Quantitative Comparison of Binary Mix of Agro-Industrial Pozzolanic Additions for Elaborating Ternary Cements: Kinetic Parameters

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Binary System SCBA and SCSA

2.1.2. Binary System SCBA and BLAsh

2.1.3. Binary System PS and FA

2.1.4. Lime

2.2. Test Methodologies

2.2.1. Pozzolanic Activity Methods

2.2.2. Mathematical Model

- −

- The spherical form of the granule is retained, and the densities of F and B are the same. Consequently, the total radius of the granule rs (considering the reaction product layer and the nucleus without reacting) does not change with time and an intermediate region does not exist between the nucleus and the layer of product [54].

- −

- The movement rate of the reaction interface, drc/dt, is small in comparison to the diffusion speed of A through the product layer (pseudo-stable state) [55]. This is valid when the density of the fluid in the pores of F is smaller than the density of the solid reactant, which is certain in general.

- −

- Taking into account the pseudo-stable conditions, where the speed equations, expressed as a mole of solution A (CH solution) that disappears per unit of time per particle, are identical, the rate equation is obtained by handling these equations and considering well-founded physical hypotheses. It is determined by the control regime or by the rate-limiting step which can be [56,57]: (i) diffusive control and (ii) kinetic control.

- −

- In accordance with all the above, Villar-Cociña et al. [36,37] proposed a kinetic-diffusive model that allows the characterization of the pozzolanic activity in the sugar cane straw-clay ash/CH solution. Subsequently, the model was perfected in the characterization of the reaction kinetics in the sugar cane straw ash/CH and sugar cane bagasse ash/CH systems, where a correction term Ccorr was incorporated. This term is related to the remaining concentration of CH, which in some systems is not consumed totally. The corrected model is [38]:

3. Results

3.1. Chemical Characterization

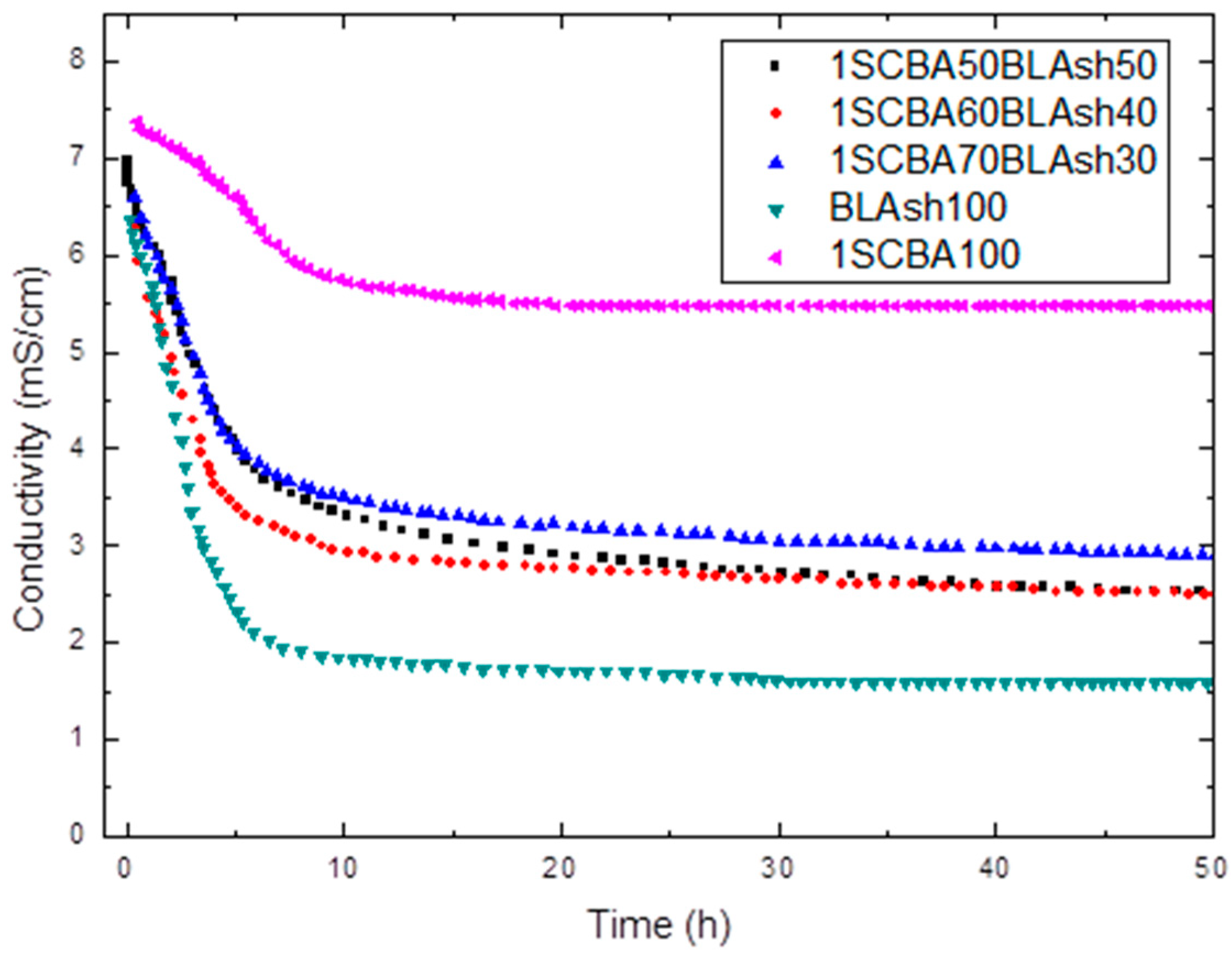

3.1.1. SCBA/BLAsh System

3.1.2. SCBA/SCSA System

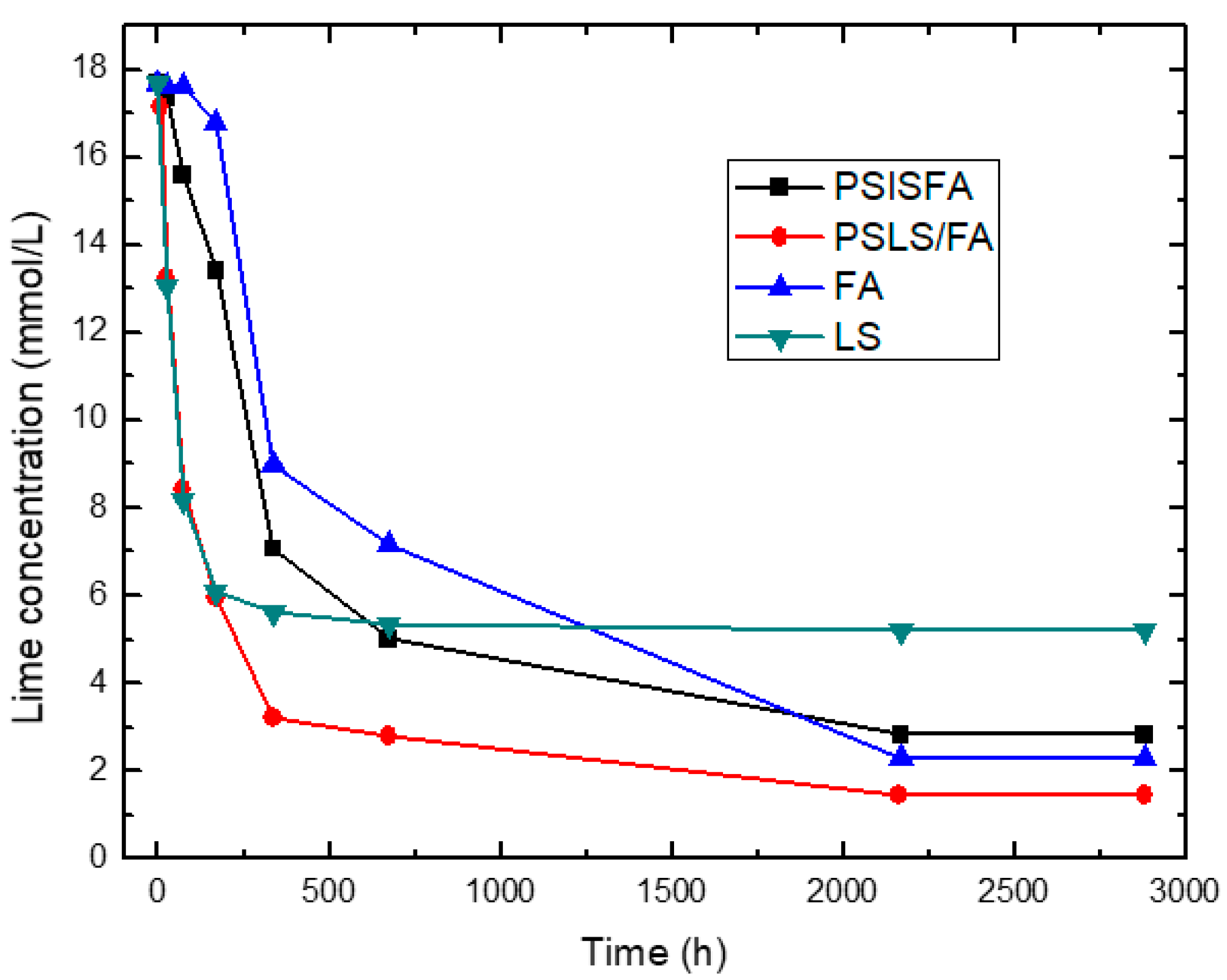

3.1.3. Paper Sludge/FA System

3.2. Pozzolanic Activity

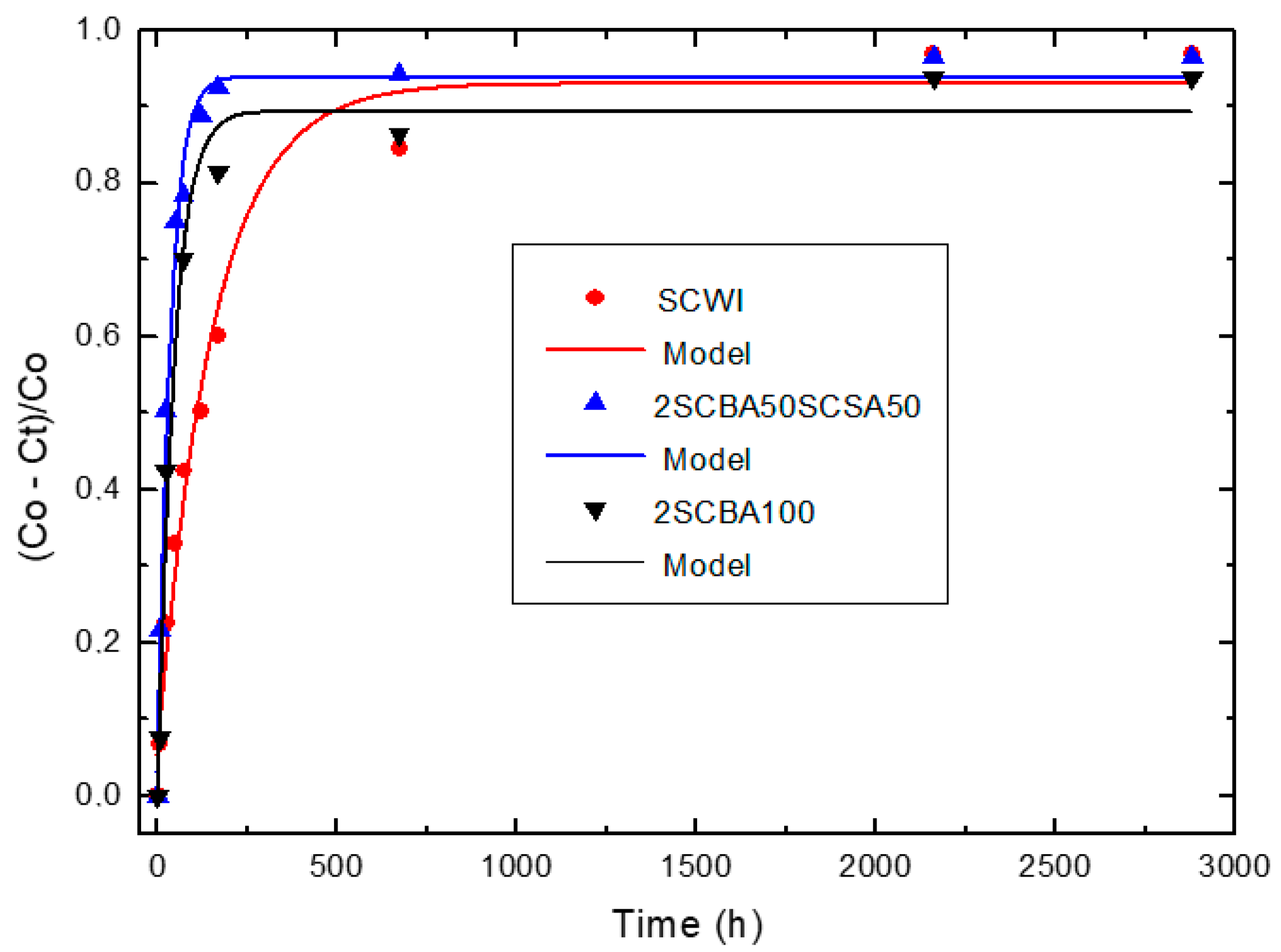

3.3. Application of the Mathematical Model and Determination of the Kinetic Parameters

4. Conclusions

- –

- Chemically, all the binary samples are formed by the same oxides but with different contents. The main oxides are silica and alumina (although PSLSFA and POISFA shows a 47% and 54% of CaO respectively), whose contents are: 71.6% (SCSA), 70.5% (BLAsh), 69.79% (2SCBA), 60.10% (SCWI), 55.70% (FA), 75.39% (LS), 72.13% (SCSA), 49.79% (2SCBA50SCSA50) and 36.20% (1SCBA).

- –

- The values of the reaction rate constant, obtained in the fitting process of the kinetic-diffusive model, show that the binary blends 1SCBA60BLAsh40 (6.18 · 10−1 h−1), 1SCBA50BLAsh50 (1.72 · 10−2 h−1), 1SCBA70BLAsh30 (2.89 · 10−1 h−1) have a very high pozzolanic reactivity followed by PSLSFA (6.26 · 10−2 h−1), 2SCBA50SCSA50 (1.72 · 10−2 h−1), PSISFA (5.51 · 10−3 h−1) and SCWI (9.32 · 10−4 h−1).

- –

- Analyzing the three binary systems we can point out that the 1SCBA + BLAsh system is, in general, the one that shows the greatest pozzolanic reactivity, showing the highest values of the reaction rate constant K (order of 10−1 h−1) for all the binary mixtures, the highest being 1SCBA60BLAsh40 (the same order of silica fume), followed by the PS + FA system, specifically the PSLSFA binary mixture, and by the 2SCBA + SCSA system, specifically the 2SCBA50SCSA50 binary mixture. In all these cases, there is a good synergy between the basic and complementary pozzolans, and the mentioned binary mixtures have greater reactivity than the basic pozzolans (1SCBA, 2SCBA and LS).

- –

- The availability of pozzolanic blends with different pozzolanic reaction rates can become an important technological advantage in the manufacturing of new ternary cements that include pozzolanic binary blends. The selection of one binary system or another as the one preferred will depend on the characteristics needed for the building site.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Massazza, F. Chemistry of pozzolanic additions and mixed cement. Cemento 1976, 73, 3–39. [Google Scholar]

- Metha, P.K. Role of cementitious material in sustainable development of the concrete industry. In Proceeding of the Sixth CANMET/ACI International Conference on the Fly Ash, Silica Fume, Slag and Natural Pozzolans in Concrete; Malhotra, V.M., Ed.; ACI International: Bangkok, Thailand, 1998; Volume 1, pp. 1–20. [Google Scholar]

- Swathi, V.; Asadi, S.S. An influence of pozzolanic materials with hybrid fibers on structural performance of concrete: A review. Mater. Today Proc. 2021, 43, 1956–1959. [Google Scholar] [CrossRef]

- AlBiajawi, M.I.; Embong, R.; Muthusamy, K. An overview of the utilization and method for improving pozzolanic performance of agricultural and industrial wastes in concrete. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Pachideh, G.; Gholhaki, M. Effect of pozzolanic materials on mechanical properties and water absorption of autoclaved aerated concrete. J. Build. Eng. 2019, 26, 100856. [Google Scholar] [CrossRef]

- Yin, K.; Ahamed, A.; Lisak, G. Environmental perspectives of recycling various combustion ashes in cement production—A review. Waste Manag. 2018, 78, 401–416. [Google Scholar] [CrossRef]

- Kumar, V.P.; Vasugi, V. Bamboo materials in cement, geopolymer and reinforced concrete as sustainable solutions for better to-morrow. IOP Conf. Ser. Earth Environ. Sci. 2020, 573, 012036. [Google Scholar] [CrossRef]

- Aprianti, E.; Shafigh, P.; Bahri, S.; Farahani, J.N. Supplementary cementitious materials origin from agricultural wastes—A review. Constr. Build. Mater. 2015, 74, 176–187. [Google Scholar] [CrossRef]

- Rodier, L.; Villar-Cociña, E.; Mejia Ballesteros, J.; Savastano, H., Jr. Potential use of sugarcane bagasse and bam-boo leaf ashes for elaboration of green cementitious materials. J. Clean. Prod. 2019, 231, 54–63. [Google Scholar] [CrossRef]

- Hale, W.M.; Freyne, S.F.; Bush, T.D.; Russell, B.W. Properties of concrete mixtures containing slag cement and fly ash for use in transportation structures. Constr. Build. Mater. 2008, 22, 1990–2000. [Google Scholar] [CrossRef]

- Sisomphon, K.; Franke, L. Carbonation rates of concretes containing high volume of pozzolanic materials. Cem. Concr. Res. 2007, 37, 1647–1653. [Google Scholar] [CrossRef]

- Ahmed, M.S.; Kayali, O.; Anderson, W. Chloride penetration in binary and ternary blended cement concretes as measured by two different rapid methods. Cem. Concr. Compos. 2008, 30, 576–582. [Google Scholar] [CrossRef]

- Garas, V.Y.; Kurtis, K. Assessment of methods for optimising ternary blended concrete containing metakaolin. Mag. Concr. Res. 2008, 60, 499–510. [Google Scholar] [CrossRef]

- Moser, R.D.; Jayapalan, A.R.; Garas, V.Y.; Kurtis, K.E. Assessment of binary and ternary blends of metakaolin and Class C fly ash for alkali-silica reaction mitigation in concrete. Cem. Concr. Res. 2010, 40, 1664–1672. [Google Scholar] [CrossRef]

- De Weerdt, K.; Ben Haha, M.; Le Saout, G.; Kjellsen, K.; Justnes, H.; Lothenbach, B. Hydration mechanisms of ternary Portland cements containing limestone powder and fly ash. Cem. Concr. Res. 2011, 41, 279–291. [Google Scholar] [CrossRef]

- Kumar, M.; Singh, N.; Singh, S.K.; Singh, N. Tertiary biocomposite cement and its hydration. Constr. Build. Mater. 2012, 29, 1–6. [Google Scholar] [CrossRef]

- Frías, M.; Villar-Cociña, E.; Valencia-Morales, E. Characterization of sugar cane straw waste as pozzolanic material for construction: Calcining temperature and kinetic parameters. Waste Manag. 2007, 27, 533–538. [Google Scholar] [CrossRef] [PubMed]

- Frías, M.; Villar-Cociña, E. Influence of calcining temperature on the activation of sugar-cane bagasse: Kinetic parameters. Adv. Cem. Res. 2007, 19, 109–115. [Google Scholar] [CrossRef]

- Villar-Cociña, E.; Frias, M.; Valencia Morales, E.; Savastano, H., Jr. Study of the pozzolanic reaction kinetics in sugar cane bagasse–clay ash/calcium hydroxide system: Kinetic parameters and pozzolanic activity. Adv. Cem. Res. 2009, 21, 23–30. [Google Scholar] [CrossRef]

- Nguyen Van Tuan, G.Y.; van Breugel, K.; Alex, L.A.F.; Bui, D.D. The study of using rice husk ash to produce ultra high performance concrete. Constr. Build. Mater. 2011, 25, 2030–2035. [Google Scholar] [CrossRef]

- Villar-Cociña, E.; Morales, E.V.; Santos, S.F.; Savastano, H.; Frías, M. Pozzolanic behavior of bamboo leaf ash: Characterization and determination of the kinetic parameters. Cem. Concr. Compos. 2011, 33, 68–73. [Google Scholar] [CrossRef]

- Morales, E.V.; Villar-Cociña, E.; Frías, M.; Santos, S.F.; Savastano, H. Effects of calcining conditions on the mi-crostructure of sugar cane waste ashes (SCWA): Influence in the pozzolanic activation. Cem. Concr. Compos. 2009, 31, 22–28. [Google Scholar] [CrossRef]

- Khodadadian, A.; Noii, N.; Parvizi, M.; Abbaszadeh, M.; Wick, T.; Heitzinger, C. A Bayesian estimation method for variational phase-field fracture problems. Comput. Mech. 2020, 66, 827–849. [Google Scholar] [CrossRef]

- Khangaonkar, P.; Rahmat, A.; Kutty, K.J. Kinetic study of the hydrothermal reaction between lime and rice-husk-ash silica. Cem. Concr. Res. 1992, 22, 577–588. [Google Scholar] [CrossRef]

- Frías, M.; Cabrera, J. The effect of temperature on the hydration rate and stability of the hydration phases of metakaolin-lime-water systems. Cem. Concr. Res. 2002, 32, 133–138. [Google Scholar]

- Jander, W. Reaktionen im festen zustande bei hoheren temperature. Z. Anorg. Allg. Chem. 1927, 163, 1–30. [Google Scholar] [CrossRef]

- Kondo, R.; Lee, K.; Diamond, M. Kinetics and mechanism of hydrothermal reaction in lime–quartz–water systems. J. Ceram. Soc. Jpn. 1976, 84, 573–578. [Google Scholar]

- Brouwers, H.J.H.; Van Eijk, R.J. Fly ash reactivity: Extension and application of a shrinking core model and thermodynamic approach. J. Mater. Sci. 2002, 37, 2129–2141. [Google Scholar] [CrossRef]

- Ninov, J.; Dimova, I.D.L.; Petrov, B.; Brakalov, L. On the kinetics of pozzolanic reaction in metakaolin–lime–water system. J. Therm. Anal. Calorim. 2011, 105, 245–250. [Google Scholar] [CrossRef]

- Rao, S.M.; Asha, K. Activation of Fly Ash–Lime Reactions: Kinetic Approach. J. Mater. Civ. Eng. 2012, 24, 1110–1117. [Google Scholar] [CrossRef]

- Wang, X.-Y. Evaluation of compressive strength of hardening silica fume blended concrete. J. Mater. Sci. 2013, 48, 5953–5961. [Google Scholar] [CrossRef]

- Glosser, D.; Suraneni, P.; Burkan, O.; Isgor, W.; Weiss, J. Estimating reaction kinetics of cementitious pastes containing fly ash. Cem. Concr. Compos. 2020, 112, 10365. [Google Scholar] [CrossRef]

- Valentini, L.; Favero, M.; Dalconi, M.C.; Russo, V.; Ferrari, G.; Artioli, G. Kinetic Model of Calcium-Silicate Hydrate Nucleation and Growth in the Presence of PCE Superplasticizers. Cryst. Growth Des. 2016, 16, 646–654. [Google Scholar] [CrossRef]

- Frías, M.; Vigil de la Villa, R.; Martínez-Ramírez, S.; Fernández-Carrasco, L.; Villar-Cociña, E.; García-Giménez, R. Mul-ti-Technique Characterization of a Fine Fraction of CDW and Assessment of Reactivity in a CDW/Lime System. Minerals 2020, 10, 590. [Google Scholar] [CrossRef]

- Honorio, T.; Bary, B.; Benboudjema, F.; Poyet, S. Modeling hydration kinetics based on boundary nucleation and space-filling growth in a fixed confined zone. Cem. Concr. Res. 2016, 83, 31–44. [Google Scholar] [CrossRef]

- Villar-Cociña, E.; Valencia-Morales, E.; Gonzalez-Rodriguez, R.; Hernandez-Ruiz, J. Kinetics of the pozzolanic re-action between lime and sugar cane straw ash by electrical conductivity measurement: A kinetic-diffusive model. Cem. Concr. Res. 2003, 33, 517–524. [Google Scholar] [CrossRef]

- Villar-Cociña, E.; Frías, M.; Valencia-Morales, E.; De Rojas, M.I.S. An evaluation of different kinetic models for determining the kinetic coefficients in sugar cane straw–clay ash/lime system. Adv. Cem. Res. 2006, 18, 17–26. [Google Scholar] [CrossRef]

- Villar-Cociña, E.; Frías, M.; Valencia-Morales, E. Sugar cane wastes as pozzolanic materials: Application of mathematical model. ACI Mater. J. 2008, 105, 258–264. [Google Scholar]

- Frías, M.; Rodriguez, O.; Nebreda, B.; Garcia, R.; Villar-Cociña, E. Influence of activation temperature of kaolinite-based clay wastes on pozzolanic activity and kinetic parameters. Adv. Cem. Res. 2010, 22, 135–142. [Google Scholar] [CrossRef]

- Frías, M.; García, R.; Vigil, R.; Ferreiro, S. Calcination of art paper sludge waste for the use as a supplementary cementing material. Appl. Clay Sci. 2008, 42, 189–193. [Google Scholar] [CrossRef]

- Frías, M.; Rodríguez, O.; Sanchez de Rojas, M.I.; Villar-Cociña, E.S.; Rodrigues, M.; Savastano, H., Jr. Advances on the development of ternary cements elaborated with biomass ashes coming from different activation process. Con. Build. Mat. 2017, 136, 73–80. [Google Scholar] [CrossRef]

- Cordeiro, G.; Filho, R.T.; Tavares, L.; Fairbairn, E. Pozzolanic activity and filler effect of sugar cane bagasse ash in Portland cement and lime mortars. Cem. Concr. Compos. 2008, 30, 410–418. [Google Scholar] [CrossRef]

- Dwivedi, V.N.; Singh, N.P.; Dasa, S.S.; Singh, N.B. A new pozzolanic material for cement industry: Bamboo leaf ash. Int. J. Phys. Sci. 2006, 1, 106–111. [Google Scholar]

- De La Villa, R.V.; Rodriguez, O.; Garcia, R.; Frías, M. Mineral phases in an activated kaolinitic waste blended cement system. Appl. Clay Sci. 2010, 50, 137–142. [Google Scholar] [CrossRef]

- International Patent. A method of preparing a pozzolanic material form paper residue and a method for the manufacture of cement from said material.

- European Standard EN197-1. Cement-Part 1: Composition, Specifications and Conformity Criteria for Common Cements. Available online: https://www.aenor.com/normas-y-libros/buscador-de-normas/une/?c=N0048623 (accessed on 1 April 2021).

- Frías, M.; Garcia, R.; De La Villa, R.V.; Villar, E. The effect of binary pozzolan mix on the mineralogical changes in the ternary activated paper sludge–fly ash–Ca(OH)2 system. Constr. Build. Mater. 2013, 38, 48–53. [Google Scholar] [CrossRef]

- British Standard BS EN 196 Methods of Testing Cement. Available online: https://www.aenor.com/normas-y-libros/buscador-de-normas (accessed on 1 April 2021).

- American Society for Testing and Materials (ASTM) C-311. Available online: https://www.astm.org/Standards/C311.htm (accessed on 1 April 2021).

- Donatello, S.; Tyrer, M.; Cheeseman, C. Comparison of test methods to assess pozzolanic activity. Cem. Concr. Compos. 2010, 32, 121–127. [Google Scholar] [CrossRef]

- Frías, M.; Villar-Cociña, E.; Sánchez de Rojas, M.I.; Valencia-Morales, E. The effect of different pozzolanic activity methods on the kinetics constants of the pozzolanic reaction: Application of a kinetic-diffusive model. Cem. Concr. Res. 2005, 35, 2137–2142. [Google Scholar] [CrossRef]

- Rodríguez, O.; Frías, M.; Sánchez de Rojas, M.I. Influence of the calcined paper sludge on the development of hydration heat in blended cement mortars. J. Therm. Anal. Cal. 2008, 92, 865–871. [Google Scholar] [CrossRef]

- Quintana-Crespo, E.; Villar-Cociña, E. A kinetic study about the pozzolanic reactivity of loessic soils by con-ductometric methods: Kinetic parameters. Adv. Cem. Res. 2011, 23, 3–10. [Google Scholar] [CrossRef]

- Yagi, S.; Kunii, D. Studies on Fluidized-Solids Reactors for Particles with Decreasing Diameters. Chem. Eng. 1955, 19, 500–506. [Google Scholar] [CrossRef]

- Bischoff, K. Accuracy of the pseudo steady state approximation for moving boundary diffusion problems. Chem. Eng. Sci. 1963, 18, 711–713. [Google Scholar] [CrossRef]

- Levenspiel, O. Chemical Reaction Engineering. Ind. Eng. Chem. Res. 1999, 38, 4140–4143. [Google Scholar] [CrossRef]

- Renedo, M.J.; Fernández, J. Kinetic modeling of the hydrothermal reaction of fly ash, Ca(OH)2 and CaSO4 in the preparation of desulphurant sorbents. Fuel 2004, 83, 525–532. [Google Scholar] [CrossRef]

- Norsuraya, S.; Fazlena, H.; Norhasyimi, R. Sugarcane Bagasse as a Renewable Source of Silica to Synthesize Santa Barbara Amorphous-15 (SBA-15). Procedia Eng. 2016, 148, 839–846. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Toledo Filho, R.D.; Fairbairn, E.D.M.R. Caracterizaç~ao de cinza do bagaço de cana-de-açúcar para emprego como pozolana em materiais cimentícios Characterization of sugar cane bagasse ash for use as pozzolan in cementitious materials. Quím. Nova 2009, 32, 82–86. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Filho, R.D.T.; Tavares, L.M.; Fairbairn, E.D.M.R. Ultrafine grinding of sugar cane bagasse ash for application as pozzolanic admixture in concrete. Cem. Concr. Res. 2009, 39, 110–115. [Google Scholar] [CrossRef]

- ASTM C618. Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; Annual Book of ASTM Standards, 04.01; American Society for Testing and Materials: Philadelphia, PA, USA, 2012. [Google Scholar]

- Demis, S.; Tapali, J.; Papadakis, V. An investigation of the effectiveness of the utilization of biomass ashes as pozzolanic materials. Constr. Build. Mater. 2014, 68, 291–300. [Google Scholar] [CrossRef]

- Bahurudeen, A.; Marckson, A.; Kishore, A.; Santhanam, M. Development of sugarcane bagasse ash based Portland pozzolana cement and evaluation of compatibility with superplasticizers. Constr. Build. Mater. 2014, 68, 465–475. [Google Scholar] [CrossRef]

- Nakanishi, E.Y.; Frías, M.; Martínez-Ramírez, S.; Santos, S.F.; Rodrigues, M.S.; Rodríguez, O.; Savastano, H. Characterization and properties of elephant grass ashes as supplementary cementing material in pozzolan/Ca(OH)2 pastes. Constr. Build. Mater. 2014, 73, 391–398. [Google Scholar] [CrossRef]

- Chusilp, N.; Jaturapitakkul, C.; Kiattikomol, K. Effects of LOI of ground bagasse ash on the compressive strength and sulfate resistance of mortars. Constr. Build. Mater. 2009, 23, 3523–3531. [Google Scholar] [CrossRef]

- Villar-Cocina, E.; Rodier, L.; Savastano, H.; Lefran, M.; Frias, M. A Comparative Study on the Pozzolanic Activity Between Bamboo Leaves Ash and Silica Fume: Kinetic Parameters. Waste Biomass Valorization 2020, 11, 1627–1634. [Google Scholar] [CrossRef]

- Sinthaworn, S.; Nimityongskul, P. Quick monitoring of pozzolanic reactivity of waste ashes. Waste Manag. 2009, 29, 1526–1531. [Google Scholar] [CrossRef]

- Rahman, A.; Rasul, M.; Khan, M.; Sharma, S. Recent development on the uses of alternative fuels in cement manufacturing process. Fuel 2015, 145, 84–99. [Google Scholar] [CrossRef]

- Frías, M.; Savastano, H.; Villar, E.; de Rojas, M.I.S.; Santos, S. Characterization and properties of blended cement matrices containing activated bamboo leaf wastes. Cem. Concr. Compos. 2012, 34, 1019–1023. [Google Scholar] [CrossRef]

| Pozzolanic Binary Systems | Samples | SCBA (%) | SCSA (%) | FA (%) | BLAsh (%) | Paper Sludge | Designation |

|---|---|---|---|---|---|---|---|

| Sugar Cane Bagasse Ash and Sugar Cane Straw Ash (2SCBA + SCSA) | 2SCBA + SCSA (industrial) | 50 | 50 | - | - | - | SCWI |

| 2SCBA + SCSA (Laboratory) | 50 | 50 | - | - | - | 2SCBA50SCSA50 | |

| SCSA | - | 100 | - | - | - | SCSA100 | |

| 2SCBA | 100 | - | - | - | - | 2SCBA100 | |

| Sugar Cane Bagasse Ash and Bamboo Leaf Ash (1SCBA + BLAsh) | 1SCBA + BLAsh | 50 | - | - | 50 | - | 1SCBA50Blash50 |

| 1SCBA + BLAsh | 60 | - | - | 40 | - | 1SCBA60Blash40 | |

| 1SCBA + BLAsh | 70 | - | - | 30 | - | 1SCBA70Blash30 | |

| 1SCBA | 100 | - | - | - | - | 1SCBA100 | |

| BLAsh | - | - | - | 100 | - | BLAsh100 | |

| Paper sludge (PS) (industrial and laboratory) and Fly Ash (FA) (PS + FA) | Paper sludge (LS) +FA | - - | - | 50 | - | 50 | PSLSFA |

| Paper sludge (IS) + FA | - | - | 50 | - | 50 | PSISFA | |

| Paper sludge | - | - | - | - | 100 | PS |

| 1SCBA/BLAsh System | 2SCBA/SCSA System | Paper Sludge/Fly Ash System | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Oxide (%) | 1SCBA 100 | BLAsh100 | 2SCBA100 | SCSA 100 | 2SCBA50SCSA50 | SCWI | PSLSFA | PSISFA | FA |

| SiO2 | 36.20 | 70.5 | 69.40 | 71.6 | 49.79 | 60.10 | 13.90 | 11.02 | 55.70 |

| Al2O3 | 12.30 | 0.63 | 11.26 | 0.58 | 7.53 | 12.50 | 8.30 | 9.37 | 24.00 |

| Fe2O3 | 8.76 | 0.47 | 5.41 | 0.37 | 4.43 | 10.35 | 0.50 | 0.72 | 4.80 |

| CaO | 7.10 | 7.86 | 2.51 | 7.47 | 11.10 | 3.11 | 47.12 | 54.36 | 2.20 |

| MgO | 4.76 | 1.84 | 1.28 | 1.48 | 7.43 | 2.10 | 1.60 | 1.20 | 0.90 |

| SO3 | 4.38 | 2.87 | 1.83 | 2.69 | 1.95 | 0.10 | 0.00 | 0.39 | 0.89 |

| K2O | 12.80 | 5.14 | 3.45 | 4.95 | 8.45 | 6.00 | 0.30 | 0.21 | 2.18 |

| P2O5 | 5.42 | 1.67 | 1.61 | 1.44 | 2.68 | 1.47 | 0.20 | 0.27 | 0.28 |

| Na2O | 0.20 | <0.001 | 0.09 | <0.001 | 0.28 | 0.16 | 0.23 | 0.12 | 0.45 |

| TiO2 | 1.98 | 0.06 | 1.38 | 0.07 | 0.86 | 2.73 | 0.25 | 0.50 | 0.69 |

| LOI | 5.37 | 7.79 | 1.56 | 8.08 | 5.08 | 1.00 | 26.66 | 21.68 | 7.60 |

| Pozzolanic Binary Sistems | Material (Ash) | τ (h) | Reaction Rate Constant K (h−1) | Diffusion Coeffient De (mm2/h) | Ccorr. | Coefficient of Multiple Determination (R2) | Residual Sum of Squares |

|---|---|---|---|---|---|---|---|

| 2SCBA + SCSA | SCWI | 152.9 ± 10.3 | (9.32 ± 0.23) · 10−4 | 0.07 ± 0.003 | 0.9775 | 0.0194 | |

| 2SCBA50SCSA50 | 33.1 ± 2.7 | (1.72 ± 0.25) · 10−2 | 0.051 ± 0.038 | 0.9788 | 0.0020 | ||

| SCSA100 | 23.2 ± 1.8 | (8.12 ± 0.67) · 10−1 | 0.09 ± 0.01 | 0.9976 | 0.0022 | ||

| 2SCBA100 | 43.5 ± 3.1 | (6.91 ± 0.82) · 10−3 | 0.10 ± 0.02 | 0.9722 | 0.0125 | ||

| 1SCBA + BLAsh | 1SCBA50Blash50 | 5.6 ± 0.2 | (3.83 ± 0.02) · 10−1 | 0.33 ± 0.03 | 0.9863 | 0.0620 | |

| 1SCBA60Blash40 | 3.6 ± 0.1 | (6.18 ± 0.03) · 10−1 | 0,41± 0.02 | 0.9780 | 0.0410 | ||

| 1SCBA70Blash30 | 4.5 ± 0.2 | (2.89 ± 0.03) · 10−1 | 0.45 ± 0.002 | 0.9810 | 0.0420 | ||

| 1SCBA100 | 5.3 ± 0.06 | (1.85 ± 0.004) · 10−2 | (1.13 ± 0.005) · 10−2 | 0.74 ± 0.0006 | 0.9952 | 0.0032 | |

| BLAsh100 | 2.9 ± 0.07 | (10.02 ± 0.03) · 10−1 | 0.25 ± 0.003 | 0.9873 | 0.0570 | ||

| PS + FA | PSLSFA | 93.9 ± 2.07 | (6.26 ± 0.90) · 10−2 | 0.13 ± 0.030 | 0.9810 | 0.0165 | |

| PSISFA | 272.1 ± 31.4 | (5.51 ± 0.12) · 10−3 | (4.71 ± 0.85) · 10−3 | 0.17 ± 0.021 | 0.9894 | 0.0072 | |

| LS | 50.2 ± 2.28 | (8.28 ± 0.09) · 10−3 | 0.30 ± 0.005 | 0.9979 | 0.0006 | ||

| FA | 301.6 ± 28.2 | (2.12 ± 0.47) · 10−3 | (2.21 ± 0.88) · 10−3 | 0.13 ± 0.04 | 0.9984 | 0.0012 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Villar-Cociña, E.; Frías, M.; Savastano, H.; Rodier, L.; Sánchez de Rojas, M.I.; Sáez del Bosque, I.F.; Medina, C. Quantitative Comparison of Binary Mix of Agro-Industrial Pozzolanic Additions for Elaborating Ternary Cements: Kinetic Parameters. Materials 2021, 14, 2944. https://doi.org/10.3390/ma14112944

Villar-Cociña E, Frías M, Savastano H, Rodier L, Sánchez de Rojas MI, Sáez del Bosque IF, Medina C. Quantitative Comparison of Binary Mix of Agro-Industrial Pozzolanic Additions for Elaborating Ternary Cements: Kinetic Parameters. Materials. 2021; 14(11):2944. https://doi.org/10.3390/ma14112944

Chicago/Turabian StyleVillar-Cociña, Ernesto, Moisés Frías, Holmer Savastano, Loic Rodier, María Isabel Sánchez de Rojas, Isabel Fuencisla Sáez del Bosque, and César Medina. 2021. "Quantitative Comparison of Binary Mix of Agro-Industrial Pozzolanic Additions for Elaborating Ternary Cements: Kinetic Parameters" Materials 14, no. 11: 2944. https://doi.org/10.3390/ma14112944

APA StyleVillar-Cociña, E., Frías, M., Savastano, H., Rodier, L., Sánchez de Rojas, M. I., Sáez del Bosque, I. F., & Medina, C. (2021). Quantitative Comparison of Binary Mix of Agro-Industrial Pozzolanic Additions for Elaborating Ternary Cements: Kinetic Parameters. Materials, 14(11), 2944. https://doi.org/10.3390/ma14112944