Recent Advances in High-Throughput Nanomaterial Manufacturing for Hybrid Flexible Bioelectronics

Abstract

1. Introduction

2. Printing Fundamentals

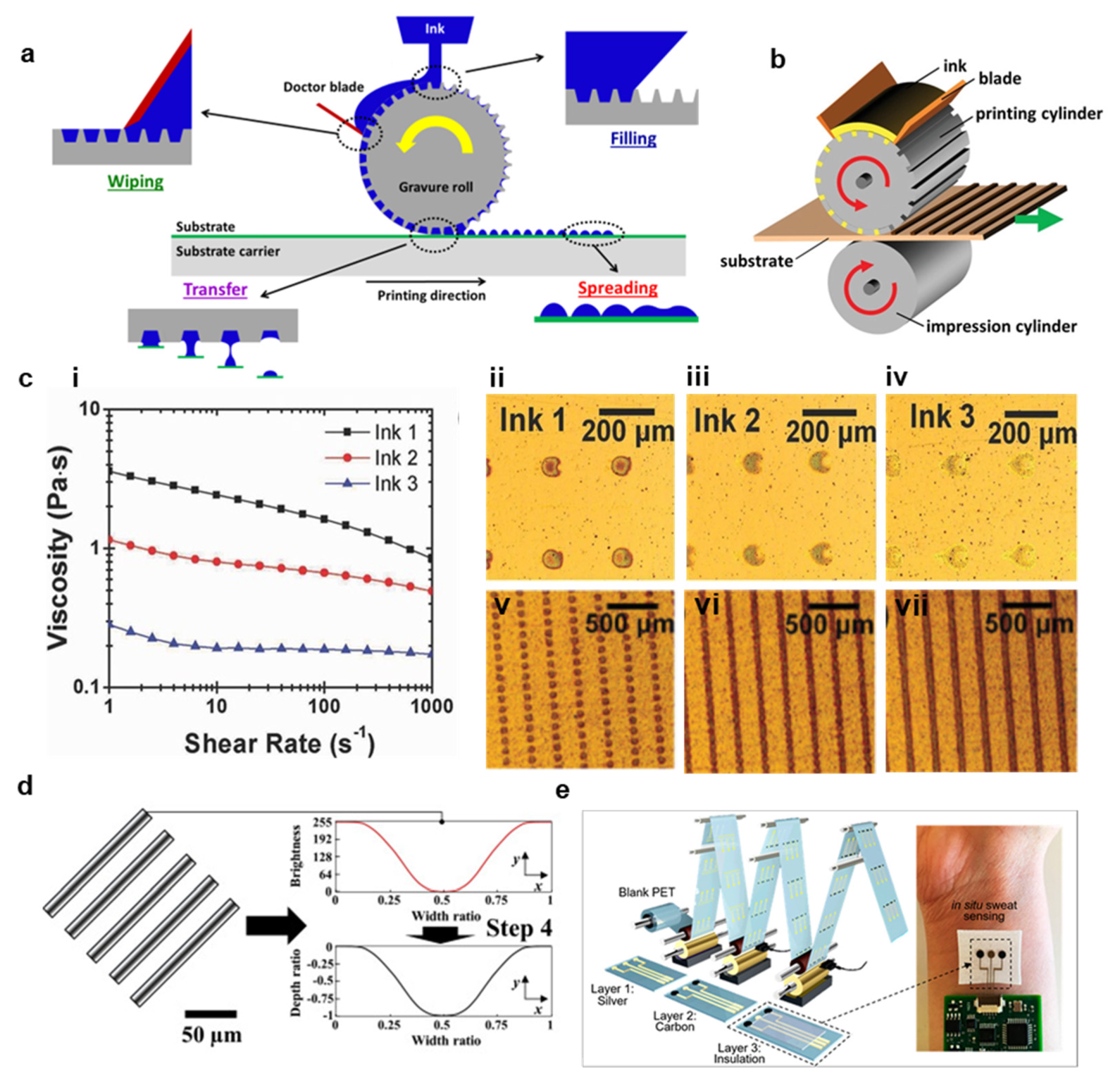

2.1. Gravure Printing

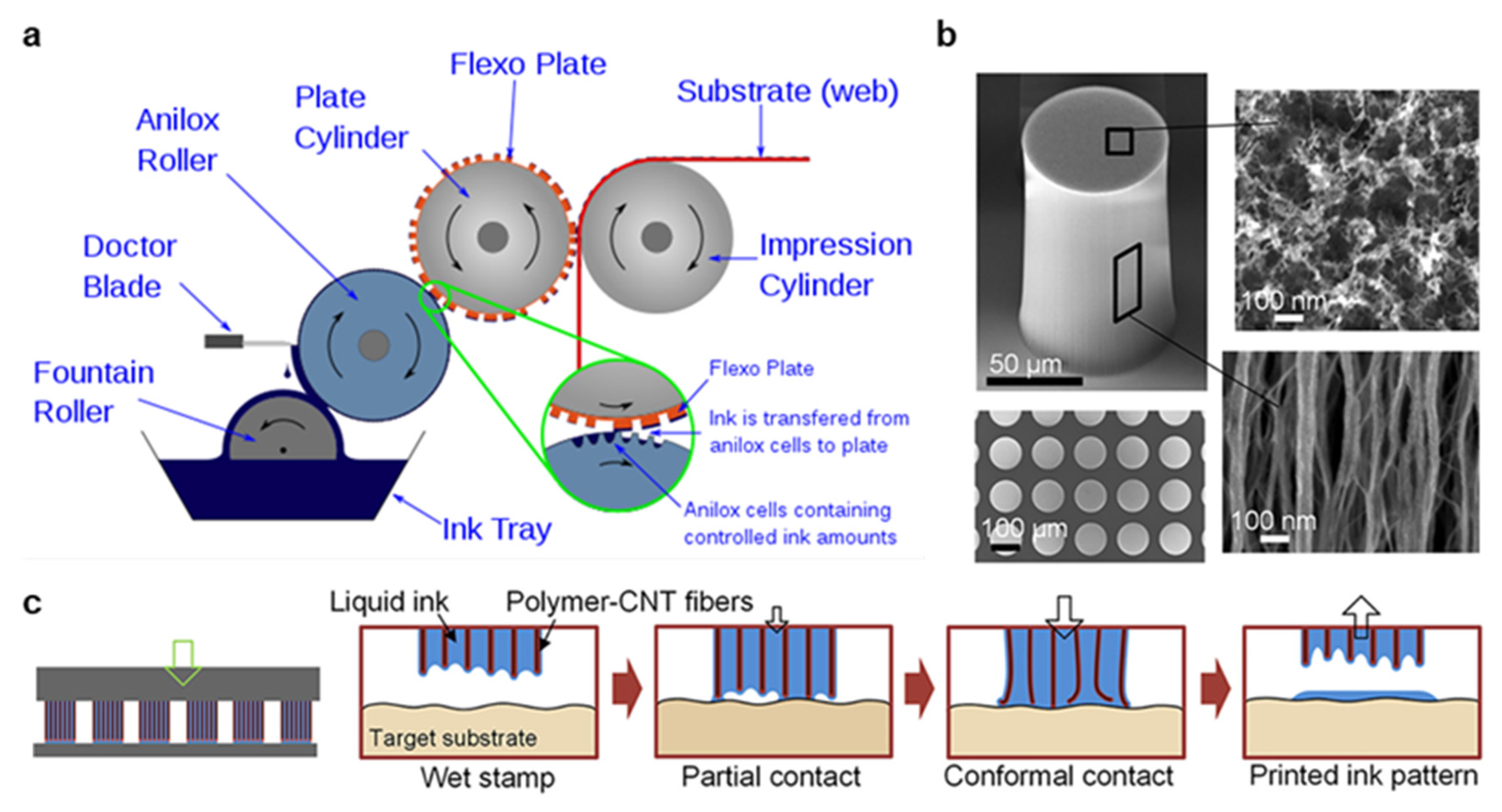

2.2. Flexographic Printing

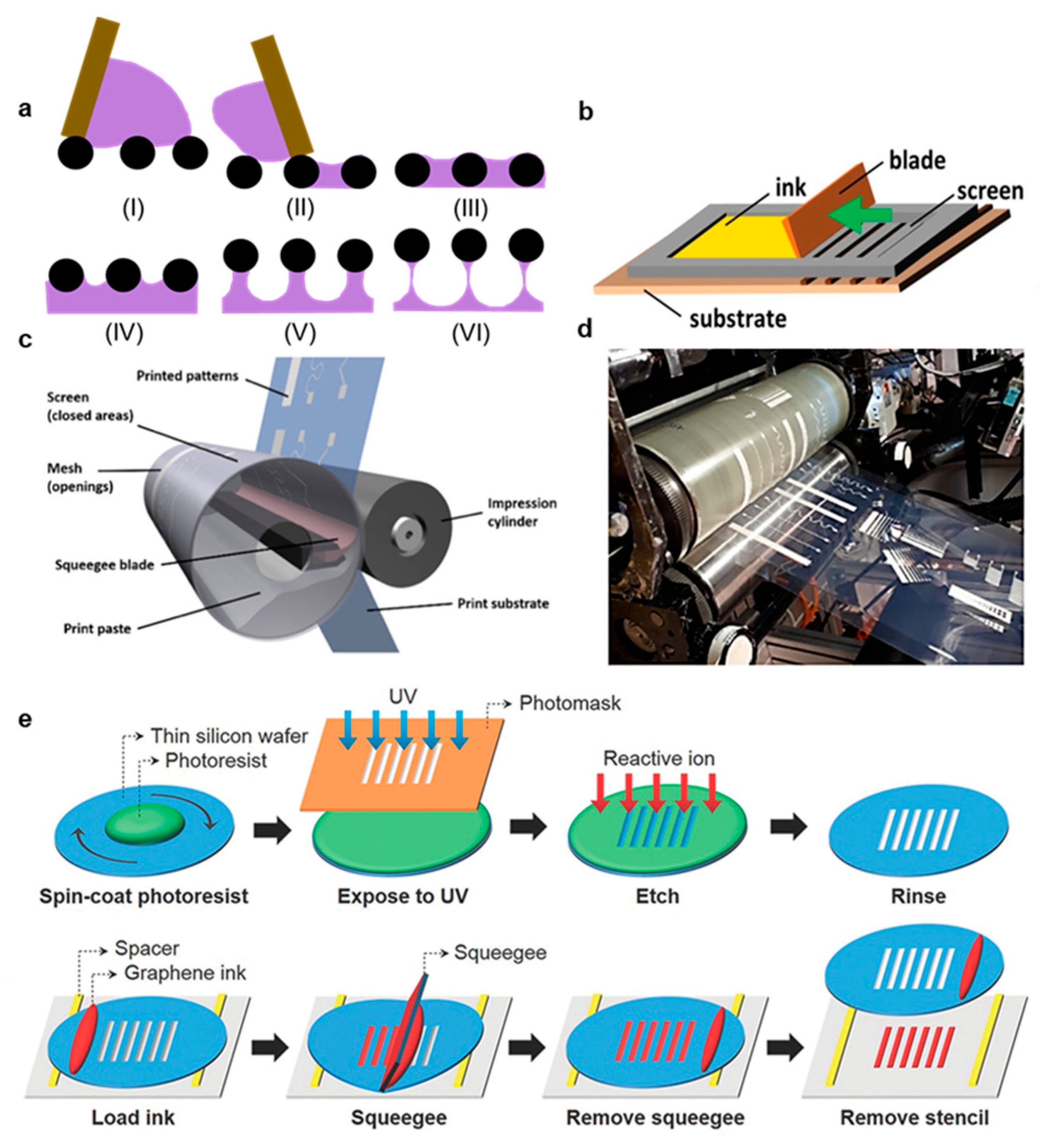

2.3. Screen Printing

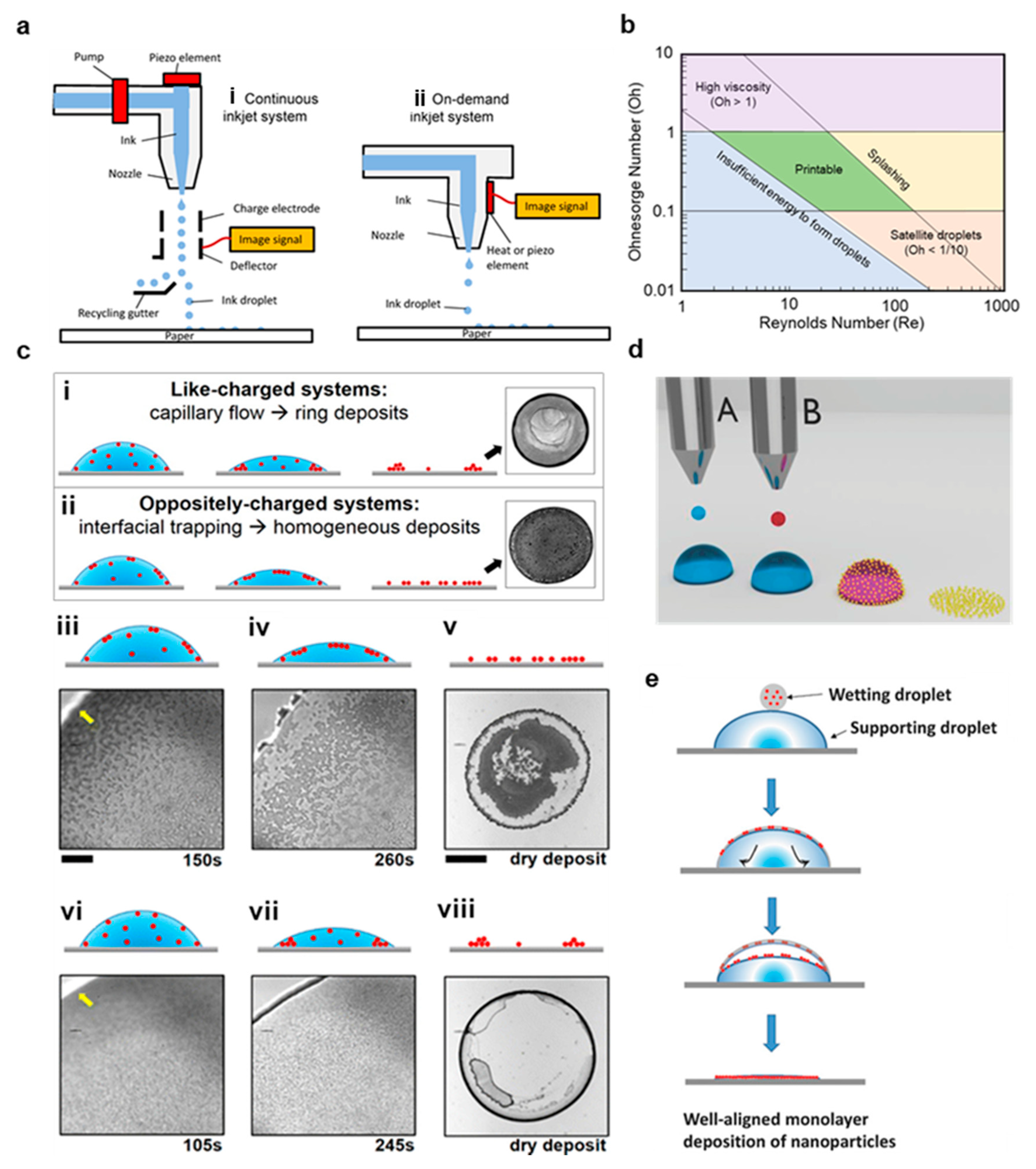

2.4. Roll to Roll Inkjet Printing

2.5. Slot Die and Blade Coating

3. Conductive Nanomaterial Printing

3.1. Fundamentals

3.2. Metal Nanoparticles (NPs)

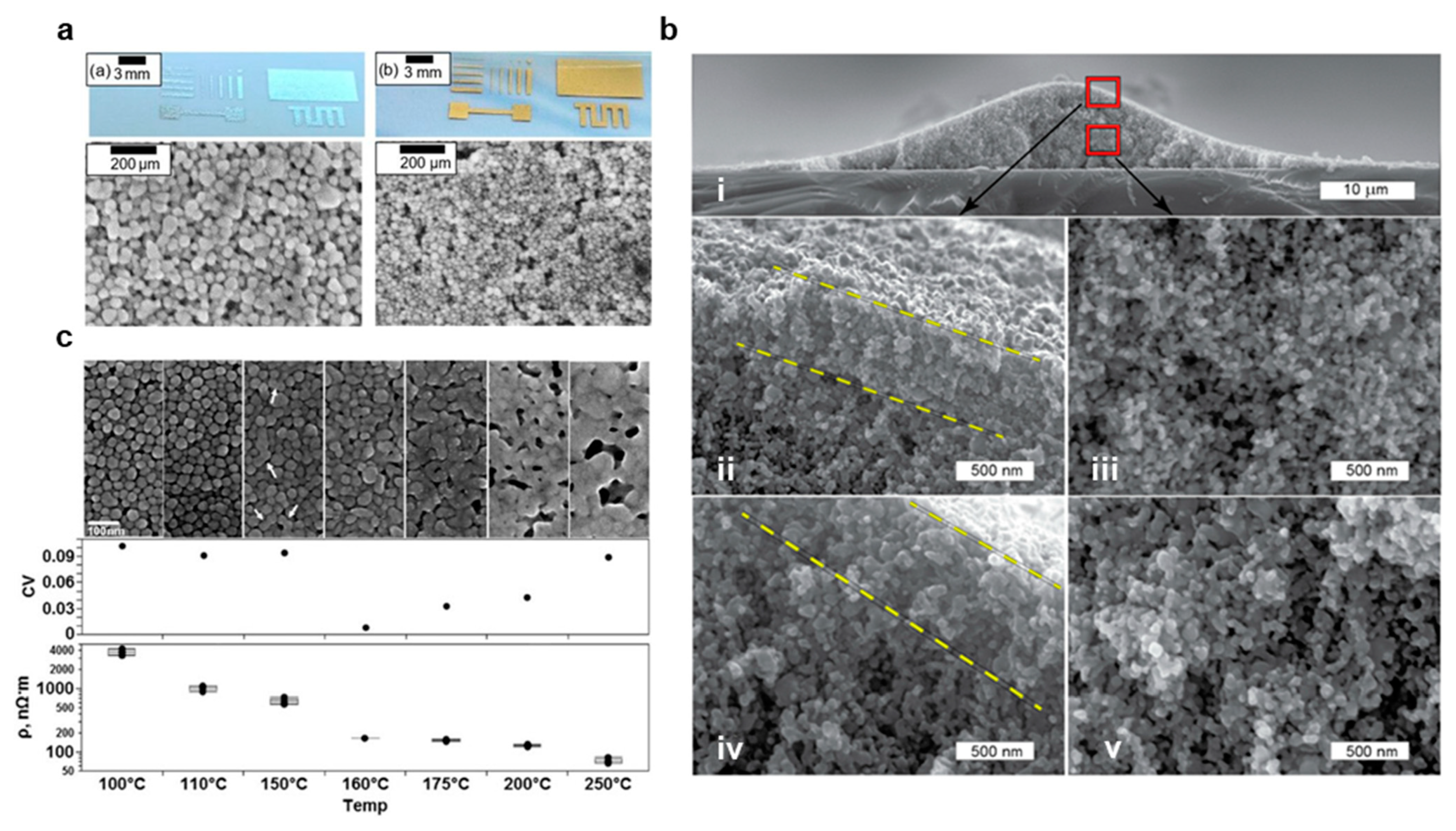

3.2.1. Material Properties, Synthesis, and Ink Formation

3.2.2. Post Print Processing

3.3. Metal Nanowires (NWs)

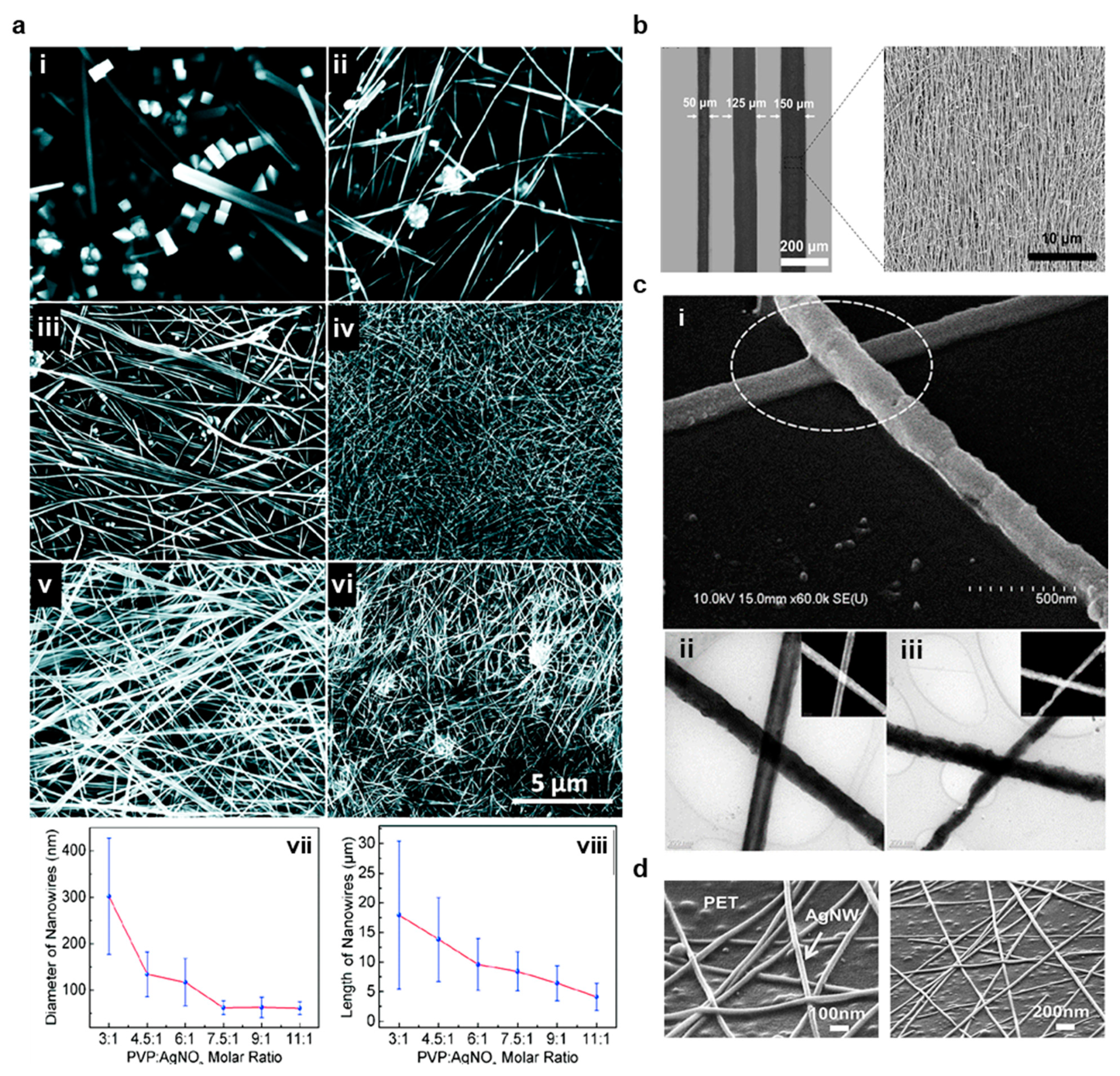

3.3.1. Material Properties, Synthesis, and Ink Formation

3.3.2. Post Print Processing

3.4. Graphene

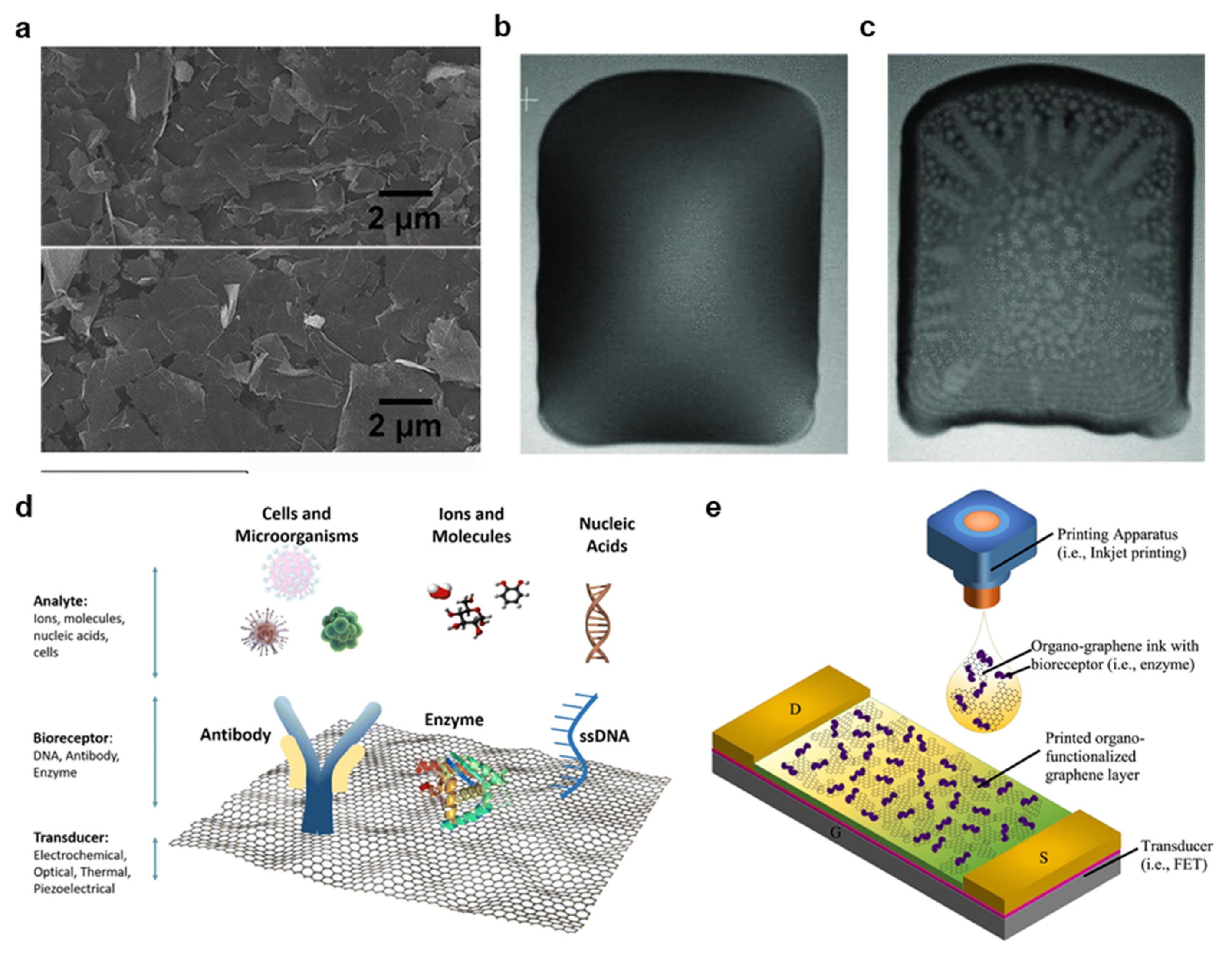

3.4.1. Material Properties, Synthesis, and Ink Formation

3.4.2. Laser Synthesis of Graphene

3.4.3. Post Print Processing

3.4.4. Graphene Functionalization for Biosensor Applications

3.5. Carbon Nanotubes

3.5.1. Material Properties, Synthesis, and Ink Formation

3.5.2. Post Print Processing

3.6. Novel 2D Nanomaterials

4. Applications for Bioelectronics

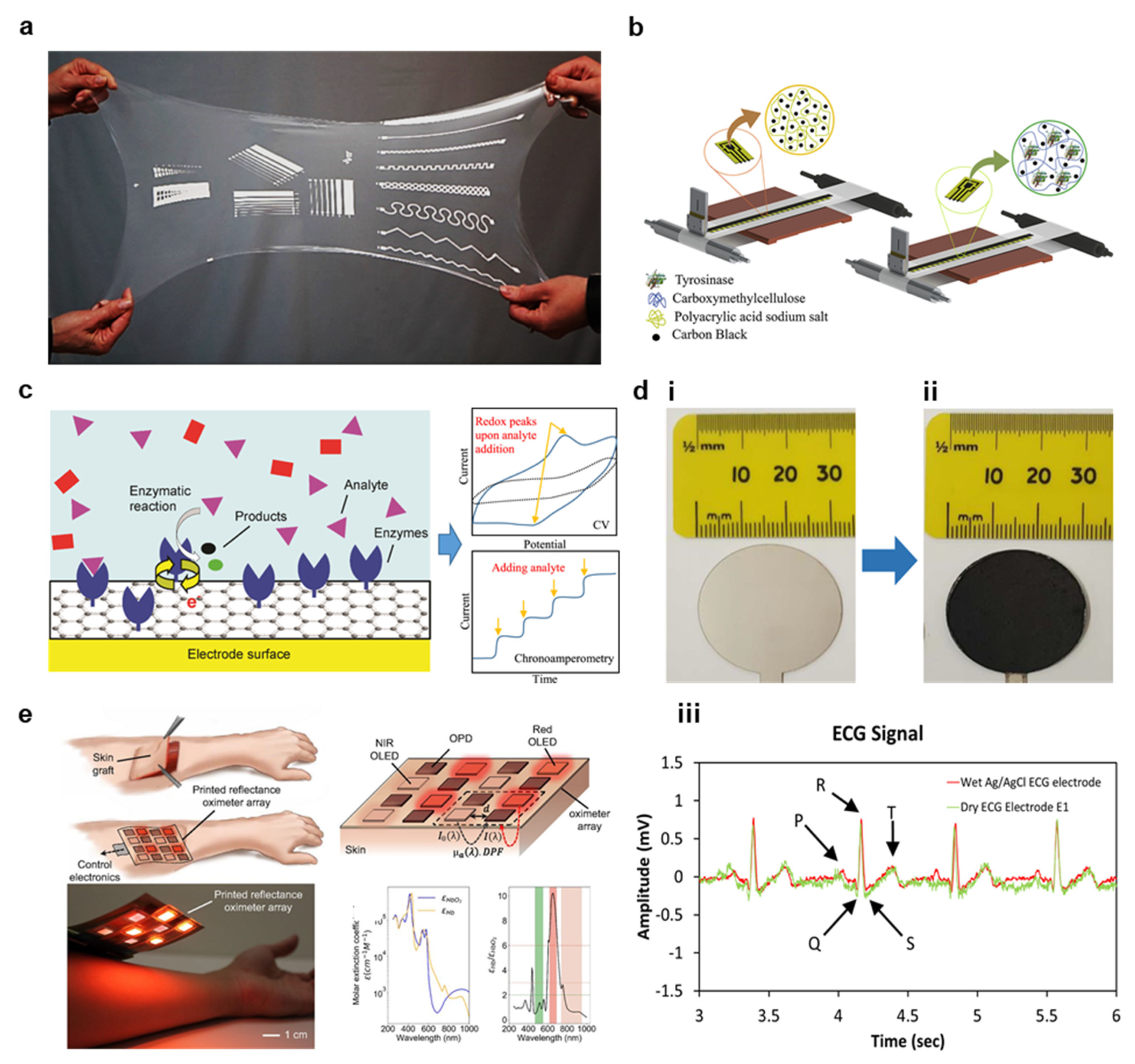

4.1. Electrical Interconnections

4.2. Biosensors

4.3. Additional Applications

5. Conclusions and Future Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Niu, Y.; Liu, H.; He, R.; Li, Z.; Ren, H.; Gao, B.; Guo, H.; Genin, G.M.; Xu, F. The New Generation of Soft and Wearable Electronics for Health Monitoring in Varying Environment: From Normal to Extreme Conditions. Mater. Today 2020, 41, 219–242. [Google Scholar] [CrossRef]

- Song, Y.; Min, J.; Gao, W. Wearable and Implantable Electronics: Moving toward Precision Therapy. ACS Nano 2019, 13, 12280–12286. [Google Scholar] [CrossRef]

- Zhang, S.; Li, S.; Xia, Z.; Cai, K. A Review of Electronic Skin: Soft Electronics and Sensors for Human Health. J. Mater. Chem. B 2020, 8, 852–862. [Google Scholar] [CrossRef]

- Sana, F.; Isselbacher, E.M.; Singh, J.P.; Heist, E.K.; Pathik, B.; Armoundas, A.A. Wearable Devices for Ambulatory Cardiac Monitoring: JACC State-of-the-Art Review. J. Am. Coll. Cardiol. 2020, 75, 1582–1592. [Google Scholar] [CrossRef]

- Mahajan, A.; Pottie, G.; Kaiser, W. Transformation in Healthcare by Wearable Devices for Diagnostics and Guidance of Treatment. ACM Trans. Comput. Healthc. 2020, 1, 1–12. [Google Scholar] [CrossRef]

- Chung, H.U.; Rwei, A.Y.; Hourlier-Fargette, A.; Xu, S.; Lee, K.; Dunne, E.C.; Xie, Z.; Liu, C.; Carlini, A.; Kim, D.H.; et al. Skin-Interfaced Biosensors for Advanced Wireless Physiological Monitoring in Neonatal and Pediatric Intensive-Care Units. Nat. Med. 2020, 26, 418–429. [Google Scholar] [CrossRef]

- Lee, K.; Ni, X.; Lee, J.Y.; Arafa, H.; Pe, D.J.; Xu, S.; Avila, R.; Irie, M.; Lee, J.H.; Easterlin, R.L.; et al. Mechano-Acoustic Sensing of Physiological Processes and Body Motions via a Soft Wireless Device Placed at the Suprasternal Notch. Nat. Biomed. Eng. 2020, 4, 148–158. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Kim, Y.S.; Mahmood, M.; Kwon, S.; Zavanelli, N.; Kim, H.S.; Rim, Y.S.; Epps, F.; Yeo, W.H. Fully Integrated, Stretchable, Wireless Skin-Conformal Bioelectronics for Continuous Stress Monitoring in Daily Life. Adv. Sci. 2020, 7, 2000810. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Emaminejad, S.; Nyein, H.Y.Y.; Challa, S.; Chen, K.; Peck, A.; Fahad, H.M.; Ota, H.; Shiraki, H.; Kiriya, D.; et al. Fully Integrated Wearable Sensor Arrays for Multiplexed In Situ Perspiration Analysis. Nature 2016, 529, 509–514. [Google Scholar] [CrossRef]

- Rogers, J.A.; Someya, T.; Huang, Y. Materials and Mechanics for Stretchable Electronics. Science 2010, 327, 1603–1607. [Google Scholar] [CrossRef]

- Liang, J.; Tong, K.; Pei, Q. A Water-Based Silver-Nanowire Screen-Print Ink for the Fabrication of Stretchable Conductors and Wearable Thin-Film Transistors. Adv. Mater. 2016, 28, 5986–5996. [Google Scholar] [CrossRef] [PubMed]

- Wisitsoraat, A.; Mensing, J.P.; Karuwan, C.; Sriprachuabwong, C.; Jaruwongrungsee, K.; Phokharatkul, D.; Daniels, T.M.; Liewhiran, C.; Tuantranont, A. Printed Organo-Functionalized Graphene for Biosensing Applications. Biosens. Bioelectron. 2017, 87, 7–17. [Google Scholar] [CrossRef] [PubMed]

- Pena-Bahamonde, J.; Nguyen, H.N.; Fanourakis, S.K.; Rodrigues, D.F. Recent Advances in Graphene-Based Biosensor Technology with Applications in Life Sciences. J. Nanobiotechnol. 2018, 16, 75. [Google Scholar] [CrossRef]

- Beitollahi, H.; Mohammadi, S.Z.; Safaei, M.; Tajik, S. Applications of Electrochemical Sensors and Biosensors Based on Modified Screen-Printed Electrodes: A Review. Anal. Methods 2020, 12, 1547–1560. [Google Scholar] [CrossRef]

- Morales-Narvaez, E.; Baptista-Pires, L.; Zamora-Galvez, A.; Merkoci, A. Graphene-Based Biosensors: Going Simple. Adv. Mater. 2017, 29, 1604905. [Google Scholar] [CrossRef]

- Kinnamon, D.S.; Krishnan, S.; Brosler, S.; Sun, E.; Prasad, S. Screen Printed Graphene Oxide Textile Biosensor for Applications in Inexpensive and Wearable Point-of-Exposure Detection of Influenza for At-Risk Populations. J. Electrochem. Soc. 2018, 165, B3084–B3090. [Google Scholar] [CrossRef]

- Huang, Q.; Zhu, Y. Printing Conductive Nanomaterials for Flexible and Stretchable Electronics: A Review of Materials, Processes, and Applications. Adv. Mater. Technol. 2019, 4, 1800546. [Google Scholar] [CrossRef]

- Khan, Y.; Thielens, A.; Muin, S.; Ting, J.; Baumbauer, C.; Arias, A.C. A New Frontier of Printed Electronics: Flexible Hybrid Electronics. Adv. Mater. 2020, 32, e1905279. [Google Scholar] [CrossRef] [PubMed]

- Zavanelli, N.; Yeo, W.-H. Advances in Screen Printing of Conductive Nanomaterials for Stretchable Electronics. ACS Omega 2021, 6, 9344–9351. [Google Scholar] [CrossRef] [PubMed]

- Secor, E.B. Principles of Aerosol Jet Printing. Flex. Print. Electron. 2018, 3, 035002. [Google Scholar] [CrossRef]

- Abbel, R.; Pit, T.; Rubingh, E.; van Lammeren, T.; Cauchois, R.; Everaars, M.; Valeton, J.; van de Geijn, S.; Groen, P. Industrial-scale Inkjet Printed Electronics Manufacturing—Production Up-Scaling from Concept Tools to A Roll-To-Roll Pilot Line. Transl. Mater. Res. 2014, 1, 015002. [Google Scholar] [CrossRef]

- Ren, P.; Liu, Y.; Song, R.; O’Connor, B.; Dong, J.; Zhu, Y. Achieving High-Resolution Electrohydrodynamic Printing of Nanowires on Elastomeric Substrates through Surface Modification. ACS Appl. Electron. Mater. 2020, 3, 192–202. [Google Scholar] [CrossRef]

- Li, W.; Yang, S.; Shamim, A. Screen Printing of Silver Nanowires: Balancing Conductivity with Transparency while Maintaining Flexibility and Stretchability. NPJ Flex. Electron. 2019, 3, 1–8. [Google Scholar] [CrossRef]

- Riemer, D. The Theoretical Fundamentals of the ScreenPrinting Process. Microelectron. Int. 1989, 6, 8–17. [Google Scholar] [CrossRef]

- Singh, M.; Haverinen, H.M.; Dhagat, P.; Jabbour, G.E. Inkjet Printing-Process and Its Applications. Adv. Mater. 2010, 22, 673–685. [Google Scholar] [CrossRef]

- Nayak, L.; Mohanty, S.; Nayak, S.K.; Ramadoss, A. A Review on Inkjet Printing of Nanoparticle Inks for Flexible Electronics. J. Mater. Chem. C 2019, 7, 8771–8795. [Google Scholar] [CrossRef]

- Grau, G.; Cen, J.; Kang, H.; Kitsomboonloha, R.; Scheideler, W.J.; Subramanian, V. Gravure-Printed Electronics: Recent Progress in Tooling Development, Understanding of Printing Physics, and Realization of Printed Devices. Flex. Print. Electron. 2016, 1, 023002. [Google Scholar] [CrossRef]

- Krainer, S.; Smit, C.; Hirn, U. The Effect of Viscosity and Surface Tension on Inkjet Printed Picoliter Dots. RSC Adv. 2019, 9, 31708–31719. [Google Scholar] [CrossRef]

- Izdebska, J. Flexographic Printing. In Printing on Polymers Fundamentals and Applications; William Andrew: Norwich, NY, USA, 2016; Chapter 11; pp. 179–197. [Google Scholar]

- Seong, J.; Park, J.; Lee, J.; Ahn, B.; Yeom, J.H.; Kim, J.; Hassinen, T.; Rhee, S.; Ko, S.; Lee, D.; et al. Practical Design Guidelines for the Development of High-Precision Roll-to-Roll Slot-Die Coating Equipment and the Process. IEEE Trans. Compon. Packag. Manuf. Technol. 2016, 6, 1677–1686. [Google Scholar] [CrossRef]

- Wu, W. Inorganic Nanomaterials for Printed Electronics: A review. Nanoscale 2017, 9, 7342–7372. [Google Scholar] [CrossRef]

- Chung, S.; Cho, K.; Lee, T. Recent Progress in Inkjet-Printed Thin-Film Transistors. Adv. Sci. 2019, 6, 1801445. [Google Scholar] [CrossRef] [PubMed]

- Al-Milaji, K.N.; Secondo, R.R.; Ng, T.N.; Kinsey, N.; Zhao, H. Interfacial Self-Assembly of Colloidal Nanoparticles in Dual-Droplet Inkjet Printing. Adv. Mater. Interfaces 2018, 5, 1701561. [Google Scholar] [CrossRef]

- Howard, I.A.; Abzieher, T.; Hossain, I.M.; Eggers, H.; Schackmar, F.; Ternes, S.; Richards, B.S.; Lemmer, U.; Paetzold, U.W. Coated and Printed Perovskites for Photovoltaic Applications. Adv. Mater. 2019, 31, e1806702. [Google Scholar] [CrossRef]

- Huttunen, O.-H.; Happonen, T.; Hiitola-Keinänen, J.; Korhonen, P.; Ollila, J.; Hiltunen, J. Roll-To-Roll Screen-Printed Silver Conductors on a Polydimethyl Siloxane Substrate for Stretchable Electronics. Ind. Eng. Chem. Res. 2019, 58, 19909–19916. [Google Scholar] [CrossRef]

- Kharissova, O.V.; Kharisov, B.I.; de Casas Ortiz, E.G. Dispersion of Carbon Nanotubes in Water and Non-Aqueous Solvents. RSC Adv. 2013, 3, 24812–24852. [Google Scholar] [CrossRef]

- Lee, S.H.; Lee, S. Fabrication and Characterization of Roll-to-Roll-Coated Cantilever-Structured Touch Sensors. ACS Appl. Mater. Interfaces 2020, 12, 46797–46803. [Google Scholar] [CrossRef]

- Pradhan, S.; Hedberg, J.; Blomberg, E.; Wold, S.; Odnevall Wallinder, I. Effect of Sonication on Particle Dispersion, Administered Dose and Metal Release of Non-Functionalized, Non-Inert Metal Nanoparticles. J. Nanopart. Res. 2016, 18, 285. [Google Scholar] [CrossRef]

- Rickey, K.M.; Nian, Q.; Zhang, G.; Chen, L.; Suslov, S.; Bhat, S.V.; Wu, Y.; Cheng, G.J.; Ruan, X. Welding of Semiconductor Nanowires by Coupling Laser-Induced Peening and Localized Heating. Sci. Rep. 2015, 5, 16052. [Google Scholar] [CrossRef]

- Bariya, M.; Shahpar, Z.; Park, H.; Sun, J.; Jung, Y.; Gao, W.; Nyein, H.Y.Y.; Liaw, T.S.; Tai, L.C.; Ngo, Q.P.; et al. Roll-to-Roll Gravure Printed Electrochemical Sensors for Wearable and Medical Devices. ACS Nano 2018, 12, 6978–6987. [Google Scholar] [CrossRef] [PubMed]

- Zhong, Z.W.; Ee, J.H.; Chen, S.H.; Shan, X.C. Parametric Investigation of Flexographic Printing Processes for R2R Printed Electronics. Mater. Manuf. Process. 2020, 35, 564–571. [Google Scholar] [CrossRef]

- Rowley-Neale, S.J.; Smith, G.C.; Banks, C.E. Mass-Producible 2D-MoS2-Impregnated Screen-Printed Electrodes that Demonstrate Efficient Electrocatalysis toward the Oxygen Reduction Reaction. ACS Appl. Mater. Interfaces 2017, 9, 22539–22548. [Google Scholar] [CrossRef]

- Potts, S.J.; Phillips, C.; Jewell, E.; Clifford, B.; Lau, Y.C.; Claypole, T. High-Speed Imaging the Effect of Snap-Off Distance and Squeegee Speed on the Ink Transfer Mechanism of Screen-Printed Carbon Pastes. J. Coat. Technol. Res. 2020, 17, 447–459. [Google Scholar] [CrossRef]

- Reinhardt, K.; Hofmann, N.; Eberstein, M. The Importance of Shear Thinning, Thixotropic and Viscoelastic Properties of Thick Film Pastes to Predict Effects on Printing Performance. In Proceedings of the 2017 21st European Microelectronics and Packaging Conference (EMPC) & Exhibition, Warsaw, Poland, 10–13 September 2017; IEEE: Piscataway, NJ, USA, 2018; Volume 2018, pp. 1–7. [Google Scholar]

- Al-Milaji, K.N.; Huang, Q.; Li, Z.; Ng, T.N.; Zhao, H. Direct Embedment and Alignment of Silver Nanowires by Inkjet Printing for Stretchable Conductors. ACS Appl. Electron. Mater. 2020, 2, 3289–3298. [Google Scholar] [CrossRef]

- Gao, M.; Li, L.; Song, Y. Inkjet Printing Wearable Electronic Devices. J. Mater. Chem. C 2017, 5, 2971–2993. [Google Scholar] [CrossRef]

- Fernandes, I.J.; Aroche, A.F.; Schuck, A.; Lamberty, P.; Peter, C.R.; Hasenkamp, W.; Rocha, T. Silver Nanoparticle Conductive Inks: Synthesis, Characterization, and Fabrication of Inkjet-Printed Flexible Electrodes. Sci. Rep. 2020, 10, 8878. [Google Scholar] [CrossRef] [PubMed]

- Deegan, R.B.; Dupont, O.; Huber, T.; Nagel, G.; Witten, S. Capillary Flow as the Cause of Ring Stains from Dried Liquid Drops. Nature 1997, 389, 827–829. [Google Scholar] [CrossRef]

- Lee, H.L.; Lee, D.; Hwang, J.; Nam, D.; Byeon, C.; Ko, S.H.; Lee, S. Silver Nanoparticle Piezoresistive Sensors Fabricated by Roll-to-Roll Slot-Die Coating and Laser Direct Writing. Opt. Express 2014, 22, 8919–8927. [Google Scholar] [CrossRef] [PubMed]

- Huang, Q.; Zhu, Y. Gravure Printing of Water-based Silver Nanowire ink on Plastic Substrate for Flexible Electronics. Sci. Rep. 2018, 8, 15167. [Google Scholar] [CrossRef]

- Nguyen, H.A.D.; Lee, C.; Shin, K.-H.; Lee, D. An Investigation of the Ink-Transfer Mechanism During the Printing Phase of High-Resolution Roll-to-Roll Gravure Printing. IEEE Trans. Compon. Packag. Manuf. Technol. 2015, 5, 1516–1524. [Google Scholar] [CrossRef]

- Lee, J.; Kim, J.; Noh, Y.; Jeong, H.; Lee, D. Advanced Technique for Achieving 10-Μm-Width Fine Lines in Roll-to-Roll Continuous Gravure Printing. Precis. Eng. 2021, 69, 1–7. [Google Scholar] [CrossRef]

- Secor, E.B.; Lim, S.; Zhang, H.; Frisbie, C.D.; Francis, L.F.; Hersam, M.C. Gravure Printing of Graphene for Large-Area Flexible Electronics. Adv. Mater. 2014, 26, 4533–4538. [Google Scholar] [CrossRef]

- Scheideler, W.J.; Jang, J.; Ul Karim, M.A.; Kitsomboonloha, R.; Zeumault, A.; Subramanian, V. Gravure-Printed Sol-Gels on Flexible Glass: A Scalable Route to Additively Patterned Transparent Conductors. ACS Appl. Mater. Interfaces 2015, 7, 12679–12687. [Google Scholar] [CrossRef]

- Kim, K.; Kim, J.; Kim, B.; Ko, S. Fabrication of Microfluidic Structure Based Biosensor Using Roll-to-Roll Gravure Printing. Int. J. Precis. Eng. Manuf. Green Technol. 2018, 5, 369–374. [Google Scholar] [CrossRef]

- Sung, D.; de la Fuente Vornbrock, A.; Subramanian, V. Scaling and Optimization of Gravure-Printed Silver Nanoparticle Lines for Printed Electronics. IEEE Trans. Compon. Packag. Technol. 2010, 33, 105–114. [Google Scholar] [CrossRef]

- Park, H.J.; Cha, J.; Choi, M.; Kim, J.H.; Tay, R.Y.; Teo, E.H.T.; Park, N.; Hong, S.; Lee, Z. One-dimensional hexagonal boron nitride conducting channel. Sci. Adv. 2020, 6, eaay4958. [Google Scholar] [CrossRef] [PubMed]

- Mogg, B.T.; Claypole, T.; Deganello, D.; Phillips, C. Flexographic printing of ultra-thin semiconductor polymer layers. Transl. Mater. Res. 2016, 3. [Google Scholar] [CrossRef]

- Tomašegović, T.; Beynon, D.; Claypole, T.; Poljaček, S.M. Modifying the qualitative properties of print by surface treatment of flexographic printing plate. J. Print Media Technol. Res. 2017, 2, 57–67. [Google Scholar]

- Kim, S.; Sojoudi, H.; Zhao, H.; Mariappan, D.; McKinley, G.H.; Gleason, K.K.; Hart, A.J. Ultrathin High-Resolution Flexographic Printing Using Nanoporous Stamps. Sci. Adv. 2016, 2, e1601660. [Google Scholar] [CrossRef] [PubMed]

- Mariappan, D.D.; Kim, S.; Boutilier, M.S.H.; Zhao, J.; Zhao, H.; Beroz, J.; Muecke, U.; Sojoudi, H.; Gleason, K.; Brun, P.T.; et al. Dynamics of Liquid Transfer from Nanoporous Stamps in High-Resolution Flexographic Printing. Langmuir 2019, 35, 7659–7671. [Google Scholar] [CrossRef]

- Messerschmitt, E. Rheological Considerations for Screen Printing Inks. Screen Print 1982, 72, 62–65. [Google Scholar]

- Kapur, N.; Abbott, S.J.; Dolden, E.D.; Gaskell, P.H. Predicting the Behavior of Screen Printing. IEEE Trans. Compon. Packag. Manuf. Technol. 2013, 3, 508–515. [Google Scholar] [CrossRef]

- Xu, C.; Willenbacher, N. How Rheological Properties Affect Fine-Line Screen Printing of Pastes: A Combined Rheological and High-Speed Video Imaging Study. J. Coat. Technol. 2018, 15, 1401–1412. [Google Scholar] [CrossRef]

- Sliz, R.; Huttunen, O.-H.; Jansson, E.; Kemppainen, J.; Schroderus, J.; Kurkinen, M.; Fabritius, T. Reliability of R2R-Printed, Flexible Electrodes for E-Clothing Applications. NPJ Flex. Electron. 2020, 4, 1–9. [Google Scholar] [CrossRef]

- Philip, B.; Jewell, E.; Greenwood, P.; Weirman, C. Material and Process Optimization Screen Printing Carbon Graphite Pastes for Mass Production of Heating Elements. J. Manuf. Process. 2016, 22, 185–191. [Google Scholar] [CrossRef]

- He, P.; Cao, J.; Ding, H.; Liu, C.; Neilson, J.; Li, Z.; Kinloch, I.A.; Derby, B. Screen-Printing of a Highly Conductive Graphene Ink for Flexible Printed Electronics. ACS Appl. Mater. Interfaces 2019, 11, 32225–32234. [Google Scholar] [CrossRef] [PubMed]

- Lau, G.K.; Shrestha, M. Ink-Jet Printing of Micro-Electro-Mechanical Systems (MEMS). Micromachines 2017, 8, 194. [Google Scholar] [CrossRef]

- Bartolo, D.; Boudaoud, A.; Narcy, G.; Bonn, D. Dynamics of non-Newtonian droplets. Phys. Rev. Lett. 2007, 99, 174502. [Google Scholar] [CrossRef]

- Wijshoff, H. Drop dynamics in the inkjet printing process. Curr. Opin. Colloid Interface Sci. 2018, 36, 20–27. [Google Scholar] [CrossRef]

- Cai, L.; Zhang, S.; Zhang, Y.; Li, J.; Miao, J.; Wang, Q.; Yu, Z.; Wang, C. Direct Printing for Additive Patterning of Silver Nanowires for Stretchable Sensor and Display Applications. Adv. Mater. Technol. 2018, 3, 1700232. [Google Scholar] [CrossRef]

- Anyfantakis, M.; Geng, Z.; Morel, M.; Rudiuk, S.; Baigl, D. Modulation of the coffee-ring effect in particle/surfactant mixtures: The importance of particle-interface interactions. Langmuir 2015, 31, 4113–4120. [Google Scholar] [CrossRef]

- Zapka, W. Handbook of Industrial Inkjet Printing: A Full System Approach; John Wiley & Sons: Hoboken, NJ, USA, 2017; pp. 1–22. [Google Scholar]

- Hu, H.L.; Larson, R.G. Marangoni Effect Reverses Coffee-Ring Depositions. J. Phys. Chem. B 2006, 110, 7090–7094. [Google Scholar] [CrossRef]

- de Gans, B.J.; Schubert, U.S. Inkjet Printing of Well-Defined Polymer Dots and Arrays. Langmuir 2004, 20, 7789–7793. [Google Scholar] [CrossRef]

- Patil, N.D.; Bange, P.G.; Bhardwaj, R.; Sharma, A. Effects of Substrate Heating and Wettability on Evaporation Dynamics and Deposition Patterns for a Sessile Water Droplet Containing Colloidal Particles. Langmuir 2016, 32, 11958–11972. [Google Scholar] [CrossRef] [PubMed]

- McBride, S.A.; Dash, S.; Varanasi, K.K. Evaporative Crystallization in Drops on Superhydrophobic and Liquid-Impregnated Surfaces. Langmuir 2018, 34, 12350–12358. [Google Scholar] [CrossRef]

- Eral, H.B.; Augustine, D.M.; Duits, M.H.; Mugele, F. Suppressing the coffee stain effect: How to control colloidal self-assembly in evaporating drops using electrowetting. Soft Matter. 2011, 7, 7090–7094. [Google Scholar] [CrossRef]

- Minemawari, H.; Yamada, T.; Matsui, H.; Tsutsumi, J.; Haas, S.; Chiba, R.; Kumai, R.; Hasegawa, T. Inkjet Printing of Single-Crystal Films. Nature 2011, 475, 364–367. [Google Scholar] [CrossRef] [PubMed]

- Vak, D.; Hwang, K.; Faulks, A.; Jung, Y.-S.; Clark, N.; Kim, D.-Y.; Wilson, G.J.; Watkins, S.E. 3D Printer Based Slot-Die Coater as a Lab-to-Fab Translation Tool for Solution-Processed Solar Cells. Adv. Energy Mater. 2015, 5, 1401539. [Google Scholar] [CrossRef]

- Whitener, K.E.; Sheehan, P.E. Graphene Synthesis. Diam. Relat. Mater. 2014, 46, 25–34. [Google Scholar] [CrossRef]

- Zaytseva, O.; Neumann, G. Carbon Nanomaterials: Production, Impact on Plant Development, Agricultural and Environmental Applications. Chem. Biol. Technol. Agric. 2016, 3, 1–26. [Google Scholar] [CrossRef]

- Chen, K.; Gao, W.; Emaminejad, S.; Kiriya, D.; Ota, H.; Nyein, H.Y.; Takei, K.; Javey, A. Printed Carbon Nanotube Electronics and Sensor Systems. Adv. Mater. 2016, 28, 4397–4414. [Google Scholar] [CrossRef]

- Manoj, D.; Saravanan, R.; Santhanalakshmi, J.; Agarwal, S.; Gupta, V.K.; Boukherroub, R. Towards Green Synthesis of Monodisperse Cu Nanoparticles: An Efficient and High Sensitive Electrochemical Nitrite Sensor. Sens. Actuators B Chem. 2018, 266, 873–882. [Google Scholar] [CrossRef]

- Iravani, S.; Korbekandi, H.; Mirmohammadi, S.V.; Zolfaghari, B. Synthesis of silver nanoparticles: Chemical, physical and biological methods. Res. Pharm. Sci. 2014, 9, 385–406. [Google Scholar]

- Li, J.; Ye, F.; Vaziri, S.; Muhammed, M.; Lemme, M.C.; Ostling, M. Efficient inkjet printing of graphene. Adv. Mater. 2013, 25, 3985–3992. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.; Ren, L.; Li, D.; Gao, H.; Yang, B. Optimization Conditions for Single-Walled Carbon Nanotubes Dispersion. J. Surf. Eng. Mater. Adv. Technol. 2013, 3, 6–12. [Google Scholar] [CrossRef]

- Ohsawa, M.; Hashimoto, N. Bending reliability of flexible transparent electrode of gravure offset printed invisible silver-grid laminated with conductive polymer. Microelectron. Reliab. 2019, 98, 124–130. [Google Scholar] [CrossRef]

- Yeom, C.; Chen, K.; Kiriya, D.; Yu, Z.; Cho, G.; Javey, A. Large-area compliant tactile sensors using printed carbon nanotube active-matrix backplanes. Adv. Mater. 2015, 27, 1561–1566. [Google Scholar] [CrossRef] [PubMed]

- Kholghi Eshkalak, S.; Chinnappan, A.; Jayathilaka, W.A.D.M.; Khatibzadeh, M.; Kowsari, E.; Ramakrishna, S. A Review on Inkjet Printing of CNT Composites for Smart Applications. Appl. Mater. Today 2017, 9, 372–386. [Google Scholar] [CrossRef]

- Gupta, N.; Gupta, S.M.; Sharma, S.K. Carbon Nanotubes: Synthesis, Properties and Engineering Applications. Carbon Lett. 2019, 29, 419–447. [Google Scholar] [CrossRef]

- Tortorich, R.; Choi, J.-W. Inkjet Printing of Carbon Nanotubes. Nanomaterials 2013, 3, 453–468. [Google Scholar] [CrossRef] [PubMed]

- Coskun, S.; Aksoy, B.; Unalan, H.E. Polyol Synthesis of Silver Nanowires: An Extensive Parametric Study. Cryst. Growth Des. 2011, 11, 4963–4969. [Google Scholar] [CrossRef]

- Cruz, B.; Albrecht, A.; Eschlwech, P.; Biebl, E. Inkjet Printing of Metal Nanoparticles for Green UHF RFID Tags. Adv. Radio Sci. 2019, 17, 119–127. [Google Scholar] [CrossRef]

- Jung, J.H.; Cheol Oh, H.; Soo Noh, H.; Ji, J.H.; Soo Kim, S. Metal Nanoparticle Generation Using a Small Ceramic Heater With a Local Heating Area. J. Aerosol Sci. 2006, 37, 1662–1670. [Google Scholar] [CrossRef]

- Shih, C.Y.; Shugaev, M.V.; Wu, C.; Zhigilei, L. The effect of pulse duration on nanoparticle generation in pulsed laser ablation in liquids: Insights from large-scale atomistic simulations. Phys. Chem. Chem. Phys 2020, 22, 7077–7099. [Google Scholar] [CrossRef]

- Richard, B.; Lemyre, J.L.; Ritcey, A.M. Nanoparticle Size Control in Microemulsion Synthesis. Langmuir 2017, 33, 4748–4757. [Google Scholar] [CrossRef]

- du Toit, H.; Macdonald, T.J.; Huang, H.; Parkin, I.P.; Gavriilidis, A. Continuous Flow Synthesis of Citrate Capped Gold Nanoparticles Using UV Induced Nucleation. RSC Adv. 2017, 7, 9632–9638. [Google Scholar] [CrossRef]

- Fuentes-Garcia, J.A.; Santoyo-Salzar, J.; Rangel-Cortes, E.; Goya, G.F.; Cardozo-Mata, V.; Pescador-Rojas, J.A. Effect of Ultrasonic Irradiation Power on Sonochemical Synthesis of Gold Nanoparticles. Ultrason. Sonochem. 2021, 70, 105274. [Google Scholar] [CrossRef] [PubMed]

- Phuruangrat, A.; Siri, S.; Wadbua, P.; Thongtem, S.; Thongtem, T. Microwave-Assisted Synthesis, Photocatalysis and Antibacterial Activity of Ag Nanoparticles Supported on Zno Flowers. J. Phys. Chem. Solids 2019, 126, 170–177. [Google Scholar] [CrossRef]

- Khabarov, K.; Kornyushin, D.; Masnaviev, B.; Tuzhilin, D.; Saprykin, D.; Efimov, A.; Ivanov, V. The Influence of Laser Sintering Modes on the Conductivity and Microstructure of Silver Nanoparticle Arrays Formed by Dry Aerosol Printing. Appl. Sci. 2019, 10, 246. [Google Scholar] [CrossRef]

- Wang, Z.; Liang, X.; Zhao, T.; Hu, Y.; Zhu, P.; Sun, R. Facile Synthesis of Monodisperse Silver Nanoparticles for Screen Printing Conductive Inks. J. Mater. Sci. Mater. Electron. 2017, 28, 16939–16947. [Google Scholar] [CrossRef]

- Shiokawa, D.; Izumi, K.; Sugano, R.; Sekine, T.; Minami, T.; Kumaki, D.; Tokito, S. Development of a Silver Nanoparticle Ink for Fine Line Patterning Using Gravure Offset Printing. Jpn. J. Appl. Phys. 2017, 56, 05EA04. [Google Scholar] [CrossRef]

- Benson, J.; Fung, C.M.; Lloyd, J.S.; Deganello, D.; Smith, N.A.; Teng, K.S. Direct Patterning of Gold Nanoparticles Using Flexographic Printing for Biosensing Applications. Nanoscale Res. Lett. 2015, 10, 127. [Google Scholar] [CrossRef] [PubMed]

- Perelaer, J.; Schubert, U.S. Novel Approaches for Low Temperature Sintering of Inkjet-Printed Inorganic Nanoparticles for Roll-to-Roll (R2R) Applications. J. Mater. Res. 2013, 28, 564–573. [Google Scholar] [CrossRef]

- Roberson, D.A.; Wicker, R.B.; Murr, L.E.; Church, K.; MacDonald, E. Microstructural and Process Characterization of Conductive Traces Printed from Ag Particulate Inks. Materials 2011, 4, 963–979. [Google Scholar] [CrossRef] [PubMed]

- Hösel, M.; Krebs, F.C. Large-Scale Roll-to-Roll Photonic Sintering of Flexo Printed Silver Nanoparticle Electrodes. J. Mater. Chem. 2012, 22, 15683–15688. [Google Scholar] [CrossRef]

- Allen, M.L.; Aronniemi, M.; Mattila, T.; Alastalo, A.; Ojanpera, K.; Suhonen, M.; Seppa, H. Electrical Sintering of Nanoparticle Structures. Nanotechnology 2008, 19, 175201. [Google Scholar] [CrossRef]

- Allen, M.; Alastalo, A.; Suhonen, M.; Mattila, T.; Leppaniemi, J.; Seppa, H. Contactless Electrical Sintering of Silver Nanoparticles on Flexible Substrates. IEEE Trans. Microw. Theory Tech. 2011, 59, 1419–1429. [Google Scholar] [CrossRef]

- Fujii, S.; Kawamura, S.; Mochizuki, D.; Maitani, M.M.; Suzuki, E.; Wada, Y. Microwave Sintering of Ag-Nanoparticle Thin Films on a Polyimide Substrate. AIP Adv. 2015, 5, 127226. [Google Scholar] [CrossRef]

- Chen, S.; Guan, Y.; Li, Y.; Yan, X.; Ni, H.; Li, L. A Water-Based Silver Nanowire Ink for Large-Scale Flexible Transparent Conductive Films and Touch Screens. J. Mater. Chem. C 2017, 5, 2404–2414. [Google Scholar] [CrossRef]

- Tilke, A.T.; Simmel, F.C.; Lorenz, H.; Blick, R.H.; Kotthaus, J.P. Quantum interference in a one-dimensional silicon nanowire. Phys. Rev. B 2003, 68, 075311. [Google Scholar] [CrossRef]

- Zhang, P.; Wyman, I.; Hu, J.; Lin, S.; Zhong, Z.; Tu, Y.; Huang, Z.; Wei, Y. Silver nanowires: Synthesis technologies, growth mechanism and multifunctional applications. Mater. Sci. Eng. B 2017, 223, 1–23. [Google Scholar] [CrossRef]

- Hemmati, S.; Harris, M.T.; Barkey, D.P. Polyol Silver Nanowire Synthesis and the Outlook for a Green Process. J. Nanomater. 2020, 2020, 1–25. [Google Scholar] [CrossRef]

- Sun, Y.; Mayers, B.; Herricks, T.; Xia, X. Polyol Synthesis of Uniform Silver Nanowires: A Plausible Growth Mechanism and the Supporting Evidence. Nano Lett. 2003, 3, 955–960. [Google Scholar] [CrossRef]

- Fung, C.M.; Lloyd, J.S.; Samavat, S.; Deganello, D.; Teng, K.S. Facile Fabrication of Electrochemical Zno Nanowire Glucose Biosensor Using Roll to Roll Printing Technique. Sens. Actuators B Chem. 2017, 247, 807–813. [Google Scholar] [CrossRef]

- Finn, D.J.; Lotya, M.; Coleman, J.N. Inkjet Printing of Silver Nanowire Networks. ACS Appl. Mater. Interfaces 2015, 7, 9254–9261. [Google Scholar] [CrossRef]

- Lee, J.-Y.; Connor, S.T.; Cui, Y.; Peumans, P. Solution-Processed Metal Nanowire Mesh Transparent Electrodes. Nano Lett. 2008, 8, 689–692. [Google Scholar] [CrossRef] [PubMed]

- Tran, N.H.; Duong, T.H.; Kim, H.C. A Fast Fabrication of Copper Nanowire Transparent Conductive Electrodes by Using Pulsed Laser Irradiation. Sci. Rep. 2017, 7, 15093. [Google Scholar] [CrossRef]

- Triambulo, R.E.; Cheong, H.-G.; Park, J.-W. All-Solution-Processed Foldable Transparent Electrodes of Ag Nanowire Mesh and Metal Matrix Films for Flexible Electronics. Org. Electron. 2014, 15, 2685–2695. [Google Scholar] [CrossRef]

- Liu, L.; Shen, Z.; Zhang, X.; Ma, H. Highly Conductive Graphene/Carbon Black Screen Printing Inks for Flexible Electronics. J. Colloid Interface Sci. 2021, 582, 12–21. [Google Scholar] [CrossRef] [PubMed]

- Hassan, S.M.; Yusof, M.S.; Maksud, M.I.; Nodin, M.N.; Rejab, N.A. Feasibility Study of Roll to Roll Printing of Graphene. Appl. Mech. Mater. 2015, 799–800, 402–406. [Google Scholar] [CrossRef]

- Wan, Z.; Nguyen, N.-T.; Gao, Y.; Li, Q. Laser Induced Graphene for Biosensors. Sustain. Mater. Technol. 2020, 25, e00205. [Google Scholar] [CrossRef]

- Rahimi, R.; Ochoa, M.; Yu, W.; Ziaie, B. Highly Stretchable and Sensitive Unidirectional Strain Sensor via Laser Carbonization. ACS Appl. Mater. Interfaces 2015, 7, 4463–4470. [Google Scholar] [CrossRef] [PubMed]

- Ortiz-Gómez, I.; Toral-López, V.; Romero, F.J.; de Orbe-Payá, I.; García, A.; Rodríguez, N.; Capitán-Vallvey, L.F.; Morales, D.P.; Salinas-Castillo, A. In Situ Synthesis of Fluorescent Silicon Nanodots for Determination of Total Carbohydrates in a Paper Microfluidic Device Combined with Laser Prepared Graphene Heater. Sens. Actuators B Chem. 2021, 332, 129506. [Google Scholar] [CrossRef]

- Wan, Z.; Streed, E.W.; Lobino, M.; Wang, S.; Sang, R.T.; Cole, I.S.; Thiel, D.V.; Li, Q. Laser-Reduced Graphene: Synthesis, Properties, and Applications. Adv. Mater. Technol. 2018, 3, 1700315. [Google Scholar] [CrossRef]

- Zahed, M.A.; Das, P.S.; Maharjan, P.; Barman, S.C.; Sharifuzzaman, M.; Yoon, S.H.; Park, J.Y. Flexible and Robust Dry Electrodes Based on Electroconductive Polymer Spray-Coated 3D Porous Graphene for Long-Term Electrocardiogram Signal Monitoring System. Carbon 2020, 165, 26–36. [Google Scholar] [CrossRef]

- Tölle, F.J.; Fabritius, M.; Mülhaupt, R. Emulsifier-Free Graphene Dispersions with High Graphene Content for Printed Electronics and Freestanding Graphene Films. Adv. Funct. Mater. 2012, 22, 1136–1144. [Google Scholar] [CrossRef]

- Alsuradi, H.; Yoo, J. Screen Printed Passives and Interconnects on Bio-Degradable Medical Hydrocolloid Dressing for Wearable Sensors. Sci. Rep. 2019, 9, 17467. [Google Scholar] [CrossRef] [PubMed]

- Desai, J.A.; Bandyopadhyay, A.; Min, M.; Saenz, G.; Kaul, A.B. A Photo-Capacitive Sensor Operational from 6 K to 350 K with A Solution Printable, Thermally-Robust Hexagonal Boron Nitride (H-BN) Dielectric and Conductive Graphene Electrodes. Appl. Mater. Today 2020, 20, 100660. [Google Scholar] [CrossRef]

- Jabari, E.; Toyserkani, E. Laser Heat Treatment of Aerosol-Jet Additive Manufactured Graphene Patterns. J. Phys. D Appl. Phys. 2015, 48, 375503. [Google Scholar] [CrossRef]

- Secor, E.B.; Ahn, B.Y.; Gao, T.Z.; Lewis, J.A.; Hersam, M.C. Rapid and Versatile Photonic Annealing of Graphene Inks for Flexible Printed Electronics. Adv. Mater. 2015, 27, 6683–6688. [Google Scholar] [CrossRef]

- Xiang, L.; Wang, Z.; Liu, Z.; Weigum, S.E.; Yu, Q.; Chen, M.Y. Inkjet Printed Flexible Biosensor Based on Graphene Field Effect Transistor. IEEE Sens. J. 2016, 16, 8359–8364. [Google Scholar] [CrossRef]

- Boumia, L.; Zidour, M.; Benzair, A.; Tounsi, A. A Timoshenko Beam Model for Vibration Analysis of Chiral Single-Walled Carbon Nanotubes. Phys. E Low. Dimens. Syst. Nanostruct. 2014, 59, 186–191. [Google Scholar] [CrossRef]

- Menon, H.; Aiswarya, R.; Surendran, K.P. Screen Printable MWCNT Inks for Printed Electronics. RSC Adv. 2017, 7, 44076–44081. [Google Scholar] [CrossRef]

- Sun, J.; Sapkota, A.; Park, H.; Wesley, P.; Jung, Y.; Maskey, B.B.; Kim, Y.; Majima, Y.; Ding, J.; Ouyang, J.; et al. Fully R2R-Printed Carbon-Nanotube-Based Limitless Length of Flexible Active-Matrix for Electrophoretic Display Application. Adv. Electron. Mater. 2020, 6, 1901431. [Google Scholar] [CrossRef]

- Jung, M.; Kim, J.; Noh, J.; Lim, N.; Lim, C.; Lee, G.; Kim, J.; Kang, H.; Jung, K.; Leonard, A.D.; et al. All-Printed and Roll-to-Roll-PrinTable 13.56-MHz-Operated 1-bit RF Tag on Plastic Foils. IEEE Trans. Electron. Devices 2010, 57, 571–580. [Google Scholar] [CrossRef]

- Okimoto, H.; Takenobu, T.; Yanagi, K.; Miyata, Y.; Shimotani, H.; Kataura, H.; Iwasa, Y. Tunable Carbon Nanotube Thin-Film Transistors Produced Exclusively via Inkjet Printing. Adv. Mater. 2010, 22, 3981–3986. [Google Scholar] [CrossRef]

- Lu, S.; Franklin, A.D. Printed Carbon Nanotube Thin-Film Transistors: Progress on Printable Materials and the Path to Applications. Nanoscale 2020, 12, 23371–23390. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.; Liu, D.; Kang, L.; Yang, Y.; Zhang, X.; Lv, Q.; Qiu, S.; Jin, H.; Song, Q.; Zhang, J.; et al. Recycling Strategy for Fabricating Low-Cost and High-Performance Carbon Nanotube TFT Devices. ACS Appl. Mater. Interfaces 2017, 9, 15719–15726. [Google Scholar] [CrossRef]

- Briggs, N.; Subramanian, S.; Lin, Z.; Li, X.; Zhang, X.; Zhang, K.; Xiao, K.; Geohegan, D.; Wallace, R.; Chen, L.-Q.; et al. A Roadmap for Electronic Grade 2D Materials. 2D Mater. 2019, 6, 022001. [Google Scholar] [CrossRef]

- Carey, T.; Cacovich, S.; Divitini, G.; Ren, J.; Mansouri, A.; Kim, J.M.; Wang, C.; Ducati, C.; Sordan, R.; Torrisi, F. Fully Inkjet-Printed Two-Dimensional Material Field-Effect Heterojunctions for Wearable and Textile Electronics. Nat. Commun. 2017, 8, 1202. [Google Scholar] [CrossRef]

- Hossain, R.F.; Deaguero, I.G.; Boland, T.; Kaul, A.B. Biocompatible, Large-Format, Inkjet Printed Heterostructure Mos2-Graphene Photodetectors on Conformable Substrates. NPJ 2D Mater. Appl. 2017, 1, 1–10. [Google Scholar] [CrossRef]

- Splendiani, A.; Sun, L.; Zhang, Y.; Li, T.; Kim, J.; Chim, C.Y.; Galli, G.; Wang, F. Emerging Photoluminescence in Monolayer Mos2. Nano. Lett. 2010, 10, 1271–1275. [Google Scholar] [CrossRef]

- Feng, Y.P.; Shen, L.; Yang, M.; Wang, A.; Zeng, M.; Wu, Q.; Chintalapati, S.; Chang, C.-R. Prospects of Spintronics Based On 2D Materials. Wiley Interdiscip. Rev. Comput. Mol. Sci. 2017, 7, e1313. [Google Scholar] [CrossRef]

- Lee, H.; Koo, M.; Park, C.; Patel, M.; Han, H.; Park, T.H.; Kumar, P.; Koh, W.-G.; Park, C. Zwitterion-Assisted Transition Metal Dichalcogenide Nanosheets for Scalable and Biocompatible Inkjet Printing. Nano Res. 2020, 13, 2726–2734. [Google Scholar] [CrossRef]

- Caldwell, J.D.; Aharonovich, I.; Cassabois, G.; Edgar, J.H.; Gil, B.; Basov, D.N. Photonics with Hexagonal Boron Nitride. Nat. Rev. Mater. 2019, 4, 552–567. [Google Scholar] [CrossRef]

- Angizi, S.; Khalaj, M.; Alem, S.A.A.; Pakdel, A.; Willander, M.; Hatamie, A.; Simchi, A. Review—Towards the Two-Dimensional Hexagonal Boron Nitride (2D h-BN) Electrochemical Sensing Platforms. J. Electrochem. Soc. 2020, 167, 126513. [Google Scholar] [CrossRef]

- Angizi, S.; Hatamie, A.; Ghanbari, H.; Simchi, A. Mechanochemical Green Synthesis of Exfoliated Edge-Functionalized Boron Nitride Quantum Dots: Application to Vitamin C Sensing through Hybridization with Gold Electrodes. ACS Appl. Mater. Interfaces 2018, 10, 28819–28827. [Google Scholar] [CrossRef] [PubMed]

- Kwon, Y.T.; Kim, Y.S.; Kwon, S.; Mahmood, M.; Lim, H.R.; Park, S.W.; Kang, S.O.; Choi, J.J.; Herbert, R.; Jang, Y.C.; et al. All-Printed Nanomembrane Wireless Bioelectronics Using a Biocompatible Solderable Graphene for Multimodal Human-Machine Interfaces. Nat. Commun. 2020, 11, 3450. [Google Scholar] [CrossRef] [PubMed]

- Yuan, W.; Wu, X.; Gu, W.; Lin, J.; Cui, Z. Printed Stretchable Circuit on Soft Elastic Substrate for Wearable Application. J. Semicond. 2018, 39, 015002. [Google Scholar] [CrossRef]

- Hyun, W.J.; Secor, E.B.; Hersam, M.C.; Frisbie, C.D.; Francis, L.F. High-resolution patterning of graphene by screen printing with a silicon stencil for highly flexible printed electronics. Adv. Mater. 2015, 27, 109–115. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Yarali, E.; Bakytbekov, A.; Anthopoulos, T.D.; Shamim, A. Highly Transparent and Conductive Electrodes Enabled by Scalable Printing-and-Sintering of Silver Nanowires. Nanotechnology 2020, 31, 395201. [Google Scholar] [CrossRef] [PubMed]

- Scheideler, W.J.; Smith, J.; Deckman, I.; Chung, S.; Arias, A.; Subramaniam, V. A Robust, Gravure-Printed, Silver Nanowire/Metal Oxide Hybrid Electrode for High-Throughput Patterned Transparent Conductors. J. Mater. Chem. C 2016, 4, 3248–3255. [Google Scholar] [CrossRef]

- Deganello, D.; Cherry, J.A.; Gethin, D.T.; Claypole, T.C. Impact of Metered Ink Volume on Reel-to-Reel Flexographic Printed Conductive Networks for Enhanced Thin Film Conductivity. Thin Solid Film. 2012, 520, 2233–2237. [Google Scholar] [CrossRef]

- Nair, M.; Johal, R.K.; Hamaia, S.W.; Best, S.M.; Cameron, R.E. Tunable Bioactivity and Mechanics of Collagen-Based Tissue Engineering Constructs: A Comparison of EDC-NHS, Genipin and TG2 Crosslinkers. Biomaterials 2020, 254, 120109. [Google Scholar] [CrossRef]

- Favero, G.; Fusco, G.; Mazzei, F.; Tasca, F.; Antiochia, R. Electrochemical Characterization of Graphene and MWCNT Screen-Printed Electrodes Modified with AuNPs for Laccase Biosensor Development. Nanomaterials 2015, 5, 1995–2006. [Google Scholar] [CrossRef]

- Narakathu, B.B.; Reddy, S.; Atashbar, M.Z.; Rebrosova, E.; Rebros, M.; Joyce, M.K. A Novel Gravure Printed Impedance Based Flexible Electrochemical Sensor. In Proceedings of the SENSORS 2011 IEEE, Limerick, Ireland, 28–31 October 2011; pp. 577–580. [Google Scholar] [CrossRef]

- Reddy, A.S.G.; Narakathu, B.B.; Atashbar, M.Z.; Rebros, M.; Rebrosova, E.; Joyce, M.K. Gravure Printed Electrochemical Biosensor. Procedia Eng. 2011, 25, 956–959. [Google Scholar] [CrossRef][Green Version]

- Rosati, G.; Ravarotto, M.; Scaramuzza, M.; De Toni, A.; Paccagnella, A. Silver Nanoparticles Inkjet-Printed Flexible Biosensor for Rapid Label-Free Antibiotic Detection in Milk. Sens. Actuators B Chem. 2019, 280, 280–289. [Google Scholar] [CrossRef]

- Cagnani, G.R.; Ibanez-Redin, G.; Tirich, B.; Goncalves, D.; Balogh, D.T.; Oliveira, O.N., Jr. Fully-Printed Electrochemical Sensors Made with Flexible Screen-Printed Electrodes Modified by Roll-to-Roll Slot-Die Coating. Biosens. Bioelectron. 2020, 165, 112428. [Google Scholar] [CrossRef]

- Jansson, E.; Korhonen, A.; Hietala, M.; Kololuoma, T. Development of a Full Roll-to-Roll Manufacturing Process of Through-Substrate Vias with Stretchable Substrates Enabling Double-Sided Wearable Electronics. Int. J. Adv. Manuf. Technol. 2020, 111, 3017–3027. [Google Scholar] [CrossRef]

- Khan, Y.; Han, D.; Pierre, A.; Ting, J.; Wang, X.; Lochner, C.M.; Bovo, G.; Yaacobi-Gross, N.; Newsome, C.; Wilson, R.; et al. A Flexible Organic Reflectance Oximeter Array. Proc. Natl. Acad. Sci. USA 2018, 115, E11015–E11024. [Google Scholar] [CrossRef] [PubMed]

- Martinez-Olmos, A.; Fernandez-Salmeron, J.; Lopez-Ruiz, N.; Rivadeneyra Torres, A.; Capitan-Vallvey, L.F.; Palma, A.J. Screen Printed Flexible Radiofrequency Identification Tag for Oxygen Monitoring. Anal. Chem. 2013, 85, 11098–11105. [Google Scholar] [CrossRef]

- Tan, R.L.S.; Tey, J.N.; Kerk, W.T.; Lok, B.K. Roll-to-Roll Manufacturing of Printed Biosensor Electrodes for ECG Monitoring. In Proceedings of the 2020 IEEE 22nd Electronics Packaging Technology Conference (EPTC), Singapore, 2–4 December 2020; pp. 213–215. [Google Scholar]

- Chlaihawi, A.A.; Narakathu, B.B.; Emamian, S.; Bazuin, B.J.; Atashbar, M.Z. Development of Printed and Flexible Dry ECG Electrodes. Sens. Bio. Sens. Res. 2018, 20, 9–15. [Google Scholar] [CrossRef]

| Printing Method | Typical Min Resolution [µm] | Printing Speed [m/min] | Ink Viscosities [mPa.s] | Ink Surface Tension [mN/m] | Pros | Cons |

|---|---|---|---|---|---|---|

| Gravure | 30 | 1–20 | 100–500 | 20–40 | High speed [40] Good reliability [27] Long production runs [27] | High startup costs [27] Expensive prototyping [27] |

| Flexography | 30 | 1–20 | 50–500 | 10–30 | High Speed [41] Easier to prototype than gravure [29] | High startup costs [29] Lower durability than gravure [41] |

| Screen | 50 | 0.1–15 | 500–10,000 | 35–50 | Inexpensive to prototype [42] Balance between speed, reliability, and cost [35] Simple process optimization [43] | Limited resolution [24] Strict ink rheology requirements [44] |

| Inkjet | 30 | 0.01–15 | 1–20 | 10–30 | No additional cost to prototype [45] Excellent resolution and pattern control [46] | Complicated to integrate with roll–to–roll systems Nozzle clogging [47] Coffee ring effect [48] |

| Slot die | 40 | 1–50 | 2–500 | – | Efficient and precise coating of homogeneous films [30] | Not suited for complex patterning [49] |

| Reference | Material | Method | Substrate | Curing | Printing Speed [m/min] | Sheet Resistance [Ω/sq] | Resolution [µm] |

|---|---|---|---|---|---|---|---|

| [53] | Graphene | Gravure | PI | Room temperature | 0.3 | 6.25 | 30 |

| [22] | AgNP | Inkjet | PEN | Laser Sintering | 10 | 2.5 | 50 |

| [155] | AgNP | Flexography | PET | 130 °C for 5 min | 5 | 45 | 150 |

| [35] | AgNP | Screen | PDMS | 140 °C for 8 min | 2 | 2.5 | 125 |

| [50] | AgNW | Gravure | PET | 150 °C for 5 min | 1.5 mm/s | ~20 | 50–150 |

| [153] | AgNW | Screen printing | PET | Flash Light Sintering | 0.2 | 9.6 | 20 |

| [154] | AgNW | Gravure | PEN | 170 °C for 10 min | 1 | 9.3 | Film was tested |

| [88] | AgNP | Gravure | PEN | 100 °C for 1 min | Not reported, roll-to-roll | 4.9 | 40 mm × 80 mm |

| Reference | Material | Method | Substrate | Curing | Printing Speed [m/min] | Application | Reported Efficacy |

|---|---|---|---|---|---|---|---|

| [161] | Carbon | Slot Die | PET | 60 °C for 2 min | 30 | Dopamine detection | Sensitivity of 0.32 µA L/μmol with limit of detection (LOD) of 0.09 μmol/L |

| [160] | AgNP | Ink-jet | PET | No Post-print treatment | - | Antibiotic detection in milk | 100–10,000 μg/mL with LOD of 10 μg/mL |

| [40] | AgNP | Gravure | Paper | 120 °C for 2 min | 6 | Sweat sensing | Error of 1.4% over a range of ~4–100 [Na+] (mM) |

| [159] | AgNP | Gravure | PET | Not reported | Not reported | IgG sensing | 2–5% sensitivity to IgG over 10 pM-10 μM concentrations |

| [158] | AgNP | Gravure | PET | Not reported | Not reported | Sacrosine sensing | Resistance changed from 299 Ω to 325 Ω with varying concentration from 1 pM to 100 mM |

| [16] | Graphene | Screen printing | Textile | Not reported | Not reported | Influenza sensing | Stabile sensing over 10 ng/mL to 10 μg/mL with a limit of detection of 10 ng/mL. |

| [157] | AuNPs and MWCNTs | Screen printing | Glass | Not reported | Not reported | Laccase sensing | Linear range of 1–100 μM with a LOD = 0.5 μM and a sensitivity of 0.051 μA·μM−1 |

| Reference | Material | Method | Substrate | Curing | Printing Speed [m/min] | Application | Reported Efficacy |

|---|---|---|---|---|---|---|---|

| [165] | Carbon Black | Doctor Blade Coating | TPU | Belt fed convection oven at 80 °C | Not reported | ECG monitoring | Quality signals after 50 wash cycles. |

| [166] | AgNP and MWCNT | Screen print AgNP then Doctor blade MWCNTs | PET | 120 °C for 20 min | Not reported | ECG monitoring | Equivalent ECG signals to gel Ag/AgCl comparison |

| [37] | AgNP | Slot Die | PET | 150 °C for 10 min. | 0.5 | Cantilever touch sensor | ΔC/C0 (%) of 0.118% for the range 0–20 kPa |

| [162] | AgNP | Screen printing | TPU | 140 °C for 2 min. | 2 | Via Filling | Low (10–40Ω resistance over the range 0–100 stretching cycles with <10% strain |

| [164] | AgNP | Screen printing | TPU | Not reported | Not reported | Oxygen sensing | 0.1 ppm of O2 sensitivity with 40 PPM LOD |

| [129] | AgNP | Screen printing | hydrocolloid dressings | Not reported | Not reported | Passive elements (e.g., capacitors) | Control of impedance and capacitance within 5% error |

| [163] | PEDOT:PSS | Blade Coating | PEN | 120 °C for 10 min. | 0.6 | Photoplethysmography (PPG) array for SpO2 monitoring | Mean error of 1.1% compared to a commercial device |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zavanelli, N.; Kim, J.; Yeo, W.-H. Recent Advances in High-Throughput Nanomaterial Manufacturing for Hybrid Flexible Bioelectronics. Materials 2021, 14, 2973. https://doi.org/10.3390/ma14112973

Zavanelli N, Kim J, Yeo W-H. Recent Advances in High-Throughput Nanomaterial Manufacturing for Hybrid Flexible Bioelectronics. Materials. 2021; 14(11):2973. https://doi.org/10.3390/ma14112973

Chicago/Turabian StyleZavanelli, Nathan, Jihoon Kim, and Woon-Hong Yeo. 2021. "Recent Advances in High-Throughput Nanomaterial Manufacturing for Hybrid Flexible Bioelectronics" Materials 14, no. 11: 2973. https://doi.org/10.3390/ma14112973

APA StyleZavanelli, N., Kim, J., & Yeo, W.-H. (2021). Recent Advances in High-Throughput Nanomaterial Manufacturing for Hybrid Flexible Bioelectronics. Materials, 14(11), 2973. https://doi.org/10.3390/ma14112973