change material. Appl. Energy 2016, 176, 221–232. [Google Scholar] [CrossRef]

- Shen, X.; Bai, P.; Yang, X.; Zhang, X.; To, S. Low Frequency Sound Absorption by Optimal Combination Structure of Porous Metal and Microperforated Panel. Appl. Sci. 2019, 9, 1507. [Google Scholar] [CrossRef]

- Yang, X.; Shen, X.; Bai, P.; He, X.; Zhang, X.; Li, Z.; Chen, L.; Yin, Q. Preparation and Characterization of Gradient Compressed Porous Metal for High-Efficiency and Thin-Thickness Acoustic Absorber. Materials 2019, 12, 1413. [Google Scholar] [CrossRef]

- Ring, T.P.; Langer, S.C. Design, Experimental and Numerical Characterization of 3D-Printed Porous Absorbers. Materials 2019, 12, 3397. [Google Scholar] [CrossRef] [PubMed]

- Teruna, C.; Manegar, F.; Avallone, F.; Ragni, D.; Casalino, D.; Carolus, T. Noise reduction mechanisms of an open-cell metal-foam trailing edge. J. Fluid Mech. 2020, 898, A18. [Google Scholar] [CrossRef]

- Fujibayashi, S.; Takemoto, M.; Neo, M.; Matsushita, T.; Kokubo, T.; Doi, K.; Ito, T.; Shimizu, A.; Nakamura, T. A novel synthetic material for spinal fusion: A prospective clinical trial of porous bioactive titanium metal for lumbar interbody fusion. Eur. Spine J. 2011, 20, 1486–1495. [Google Scholar] [CrossRef]

- Muth, J.; Poggie, M.; Kulesha, G.; Michael Meneghini, R. Novel Highly Porous Metal Technology in Artificial Hip and Knee Replacement: Processing Methodologies and Clinical Applications. JOM 2012, 65, 318–325. [Google Scholar] [CrossRef]

- Wu, S.; Liu, X.; Yeung, K.W.K.; Liu, C.; Yang, X. Biomimetic porous scaffolds for bone tissue engineering. Mater. Sci. Eng. R Rep. 2014, 80, 1–36. [Google Scholar] [CrossRef]

- Dumee, L.F.; She, F.; Duke, M.; Gray, S.; Hodgson, P.; Kong, L. Fabrication of Meso-Porous Sintered Metal Thin Films by Selective Etching of Silica Based Sacrificial Template. Nanomaterials 2014, 4, 686–699. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.; Li, G.Z.; Xiang, C.S.; Zhao, S.Y.; Tan, P.; Tang, H.P.; Cao, P. Characterisation and properties of powder-rolled porous Ti sheets and IrO2/Ti electrodes. Powder Metall. 2016, 59, 249–255. [Google Scholar] [CrossRef]

- Pan, M.; Dong, G.; Huang, P.; Wang, H. Laser sintering and laser parameters optimization for porous foam microchannel reactor. J. Mater. Process. Technol. 2018, 262, 299–307. [Google Scholar] [CrossRef]

- Liu, J.; Gao, Y.; Fan, Y.; Zhou, W. Fabrication of porous metal by selective laser melting as catalyst support for hydrogen production microreactor. Int. J. Hydrog. Energy 2020, 45, 10–22. [Google Scholar] [CrossRef]

- Ma, C.C.; Lan, F.C.; Chen, J.Q.; Liu, J.; Zeng, F.B. Automobile crashworthiness improvement by energy-absorbing characterisation of aluminium foam porosity. Mater. Res. Innov. 2015, 19, S109–S112. [Google Scholar] [CrossRef]

- Straffelini, G.; Molinari, A.; Danninger, H. Impact notch toughness of high-strength porous steels. Mater. Sci. Eng. A 1999, 272, 300–309. [Google Scholar] [CrossRef]

- Liu, P.; He, G.; Wu, L.H. Impact behavior of entangled steel wire material. Mater. Charact. 2009, 60, 900–906. [Google Scholar] [CrossRef]

- Zhao, Y.; Yang, Z.; Yu, T.; Xin, D. Mechanical properties and energy absorption capabilities of aluminium foam sandwich structure subjected to low-velocity impact. Constr. Build. Mater. 2021, 273, 121996. [Google Scholar] [CrossRef]

- Wu, M.W.; Tsao, L.C.; Shu, G.J.; Lin, B.H. The effects of alloying elements and microstructure on the impact toughness of powder metal steels. Mater. Sci. Eng. A 2012, 538, 135–144. [Google Scholar] [CrossRef]

- Zou, S.; Wan, Z.; Lu, L.; Tang, Y. Experimental Study on Tensile Properties of a Novel Porous Metal Fiber/Powder Sintered Composite Sheet. Materials 2016, 9, 712. [Google Scholar] [CrossRef]

- Yao, B.; Zhou, Z.; Duan, L.; Xiao, Z. Compressibility of 304 Stainless Steel Powder Metallurgy Materials Reinforced with 304 Short Stainless Steel Fibers. Materials 2016, 9, 161. [Google Scholar] [CrossRef]

- Zhou, Z.; Duan, L.; Wu, F. Investigation of Charpy impact behavior of porous twisted wire material. J. Mater. Res. 2017, 32, 2276–2285. [Google Scholar] [CrossRef]

- Asl, M.S.; Namini, A.S.; Motallebzadeh, A.; Azadbeh, M. Effects of sintering temperature on microstructure and mechanical properties of spark plasma sintered titanium. Mater. Chem. Phys. 2018, 203, 266–273. [Google Scholar] [CrossRef]

- Veyhl, C.; Fiedler, T.; Jehring, U.; Andersen, O.; Bernthaler, T.; Belova, I.V.; Murch, G.E. On the mechanical properties of sintered metallic fibre structures. Mater. Sci. Eng. A 2013, 562, 83–88. [Google Scholar] [CrossRef]

- Jiang, G.; He, G. Enhancement of the porous titanium with entangled wire structure for load-bearing biomedical applications. Mater. Des. 2014, 56, 241–244. [Google Scholar] [CrossRef]

- Ismail, M.H.; Goodall, R.; Davies, H.A.; Todd, I. Porous NiTi alloy by metal injection moulding/sintering of elemental powders: Effect of sintering temperature. Mater. Lett. 2012, 70, 142–145. [Google Scholar] [CrossRef]

- Li, J.; Mao, Q.; Nie, J.; Huang, Z.; Wang, S.; Li, Y. Impact property of high-strength 316L stainless steel with heterostructures. Mater. Sci. Eng. A 2019, 754, 457–460. [Google Scholar] [CrossRef]

- Shanmugam, K.; Lakshminarayanan, A.K.; Balasubramanian, V. Tensile and Impact Properties of Shielded Metal Arc Welded AISI 409M Ferritic Stainless Steel Joints. J. Mater. Sci. Technol. 2009, 25, 181–186. [Google Scholar] [CrossRef]

- Suri, P.; Smarslok, B.P.; German, R.M. Impact properties of sintered and wrought 17-4 PH stainless steel. Powder Metall. 2013, 49, 40–47. [Google Scholar] [CrossRef]

- Angioni, S.L.; Meo, M.; Foreman, A. Impact damage resistance and damage suppression properties of shape memory alloys in hybrid composites-a review. Smart Mater. Struct. 2011, 20, 013001. [Google Scholar] [CrossRef]

- Pandya, S.; Ramakrishna, K.S.; Raja Annamalai, A.; Upadhyaya, A. Effect of sintering temperature on the mechanical and electrochemical properties of austenitic stainless steel. Mater. Sci. Eng. A 2012, 556, 271–277. [Google Scholar] [CrossRef]

| Volume Fraction (%) | Wire Mesh Diameter (μm) | Sintering Temperatures (°C) |

|---|---|---|

| 12.45 | 40 | 1310 |

| 27 | 40 | 1310 |

| 41.57 | 40 | 1310 |

| 56.18 | 40 | 1310 |

| 70.81 | 40 | 1310 |

| 65.19 | 50 | 1310 |

| 65.17 | 60 | 1310 |

| 64.98 | 70 | 1310 |

| 65.57 | 80 | 1310 |

| 65.35 | 100 | 1310 |

| 65.7 | 120 | 1160 |

| 65.7 | 120 | 1210 |

| 65.7 | 120 | 1260 |

| 65.7 | 120 | 1310 |

| 65.7 | 120 | 1360 |

| Volume Fraction (%) | Thickness (mm) | Porosity (%) | Impact Absorbing Energy (J) | Impact Toughness (J/cm2) |

|---|---|---|---|---|

| 12.45 | 1.65 | 5.47 | 6.74 ± 0.76 | 51.07 ± 5.75 |

| 27 | 1.68 | 5.59 | 6.62 ± 0.88 | 49.23 ± 6.53 |

| 41.57 | 1.65 | 5.82 | 6.39 ± 0.22 | 48.37 ± 1.67 |

| 56.18 | 1.64 | 6.01 | 6.13 ± 0.36 | 46.73 ± 2.72 |

| 70.81 | 1.61 | 6.22 | 5.67 ± 0.80 | 43.99 ± 6.18 |

| Wire Mesh Diameter (μm) | Thickness (mm) | Porosity (%) | Impact Absorbing Energy (J) | Impact Toughness (J/cm2) |

|---|---|---|---|---|

| 50 | 1.58 | 7.26 | 6.36 ± 0.40 | 50.28 ± 3.13 |

| 60 | 1.55 | 7.51 | 5.05 ± 0.26 | 40.73 ± 2.10 |

| 70 | 1.56 | 7.62 | 4.78 ± 0.58 | 38.27 ± 4.63 |

| 80 | 1.58 | 7.96 | 4.67 ± 0.09 | 36.92 ± 0.68 |

| 100 | 1.54 | 8.21 | 4.93 ± 0.45 | 39.99 ± 3.63 |

| Sintering Temperatures (°C) | Thickness (mm) | Porosity (%) | Impact Absorbing Energy (J) | Impact Toughness (J/cm2) |

|---|---|---|---|---|

| 1160 | 2.12 | 6.46 | 6.71 ± 0.49 | 39.54 ± 2.86 |

| 1210 | 2.08 | 6.04 | 6.97 ± 0.94 | 41.87 ± 5.68 |

| 1260 | 2.12 | 5.82 | 8.04 ± 1.14 | 47.42 ± 6.74 |

| 1310 | 2.18 | 5.66 | 9.99 ± 1.31 | 57.30 ± 7.51 |

| 1360 | 2.06 | 5.41 | 12.02 ± 2.08 | 72.95 ± 12.65 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Zhou, Z. Charpy Impact Behavior of a Novel Stainless Steel Powder Wire Mesh Composite Porous Plate. Materials 2021, 14, 2924. https://doi.org/10.3390/ma14112924

Li C, Zhou Z. Charpy Impact Behavior of a Novel Stainless Steel Powder Wire Mesh Composite Porous Plate. Materials. 2021; 14(11):2924. https://doi.org/10.3390/ma14112924

Chicago/Turabian StyleLi, Chaozhong, and Zhaoyao Zhou. 2021. "Charpy Impact Behavior of a Novel Stainless Steel Powder Wire Mesh Composite Porous Plate" Materials 14, no. 11: 2924. https://doi.org/10.3390/ma14112924

APA StyleLi, C., & Zhou, Z. (2021). Charpy Impact Behavior of a Novel Stainless Steel Powder Wire Mesh Composite Porous Plate. Materials, 14(11), 2924. https://doi.org/10.3390/ma14112924