Recycled Fibers for Sustainable Hybrid Fiber Cement Based Material: A Review

Abstract

:1. Introduction

2. Research Significance

3. Data Collection Procedure

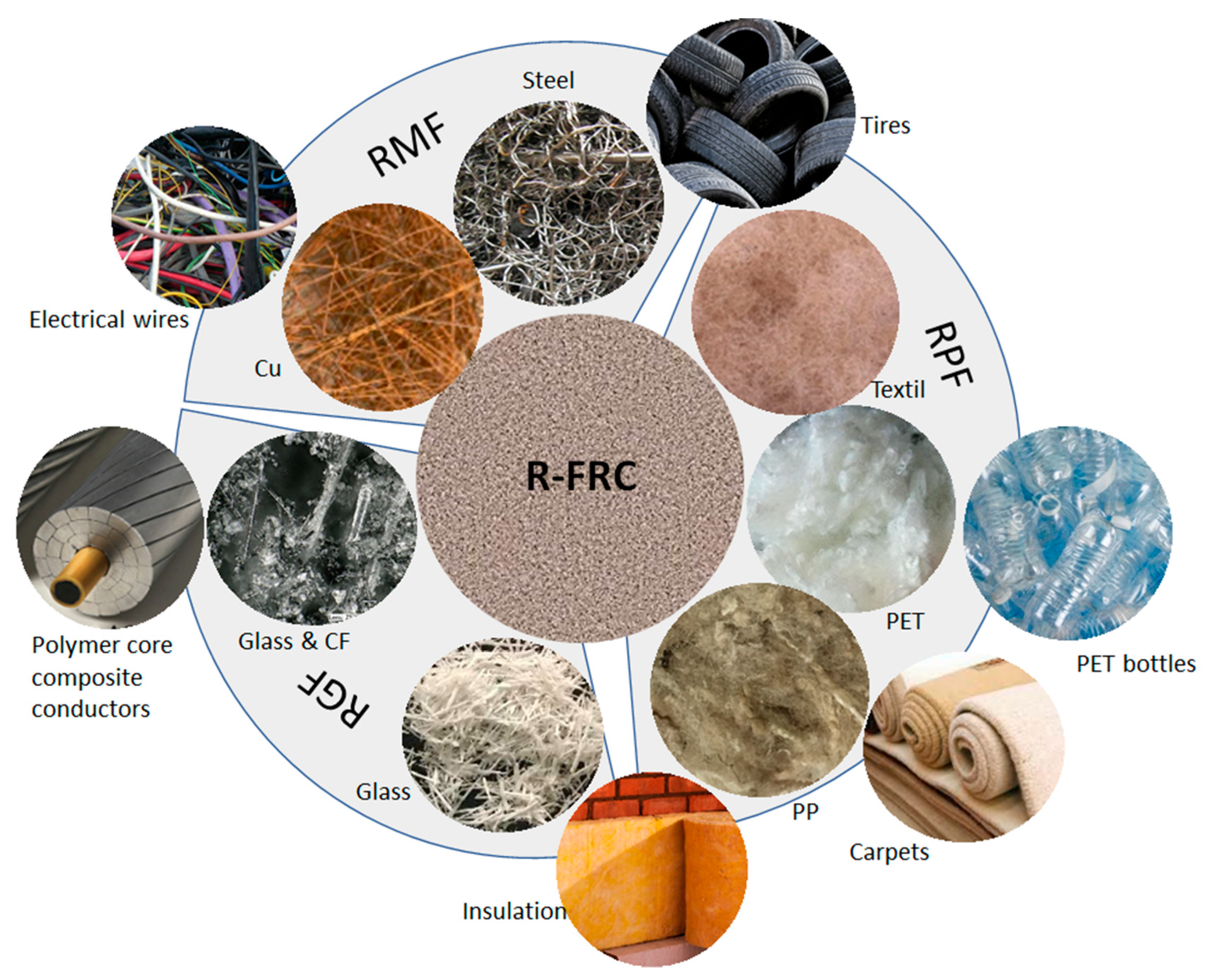

4. Recycled Fiber Reinforced Composites (R-FRC)

4.1. Type of Recycled Fibers

4.2. Physical, Mechanical and Chemical Properties of Recycled Fibers

4.3. Effect on Fiber-Cement Properties

4.4. Effect on Fiber-Cement Production Process, Economy and Sustainability

5. Hybrid R-FRC

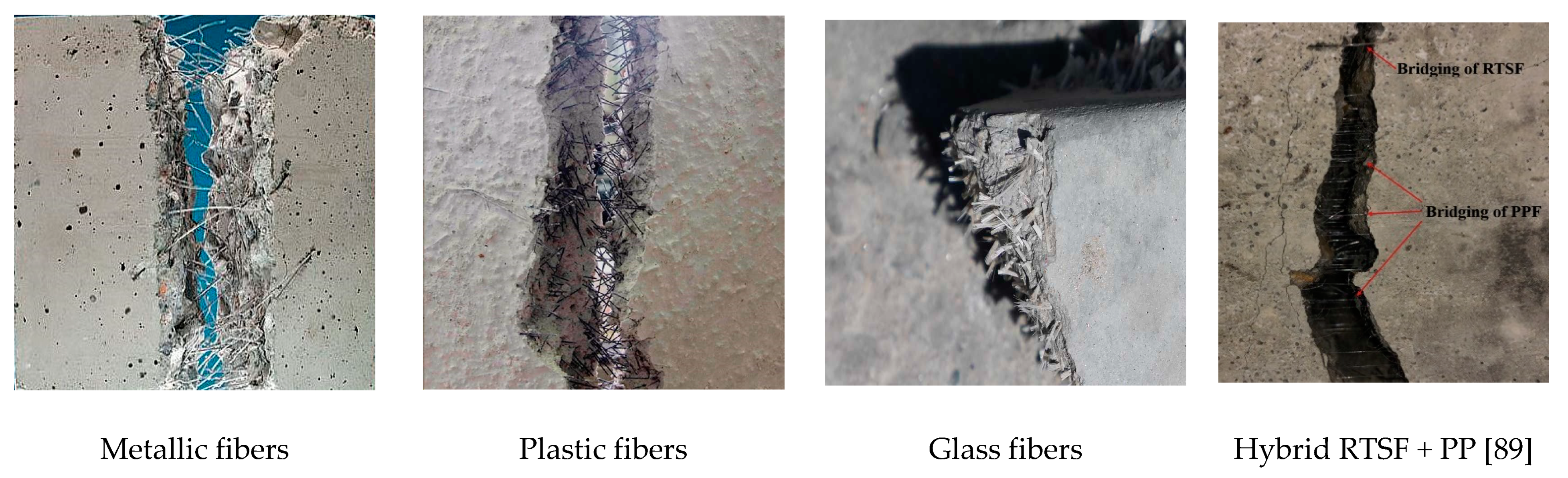

5.1. Metallic Fibers

5.2. Synthetic Polymeric Fibers

6. Complex Hybrid R-FRC

7. Potential Applications of Recycled Hybrid Composites in Civil Engineering

- Tunnel Engineering, for construction of lined tunnels [150].

8. Conclusions

- The highest effort in using recycled hybrid reinforcement has been carried out in the framework of structural applications, where FRC must accomplish strict and tough mechanical requirements. For this application, the combination of steel fibers from waste tires with hooked ends of industrial steel fibers or with industrial PP fibers is the most efficient reinforcing approach. This combination (i) improves the final product: increases impact energy absorption, increases chemical resistance in seawater, and decreases shrinkage; (ii) saves costs; and (iii) reduces the environmental impact. On the other hand, the effect of hybridization on compressive strength can be detrimental. In most cases, there is only a slight decrease, but if polymeric fibers are present the decrease is up to a 30%. However, when different steel fibers are used the compressive strength may increase with respect to plain concrete. Therefore, each fiber fraction must be optimized for each application. Liew and Akbar (2020) [40] have recently concluded that the effect of using recycled steel fibers on compressive strength is not clear yet, which is further confirmed by the results analyzed at this review.

- For applications with high tensile strength requirements, three good options have been identified: (i) hybrid R-FRC with RGF and unsaturated polyester, both obtained from thermoset composites; (ii) recycled PP fibers combined with acrylic fibers; and (iii) the hybridization of recycled PET with industrial PP fibers. The last can be the best option to manage part of the recovered PET from waste PET bottles in R-FRC, with a notable increase in R-FRC tensile strength compared to plain concrete.

- Besides the potential valuable of recycled hybrid FRC, there are several challenges that must be solved for the implementation and consolidation of these processes, which require further research efforts in several topics:

- Challenges related to the optimal morphology of the recycled fibers, because size and shape distributions are too broad to obtain good results at industrial scale. In most studies, researchers have cut or selected the fibers manually, which is not possible in a large scale FRC production. The broad size and shape distribution of fibers reduces workability in excess and favors their mechanical entanglement, increasing the consumption of superplasticizer and challenging the homogeneous distribution of the fibers in the matrix;

- The way to extend the limits of the reinforcing effect of recycled polymers;

- The optimal dispersion of polymers and the improvement of their interaction with the matrix, which is limited due the polymer hydrophobic nature, to decrease air entrapment in the fresh mixture;

- The rubber attached to polymeric and steel fibers from waste tires is another issue that requires deep study. It is true that it contributes to increase notably the impact energy absorption at first crack and at ultimate stage, but rubber particles reduce the fiber-matrix interactions, decreasing the compressive and flexural strengths compared to those of industrial steel FRC;

- The durability of hybrid R-FRC could be affected if the specific surface of recycled fibers is higher than that of industrial fibers. This is especially relevant in the case of recycled steel fibers because steel corrosion would be faster. On another hand, rubber attached to steel fibers would protect them from corrosion. Therefore, durability must be further studied in these cases;

- The interest and consolidation of 3D printing of concrete is increasing fast. Reinforcement of concrete structures made by 3D printing can be manually placed, for example, in form of steel bars. However, a better alternative is reinforcement by means of fiber dispersion, which need to be further explored [154]. In this sense, the use of hybrid recycled fiber reinforced SCC could be a good approach. However, the concrete for 3D printing must be easily pumped and its hydration rate must be fast enough to avoid the structure collapse. Therefore, the effect of fibers on workability and pumpability must be controlled without increasing the requirements of superplasticizer, which delay hardening.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviation

| CF | carbon fibers |

| CFRP | carbon fiber reinforced plastic |

| CS | compressive strength |

| d | diameter |

| EM | elastic modulus |

| EPS | expanded polystyrene foam |

| FRC | fiber reinforced composites |

| FS | flexural strength |

| HDPE | high density polyethylene |

| HE | hook-end steel fibers |

| IEA1 | impact energy absorption at first crack |

| IEAU | impact energy absorption at ultimate stage |

| L | length |

| LCA | life cycle assessment |

| LDPE | low density polyethylene |

| LWC | lightweight concrete |

| OP | ordinary Portland cement |

| PA | polyamide |

| PAN | polyacrylonitrile |

| PET | polyethylene terephthalate |

| PP | polypropylene |

| PPC | Portland pozzolana cement |

| PVA | polyvinyl alcohol |

| PVC | polyvinyl chloride |

| R-FRC | recycled fiber reinforced composites |

| RGF | recycled glass fibers |

| RMF | recycled metallic fibers |

| RPF | recycled synthetic polymeric fibers |

| RS | residual strength |

| RTSF | recycled-tire steel fibers |

| SBF | sugar beet fiber |

| SCC | self-consolidating concrete |

| SHCC | strain-hardening cementitious composite |

| SSF | scrap tire steel fiber |

| T | thickness |

| TS | tensile strength |

| W | width |

| WFPRC | waste fiber and powder reinforced concrete |

References

- Ghasemi, M.; Mousavi, S.R. Studying the fracture parameters and size effect of steel fiber-reinforced self-compacting concrete. Constr. Build. Mater. 2019, 201, 447–460. [Google Scholar] [CrossRef]

- Balea, A.; Fuente, E.; Monte, M.C.; Blanco, Á.; Negro, C. Fiber reinforced cement based composites. In Fiber Reinforced Composites; Joseph, K., Oksman, K., George, G., Wilson, R., Appukuttan, S., Eds.; Woodhead Publishing: Cambridge, MA, USA, 2021; pp. 597–648. [Google Scholar]

- Chen, B.; Liu, J. Contribution of hybrid fibers on the properties of the high-strength lightweight concrete having good workability. Cem. Concr. Res. 2005, 35, 913–917. [Google Scholar] [CrossRef]

- Cao, M.; Li, L.; Khan, M. Effect of hybrid fibers, calcium carbonate whisker and coarse sand on mechanical properties of cement-based composites. Mater. Constr. 2018, 68, 156. [Google Scholar] [CrossRef] [Green Version]

- Cao, M.; Liu, Z.; Xie, C. Effect of steel-PVA hybrid fibers on compressive behavior of CaCO3 whiskers reinforced cement mortar. J. Build. Eng. 2020, 31, 101314. [Google Scholar] [CrossRef]

- Meng, W.; Khayat, K.H. Effect of Hybrid Fibers on Fresh Properties, Mechanical Properties, and Autogenous Shrinkage of Cost-Effective UHPC. J. Mater. Civ. Eng. 2018, 30, 04018030. [Google Scholar] [CrossRef]

- Pakravan, H.; Latifi, M.; Jamshidi, M. Hybrid short fiber reinforcement system in concrete: A review. Constr. Build. Mater. 2017, 142, 280–294. [Google Scholar] [CrossRef]

- Silva, E.; Coelho, J.; Bordado, J.C. Strength improvement of mortar composites reinforced with newly hybrid-blended fibres: Influence of fibres geometry and morphology. Constr. Build. Mater. 2013, 40, 473–480. [Google Scholar] [CrossRef]

- Blanco Suárez, Á.; Negro Álvarez, C.M.; Sánchez, L.M. Alternative use of deinking sludge as a source of fibers in fiber-cement manufacture. Cellul. Chem. Technol. 2008, 42, 89–95. [Google Scholar]

- Brandt, A. Cement-based Composites: Materials, Mechanical Properties and Performance; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Jarabo, R.; Monte, M.; Fuente, E.; Santos, S.; Negro, C. Corn stalk from agricultural residue used as reinforcement fiber in fiber-cement production. Ind. Crop. Prod. 2013, 43, 832–839. [Google Scholar] [CrossRef] [Green Version]

- Jawaid, M.; Khalil, H.A. Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review. Carbohydr. Polym. 2011, 86, 1–18. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Mahmoudi, A.; Shadkam, H.R. Hybrid Polyvinyl Alcohol and Cellulose Fiber Pulp Instead of Asbestos Fibers in Cement-Based Composites. Mech. Compos. Mater. 2015, 51, 231–238. [Google Scholar] [CrossRef]

- Ahmed, S.; Maalej, M.; Paramasivam, P. Strain-hardening behaviour of hybrid fibre reinforced cement composites. J. Ferrocem. 2003, 33, 172–182. [Google Scholar]

- Singh, N.K.; Rai, B. A Review of Fiber Synergy in Hybrid Fiber Reinforced Concrete. J. Appl. Eng. Sci. 2018, 8, 41–50. [Google Scholar] [CrossRef] [Green Version]

- Kurtis, K.E. Innovations in cement-based materials: Addressing sustainability in structural and infrastructure applications. MRS Bull. 2015, 40, 1102–1109. [Google Scholar] [CrossRef] [Green Version]

- Abdulkareem, M.; Havukainen, J.; Horttanainen, M. How environmentally sustainable are fibre reinforced alkali-activated concretes? J. Clean. Prod. 2019, 236, 117601. [Google Scholar] [CrossRef]

- Tonoli, G.H.D.; Savastano, H., Jr.; Fuente, E.; Negro, C.; Blanco, A.; Lahr, F.R. Eucalyptus pulp fibres as alternative reinforcement to engineered cement-based composites. Ind. Crops Prod. 2010, 31, 225–232. [Google Scholar] [CrossRef]

- Jarabo, R.; Fuente, E.; Monte, M.C.; Savastano, H., Jr.; Mutjé, P.; Negro, C. Use of cellulose fibers from hemp core in fiber-cement production. Effect on flocculation, retention, drainage and product properties. Ind. Crops Prod. 2012, 39, 89–96. [Google Scholar] [CrossRef] [Green Version]

- Ardanuy, M.; Claramunt, J.; García-Hortal, J.A.; Barra, M. Fiber-matrix interactions in ce-ment mortar composites reinforced with cellulosic fibers. Cellulose 2011, 18, 281–289. [Google Scholar] [CrossRef]

- Negro, C.; Sánchez, L.M.; Fuente, H.; Blanco, A. Effects of flocculants and sizing agents on bending strength of fiber cement composites. Cem. Concr. Res. 2005, 35, 2104–2109. [Google Scholar] [CrossRef]

- Mármol, G.; Savastano, H., Jr. Study of the degradation of non-conventional MgO-SiO2 cement reinforced with lignocellulosic fibers. Cem. Concr. Compos. 2017, 80, 258–267. [Google Scholar] [CrossRef]

- Marmol, G.; Savastano, H., Jr.; de la Fuente, E.; Miranda, R.; Blanco, A.; Negro, C. Effect of sepiolite addition on fibre-cement based on MgO-SiO₂ systems. Cem. Concr. Res. 2019, 124, 105816. [Google Scholar] [CrossRef]

- Xiao, H.; Zhang, F.; Liu, R.; Zhang, R.; Liu, Z.; Liu, H. Effects of pozzolanic and non-pozzolanic nanomaterials on cement-based materials. Constr. Build. Mater. 2019, 213, 1–9. [Google Scholar] [CrossRef]

- Shukla, A.; Gupta, N.; Gupta, A.; Goel, R.; Kumar, S. Natural Pozzolans a Com-parative Study: A Review. IOP Conf. Ser. Mater. Sci. Eng. 2020, 804, 012040. [Google Scholar] [CrossRef]

- Balea, A.; Fuente, E.; Blanco, A.; Negro, C. Nanocelluloses: Natural-Based Materials for Fiber-Reinforced Cement Composites. A Critical Review. Polymers 2019, 11, 518. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Blanco, A.; Monte, M.C.; Campano, C.; Balea, A.; Merayo, N.; Negro, C. Nanocellulose for industrial use: Cellulose nanofibers (CNF), cellulose nanocrystals (CNC), and bacterial cellulose (BC). In Handbook of Nanomaterials for Industrial Applications; Hussain, C.M., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 74–126. [Google Scholar]

- Negro, C.; Martín, A.B.; Sanchez-Salvador, J.L.; Campano, C.; Fuente, E.; Monte, M.C.; Blanco, A. Nanocellulose and its Potential Use for Sustainable Industrial Applications. Lat. Am. Appl. Res. Int. J. 2020, 50, 59–64. [Google Scholar] [CrossRef]

- Negro, C.; Alonso, A.; Blanco, A.; Tijero, J. Optimization of the Fiber Cement Composite Process. Ind. Eng. Chem. Res. 2006, 45, 197–205. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef] [Green Version]

- Merli, R.; Preziosi, M.; Acampora, A.; Lucchetti, M.C.; Petrucci, E. Recycled fibers in reinforced concrete: A systematic literature review. J. Clean. Prod. 2020, 248, 119207. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Khatib, J.; Colangelo, F.; Tuladhar, R. (Eds.) Use of Recycled Plastics in Eco-Efficient Concrete; Woodhead Publishing: Cambridge, MA, USA, 2018. [Google Scholar]

- Ahmed, W.; Lim, C.W. Production of sustainable and structural fiber reinforced recycled aggregate concrete with im-proved fracture properties: A review. J. Clean. Prod. 2020, 279, 123832. [Google Scholar] [CrossRef]

- Gursel, A.P.; Masanet, E.; Horvath, A.; Stadel, A. Life-cycle inventory analysis of concrete production: A critical review. Cem. Concr. Compos. 2014, 51, 38–48. [Google Scholar] [CrossRef]

- Marinković, S.; Dragaš, J.; Ignjatović, I.; Tošić, N. Environmental assessment of green concretes for structural use. J. Clean. Prod. 2017, 154, 633–649. [Google Scholar] [CrossRef]

- Vieira, D.R.; Calmon, J.L.; Coelho, F.Z. Life cycle assessment (LCA) applied to the manufacturing of common and ecological concrete: A review. Constr. Build. Mater. 2016, 124, 656–666. [Google Scholar] [CrossRef]

- Caggiano, A.; Folino, P.; Lima, C.; Martinelli, E.; Pepe, M. On the mechanical response of Hybrid Fiber Reinforced Concrete with Recycled and Industrial Steel Fibers. Constr. Build. Mater. 2017, 147, 286–295. [Google Scholar] [CrossRef]

- Baricevic, A.; Bjegovic, D.; Skazlic, M. Hybrid fiber–reinforced concrete with unsorted recycled-tire steel fibers. J. Mater. Civil Eng. 2017, 29, 06017005. [Google Scholar] [CrossRef]

- Asokan, P.; Osmani, M.; Price, A. Improvement of the mechanical properties of glass fibre reinforced plastic waste powder filled concrete. Constr. Build. Mater. 2010, 24, 448–460. [Google Scholar] [CrossRef]

- Liew, K.; Akbar, A. The recent progress of recycled steel fiber reinforced concrete. Constr. Build. Mater. 2020, 232, 117232. [Google Scholar] [CrossRef]

- Awolusi, T.F.; Oke, O.L.; Atoyebi, O.D.; Akinkurolere, O.O.; Sojobi, A.O. Waste tires steel fiber in concrete: A review. Innov. Infrastruct. Solutions 2021, 6, 1–12. [Google Scholar] [CrossRef]

- Toghroli, A.; Shariati, M.; Sajedi, F.; Ibrahim, Z.; Koting, S.; Mohamad, E.T.; Khorami, M. A review on pavement porous concrete using recycled waste materials. Smart Struct. Syst. 2018, 22, 433–440. [Google Scholar]

- Gu, L.; Ozbakkaloglu, T. Use of recycled plastics in concrete: A critical review. Waste Manag. 2016, 51, 19–42. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, H.U.; Faraj, R.H.; Hilal, N.; Mohammed, A.A.; Sherwani, A.F.H. Use of recycled fibers in concrete composites: A systematic comprehensive review. Compos. Part B Eng. 2021, 215, 108769. [Google Scholar] [CrossRef]

- Park, J.; Kim, M. Mechanical Properties of Cement-Based Materials with Recycled Plastic: A Review. Sustainability 2020, 12, 9060. [Google Scholar] [CrossRef]

- Wahlström, M.; Bergmans, J.; Teittinen, T.; Bachér, J.; Smeets, A.; Paduart, A. Construction and Demolition Waste: Challenges and Opportunities in a Circular Economy; ETC/WMGE 2020/1; European Environment Agency European Topic Centre Waste and Materials in a Green Economy: Copenhagen, Denmark, 2020. [Google Scholar]

- Ghani, S.S. A comprehensive review of database resources in chemistry. Eclética Quim. J. 2020, 45, 57–68. [Google Scholar] [CrossRef]

- Gabrielson, S.W. SciFinder. J. Med Libr. Assoc. 2018, 106, 588–590. [Google Scholar] [CrossRef] [Green Version]

- Jacso, P. As we may search—Comparison of major features of the Web of Science, Scopus, and Google Scholar citation-based and citation-enhanced databases. Curr. Sci. 2005, 89, 1537–1547. [Google Scholar]

- Abbas, A. Management of steel solid waste generated from lathes as fiber reinforced concrete. Eur. J. Sci. Res. 2011, 50, 481–485. [Google Scholar]

- Medina, N.F.; Medina, D.F.; Hernández-Olivares, F.; Navacerrada, M. Mechanical and thermal properties of concrete incorporating rubber and fibres from tyre recycling. Constr. Build. Mater. 2017, 144, 563–573. [Google Scholar] [CrossRef]

- Flores-Medina, D.; Medina, N.F.; Hernández-Olivares, F. Static mechanical properties of waste rests of recycled rubber and high quality recycled rubber from crumbed tyres used as aggregate in dry consistency concretes. Mater. Struct. 2013, 47, 1185–1193. [Google Scholar] [CrossRef]

- Gupta, T.; Sharma, R.K.; Chaudhary, S. Impact resistance of concrete containing waste rubber fiber and silica fume. Int. J. Impact Eng. 2015, 83, 76–87. [Google Scholar] [CrossRef]

- Gupta, T.; Siddique, S.; Sharma, R.K.; Chaudhary, S. Effect of elevated temperature and cooling regimes on mechanical and durability properties of concrete containing waste rubber fiber. Constr. Build. Mater. 2017, 137, 35–45. [Google Scholar] [CrossRef]

- Sudharsan, N.; Palanisamy, T.; Subhash, C.Y. Environmental sustainability of waste glass as a valuable construction material-A critical review. Ecol. Environ. Conserv. 2018, 24, S331–S338. [Google Scholar]

- Sebaibi, N.; Benzerzour, M.; Abriak, N.E. Influence of the distribution and orientation of fibres in a reinforced concrete with waste fibres and powders. Constr. Build. Mater. 2014, 65, 254–263. [Google Scholar] [CrossRef]

- Clark, E.; Bleszynski, M.; Valdez, F.; Kumosa, M. Recycling carbon and glass fiber polymer matrix composite waste into cementitious materials. Resour. Conserv. Recycl. 2020, 155, 104659. [Google Scholar] [CrossRef]

- Ismail, Z.Z.; Al-Hashmi, E.A. Use of waste plastic in concrete mixture as aggregate replacement. Waste Manag. 2008, 28, 2041–2047. [Google Scholar] [CrossRef]

- Guendouz, M.; Debieb, F.; Boukendakdji, O.; Kadri, E.; Bentchikou, M.; Soualhi, H. Use of plastic waste in sand concrete. J. Mater. Environ. Sci. 2016, 7, 382–389. [Google Scholar]

- De Oliveira, L.A.P.; Castro-Gomes, J.P. Physical and mechanical behaviour of recycled PET fibre reinforced mortar. Constr. Build. Mater. 2011, 25, 1712–1717. [Google Scholar] [CrossRef]

- Kim, S.B.; Yi, N.H.; Kim, H.Y.; Kim, J.-H.J.; Song, Y.-C. Material and structural performance evaluation of recycled PET fiber reinforced concrete. Cem. Concr. Compos. 2010, 32, 232–240. [Google Scholar] [CrossRef]

- Hannawi, K.; Kamali-Bernard, S.; Prince, W. Physical and mechanical properties of mortars containing PET and PC waste aggregates. Waste Manag. 2010, 30, 2312–2320. [Google Scholar] [CrossRef]

- Dar, U.N.; Salhotra, S. Effect of Metakaolin and Plastic Bottles on Durability of Concrete: Experimental Work. Int. J. Civ. Eng. 2017, 7, 830–835. [Google Scholar]

- Dinesh, Y.; Chappidi, H. Strength characteristics of fibre reinforced concrete using recycled PET. Int. J. Civ. Eng. Technol. 2017, 8, 92–99. [Google Scholar]

- Yang, E.-H.; Li, V.C. Strain-hardening fiber cement optimization and component tailoring by means of a micromechanical model. Constr. Build. Mater. 2010, 24, 130–139. [Google Scholar] [CrossRef]

- Kou, S.; Lee, G.; Poon, C.; Lai, W. Properties of lightweight aggregate concrete prepared with PVC granules derived from scraped PVC pipes. Waste Manag. 2009, 29, 621–628. [Google Scholar] [CrossRef]

- Naik, T.; Singh, S.; Huber, C.; Brodersen, B. Use of post-consumer waste plastics in cement-based composites. Cem. Concr. Res. 1996, 26, 1489–1492. [Google Scholar] [CrossRef]

- Bhavi, B.K.; Reddy, V.V.; Ullagaddi, P. Effect of different percentages of waste high density polyethylene (HDPE) fibres on the properties of fibre reinforced concrete. Nat. Environ. Pollut. Technol. 2012, 11, 461. [Google Scholar]

- Pešić, N.; Živanović, S.; Garcia, R.; Papastergiou, P. Mechanical properties of concrete reinforced with recycled HDPE plastic fibres. Constr. Build. Mater. 2016, 115, 362–370. [Google Scholar] [CrossRef] [Green Version]

- Girardi, F.; Giannuzzi, G.; Mazzei, D.; Salomoni, V.; Majorana, C.; Di Maggio, R. Recycled additions for improving the thermal conductivity of concrete in preparing energy storage systems. Constr. Build. Mater. 2017, 135, 565–579. [Google Scholar] [CrossRef]

- Panyakapo, P.; Panyakapo, M. Reuse of thermosetting plastic waste for lightweight concrete. Waste Manag. 2008, 28, 1581–1588. [Google Scholar] [CrossRef] [PubMed]

- Al-Manaseer, A.; Dalal, T. Concrete containing plastic aggregates. Concr. Int. 1997, 19, 47–52. [Google Scholar]

- Ghernouti, Y.; Rabehi, B.; Bouziani, T.; Ghezraoui, H.; Makhloufi, A. Fresh and hardened properties of self-compacting concrete containing plastic bag waste fibers (WFSCC). Constr. Build. Mater. 2015, 82, 89–100. [Google Scholar] [CrossRef]

- Kandasamy, R.; Murugesan, R. Fibre reinforced concrete using domestic waste plastics as fibres. ARPN J. Eng. Appl. Sci. 2011, 6, 75–82. [Google Scholar]

- Awal, A.; Mohammadhosseini, H.; Hossain, M.Z. Strength, modulus of elasticity and shrinkage behaviour of concrete containing waste carpet fiber. Int. J. Geomate 2015, 9, 1441–1446. [Google Scholar]

- Awal, A.A.; Mohammadhosseini, H. Green concrete production incorporating waste carpet fiber and palm oil fuel ash. J. Clean. Prod. 2016, 137, 157–166. [Google Scholar] [CrossRef]

- Kan, A.; Demirboğa, R. A novel material for lightweight concrete production. Cement Concrete Comp. 2009, 31, 489–495. [Google Scholar] [CrossRef]

- Domski, J.; Katzer, J.; Zakrzewski, M.; Ponikiewski, T. Comparison of the mechanical characteristics of engineered and waste steel fiber used as reinforcement for concrete. J. Clean. Prod. 2017, 158, 18–28. [Google Scholar] [CrossRef]

- Ozerkan, N.; Tokgoz, D.; Kowita, O.; Antony, S. Assessment of Microstructural and Mechanical Properties of Hybrid Fibrous Self-Consolidating Concretes Using Ingredients of Plastic Wastes. Nat. Environ. Pollut. Technol. 2016, 15, 1161. [Google Scholar]

- Al-Tikrite, A.; Hadi, M.N. Mechanical properties of reactive powder concrete containing industrial and waste steel fibres at different ratios under compression. Constr. Build. Mater. 2017, 154, 1024–1034. [Google Scholar] [CrossRef] [Green Version]

- Onuaguluchi, O.; Banthia, N. Scrap tire steel fiber as a substitute for commercial steel fiber in cement mortar: Engineering properties and cost-benefit analyses. Resour. Conserv. Recycl. 2018, 134, 248–256. [Google Scholar] [CrossRef]

- Pająk, M.; Janiszewski, J.; Kruszka, L. Laboratory investigation on the influence of high compressive strain rates on the hybrid fibre reinforced self-compacting concrete. Constr. Build. Mater. 2019, 227, 116687. [Google Scholar] [CrossRef]

- Jandiyal, A.; Salhotra, S.; Sharma, R.; Nazir, U. A review on using fibers made from waste PET bottles in concrete. Int. J. Civ. Eng. Technol. 2016, 7, 553–564. [Google Scholar]

- Yin, S.; Tuladhar, R.; Combe, M.; Collister, T.; Jacob, M.; Shanks, R. Mechanical properties of recycled plastic fibres for reinforcing concrete. In Proceedings of the 7th International Conference Fibre Concrete, Prague, Czech Republic, 12–13 September 2013. [Google Scholar]

- Hu, H.; Papastergiou, P.; Angelakopoulos, H.; Guadagnini, M.; Pilakoutas, K. Mechanical properties of SFRC using blended manufactured and recycled tyre steel fibres. Constr. Build. Mater. 2018, 163, 376–389. [Google Scholar] [CrossRef]

- Chen, M.; Zhong, H.; Zhang, M. Flexural fatigue behaviour of recycled tyre polymer fibre reinforced concrete. Cem. Concr. Compos. 2020, 105, 103441. [Google Scholar] [CrossRef]

- Chen, M.; Zhong, H.; Chen, L.; Zhang, Y.; Zhang, M. Engineering properties and sustainability assessment of recycled fibre reinforced rubberised cementitious composite. J. Clean. Prod. 2021, 278, 123996. [Google Scholar] [CrossRef]

- Wang, Y.; Chan, C.L.; Leong, S.H.; Zhang, M. Engineering properties of strain hardening geopolymer composites with hybrid polyvinyl alcohol and recycled steel fibres. Constr. Build. Mater. 2020, 261, 120585. [Google Scholar] [CrossRef]

- Zhong, H.; Zhang, M. Experimental study on engineering properties of concrete reinforced with hybrid recycled tyre steel and polypropylene fibres. J. Clean. Prod. 2020, 259, 120914. [Google Scholar] [CrossRef]

- Naser, M.H.; Naser, F.H.; Dhahir, M.K. Tensile behavior of fiber reinforced cement mortar using wastes of electrical connections wires and galvanized binding wires. Constr. Build. Mater. 2020, 264, 120244. [Google Scholar] [CrossRef]

- Yin, S.; Tuladhar, R.; Sheehan, M.; Combe, M.; Collister, T. A life cycle assessment of recycled polypropylene fibre in concrete footpaths. J. Clean. Prod. 2016, 112, 2231–2242. [Google Scholar] [CrossRef]

- Tian, S.; An, H.; Hu, Z.; Pei, C. Effects of Waste Hybrid Fibers with Different Mixing Ratios on Properties of Recycled Concrete. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 563, p. 022043. [Google Scholar]

- Signorini, C.; Volpini, V. Mechanical Performance of Fiber Reinforced Cement Composites Including Fully-Recycled Plastic Fibers. Fibers 2021, 9, 16. [Google Scholar] [CrossRef]

- Cheng, W.; Liu, G.; Chen, L. Pet Fiber Reinforced Wet-Mix Shotcrete with Walnut Shell as Replaced Aggregate. Appl. Sci. 2017, 7, 345. [Google Scholar] [CrossRef] [Green Version]

- Fadhil, S.; Yaseen, M. The production of economical precast concrete panels reinforced by waste plastic fibers. Am. J. Civ. Eng. 2015, 3, 80–85. [Google Scholar]

- Zhou, B.; Zhang, M.; Wang, L.; Ma, G. Experimental study on mechanical property and microstructure of cement mortar reinforced with elaborately recycled GFRP fiber. Cem. Concr. Compos. 2021, 117, 103908. [Google Scholar] [CrossRef]

- Meddah, M.S.; Bencheikh, M. Properties of concrete reinforced with different kinds of industrial waste fibre materials. Constr. Build. Mater. 2009, 23, 3196–3205. [Google Scholar] [CrossRef]

- Grzymski, F.; Musiał, M.; Trapko, T. Mechanical properties of fibre reinforced concrete with recycled fibres. Constr. Build. Mater. 2019, 198, 323–331. [Google Scholar] [CrossRef]

- Pelisser, F.; Montedo, O.R.K.; Gleize, P.J.P.; Roman, H.R. Mechanical properties of recycled PET fibers in concrete. Mater. Res. 2012, 15, 679–686. [Google Scholar] [CrossRef]

- García, D.; Vegas, I.; Cacho, I. Mechanical recycling of GFRP waste as short-fiber reinforcements in microconcrete. Constr. Build. Mater. 2014, 64, 293–300. [Google Scholar] [CrossRef]

- Ogi, K.; Shinoda, T.; Mizui, M. Strength in concrete reinforced with recycled CFRP pieces. Compos. Part A: Appl. Sci. Manuf. 2005, 36, 893–902. [Google Scholar] [CrossRef]

- Aiello, M.; Leuzzi, F.; Centonze, G.; Maffezzoli, A. Use of steel fibres recovered from waste tyres as reinforcement in concrete: Pull-out behaviour, compressive and flexural strength. Waste Manag. 2009, 29, 1960–1970. [Google Scholar] [CrossRef] [PubMed]

- Anandan, S.; Alsubih, M. Mechanical Strength Characterization of Plastic Fiber Reinforced Cement Concrete Composites. Appl. Sci. 2021, 11, 852. [Google Scholar] [CrossRef]

- Ahmadi, M.; Farzin, S.; Hassani, A.; Motamedi, M. Mechanical properties of the concrete containing recycled fibers and aggregates. Constr. Build. Mater. 2017, 144, 392–398. [Google Scholar] [CrossRef]

- Fauzan, I.F.A.; Sandi, R.; Al Jauhari, Z. The Influence of Steel Fibers Extracted from Waste Tyre on Properties of Concrete Containing Fly Ash. Int. J. Adv. Sci. Eng. Inf. Technol. 2017, 7, 2232–2236. [Google Scholar] [CrossRef]

- Martinelli, E.; Caggiano, A.; Xargay, H. An experimental study on the post-cracking behaviour of Hybrid Industrial/Recycled Steel Fibre-Reinforced Concrete. Constr. Build. Mater. 2015, 94, 290–298. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A.; Sattarifard, A.; Illikainen, M. Development of eco-efficient and cost-effective reinforced self-consolidation concretes with hybrid industrial/recycled steel fibers. Constr. Build. Mater. 2018, 166, 214–226. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A.; Sattarifard, A.; Abdollahnejad, Z.; Illikainen, M. Characterization and optimization of hardened properties of self-consolidating concrete incorporating recycled steel, industrial steel, polypropylene and hybrid fibers. Compos. Part B Eng. 2018, 151, 186–200. [Google Scholar] [CrossRef]

- Cojocaru, R.; Andrei, R.; Muscalu, M.; Taranu, N.; Budescu, M.; Lungu, I. The behavior of cement concrete made with recycled materials for airport rigid pavements. Rev. Rom. Mater. 2013, 43, 363–372. [Google Scholar]

- Groli, G.; Caldentey, A.P. Improving cracking behaviour with recycled steel fibres targeting specific applications—Analysis according to fib Model Code 2010. Struct. Concr. 2017, 18, 29–39. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A.; Sattarifard, A. The impact resistance and mechanical properties of reinforced self-compacting concrete with recycled glass fibre reinforced polymers. J. Clean. Prod. 2016, 124, 312–324. [Google Scholar] [CrossRef]

- Chen, C.; Huang, R.; Wu, J.; Yang, C. Waste E-glass particles used in cementitious mixtures. Cem. Concr. Res. 2006, 36, 449–456. [Google Scholar] [CrossRef]

- Pereira, E.L.; Junior, A.L.D.O.; Fineza, A.G. Optimization of mechanical properties in concrete reinforced with fibers from solid urban wastes (PET bottles) for the production of ecological concrete. Constr. Build. Mater. 2017, 149, 837–848. [Google Scholar] [CrossRef]

- Spadea, S.; Farina, I.; Berardi, V.P.; Dentale, F.; Fraternali, F. Energy dissipation capacity of concretes reinforced with recycled PET fibers. Ing. Sismica 2014, 31, 61–70. [Google Scholar]

- Marthong, C. Effects of PET fiber arrangement and dimensions on mechanical properties of concrete. IES J. Part A Civ. Struct. Eng. 2015, 8, 111–120. [Google Scholar] [CrossRef]

- Marthong, C.; Sarma, D.K. Influence of PET fiber geometry on the mechanical properties of concrete: An experimental investigation. Eur. J. Environ. Civ. Eng. 2016, 20, 771–784. [Google Scholar] [CrossRef]

- Borg, R.P.; Baldacchino, O.; Ferrara, L. Early age performance and mechanical characteristics of recycled PET fibre reinforced concrete. Constr. Build. Mater. 2016, 108, 29–47. [Google Scholar] [CrossRef] [Green Version]

- Irwan, J.; Othman, N.; Koh, K.H.; Asyraf, R.; Faisal, S.; Annas, M.; Shahrizan, A.; Koh, H. Development of Mix Design Nomograph for Polyethylene Terephthalate Fiber Concrete. Appl. Mech. Mater. 2012, 253-255, 408–416. [Google Scholar] [CrossRef] [Green Version]

- Karthikeyan, S.; Vennila, G. Analysis of compressive strength of concrete using polyethylene terephthalate [PET] fibres. Int. J. Appl. Eng. Res. 2015, 10, 34776–34778. [Google Scholar]

- Fraternali, F.; Spadea, S.; Berardi, V.P. Effects of recycled PET fibres on the mechanical properties and seawater curing of Portland cement-based concretes. Constr. Build. Mater. 2014, 61, 293–302. [Google Scholar] [CrossRef]

- Saikia, N.; de Brito, J. Use of plastic waste as aggregate in cement mortar and concrete preparation: A review. Constr. Build. Mater. 2012, 34, 385–401. [Google Scholar] [CrossRef]

- Alhozaimy, A.; Shannag, M. Performance of concretes reinforced with recycled plastic fibres. Mag. Concr. Res. 2009, 61, 293–298. [Google Scholar] [CrossRef]

- Zhang, P.; Li, Q.-F. Effect of polypropylene fiber on durability of concrete composite containing fly ash and silica fume. Compos. Part B Eng. 2013, 45, 1587–1594. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A. Use of silica fume and recycled steel fibers in self-compacting concrete (SCC). Constr. Build. Mater. 2016, 125, 196–209. [Google Scholar] [CrossRef]

- Chu, S. Development of infilled cementitious composites. Compos. Struct. 2021, 267, 113885. [Google Scholar] [CrossRef]

- Centonze, G.; Leone, M.; Aiello, M. Steel fibers from waste tires as reinforcement in concrete: A mechanical characterization. Constr. Build. Mater. 2012, 36, 46–57. [Google Scholar] [CrossRef]

- Dehghan, A.; Peterson, K.; Shvarzman, A. Recycled glass fiber reinforced polymer additions to Portland cement concrete. Constr. Build. Mater. 2017, 146, 238–250. [Google Scholar] [CrossRef]

- Zotov, R.; Meshcheryakov, E.; Livanova, A.; Minakova, T.; Magaev, O.; Isupova, L.; Kurzina, I. Influence of the Composition, Structure, and Physical and Chemical Properties of Aluminium-Oxide-Based Sorbents on Water Adsorption Ability. Mater. 2018, 11, 132. [Google Scholar] [CrossRef] [Green Version]

- Achilleos, C.; Hadjimitsis, D.; Neocleous, K.; Pilakoutas, K.; Neophytou, P.O.; Kallis, S. Proportioning of Steel Fibre Reinforced Concrete Mixes for Pavement Construction and Their Impact on Environment and Cost. Sustainability 2011, 3, 965–983. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Xiao, F.; Zhang, L.; Amirkhanian, S.N. Life cycle assessment and life cycle cost analysis of recy-cled solid waste materials in highway pavement: A review. J. Clean. Prod. 2019, 233, 1182–1206. [Google Scholar] [CrossRef]

- Li, V.C. A simplified micromechanical model of compressive strength of fiber-reinforced cementitious composites. Cem. Concr. Compos. 1992, 14, 131–141. [Google Scholar] [CrossRef] [Green Version]

- Bjegovic, D.; Baricevic, A.; Lakušić, S. Innovative low cost fibre-reinforced concrete. Part I: Mechanical and durability properties. In Proceedings of the Third International Conference on Concrete Repair, Rehabilitation and Retrofitting (ICCRRR 2012), Cape Town, South Africa, 3–5 September 2012. [Google Scholar]

- Bjegovic, D.; Baricevic, A.; Lakusic, S.; Damjanovic, D.; Duvnjak, I. Positive Interaction of Industrial and Recycled Steel Fibres in Fibre Reinforced Concrete. J. Civ. Eng. Manag. 2014, 19, S50–S60. [Google Scholar] [CrossRef] [Green Version]

- Serdar, M.; Baričević, A.; Lakušić, S.; Bjegović, D. Special purpose concrete products from waste tyre recyclates. Građevinar 2013, 65, 793–801. [Google Scholar]

- Hu, H.; Papastergiou, P.; Angelakopoulos, H.; Guadagnini, M.; Pilakoutas, K. Mechanical properties of SFRC using blended Recycled Tyre Steel Cords (RTSC) and Recycled Tyre Steel Fibres (RTSF). Constr. Build. Mater. 2018, 187, 553–564. [Google Scholar] [CrossRef]

- Portland Cemen; IQS No.5/1984; Central Agency for Standardization and Quality Control: Baghdad, Iraq, 1984.

- UNI-11039-2. Steel Fiber Reinforced Concrete—Test Method to Determine the First Crack Strength and Ductility Indexes; UNI Editions: Milan, Italy, 2003. [Google Scholar]

- Naaman, A.E.; Reinhardt, H.W. Proposed classification of HPFRC composites based on their tensile response. Mater. Struct. 2006, 39, 547–555. [Google Scholar] [CrossRef]

- Schmidt, H.; Cieślak, M. Concrete with carpet recyclates: Suitability assessment by surface energy evaluation. Waste Manag. 2008, 28, 1182–1187. [Google Scholar] [CrossRef] [PubMed]

- Choi, W.-C.; Yun, H.-D.; Kang, J.-W.; Kim, S.-W. Development of recycled strain-hardening cement-based composite (SHCC) for sustainable infrastructures. Compos. Part B Eng. 2012, 43, 627–635. [Google Scholar] [CrossRef]

- Yu, J.; Yao, J.; Lin, X.; Li, H.; Lam, J.Y.; Leung, C.K.; Sham, I.M.; Shih, K. Tensile performance of sustainable Strain-Hardening Cementitious Composites with hybrid PVA and recycled PET fibers. Cem. Concr. Res. 2018, 107, 110–123. [Google Scholar] [CrossRef]

- Chi, C.-P.; Pei, C.-C. Finite Element Simulation Analysis on Crack Resistance of Recycled Concrete Beams of Hybrid Fiber with Waste Polypropylene Fiber. IOP Conf. Series: Mater. Sci. Eng. 2018, 423, 012124. [Google Scholar] [CrossRef]

- Cui, X.; Pei, C.-C.; Chi, C.-P. Experimental Study on Cracking Resistance of Recycled Concrete Beams Reinforced with Hybrid Polyacrylonitrile and Recycled Fibers. IOP Conf. Ser. Earth Environ. Sci. 2019, 330, 022122. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A. Fresh and Hardened Properties of Self-Compacting Concrete Reinforced with Hybrid Recycled Steel–Polypropylene Fiber. J. Mater. Civ. Eng. 2017, 29, 04017012. [Google Scholar] [CrossRef]

- Karthik, M.P.; Maruthachalam, D. Experimental study on shear behaviour of hybrid Fibre Reinforced Concrete beams. KSCE J. Civ. Eng. 2014, 19, 259–264. [Google Scholar] [CrossRef]

- Foglar, M.; Hajek, R.; Kovar, M.; Štoller, J. Blast performance of RC panels with waste steel fibers. Constr. Build. Mater. 2015, 94, 536–546. [Google Scholar] [CrossRef]

- Thirumurugan, A.; Sivaraja, M. Workability and Strength Properties of Hybrid Fibre Reinforced Concrete from Industrial Waste. Asian J. Civ. Eng. 2013, 14, 477–485. [Google Scholar]

- Thirumurugan, A.; Sivaraja, M. Strength and fracture properties of hybrid fibre reinforced concrete. IJST-T. Civ. Eng. 2015, 39, 93. [Google Scholar]

- Figueiredo, F.P.; Huang, S.-S.; Angelakopoulos, H.; Pilakoutas, K.; Burgess, I. Effects of Recycled Steel and Polymer Fibres on Explosive Fire Spalling of Concrete. Fire Technol. 2019, 55, 1495–1516. [Google Scholar] [CrossRef] [Green Version]

- Serdar, M.; Baričević, A.; Bjegović, D.; Lakušić, S. Possibilities of use of products from waste tyre recycling in concrete industry. J. Appl. Eng. Sci. 2014, 12. [Google Scholar] [CrossRef] [Green Version]

- Papakonstantinou, C.G.; Tobolski, M.J. Use of waste tire steel beads in Portland cement concrete. Cem. Concr. Res. 2006, 36, 1686–1691. [Google Scholar] [CrossRef]

- Onuaguluchi, O. Effects of surface pre-coating and silica fume on crumb rubber-cement matrix interface and cement mortar properties. J. Clean. Prod. 2015, 104, 339–345. [Google Scholar] [CrossRef]

- Farhan, A.H.; Dawson, A.R.; Thom, N.H. Recycled hybrid fiber-reinforced & cement-stabilized pavement mixtures: Tensile properties and cracking characterization. Constr. Build. Mater. 2018, 179, 488–499. [Google Scholar] [CrossRef]

- Paul, S.C.; Van Zijl, G.P.; Tan, M.J.; Gibson, I. A review of 3D concrete printing systems and materials properties: Current status and future research prospects. Rapid Prototyp. J. 2018, 24, 784–798. [Google Scholar] [CrossRef] [Green Version]

| Length (mm) | Width (µm) | Apparent Density (kg/m3) | Melting Point (°C) | Young’s Modulus (GPa) | Tensile Strength (MPa) | Ref. | |

|---|---|---|---|---|---|---|---|

| Steel (tire) | 11 | 530 | 7850 | 1435 | 210 | 400 | [70] |

| Steel (tire) | 2–30 | 150 | 7850 | - | 210 | 2850 | [82] |

| Steel (tire) | 23 | 220 | - | 200 | 2570 | [85,86,87] | |

| Steel (tire) | 20 | 150 | 7800 | - | 200 | 2850 | [88] |

| Recycled polymer fiber (tire) | 8.7 | 21.1 | 1160 | >210 | 3.21 | 475 | [86,87,89] |

| Copper (electrical conductors) | 10 | 170 | 8760 | - | - | 387 | [90] |

| Steel (galvanized binding wire) | 20 | 800 | 7500 | - | - | 510 | [90] |

| PP | 47 | 700–1500 | 900–920 | 154–170 | 0.619 | 313 | [84,91] |

| PP (carpets) | 6 | - | 900 | 93.1–110 | - | [92] | |

| PE/PP (artificial turf) | 10–40 | 330 | 985 | - | - | - | [93] |

| PA (carpets) | 5–11 | 38–41 | - | 258 | 5 | 286 | [70] |

| PET (bottles) | 4 | 500 | 1230 | 260 | 2.4 | 60 | [59] |

| PET (embossed) | 50 | 200 | 1380 | - | 10.2 | 420.7 | [61] |

| PET | 20–25 | 340 | - | - | 3.83 | 108 | [94] |

| PET | 40 | 2000–2500 | 1380 | - | 2.758 | 79.3 | [95] |

| PET/PE (packaging) | 10 | 800 | 1350 | - | - | - | [93] |

| HDPE | 3–10 | 100 | - | - | 0.672 | 25.22 | [79] |

| Glass Fiber Reinforced Polymer | 3.1–9.5 | 1.1–3.2 | 1760–2080 | - | 47.8–73.1 | 11.2–13.9 | [96] |

| Cement Type | Fiber 1-(Dimensions: L, W, T or d)–Doses (in Volume Fraction) | Fiber 2- (Dimensions: L, W, T or d)–Doses (in Volume Fraction) | Recycling Source | Effect on Mechanical Properties | Other Effects | Application | Ref. |

|---|---|---|---|---|---|---|---|

| FRC: - OP 42.5 - w/c = 0.49 - Sand and coarse aggregates - Superplasticizer | Recycled steel fiber (L = 6–74 mm, d = 0.11–0.44 mm)—0.375%, 0.625% and 0.875% | Steel fiber (Non-recycled) (L = 6–70 mm, d = 0.15–1.20 mm)—0.375% | Recycled steel: waste tires | ΔCS ≈ 5–10% * ΔFirst crack strength ≈ 20% ** ΔDuctibility ≈ −3.8% ** (D0 index) and −14.5% ** (D1 index) (0.75% of mixed-total fibers, 50 recycled:50 non-recycled) | Recycled steel fibers turns the post-cracking behaviour of the FRC from crack-hardening to crack-plastic (reduction in the D1 index) | Structural applications | [37] |

| FRC: - OP 42.5 - w/c = 0.50 - Sand - Coarse aggregates - Superplasticizer | Recycled steel fiber (L = 9–15 mm, d = 0.11–1.64 mm)—0.5% (with 25%, 50% and 100% of non-recycled steel fibers replaced by an equal amount of recycled steel fibers) | Steel fiber (Non-recycled)—0.5% | Recycled steel: waste tires | ΔCS ≈ −6% ** ΔFirst crack strength ≈ 10.4% ** ΔDuctibility ≈ −28.2% ** (D0 index) and −9.2% ** (D1 index) (0.50% of mixed-total fibers, 50% of non-recycled steel fibers replaced by an equal amount of recycled steel fibers) | All R-FRC can be classified as “crack-softening” (both D0 and D1 < 1) | Structural applications | [106] |

| Rubberized FRC: - d = 0.5–2 mm - Replacing 5% vol of aggregates - Recycled rubber granules | Industrial steel fibers (L = 35 mm, d = 0.55 mm)—1.5% and 3% (w/v) | Recycled steel fibers (L < 15 mm, d = 0.18 mm)—1.5% and 3% (w/v) | Mechanical recycling of waste tires | Without rubber: ΔCS ≈ 0% ***, ΔT/L150 = 49% ** With rubber: ΔCS ≈- 20% ***, ΔT/L150 = 70% *** (50% industrial + 50% recycled steel fibers) | Cost savings up to 50% Impact strength increased up to 15% *** by using 5% rubber in FRC | Construction of high speed railways | [133] |

| FRC: - CEM II/ B-M SV 42.5N - w/c =0.46 - Crushed dolomite river sand - Superplasticiser | Recycled unshorted steel fiber (L = 0-15 mm (85% of the fibers), d = 0.55 mm)—3%, 5%, 8%, 12% and 15% (w/w) | Steel fiber (Non-recycled) (L = 35 mm, d = 0.55 mm)—1.7%, 2.4% (w/w) | Recycled steel: waste tires | ΔCS ≈ −1% ** ΔFS ≈ −4% ** (3% recycled + 1.7% industrial) | Does not affect workability (compared to industrial fibers) if dose of recycled fibers is less than 1.2% v | Structural applications | [38] |

| SCC: - OP 42.5R, - w/c =0.76 - Fly ash - Sand - Superplasticiser | Recycled steel fiber (L > 50 mm (63% of the fibers), d = 0.15 mm) –0.5–1% | Industrial steel fiber (non-recycled) (L/D = 47)—0.5–1% | Recycled steel: waste tires | ΔCS ≈ 50% * ΔTS ≈ 27%; ΔFS ≈ 35%* (0.5% recycled + 1% industrial fiber) | Impact strength increased up to 300% * (0.5% Recycled + 1% industrial fiber.) | Structural applications | [108] |

| SCC: - OP 42.5R, - w/c = 0.76 - Fly ash - Sand - Superplasticiser | Recycled steel fiber –0.15–1.35% | Steel fiber—0.15–1.35% | Recycled steel: waste tires | ΔCS ≈ 40–55% * ΔFS ≈ 25–40% * Both decreased with increasing recycled fiber fraction. | Impact strength increased up to 300% *. It decreased with increasing recycled fiber fraction | Structural applications | [108] |

| FRC: - OP - w/c = 0.55 - Coarse aggregate - Sand | Recycled steel fiber (L = 23 mm, d = 0.22 mm)—0.35%, 0.45% and 0.57% | Steel long fiber (LSF)(Non-recycled) (L = 60 mm, d = 1 mm)—0.35%, 0.45% and 0.57% Steel short fiber (SSF)(Non-recycled) (L = 55 mm, d = 0.8 mm)—0.35%, 0.45% and 0.57% | Recycled steel: post-processed steel fibers recovered from end-of-life tires | ΔCS ≈ 5% * ΔCS ≈ 20% ** ΔFS ≈ 70% * ΔFS ≈ 11% ** (0.28 recycled + 0.28 SSF) ΔCS ≈ −6% * ΔCS ≈ 1.6% ** ΔFS ≈ 20% * ΔFS ≈ −14% ** (0.28 recycled + 0.28 LSF) | Replaced of LSF or SSF by recycled fibers increased slump | Slabs-on grade and suspended slabs. | [85] |

| FRC: - OP - w/c = 0.55 - Coarse aggregate - Sand | Recycled steel short fibers (RSF) (L = 23 mm, d = 0.22 mm)—0.65%, 1%, 1.3 and 2% (w/w) | Recycled steel cord (RSC) (L = 60 mm, d = 0.75 mm)—0.65%, 1%, 1.3 and 2% (w/w) | RSC: un-vulcanised rubber belt off-cuts RSF: post-processed steel fibers from waste tires | ΔCS ≈ 22% * ΔCS ≈ 15% ** ΔFS ≈ 19% * ΔFS ≈ 13% ** (1% RSF + 1% RSC) | Deflection hardening behaviour Post-cracking strength increased 103% ** | Concrete flooring applications | [135] |

| Reactive powder concrete: - w/c = 0.55 - Silica fume - Sand (0.6 mm) - Silica powder - Superplasticiser | Recycled steel fibers (L = 20–30 mm (47.6% of the fibers), d = 0.15–20 mm (40.9% of the fibers))—1%, 2%, 3% and 4% | Micro-steel fibers (Non-recycled) (L = 6 mm, d = 0.2 mm)—1%, 2%, 3% and 4% | Recycled steel: waste tires | ΔCS ≈ 25% *, ΔCS ≈ 20% ** ΔToughness = 200%*, 20% *** | Flowability decreases caused by fibers addition Better flowability with hybrid fibers than that for the non-hybrid mixture with the same amount of fibers | Structural applications | [80] |

| Deformed steel fibers (Non-recycled) (L = 18 mm, d = 0.55 mm)—1%, 2%, 3%, 4% (v/v) | |||||||

| FRC: - OP: IQS No.5 [136] - w/c = 0.39 - Sand - Superplasticizer | Recycled steel fiber (L = 20 mm, d = 800µm) —0.25–2.0% | Recycled copper fibers (L = 10 mm, d = 170 µm) —0.25–2.0% | Wastes from electrical connections and galvanized binding wires | ΔCS ≈ 20% *, ΔCS ≈ 77% *** ΔFS ≈ 105% *, ΔTS ≈140% * ΔFS ≈ −4% **, ΔTS ≈ −6% * (0.3% Coper + 0.7% Steel) | Flow table decreased 13% * | - | [90] |

| FRC: - OP 42.5R - w/c = 0.5 - Natural sand - Fine aggregate | Micro SSF (L = 10–16 mm, d = 200–300 µm)— 0%, 0.12%, 0.16%, 0.175%, 0.25%, 0.35% and 0.5% | HE (L = 30 mm, d = 650 µm)—0.12%, 0.16%, 0.175%, 0.25%, 0.35% and 0.5% | Scrap waste tires | ΔCS ≈ 0% *, ΔCS ≈ 0% ** ΔTS ≈ 13–28% * ΔRS ≈ 39% ** (0.175% SSF + 0.175% HE) | Enhancement of the resistance to abrasion (0.175% SSF + 0.175% HE; 0.25% SSF + 0.25% HE) | Repair mortar | [81] |

| Cement Type | Fiber 1- (Dimensions: L, W, T or d)—Doses (in Volume Fraction) | Fiber 2- (Dimensions: L, W, T or d)—Doses (in Volume Fraction) | Effect on Mechanical Properties | Other Effects | Application | Ref. |

|---|---|---|---|---|---|---|

| Lightweight wet-mix shotcrete (spray concrete): - OP 42.5 - w/c = 0.48 - Sand, natural gravel, walnut shell (as a replacement of natural gravel) - SF | Recycled PET (L = 20–25 mm, W= 2–3 mm, T = 0.34 mm)—0.045% (w/v) | PP (Non-recycled) —0.325% (w/v) | ΔTS ≈ 56% * (or 27% **) ΔCS ≈ 5% * (or 8% **) | ΔSlump ≈ −16% * ΔPdrop ≈ −20% * ΔRebound rate ≈ −15% * ΔBuilt-up thickness ≈ 25% * | Mine roof and mine roadways | [94] |

| SHCC: - OP - w/c = 0.48 - Class F fly ash - Sand (Silica or recycled sand) | Recycled PET fibers (L = 10 mm, d = 0.033 mm)—0.4% | PVA fibers (Non-recycled) (L = 12 mm, d = 0.039 mm)—1.6% | ΔCS ≈ 4.8% ** ΔFS ≈ −10.4% ** ΔTS ≈ −39.7% ** | Environmental impact reduction ΔCO2 emissions = −0.5%** | Advanced construction material | [140] |

| SHCC: - OP 52.5 + calcium sulfoaluminate cement - Class F fly ash - Limestone powder - Silica sand (d: 120–212 μm) - Polycarboxylate-based superplasticizers | Untreated (U) and treated (T) recycled PET (rPET) fibers (L = 12 mm, d = 0.038 mm)—0.5%, 1%, 1.5% and 2% | PVA fibers (Non-recycled) (L = 12 mm, d = 0.039 mm)—0.5%, 1%, 1.5% and 2% | ΔCS ≈ −4.2 to 4.2% ** (for 28 days curing) and 11.2–29.6% ** (for accelerated curing) ΔTS ≈ −15, −30 and −44% **, (for 28 days curing); −26, −38 and −43% (for accelerated curing); for 25%, 50% and 75% of PVA replacement, respectively | Environmental impact and cost reduction ΔEmbody energy = −18.7% ** ΔCO2 emissions = −3.8% ** ΔCost = −39.9% ** (for 50% of PVA replacement) | Advanced construction material | [141] |

| Cement Type | Fiber 1- (Dimensions: L, W, T or d)—Doses (in Volume Fraction) | Fiber 2- (Dimensions: L, W, T or d)—Doses (in Volume Fraction) | Recycling Source | Effect on Mechanical Properties | Other Effects | Application | Ref. |

|---|---|---|---|---|---|---|---|

| FRC: - CEM II B-S 32.5R - River sand of grains <2 mm - Butadiene-styrene resin with chalk filler | Recycled PA | Recycled PP | Recycled carpet | PA + PP fibers form a strong and water-resistant bond with concrete | PP or PA fibers has an insignificant impact on the wetting rate and the amount of imbibed water | - | [139] |

| CFRP concrete: - w/c = 0.45 - Melaminesulfonic acid agent (MA) (MA/c = 0.005) - Fine and coarse aggregate | Small and medium recycled and crushed CFRP (pieces made of epoxy reinforced with CF) (Small: L = 3.4 mm, d = 0.4 mm; Medium: L = 9.9 mm, d = 2.2 mm)—0.013%, 0.020% and 0.026% | Large recycled and crushed CFRP (pieces made of epoxy reinforced with CF) (L = 21 mm, d = 7.7 mm)—0.013%, 0.020% and 0.026% | CFRP | ΔFS ≈ 0–17%* (large-testing specimen = 100 × 100 × 400 mm) ΔCS ≈ −5–8.5%* (large-testing specimen = 100 × 200 mm) ΔWork of fracture (in the flexural test) ≈ 175–275%* (0.013–0.026% small size CFRP, respectively) | ΔSlump ≈ −54–90%* (0.013–0.026% small size CFRP, respectively) | Materials for repair and reinforcement buildings and infrastructures | [101] |

| Hybrid FRC beams: - Ordinary concrete - Natural aggregate and recycled aggregate (30% replacement) | Recycled PP fibers —0.038%, 0.075%, 0.113% and 0.151% (w/v) | Acrylic fiber —0.015%, 0.029%, 0.044% and 0.059% (w/v) | Textile waste | ΔCS ≈ 23.1%* ΔEM ≈ 28.2%* ΔTS ≈ 32.3%* (for 0.20% of mixed-fiber addition) ΔInitial cracking load ≈ 9.5% * (for 0.20% of mixed-fiber addition) | - | Structural components | [142] |

| Hybrid FRC beams: - OP 42.5 - w/c = 0.44 - Sand, natural aggregate and recycled aggregate (30% replacement) - Fly ash - Polycarboxylic acid superplasticizer | Recycled PP fibers (L = 19 mm)—0.038%, 0.075% and 0.113% (w/v) | PAN fibers (L = 19 mm)—0.133%, 0.089% and 0.044% (w/v) | PP: carpet | ΔCS ≈ 1.1% ** (for 25% of PAN replacement) ΔEM ≈ 5.3% ** (for 25% of PAN replacement) ΔTS ≈ 0.26% ** (for 75% of PAN replacement) ΔInitial cracking load of oblique section ≈ −20% ** (for 50% of PAN replacement) | - | Structural components | [143] |

| Cement Type | Fiber 1- (Dimensions: L, W, T or d)—Doses (in Volume Fraction) | Fiber 2 (Dimensions: L, W, T or d)—Doses (in Volume Fraction) | Recycling Source | Effect on Mechanical Properties | Other Effects | Application | Ref. |

|---|---|---|---|---|---|---|---|

| Hybrid FRC Beams: - PPC 53 Grade (IS1489) - w/c = 0.4 - Sand IS 4.75 - Crushed granite stones 10-20 mm - Superplasticiser | Scrim bled steel (Non-recycled) (L = 50 mm, d = 1 mm)—0.38%, 0.25% and 0.12% | Recycled PET (L = 38 mm, d = 0.02 mm)—0.38%, 0.25% and 0.12% PP (Non recycled) (L = 38 mm, d = 0.1 mm) —0.38%, 0.25% and 0.12% | - | ΔCS = 22% *, ΔTS = 17% * ΔFS = 19% *, ΔTS = 2% ** (0.38% steel fibers + 0.12% PET) ΔCS = 7.5% **, ΔTS = 12% **, ΔFS = 15% ** (0.38% steel fibers + 0.12% PP) 28 days curing | Increase in shear performance. First crack load increased 7% * | Structural applications | [145] |

| FRC: - C30/37 grade concrete -C55/67 grade concrete | Recycled steel (L = 25 mm)—4% (w/v) | PP (Non-recycled) (L = 54 mm)—0.45% (w/v) | Automotive industry waste steel fibers | ΔCS = −6% ** (for Concrete of 60 MPa) ΔCS = −11% ** (for concrete of 80 MPa) | Blast performance was kept | Protection of transport infrastructure against blast loading | [146] |

| Concrete: - OP ASTM type I - Crushed limestone 16 mm - Sand - Superplasticiser | Recycled metallic fibers (L = 30–60 mm)—1–3% | Recycled PP fibers (L = 30, 50, 60 mm)—0.5–1% | Metal—Locally available metal lathe workshop; PP—Storage bags | ΔCS = −20% *; ΔFS = 12% * 0.75% steel 60mm + 0.75% PP 60 mm | Improved post cracking behaviour | Normal concrete applications | [97] |

| FRC: - CEM I 42.5R - Sand - Coarse aggregate (river stones) - Rubber aggregate | Recycled steel and plastic fibers partially coated with rubber—8.5–42% (in weight/volume) replacing rubber aggregates. (L= 10–45 mm; d = 75% of them lower than 25 µm) | Waste tires | ΔCS = −36% *; ΔEM = −35% *, ΔFS = −7.3% *; ΔIEA1 = 100% *, ΔIEAU = 600% *;ΔCS = 9% ***; ΔEM = −3% ***; ΔFS = 15% *** (8.5% complex fibers) ΔIEA1 = 4500% * (33.5% complex fibers) | Bulk density increased 7% keeping similar thermal conductivity *** (8.5% complex fibers) | Conventional rubberized concrete for thermal rehabilitation of buildings | [51,52] | |

| FRC: - CEM II/A-LL 42.5N w/c = 0.35 - Coarse aggregate - Fine aggregate - Sand - Superplasticiser | Metallic powders (mean size = 12 mm) – ~1% | Recycled PA fibers (L = 8 mm, d = 0.038 mm)—0.5% | PA – Textile carpet waste Rail steel | ΔCS = 18% * | Thermal conductivity increased due to steel 120–170% * | Thermal storage units for solar plants | [70] |

| Recycled metallic shavings (L = 10–20 mm)—1% | ACS = −10% * | ||||||

| SCC: - CEM I 42.5R - w/c = 0.6–0.64 - Fly ash - Silica fume - Superplasticiser | Micro-steel (L = 6 mm, d = 0.16 mm)—0.82% (w/v) | HDPE (L = 3–10 mm, d = 0.1 mm)—0.82% (w/v) | Municipal wastes | ACS = −30% * ACS = 0% ** AFS = −10% * AFS = 0% ** | Drying shrinkage reduction: 11% * Flowing diameter reduction: 10% * | - | [79] |

| FRC: - CEM I 42.5R - Sand - Coarse aggregate - Rubber aggregate | Steel and textile fibers coated with rubber and rubber dust (7.7%—38.4% v/v) (replacing coarse aggregates 20—100%) | Waste from recycling rubber from waste tires | ΔCS = 9% *** (7.7% complex fiber with rubber)(28d) | Shrinkage 62% *** (7.7% complex fiber with rubber) Bulk density decreased | - | [52] | |

| SCC: - OP 42.5R - w/c = 0.76 - Fly ash - Aggregate - Superplasticizer | Recycled steel fiber (L = 50 mm, d = 0.15 ± 0.5 mm) 0.5%, 0.75% and 1% | PP (Non-recycled) (aspect ratio = 461) 0.5%, 0.75% and 1% | Recycled steel: waste tires | ΔCS = 30% *; ΔCS = −12% ** ΔFS = 20% *; ΔFS = −10% ** (0.5%PP + 1% recycled steel) | Impact energy absorption increased 1800% * (0.5%PP + 1% recycled steel) | - | [108] |

| - OP IS 12269 - w/c= 0.4 - Sand IS 4.75 - Crushed granite stones 10–20 mm - Silica fume - Superplasticiser | Recycled steel fibers (L = 10–15 mm) | Recycled nylon fibers (L = 40 mm) | Steel lathe waste Nylon waste from local industries | Best performance: total fiber = 2% ΔCS = 12% *; ΔTS = 54% * (steel/nylon ratio = 2) ΔMOR = 50% * ΔIE1 = 238% *; ΔIEU = 205% *; ΔFE = 197% * (steel/nylon ratio = 1) | Air content increased up 75% | - | [147,148] |

| Total fiber fraction 0.5%, 1.0%, 1.5% and 2.0% Steel/nylon ratios: 1/2, 1, 2 Superplasticiser at demand to get desired workability | |||||||

| SCC: - CEM I 42.5 R -w/c = 0.38 - Fine aggregates -superplasticiser | Recycled steel fiber (L = 50 mm, d = 0.15 mm)—0.35%, 0.7% and 1.05% (in volume fraction) | PP (Non-recycled) (L = 12 mm, d = 0.018 mm)—0.35% and 0.7% (in volume fraction) | Recycled steel: waste tires | Best performance: ΔCS = 39% *; ΔFS = 31% * ΔCS = 11% **; ΔFS = 10% ** (1.05% steel + 0.7% PP) ΔIE1 = 27% * (0.7% steel + 0.7% PP) | Slump flow diameter decreased linearly with fiber fraction ΔSlump = −19% * (1.05% steel + 0.7% PP) | - | [144] |

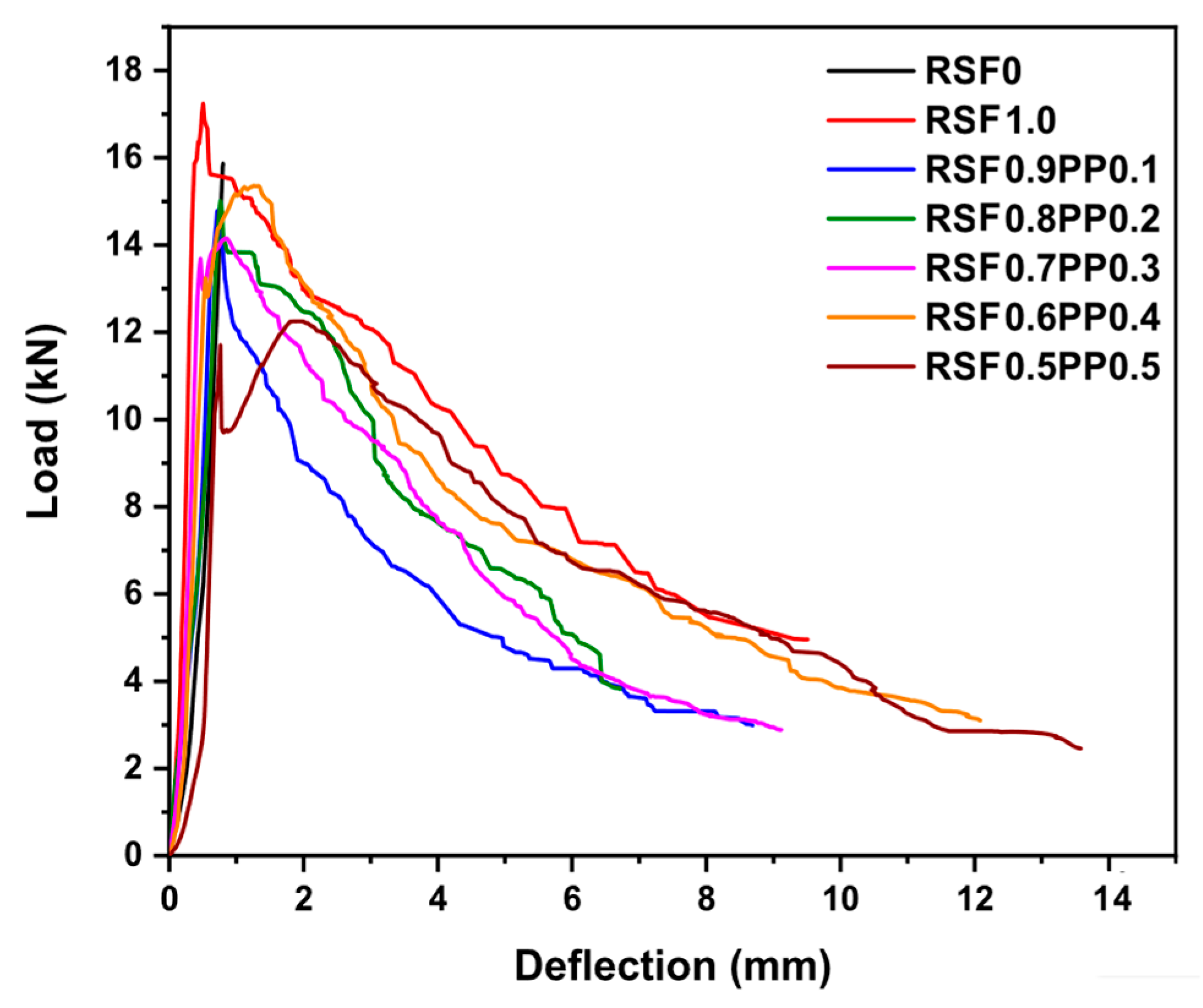

| FRC: - CEM I 52.5N - w/c = 0.4 - Sand - Crushed granites - Superplasticiser | Recycled steel fiber (L = 23 mm, d = 0.22 mm)—0.5–0.9% | PP (Non-recycled) (L = 12 mm, d = 0.05 mm)—0.1–0.5% | Recycled steel: waste tires | Best performance: ΔCS = −5% *; ΔFS = −1% * ΔCS = −10% **; ΔFS = −14% ** ΔTS = 40% *; ΔTS = −34% ** (0.9% steel + 0.1% PP) | Increase chemical resistance in chlorine environments Decrease shrinkage 5% **–35% ** (0.4%PP + 0.6% steel) | - | [89] |

| - CEM II 52.5 - w/c = 0.56 - Coarse aggregate - Fine aggregate - Superplasticizer | Recycled steel fibers (L = 19–21 mm, d= 0.11–0.19 mm) 40 kg/m3 | Recycled polymer fibers (L = 4–30 mm, d= 0.02–0.03 mm) 2 kg/m3 and 5 kg/m3 | Waste tires | ΔCS = −1% * (40 kg/m3 steel + 5 kg/m3 polymer) | Prevention of fire spalling | FRC-lined tunnels | [149] |

| Cement Type | Fiber 1- (Dimensions: L, W, T or d)—Doses (in Volume Fraction) | Fiber 2 (Dimensions: L, W, T or d)—Doses (in Volume Fraction) | Recycling Source | Effect on Mechanical Properties | Other Effects | Application | Ref. |

|---|---|---|---|---|---|---|---|

| SCC: - CEM I 42.5 R - w/c = 0.35–0.38 - Sand - Coarse aggregates | Recycled steel fibers (L = 8 mm, d = 0.175 mm) + Recycled steel fibers (L = ~2–30 mm, d = 0.15 mm)—1.5% | Glass fibers (L = 12 mm, d = 0.014 mm)—0.5% | Recycled steel: waste tires | ΔCS = 2% * | Increase energy absorption up to 30% * | Building structures | [82] |

| - OP 42.5 R - w/c = 0.5 - Fly ash - Sand - Crushed waste concrete - Superplasticiser | Recycled PP (L = 6 mm)— 0–0.3% | Basalt fibers (L = 18 mm)— 0—0.3% | Used carpets | ΔCS = −25% ** ΔTS = −20% ** ΔFS = 10% ** (0.15% of each fiber) | Workability did not change with the hybridaton | - | [92] |

| - CEM I 52.5 N - w/c =0.21 - Silica fume - Sand - Superplasticiser | Recycled fibers (glass + unsaturated polyester) (L = 0.4–23 mm)—4.41% and 6.2% | Recycled powder (glass + unsaturated polyester) (L = 0.1–0.4 mm)—7.13% | Thermoset composite | ΔTS = 80% * (4.41% hybrid fibers 7.13% powder) ΔTS = 54% * (4.41% hybrid fibers) | Slump flow decreased −40% * when fibers and powder were used | - | [56] |

| - OP - w/c = 0.33 | Recycled carbon | Recycled glass | Polymer core composite conductors | ΔCS = −25% * | ΔHardness = 11% * Increase resistance to sea water | [57] | |

| Particle fiber powder 6 wt.% | |||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Balea, A.; Fuente, E.; Monte, M.C.; Blanco, A.; Negro, C. Recycled Fibers for Sustainable Hybrid Fiber Cement Based Material: A Review. Materials 2021, 14, 2408. https://doi.org/10.3390/ma14092408

Balea A, Fuente E, Monte MC, Blanco A, Negro C. Recycled Fibers for Sustainable Hybrid Fiber Cement Based Material: A Review. Materials. 2021; 14(9):2408. https://doi.org/10.3390/ma14092408

Chicago/Turabian StyleBalea, Ana, Elena Fuente, M. Concepcion Monte, Angeles Blanco, and Carlos Negro. 2021. "Recycled Fibers for Sustainable Hybrid Fiber Cement Based Material: A Review" Materials 14, no. 9: 2408. https://doi.org/10.3390/ma14092408

APA StyleBalea, A., Fuente, E., Monte, M. C., Blanco, A., & Negro, C. (2021). Recycled Fibers for Sustainable Hybrid Fiber Cement Based Material: A Review. Materials, 14(9), 2408. https://doi.org/10.3390/ma14092408